Physicochemical and Techno-Functional Properties of Extruded Corn Starch Snacks Enriched with Huitlacoche (Ustilago maydis): Effects of Extrusion Parameters and Process Optimization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extrusion Cooking Process

2.3. Variables of the Extrusion Process

Residence Time (RT) and Specific Mechanical Energy (SME)

2.4. Characterization of Extruded Products

2.4.1. Expansion Index (EI) and Bulk Density (BD)

2.4.2. Texture (Tex)

2.4.3. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.4.4. Color Parameters and pH

2.5. Experimental Design and Statistical Analysis

3. Results and Discussion

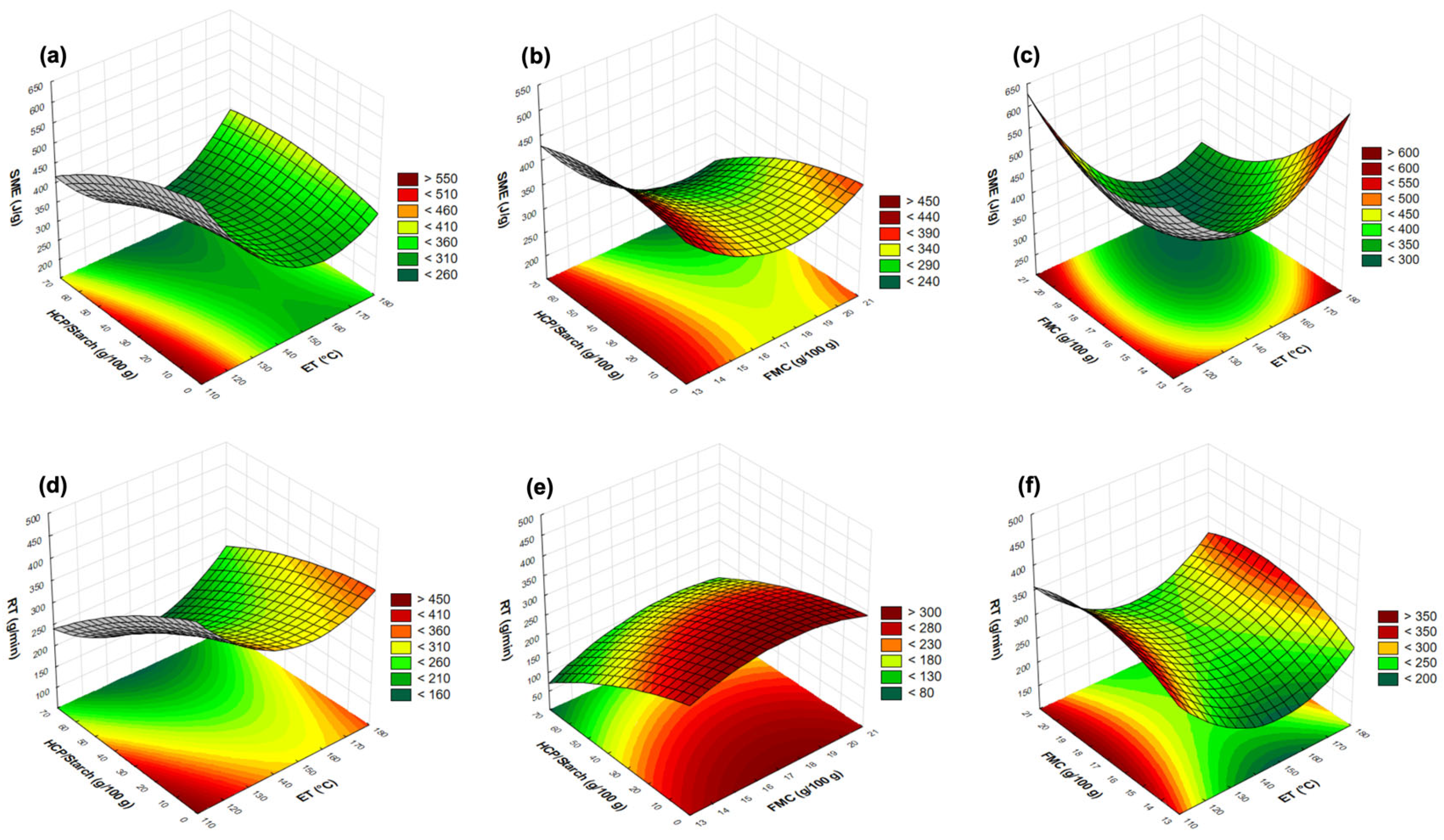

3.1. Residence Time (RT)

| Extrusion Process Variables | Response Variables | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| ET (°C) | FMC (g/100 g) | HCP/Starch (g/100 g) | RT (g/min) | SME (J/g) | EI | BD (g/cm3) | Tex (N) | WAI (g/g) | WSI (%) |

