1. Introduction

Pharmaceutical companies are one of the most strictly regulated companies where precise control of the end product quality is highly desired to satisfy the high standard set by regulatory authorities to ensure the efficiency and efficacy of the drug products [

1,

2]. Continuous pharmaceutical manufacturing enables the implementation of efficient automatic real time monitoring and control of the critical process parameters (CPP’s) and critical quality attributes (CQA’s) as desired for quality by design (QbD)—rather than quality by testing (QbT)—based manufacturing [

3,

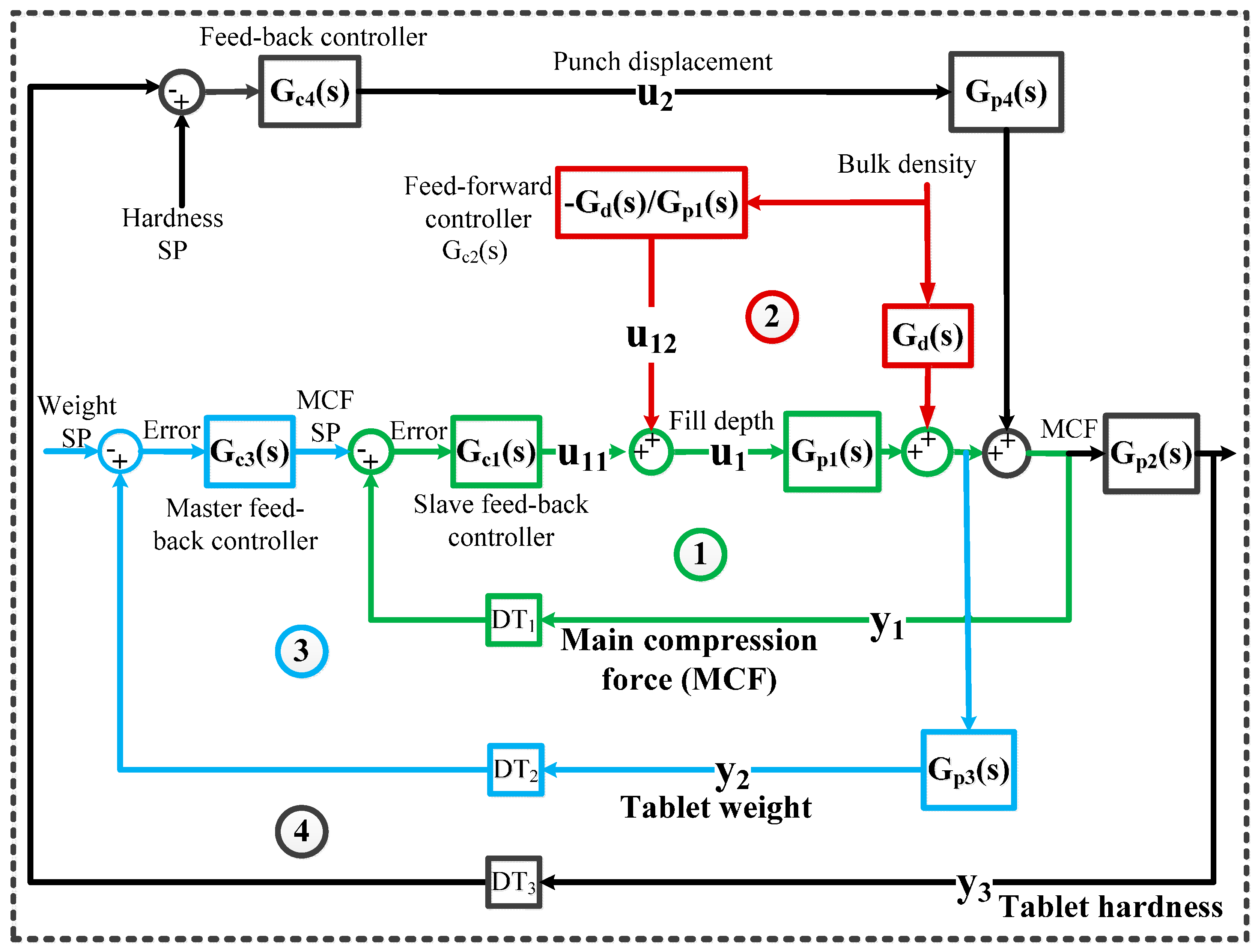

4]. There are many factors that can affect the end product quality of the pharmaceutical products involving solid dosage forms. For example, the raw materials and process variability and any other measurable and non-measurable process disturbances can upset the process and thereby can affect the product quality. An automatic feed-back control system, though essential to ensure the end product quality in real time, can take action only after the disturbances affect the product quality. Therefore, a feed-back standalone strategy is insufficient to provide near perfect control of the process which is often needed for the manufacture of pharmaceutical products. A feed-forward control strategy takes actions before process disturbances can affect the product quality. However, a feed-forward only control strategy does not take into account the feed-back signal of the control variables and, as a result of other unmeasured process disturbances, the control variables or end product quality can deviate from the desired values. Therefore, a combined feed-forward/feed-back control strategy is needed in which the measured process disturbances (feed-forward signals) can be taken into account before it affects the end product quality and the feed-back signal of the control variables can be utilized to ensure the consistent predefined end product quality.

In the last few years, extensive work has been done to study the continuous tablet manufacturing process [

3,

4,

5,

6]. The main focus, however, has been on powder blend uniformity, drug concentration and final end product qualities. For example, Vanarase

et al. (2010) have applied NIR for inline monitoring of powder blend homogeneity [

7]. Singh

et al. have demonstrated the advanced model predictive control (MPC) as well as classical PID (proportional integral derivative) based real time automatic feed-back control of the drug concentration [

3]. Much less attention, however, has been paid to the development of PAT and control methods for physical properties of blends. Some physical properties (e.g., blend bulk density, shear) have significant effects on the end product quality (e.g., weight, hardness, dissolution) of the pharmaceutical tablets. Blend physical properties such as bulk density can vary during processing because of many factors. For example, variations in raw material properties (e.g., particle