Development of a Numerically Inexpensive 3D CFD Model of Slag Reduction in a Submerged Arc Furnace for Phosphorus Recovery from Sewage Sludge

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Submerged Arc Furnace Structure and Multiphase Flow

- Bubble-induced stirring, resulting from the bubble generation caused by the reduction reaction. Rising gas bubbles impart a substantial amount of their momentum to the surrounding slag, therefore increasing the velocities in bubble-rich regions and enhancing mixing.

- Natural buoyancy, which is caused by density differences induced by temperature gradients.

- Electromagnetic stirring, arising from the electric current, though typically small compared to bubble- and buoyancy-driven effects.

1.3. Computational Modelling of Submerged Arc Furnaces

- The absence of process data, as the investigated concept represents a novel approach.

- The simplified treatment of bubble generation in current models, despite its expected importance for the present process, since the reduction reaction is not limited to the electrode surface.

- The modelling of the energy sink primarily as a volumetric distribution, without considering the local cell temperature.

- The lack of furnace control simulations aimed at reaching and maintaining a specified process temperature in the existing literature.

1.4. Objective of This Study

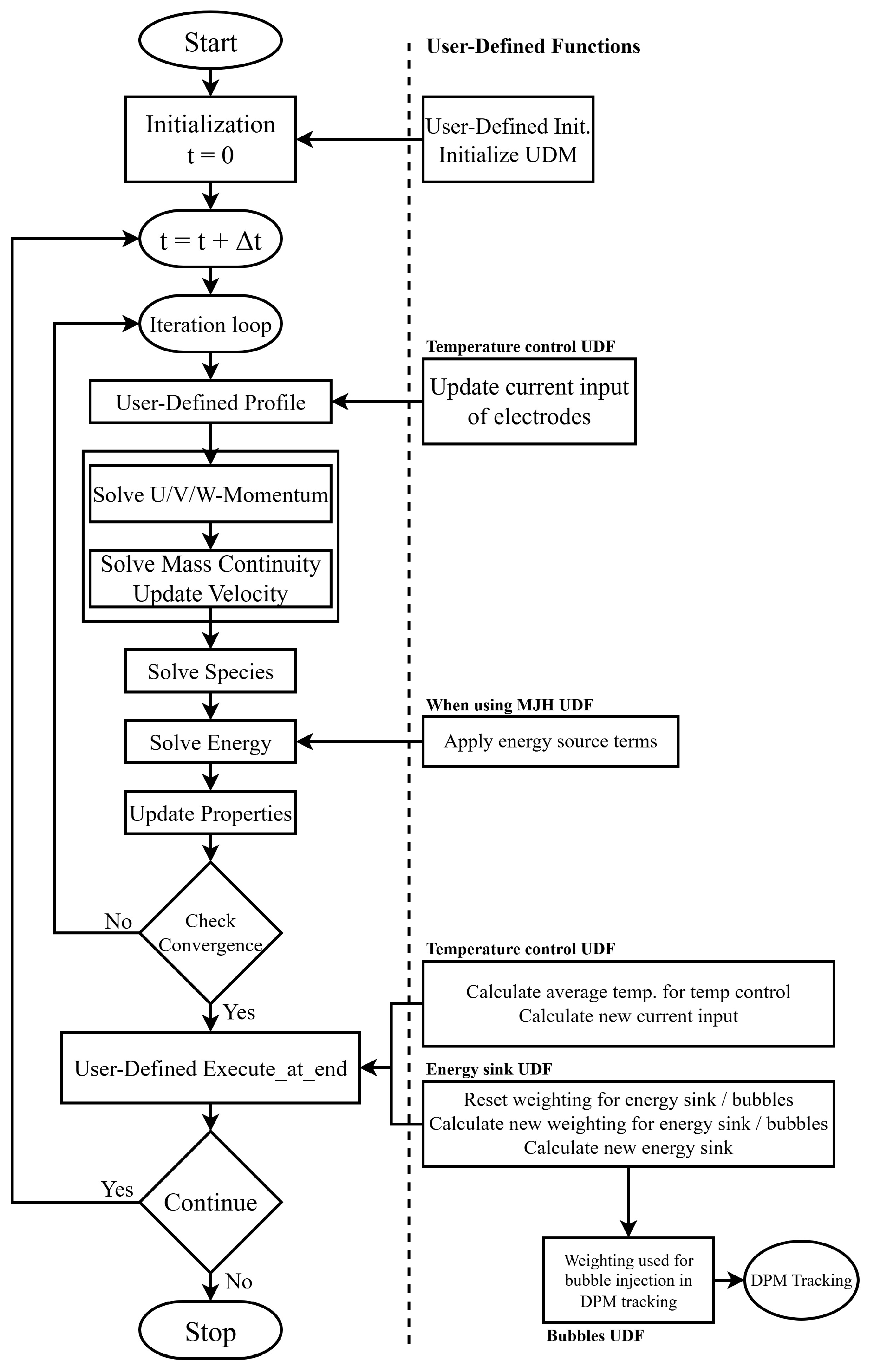

2. Model Development and Methods

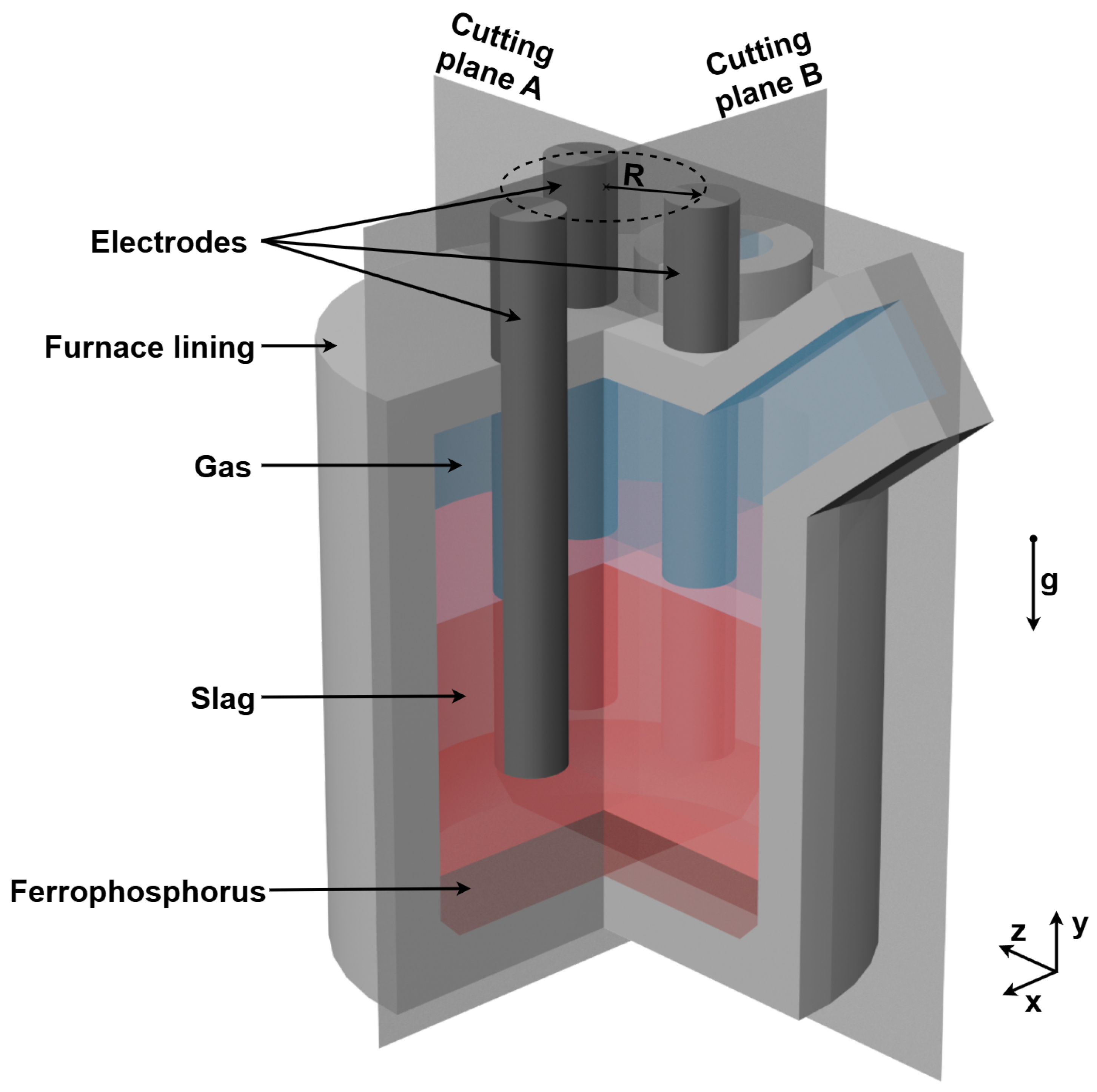

2.1. Geometry and Materials

- The slag, which is supplied from the flash reactor and consisting of the residues of dried and burnt sewage sludge.