| 120 | 14 | 35 | 267.46 | 525.08 | 2.21 | 0.51 | 27.89 | 5.43 | 10.79 |

| 170 | 14 | 35 | 240.17 | 456.06 | 2.02 | 0.57 | 30.90 | 5.50 | 8.34 |

| 120 | 20 | 35 | 323.85 | 506.34 | 1.72 | 0.70 | 48.40 | 4.13 | 22.91 |

| 170 | 20 | 35 | 304.84 | 271.20 | 1.32 | 0.89 | 19.15 | 5.77 | 11.26 |

| 120 | 17 | 10 | 438.83 | 460.09 | 2.20 | 0.60 | 16.60 | 6.48 | 16.64 |

| 170 | 17 | 10 | 361.01 | 373.72 | 2.22 | 0.31 | 12.76 | 6.85 | 16.00 |

| 120 | 17 | 60 | 199.91 | 338.69 | 1.20 | 1.13 | 53.68 | 4.25 | 15.79 |

| 170 | 17 | 60 | 188.76 | 361.95 | 1.17 | 0.68 | 19.05 | 4.89 | 14.24 |

| 145 | 14 | 10 | 251.65 | 393.08 | 2.81 | 0.32 | 22.32 | 7.07 | 14.34 |

| 145 | 20 | 10 | 240.00 | 350.00 | 1.81 | 0.54 | 26.33 | 5.91 | 14.29 |

| 145 | 14 | 60 | 191.59 | 389.13 | 1.05 | 0.69 | 21.76 | 4.35 | 14.57 |

| 145 | 20 | 60 | 215.23 | 274.23 | 1.69 | 0.65 | 59.19 | 4.15 | 21.73 |

| 145 | 17 | 35 | 257.71 | 322.14 | 1.81 | 0.56 | 21.41 | 5.15 | 8.72 |

| 145 | 17 | 35 | 257.79 | 321.74 | 1.83 | 0.50 | 21.77 | 5.71 | 8.70 |

| 145 | 17 | 35 | 257.87 | 322.54 | 1.80 | 0.62 | 21.06 | 5.52 | 8.74 |

| Extrusion Process Variables | Response Variables | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| ET (°C) | FMC (g/100 g) | HCP/Starch (g/100g) | pH | L* | a* | b* | C* | h° | ΔE |

| 120 | 14 | 35 | 5.29 | 45.03 | 1.12 | 4.36 | 4.5 | 75.92 | 54.59 |

| 170 | 14 | 35 | 5.08 | 44.89 | 1.58 | 5.53 | 5.75 | 74.07 | 54.81 |

| 120 | 20 | 35 | 5.34 | 39.94 | 0.73 | 2.72 | 2.82 | 74.97 | 59.52 |

| 170 | 20 | 35 | 5.35 | 43.41 | 1.32 | 4.66 | 4.84 | 74.16 | 56.19 |

| 120 | 17 | 10 | 5.49 | 46.14 | 0.86 | 4.03 | 4.12 | 78.13 | 53.41 |

| 170 | 17 | 10 | 5.50 | 51.04 | 1.50 | 5.88 | 6.07 | 75.75 | 48.80 |

| 120 | 17 | 60 | 5.30 | 40.57 | 0.52 | 2.79 | 2.84 | 79.43 | 58.89 |

| 170 | 17 | 60 | 5.27 | 41.47 | 1.26 | 4.25 | 4.43 | 73.59 | 58.09 |

| 145 | 14 | 10 | 5.27 | 51.98 | 1.90 | 6.71 | 6.97 | 74.21 | 47.92 |

| 145 | 20 | 10 | 5.71 | 48.42 | 1.34 | 5.93 | 6.08 | 77.16 | 51.38 |

| 145 | 14 | 60 | 5.31 | 41.09 | 0.91 | 3.56 | 3.68 | 75.83 | 58.42 |

| 145 | 20 | 60 | 5.05 | 41.92 | 1.17 | 3.59 | 3.77 | 72.14 | 57.59 |

| 145 | 17 | 35 | 5.30 | 42.78 | 1.13 | 4.17 | 4.32 | 74.07 | 57.14 |

| 145 | 17 | 35 | 5.31 | 42.41 | 1.16 | 4.40 | 4.56 | 74.21 | 56.42 |

| 145 | 17 | 35 | 5.32 | 42.91 | 1.19 | 4.39 | 4.32 | 74.14 | 55.18 |

| Term | RT | SME | EI | BD | Tex | WAI | WSI | pH | L* | a* | b* | C* | h° | ΔE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | 257.790 | 322.140 | 1.813 | 0.560 | 21.413 | 5.460 | 8.720 | 5.310 | 42.700 | 1.160 | 4.320 | 4.400 | 74.140 | 56.247 |