size), feeder hopper level, amounts of lubrication, milling and blending action, applied shear in different processing stages can affect the blend bulk density significantly and thereby tablet weight, hardness and dissolution. Therefore, the inline real time monitoring of the physical properties of the blend (e.g., bulk density) and its incorporation into the control system so that it does not affect the end product quality is highly desired [

8]. However, due to the different levels of complexity associated with powder handling and the unavailability of the PAT and control methods, the integration of the physical properties to the control system is still a challenging task.

Feed-forward control systems have been very successful in various manufacturing industries to take proactive actions on process variations/disturbances. Using both feed-forward and feed-back control to respond in real time to disturbances throughout the multiple unit operations is a hallmark of continuous manufacturing [

9]. However, to date, no attempts have been made to design a feed-forward control system for a pharmaceutical manufacturing process. Moreover, feed-back control strategy of presently available tablet press also needs to be improved because these control logics are based on empirical law rather than real control algorithm (e.g., PID, MPC); all three control loops in these tablet press can not be activated at the same time meaning that tablet weight and hardness are not really controlled in real time, and the tablet weight and hardness control-loops are not decoupled. Therefore, new feedback control logic has been developed in this manuscript to address these issues as well.

In the last few years, very few attempts have been made toward the control of a tablet manufacturing process utilizing feed-back control algorithm. Hsu

et al. (2010) have suggested a feed-back control system for a roller compactor, an important unit operation used for a dry granulated continuous tablet manufacturing process [

10,

11]. A detailed review on the feed-back control of a fluid bed granulation process has been performed by Burggraeve

et al. (2012), and discussion has been provided by Bardin

et al. (2004) on the control aspects for efficient operation of a high shear mixer [

12,

13]. Sanders

et al. (2009) have performed extensive feed-back control studies using PID and model predictive control (MPC) methods on an experimentally validated fluidized bed granulation model [

14]. Recently, Singh

et al. (2014) have implemented a MPC based feed-back control system into the direct compaction tablet manufacturing process with focus on drug concentration control at blending unit operation [

3]. However, no attempt has been made to design a combined feed-forward/feed-back control system for an integrated continuous tablet manufacturing process. Moreover, the simultaneous control of tablet weight and hardness, which are two important control variables in tablet press, is still a challenging task.