- The ferrophosphorus, which is formed as an unwanted by-product when iron (Fe) is present in the slag since it binds phosphorus and therefore reduces the recoverable amount of phosphorus.

2.2. Computational Grid

2.3. Boundary Conditions

2.4. Flow Modelling

Consideration of Turbulence

2.5. Multiphase Modelling

2.5.1. Liquid Phases

2.5.2. Gas Bubbles

2.6. Radiation

2.7. Electric Field Modelling

2.8. Specific Model Extensions

2.8.1. Power Input

2.8.2. Energy Sink Due to Reduction Reaction

2.8.3. Bubbles

2.8.4. Temperature Control

2.8.5. Mean-Joule-Heating Approach

2.9. Numerical Methods

2.10. Convergence

3. Results and Discussion

3.1. Grid Independence Study

3.2. Slag Velocity Distribution: Influence of Bubbles and Convection

- Natural buoyancy— slag heats up near the electrodes, which reduces its density and therefore causes it to rise.

- Bubbles—the bubbles, which have a much lower density than the slag, ascend and impart a substantial amount of their momentum to the surrounding slag, increasing the velocities in the bubble-rich regions.

3.3. Electric Results

3.3.1. Electric Potential Distribution

3.3.2. Current Density Distribution

3.3.3. Power Distribution (Joule-Heating)

3.4. Temperature Distribution

3.5. Implications of the Results on Phosphorus Recovery

3.6. Parameter Study

3.7. Results Using the Mean-Joule-Heating Approach

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| BC | Boundary Condition |

| CFD | Computational Fluid Dynamics |

| CSV | Comma-separated Values |

| DO | Discrete Ordinates |

| DPM | Discrete Phase Model |

| EAF | Electric Arc Furnace |

| FVM | Finite Volume Method |

| MJH | Mean-Joule-heating |

| PISO | Pressure-Implicit with Splitting of Operators |

| SAF | Submerged Arc Furnace |

| UDF | User-Defined Function |

| UDM | User-Defined Memory |

| VOF | Volume of Fluid |

References

- McDowell, R.W.; Pletnyakov, P.; Haygarth, P.M. Phosphorus applications adjusted to optimal crop yields can help sustain global phosphorus reserves. Nat. Food 2024, 5, 332–339. [Google Scholar] [CrossRef]

- Yu, M.; Gao, Z.; Xie, W.; Shi, X.; Zhang, O.; Shen, Z.; Fang, L.; Ren, M.; Sun, J. A novel strategy utilizing oxidation states of phosphorus for designing efficient phosphorus-containing flame retardants and its performance in epoxy resins. Polym. Degrad. Stab. 2024, 230, 111016. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Assessment of One Published Review on Health Risks Associated with Phosphate Additives in Food. EFSA J. 2013, 11, 3444. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Gea, G.; Arauzo, J.; Kersten, S.R.; Kootstra, A.M.J. Phosphorus recovery from sewage sludge char ash. Biomass Bioenergy 2014, 65, 42–50. [Google Scholar] [CrossRef]

- Ortner, B.; Schmidberger, C.; Gerhardter, H.; Prieler, R.; Schröttner, H.; Hochenauer, C. Application of computationally inexpensive CFD model in steady-state and transient simulations of pulverized sewage sludge combustion. Adv. Powder Technol. 2023, 34, 104260. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, L.; Chen, J.; Liu, T.; Li, N.; Xu, J.; Yin, W.; Li, D.; Zhang, Y.; Zhou, X. Phosphorus recovery from sewage sludge ash (SSA): An integrated technical, environmental and economic assessment of wet-chemical and thermochemical methods. J. Environ. Manag. 2023, 344, 118691. [Google Scholar] [CrossRef] [PubMed]

