Experimental Study on Proppant Backflow and Fiber Sand Control in Vertical Fracture Based on the Visual Diversion Chamber Simulation

Abstract

1. Introduction

2. Methodology

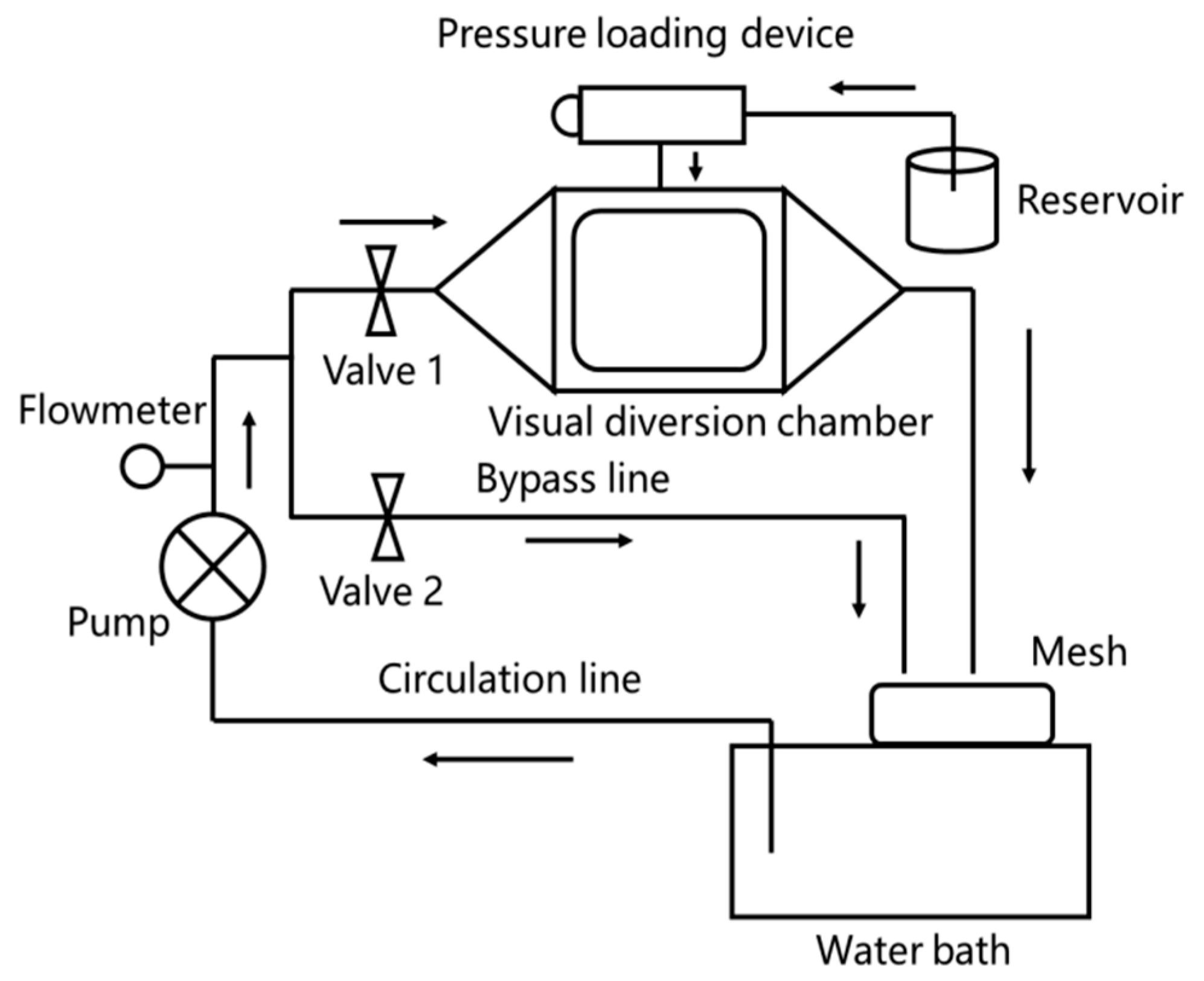

2.1. Experimental Device

2.2. Experimental Design

- Position the chamber body horizontally and shield the inlet and outlet to prevent the spillage of proppants and fibers. Subsequently, place the rock slab into the chamber body, ensuring it fits snugly against the inner wall without any gaps. Then, evenly distribute the pre-weighed proppants and fibers onto the rock slab, making sure the surface of the filling layer formed by the proppants and fibers is level. Finally, cover the visual plate and connect it to the chamber body through threads without any looseness.