In this study, for the first time, a combined feed-forward/feed-back control system has been developed for an integrated continuous direct compaction pharmaceutical tablet manufacturing process. The tablet weight and hardness control loops have been decoupled so that these variables can be controlled simultaneously. The powder blend bulk density has been used as the feed-forward variable of a tablet press control system consisting of loops to control the tablet weight and hardness. The performance of the proposed control system has been evaluated for set point tracking and disturbances rejection ability through process simulation. The systematic application of the feed-forward/feed-back control can take proactive action on a process disturbance and therefore will enable the industrial practitioners to achieve a predefined end product quality more consistently.

4. Results and Discussion

Prior to the implementation of the control system to the continuous tablet manufacturing pilot-plant, the performance of the designed feed-forward/feed-back control system is evaluated using process simulation as described in this section. The model-based performance evaluation of the control system reduces the time and resources needed for the implementation of the control system into the pilot-plant and increases the chance of success during implementation. In this section, the ability of the control system to track the set point and reject the disturbances is evaluated. For set point tracking, the step changes in the set point are applied, and the controller is allowed to track those changes. For disturbance rejection, structural disturbances (e.g., sinusoidal) and random disturbances are introduced during closed-loop operation.

A step change in the hardness set point has been introduced while keeping the tablet weight set point at a constant value. The blend density acts as the disturbance and can affect the tablet weight and hardness significantly. The blend density can change because of many factors. For example, the particle size of the powder, lubrication level and shear applied in blender can change the blend density. Since the powder is filled in the tablet press die by volume (not by weight), different blend densities can lead to different tablet weight and hardness. Random disturbances have been added to the blend density throughout the operation. A step change in the blend density has been also introduced at t = 2500 s in order to analyze its effects.

