Utilization of Plastic Waste in Concrete Pavement

Abstract

1. Introduction

- Polyethylene Terephthalate (PET or PETE);

- High-Density Polyethylene (HDPE);

- Polyvinyl Chloride (PVC or Vinyl);

- Low-Density Polyethylene (LDPE);

- Polypropylene (PP);

- Polystyrene (PS or Styrofoam).

- Workability (it might be decreased because of the shredding size);

- Density (the material is lighter in weight, rendering it suitable for non-structural applications);

- Compressive and tensile strength (its strength can be comparable to conventional materials, given that the plastic waste is adequately shredded and treated);

- Shredding size;

- Water absorption (elevated levels may occur if the shredding size and compaction processes are not properly executed);

- It is crucial to note that the percentage of plastic in the mix should not exceed 15%, as higher concentrations may lead to voids that weaken the concrete. In contrast, including less than 10% plastic typically has little to no notable effect on strength.

- GHG emissions;

- Monetary costs and benefits;

- Number of jobs created.

- Types of Eco-friendly Paver Tiles

- (1)

- Recyclable pavers: Eco-friendly pavement is another approach to recyclable material. The advantage of this type of pavement is that it is economically less costly and environmentally sustainable. The pavement includes recycled conventional materials, such as asphalt and concrete. Although the materials are not initially sustainable, the implementation process is more environmentally friendly. This can be used for various applications, such as sidewalks, parking lots, and pavement tiles. Also, it can be used for fire lanes, recycled, and mixed in with new surfaces [7,17].

- (2)

- Permeable and porous pavers: These innovative pavers, crafted from recycled plastic grids, obviate the need for asphalt or concrete in their production, thereby reducing equipment utilization. From an economic and environmental standpoint, permeable pavers demonstrably outperform porous paver tiles, offering superior cost-effectiveness and durability, along with reduced maintenance requirements. Their versatility makes them suitable for a wide array of applications, including residential areas, light commercial zones, areas with moderate traffic, bicycle paths, and pedestrian thoroughfares [17].

- Exceptional outdoor durability as it effectively withstands extreme weather conditions.

- Efficient recyclability as it is amenable to straightforward recycling processes and applications.

- Ease of molding as its properties facilitate shaping and fabrication.

- Lightweight and robust: it offers a favorable strength-to-weight ratio.

- High chemical resistance; “HDPE plastic features a high chemical and impact resistance, in addition to being immune to rust, rotting, insects, mildew, and mold.” The stated chemical properties reflect the potential of HDPE in certain construction materials, such as outdoor applications.

- HDPE is a contributor towards achieving LEED credits. This is because HDPE is considered one of the safest recycled plastic materials for the environment. It is a totally recyclable plastic material.

- Affordable;

- High-quality;

- Operate at high temperatures;

- Non-leaching;

- UV resistant;

- Resistant to most chemicals;

- Stiff material;

- Amazing durability;

- Highly versatile.

- Poor weathering;

- Sensitive to stress cracking;

- Not resistant to chlorinated hydrocarbons;

- High thermal expansion.

- Shampoo bottles;

- Toys;

- Flower pots;

- Chemical containers;

- Pipe systems;

- Milk jugs;

- Recycling bins;

- Grocery bags;

- Cereal box liners.

2. Materials and Methods

- Molded concrete cubes of 0.15 × 0.15 × 0.15 m3;

- Experiments conducted at normal room temperature,

- Sieve analysis for the size of aggregates with a sieve opening size of 14 mm;

- Recommended size of shredded plastic is with sieve size of 5–6 mm.

2.1. Performance Measures

2.2. Formatting of Mathematical Components [13]

3. Results

- The temperature of the lab during the experiments is an effective factor, at 30–37 °C.

- The plastic waste preparation procedure should be accurately achieved, as depicted in Figure 9.

- The air content test is a pressure method to measure the air content inside the concrete mix design and the unit weight, as well. This is as shown in Figure 10.