- Ortner, B.; Schmidberger, C.; Prieler, R.; Mally, V.; Hochenauer, C. Analysis of the shear-driven flow in a scale model of a phase separator: Validation of a coupled CFD approach using experimental data from a physical model. Int. J. Multiph. Flow 2024, 177, 104852. [Google Scholar] [CrossRef]

- Ortner, B.; Peham, L.; Schmidberger, C.; Prieler, R.; Hochenauer, C. CFD modeling of sewage sludge combustion in an experimental entrained flow reactor with integrated slag flow dynamics. Appl. Therm. Eng. 2025, 267, 125779. [Google Scholar] [CrossRef]

- Askarizadeh, H.; Lotfollahzadeh, A.; Wolfersdorf, C.; Pielsticker, S.; Kneer, R. An equilibrium calculation tool with development potential for predicting phosphorus recovery from sewage sludge in entrained-flow gasifiers. Chem. Eng. Res. Des. 2023, 197, 53–64. [Google Scholar] [CrossRef]

- Scheepers, E.; Yang, Y.; Adema, A.T.; Boom, R.; Reuter, M.A. Process Modeling and Optimization of a Submerged Arc Furnace for Phosphorus Production. Metall. Mater. Trans. B 2010, 41, 990–1005. [Google Scholar] [CrossRef]

- Piro, N.A.; Figueroa, J.S.; Mckellar, J.T.; Cummins, C.C. Triple-Bond Reactivity of Diphosphorus Molecules. Science 2006, 313, 1276–1279. [Google Scholar] [CrossRef]

- Kotze, A.; Messina, D.; Cryns, Y.; Nagels, E.; Arnout, S. Thermochemical evaluation of elemental phosphorus recovery from sewage sludge. J. South. Afr. Inst. Min. Metall. 2025, 125, 501–508. [Google Scholar] [CrossRef]

- Jones, P.L.; Taylor, S.; Nakai, S.; Jennings, J. Electroheat and Materials Processing. In Electrical Engineer’s Reference Book; Elsevier: Amsterdam, The Netherlands, 2003; pp. 9-1, 9-3–9-38. [Google Scholar] [CrossRef]

- Sheng, Y.Y.; Irons, G.A.; Tisdale, D.G. Transport phenomena in electric smelting of nickel matte: Part I. Electric potential distribution. Metall. Mater. Trans. B 1998, 29, 77–83. [Google Scholar] [CrossRef]

- Karalis, K.T.; Karkalos, N.; Cheimarios, N.; Antipas, G.; Xenidis, A.; Boudouvis, A.G. A CFD analysis of slag properties, electrode shape and immersion depth effects on electric submerged arc furnace heating in ferronickel processing. Appl. Math. Model. 2016, 40, 9052–9066. [Google Scholar] [CrossRef]

- Vångö, M.; Pirker, S.; Lichtenegger, T. Unresolved CFD–DEM modeling of multiphase flow in densely packed particle beds. Appl. Math. Model. 2018, 56, 501–516. [Google Scholar] [CrossRef]

- Barral, P.; Pérez-Pérez, L.J.; Quintela, P. Transient thermal response with nonlocal radiation of a blast furnace main trough. Appl. Math. Model. 2022, 105, 197–225. [Google Scholar] [CrossRef]

- Bermúdez, A.; Crego, O.; Ferrín, J.L.; García, B.; Gómez, D.; Martínez, I.; Pérez-Pérez, L.J.; Salgado, P. Multiphysics simulation of slag melting in an induction furnace for sustainable silicon production. Appl. Math. Model. 2025, 145, 116107. [Google Scholar] [CrossRef]

- Bezuidenhout, J.J.; Eksteen, J.J.; Bradshaw, S.M. Computational fluid dynamic modelling of an electric furnace used in the smelting of PGM containing concentrates. Miner. Eng. 2009, 22, 995–1006. [Google Scholar] [CrossRef]

- Sheng, Y.Y.; Irons, G.A.; Tisdale, D.G. Transport phenomena in electric smelting of nickel matte: Part II. Mathematical modeling. Metall. Mater. Trans. B 1998, 29, 85–94. [Google Scholar] [CrossRef]

- Jardy, A.; Ablitzer, D.; Wadier, J.F. Magnetohydronamic and thermal behavior of electroslag remelting slags. Metall. Trans. B 1991, 22, 111–120. [Google Scholar] [CrossRef]