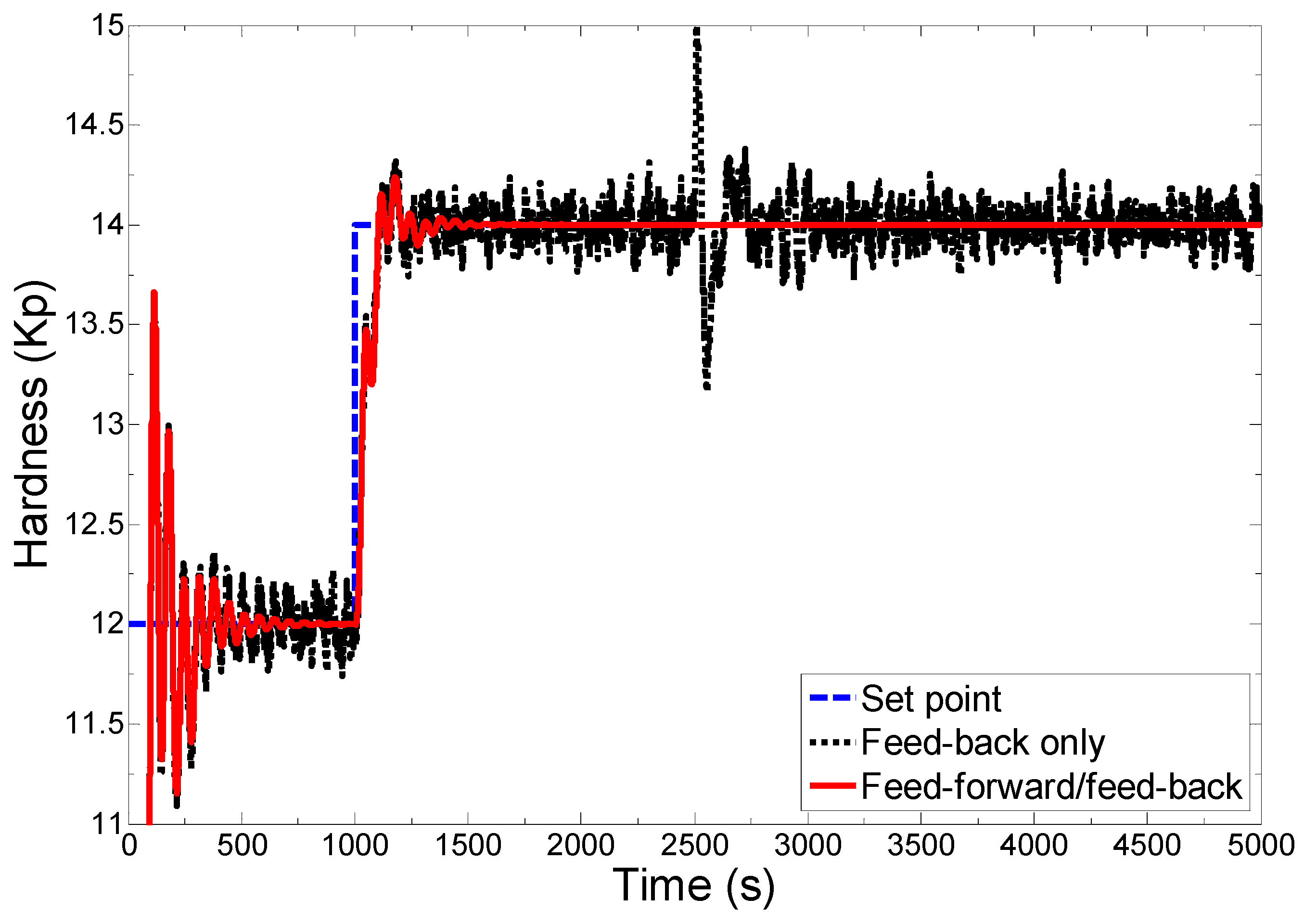

Figure 5 shows a closed-loop response of the tablet hardness under the combined feed-forward/feed-back control strategy and feed-back only control strategy. As shown in the figure, under the combined control strategy, the feed-forward controller rejects the variation in the blend density before it can affect the hardness. Therefore, under the combined control scheme, the tablet hardness has been controlled more effectively. A small oscillation can be seen at process startup and at the point where the step change in the hardness set point has been made, which is acceptable. As desired for a good controller, the rise time is less and decay ratio is high. A significant variation in the achieved hardness can be seen in case of only feed-back control scheme (see

Figure 5). This variation is because of random variation in the blend density. It should be noted that the hardness variation is more at

t = 2500 s where the step change in the blend density has been introduced. The results shown in

Figure 5 demonstrate the advantages of coupling feed-forward controller with the feed-back control system. It should be noted that only feed-forward control is practically insignificant because there may always be some unknown disturbances that cannot be measured. Feed-back control system is essential to reject the unknown disturbances that can occur during plant operation.

Figure 5.

Comparison of combined feed-forward/feed-back control strategy with feed-back only control strategy for hardness control.

Figure 5.

Comparison of combined feed-forward/feed-back control strategy with feed-back only control strategy for hardness control.