| ET | −16.909 | −45.909 | −0.075 | −0.061 | −8.089 | 0.340 | −2.036 | −0.028 | 1.141 | 0.304 | 0.803 | 0.851 | −1.360 | −1.065 |

| FMC | 16.631 | −45.198 | −0.194 | 0.086 | 6.275 | −0.299 | 2.769 | 0.062 | −1.163 | −0.119 | −0.408 | −0.424 | −0.200 | 1.118 |

| HCP/Starch | −62.000 | −26.611 | −0.491 | 0.173 | 9.459 | −1.084 | 0.633 | −0.130 | −4.066 | −0.218 | −1.045 | −1.065 | −0.533 | 3.935 |

| ET2 | 49.400 | 74.766 | −0.069 | 0.119 | 1.647 | −0.002 | 2.020 | 0.005 | −0.215 | −0.134 | −0.356 | −0.341 | 1.265 | 0.500 |

| FMC2 | −23.110 | 42.764 | 0.073 | −0.011 | 8.525 | −0.250 | 2.585 | −0.050 | 0.833 | 0.161 | 0.354 | 0.419 | −0.625 | −0.470 |

| HCP/Starch2 | −10.063 | −13.294 | −0.047 | 0.001 | 2.462 | 0.160 | 4.928 | 0.075 | 2.320 | 0.009 | 0.274 | 0.306 | 1.320 | −1.950 |

| ET-FMC | 2.070 | −41.530 | −0.053 | 0.033 | −8.065 | 0.393 | −2.300 | 0.055 | 0.902 | 0.033 | 0.193 | 0.193 | 0.260 | −0.888 |

| ET-HCP/Starch | 16.668 | 27.408 | −0.013 | −0.040 | −7.698 | 0.068 | −0.227 | −0.010 | −1.000 | 0.025 | −0.098 | −0.090 | −0.865 | 0.952 |

| FMC-HCP/Starch | 8.822 | −17.955 | 0.410 | −0.065 | 8.355 | 0.240 | 1.803 | −0.175 | 1.098 | 0.205 | 0.203 | 0.245 | −1.660 | −1.073 |

| R2 | 0.76 | 0.91 | 0.96 | 0.71 | 0.94 | 0.98 | 0.86 | 0.97 | 0.98 | 0.95 | 0.93 | 0.93 | 0.91 | 0.97 |

| Lack of fit (p-value) | <0.0001 | <0.0001 | 0.0053 | 0.0646 | 0.0023 | 0.7975 | <0.0001 | 0.0255 | 0.0593 | 0.0369 | 0.0392 | 0.0425 | 0.0031 | 05472 |

| Response | Quadratic Polynomial Model | p Value |

|---|---|---|

| RT | RT = 257.790 − 16.909*A +16.631*B − 62.000*C +49.400*A2 − 23.110*B2 − 10.063*C2 +2.070*AB +16.668*AC +8.822*BC | 0.0266 |

| SME | SEM = 322.140 − 45.909*A − 45.198*B − 26.611*C +74.766*A2 +42.764*B2 − 13.294*C2 − 41.530*AB +27.408*AC − 17.955*BC | 0.0380 |

| EI | EI = 1.813 − 0.075*A − 0.194*B − 0.491*C − 0.069*A2 +0.073*B2 − 0.047*C2 − 0.053*AB − 0.013*AC +0.410*BC | 0.0061 |

| BD | BD = 0.560 − 0.061*A +0.086*B +0.173*C +0.119*A2 − 0.011*B2 +0.001*C2 +0.033*AB − 0.040*AC − 0.065*BC | 0.0384 |

| Tex | Tex = 21.413 − 8.089*A +6.275*B +9.459*C +1.647*A2 +8.525*B2 +2.462*C2 − 8.065*AB − 7.698*AC +8.355*BC | 0.0143 |

| WAI | WAI = 5.460 +0.340*A − 0.299*B − 1.084*C − 0.002*A2 − 0.250*B2 +0.160*C2 +0.393*AB +0.068*AC +0.240*BC | 0.0010 |

