Energy Considerations for Plasma-Assisted N-Fixation Reactions

Abstract

:1. Introduction

2. Methodology-Approach

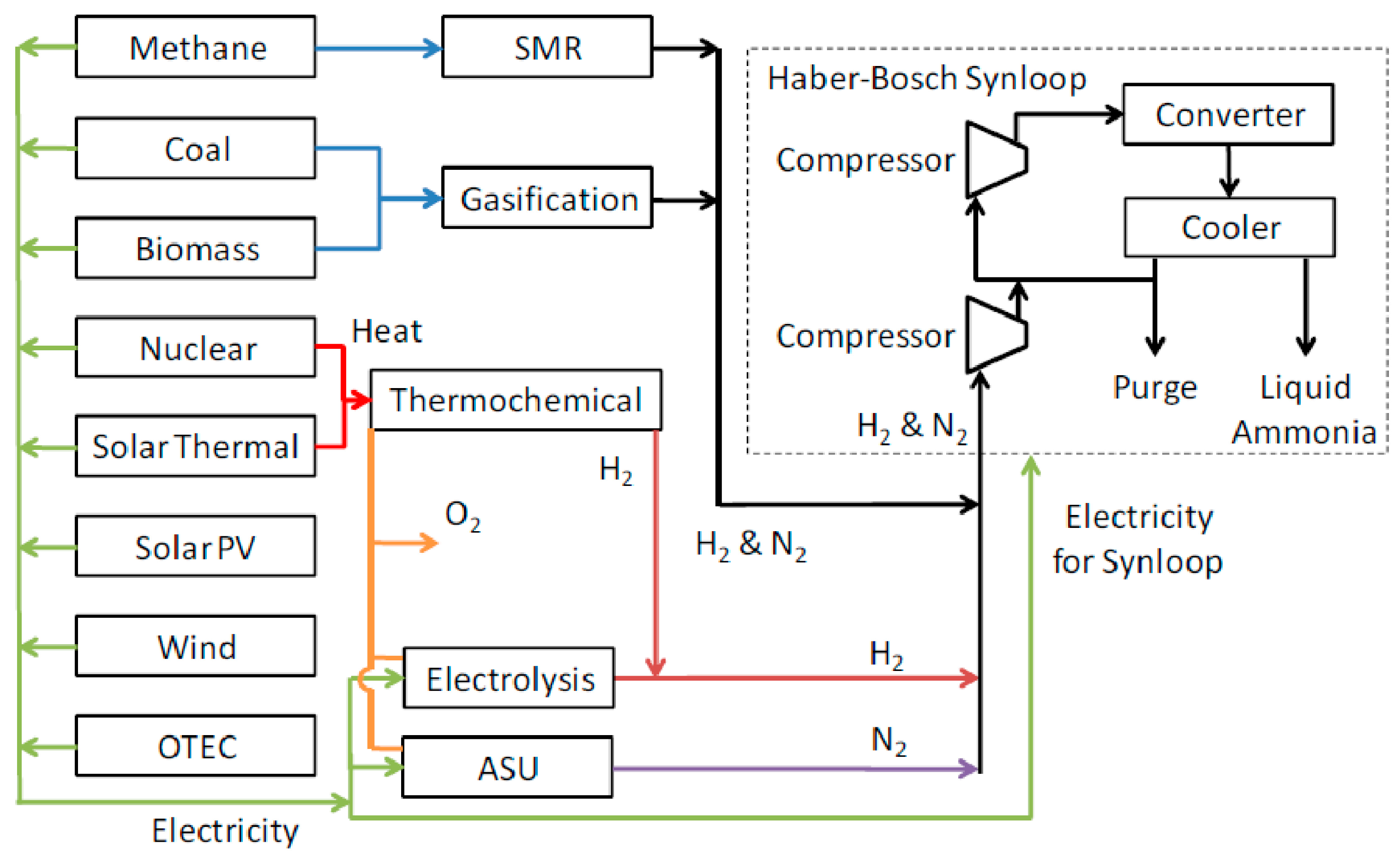

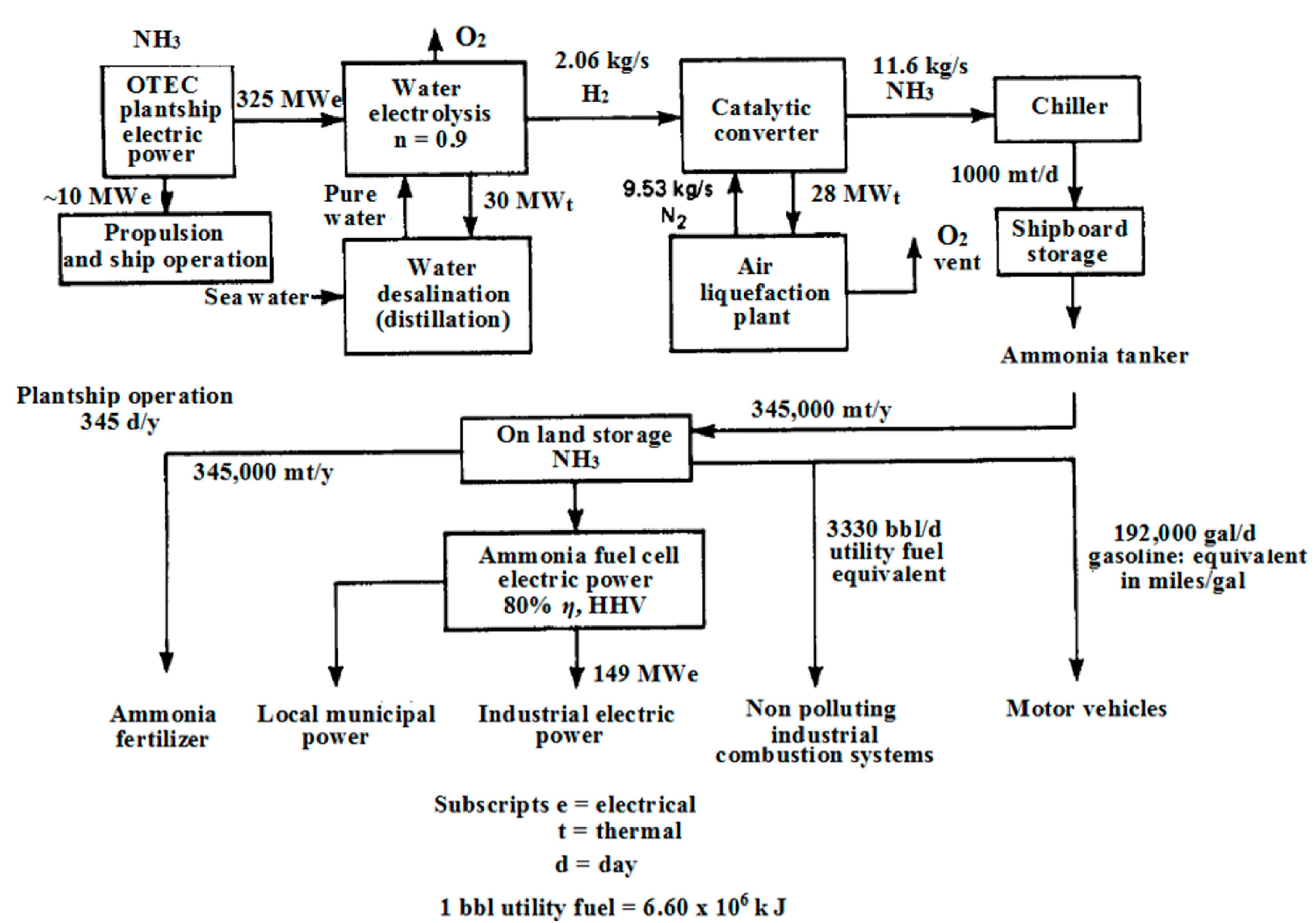

2.1. Integration of Renewable Energy Sources

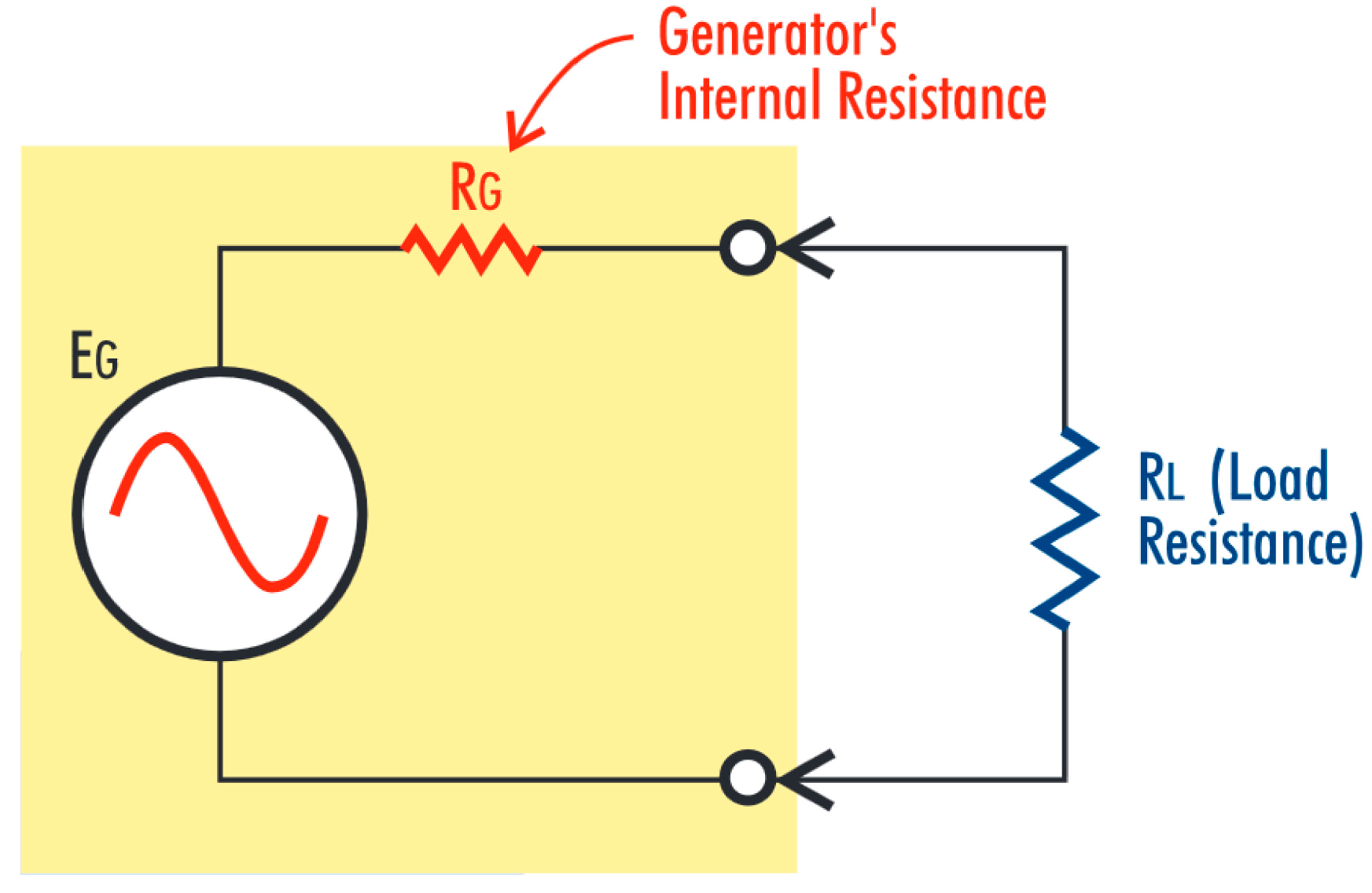

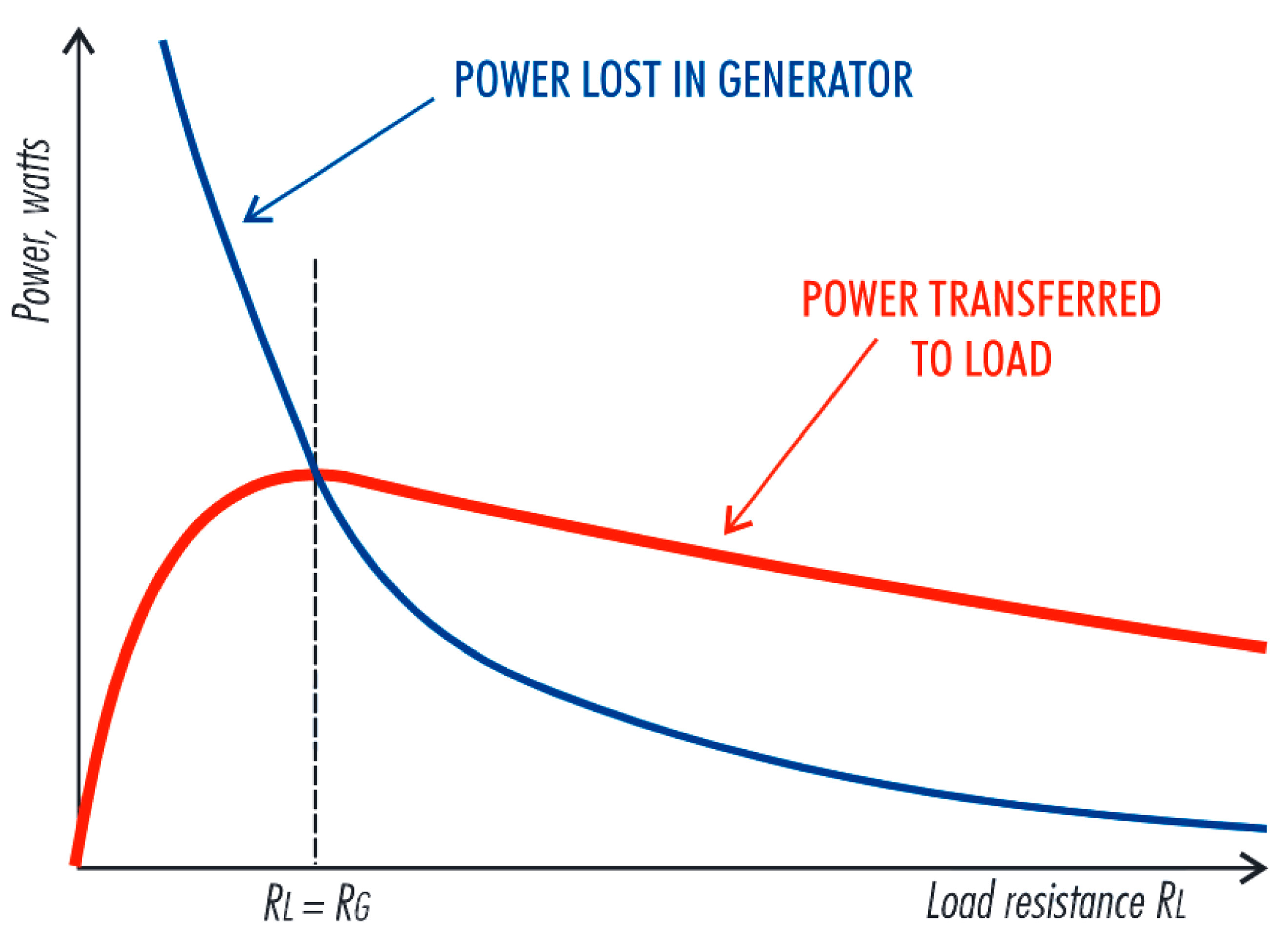

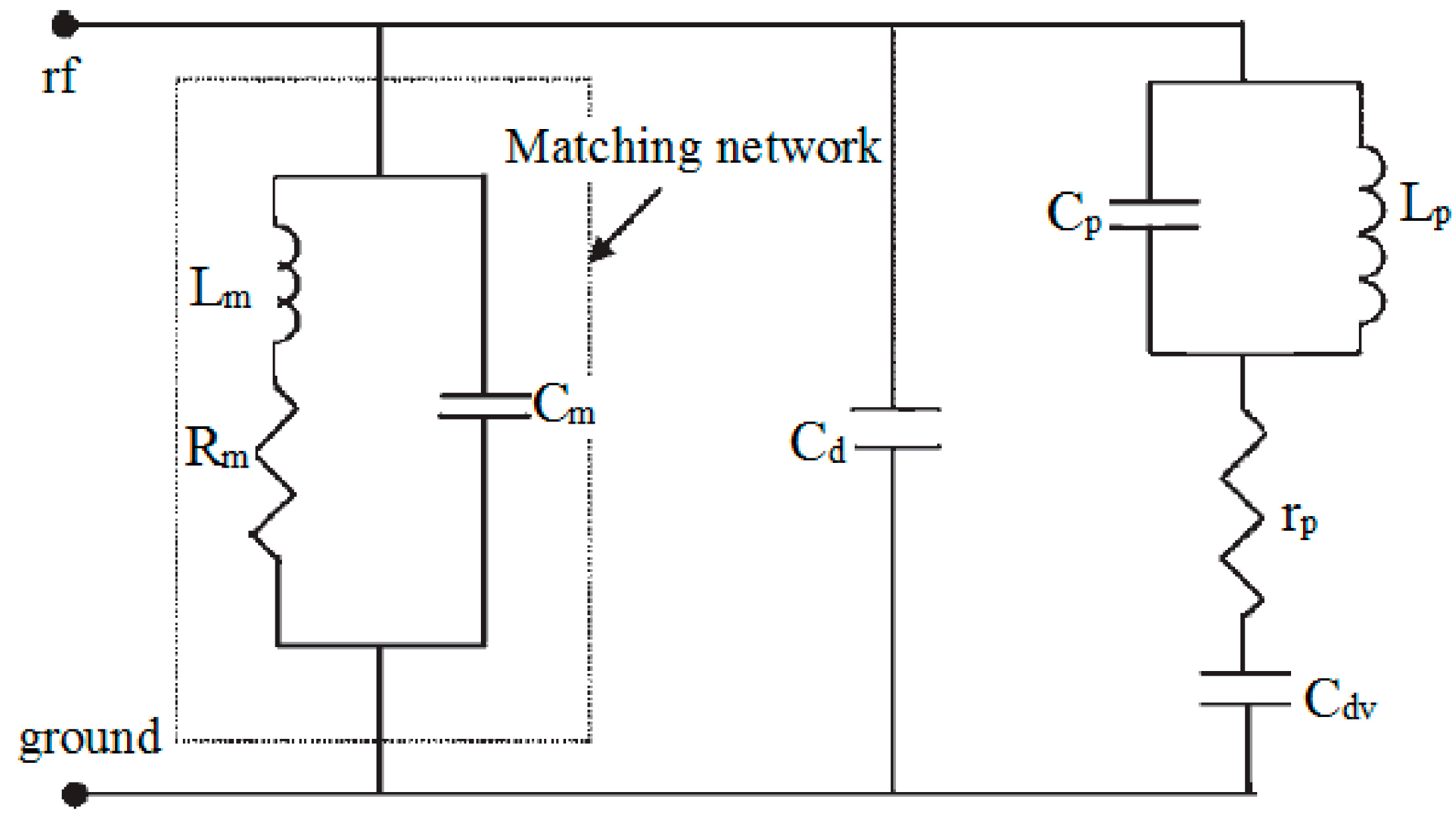

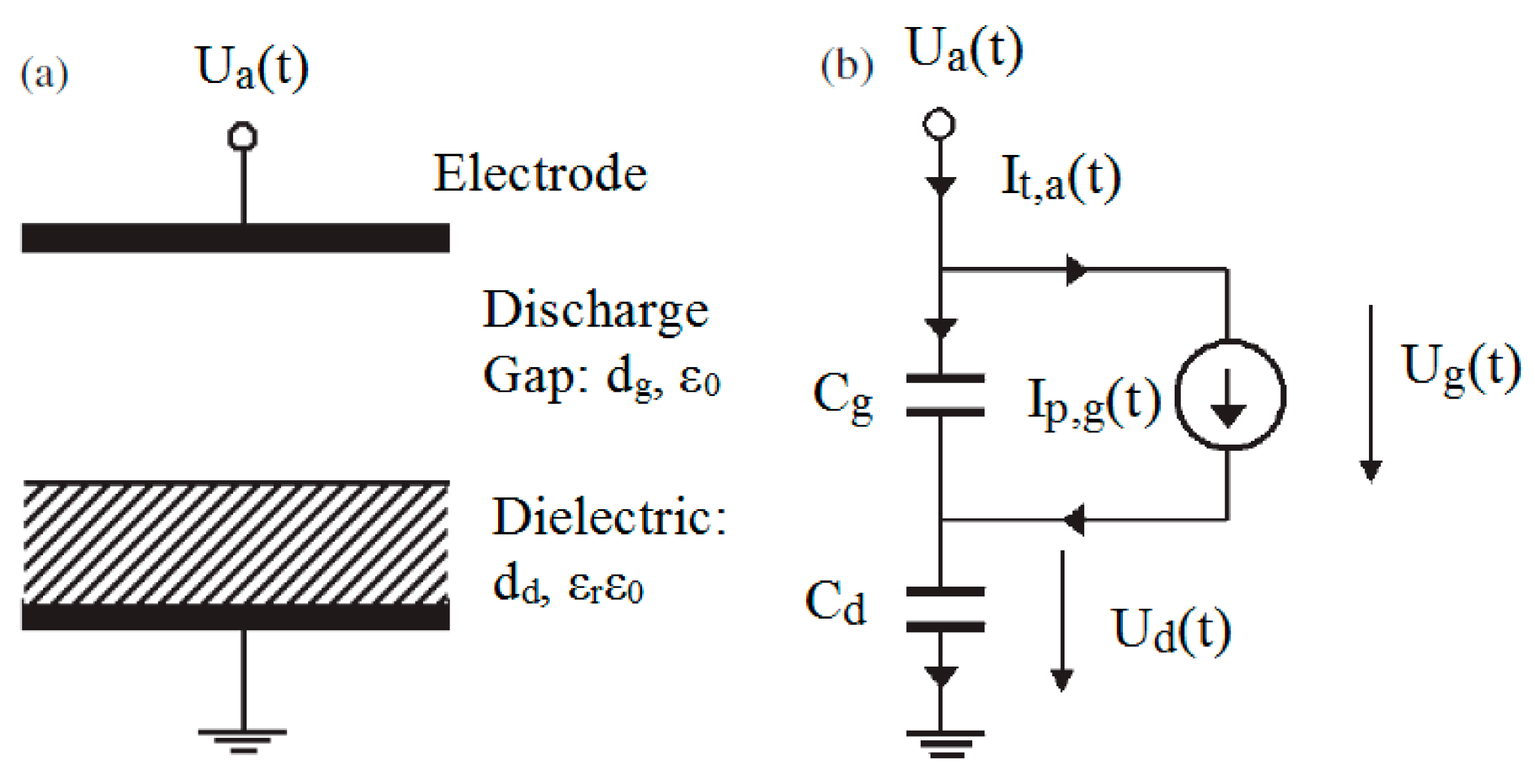

2.2. Power Supply System of Plasma Reactors

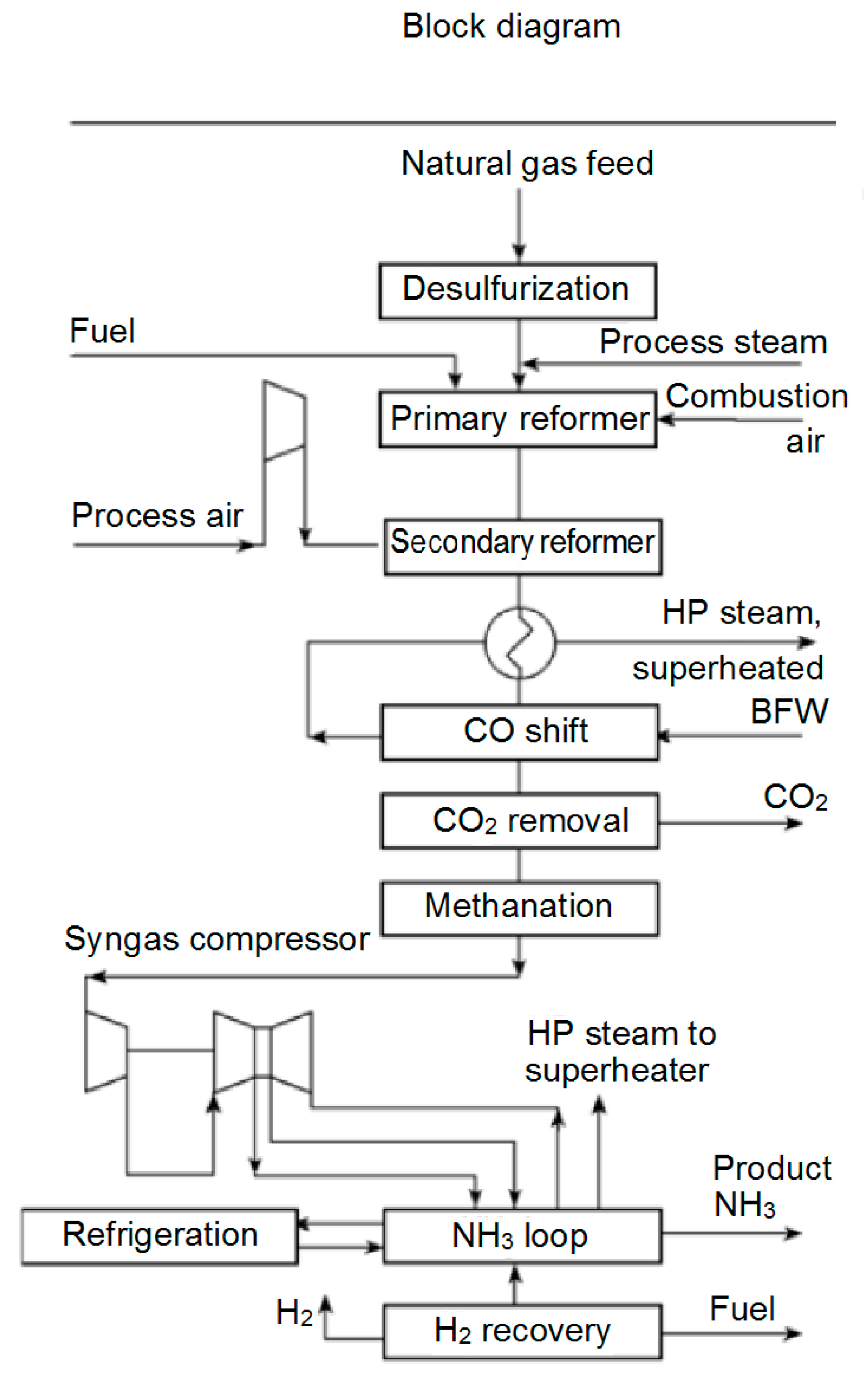