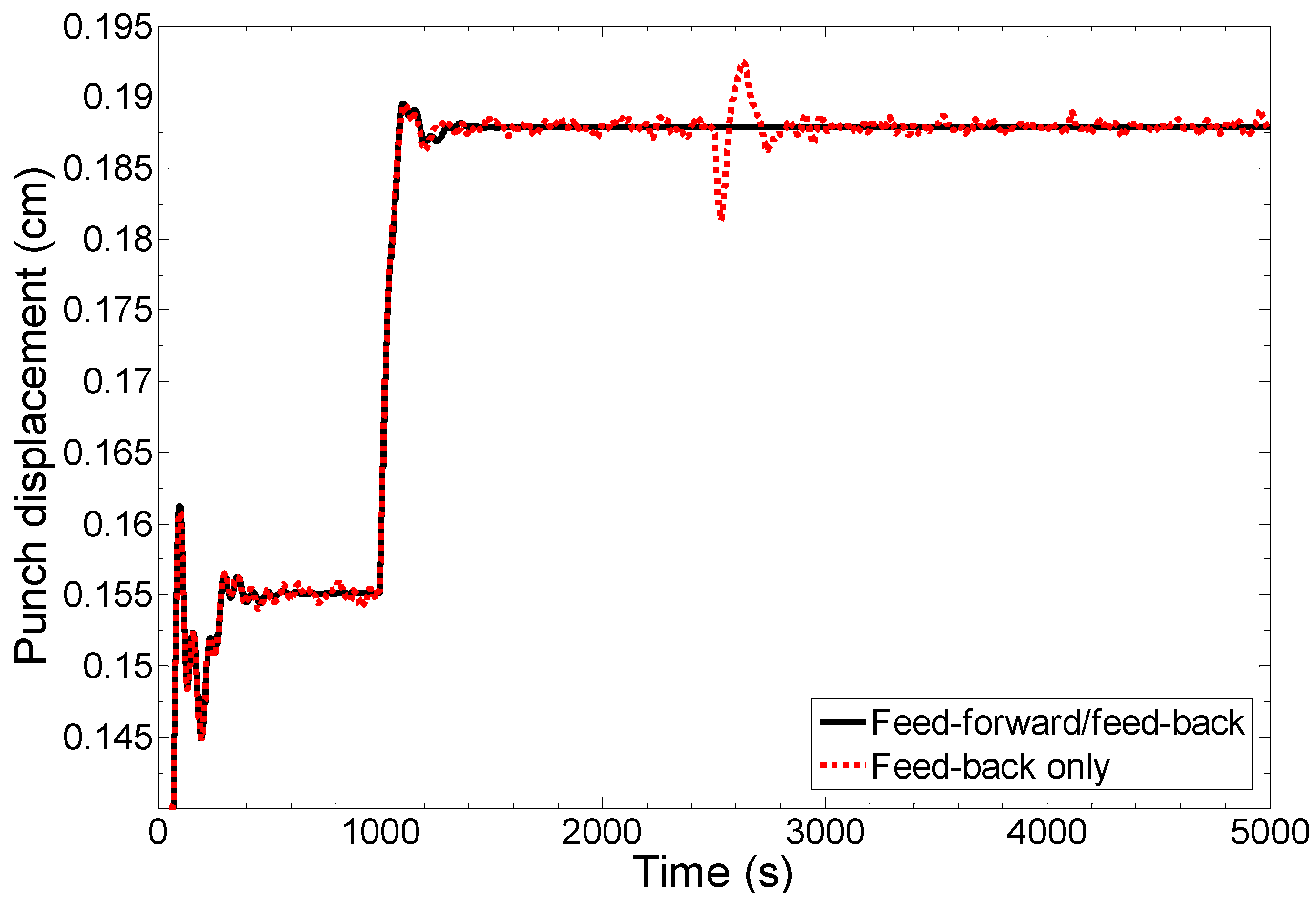

Actuators values obtained from combined feed-forward/feed-back control strategy with that obtained from feed-back only control strategy for tablet hardness control is shown in

Figure 6. As shown in the figure, the combined control strategy provides a more consistent and steady actuator response in comparison to the feed-back only control strategy. The oscillations in the actuator obtained by feed-back only control strategy can be attributed to random disturbances introduced in the powder bulk density. In case of a feed-back only control strategy, the hardness is affected by the disturbances introduced in the powder bulk density while, in case of combined control strategy, this effect is compensated proactively. A significant oscillation can be seen at

t = 2500 s where a step change in the powder bulk density has been introduced.

Figure 6.

Comparison of actuators obtained from combined feed-forward/feed-back control strategy with feed-back only control strategy for hardness control.

Figure 6.

Comparison of actuators obtained from combined feed-forward/feed-back control strategy with feed-back only control strategy for hardness control.