- The slump test is to measure the workability of the fresh concrete mix, to avoid air voids and weak concrete properties. This is shown in Table 2.

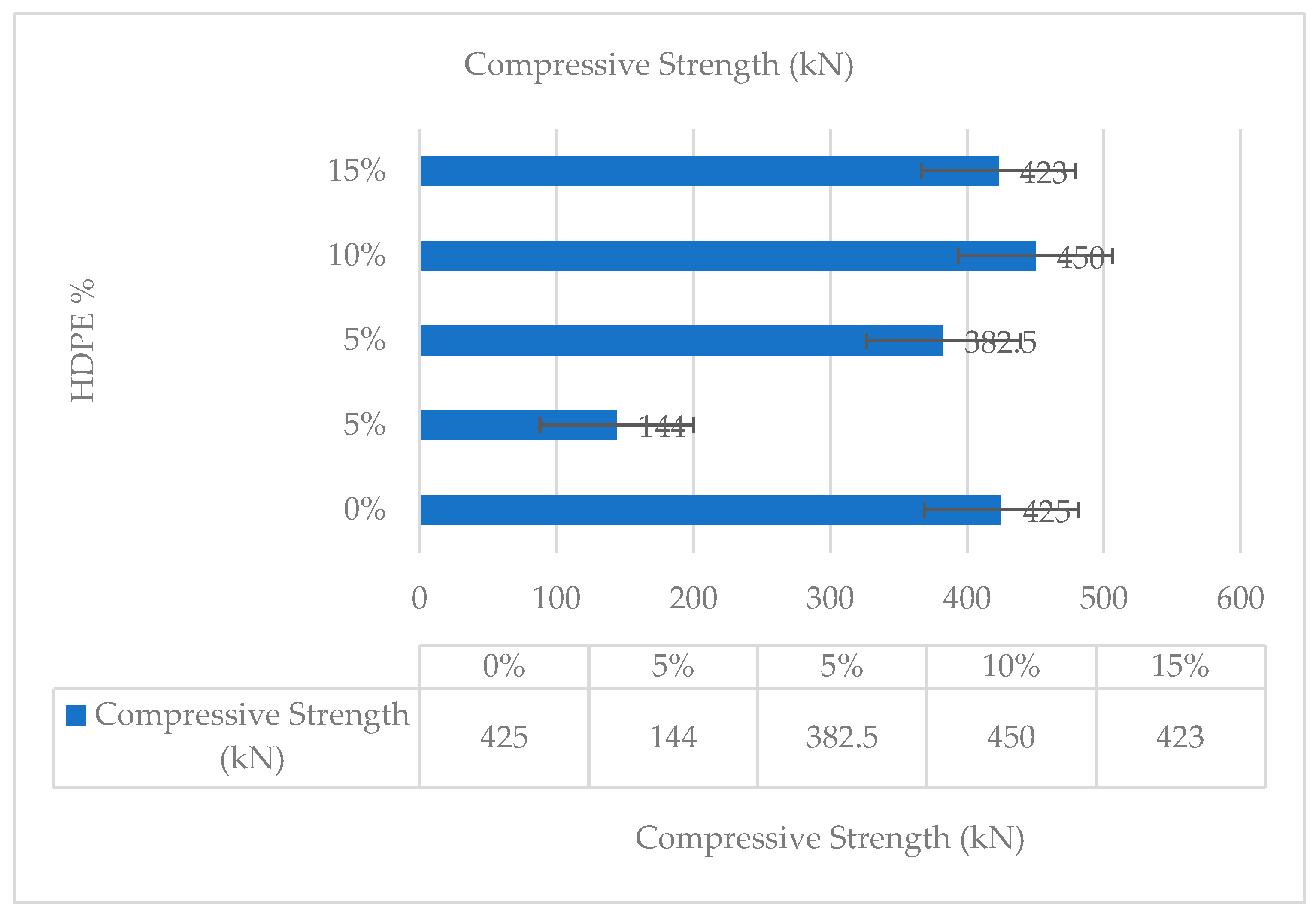

- The compressive strength test is to measure the concrete’s capacity to carry loads. The conventional compressive strength ranges between 2500 and 5000 psi after 28 days.

