1. Introduction

The principle of design for remanufacturing is to consider the remanufacturability in the product development stage and make the products have good remanufacturability at the end of their life [

1], which can achieve the goals of maximizing the utilization of waste resources and minimizing environmental pollution and manufacturing costs. DfRem not only determines the product remanufacturability, but also directly affects the successful implementation of remanufacturing.

Since DfRem directly affects the effective remanufacturing process of used products, many scholars have studied DfRem [

2], which mainly includes decision-making of DfRem scheme and DfRem scheme optimization and generation. DfRem is a design method to improve product remanufacturability; for example, Jiang et al. [

3] applied fuzzy nonlinear regression to divide the relationship between customer demand and remanufacturing design parameters as well as the fuzzy relationship between remanufacturing design parameters. Zwolinski et al. [

4] identified eight categories of design guidelines by creating a remanufacturable product outline document and encapsulating the knowledge related to remanufacturing conditions and remanufactured product characteristics. Yueksel [

5] proposed the quality function deployment (QFD) methodology in the design of products for remanufacture, which can obtain the accurate importance of remanufacturing design elements. Zhang et al. [

6] constructed a product failure mode recursive transfer model and used multicolor ensemble theory to mathematically express and derive the model, which provides support for the remanufacturing design process. The abovementioned works have studied the DfRem method from the aspects of customer demand, failure mode, and remanufactured product characteristics, which helps to generate DfRem solutions in a more comprehensive and reasonable way, but the above studies have not conducted DfRem from the perspective of product remanufacturability, and it is not possible to judge whether the DfRem solution can enable the product to be remanufactured smoothly at the end of its life.

Therefore, it is necessary to consider the remanufacturability of products at the design stage, allowing for the smooth implementation of remanufacturing at the end of the product’s life. There are scholars who have conducted relevant studies. For example, Gong et al. [

7] integrated the remanufacturing characteristics of the product into all aspects of the design and applied hesitant fuzzy sets to make decisions on design schemes. Yang et al. [

8] enhanced the material selection process during the early design phase to facilitate the remanufacturing of automotive parts and implemented a multi-criteria decision-making technique to assess the performance of potential materials. Xiao et al. [

9] proposed a master–slave association optimization method to achieve synergistic optimization between product architecture and eco-upgrade design, which can prolong the product’s lifecycle and improve the usage efficiency. The above studies have considered the factors affecting the remanufacturability at the design stage, including material, energy, and environmental factors, which make it easier for product remanufacturing at the end of life, but these studies only considered certain characteristics of product remanufacturability, resulting in difficulties in achieving other remanufacturability characteristics. In addition, as the generated DfRem parameters have not been verified in practice, it is impossible to judge whether the DfRem solution can successfully guide product remanufacturing at the end of life, which will create uncertainty for the remanufacturing of used products.