| WSI | WSI = 8.720 − 2.036*A +2.769*B +0.633*C +2.020*A2 +2.585*B2 +4.928*C2 − 2.300*AB − 0.227*AC +1.803*BC | 0.0088 |

| pH | pH = 5.310 − 0.028*A +0.062*B − 0.130*C +0.005*A2 − 0.050*B2 +0.075*C2 +0.055*AB − 0.010*AC − 0.175*BC | 0.0035 |

| L* | L* = 42.700 +1.141*A − 1.163*B − 4.066*C − 0.215*A2 +0.833*B2 +2.320*C2 +0.902*AB − 1.000*AC +1.098*BC | 0.0007 |

| a* | a* = 1.160 +0.304*A − 0.119*B − 0.218*C − 0.134*A2 +0.161*B2 +0.009*C2 +0.033*AB +0.025*AC +0.205*BC | 0.0068 |

| b* | b* = 4.320 +0.803*A − 0.408*B − 1.045*C − 0.356*A2 +0.354*B2 +0.274*C2 +0.193*AB − 0.098*AC +0.203*BC | 0.0207 |

| C* | C* = 4.400 +0.851*A − 0.424*B − 1.065*C − 0.341*A2 +0.419*B2 +0.306*C2 +0.193*AB − 0.090*AC +0.245*BC | 0.0194 |

| h° | hº = 74.140 − 1.360*A − 0.200*B − 0.533*C +1.265*A2 − 0.625*B2 +1.320*C2 +0.260*AB − 0.865*AC − 1.660*BC | 0.0388 |

| ΔE | ΔE = 56.247 − 1.065*A +1.118*B +3.935*C +0.500*A2 − 0.470*B2 − 1.950*C2 − 0.888*AB +0.952*AC − 1.073*BC | 0.0021 |

