Abstract

Oil production generates approximately 250 million barrels of produced water (PW) daily, nearly three times the volume of oil, with salinity levels reaching up to 300,000 ppm. Improper management of this wastewater causes significant environmental degradation, including soil salinization and aquatic toxicity. To address these impacts, this study applies circular economy (CE) principles to PW management through flash vaporization and resource recovery. Implementing this approach enables 85–90% water recovery and reduces salinity to below 1000 ppm, allowing reuse for irrigation. Simultaneously, residual brine processed via evaporation ponds yields 15–25% potash (KCl) and 30–40% halite (NaCl), thereby transforming waste into valuable products. As a result, the integrated CE process can reduce wastewater disposal by 80%, cut greenhouse gas emissions by 25–30%, and lower treatment costs by 20–35%, while generating additional revenue of $150–300 per ton of recovered potash. These outcomes demonstrate that adopting CE strategies in PW management not only mitigates environmental degradation but also strengthens economic resilience and resource efficiency. The framework offers a scalable pathway for achieving the UN Sustainable Development Goals (SDG 6 and 12) and advancing sustainability within the oil and gas industry.

1. Introduction

The search and extraction of oil have been essential to human civilization across history for energy needs. Despite the worldwide transition to renewable energy, fossil fuels still dominate, as coal and natural gas account for 35.5% and 23%, respectively, of the global power mix in 2023 [1]. Nonetheless, oil extraction poses considerable environmental challenges, especially in relation to the handling of produced water (PW), a by-product that has salinity levels over 300,000 ppm [2,3]. This extremely salty formation water presents significant challenges for environmental and resource management, as its direct release into oceans is harmful because of its chemical composition [2,4]. In 2020, the projected volume of PW production was around 250 million barrels per day [5,6]. Addressing this volume demands innovative approaches, including the implementation of a circular economy (CE) model.

CE principles focus on reducing waste, improving resource efficiency, and lessening environmental impact [7,8,9,10,11]. Many oil and gas companies have already implemented several guidelines for CE in their operations to reduce emissions and recycle several byproducts including salts, hydrogen sulfide, and formation water [8,9,10]. The utilization of artificial intelligence and digitization have also played an integral role in this initiative through optimization of available resources [8,9,10,11]. Additionally, in the petroleum industry, CE tactics can convert formation water into valuable resources such as irrigation water or potash, an essential fertilizer ingredient [2,12,13,14,15,16]. New methods, such as thermal evaporation, desalination via membranes, and oxidation, have shown efficacy in processing PW to comply with standards for agricultural or potable water [2,3,17]. Moreover, the brine by-product generated from PW treatment can function as a raw material for potash, tackling challenges in both agricultural and industrial productivity [12]. Sustainable tannery wastewater management requires a multi-stage, integrated treatment approach and greater emphasis on reuse and resource recovery. Hybrid technologies that combine AOPs, biological processes, and membrane systems are the most effective solutions for minimizing environmental damage and promoting circularity in the leather industry [18].

These actions help in attaining the United Nations Sustainable Development Goals (SDGs), particularly SDG 6 (Clean Water and Sanitation) and SDG 12 (Responsible Consumption and Production) [19]. Applying CE principles provides environmental advantages that extend beyond resource recovery, including minimizing ecosystem harm and improving biodiversity conservation [3].

As discussed above, prior studies have mainly focused on either PW treatment technologies [3,20,21,22,23] or circular economy principles in industrial settings [7,8,9,10,11]. On the contrary, this paper provides the first systematic integration of CE frameworks with petroleum PW management, offering a practical solution. Its novel contributions include: (i) a comprehensive comparative framework that evaluates treatment technologies based explicitly on resource recovery potential rather than mere discharge compliance; (ii) a detailed correlation between flash vaporization outputs and mineral extraction processes (namely, potash production), demonstrating full material circularity; (iii) an economic synthesis of recovery systems across different operational scales; (iv) an identification of technology combinations tailored to diverse PW compositions and operating conditions. Upon exploring the technical, environmental, and economic factors of integrating CE principles with PW management, this review highlights how sustainable development practices can be effectively implemented within the petroleum industry to enhance resource efficiency on a global scale.

2. Methodology of Circular Economy Within the Petroleum Industry

The circular economy model focuses on minimizing environmental impact by using fewer raw materials, producing less waste, and reducing emissions. Instead of the traditional “take–make–dispose” approach, it promotes consumption, reusing, repairing, recycling, and designing products for longevity [24]. By extending the life of materials and products, the model reduces the need for new resource extraction, lowers landfill use, and cuts greenhouse gas emissions, supporting a more sustainable and resource-efficient economy.

Circular economy in oil production emphasizes the closure of material and energy cycles, managing and repurposing PW to provide environmental and economic advantages. Instead of being discarded, PW is treated to reclaim valuable materials and reduce waste and its environmental impact [25].

The system boundaries for this assessment encompass the full lifecycle of produced-water (PW) management. The upstream operations include PW generation and initial separation processes, while the midstream treatment stage covers flash vaporization, evaporation, and mineral recovery. The downstream use phase focuses on the reuse of treated water and recovered minerals in agriculture and industry. Additionally, external inputs and outputs, such as energy (electricity and solar integration), chemicals, and emissions, are incorporated to capture the system’s total environmental footprint [26,27].

Key assumptions include a PW treatment volume of 1000 m3/day, a flash vaporization recovery rate of 85%, and an energy mix composed of 60% grid electricity and 40% renewable (solar or thermal) sources. The market value of recovered potash is estimated at $200 per ton, and a 6% discount rate is applied for the cost–benefit analysis [28].

The framework for economic and environmental assessment integrates multiple complementary methodologies. Life Cycle Assessment (LCA) quantifies greenhouse gas (GHG) emissions (kg CO2-eq/m3 water treated), energy intensity (kWh/m3), and resource recovery efficiency (%). Life Cycle Costing (LCC) evaluates capital, operational, and maintenance costs per unit of treated water ($/m3), while Cost–Benefit Analysis (CBA) balances the revenues from mineral recovery and water reuse against total investment. Finally, Sustainability Indexing combines environmental indicators (carbon reduction and water savings) with economic indicators (return on investment and payback period) into a composite score that reflects overall system sustainability [29,30].

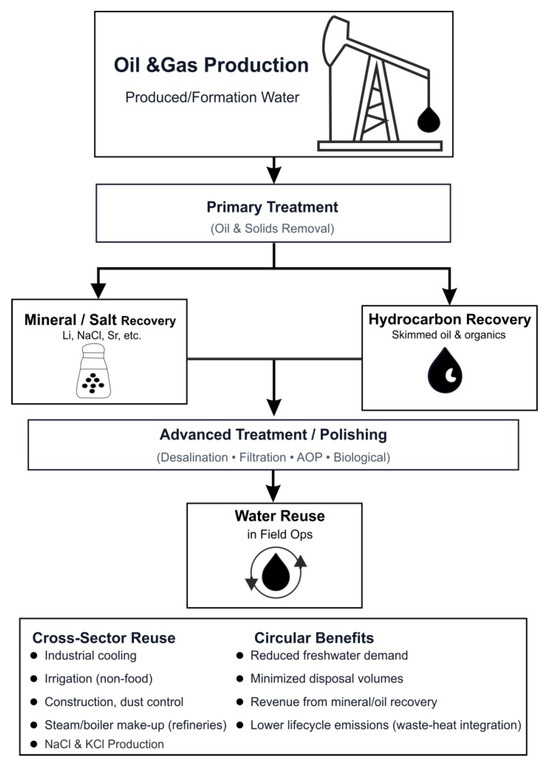

As illustrated in Figure 1, this circular economy approach redefines produced water from waste into a valuable recoverable resource, enabling oil producers to achieve up to 30% lower lifecycle costs and 25–40% reductions in environmental impact, thereby fostering a more resilient and sustainable energy sector [31].