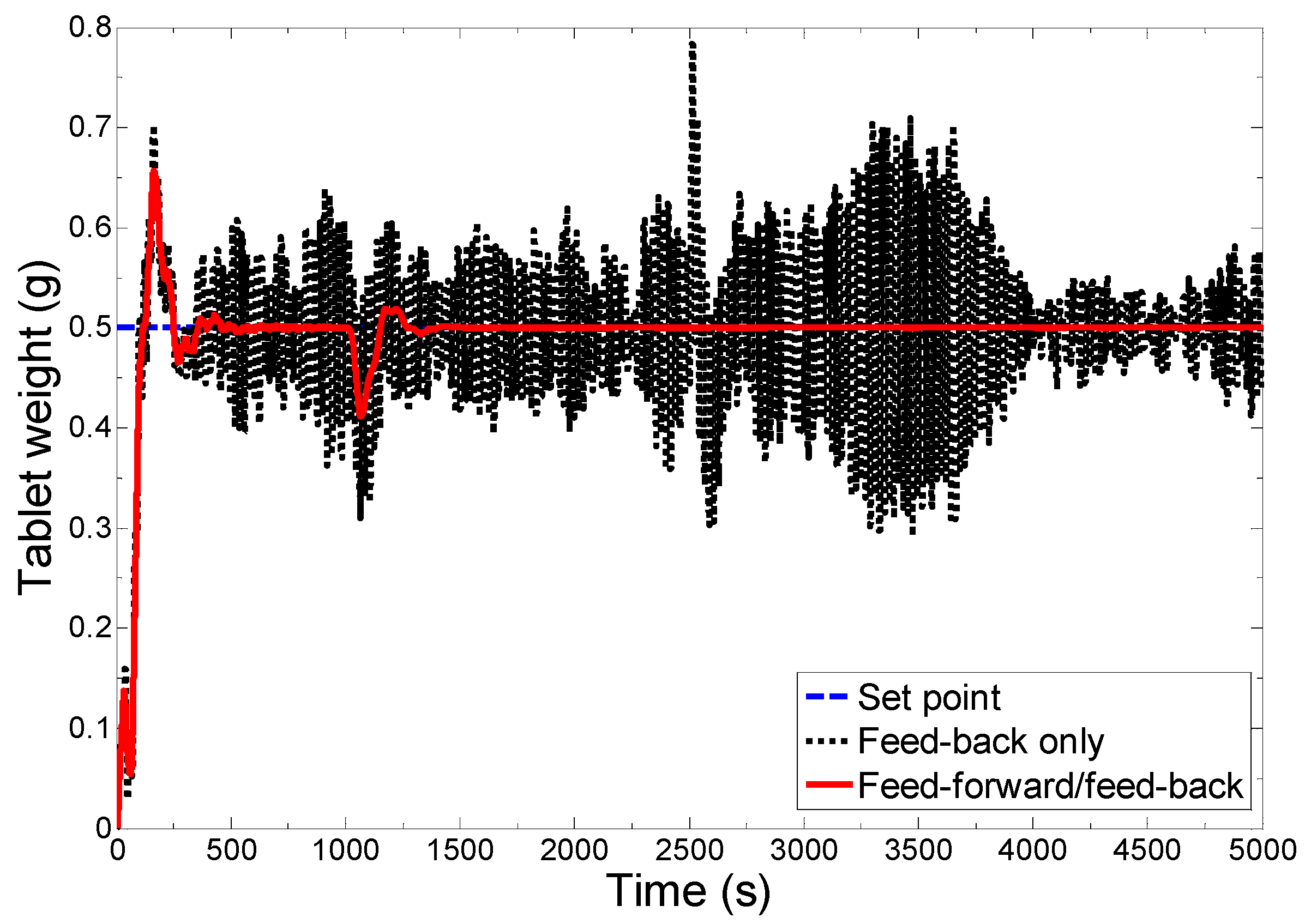

The closed-loop response of the tablet weight under the combined feed-forward/feed-back control strategy and only feed-back control strategy is shown in

Figure 7. As shown in the figure, the variation in tablet weight is less under combined control scheme in compare to only feed-back control scheme. Under the combined control scheme, a small oscillation can be seen at startup, which is acceptable because the decay ratio is high. Higher decay ratios reduce the oscillation and overshoot faster. A small oscillation can be seen at

t =1000 s where the step change in the hardness set point has been made and this is essentially because the hardness and weight control loops are highly interactive. Note that the step change in the hardness set point has been made for demonstration of the set point tracking ability of the designed control system and in practice for a given formulation hardness and weight set points need to be fixed. At

t = 2500 s, a step change in the blend density has been introduced but the combined feed-forward/feed-back control system has efficiently rejected its effect and thereby a consistent desired tablet weight has been achieved. In the case of the feed-back only control scheme, the variation in achieved tablet weight is very high and corresponds to the random variations introduced to the blend density. The deviation of the tablet weight from the desired set point in the interval of 2500–2600 s is significantly higher because of the introduced step change in the blend density. The tablets produced in this range need to be rejected.