- Position the chamber body vertically to simulate a vertical fracture. Then, assemble the piston and connect it to the pressure-loading device, using it to inject liquid into the pressure-loading cavity to provide pressure on the vertical walls, simulating closure pressure. Simultaneously turn on the pump and saturate the proppant/fiber fill layer within the chamber body with liquid at a displacement rate of 10 mL/min.

- After the proppant/fiber fill layer is fully saturated with fluid, remove the shields from the inlet and outlet ends. Begin the flow-back process by incrementally increasing the displacement rate from an initial speed of 20 mL/min up to 700 mL/min to simulate the proppant transport during flow-back. Place a camera at the visualization window to continuously record the state changes of the fill layer within the fracture. Position a collector at the outlet end to gather and weigh the expelled sand.

3. Results and Discussion

3.1. The Migration Law of Proppant Backflow

- Channels are formed on the surface of the sand bank or at weak structural points due to erosion by high-speed fluid, and the proppants are carried away by the fluid.

- After the proppants flow back, the flow channel of the liquid becomes larger, the fluid velocity decreases, the sand-carrying capacity weakens, the proppants roll back and the amount of backflow decreases.

- The channel further expands, and the flow velocity decreases to the point where the scouring force on the proppants is less than the interlocking force between the particles, causing the proppants to cease movement. The movement patterns of proppant flow-back can be seen in Figure 7.

3.2. Comparison of Fiber Sand Control Under Different Processes

3.3. Optimization of Construction Parameters for Sand Control Technology

- Under low sand concentrations, excessive fiber concentration may reduce dispersion within the composite structure and cause overflow, thereby compromising structural stability.

- At high sand concentrations, the proppant-dominated composite structure effectively prevents fiber overflow, enabling fibers to consistently enhance structural strength.

- Experimental results recommend 0.8% fiber concentration for low sand concentrations and 1.2% fiber concentration for high sand concentrations.

4. Field Application

5. Conclusions

- Proppant flow-back occurs at the interface between two phases (i.e., irregular voids or structurally weak zones at the top of the proppant fill layer). The essence of proppant flow-back is the erosion of proppant particles in structurally weak areas of the proppant fill layer by backflow fluids.

- The movement of proppants during flow-back can be divided into three stages. Its resistance to fluid erosion varies with each stage, and this capability is strongly correlated with fluid flow channels and sand bank morphology.

- The optimal sand control technique identified in the experiments is MFI, with the following recommended parameters:

- At low proppant concentrations (<10 kg/m2), the fiber concentration should be 0.8%;

- At high proppant concentrations (>10 kg/m2), the fiber concentration should be 1.2%;

- The recommended fiber length is 6 mm.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Sang, Y.; Guo, J.; Yang, J.; Chen, W.; Tang, B.; Feng, F.; Gou, X.; Zhang, Y. Experimental study on the backflow mechanism of proppants in induced fractures and fiber sand control under condition of large scale and fully measurable flow field. ACS Omega 2023, 8, 42467–42478. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.; Zhang, C.; Wang, Z.; Sun, B.; Gao, Y.; Wang, X.; Bi, C.; Zhang, Q.; Wang, J.; Shi, J. Proppant transport in rough fractures of unconventional oil and gas reservoirs. Pet. Explor. Dev. 2023, 50, 712–721. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, P.; Wang, K.; Wang, S.; Meng, Q.; Li, M.; Ma, Y.; Zeng, J. A Novel Slick-water System with Strong-Polarity Fibers for High-Efficiency Proppant Flowback Mitigation. Processes 2024, 12, 12040724. [Google Scholar]

- Guo, J.; Ren, S.; Zhang, S.; Diao, S.; Lu, Y.; Zhang, T. Efficient placement technology of proppants based on structural stabilizers. Pet. Explor. Dev. 2024, 51, 706–714. [Google Scholar] [CrossRef]

- Xiao, L.; Xiao, L.; Lu, X.; Liu, J.; Liu, C.; Lan, X. Review and Perspectives of Coated Proppant Technology. Energy Fuels 2023, 37, 3355–3370. [Google Scholar] [CrossRef]

- Mark, P. Understanding Proppant Flow-back. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1999. [Google Scholar]

- Goel, N. Experimental Investigation of Proppant Flow-back Phenomena Using a Large-Scale Fracturing Simulator. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1999. [Google Scholar]

- Canon, J. Avoiding Proppant Flow-back in Tight-Gas Completions with Improved Fracture Design. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 5–8 October 2003. [Google Scholar]

- Dimitry, C. Proppant Flow-back: Can We Mitigate the Risk? In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar]