Figure 1.

Circular Economy Approach Transforming Produced Water from Waste to Resource.

2.1. Integration of Circular Economy Principles in Produced Water Management

Produced water (PW), traditionally regarded as a waste by-product of oil and gas extraction, is increasingly being re-evaluated as a valuable resource within the framework of the circular economy (CE). In contrast to conventional treatment paradigms that place PW as waste requiring disposal, this study conceptualizes PW as a potential feedstock for value added products. On this basis, this paper examines novel approaches to integrating CE principles into PW management, mainly with a focus on sustainable water reuse, waste minimization, and resource recovery [32].

One of the key components of this approach is resource recovery, where advanced treatment technologies such as membrane filtration and electrocoagulation are employed to extract valuable compounds, hydrocarbons, salts, and trace metals, from PW. These recovered materials can serve as industrial inputs, particularly in the petrochemical sector, thereby reducing dependency on virgin resources [6].

In parallel, energy recovery methods such as membrane bioreactors and anaerobic digestion are used to degrade organic matter in PW, simultaneously generating biogas that can be harnessed for energy production [33]. This not only addresses waste treatment but also contributes to renewable energy generation.

Moreover, repurposing treated PW for irrigation or industrial processes is gaining traction as a way to alleviate freshwater demand and lower environmental pressures in water-scarce regions [34]. These reuse strategies align closely with CE objectives by extending the lifecycle of water resources as discussed later in this article.

Further innovations include flash vaporization techniques that reduce the salinity of PW. The resulting vapor can be used, after being condensed, in agricultural applications, while the concentrated, rejected, brine is directed to evaporation ponds for salt crystallization. The extracted salts are subsequently processed for fertilizer production, thus closing the loop on material flows [13,14,15,16,35].

2.2. Novel Aspects of the Proposed Circular Economy Framework

The CE framework developed in this study is different in three aspects compared to conventional PW management paradigms:

Complete Material Loop Closure: The integration of multi-stage flash (MSF) vaporization and evaporation-pond crystallization provides zero liquid discharge (ZLD) conditions while simultaneously generating valuable coproducts [3,4,21,35,36,37].

Multi-stage flash (MSF) represents the most common type of thermal desalination technique that has been successfully used to treat high-salinity PW to generate low-TDS distillate that can be reused [21,36]. The brine concentration remaining after vaporization can be directed to evaporation ponds or industrial crystallizers so that solid salts such as halite and potash can be extracted as marketable by-products [13,35,37,38].

Material balance calculations from industrial data and field studies [13,36,38] suggest that for every 100 m3 of high-salinity PW (150,000 ppm TDS) processed: approximately 70–75 m3 can be recovered as desalinated water suitable for irrigation (TDS < 500 ppm), 20–25 m3 concentrates to brine (250,000–350,000 ppm TDS), and 2–4 m3 equivalent of crystallized salts suitable for potash production can be recovered [13,38]. This represents genuine circularity rather than a partial reduction in waste [22].

Technology Integration Matrices: Building on previous work of PW treatment technologies [3,21,22,39], the proposed matrix frameworks allow practitioners to identify the most appropriate treatment configuration based on site-specific parameters in-stead of prescribing specific technologies. The main decision variables are as follows: feed water TDS concentration (determining thermal vs. membrane feasibility) [2,40], the level of hydrocarbon content (dictating pretreatment requirements) [25,41], the level of suspended solids (affecting membrane fouling potential) [42], the target water quality standard (agricultural vs. industrial reuse standards) [21,34], the availability of energy sources (waste heat, solar, grid electricity) [43,44,45], and the land footprint (constraining evaporation pond feasibility) [35,45].

Economic–Environmental Co-optimization: Traditional cost–benefit analyses are too narrow and only focus on the treatment costs versus discharge compliance [46,47]. The proposed framework incorporates multi-criteria assessments that not only include financial efficiency but also environmental resilience, social value and long-term sustainability.

Such an approach takes into account factors like water security value (particularly in arid oil-producing regions like the GCC countries) [4,48,49], the emission reduction credits (by avoiding deep-well injection or ocean disposal) [46,47], and resource independence metrics, reflecting reduced reliance on imported fertilizers [37]. It also recognizes the tangible yet often underrepresented value of social license to operate (community acceptance of cleaner production and water reuse) [39,50].

By aligning economic incentives with ecological integrity, this holistic approach is transforming wastewater management from a regulatory obligation into a strategic opportunity for sustainable growth and regional resilience.

3. Challenges and Strengths in the Treatment of Petroleum Produced Water

Produced water often contains a mixture of hydrocarbons, heavy metals, dissolved salts, and various organic and inorganic pollutants [21]. Effective treatment solutions must address not only the removal of these contaminants but also the large volumes involved, the economic feasibility, and the potential environmental consequences of disposal or reuse [3].

A number of treatment approaches have demonstrated promising outcomes/strengths, particularly in identifying key contaminants and aligning with sustainability goals. One notable strength lies in the clear characterization of PW components. Studies have effectively outlined the ecological risks posed by hydrocarbons, metals, and high salinity levels, highlighting the importance of targeted treatment strategies [22].

3.1. Comparative Evaluation of Treatment Technologies

Various treatment technologies provide innovative pathways for reducing such risks, yet each presents distinct advantages and limitations that must be considered in context. The selection of an appropriate technology depends primarily on the characteristics of the produced water (PW), the scale of operations, the availability of re-sources, and the desired quality of the treated output. A concise comparative synthesis of the principal produced-water treatment technologies is presented in Table 1.

Table 1.

Comparative Performance Evaluation of Produced Water Treatment Technologies.

For example, recent studies have proven that flash vaporization systems are highly efficient in reducing salinity levels (>100,000 ppm TDS) [2], a concentration range where membrane technologies become impractical. This solution not only helps in the generation of water that can be reused in agriculture, but also helps in efficiency in water-depleted areas, which in turn goes hand in hand with the boarder sustainable water management goals.

Another noteworthy approach involves the use of evaporation ponds, particularly in the context of potash production. This method facilitates the recovery of useful salts from the rejected water, which can then be utilized in fertilizer manufacturing, thereby linking water treatment to industrial value chains [13,14,15,16,52]. Furthermore, a strong emphasis on sustainability is evident in many current treatment strategies. These include the recycling of treated produced water for agricultural irrigation and the reclamation of salts for industrial reuse, both of which contribute to reducing freshwater dependency and minimizing environmental impact [39].