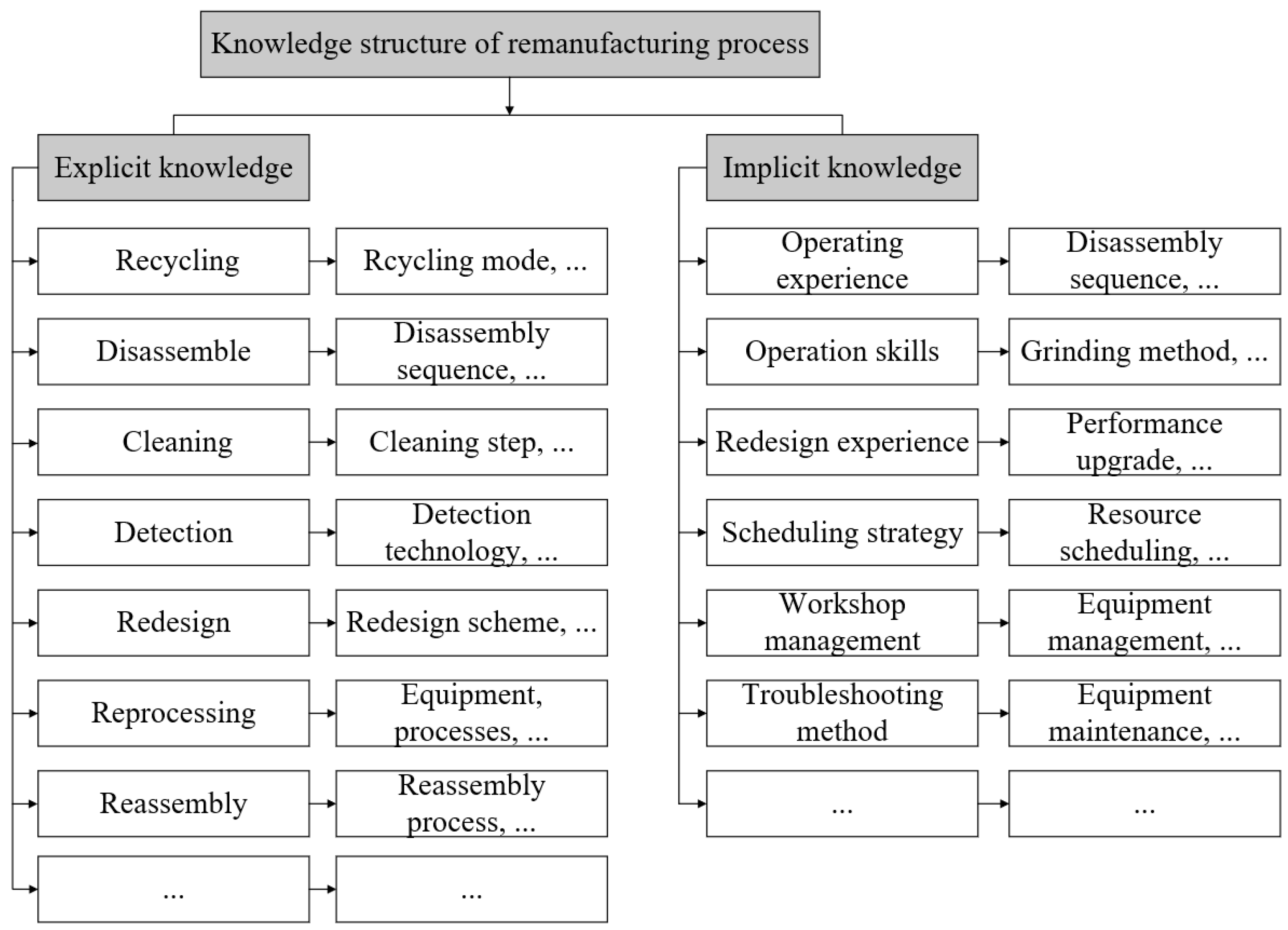

Moreover, the remanufacturing process contains a large amount of remanufacturing information, which can reflect the difficulty of product remanufacturing in the EOL. Since remanufacturing information has already been verified in actual processes, it can reflect whether product remanufacturability is good. Therefore, it is necessary to reuse historical remanufacturing information for DfRem and feed the valid remanufacturing information back into the DfRem process to solve the DfRem solution. Currently, there have been studies on remanufacturing information feedback to support DfRem. For example, Yao et al. [

10] presented some concepts related to remanufacturing and remanufactured product design based on the complete remanufacturing process and proposed the inclusion of remanufacturability research in the product design stage and qualitative design principles. Haziri et al. [

11] proposed a framework for the implementation of remanufacturing information feedback to product design and described a framework for the practical application of the process. The abovementioned scholars have studied the acquisition of effective information from the remanufacturing process and its feedback to the DfRem process, which is conducive to accurately obtaining design parameters that can satisfy remanufacturability as well as contributing to the accurate implementation of EOL remanufacturing.