3.2. Specific Mechanical Energy (SME)

3.3. Expansion Index (EI), Bulk Density (BD), and Texture (Tex)

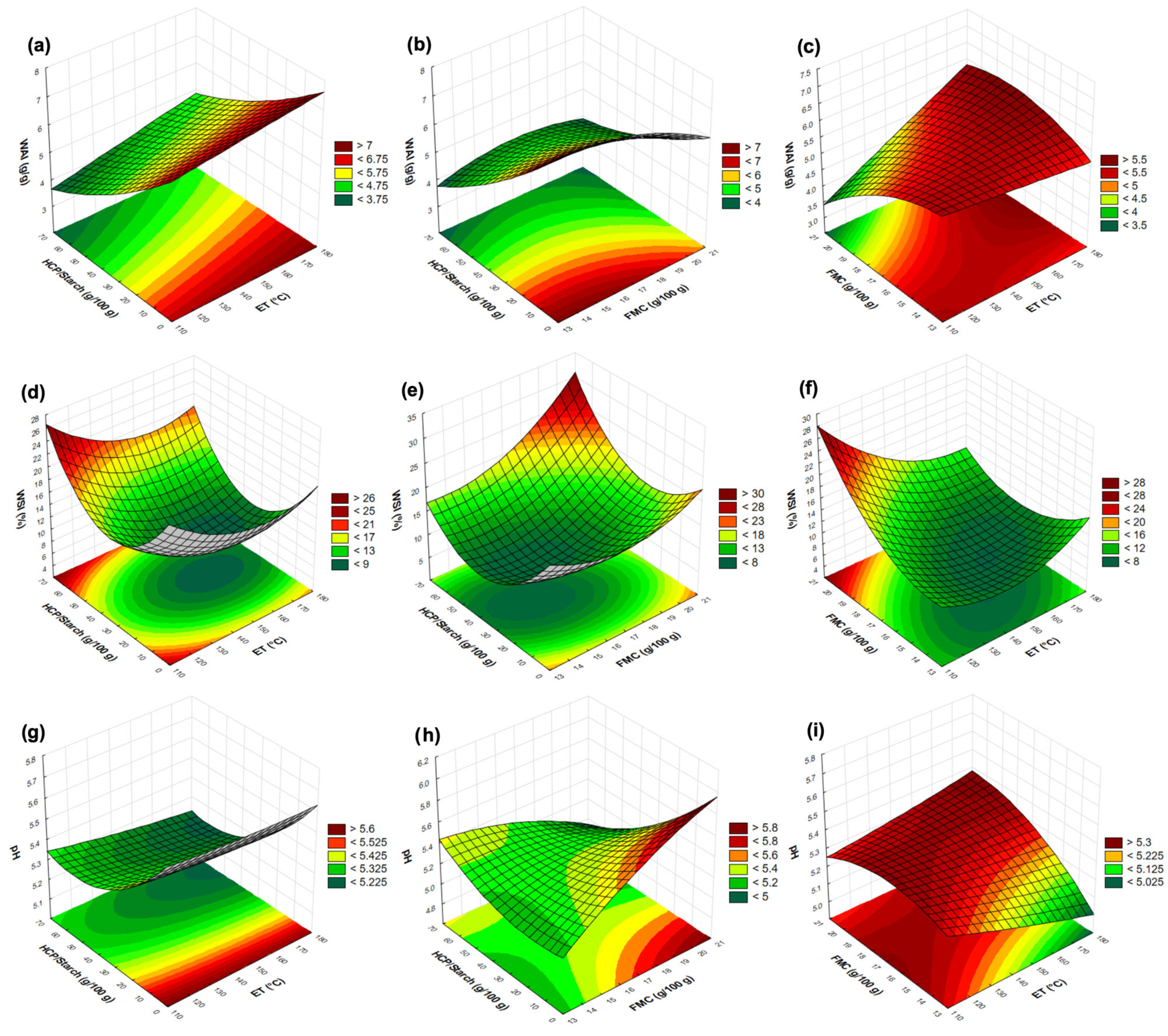

3.4. Water Absorption Index (WAI), Water Solubility Index (WSI), and pH

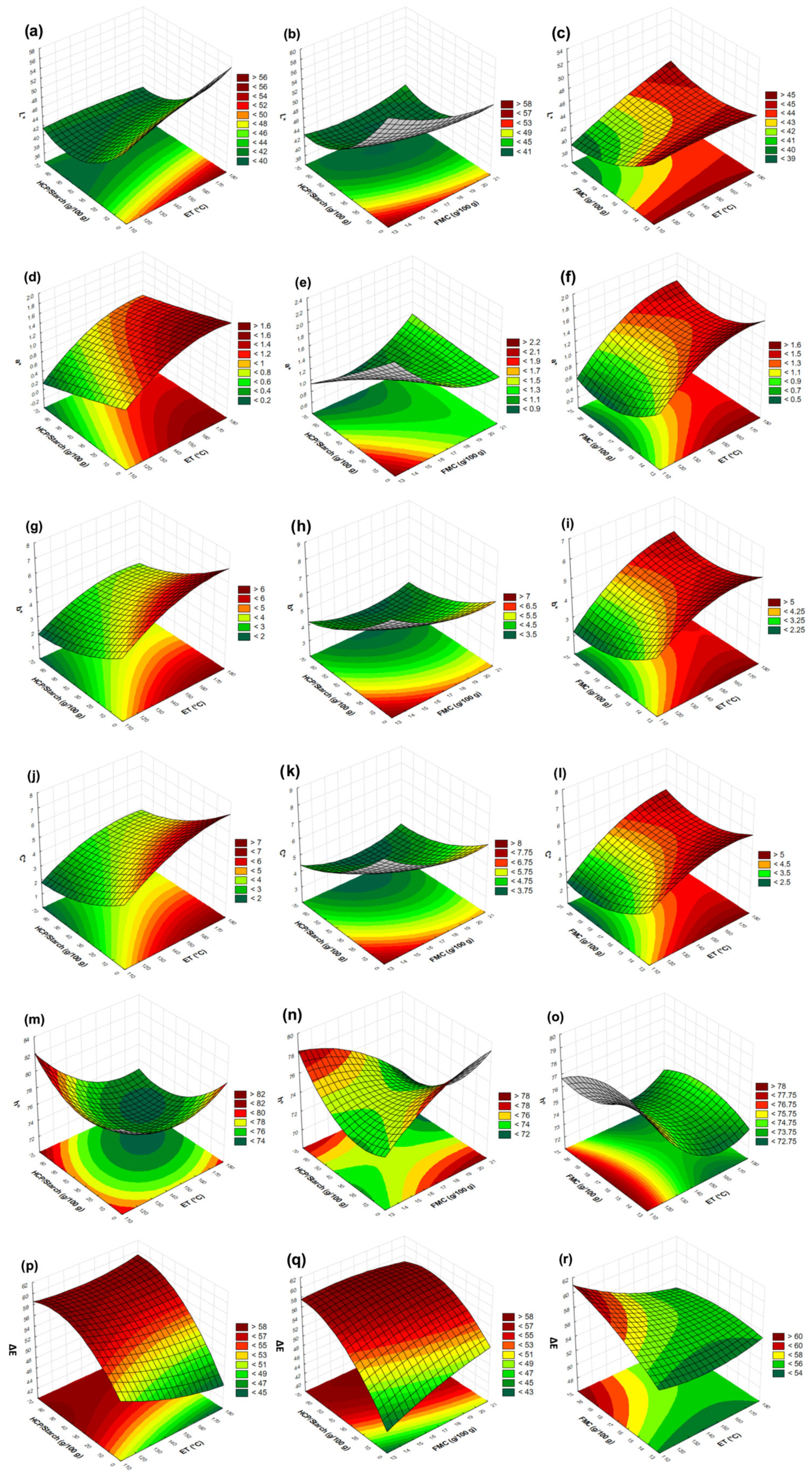

3.5. Color Parameters (L*, a*, b*, C*, h°, and ΔE)

3.6. Optimal Condition for the Extruded Product

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BD | Bulk density |

| EI | Expansion index |

| ET | Extrusion temperature |

| HCP/Starch | Huitlacoche/Starch proportion |

| MCF | Feed moisture content |

| RT | Residence time |

| SME | Specific mechanical energy |

| Tex | Texture |

| WAI | Water absorption index |

| WSI | Water solubility index |

| ΔE | Total color difference |

References

- Ramírez-Rivera, E.J.; Hernández-Santos, B.; Juárez-Barrientos, J.M.; Torruco-Uco, J.G.; Ramírez-Figueroa, E.; Rodríguez-Miranda, J. Effects of formulation and process conditions on chemical composition, color parameters, and acceptability of extruded insect-rich snack. J. Food Process. Preserv. 2021, 45, e15499. [Google Scholar] [CrossRef]

- Nandane, A.S.; Ganorkar, P.M.; Ranveer, R.C.; Patil, H.; Al-Asmari, F.; Sangsawad, P.; Nirmal, N.; Ozogul, F. Impact of Extrusion Process on the Macro- and Micro-nutrient in Extruded Food Products: Challenges and Future Trends. Food Bioprocess Technol. 2025, 18, 6939–6963. [Google Scholar] [CrossRef]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci. Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- Rivera-Mirón, M.I.; Torruco-Uco, J.G.; Carmona-García, R.; Rodríguez-Miranda, J. Optimization of an extrusion process for the development of a fiber-rich, ready-to-eat snack from pineapple by-products and sweet whey protein based on corn starch. J. Food Process Eng. 2020, 43, e13532. [Google Scholar] [CrossRef]

- Lotfi-Shirazi, S.; Koocheki, A.; Milani, E.; Mohebbi, M. Production of high fiber ready-to-eat expanded snack from barley flour and carrot pomace using extrusion cooking technology. J. Food Sci. Technol. 2020, 57, 2169–2181. [Google Scholar] [CrossRef]