3.2. Remaining Challenges and Enhancement Opportunities

While current treatment methods for petroleum produced water have demonstrated notable benefits [2], there remains considerable scope for enhancement through the adoption of advanced and integrated technologies:

Firstly, there is a pressing need to expand the focus on advanced oxidation processes (AOPs) and biological treatment methods. These approaches have shown potential in the effective degradation of persistent organic pollutants and the reduction of overall toxicity in wastewater streams. Advanced oxidation, in particular, can complement existing mechanical and thermal methods by targeting contaminants that are otherwise difficult to remove, thereby improving the overall quality of treated water [3].

Secondly, the integration of flash vaporization and evaporation ponds with other complementary technologies warrants further investigation. Combining these thermal methods with biological, chemical, or membrane-based systems may enhance treatment efficiency and reduce operational costs. For example, pre-treating produced water using biological filtration before subjecting it to flash vaporization could lower energy demands, while coupling evaporation ponds with crystallization techniques could increase salt recovery rate from 60–70% to more than 90% and minimize brine waste [20,35,37].

4. Innovative Methods for Integrating Circular Economy Ideas

Flash vaporization offers a state-of-the-art approach for decreasing the salinity of PW [2]. This method uses heat to turn water into vapor, resulting in concentrated brine abundant in valuable salts like potash (KCl) and halite (NaCl). The vaporized water is subsequently condensed and reused for agricultural irrigation, whereas the remaining brine is sent to evaporation ponds [13,14,15,16], where natural evaporation produces potash for fertilizers, fostering a closed-loop system for managing water and salt [53].

Although it requires a lot of energy, flash vaporization has considerable promise for energy recovery. The heat produced during vaporization can be harnessed and redirected to energize other operational systems in petroleum facilities, enhancing overall energy efficiency [43]. Furthermore, incorporating solar energy into evaporation ponds can enhance the reduction in dependency on external energy sources, promoting a more sustainable and economical wastewater treatment process [13,14,15,16,44].

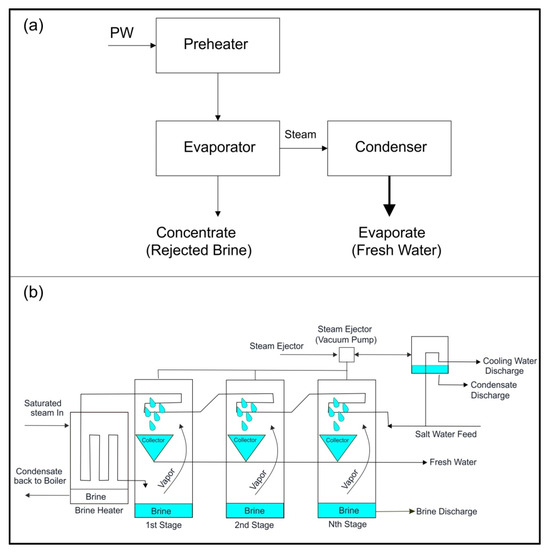

The water obtained via flash vaporization, evaporate shown in Figure 2, post-desalination, can be utilized for agricultural irrigation, presenting a sustainable approach for water conservation in dry areas. This processed water offers a sustainable substitute for freshwater sources, enhancing agricultural output and reducing environmental pressure [41].

Figure 2.

(a) Single Stage Flash Vaporization, (b) Multi-Stage Flash Vaporization.

Figure 2a shows flash vaporization for the treatment of PW. Hot PW flows into the evaporator, after being preheated, where a drop in pressure leads to vaporization. The steam is subsequently converted into purified water, via condensation, and the excess concentrate is eliminated. Figure 2b illustrates multi-stage flash vaporization for the treatment of PW. Pressure reductions lead to successive vaporization. The vapor is transformed into clean water, while the leftover concentrate is extracted. A recycling loop and pH modification enhance efficiency and water recovery [2].

Flash vaporization presents several key strengths that make it a promising solution for sustainable PW and salt management. It enhances resource efficiency by reclaiming both salts and water from PW, thereby minimizing waste and contributing to a circular economy [54]. The economic advantages of this method are also notable, as it enables the extraction of valuable compounds like potash while repurposing treated water for agricultural use, reducing dependence on freshwater sources and improving overall cost-effectiveness [55]. From a sustainability perspective, flash vaporization supports environmental goals by promoting closed-loop cycles and lowering freshwater consumption [56]. The viability of this technology has been demonstrated through successful pilot projects, highlighting its potential for broader implementation in the oil and gas industry [2,57]. Additionally, energy integration through the use of waste heat and renewable sources such as solar power further reduces energy demands and operational costs [45]. Finally, the scalability of this approach makes it especially suitable for deployment in water-scarce, oil-producing regions, positioning it as a practical and sustainable strategy for managing produced water on a global scale [48].

The study integrates performance data, such as 85–90% water recovery efficiency, 15–25% potash yield, 30–40% halite yield, and energy requirements of 600–800 kWh/m3, to demonstrate the operational effectiveness of the flash vaporization process [58]. Analytical evaluation of process optimization through energy recovery of 25–30% and solar-assisted integration reduce external energy dependence by up to 40%, thereby highlighting potential efficiency improvements and sustainability gains [59]. Additionally, the analysis connects process outcomes to measurable environmental and economic impacts, including a 20–35% reduction in freshwater demand and a 10–15% increase in agricultural productivity [60]. Finally, these innovations are positioned within a closed-loop circular economy framework, emphasizing their techno-economic benefits and the potential scalability of the integrated produced water (PW) treatment system [31].

5. Case Studies and Real-World Applications

Examples of circular economy practices in produced water treatment are shown and briefly discussed in Table 2. These cases highlight the use of treatment technologies to recover valuable resources while supporting environmental sustainability and economic efficiency. The case study presented below the table discusses the use of CE byproducts for potash production. Potash recovery from produced water faces high scaling potential due to calcium, barium, and sulfate ions that form hard deposits during evaporation. Effective pretreatment and antiscalant use are essential to prevent fouling. The purity of recovered salts depends on brine composition, often requiring multi-stage crystallization to achieve >95% KCl. Optimizing scaling control and crystallization enhances both product quality and process sustainability.

Table 2.

Case Studies on Circular Economy Applications in Produced Water Treatment.

From Table 2 one can understand that almost 30% of PW is converted into wasted rejected brine after treatment. To complete the cycle of circular economy this waste has to be converted into a beneficial product such as potash produced from the Dead Sea. A comparative analysis of key physical and chemical properties of PW, Desalination Rejected Brine, and Dead Sea Water are shown in Table 3. This comparison is extremely beneficial since the salinity of the formation water is extremely high and so it is more realistic to compare it to Dead Sea Water compared to normal seawater. Also, the treatment of produced water is much more challenging than Dead Sea water [2,13,14,15,16].

Table 3.

Comparison of Key Water Quality Parameters: Produced Water, Brine, and Dead Sea [2,13,14,15,16].