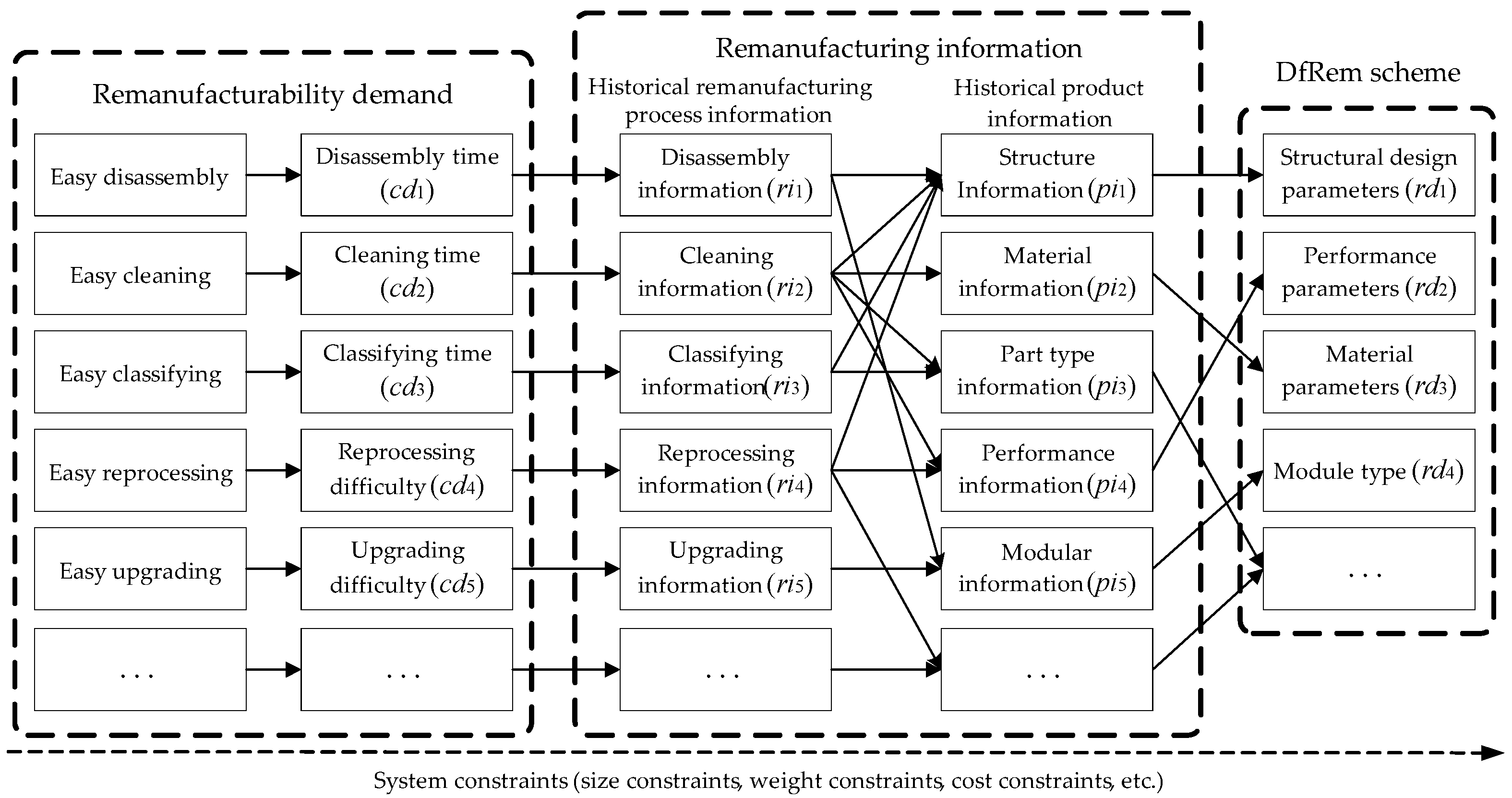

However, these studies are still in the conceptual design stage and have not established a mapping relationship between remanufacturing information and DfRem parameters. Remanufacturing information includes disassembly information, cleaning information, reprocessing information, and upgrading information, which are all related to product design information. For example, disassembly information is related to information on the connection structure of the product, cleaning information is related to information on the surface structure and appearance structure, reprocessing information is related to information on the material properties, and upgrading information is related to information on the module structure of the product, etc. The remanufacturing information is complex and heterogeneous, which makes it difficult to represent, organize, and reuse remanufacturing knowledge in a complete way with an effective method. Therefore, it is a critical step in accurately implementing DfRem to effectively map and integrate remanufacturing information and there are many methods to achieve this, such as the matter-element method [

12,

13], Petri nets [

14,

15], ontology technology [

16,

17,

18], etc. These methods can integrate information and characterize the relationships between different pieces of information. However, the matter-element method is suitable for modeling contradictory problems and uncertain phenomena, while Petri nets are suitable for modeling dynamic processes. Neither are suitable for modeling domain knowledge or describing semantic relationships between internal information, and neither can perform accurate knowledge inference. The ontology technology is a standardized and formalized description of domain knowledge. By clearly defining “concepts”, “relationships”, “attributes”, and “axioms”, it enables the sharing and reuse of domain knowledge. Therefore, the ontology technology is capable of modeling remanufacturing information to obtain effective DfRem knowledge.

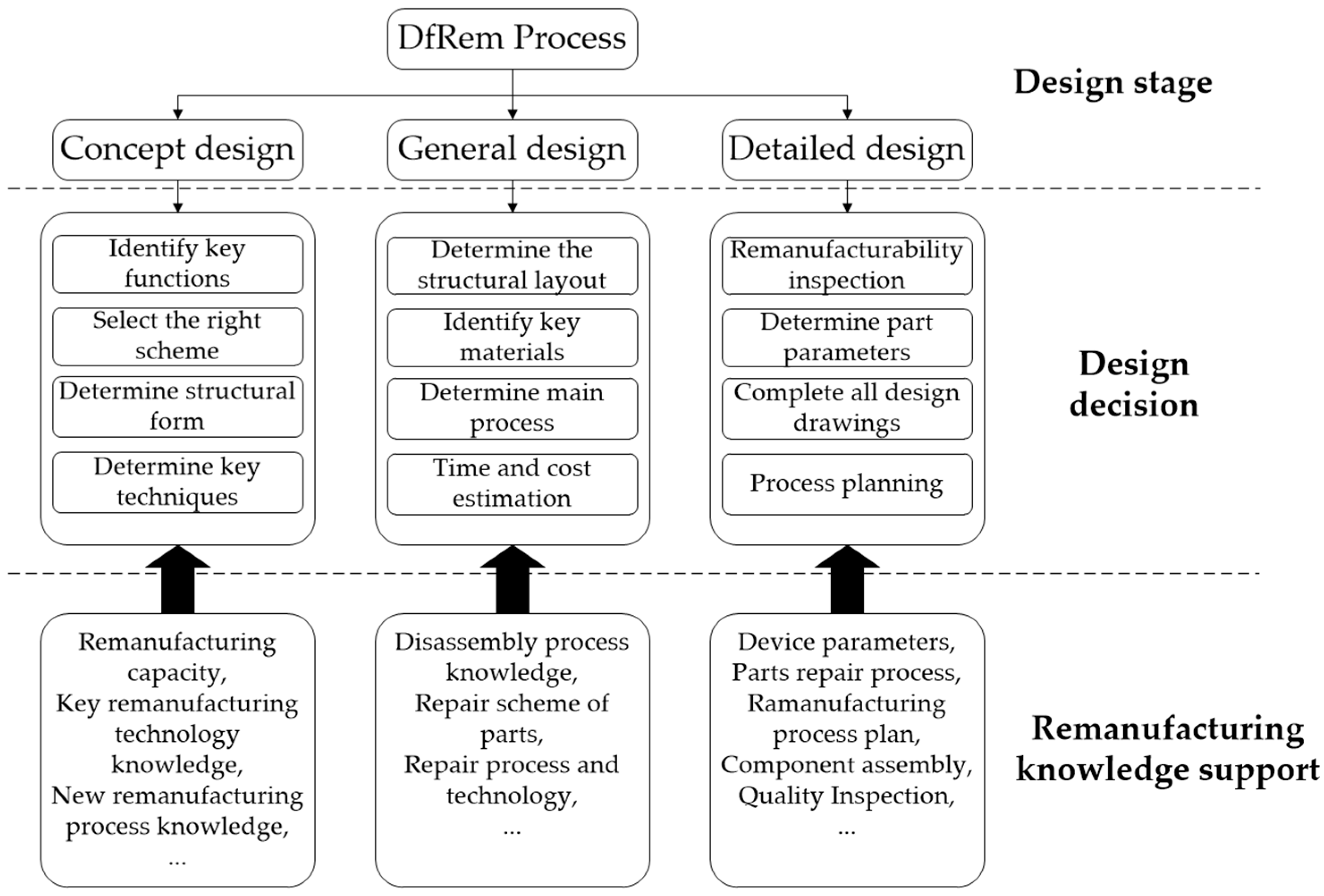

Nevertheless, the DfRem is a complex process that includes conceptual design, structural design, process design, and other stages. Traditional design methods are time-consuming and inefficient. Therefore, intelligent technology needs to be used to generate design solutions. There have been many studies related to intelligent design; for example, Liu et al. [