Figure 7.

Comparison of the performance of the combined feed-forward/feed-back control scheme with feed-back only control scheme for tablet weight control.

Figure 7.

Comparison of the performance of the combined feed-forward/feed-back control scheme with feed-back only control scheme for tablet weight control.

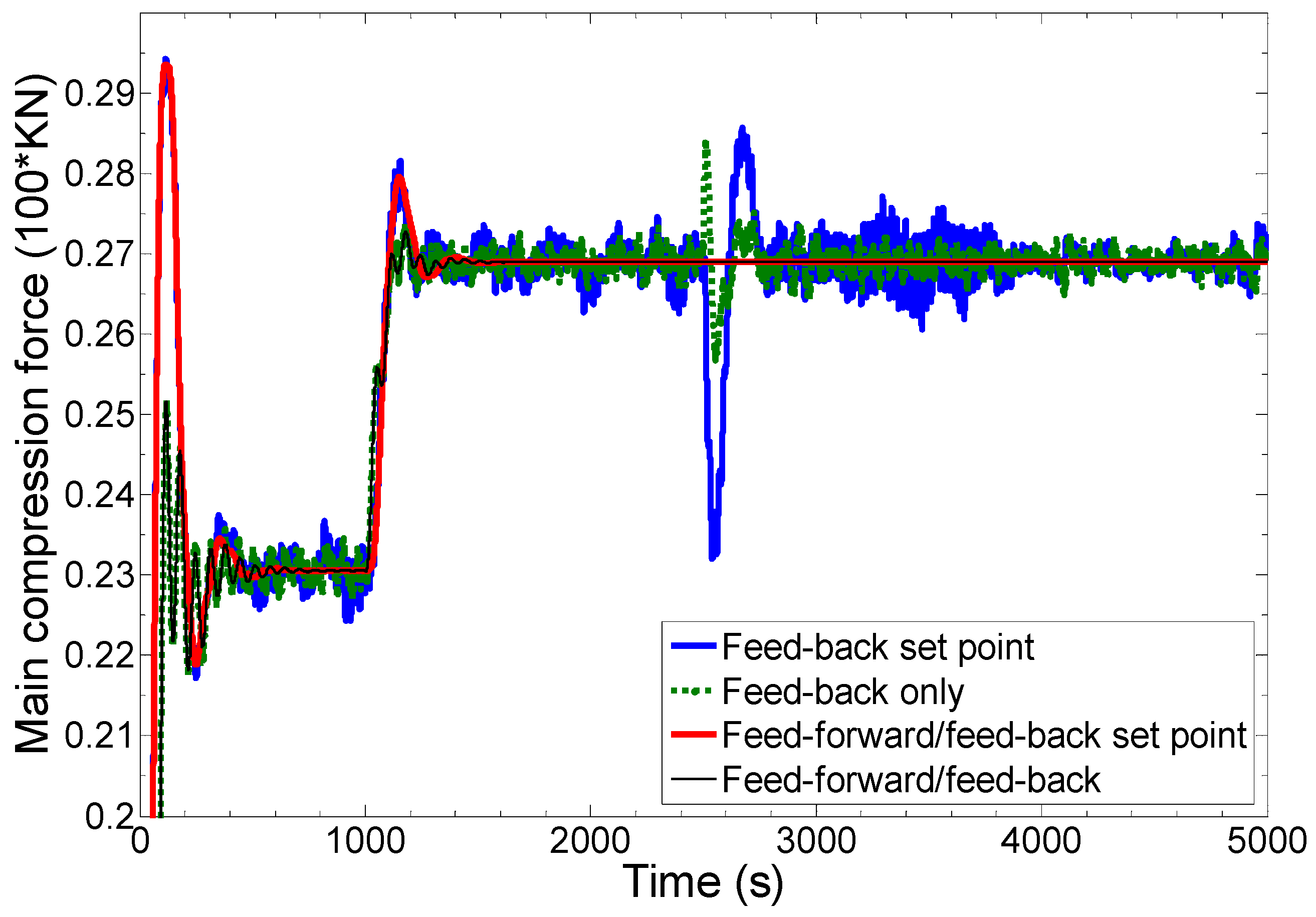

The main compression force has been controlled in real time through a slave controller. The performance of the tablet weight and hardness master controller depends significantly on the performance of the slave ‘main compression force’ controller. The closed-loop response of the main compression force under the combined and feed-back only control strategy is shown in