- Zhong, L.; Fang, Z.; Wahlqvist, M.L.; Hodgson, J.M.; Johnson, S.K. Extrusion cooking increases soluble dietary fibre of lupin seed coat. LWT 2019, 99, 547–554. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Integration of β-glucan fibre rich fractions from barley and mushrooms to form healthy extruded snacks. Plant Foods Hum. Nutr. 2013, 68, 78–82. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and extruded products: Changes in quality attributes as affected by extrusion process parameters: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Ali, I.M.; Forsido, S.F.; Kuyu, C.G.; Ahmed, E.H.; Andersa, K.N.; Chane, K.T.; Regasa, T.K. Effects of extrusion process conditions on nutritional, anti-nutritional, physical, functional, and sensory properties of extruded snack: A review. Food Sci. Nut. 2024, 12, 8755–8761. [Google Scholar] [CrossRef]

- Tepsongkroh, B.; Jangchud, K.; Jangchud, A.; Chonpracha, P.; Ardoin, R.; Prinyawiwatkul, W. Consumer perception of extruded snacks containing brown rice and dried mushroom. Int. J. Food Sci. Technol. 2020, 55, 46–54. [Google Scholar] [CrossRef]

- Vattapparambil, A.; Pulickakudy-Ajithkumar, A.; Dubey, P.K.; Kumar, S. Exploring the potential of mushrooms in ready-to-eat snack formulations. Int. J. Food Sci. Technol. 2024, 59, 9562–9570. [Google Scholar] [CrossRef]

- Ogwu, M.C.; Kosoe, E.A.; Izah, S.C. Future Trends and Research Directions: Emerging Uses and Trends in Mushroom Consumption Utilization. In Bioactive Compounds in Edible Mushrooms: Sustainability and Health Applications; Springer: Cham, Switzerland, 2015; pp. 1–16. [Google Scholar]

- Thomas, B.; Sudheer, K.P.; Saranya, S.; Kothakota, A.; Pandiselvam, R.; Joseph, M. Development of protein enriched cold extruded pasta products using hybrid dried processed mushroom powder and defatted flours: A study on nutraceutical, textural, colour and sensory attributes. LWT 2022, 170, 113991. [Google Scholar] [CrossRef]