19] introduced an intelligent generative design framework for industrial products. This method facilitates the swift creation of nearly optimal design solutions, which can then be refined further. Bai et al. [

20] introduced an intelligent conceptual design method for railway bridges using graph neural networks, enhancing design efficiency. Zhang et al. [

21] applied the non-parametric machine learning and intelligent recognition algorithms to generate the product appearance design scheme, which can improve the accuracy of the design scheme. Although these intelligent design methods improve design efficiency and accuracy, they do not fully utilize design knowledge to generate design solutions and cannot accurately explain the intrinsic relationship between design requirements and design solutions. Furthermore, the robustness of design solutions still has shortcomings. CBR is an intelligent method for solving new problems based on solutions to similar problems in the past. This method mirrors human thought processes, swiftly identifying the most relevant past examples while also assessing and refining them. In addition, new cases are added to the case database, enhancing the success rate of retrieval. Case-based reasoning (CBR) technology has found extensive application in the field of intelligent manufacturing, such as in sustainable rural development [

22], question answering [

23], urban rail transportation [

24], etc. CBR is extensively utilized in product design, where past similar solutions are adapted to create design solutions for new, unknown design challenges. Therefore, CBR efficiently retrieves suitable DfRem schemas from existing DfRem databases and remanufacturing processes, ensuring quick and accurate results. Unfortunately, there are few studies on knowledge reuse for generating DfRem solutions based on CBR. Ke et al. [

25] applied CBR to generate the DfRem scheme, which improved design efficiency. However, this study did not make full use of remanufacturing knowledge to generate design solutions.

Furthermore, before conducting design knowledge retrieval, it is also necessary to define the DfRem objectives to ensure the accuracy of the resulting design solutions. Remanufacturability demands determine design objectives, and it is an essential step to accurately capture design objectives by extracting the key demands from a vast amount of disorganized information. Currently, numerous techniques exist for analyzing demand information, such as clustering analysis, support vector machines, and neural networks. These methods can efficiently process unstructured demand data, but they are highly dependent on data quality. Furthermore, these approaches lack interpretability regarding their analytical principles, making it difficult to demonstrate the correlation between demand characteristics and products. Rough set theory (RST) is a mathematical approach for handling imprecise, uncertain, and incomplete data [

26]. It treats demand as decision systems, using property reduction to eliminate redundant conditions while retaining the most critical demand characteristics for decision-making, thereby identifying core demand. Remanufacturability demands are often expressed colloquially by customers and cannot serve as engineering design objectives to guide product manufacturing. Therefore, key demands need to be converted into engineering terms to make them easier for technical personnel to understand. Quality function deployment (QFD) is a systematic product design and quality management approach centered on customer demand [

27]. It employs structured tools to translate ambiguous customer requirements into quantifiable, actionable engineering specifications, which can effectively convert remanufacturability demand into engineering design objectives. Therefore, RST and QFD were jointly employed in this study to extract key demands and convert them into engineering features.