Figure 8. In each case, the set point of the main compression force has been obtained by master controller specifically designed to control the tablet weight. As shown in

Figure 8, in the case of the combined feed-forward/feed-back control scheme, the main compression force is controlled at the set pint generated by master controller. A small oscillation can be seen at startup and at the point where step change in the hardness set point has been made. The decay ratio is however higher as is desired for a well-tuned controller. The step change in the main compression force set point (generated by master controller) can be seen at

t = 1000 s. This step change in the main compression force set point is to achieve the step change in the hardness. More compression force is needed to produce the higher hardness tablet. In spite of an increase in compression force, the tablet weight has not been increased meaning that this increase in compression force is because of increased upper punch displacement while keeping the consistent fill depth (see

Figure 5,

Figure 6,

Figure 7 and

Figure 8). In the case of the feed-back only control scheme, first the main compression force set point generated from master controller is oscillatory and second this set point has not been tracked precisely. The variation in the achieved main compression force under the feed-back only control scheme can be seen in

Figure 8 which is because of variation in the blend density. The major variation can be seen at

t = 2500 s where a step change in the blend density has been introduced.

Figure 8.

Closed-loop response of main compression force (performance of slave controller).

Figure 8.

Closed-loop response of main compression force (performance of slave controller).

Results shown in

Figure 5,

Figure 6,

Figure 7 and

Figure 8 demonstrate that the tablet weight and hardness control loops have been decoupled so that both variables can be controlled simultaneously. In order to verify the performance of decoupling control mechanism, a step change in the hardness set point has been made (see

Figure 5) while keeping the tablet weight set point at a constant value (see

Figure 7). As shown in

Figure 5,

Figure 6 and

Figure 7, the tablet hardness value has been changed successfully while maintaining a consistent tablet weight.

Figure 8 shows that in order to achieve the increased tablet hardness, the set point of the main compression force has been increased. Note that the hardness set point has been changed just for demonstration of the performance of decoupling control mechanism and set point tracking ability of the control system and, for a given formulation, the hardness needs to be consistent throughout the operation.

The response of the fill depth is shown in

Figure 9. As shown in the figure under the feed-forward/feed-back control scheme, the control system changes the fill depth more precisely to compensate for the disturbances introduced in the powder bulk density. More change can be seen at

t = 1000 s where the step change in hardness set point has been introduced. A step change in the fill depth can be seen at

t = 2500 s where step change in the powder bulk density has been introduced. Note that, there are also random disturbances throughout the operation. The fill depth was within the acceptable range during closed-loop operation indicating that the proposed control system is feasible.

Figure 9.

Comparison of actuators obtained from combined feed-forward/feed-back control strategy with feed-back only control strategy for main compression force control.

Figure 9.

Comparison of actuators obtained from combined feed-forward/feed-back control strategy with feed-back only control strategy for main compression force control.

The set point of the proposed control system can be changed within a feasible operating range of a tablet press. This range depends on many factors such as tablet press configuration and the properties of the raw materials. The actuators should be within the feasible operating range in order to maintain the control variables within the control limits. For example, in case of Kikusui rotary tablet press, the powder filling depth range is 1–15 mm. Maximum tablet diameter is 16 mm and tablet thickness range is 0–5 mm. The range of tablet weight and hardness that can be produced from a tablet press also depends on the raw materials (API, Excipient, Lubricant) and blend properties along with tablet press specifications. Some of the ranges mentioned above can be changed by changing the tooling used in the tablet press. The control architecture will be same for different tablet presses and raw materials but the controller parameters need to be returned.