- Tangsrianugul, N.; Hongsanyatham, S.; Kapcum, C.; Sungayuth, N.; Boonsanong, N.; Somprasong, N.; Meejoo-Smith, S.; Amornsakchai, T.; Pinyo, J.; Wongsagonsup, R. Physicochemical and sensory properties of corn grits and pineapple stem starch-based extruded snacks enriched with oyster mushroom powder. Int. J. Food Sci. Technol. 2023, 58, 1528–1540. [Google Scholar] [CrossRef]

- Cheung, P.C.K. Mini-review on edible mushrooms as source of dietary fiber: Preparation and health benefits. Food Sci. Hum. Wellness 2013, 2, 162–166. [Google Scholar] [CrossRef]

- Sharma, E.; Bairwa, R.; Lal, P.; Pattanayak, S.; Chakrapani, K.; Poorvasandhya, R.; Kumar, A.; Altaf, A.; Tiwari, R.K.; Lal, M.K.; et al. Edible mushrooms trending in food: Nutrigenomics, bibliometric, from bench to valuable applications. Heliyon 2024, 10, e36963. [Google Scholar] [CrossRef]

- Sudhakar, A.; Dash, S.K.; Bal, L.M.; Sahoo, N.R.; Rayaguru, K. Extrudate snacks from rice flour and oyster mushroom powder: Physico-chemical and functional properties characterization and storability evaluation. J. Indian Chem. Soc. 2021, 98, 100160. [Google Scholar] [CrossRef]

- Beas, F.R.; Guevara, L.F.; Vasco, M.N.L.; Loarca, P.G.; Rodríguez, M.G.; Guzmán, M.S.H. Potencial nutracéutico de componentes bioactivos presentes en huitlacoche de la zona centro de México. Rev. Mex. Cienc. Farm. 2011, 42, 36–44. [Google Scholar]

- Amador-Rodríguez, K.Y.; Martínez-Bustos, F.; Pérez-Cabrera, L.E.; Posadas-Del-Río, F.A.; Chávez-Vela, N.A.; Sandoval-Cardoso, M.; Guevara-Lara, F. Effect of huitlacoche (Ustilago maydis DC Corda) paste addition on functional, chemical and textural properties of tortilla chips. Food Sci. Technol. (Campinas) 2015, 35, 452–459. [Google Scholar] [CrossRef]

- Amador-Rodríguez, K.Y.; Pérez-Cabrera, L.E.; Guevara-Lara, F.; Chávez-Vela, N.A.; Posadas-Del Río, F.A.; Silos-Espino, H.; Martínez-Bustos, F. Physicochemical, thermal, and rheological properties of nixtamalized blue-corn flours and masas added with huitlacoche (Ustilago maydis) paste. Food Chem. 2019, 278, 601–608. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC, 18th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Rodríguez-Miranda, J.; Ramírez-Wong, B.; Vivar-Vera, M.A.; Solís-Soto, A.; Gómez-Aldapa, C.A.; Castro-Rosas, J.; Medrano-Roldan, H.; Delgado-Licon, E. Effect of bean flour concentration (Phaseolus vulgaris L.), moisture content and extrusion temperature on the functional properties of aquafeeds. Rev. Mex. Ing. Quím. 2014, 13, 649–663. [Google Scholar]

- Téllez-Morales, J.A.; Gómez-Aldapa, C.A.; Herman-Lara, E.; Carmona-García, R.; Rodríguez-Miranda, J. Effect of the concentrations of corn starch and whey protein isolate on the processing parameters and the physicochemical characteristics of the extrudates. J. Food Process. Preserv. 2021, 45, e15395. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Hernández-Santos, B.; Navarro-Cortez, R.O.; Rodríguez-Miranda, J. Impact of the addition of cricket flour (Sphenarium purpurascens) on the physicochemical properties, optimization and extrusion conditions of extruded nixtamalized corn flour. Appl. Food Res. 2022, 2, 100149. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Pérez-Carrillo, E.; Serna-Saldívar, S.O.; Campanella, O.H.; Welti-Chanes, J. Functional and compositional changes of orange peel fiber thermally-treated in a twin extruder. LWT 2019, 111, 673–681. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Tucker, G.; Marson, H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J. Food Eng. 2005, 66, 283–289. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-eat snack products: The role of extrusion technology in developing consumer acceptable and nutritious snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar]