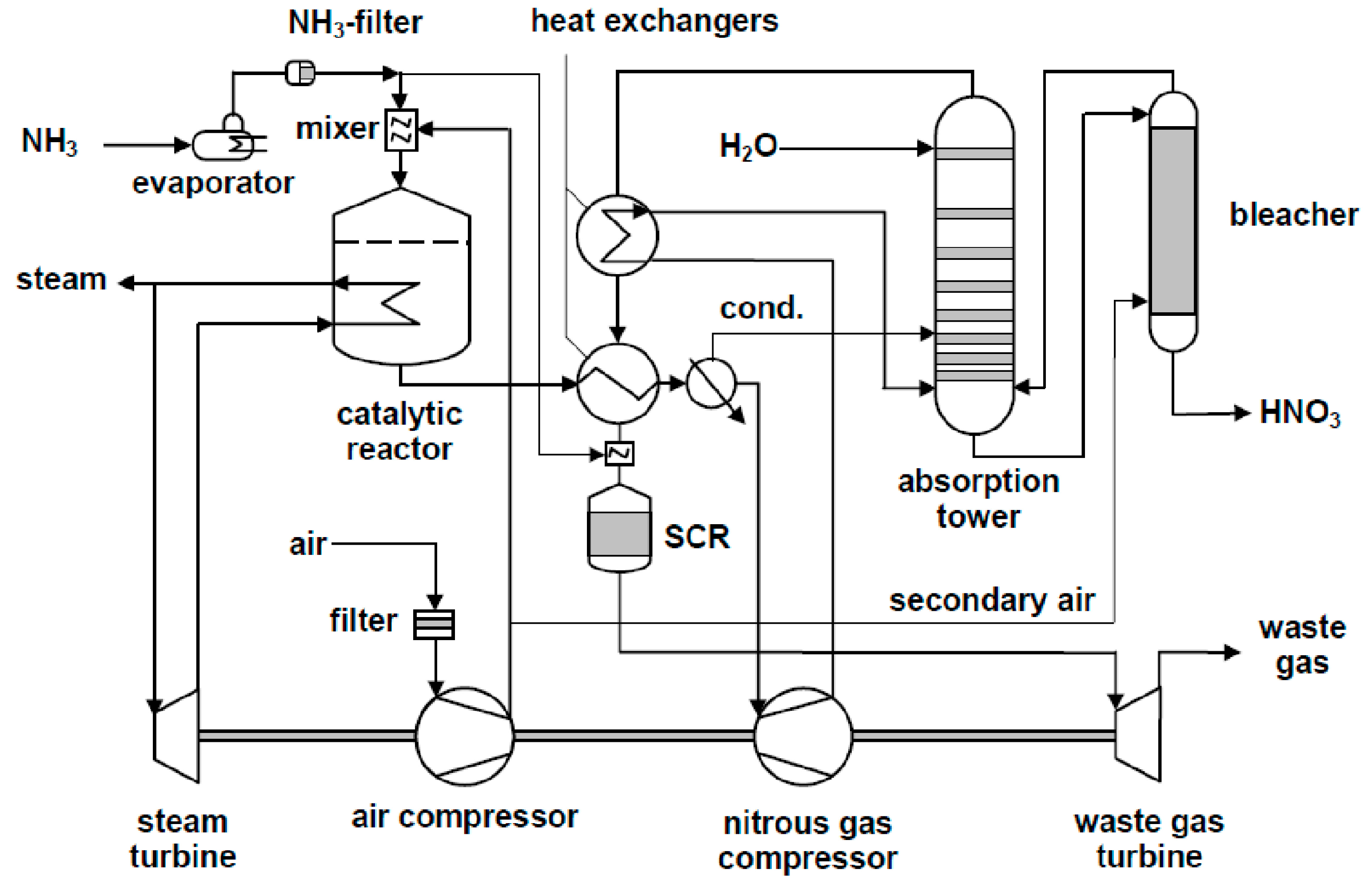

2.3. Synthesis Loop and Downstream Activities

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Willem, E.J.; Sutton, M.A.; Galloway, J.; Klimont, Z.; Winiwarter, W. How a Century of Ammonia Synthesis Changed the World. Nat. Geosci. 2008, 1, 636–639. [Google Scholar]

- Companies and Markets. Ammonia Global Market to 2020. Available online: http://www.companiesandmarkets.com/Market/Chemicals/Market-Research/Ammonia-Global-Market-to-2020/RPT1145125 (accessed on 21 February 2014).