- Choudhary, M.; Szekely, J. Some General Characteristics of Heat and Fluid Flow Phenomena in Electric Melting and Smelting Operation. J. Min. Metall. Sect. B Metall. 1981, 90, 164. [Google Scholar]

- Bezuidenhout, J.J.; Eksteen, J.J.; Bradshaw, S.M. CFD modelling of molten matte and slag flows in a circular three-phase smelting furnace. Prog. Comput. Fluid Dyn. Int. J. 2009, 9, 316. [Google Scholar] [CrossRef]

- Liu, W.; Lee, J.; Guo, X.; Silaen, A.K.; Zhou, C.Q. Argon Bubble Coalescence and Breakup in a Steel Ladle with Bottom Plugs. Steel Res. Int. 2019, 90, 1800396. [Google Scholar] [CrossRef]

- Fletcher, D.F.; McClure, D.D.; Kavanagh, J.M.; Barton, G.W. CFD simulation of industrial bubble columns: Numerical challenges and model validation successes. Appl. Math. Model. 2017, 44, 25–42. [Google Scholar] [CrossRef]

- Wang, H.; Jia, X.; Wang, X.; Zhou, Z.; Wen, J.; Zhang, J. CFD modeling of hydrodynamic characteristics of a gas–liquid two-phase stirred tank. Appl. Math. Model. 2014, 38, 63–92. [Google Scholar] [CrossRef]

- Jønck, K.M. CFD Modelling of Melting Cyclones for Stone Wool Production. Ph.D. Thesis, Technical University of Denmark, Kgs. Lyngby, Denmark, 2021. [Google Scholar]

- SGL Carbon SE. SIGRAFINE® HLM Datasheet; SGL Carbon SE: Wiesbaden, Germany, 2025; Available online: https://www.sglcarbon.com/pdf/SGL-Datasheet-SIGRAFINE-HLM-EN.pdf (accessed on 5 June 2025).

- Entegris POCO Materials. Graphite Properties and Characteristics; Entegris POCO Materials: Billerica, MA, USA, 2025. Available online: https://poco.entegris.com/content/dam/poco/resources/reference-materials/brochures/brochure-graphite-properties-and-characteristics-11043.pdf (accessed on 5 June 2025).

- Yin, Y.; Zhai, K.; Zhang, B.; Zhai, S. Electrical Resistivity of Iron Phosphides at High–Pressure and High–Temperature Conditions With Implications for Lunar Core’s Thermal Conductivity. J. Geophys. Res. Solid Earth 2019, 124, 5544–5556. [Google Scholar] [CrossRef]

- Vargas, S.; Frandsen, F.J.; Dam-Johansen, K. Rheological properties of high-temperature melts of coal ashes and other silicates. Prog. Energy Combust. Sci. 2001, 27, 237–429. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide (Release 2024 R1); ANSYS Inc.: Canonsburg, PA, USA, 2024. [Google Scholar]

- Michaelides, E.E.; Crowe, C.T.; Schwarzkopf, J.D. Multiphase Flow Handbook; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Safarian, J.; Tangstad, M. Wettability of Silicon Carbide by CaO-SiO2 Slags. Metall. Mater. Trans. B 2009, 40, 920–928. [Google Scholar] [CrossRef]

- Sundström, A.W.; Eksteen, J.; Georgalli, G. A review of the physical properties of base metal mattes. J. South. Afr. Inst. Min. Metall. 2008, 108, 431–448. [Google Scholar]

- Bidi, M.; Hosseini, R.; Nobari, M. Numerical analysis of methane–air combustion considering radiation effect. Energy Convers. Manag. 2008, 49, 3634–3647. [Google Scholar] [CrossRef]

- Derby, J.; Brandon, S.; Salinger, A.G. The diffusion and P1 approximations for modeling buoyant flow of an optically thick fluid. Int. J. Heat Mass Transf. 1998, 41, 1405–1415. [Google Scholar] [CrossRef]

- Herland, E.V.; Sparta, M.; Halvorsen, S.A. Skin and Proximity Effects in Electrodes and Furnace Shells. Metall. Mater. Trans. B 2019, 50, 2884–2897. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent User Guide (Release 2024 R1); ANSYS Inc.: Canonsburg, PA, USA, 2024. [Google Scholar]