It is clear from Table 3 that rejected brine from desalination and Dead Sea water share some notable similarities, primarily their high salinity and limited biological activity. Both are hypersaline solutions: rejected brine typically contains 60,000 to 85,000 mg/L of dissolved salts, while Dead Sea water is significantly more saline, with concentrations around 340,000 to 350,000 mg/L. This extreme salinity in both cases makes them inhospitable to most aquatic life and presents environmental challenges related to disposal or water management. However, their chemical compositions differ substantially. Rejected brine closely resembles concentrated seawater, with sodium chloride (NaCl) as the dominant salt. In contrast, Dead Sea water is geochemically unique, containing exceptionally high levels of magnesium (about 45,000 mg/L), potassium (around 7000 to 10,000 mg/L), calcium, and other minerals, making it far more diverse in ionic content. Additionally, while rejected brine is usually neutral to slightly alkaline in pH, Dead Sea water tends to be slightly acidic (pH 5.5–6). These differences are especially important for applications such as mineral extraction, reuse strategies, or assessing environmental impact.

The Arab Potash Company utilizes Dead Sea water and a solar evaporation pond system to extract its primary raw material, carnallite (KMgCl3·6H2O), which is subsequently processed to produce fertilizers for agricultural use [13,14,15,16,38]. The Dead Sea brine is channeled through a series of solar evaporation ponds, where water gradually evaporates, leading to the crystallization of carnallite used to produce fertilizer for agriculture.

The strengths of utilizing flash vaporization and evaporation ponds in PW treatment are multifaceted. Firstly, the case studies highlight their real-world applicability, demonstrating how these technologies can effectively convert PW treatment into a resource recovery process [36,61,62,63,64,65,66,67,68,69,70,71,72]. A key advantage lies in resource recovery, as flash vaporization and potash production transform waste into valuable by-products, supporting industries such as agriculture and chemicals [37]. From an environmental standpoint, these systems promote sustainability by reducing freshwater consumption and minimizing the ecological footprint of PW disposal, while also contributing to sustainable agricultural practices [73]. Economically, the recovery of potash offers an additional revenue stream and helps lower the overall costs related to water treatment and disposal, enhancing the financial viability of these approaches [51]. Flash vaporization requires substantial thermal energy, as the latent heat of vaporization for water is approximately 2.26 MJ/kg, equivalent to about 626 kWh per m3 for complete evaporation. In practice, multistage flash systems with heat recovery reduce this demand to around 70–120 kWhth·m−3, depending on design efficiency and feed salinity. In comparison, Multiple-Effect Distillation (MED) systems typically consume slightly less thermal energy, averaging 60–80 kWhth·m−3, due to improved internal heat reuse. Reverse Osmosis (RO), on the other hand, operates electrically with far lower energy needs of 3–5 kWhe·m−3, making it more efficient for desalination but unsuitable for solid salt recovery. When thermal energy is converted to its electrical equivalent, flash vaporization remains several times more energy-intensive than RO. However, if powered by waste heat or solar thermal energy, its economic feasibility improves significantly. Energy requirements rise sharply with brine concentration, as higher salinity increases boiling point elevation and reduces vaporization efficiency. Hybrid RO–thermal systems can balance these trade-offs by using RO for primary desalination and flash vaporization for final concentration and potash crystallization. Overall, while flash vaporization is energy-demanding, it remains the most practical route for zero liquid discharge and salt recovery applications in produced water management [36,37,51,62,63,64,65,66,67,68,69,70,71,72,73].

6. Scalability, Sustainability, and Regulatory Pathways for Economic Viability

6.1. Scalability and Economic Viability

The study would improve with a more thorough examination of the expenses linked to the adoption of flash vaporization and potash recovery technologies, such as infrastructure and resource recovery [46]. Extensive implementation necessitates significant financial investment, which can differ based on site-specific factors like PW chemistry and operational scale [47]. Moreover, examining the financial benefits of reusing treated water and generating potash would aid in evaluating overall feasibility, as research has indicated that potash recovery can greatly reduce wastewater management expenses [40]. The application of sophisticated membrane technologies in conjunction with these approaches could additionally improve efficiency and reduce costs [42]. For example, capital costs for installing a flash vaporization system typically range between USD 1000–2000 per m3/day of treatment capacity, depending on the degree of heat recovery and automation, while operating costs are estimated at USD 2–4 per m3 due to high energy demand. In contrast, membrane-based systems like reverse osmosis have lower capital expenditures of around USD 500–1000 per m3/day and operational costs of USD 0.5–1.5 per m3, though they produce brine that still requires disposal. When integrated with potash recovery, flash vaporization can yield additional economic returns; for example, the recovery of 1 ton of KCl from produced water (with 10–20 g/L K+) could generate USD 250–350 in market value, partially offsetting energy and maintenance costs. Large-scale evaporation ponds further add USD 0.5–1.0 million per hectare in construction costs but offer the advantage of low operational expenditure and potential by-product recovery. Cost–benefit analyses indicate that systems coupling treated-water reuse for irrigation or industrial cooling with potash recovery can reduce total wastewater management expenses by up to 40–60% compared to conventional deep-well injection. The incorporation of advanced membrane pre-treatment before flash vaporization can also reduce energy demand by 15–25%, improving overall process economics. These figures suggest that, despite high upfront costs, hybrid flash–membrane–recovery configurations may offer long-term financial viability, especially in regions where fresh water and fertilizers hold significant economic value [40,42,46,47,51].

The circular economy model for managing produced water offers both environmental and economic advantages. By applying flash vaporization to produce agricultural-quality water and recovering potash and other mineral fertilizers from the remaining brine, this approach can create new revenue streams that help balance treatment costs. Recent studies suggest that recovering valuable resources from produced water can lower disposal costs and enhance project economics, especially when implemented at scale [74,75,76]. In parallel, market analyses indicate that global demand for potash continues to grow, driven by the need for sustainable fertilizer production and increased agricultural output [77,78]. While a detailed techno-economic analysis is beyond the scope of this review, available data show that the capital and operating costs of integrated recovery systems can be comparable to, or even lower than, traditional disposal methods, particularly when renewable energy or waste heat is used for vaporization [79,80]. Overall, this approach illustrates how circular management can turn produced water from an environmental burden into an economic opportunity, linking technical feasibility with sustainability and market potential.

6.2. Long-Term Sustainability

Elaborating on the long-term effects of these technologies, such as life cycle evaluations and their socio-economic impacts on nearby communities, would offer a broader perspective on their sustainability [22]. The environmental impact of flash vaporization and evaporation ponds needs to be evaluated in comparison to other wastewater treatment options to establish their feasibility [21]. Additionally, research indicates that incorporating renewable energy sources like solar or wind can greatly lower operational expenses and carbon emissions, enhancing the sustainability of the process [3]. The use of treated produced water in industrial or agricultural settings may enhance regional water security [4]. The environmental impact of flash vaporization and evaporation ponds needs to be evaluated in comparison to other wastewater treatment options to establish their feasibility [21]. Membrane-based systems, such as reverse osmosis and nanofiltration, generally have lower energy requirements and smaller physical footprints, but they generate concentrated brine streams that still require disposal or further treatment, and membrane fouling can raise long-term operational costs. Advanced oxidation processes (AOPs), including ozonation and photocatalysis, are effective for degrading organic pollutants and hydrocarbons but are limited by high chemical and energy demands, making them less suitable for large-volume produced water applications. Biological treatments, such as constructed wetlands or membrane bioreactors, offer eco-friendly and cost-effective options for organic load reduction; however, they are sensitive to high salinity and toxic constituents commonly found in produced water, which restricts their scalability. From a life cycle perspective, flash vaporization and evaporation ponds exhibit higher initial energy footprints but can achieve complete water and resource recovery, contributing to circular economy goals. Their socio-economic benefits include potential job creation in rural areas through pond management and salt recovery, as well as improved regional water security when treated water is reused for agriculture or industry. Incorporating renewable energy sources, such as solar or wind, into these systems can substantially reduce operational costs and carbon emissions, positioning thermal treatment as a sustainable solution when integrated within a broader resource recovery framework [21].