- Rafiqul, I.; Weber, C.; Lehmann, B.; Voss, A. Energy Efficiency Improvements in Ammonia Production—Perspectives and Uncertainties. Energy 2005, 30, 2487–2504. [Google Scholar]

- International Energy Agency (IEA). Tracking Industrial Energy Efficiency and CO2 Emissions; IEA Publications: Paris, France, 2007; p. 324. [Google Scholar]

- Feibelman, P.J.; Stumpf, R. Comments on Potential Roles of Ammonia in a Hydrogen Economy—A Study of Issues Related to the Use of Ammonia for On-Board Vehicular Hydrogen Storage. Available online: http://www.sandia.gov/surface_science/pjf/On_NH3_roles_in_H2_economy.pdf (accessed on 21 February 2014).

- Lan, R.; Tao, S. Direct Ammonia Alkaline Anion-Exchange Membrane Fuel Cells. Electrochem. Solid-State Lett. 2010, 13, B83–B86. [Google Scholar]

- European Fertilizer Manufacturers Association (EFMA). Best Available Techniques for Pollution Prevention and Control in the European Fertilizer Industry. Booklet No. 1 of 8: Production of Ammonia; EFMA: Brussels, Belgium, 2000. [Google Scholar]

- Kool, A.; Marinussen, M.; Blonk, H.; Consultants, B. LCI Data for the Calculation Tool Feedprint for Greenhouse Gas Emissions of Feed Production and utilization. GHG Emissions of N, P and K Fertilizer Production; Blonk Consultants: Gouda, The Netherlands, 2012; p. 15. [Google Scholar]

- Bai, M.; Zhang, Z.; Bai, X.; Bai, M.; Ning, W. Plasma Synthesis of Ammonia with a Microgap Dielectric Barrier Discharge at Ambient Pressure. IEEE Trans. Plasma Sci. 2003, 31, 1285–1291. [Google Scholar] [CrossRef]

- Mutel, B.; Dessaux, O.; Goudmand, P. Energy Cost Improvement of the Nitrogen Oxides Synthesis in a Low Pressure Plasma. Rev. Phys. Appl. 1984, 19, 461–464. [Google Scholar] [CrossRef]

- Fridman, A.; Cho, Y.-I. Transport Phenomena in Plasma-Advances in Heat Transfe; Academic Press, Elsevier: Waltham, MA, USA, 2007; Volume 1, pp. 1–4. [Google Scholar]