- Compressive strength results and properties are also based on the concrete functionality. The compressive strength is measured by breaking the concrete cube after 28 days. It is calculated from the load and the cross-sectional area per square meter.

- The tensile strength test determines the maximum load that a material can withstand without cracking. This measure assesses the strength of the concrete when subjected to tensile forces and its capacity to resist bending.

- The chemical durability test is for testing one of the limitations of HDPE. The concrete cube is divided into six pieces merged into sulfur for 28 days.

- Most of the admixture’s typical dosage ranges between 0.2 and 0.5% by weight of cement; it counts for 0.2–0.5% of the weight of the cement at a lower water–cement ratio (w/c). The type of admixture is chosen based on the weak point in the mix, such as water reducer, retarder, and accelerator, as referred to in Equation (2).

- The oven test is for 24 h at 120 °C.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HDPE | High-Density Polyethylene |

| PET | Polyethylene Terephthalate |

| LDPE | Low-Density Polyethylene |

| PVC | Polyvinyl Chloride |

| PP | Polypropylene |

| ASTM | American Society for Testing and Materials |

| ACI | American Concrete Institute |

| HDPE.0 (num) | Plastic Percentage in the Concrete Mix |

| SRI | Solar Reflective Index |

| SDG | Sustainable Development Goals |

| MSW | Municipal Solid Waste |

References

- Climate Change and Plastics Pollution—OECD.ORG—OECD. Available online: www.oecd.org/environment/plastics/Policy-Highlights-Climate-change-and-plastics-pollution-Synergies-between-two-crucial-environmental-challenges.pdf (accessed on 15 October 2023).

- Statista. Plastic Waste Generated by Select Countries Worldwide in 2016. 2016. Available online: https://www.statista.com/statistics/1166177/plastic-waste-generation-of-select-countries/ (accessed on 8 April 2025).

- El-Haggar, S.M. Sustainable Industrial Design and Waste Management; Academic Press: Cambridge, MA, USA, 2007; pp. 149–196. [Google Scholar] [CrossRef]

- Marceau, M.L.; VanGeem, M.G. Solar Reflectance of Concretes for LEED Sustainable Sites Credit: Heat Island Effect; Portland Cement Association: Skokie, IL, USA, 2023; Available online: http://www2.cement.org/DVD021.02/code/reports/SN2982.pdf (accessed on 15 October 2023).

- Awodiji, C.T.G.; Sule, S.; Oguguo, C.V. Comparative Study on the Strength Properties of Paving Cubes Produced from Municipal Plastic Waste. Niger. J. Technol. 2022, 40, 762–770. [Google Scholar] [CrossRef]

- Atlas & Boots. Ranked: The Countries That Produce the Most Plastic Waste; Atlas & Boots: London, UK, 2021; Available online: www.atlasandboots.com/travel-blog/which-countries-produce-the-most-plastic-waste/ (accessed on 16 December 2021).

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, N. Utilizing plastic waste in the building and construction industry: A pathway towards the circular economy. Constr. Build. Mater. 2023, 383, 131311. [Google Scholar] [CrossRef]

- HDPE Plastic (High Density Polyethylene)—Industrial Plastics. 2018. ASTM Standard List. Available online: https://pdfcoffee.com/astm-standard-list-pdf-free.html (accessed on 8 April 2025).

- Ahmed, S.; Ali, M. Potential Applications of Different Forms of Recycled Plastics as Construction Materials—A Review. Eng. Proc. 2023, 53, 5. [Google Scholar] [CrossRef]

- da Silva, T.R.; de Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Ammari, M.Z.J.; Sezen, H.; Castro, J. Effect of Different Plastics on Mechanical Properties of Concrete. Constr. Mater. 2025, 5, 60. [Google Scholar] [CrossRef]

- Sakr, N.; AbouZeid, M. Recycling of Plastic Waste in the Construction Industry. Polymers 2025, 17, 1282. [Google Scholar] [CrossRef] [PubMed]

- The World Bank Group. Trends in Solid Waste Management. 2025. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 27 June 2025).