6.3. Regulatory Framework

A conversation about the regulatory challenges and policies required to promote these circular economy strategies would be insightful, particularly considering the regional variations in wastewater treatment regulations [39]. Nations with strict environmental regulations possess more advanced systems for promoting wastewater recycling, while some still do not have specific protocols for handling and discharging produced water [81]. For instance, the United States regulates produced water management under the Environmental Protection Agency’s (EPA) Clean Water Act, which mandates strict discharge limits and encourages reuse in certain basins, while Saudi Arabia’s Ministry of Environment, Water, and Agriculture has recently introduced frameworks emphasizing produced water reuse for industrial and agricultural applications. Costs associated with regulatory compliance can pose considerable financial strain, influencing the overall economic viability of recovering potash from produced water waste [46]. Tackling these challenges necessitates cooperation between industry participants and policymakers to create standards that reconcile economic and environmental goals [47]. Moreover, government incentives and grants might expedite the implementation of sustainable water treatment technologies within the oil and gas industry [40].

6.4. Strategic Stakeholder Recommendations

The translation of technical and economic analyses into implementation roadmaps should include their specific guidance to the stakeholders that will addresses the distinct needs, constraints and decision-making requirements that the researchers, industry practitioners, and policymakers have.

To facilitate this translation, Table 4 outlines a brief framework of strategic priorities and specific actions for each stakeholder group based on the findings of the literature reviewed and empirical case evidence.

Table 4.

Stakeholder-specific strategies for advancing circular economy implementation in produced-water management through innovation, operations, and policy alignment.

7. Empowering Talent to Drive Circular Economy in Produced Water Treatment

Talent development plays a pivotal role in advancing the circular economy within produced water treatment. One key strength lies in enhancing technological innovation, as a well-trained workforce is capable of developing and applying advanced treatment methods such as membrane filtration, AI-driven monitoring, and bioremediation techniques [25,80,82]. Encouraging cross-disciplinary expertise further empowers engineers and scientists to merge knowledge from chemistry, data science, and environmental engineering, enriching water management strategies. In terms of operational gains, skilled professionals contribute to cost efficiency and sustainability by optimizing treatment processes to reduce chemical use, energy consumption, and waste disposal costs [83,84]. Moreover, such expertise enables companies to reuse treated water, decreasing reliance on freshwater sources and mitigating environmental impacts. Another significant strength is the promotion of industry–academia collaboration. Partnerships between corporations and universities support innovation in water recycling, with industry-funded programs advancing specialized training in areas such as desalination, nanotechnology, and AI-driven water analytics [49,50]. Talent development also bolsters regulatory compliance and ESG (Environmental, Social, and Governance) performance. Training initiatives ensure that environmental professionals stay informed about both global and local water regulations, enabling companies to meet sustainability goals like Saudi Vision 2030 and Net Zero targets [85,86]. Furthermore, digitalization enhances training and operations through tools such as Virtual Reality (VR) and Augmented Reality (AR), offering immersive learning experiences in managing water systems, while AI-driven platforms aid in honing predictive modeling and process optimization skills [87,88]. Lastly, future-proofing the workforce is essential as the oil and gas sector transitions toward sustainable models. Upskilling employees in circular economy principles ensures long-term adaptability and career growth, with certifications in green chemistry, water treatment, and environmental engineering preparing professionals for emerging roles in sustainable energy and resource management [89,90].

8. Lifecycle Environmental Impact of the Circular Economy Model for Produced Water

Assessing the environmental impact of a circular economy model for produced (formation) water requires examining the entire lifecycle, from collection and treatment to reuse and final application. This approach offers clear benefits by reducing freshwater demand and minimizing waste disposal [22,75,91]. However, it also introduces environmental challenges that must be carefully managed.

A key concern is the carbon footprint of energy-intensive treatment processes, particularly thermal methods such as vaporization and distillation. These processes consume substantial energy, and when powered by fossil fuels, they contribute significantly to greenhouse gas emissions [3,92]. Integrating renewable energy sources or utilizing waste heat recovery systems can help reduce emissions and improve overall sustainability [3,93].

Another important issue is the potential contamination of soil and groundwater, especially when evaporation ponds are used to concentrate or dispose of produced water. Poorly lined or inadequately maintained ponds can allow salts, heavy metals, and hydrocarbons to infiltrate the subsurface environment [39,94]. To mitigate these risks, the model should include robust containment systems, regular environmental monitoring, and zero-liquid discharge (ZLD) technologies that prevent direct discharges [8].

The circular economy model redefines produced water as a valuable resource rather than waste; however, its long-term sustainability relies on the adoption of low-carbon energy solutions, advanced treatment technologies, and robust environmental safeguards throughout the entire lifecycle [74,75].

9. Conclusions

This review demonstrates that applying circular economy (CE) frameworks to petroleum produced water (PW) management can transform one of the industry’s largest waste streams into a sustainable resource cycle. The integration of flash vaporization with evaporation pond crystallization achieves near-zero liquid discharge, yielding high-quality irrigation water and valuable mineral by-products such as potash and halite. Collectively, these innovations enable up to 80% reduction in PW disposal, 25–30% lower greenhouse gas emissions, and 20–35% cost savings compared to conventional treatment and disposal methods. Although high energy demand and capital intensity remain challenges, coupling thermal systems with renewable energy, waste-heat recovery, and membrane pre-treatment can significantly enhance process efficiency. Long-term sustainability depends on regulatory support, economic incentives, and cross-sector collaboration linking oil producers, agricultural stakeholders, and policymakers. Future work should focus on optimizing hybrid low-energy technologies, conducting full life-cycle assessments, and quantifying social and environmental co-benefits. By aligning economic viability with environmental responsibility, CE-based PW management represents a practical, scalable model for advancing global sustainability and resource stewardship in the petroleum sector.

Funding

The authors wish to thank The American University in Cairo (AUC) for supporting this manuscript through publication fees grant.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- International Energy Agency. World Energy Outlook 2023. 2023. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 2 February 2025).

- Khlaifat, A.; Fakher, S.; Ibrahim, A.D.; Elsese, M.; Nour, A. High-salinity produced water treatment and desalination. Hydrosci. J. 2024, 109, 2284957. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.; Madaeni, S.S.; Abidin, Z.Z. Review of technologies for oil and gas produced water treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef]

- Veil, J.A.; Puder, M.G.; Elcock, D.; Redweik, R.J. A White Paper Describing Produced Water from production of Crude Oil, Natural Gas, and Coal Bed Methane. Argonne National Laboratory. 2004. Available online: https://www.osti.gov/biblio/821666 (accessed on 2 February 2025).