- Pekárek, S. Non-Thermal Plasma Ozone Generation. Acta Polytech. 2003, 43, 47–51. [Google Scholar]

- Bartels, J.R. A Feasibility Study of Implementing an Ammonia Economy. Master’s Thesis, Iowa State University, Ames, IA, USA, 2008. [Google Scholar]

- Hessel, V.; Anastasopoulou, A.; Wang, Q.; Kolb, G.; Lang, J. Energy, Catalyst and Reactor Considerations for (near)-Industrial Plasma Processing and Learning for Nitrogen-Fixation Reactions. Catal. Today 2013, 211, 9–28. [Google Scholar] [CrossRef]

- Hessel, V.; Cravotto, G.; Fitzpatrick, P.; Patil, B.S.; Lang, J.; Bonrath, W. Industrial applications of plasma, microwave and ultrasound techniques: Nitrogen-fixation and hydrogenation reactions. Chem. Eng. Process. 2013, 71, 19–30. [Google Scholar] [CrossRef]

- Gieshoff, J.; Lang, J. Process for the Plasma-Catalytic Production of Ammonia. U.S. Patent 6471932B1, 29 October 2002. [Google Scholar]

- Tallaksen, J.; Reese, M. Ammonia Production Using Wind Energy. Available online: http://nh3fuel.files.wordpress.com/2013/10/nh3fcx-joel-tallaksen.pdf (accessed on 21 February 2014).

- Dugger, G.; Francis, E. Design of an Ocean Thermal Energy Plant Ship to Produce Ammonia via Hydrogen. Int. J. Hydrog. Energy 1977, 2, 231–249. [Google Scholar] [CrossRef]

- Lu, X.; McElroy, M.B.; Kiviluoma, J. Global Potential for Wind-Generated Electricity. Proc. Natl. Acad. Sci. USA 2009, 106, 10933–10938. [Google Scholar] [CrossRef]

- Alosaimy, A.S.; Hamed, A.M.; Balabel, A.; Mahrous, A. Experimental Investigation of Solar Hydrogen Production Unit in Taif, Saudi Arabia. Int. J. Adv. Sci. Tech. Res. 2013, 6, 61–73. [Google Scholar]

- Union of the Electric Industry-EURELECTRIC & VGB PowerTech. Efficiency in Electric Generation; Union of the Electricity Industry-EURELECTRIC & VGB: Brussels, Belgium, 2003. [Google Scholar]

- Waid, R.L. The Mini-Otec Test. In Proceedings of the OCEANS '79: Fifth Annual Combined Conference, San Diego, CA, USA, 17–19 September 1979; pp. 548–552.

- Avery, W.H.; Richards, D.; Dugger, G.L. Hydrogen Generation by OTEC Electrolysis, and Economical Energy Transfer to World Markets via Ammonia and Methanol. Int. J. Hydrog. Energy 1985, 10, 727–736. [Google Scholar] [CrossRef]

- NH3 Fuel Association. Ammonia Production Using Wind Energy. Available online: http://nh3fuelassociation.org/2013/08/28/ammonia-production-using-wind-energy/ (accessed on 21 February 2014).

- Ammonia Industry. Ammonia Plants: Morris, MN—University of Minnesota. Available online: http://ammoniaindustry.com/morris-mn-university-of-minnesota/ (accessed on 23 June 2014).

- Chen, Z. Impedance Matching for One Atmosphere Uniform Glow Discharge Plasma (OAUGDP) Reactors. IEEE Trans. Plasma Sci. 2002, 30, 1922–1930. [Google Scholar] [CrossRef]

- Spiliopoulos, N.; Mataras, D.; Rapakoulias, D.E. Power Dissipation and Impedance Measurements in Radio-Frequency Discharges. J. Vac. Sci. Technol. A 1996, 14, 2757–2765. [Google Scholar] [CrossRef]

- Diatczyk, J.; Komarzyniec, G.; Stryczewska, H.D. Power Consumption of Gliding Arc Discharge Plasma Reactor a B. Int. J. Plasma Environ. Sci. Technol. 2011, 5, 12–16. [Google Scholar]

- Holub, M.; Kalisiak, S.; Jakubowski, T.; Balcerak, M. Power Electronic Supply Systems for Non-Thermal Plasma Sources. In Proceedings of the XVIII International Conference on Gas Discharge and Their Applications (GD2010), Greifswald, Germany, 5–10 September 2010.

- Sheykhrajeh, S.Z. Flexible High Voltage Pulsed Power Supply for Plasma Applications. Ph.D. Thesis, Queensland University of Technology, Brisbane, QLD, Australia, 2011. [Google Scholar]

- Van Dijk, J.; Kroesen, G.M.W.; Bogaerts, A. Plasma Modelling and Numerical Simulation. J. Phys. D 2009, 42, 190301. [Google Scholar]

- Jaycar Electronics Group. Impedance Matching : A primer. Available online: http://www.jaycar.com.au/images_uploaded/impmatch.pdf (accessed on 21 February 2014).

- Singh, K.P.; Roy, S. Impedance Matching for an Asymmetric Dielectric Barrier Discharge Plasma Actuator. Appl. Phys. Lett. 2007, 91, 081504. [Google Scholar] [CrossRef]

- Zito, J.C.; Arnold, D.P.; Duscher, R.J.; Roy, S. Investigation of Impedance Characteristics and Power Delivery for Dielectric Barrier Discharge Plasma Actuators. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlnado, FL, USA, 4–7 January 2010; pp. 1–17.