- Liu, Y.; Mu, S.; Guo, J.; Li, Q.; Hu, D.; Wang, S. Analytical model for fracture conductivity considering rod proppant in pulse fracturing. J. Pet. Sci. Eng. 2022, 217, 110904. [Google Scholar] [CrossRef]

- Li, T.C.; Guo, J.C.; Zhao, J.Z. Study on the proppant backflow control and the sanding control of fractured gas wells and its application. J. Xi’an Shiyou Univ. 2006, 44–47+115–116. [Google Scholar]

- McLennan, J.; Walton, I.; Moore, J.; Brinton, D.; Lund, J. Proppant backflow: Mechanical and flow considerations. Geothermics 2015, 57, 224–237. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, B.; Tan, M.; Zhang, S.; Jing, Q. New Advancement of Proppant Backflow Control Technology. Nat. Gas Ind. 2006, 26, 101–103. [Google Scholar]

- Aslanyan, I.; Llc, R.T.S.; Minakhmetova; Trusov, A.; Lutfullin, A.; Habibrahmanov, A.; Afljatunov, R.; Habipov, R.; Pjsc, R.T. Proppant backflow zones determination by spectral noise logging. Oil Ind. J. 2018, 2018, 68–71. [Google Scholar]

- Guo, T.K.; Zhang, S.C.; Xiao, B.; Liu, G.Q.; Wang, F.; Zhang, J.C.; Bian, X.B. Evaluation and Optimization of New Nanocomposite Fiber for Fracturing Technology Based on a New Equipment. Transp. Porous Media 2012, 94, 243–257. [Google Scholar] [CrossRef]

- Wang, P.; Gu, T.; Gao, Z.; Fan, J.; Huang, H.; Qu, Z.; Han, Q.; Ren, Z.; Cui, X. Stability Evaluation of Proppant in Fractures of Gas Storage in Yulin Gas Field. Adv. Civ. Eng. 2022, 2022, 2044561. [Google Scholar] [CrossRef]

- Verisokin, A.E.; Shlein, G.A.; Dimitriadi, Y.K. Combined technological solutions to increase inflow in oil wells of offshore fields. IOP Conf. Ser. Earth Environ. Sci. 2021, 872, 012012. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, J.; Rutter, R.; Zhang, H.-Q. A Numerical Study on Erosion Model Selection and Effect of Pump Type and Sand Characters in Electrical Submersible Pumps by Sandy Flow. J. Energy Resour. Technol. 2019, 141, 4044941. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Gu, D.H.; Zhu, M.; He, S.L.; Men, C.Q.; Luan, G.H.; Mo, S.Y. Optimization of Fracturing Fluid Flowback Based on Fluid Mechanics for Multilayer Fractured Tight Reservoir. Adv. Mater. Res. 2014, 886, 448. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S. Influence of the backflow velocity of fracturing fluid on the backflow volume and distribution of proppant in fractures. Pet. Geol. Recovery Effic. 2008, 101–102+110+118. [Google Scholar]

- Lei, W.; Heng, W. Experimental Research on Proppant Backflow Volume Influenced by the Velocity of Backflow Fracturing Fluid. Sci. Technol. Eng. 2016, 16, 200–202+206. [Google Scholar]

| Qe (mL/min) | Qf (m3/min) | He(mm) | Hf (mm) | We(mm) | Wf (mm) |

|---|---|---|---|---|---|

| 5330.36 | 1.00 | 100 | 20,000 | 10 | 10 |

| 1110.49 | 0.83 | 100 | 20,000 | 10 | 10 |

| 888.39 | 0.67 | 100 | 20,000 | 10 | 10 |

| 666.29 | 0.50 | 100 | 20,000 | 10 | 10 |

| 444.20 | 0.33 | 100 | 20,000 | 10 | 10 |

| 222.10 | 0.17 | 100 | 20,000 | 10 | 10 |

| 199.89 | 0.15 | 100 | 20,000 | 10 | 10 |

| 177.68 | 0.13 | 100 | 20,000 | 10 | 10 |

| 155.47 | 0.12 | 100 | 20,000 | 10 | 10 |

| 133.26 | 0.10 | 100 | 20,000 | 10 | 10 |

| 111.05 | 0.08 | 100 | 20,000 | 10 | 10 |

| 88.84 | 0.07 | 100 | 20,000 | 10 | 10 |

| 66.63 | 0.05 | 100 | 20,000 | 10 | 10 |

| 44.42 | 0.03 | 100 | 20,000 | 10 | 10 |

| 22.21 | 0.02 | 100 | 20,000 | 10 | 10 |

| Number | Fiber Concentration (%) | Sand Concentration (kg/m2) | Fiber Length (mm) | Cumulative Sand Production Rate (%) | Critical Flow Velocity (mL/min) |