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Ordonez-Ponce, E. Exploring the Impact of the Sustainable Development Goals on Sustainability Trends. Sustainability 2023, 15, 16647. [Google Scholar] [CrossRef]

- Patrick Steele June. Permeable Pavers. Farley Pavers. 2018. Available online: https://farleypavers.com/permeable-paver-installation/ (accessed on 22 May 2018).

- Ibrahim, N.A.; Abo El-Ata, G.A.; El-Hattab, M.M. Status, problems and challenges for municipal solid waste management in assiut governate. J. Environ. Stud. Res. 2020, 10, 362–384. Available online: https://journals.ekb.eg/article_136575_6b95fba57143b1ef6b51806116ae295f.pdf (accessed on 4 November 2023). [CrossRef]

- “What Is High Density Polyethylene (HDPE)?” Xometrys RSS, Xometry. Available online: www.xometry.com/resources/materials/high-density-polyethylene-hdpe/#:~:text=High%20Density%20Polyethylene%20(HDPE%20for,a%20poly%2Dethylene%20molecular%20chain (accessed on 13 September 2023).

- Thabit, Q.; Nassour, A.; Nelles, M. Facts and Figures on Aspects of Waste Management in Middle East and North Africa Region. Waste 2023, 1, 52–80. [Google Scholar] [CrossRef]

- ASTM C936; Standard Specification for Solid Concrete Interlocking Paving Units. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM E.119; Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM: West Conshohocken, PA, USA, 2020.

- Shaaban, I.G.; Rizzuto, J.P.; El-Nemr, A.; Bohan, L.; Ahmed, H.; Tindyebwa, H. Mechanical Properties and Air Permeability of Concrete Containing Waste Tyres Extracts. J. Mater. Civ. Eng. 2021, 33, 04020472. [Google Scholar] [CrossRef]

- Hossain, S.; Islam, A.; Badhon, F.F.; Imtiaz, T. Sieve Analysis. Available online: https://uta.pressbooks.pub/soilmechanics/chapter/sieve-analysis/ (accessed on 14 January 2021).

- ASTM C 143; Code for Slump Test, Case Studies in Construction Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C 138; Code for Unit Weight Test, Case Studies in Construction Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C231-97; Code for Air Content Test, Case Studies in Construction Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C936; Code for Compressive Strength Test, Case Studies in Construction Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1371-15; Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM 1549-16; Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer. ASTM International: West Conshohocken, PA, USA, 2022.

| Plastic Source | Characteristics | Common Use of Virgin Plastic | Common Uses for Recycled Plastic |

|---|---|---|---|

| PET | Clear, hard plastic, suitable for fiber | Soft drink and mineral water bottles | Clear and soft film for packaging and wrapping, rug fibers, rain coats |

| LDPE | Soft, flexible plastic, milky white unless a pigment is added | Lids of food, containers, garbage bags, and rubbish bins | Soft film, wrapping industry, plant packaging, and nursery bags |

| HDPE | Commonly used plastic, white or colored | Shopping bags, milk storage bags | Compost bins, detergent bottles, and mobile rubbish bins |

| UPVC | Hard plastic, clear type | Garden hose, shoe soles, blood bags | Hose inner core and industrial flooring |

| PPVC | Hard but flexible plastic | Ice cream containers and potato crisp bags | Compost bins, curb side recycling crates |

| PS | Stiff but brittle plastic, clear and glossy | Stools and chairs, cheap transparent kitchenware, light fittings, bottles, toys, and food containers | Laundry bags and coat hangers |

| EPS | Foamed, lightweight, energy absorbing and thermal insulation | Hot drink cups and takeaway food | Spools, rulers, and video and CD boxes |