- Tas-Koehler, S.; Liao, Y.; Hampel, U. A critical analysis of drag force modelling for disperse gas-liquid flow in a pipe with an obstacle. Chem. Eng. Sci. 2021, 246, 117007. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Customization Manual (Release 2024 R1); ANSYS Inc.: Canonsburg, PA, USA, 2024. [Google Scholar]

- Wu, M.; Ludwig, A.; Kharicha, A. Volume-Averaged Modeling of Multiphase Flow Phenomena during Alloy Solidification. Metals 2019, 9, 229. [Google Scholar] [CrossRef]

| Properties | Slag | Ferrophosphorus | Gas (Mixture) | Electrodes | Furnace Lining |

|---|---|---|---|---|---|

| Density [kg/m3] | 2999.1–0.1942 · T [K] [27] | 5000 [10] | ideal-gas | 1720 [28] | 1520 |

| Heat capacity [J/(kg K)] | 1400 * | 850 [10] | mixing-law | 720 * [29] | 1000 |

| Thermal conductivity [W/(m K)] | * [8,10] | 15 [10] | [10] | 160 [28] | 6 |

| Electrical conductivity [S/m] | 22 * [19,20] | 200,000 * [30] | * | 128,000 [28] | 15,000 * |

| Viscosity [kg/(m s)] | [8,31] | * | * | – | – |

| 190 k Cells | 280 k Cells | 478 k Cells | |

|---|---|---|---|

| time avg. of volume avg. velocity magnitude [m/s] | 0.0892 | 0.0801 | 0.0884 |

| standard deviation of time avg. vel. magnitude [m/s] | 0.00543 | 0.00534 | 0.00521 |

| Base Case (R = 200 mm) | R = 150 mm | |||||

|---|---|---|---|---|---|---|

| Viscosity [Pa·s] | 0.3 | 0.2 | 0.1 | 0.3 | 0.2 | 0.1 |

| Max. velocity magnitude in slag phase [m/s] | 1.0128 | 1.1610 | 1.3094 | 1.0315 | 1.1261 | 1.2095 |

| Vol. avg. velocity magnitude in slag phase [m/s] | 0.0884 | 0.1216 | 0.1657 | 0.0927 | 0.1101 | 0.1237 |

| Max. temperature in slag phase [°C] | 1633 | 1634 | 1633 | 1633 | 1633 | 1633 |

| Vol. avg. temperature in slag phase [°C] | 1629 | 1628 | 1628 | 1628 | 1628 | 1628 |

| Potential Model | MJH Model | |

|---|---|---|

| Max. velocity magnitude in slag phase [m/s] | 1.0128 | 0.9748 |

| Vol. avg. velocity magnitude in slag phase [m/s] | 0.0884 | 0.0866 |

| Max. temperature in slag phase [°C] | 1633 | 1632 |

| Vol. avg. temperature in slag phase [°C] | 1629 | 1630 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Wieser, D.; Ortner, B.; Prieler, R.; Mally, V.; Hochenauer, C. Development of a Numerically Inexpensive 3D CFD Model of Slag Reduction in a Submerged Arc Furnace for Phosphorus Recovery from Sewage Sludge. Processes 2026, 14, 289. https://doi.org/10.3390/pr14020289

Wieser D, Ortner B, Prieler R, Mally V, Hochenauer C. Development of a Numerically Inexpensive 3D CFD Model of Slag Reduction in a Submerged Arc Furnace for Phosphorus Recovery from Sewage Sludge. Processes. 2026; 14(2):289. https://doi.org/10.3390/pr14020289

Chicago/Turabian StyleWieser, Daniel, Benjamin Ortner, René Prieler, Valentin Mally, and Christoph Hochenauer. 2026. "Development of a Numerically Inexpensive 3D CFD Model of Slag Reduction in a Submerged Arc Furnace for Phosphorus Recovery from Sewage Sludge" Processes 14, no. 2: 289. https://doi.org/10.3390/pr14020289

APA StyleWieser, D., Ortner, B., Prieler, R., Mally, V., & Hochenauer, C. (2026). Development of a Numerically Inexpensive 3D CFD Model of Slag Reduction in a Submerged Arc Furnace for Phosphorus Recovery from Sewage Sludge. Processes, 14(2), 289. https://doi.org/10.3390/pr14020289