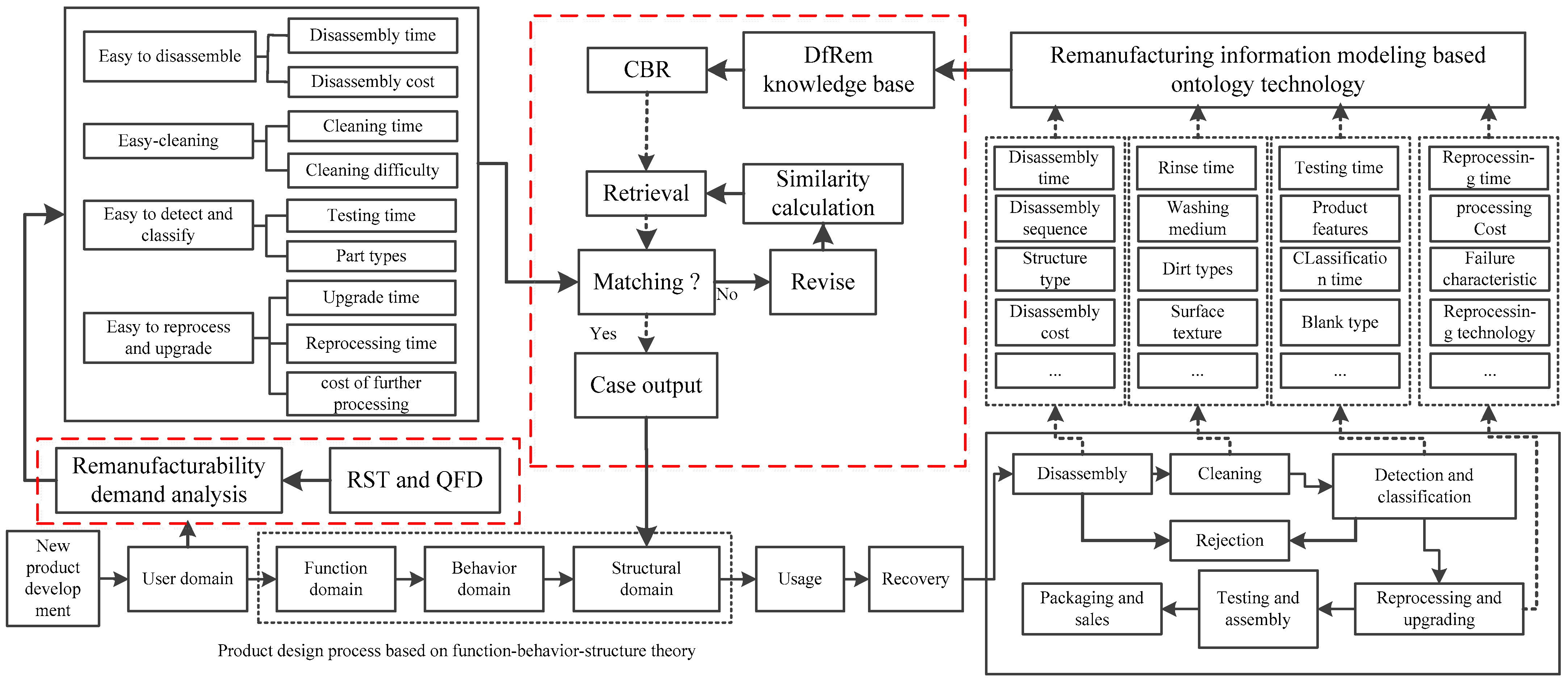

To improve the accuracy of DfRem solutions and the utilization rate of remanufacturing information, this paper proposes an intelligent design method for product remanufacturing based on remanufacturing information reuse. The novelties of this paper lie in its following attributes: (1) analysis of the correlation between information on remanufacturability demand, remanufacturing process, and DfRem scheme, and construction of a remanufacturing information model based on ontology technology; (2) proposal to formulate the DfRem scheme solution generation method based on CBR, which is conducive to the designers to formulate the DfRem scheme reasonably and effectively; (3) a DfRem interface application was developed to improve the operability and design efficiency. The remainder of this paper is structured as follows.

Section 2 proposes the intelligent DfRem framework based on remanufacturing information reuse, which contains remanufacturability demand analysis, and the generation of DfRem solutions.

Section 3 analyses remanufacturability demand and identifies key design objectives.

Section 4 proposes a DfRem solution generation method based on CBR.

Section 5 validates the method with a DfRem case for a lathe, and

Section 6 draws conclusions for this study.

3. Remanufacturability Demand Analysis

Remanufacturability demands refer to the remanufacturing characteristic that customers or manufacturers require for new products, so as to facilitate the smooth implementation of remanufacturing in the EOL stage of the products. The main remanufacturability demands are easy disassembly, easy cleaning, easy sorting, easy processing, and easy upgrading. Since the description of remanufacturaibily demand by customers is colloquial and ambiguous, which is not conducive to the designers’ extraction of DfRem objectives, there is a need for a unified and standardized description of remanufacturaibily demand. Rough set theory is used to approximate the demand information and calculate the remanufacturability demand importance to ensure the accurate extraction of key DfRem objectives; moreover, the QFD is applied to convert remanufacturability demand into engineering features, which make the design goals easier for engineers to understand.

Remanufacturability demands mainly include easy disassembly, easy cleaning, easy testing, easy processing, and easy upgrading. The types of remanufacturability demands and their corresponding engineering descriptions are shown in

Table 1.

3.1. Importance Analysis of Remanufacturability Demand

The remanufacturability demand information is extensive and intricate, making it imperative to analyze, simplify, and identify the core demand, the specific process is as follows:

(1) Analyzing examples of historical remanufactured products from manufacturers and evaluating the satisfaction of design solutions using the expert scoring method.

(2) Constructing a decision table for remanufacturability demand , where is a non-empty finite object representing the sample domain of remanufactured product instances and is the m-th historical remanufactured product instance. , is the set of remanufacturability demand condition attributes and ri denotes the i-th remanufacturability demand condition attribute. is the set of decision attributes used to determine the satisfaction of DfRem options. indicates that the DfRem scheme is highly satisfactory, indicates that the design scheme is satisfactory, and indicates that the design program is unsatisfactory. denotes the set of attribute value domains, and the conditional attributes of the elements in R can be expressed in terms of importance by V. indicates very important, indicates important, indicates average, and indicates not important. denotes the value of the function between U, R, and V, i.e., ,,.

(3) Attribute approximate simplicity. Assuming that V is a set of conditional attributes with an equivalence relation, then is an equivalence set of conditional attributes, which can partition domains through equivalence classes, quantify the discriminating power of attributes over objects, and handle uncertainty and attribute reduction. If , then r in the conditional attribute R is a redundant attribute that can be simplified.

Also, noting that the positive domain of the decision attribute

S with respect to the conditional attribute

R, i.e., the lower approximation of the set is

.

U denotes the domain (i.e., the set of all objects being studied). U/S denotes the quotient set obtained by partitioning the domain U according to a certain classification criterion S. r is any element in the sample domain. denotes the lower approximation of the element r. denotes each equivalence class u in the set of equivalence classes U/S.

(4) Calculate the dependence of the decision attribute

S on the conditional attribute

R. The formula is as follows:

denotes the degree of dependency and denotes the number of U-set elements.

Equation (5) Calculate the importance of the remanufacturability demand condition attribute R.

The absolute importance of

R is need to be calculated firstly. The calculation process is as follows:

denotes the degree of dependency with element

ri. The importance of

R is then normalized and calculated as follows:

where

is the

importance of the normalized conditional attribute, as well as the importance of the

i-th remanufacturability demand.