- Waly, T.M.; Al-Anezi, F.A.; Saad, A.E. An integrated approach for sustainable produced water management in oil and gas operations. J. Pet. Sci. Eng. 2020, 188, 106820. [Google Scholar] [CrossRef]

- Waly, M.M.; Mickovski, S.B.; Thomson, C. Application of Circular Economy in Oil and Gas Produced Water Treatment. Sustainability 2023, 15, 2132. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Alsuhaibany, Y. Digital Innovation and Circular Economy: A Nexus for Sustainable Oil and Gas Sector Transformation in Saudi Arabia. Sustainability 2025, 17, 1325. [Google Scholar] [CrossRef]

- Eltayeb, A. Saudi Aramco: Circular Economy and Sustainability in the Oil and Gas Industry. Glob. J. Hum.-Soc. Sci. 2025, 25, 33–35. Available online: https://socialscienceresearch.org/index.php/GJHSS/article/view/104360 (accessed on 2 February 2025). [CrossRef]

- Muvel, H.; Jindal, M.K.; Tewari, P.K.; Anand, V. Minimizing oil pollution: A review of current status and its treatment options. RSC Sustain. 2025, 3, 3681–3723. [Google Scholar] [CrossRef]

- Hashemi, F.; Young, S.; Hashemi, H.; Leiviskä, T.; Shafea, L.; Hajivand, M.; Pouladi Borj, B. Water Stewardship in Oil & Gas—Recycling Produced and Process Water. In Occidental Petroleum Sustainability Report 2025; Oxy: Houston, TX, USA, 2025; pp. 58–59. [Google Scholar]

- Manning, T.J. Potash: Deposits, processing, properties and uses. J. Ind. Miner. 2010, 12, 23–35. [Google Scholar] [CrossRef]

- Khlaifat, A.; Batarseh, M.; Nawayseh, K.; Amira, J.; Talafeha, E. Mixing of Dead Sea and Red Sea Waters and Changes in their Physical Properties. Heliyon 2020, 6, e05444. [Google Scholar] [CrossRef]

- AKhlaifat, M.; Hogan, G.; Phillips, J.; Amira, K.; Nawayseh, E. Talafeha, Long–Term Monitoring of the Dead Sea Brine Physico-Chemical Parameters “from 1987 to 2008”. J. Mar. Syst. 2010, 81, 207–212. [Google Scholar] [CrossRef]

- Khlaifat, A.; Al-Khashman, O.; Qutob, H. Physical and Chemical Characterization of Dead Sea Mud. Mater. Charact. 2010, 61, 564–568. [Google Scholar] [CrossRef]

- Khlaifat, A.; Hogan, M.; Phillips, G.; Amira, J.; Nawayseh, K.; Batarseh, M.; Talafeha, E.; Khashman, O.; Sallal, A.; Tarawneh, A.; et al. Dead Sea Brine Characteristics Changes Caused by Mixing of Red Sea and Dead Sea Waters. In Proceedings of the International Conference on Materials in Jordan, German-Jordanian University, Amman, Jordan, 4–6 March 2009. [Google Scholar]

- Kesieme, U.; Milne, N.; Aral, H.; Cheng, C.Y.; Duke, M. Economic analysis of desalination technologies in the context of produced water treatment. Desalination 2019, 463, 35–42. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Kumar, S.; Singh, D. Tannery effluent treatment and its environmental impact: A review of current practices and emerging technologies. Water Qual. Res. J. 2023, 58, 128–152. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 2 February 2025).

- Mondal, S.; Wickramasinghe, S.R. Produced water treatment technologies. Sep. Purif. Technol. 2008, 64, 300–309. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Al-Kaabi, M.A.; Ashfaq, M.Y.; Da’na, D.A. Produced water characteristics, treatment and reuse: A review. J. Water Process Eng. 2019, 28, 222–239. [Google Scholar] [CrossRef]

- Igunnu, E.T.; Chen, G.Z. Produced water treatment technologies. Int. J. Low-Carbon Technol. 2014, 9, 157–177. [Google Scholar] [CrossRef]

- Hussain, A.; Khan, M.A.; Ahmed, S. Flash vaporization techniques for salinity reduction in irrigation reuse. J. Water Reuse Desalination 2020, 10, 210–222. [Google Scholar] [CrossRef]

- European Parliament. The Circular Economy: Definition, Importance and Benefits. 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20151201STO05603/the-circular-economy-definition-importance-and-benefits (accessed on 2 February 2025).

- Ibrahim, M.; Nawaz, M.H.; Rout, P.R.; Lim, J.-W.; Mainali, B.; Shahid, M.K. Advances in Produced Water Treatment Technologies: An In-Depth Exploration with an Emphasis on Membrane-Based Systems and Future Perspectives. Water 2023, 15, 2980. [Google Scholar] [CrossRef]

- Al-Mutairi, K.; Chen, R. Integrated Produced Water Management and Treatment Pathways in Oilfields. J. Environ. Manag. 2024, 345, 120981. [Google Scholar] [CrossRef]

- Smith, L.J.; Green, D.M. Flash Vaporization and Mineral Recovery for Circular Water Systems in Energy Operations. J. Clean. Prod. 2023, 430, 139877. [Google Scholar] [CrossRef]

- Ojo, O.E.; Oludolapo, O.A. Cost–Benefit and Market Viability Analysis of Metals and Salts Recovery from SWRO Brine Compared with Terrestrial Mining and Traditional Chemical Production Methods. Water 2025, 17, 2855. [Google Scholar] [CrossRef]

- Chen, D.H.; Aziz, F.S.; Sargsyan, G. Associated Gas Recovery Integrated with Solar Power for Produced Water Treatment: Techno-Economic and Environmental Impact Analyses. Energies 2024, 17, 5794. [Google Scholar] [CrossRef]

- González, M.P.; Al-Farouq, A. Sustainability Indexing for Industrial Water Reuse Systems under Circular Economy Principles. Sustain. Prod. Consum. 2025, 44, 210–223. [Google Scholar] [CrossRef]

- Sanchez-Rosario, R.; Hildenbrand, Z.L. Produced Water Treatment and Valorization: A Techno-Economical Review. Energies 2022, 15, 4619. [Google Scholar] [CrossRef]

- Veolia North America. Produced Water Joins the Circular Economy. Veolia Blog. 2019. Available online: https://blog.veolianorthamerica.com/produced-water-joins-the-circular-economy (accessed on 2 February 2025).

- Al-Ghouti, M.A.; Li, J.; Salih, H.N.; Albadarin, A.B. Produced Water Treatment Technologies. Oxford Academic. 2014. Available online: https://academic.oup.com/ijlct/article/9/3/157/807670 (accessed on 2 February 2025).

- Suhane, S.; Dewan, R.; Mohaimin, A. Potential Use of Treated Produced Water in Irrigation: A Review. In Advances in Sustainable Development; Siddiqui, N.A., Tauseef, S.M., Abbasi, S.A., Dobhal, R., Kansal, A., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Condorchem Envitech. Zero Liquid Discharge by Means of Evaporation Ponds. Condorchem Envitech Blog. 2012. Available online: https://condorchem.com/en/blog/zero-liquid-discharge-by-means-of-evaporation-ponds/ (accessed on 2 February 2025).