- Kriegseis, J.; Grundmann, S.; Tropea, C. Power Consumption, Discharge Capacitance and Light Emission as Measures for Thrust Production of Dielectric Barrier Discharge Plasma Actuators. J. Appl. Phys. 2011, 110, 013305. [Google Scholar] [CrossRef]

- Ebato, S.; Ogino, Y.; Ohnishi, N. Computational Study of Discharge Processes in DBD Plasma Actuators. J. Space Technol. Sci. 2011, 25, 19–33. [Google Scholar]

- Kriegseis, J.; Möller, B.; Grundmann, S.; Tropea, C. Capacitance and Power Consumption Quantification of Dielectric Barrier Discharge (DBD) Plasma Actuators. J. Electrost. 2011, 69, 302–312. [Google Scholar] [CrossRef]

- Pipa, A.V.; Koskulics, J.; Brandenburg, R.; Hoder, T. The Simplest Equivalent Circuit of a Pulsed Dielectric Barrier Discharge and the Determination of the Gas Gap Charge Transfer. Rev. Sci. Instrum. 2012, 83, 115112. [Google Scholar] [CrossRef]

- Tran, N.D.; Sasaki, T.; Kikuchi, T.; Harada, N. Optimization Input Power to Obtain the Stable Annealing Conditions of a Plasma Annealing System at Atmospheric Pressure. J. Plasma Fusion Res. Ser. 2010, 9, 503–508. [Google Scholar]

- Dai, J.; Hao, R.; You, X.; Sun, H.; Huang, X.; Li, Y. Modeling of Plasma Arc for the High Power Arc Heater in MATLAB. In Proceedings of the 5th IEEE Conference on Industrial Electronics and Applications, Taichung, Taiwan, 15–17 June 2010; pp. 463–468.

- Tseng, K.-J.; Wang, Y.; Vilathgamuwa, D.M. An Experimentally Verified Hybrid Cassie-Mayr Electric Arc Model for Power Electronics Simulations. IEEE Trans. Power Electron. 1997, 12, 429–436. [Google Scholar] [CrossRef]

- Jaroszyński, L.; Stryczewska, H.D. Computer Simulation of the Electric Discharge in Glidarc Plasma Reactor. In Proceedings of the 3rd International Conference: Electromagnetic devices and processes in environment protection ELMECO-3, Naleczow, Poland, 4–6 June 2000.

- Valdivia-Barrientos, R.; Pacheco-Sotelo, J.; Pacheco-Pacheco, M.; Benítez-Read, J.S.; López-Callejas, R. Analysis and Electrical Modelling of a Cylindrical DBD Configuration at Different Operating Frequencies. Plasma Sources Sci. Technol. 2006, 15, 237–245. [Google Scholar] [CrossRef]

- Liu, S.; Neiger, M. Electrical Modelling of Homogeneous Dielectric Barrier Discharges under an Arbitrary Excitation Voltage. J. Phys. D Appl. Phys. 2003, 36, 3144–3150. [Google Scholar] [CrossRef]

- Stryczewska, H.D.; Janowski, T.; Jaroszyński, L. Mathematical Model of the Non-Thermal Plasma Reactor. In Proceedings of the IV International Workshop on Advanced Plasma Tools and Process Engineering, Millbrae, CA, USA, 26–27 May 1998.

- Gustavsson, N. Evaluation and Simulation of Black-Box Arc Models for High Voltage Circuit-Breakers. Master’s Thesis, Linkoping University, Linkoping, Sweden, 2004. [Google Scholar]

- Nitu, S.; Nitu, C.; Mihalache, C.; Anghelita, P.; Pavelescu, D. Comparison between Model and Experiment in Studying the Electric Arc. J. Optoelectron. Adv. Mater. 2008, 10, 1192–1196. [Google Scholar]

- Russamee, N. Simulation and Design of Ammonia Process from Natural Gas Reforming. Master’s Thesis, Kasetsart University, Bangkok, Thailand, 2009. [Google Scholar]

- Ruan, R.; Deng, S.; Le, Z.; Chen, P. Non-Thermal Plasma Synthesis of Ammonia. WO Patent 2009025835 A1, 26 February 2009. [Google Scholar]

- Thyssenkrupp Uhde. Ammonia. Available online: http://www.thyssenkrupp-uhde-asia-pacific.com/fileadmin/documents/brochures/0a2d5391-b166-484d-847d-3cbfd941f06b.pdf (accessed on 21 February 2014).

- Appl, M. Ammonia. In Ullmann's Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; p. 85. [Google Scholar]

- Thyssenkrupp Uhde. Nitric acid. Available online: http://www.thyssenkrupp-uhde-asia-pacific.com/fileadmin/documents/brochures/cc0d66ab-c015-4512-8c70-1dd5d2917b9e.pdf (accessed on 21 February 2014).

- Wiesenberger, H. State-of-the-Art for the Production of Nitric Acid with Regard to the IPCC Directive; Umweltbundesamt-Federal Environment Agency Austria: Vienna, Austria, 2001; p. 66. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastasopoulou, A.; Wang, Q.; Hessel, V.; Lang, J. Energy Considerations for Plasma-Assisted N-Fixation Reactions. Processes 2014, 2, 694-710. https://doi.org/10.3390/pr2040694

Anastasopoulou A, Wang Q, Hessel V, Lang J. Energy Considerations for Plasma-Assisted N-Fixation Reactions. Processes. 2014; 2(4):694-710. https://doi.org/10.3390/pr2040694

Chicago/Turabian StyleAnastasopoulou, Aikaterini, Qi Wang, Volker Hessel, and Juergen Lang. 2014. "Energy Considerations for Plasma-Assisted N-Fixation Reactions" Processes 2, no. 4: 694-710. https://doi.org/10.3390/pr2040694

APA StyleAnastasopoulou, A., Wang, Q., Hessel, V., & Lang, J. (2014). Energy Considerations for Plasma-Assisted N-Fixation Reactions. Processes, 2(4), 694-710. https://doi.org/10.3390/pr2040694