| PA | Nylons | Fibers, toothbrush bristles, and fishing lines |

| Product | Solar Reflectance | Emissivity | Temperature Rise | Solar Reflective Index (SRI) |

|---|---|---|---|---|

| Clay tile, red | 0.33 | 0.9 | 58 | 36 |

| Concrete tile, red | 0.18 | 0.91 | 71 | 17 |

| Concrete tile, white | 0.73 | 0 | 21 | 90 |

| Asphalt shingles, white | 0.21 | 0.91 | 68 | 21 |

| Limestone pavers | 0.53 | 0.89 | 30 | 62 |

| Material Properties | ASTM Standards for Concert Pavement |

|---|---|

| Slump | ASTM C 143 [24] |

| Unit Weight | ASTM C 138 [14] |

| Air Content | ASTM C231-97 [25] |

| Compressive Strength | ASTM C936/C936M, BS 1881 [26] |

| Emittance | ASTM C1371 [27] |

| Solar Reflectance (Non-Roof, Pavement) | ASTM C1549 [28] |

| Recycling Technique | Recycling Process |

|---|---|

| Mechanical Recycling | Sorting, cleaning, shredding, and substituting with coarse aggregate in the concrete mix design. This technique is the widest and most commonly used. Advantages:

|

| Chemical Recycling | Plastic waste breaks down into molecules through chemical processing. PET material can be consequently re-polymerized for other PET products. Limitations:

|

| Thermal Recycling | Plastic waste breaks down into molecules through heating at a high temperature. Limitations:

|

| Biological Recycling (Enzymatic Recycling) | Plastic waste conversion into biomass or any other products through microorganisms like fungi or bacteria. Advantages:

|

| Tests | Slump (cm) | Temperature °C | Unit Weight kg/m3 | Air Content |

|---|---|---|---|---|

| Mix 1(Conventional) | 1 | 26.3 | 2500 | 4.5 |

| Mix–HDPE.05–Cube 1 | 2 | 24 | 2300 | 4 |

| Mix–HDPE.10–Cube 1 | 5 | 25.5 | 2350 | 5 |

| Mix–HDPE.15–Cube 1 | 2 | 26 | 3000 | 7 |

| Concrete Mix | Compressive Strength kN | Tensile Strength kN | HDPE Sieve Size (mm) | Plastic % from Coarse Aggregates (HDPE) |

|---|---|---|---|---|

| Mix 1 | 425 | 64 | - | 0 |

| Mix–HDPE.05 | 144 | 22.5 | 19 | 5% |

| Mix–HDPE.05 | 382.5 | 42.7 | 4.75 | 5% |

| Mix–HDPE.10 | 450 | 55 | 4.75 | 10% |

| Mix–HDPE.15 | 423 | 45 | 4.75 | 15% |

| Conducted Tests | Performance Measures Function: Recycled Nonstructural Concrete Pavement Tiles—Light |

|---|---|

| Compressive strength | Achievable and exceeded the conventional standards in some tests. |

| Tensile strength | Achievable and met the conventional tests. |

| Chemical durability (sulfur attack) |

|

| Water permeability | Achievable. |

| Oven exposure | Achievable. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Sakr, N.; AbouZeid, M. Utilization of Plastic Waste in Concrete Pavement. Processes 2026, 14, 38. https://doi.org/10.3390/pr14010038

Sakr N, AbouZeid M. Utilization of Plastic Waste in Concrete Pavement. Processes. 2026; 14(1):38. https://doi.org/10.3390/pr14010038

Chicago/Turabian StyleSakr, Nancy, and Mohamed AbouZeid. 2026. "Utilization of Plastic Waste in Concrete Pavement" Processes 14, no. 1: 38. https://doi.org/10.3390/pr14010038

APA StyleSakr, N., & AbouZeid, M. (2026). Utilization of Plastic Waste in Concrete Pavement. Processes, 14(1), 38. https://doi.org/10.3390/pr14010038