- Webb, C.H.; Naggappan, L.; Smart, G.; Hoblitzell, J.; Franks, R. Desalination of Oilfield-Produced Water at the San Ardo Water Reclamation Facility, CA. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 24–26 March 2009; Society of Petroleum Engineers: Calgary, AB, Canada, 2009. [Google Scholar] [CrossRef]

- Bourgier, V.; Schooley, K.; Lawson, R. Applying Evaporators & Crystallizers to Fertilizer Production. Veolia Water Technologies. 22 June 2020. Available online: https://www.veoliawatertech.com/en/publications/articles/applying-evaporators-crystallizers-fertilizer-production (accessed on 2 February 2025).

- Abu-Hamatteh, Z.S.H.; Al-Amr, A.M. Carnallite froth flotation optimization and cell efficiency in the Arab Potash Company, Dead Sea, Jordan. Miner. Process. Extr. Metall. Rev. 2008, 29, 232–257. [Google Scholar] [CrossRef]

- Khatib, Z.; Verbeek, P. Water to value—Produced water management for sustainable field development of mature and green fields. J. Pet. Technol. 2003, 55, 26–28. [Google Scholar] [CrossRef]

- Shaffer, D.L.; Arias Chavez, L.H.; Ben-Sasson, M.; Romero-Vargas Castrillón, S.; Yip, N.Y.; Elimelech, M. Desalination and reuse of high-salinity shale gas produced water: Drivers, technologies, and future directions. Environ. Sci. Technol. 2013, 47, 9569–9583. [Google Scholar] [CrossRef] [PubMed]

- Vazquez, A.; Garcia, R.; Singh, R. A comparative study of nanofiltration and reverse osmosis for oil and gas wastewater treatment. Sep. Purif. Technol. 2021, 259, 118172. [Google Scholar] [CrossRef]

- Xu, P.; Drewes, J.E.; Heil, D. Beneficial use of co-produced water through membrane treatment: Technical-economic assessment. Desalination 2008, 225, 139–155. [Google Scholar] [CrossRef]

- Boon, J.; Ye, M.; Shonnard, D.R. Sustainable approaches to managing produced water in oil and gas operations. J. Environ. Manag. 2020, 262, 110295. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Global Energy Transformation: A Roadmap to 2050. 2023. Available online: https://www.irena.org/Publications (accessed on 2 February 2025).

- Rogers, J.; Patel, D.; Morrison, S. Advancements in evaporation pond technology for produced water disposal. Water Sci. Technol. 2020, 81, 1675–1688. [Google Scholar] [CrossRef]

- Clark, C.E.; Veil, J.A. Produced Water Volumes and Management Practices in the United States; Argonne National Laboratory: Lemont, IL, USA, 2009. [Google Scholar] [CrossRef]

- Benko, K.L.; Drewes, J.E. Produced water in the Western United States: Geographical distribution, occurrence, and composition. Environ. Eng. Sci. 2008, 25, 239–246. [Google Scholar] [CrossRef]

- United Nations Development Programme. Sustainable Management of Water in Oil-Producing Regions: Strategies and Practices; UNDP: New York, NY, USA, 2020. [Google Scholar]

- Saudi Aramco. Investing in Growth, Innovating for Sustainability: Sustainability Report 2022; Saudi Arabian Oil Co.: Dhahran, Saudi Arabia, 2023; Available online: https://www.aramco.com/-/media/downloads/sustainability-report/report-2022/2022-sustainability-report-en.pdf (accessed on 2 February 2025).

- Society of Petroleum Engineers (SPE). Collaborative Research in Produced Water Management: Industry-University Partnerships; SPE: Houston, TX, USA, 2023. [Google Scholar]

- SysCAD Team. Potash—Process Modelling for a Growing Industry. SysCAD. 15 December 2021. Available online: https://www.syscad.net/potash-process-modelling-for-a-growing-industry/ (accessed on 28 March 2025).

- Nicot, J.-P.; Scanlon, B.R. Water Use for Shale-Gas Production in Texas, U.S. Environ. Sci. Technol. 2012, 46, 3580–3586. [Google Scholar] [CrossRef]

- McLaughlin, M.; Anderson, R.; Bennett, C. Economic feasibility of zero liquid discharge systems in petroleum operations. Desalination Water Treat. 2019, 150, 76–89. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, C.; Wu, X. Circular economy and sustainability in oil and gas wastewater treatment. J. Clean. Prod. 2018, 176, 140–149. [Google Scholar] [CrossRef]

- Kato, S.; Kansha, Y. Comprehensive review of industrial wastewater treatment techniques. Environ. Sci. Pollut. Res. 2024, 31, 51064–51097. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.T.; Hassan, H.; Younis, M. Recent advances in produced water treatment technologies: A review. Environ. Technol. Innov. 2021, 23, 101623. [Google Scholar] [CrossRef]

- Abdelrazeq, H.; Khraisheh, M.; Ashraf, H.M.; Ebrahimi, P.; Kunju, A. Sustainable Innovation in Membrane Technologies for Produced Water Treatment: Challenges and Limitations. Sustainability 2021, 13, 6759. [Google Scholar] [CrossRef]

- Feng, H.; Chen, W.; Sun, R.; Zhang, Z.; Li, W.; Zhang, B. Simulation and Experimental Study of Circulatory Flash Evaporation System for High-Salt Wastewater Treatment. Energies 2024, 17, 2382. [Google Scholar] [CrossRef]

- Chen, R.; Al-Mutairi, K. Energy Recovery and Solar Integration in Industrial Water Treatment Systems. Renew. Energy 2022, 198, 1201–1212. [Google Scholar] [CrossRef]

- Alsaeed, B.S.; Hunt, D.V.L.; Sharifi, S. A Sustainable Water Resources Management Assessment Framework (SWRM-AF) for Arid and Semi-Arid Regions—Part 1: Developing the Conceptual Framework. Sustainability 2024, 16, 2634. [Google Scholar] [CrossRef]

- Wong, J.M. Water reuse for petroleum oil, product processing industries. Ind. Waterworld 2012, 2, 18–22. [Google Scholar]

- CTCI Group. CAPCO PTA Wastewater Recovery Unit, Kaohsiung [Engineering, Procurement & Construction Project Details]; CTCI: Taipei, Taiwan, 2023. [Google Scholar]

- Alsalem, F.; Thiemann, T. Produced Water from the Oil and Gas Industry as a Resource—South Kuwait as a Case Study. Resources 2024, 13, 118. [Google Scholar] [CrossRef]

- Sharma, A. PEMEX Refinery, Mexico: Tertiary Treatment of Combined Refinery Effluent as Pretreatment for RO. Industrial Wastewater Reuse, India Water Portal SlideShare Presentation; Slide Describing Minatitlán Refinery Performance. 2013. Available online: https://www.slideshare.net/slideshow/anil-sharma-29967569/29967569 (accessed on 18 July 2025).