3.2. Remanufacturing Demand Engineering Feature Conversion

Data on remanufacturability demands are typically sourced from online reviews, customer interviews, and questionnaires; these data are frequently informal and inaccurate, which complicates the precise description of DfRem objectives. To accurately describe DfRem objectives, the traditional method is to use Quality Function Development (QFD) to establish the relationship between remanufacturability demand and engineering features. Subsequently, by examining the significance of remanufacturability demand and its relationship with engineering features, we can gain valuable insights. To more conveniently describe the relationship between demand and functional characteristics, a Quality Function Deployment (QFD) matrix is utilized to establish the mapping relationship between the two, as illustrated in

Table 2.

RD represents remanufacturability demand,

wj represents the weight of the

j-th remanufacturability demand,

v represents the absolute value of the importance of the engineering characteristic, and

FRk represents the

k-th functional characteristic. These need to be assigned by the designer based on the specific product and entered into the QFD matrix table. Then, designers score the strength of the association between customer requirements and functional features, categorizing the association strength into four levels: strong, moderate, weak, unrelated, with corresponding scores of 3, 2, 1, 0, where

R denotes the association strength level. Finally, the importance of functional features is ranked, and the DfRem target is selected based on the ranking.

5. Case Study

5.1. Demand Analysis for DfRem

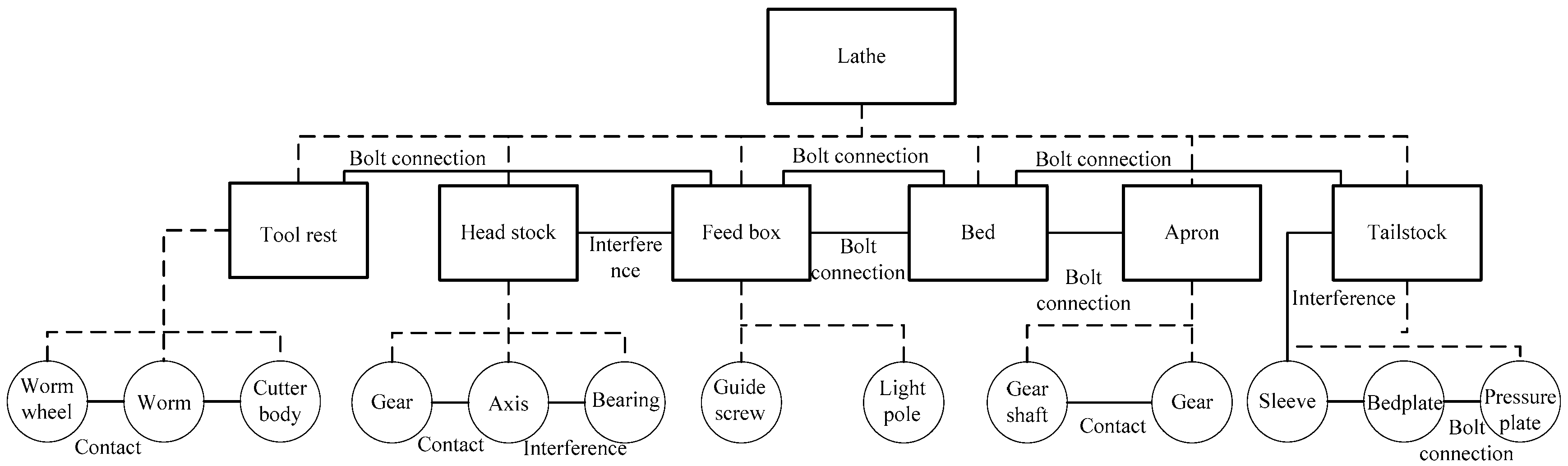

The feasibility of the proposed method is verified by taking the DfRem for a certain type of ordinary lathe as an example. The lathe is required to be a horizontal lathe, and the maximum cutting rotation diameter is 400 mm. The ordinary lathe is mainly composed of a gearbox, guide rail, bed body, tool holder, and tailstock. First, it is necessary to construct the topological structure network of the lathe, as shown in

Figure 6.

Then, by collecting and analyzing customer demand information, the main remanufacturability demands of the lathe are determined, and the specific demand information is shown in

Table 5.

Taking the manufacturer’s historical remanufacturing case as the decision sample, the remanufacturability demand decision table is established, and the attribute reduction and importance calculation are carried out. The details are as follows.

According to the definition of attribute reduction, the decision-making samples are classified. The results are as follows:

Meanwhile, the set satisfying the attribute R is

. Among them,

. Therefore, the remanufacturability demand attribute r11 can be reduced. Then the calculation of the basic set of all S decision attributes of the universe U is achieved as follows:

, calculating the lower approximation set of decision attribute S relative to R entails

;;, By combining the lower approximation sets of each sub-decision attribute, it can be obtained that . According to Formula (2), the dependence of decision attribute S on condition attribute R can be calculated as .

The lower approximation set and dependence degree after removing each sub-condition attribute are calculated, respectively. The calculation results are as follows:

Finally, according to Formulas (3) and (4), the importance of each remanufacturability demand condition attribute is solved, and the calculation results are as follows.

It can be seen from

Table 6 that the importance of

,

, and

is relatively small. In order to reduce the remanufacturing workload of used products

,

, and

are discarded. Therefore, the key remanufacturability demand information is

(

Table 7).

In order to accurately describe the design objectives, QFD was used to map remanufacturability demands to product characteristics. The analysis results are shown in

Table 8.