|---|---|---|---|---|---|

| 1 | 0.4 | 5 | 3 | / | / |

| 2 | 0.4 | 10 | 6 | / | / |

| 3 | 0.4 | 15 | 9 | / | / |

| 4 | 0.8 | 5 | 6 | / | / |

| 5 | 0.8 | 10 | 9 | / | / |

| 6 | 0.8 | 15 | 3 | / | / |

| 7 | 1.2 | 5 | 9 | / | / |

| 8 | 1.2 | 10 | 3 | / | / |

| 9 | 1.2 | 15 | 6 | / | / |

| Number | Fiber Concentration (%) | Sand Concentration (kg/m2) | Fiber Length (mm) | Cumulative Sand Production Rate (%) | Critical Flow Velocity (mL/min) |

|---|---|---|---|---|---|

| 1 | 0.4 | 5 | 3 | 0.06 | 110 |

| 2 | 0.4 | 10 | 6 | 0.13 | 140 |

| 3 | 0.4 | 15 | 9 | 0.12 | 110 |

| 4 | 0.8 | 5 | 6 | 0.04 | 140 |

| 5 | 0.8 | 10 | 9 | 0.18 | 190 |

| 6 | 0.8 | 15 | 3 | 0.20 | 140 |

| 7 | 1.2 | 5 | 9 | 0.04 | 190 |

| 8 | 1.2 | 10 | 3 | 0.10 | 230 |

| 9 | 1.2 | 15 | 6 | 0.05 | 400 |

| Main Effect Values | Indicators | Fiber Concentration (%) | Sand Concentration (kg/m2) | Fiber Length (mm) |

|---|---|---|---|---|

| K1 | sand production rate | 0.30 | 0.14 | 0.36 |

| K2 | 0.41 | 0.40 | 0.22 | |

| K3 | 0.19 | 0.37 | 0.33 | |

| k1 | 0.10 | 0.05 | 0.12 | |

| k2 | 0.14 | 0.13 | 0.07 | |

| k3 | 0.06 | 0.12 | 0.11 | |

| R | 0.07 | 0.09 | 0.05 | |

| K1 | critical flow velocity | 360 | 440 | 480 |

| K2 | 470 | 560 | 680 | |

| K3 | 820 | 650 | 490 | |

| k1 | 120 | 146.67 | 160 | |

| k2 | 156.67 | 186.67 | 226.67 | |

| k3 | 273.33 | 216.67 | 163.33 | |

| R | 153.33 | 70.00 | 66.67 |

| Well | Proppants | Injection Method | Total Sand Volume (t) | Total Liquid Volume (m3) | Fiber Concentration (%) | Fiber Length (mm) | Sand Production (m3) |

|---|---|---|---|---|---|---|---|

| QL220-8-H2 | sand | MFI | 5804 | 22,925.8 | 0.8 | 6 | 40 |

| QL220-8-H1 | sand + resin-coated sand | tail-end resin-coated sand injection | 5628 | 20,542.2 | / | / | 104 |

| QL220-8-H3 | sand + resin-coated sand | tail-end resin-coated sand injection | 5488 | 19,070.8 | / | / | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Sang, Y.; Guo, J.; Chen, W.; Feng, F.; Tang, B.; Fang, H.; Fan, J.; Ma, Z. Experimental Study on Proppant Backflow and Fiber Sand Control in Vertical Fracture Based on the Visual Diversion Chamber Simulation. Processes 2025, 13, 2983. https://doi.org/10.3390/pr13092983

Chen Y, Sang Y, Guo J, Chen W, Feng F, Tang B, Fang H, Fan J, Ma Z. Experimental Study on Proppant Backflow and Fiber Sand Control in Vertical Fracture Based on the Visual Diversion Chamber Simulation. Processes. 2025; 13(9):2983. https://doi.org/10.3390/pr13092983

Chicago/Turabian StyleChen, Yixin, Yu Sang, Jianchun Guo, Weihua Chen, Feng Feng, Botao Tang, Hongming Fang, Jinming Fan, and Zhongjun Ma. 2025. "Experimental Study on Proppant Backflow and Fiber Sand Control in Vertical Fracture Based on the Visual Diversion Chamber Simulation" Processes 13, no. 9: 2983. https://doi.org/10.3390/pr13092983

APA StyleChen, Y., Sang, Y., Guo, J., Chen, W., Feng, F., Tang, B., Fang, H., Fan, J., & Ma, Z. (2025). Experimental Study on Proppant Backflow and Fiber Sand Control in Vertical Fracture Based on the Visual Diversion Chamber Simulation. Processes, 13(9), 2983. https://doi.org/10.3390/pr13092983