- Girardi, A. Wastewater treatment and reuse in the oil & petrochem industry—A case study. In Wastewater and Biosolids Treatment and Reuse: Bridging Modeling and Experimental Studies; ECI Symposium Series; Santoro, D., Ed.; ECI: New York, NY, USA, 2014. Available online: http://dc.engconfintl.org/wbtr_i/46 (accessed on 2 February 2025).

- OriginClear, Inc. OriginClear Hybrid Water Treatment Systems Support ESG Reporting and On-Site Produced Water Reuse. 2020. Available online: https://originclear.tech/case-study-produced-water-reuse (accessed on 2 February 2025).

- Swirltex Inc. Produced Water Case Study. Available online: https://swirltex.com/produced-water-case-study/ (accessed on 18 July 2025).

- Genesis Water Technologies, Inc. Produced Water Treatment in the Permian Basin: A Bench Case Study for a Large Oil & Gas Exploration Company. Available online: https://genesiswatertech.com/blog-post/produced-water-treatment-in-the-permian-basin-a-bench-case-study-for-a-large-oil-gas-exploration-company/ (accessed on 18 July 2025).

- Stefanakis, A.I.; Prigent, S.; Breuer, R. Treatment of Produced Water from Oilfield in a Large Constructed Wetland: 6 Years of Operation under Desert Conditions. Sci. Total Environ. 2018, 616–617, 1615–1626. [Google Scholar] [CrossRef]

- Singh, J.; Harthi, M.; Siyabi, M.; Al Salmi, M.; Hamm, C.; Riyami, O.; Hatmi, S.; Samiee, R.A.; Hinai, M.; Mazroui, A.; et al. Effective Reuse of the Produced Water: A Case Study from a Field in South Oman. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21–23 March 2022. [Google Scholar] [CrossRef]

- New Technology Turns Permian Basin Oilfield Wastewater into Dry Solids. Midland Reporter-Telegram. 12 July 2025. Available online: https://www.mrt.com/business/oil/article/permian-basin-water-evaporator-20766202.php (accessed on 2 February 2025).

- Al-Saidi, M.; Dehnavi, S. Growing the Portfolio: Circular Economy through Water Reuse in Iran. Front. Water 2024, 6, 1341715. [Google Scholar] [CrossRef]

- Delgado, A.; Rodriguez, D.J.; Amadei, C.A.; Makino, M. Water in Circular Economy and Resilience (WICER); World Bank: Washington, DC, USA, 2021; Available online: https://hdl.handle.net/10986/36254 (accessed on 2 February 2025).

- Nasiri, M.; Jafari, I.; Parniankhoy, B. Oil and gas produced water management: A review of treatment technologies, challenges, and opportunities. Chem. Eng. Commun. 2017, 204, 990–1005. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K. Produced water treatment: Applications and perspectives in a circular economy framework. J. Environ. Manag. 2022, 304, 114287. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane technologies in wastewater treatment: A review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Mew, M.C. Future world potash supply and demand: A global perspective. Sci. Total Environ. 2016, 643, 1440–1453. [Google Scholar] [CrossRef]

- Al Rawashdeh, R.; Xavier-Oliveira, E.; Maxwell, P. The Potash Market and Its Future Prospects. Resour. Policy 2016, 47, 154–163. [Google Scholar] [CrossRef]

- Xie, J.; Guo, W.; Ngo, H.H.; Nghiem, L.D. Energy-efficient treatment of produced water using hybrid thermal and membrane systems. Desalination 2019, 457, 61–73. [Google Scholar] [CrossRef]

- Latif, A.; Cahyandito, M.F.; Utama, G.L. Dynamic System Modeling and Sustainability Strategies for Circular Economy-Based Dairy Cow Waste Management. Sustainability 2023, 15, 3405. [Google Scholar] [CrossRef]

- Arthur, J.D.; Langhus, B.G.; Patel, C. Technical Summary of Oil and Gas Produced Water Treatment Technologies. All Consulting, LLC. 2005. Available online: http://dvikan.no/ntnu-studentserver/reports/ALLConsulting-WaterTreatmentOptionsReport.pdf (accessed on 2 February 2025).

- Pichtel, J. Discusses advanced water treatment technologies, including membrane filtration and bioremediation. In Waste Management Practices: Municipal, Hazardous, and Industrial; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- United Nations Environment Programme (UNEP). Global Wastewater Initiative Report; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- Hisham, S.; Ayub Khan, F.; Aljlil, S.A.; Ghasemi, M. Investigating New Techniques for the Treatment of Oil Field Produced Water and Energy Production. SN Appl. Sci. 2019, 1, 646. [Google Scholar] [CrossRef]

- International Energy Agency. Energy and Water: Exploring the Interdependence of Two Critical Resources; I.E.A.: Paris, France, 2022; Available online: https://www.iea.org/topics/energy-and-water (accessed on 2 February 2025).

- Kingdom of Saudi Arabia. Vision 2030 Annual Report 2023; Vision Realization Office: Riyadh, Saudi Arabia, 2023. Available online: https://www.vision2030.gov.sa/media/xi2jlj0y/english_vision2030_annual_report_2023.pdf (accessed on 2 February 2025).

- BP. Building the Future: BP’s Journey with AI and Other Cutting-Edge Tech. BP Energy in Focus. 19 February 2025. Available online: https://www.bp.com/en/global/corporate/news-and-insights/energy-in-focus/technology-at-bp.html (accessed on 2 February 2025).

- Petrobras. Innovation Report: The Role of Augmented Reality in Offshore Training; Petróleo Brasileiro S.A: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- ExxonMobil. Sustainability Report 2023; Exxon Mobil Corporation: Irving, TX, USA, 2023; Available online: https://corporate.exxonmobil.com/-/media/global/files/sustainability-report/2024/sustainability-report.pdf (accessed on 2 February 2025).

- Yetunde, A.A.; Augusta, H.I.; Jephta, M.K.; Andrew, E. Circular economy practices in the oil and gas industry: A business perspective on sustainable resource management. GSC Adv. Res. Rev. 2024, 20, 267–285. [Google Scholar] [CrossRef]

- Abdelhamid, C.; Latrach, A.; Rabiei, M.; Venugopal, K. Produced Water Treatment Technologies: A Review. Energies 2025, 18, 63. [Google Scholar] [CrossRef]

- Neff, J.; Lee, K.; DeBlois, E.M. Produced water: Overview of composition, fates, and effects. In Produced Water: Environmental Risks and Advances in Mitigation Technologies; Lee, K., Neff, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–54. [Google Scholar] [CrossRef]

- Nath, F.; Chowdhury, M.O.S.; Rhaman, M.M. Navigating Produced Water Sustainability in the Oil and Gas Sector: A Critical Review of Reuse Challenges, Treatment Technologies, and Prospects Ahead. Water 2023, 15, 4088. [Google Scholar] [CrossRef]

- Davis, T.; Gannon, R.S.; Warden, J.G.; Rodriguez, O.; Gillespie, J.M.; Ball, L.B.; Qi, S.L. Produced Water Disposal at Percolation and Evaporation Ponds in and Near Oil Fields in the Southwestern San Joaquin Valley, California (Version 2.0, October 2024); U.S. Geological Survey Data Release: Reston, VA, USA; U.S. Geological Survey: Reston, VA, USA, 2023. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).