In

Table 8, based on technical advice from the lathe manufacturing company, seven general engineering characteristics can be summarized as follows:

(FR1) Transmission disassembly time ≤ 1 h;

(FR2) Gear hardness ≥ 60 HRC;

(FR3) Hydraulic clamping module is used;

(FR4) Surface hardness of the guideways ≥ 55 HRC;

(FR5) Capable of expanding the CNC system;

(FR6) Capable of achieving stepless speed regulation;

(FR7) Bed disassembly time ≤ 1 h.

5.2. DfRem Scheme Generation for Ordinary Lathe

The engineering characteristics of product design were determined through remanufacturability demand analysis. According to the product design process, functional unit knowledge matching was first retrieved from the remanufacturing knowledge base. The retrieval content mainly included component concept names, functional feature concepts, and functional feature attribute values. When the similarity exceeded 0.8, the functional knowledge information was output.

The main design objectives include easy disassembly of the gearbox and stepless speed regulation, wear resistance of the guide rails and gears, easy disassembly and expandability of the bed, and easy disassembly of the tailstock. H(x) is the target case and H(1)–H(5) are the existing cases in the case base. Designers need to retrieve the most relevant design cases from existing examples based on the target case.

To facilitate similarity calculations, numerical calculations need to be performed based on attribute types. The knowledge information for each unit is as follows (

Table 9).

The overall similarity between the existing functional cases and the target functional cases was calculated using MATLAB 2024 based on Formulas (5) and (6), the calculation results are shown in

Table 10. As can be seen from the table, case

H(1) has a similarity greater than 0.8 and the highest similarity value, indicating that it is most similar to the target functional case. The detailed information of functional case

H(1) is shown in

Table 11.

To ensure the objectivity of the case, a comprehensive evaluation of the functional case is required, with the calculation process as follows:

If the comprehensive evaluation factor of Case 1 exceeds the threshold of 0.8, it is considered reliable. Then, the historical product design information is output, which corresponds to the functional knowledge. The details of the design case are shown in

Table 12.

Table 12 covers the design information of components such as the gearbox, gear, guide rail, bed, tailstock, and lathe body. The setting of each parameter is based on the remanufacturability demand, material properties, and process requirements of the components. For the nut and screw of the gearbox, triangular threads, a major diameter of 10 mm, and low-carbon alloy steel are selected to ensure self-locking performance, strength, and wear resistance; meanwhile, threaded connections are beneficial for gearbox disassembly and improve disassembly efficiency. The gear is made of 45 steel with carburizing treatment, featuring a carburized layer depth of 0.4 mm, a treatment duration of 2 h, and a temperature of 900 °C, aiming to enhance surface hardness and wear resistance. The guide rail is made of 45Cr with solid carburizing, having a carburized layer depth of 2.3 mm, a treatment duration of 2 h, and a temperature of 930 °C. Since it needs to bear large loads and friction, a thicker hardened layer is more suitable. The FANUC-0i-TF extended interface of the machine bed uses a 9-pin and RS232 communication, which is adapted to the system’s function upgrading and equipment communication. Triangular threads are selected for the bolts of the tailstock and the lathe body, which is beneficial for disassembly between them. The tailstock uses a 40 mm major diameter to cope with large loads, while the lathe body uses a 6 mm major diameter to match small loads or space constraints. Moreover, the tailstock and lathe body are made of Q235 low-carbon steel, balancing strength, toughness, and cost; this is beneficial for their end-of-life remanufacturing, reducing remanufacturing time and costs.

In conclusion, the parameter settings of each component are reasonable choices after comprehensively considering various factors such as function, material, and process, so as to ensure the performance and reliability of the component. The design case can provide reliable design parameters for the DfRem of new lathes, improve the remanufacturability of lathe, and facilitate the remanufacturing implementation of the lathe at its EOL stage. The new lathe manufactured according to the DfRem scheme is shown in

Figure 7.

In comparison with other DfRem research, such as [

25], the latter employed intelligent technologies to analyze customer demand and generate DfRem scheme, which promote the DfRem efficiency. However, it failed to establish an inherent link between remanufacturing information and DfRem. Moreover, it did not construct reliable DfRem knowledge.

Consequently, this current research not only enhances the efficiency of DfRem but also establishes a connection between remanufacturing information and DfRem. This not only improves the feasibility of design solutions but also better promotes the implementation of product remanufacturing.