- Moraru, C.I.; Kokini, J.L. Nucleation and expansion during extrusion and microwave heating of cereal foods. Compr. Rev. Food Sci. Food Saf. 2003, 2, 147–165. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of food extrusion: A review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

| Independent Variables | Code | Levels | ||

|---|---|---|---|---|

| Extrusion temperature (°C) | ET = A | 120 | 145 | 170 |

| Feed moisture content (g/100 g) | FMC = B | 14 | 17 | 20 |

| Huitlacoche/Starch proportion (g/100 g) | HCP/Starch = C | 10 | 35 | 60 |

| Process Parameters | Importance | Target | Experimental Range | Optimum Value | |||

|---|---|---|---|---|---|---|---|

| Min | Max | ||||||

| ET (°C) | 3 | Range | 120 | 170 | 149.85 | 150.15 | 150.38 |

| FMC (g/100 g) | 3 | Range | 14 | 20 | 15.71 | 15.76 | 15.80 |

| HCP/Starch (g/100 g) | 5 | Range | 10 | 60 | 10.00 | 15.00 | 20.00 |

| Responses | Predicted values | ||||||

| RT (g/min) | 3 | Range | 188.76 | 438.83 | 297.30 | 288.70 | 279.43 |

| SME (J/g) | 5 | Minimize | 271.2 | 525.08 | 347.03 | 347.80 | 347.62 |

| EI | 5 | Maximize | 1.05 | 2.81 | 2.52 | 2.40 | 2.27 |

| BD (g/cm3) | 5 | Minimize | 0.31 | 1.13 | 0.32 | 0.36 | 0.40 |

| Tex (N) | 5 | Minimize | 12.76 | 59.19 | 17.53 | 17.42 | 17.51 |

| WAI (g/g) | 3 | Range | 4.13 | 7.07 | 6.91 | 6.61 | 6.34 |

| WSI (%) | 3 | Range | 8.34 | 22.91 | 12.99 | 11.16 | 9.74 |

| pH | 3 | Range | 5.05 | 5.71 | 5.54 | 5.36 | 5.33 |

| L* | 3 | Range | 39.94 | 51.98 | 50.54 | 48.74 | 47.12 |

| a* | 3 | Range | 0.52 | 1.90 | 1.60 | 1.53 | 1.47 |

| b* | 3 | Range | 2.72 | 6.71 | 6.11 | 5.78 | 5.47 |

| C* | 3 | Range | 2.82 | 6.97 | 6.29 | 5.94 | 5.61 |

| h° | 3 | Range | 72.14 | 79.43 | 75.18 | 74.73 | 74.37 |

| ΔE | 3 | Range | 47.92 | 59.52 | 49.04 | 50.67 | 52.15 |

| Desirability | 0.88 | 0.85 | 0.83 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Santos, B.; Rodríguez-Miranda, J.; Juárez-Barrientos, J.M.; Torruco-Uco, J.G.; Ramírez-Rivera, E.J.; Herman-Lara, E.; Gómez-Aldapa, C.A.; González-García, A. Physicochemical and Techno-Functional Properties of Extruded Corn Starch Snacks Enriched with Huitlacoche (Ustilago maydis): Effects of Extrusion Parameters and Process Optimization. Processes 2025, 13, 2898. https://doi.org/10.3390/pr13092898

Hernández-Santos B, Rodríguez-Miranda J, Juárez-Barrientos JM, Torruco-Uco JG, Ramírez-Rivera EJ, Herman-Lara E, Gómez-Aldapa CA, González-García A. Physicochemical and Techno-Functional Properties of Extruded Corn Starch Snacks Enriched with Huitlacoche (Ustilago maydis): Effects of Extrusion Parameters and Process Optimization. Processes. 2025; 13(9):2898. https://doi.org/10.3390/pr13092898

Chicago/Turabian StyleHernández-Santos, Betsabé, Jesús Rodríguez-Miranda, José M. Juárez-Barrientos, Juan G. Torruco-Uco, Emmanuel J. Ramírez-Rivera, Erasmo Herman-Lara, Carlos A. Gómez-Aldapa, and Ariana González-García. 2025. "Physicochemical and Techno-Functional Properties of Extruded Corn Starch Snacks Enriched with Huitlacoche (Ustilago maydis): Effects of Extrusion Parameters and Process Optimization" Processes 13, no. 9: 2898. https://doi.org/10.3390/pr13092898

APA StyleHernández-Santos, B., Rodríguez-Miranda, J., Juárez-Barrientos, J. M., Torruco-Uco, J. G., Ramírez-Rivera, E. J., Herman-Lara, E., Gómez-Aldapa, C. A., & González-García, A. (2025). Physicochemical and Techno-Functional Properties of Extruded Corn Starch Snacks Enriched with Huitlacoche (Ustilago maydis): Effects of Extrusion Parameters and Process Optimization. Processes, 13(9), 2898. https://doi.org/10.3390/pr13092898