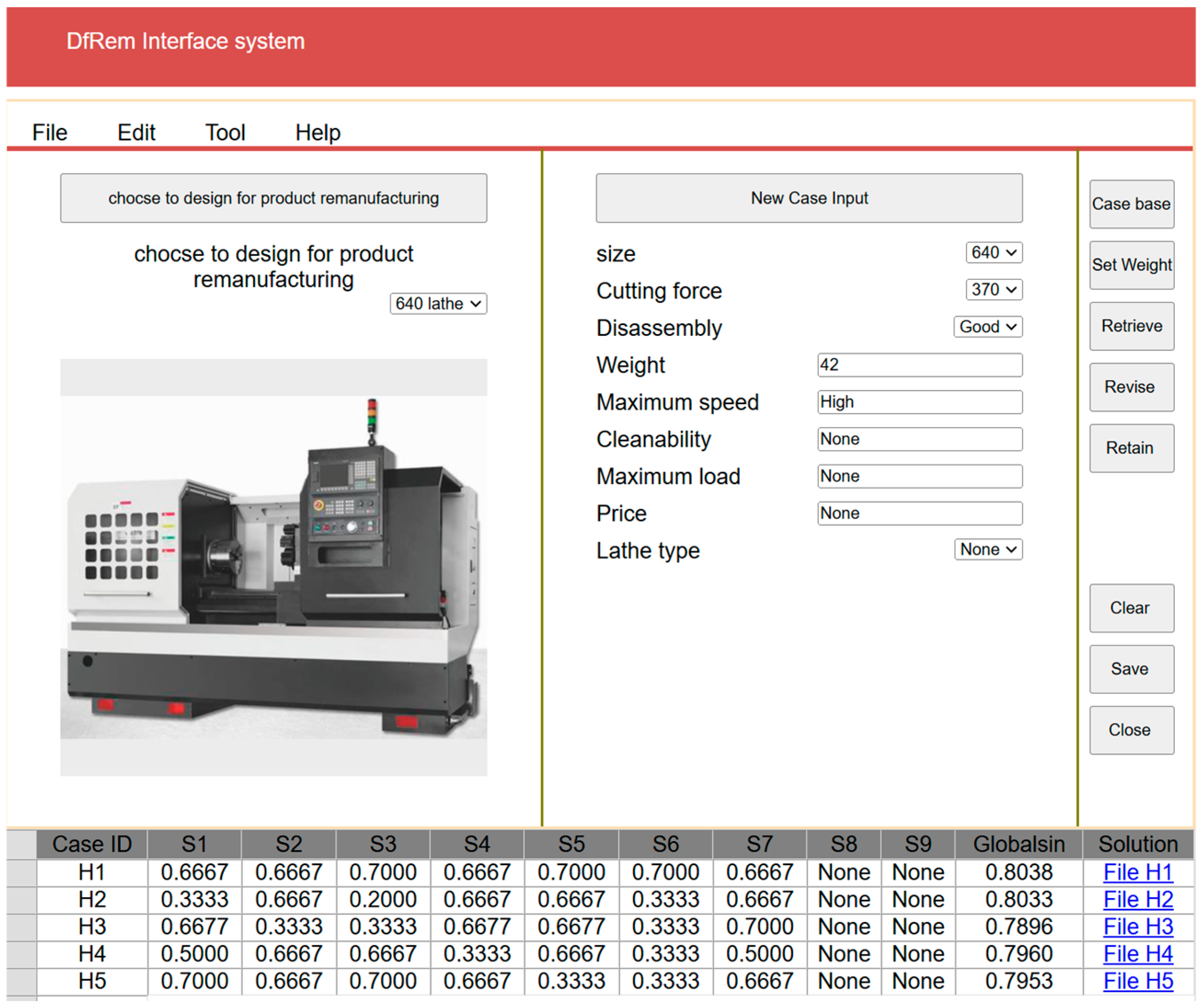

5.3. DfRem Interface Application Construction

To expedite DfRem scheme generation, a case-based reasoning (CBR) application was implemented using Visual Studio and SQL Server. This application automates the retrieval of similar cases, as illustrated in

Figure 8. The process begins with the selection of a candidate product for DfRem and the inputting of corresponding attribute values for each remanufacturability demand. Users subsequently assign weight values to each attribute. The system then queries the case base for similar cases based on these weighted attribute values. The retrieval process contains three parts, outlined as follows. (1) If the similarity score falls below 0.8, the existing case requires modification until it exceeds this threshold before being saved to the knowledge base. (2) If no similar case is identified, a new case can be created and stored for future reference. (3) When the similarity score exceeds 0.8, the case is directly applicable and saved to the case base. Continuously archiving successful or revised cases enhances the diversity of case types, thereby improving case retrieval success rates. Compared to traditional DfRem methods, such as the two-stage QFD model, which necessitates labor-intensive manual processing of extensive failure data to identify product features and DfRem criteria, this intelligent approach processes demand analysis more efficiently, enabling the more rapid generation of the DfRem scheme.

6. Conclusions

This paper proposes an intelligent design method for product remanufacturing based on remanufacturing information reuse, which constructs the mapping relationship between remanufacturing information and DfRem parameters. Moreover, RST and QFD are applied to analyze the remanufacturability demand and extract the intelligent design goal. Ontology technology is used to construct the remanufacturing information model, which can support the DfRem process. Then, CBR is applied to retrieve the most similar design case from the DfRem case base that match the design target. Meanwhile, gray relational analysis (GRA) is used to calculate the similarity between pieces of design knowledge. Finally, a DfRem interface application is constructed to improve design efficiency and operability. Finally, the DfRem of an ordinary lathe is used as an example to verify the feasibility of the proposed method.

Compared to existing DfRem methods, this method offers three key advantages. (1) This method establishes a correlation between remanufacturing information and product design parameters, thereby improving the reuse rate of remanufacturing information and design accuracy. (2) CBR is utilized to create the DfRem scheme, which effectively shortens the design cycle and enhances the utilization of remanufacturing information. (3) A comprehensive set of DfRem interface applications have been developed, facilitating the rapid generation of design schemes.

The prospective research needs to work in the following directions. (1) Remanufacturing information is extensive and fragmented, posing significant challenges for ontology technology to structurally integrate diverse types of remanufacturing information and establish precise relationships among them, ultimately leading to decreased utilization rates and accuracy. In future research, knowledge graph technology will be used to construct a remanufacturing information integration model, which is beneficial for building semantic relationships between different information, improving the accuracy of knowledge retrieval, and increasing knowledge reuse rate. (2) The reliability of the design implementation needs to be improved. In the future, digital twin technology will be considered to construct the virtual–physical model for the DfRem process, and the design parameters can be dynamically adjusted based on remanufacturing process data, which is conducive to verifying the reliability of the DfRem scheme in real time, thereby reducing manufacturing process consumption.