1. Introduction

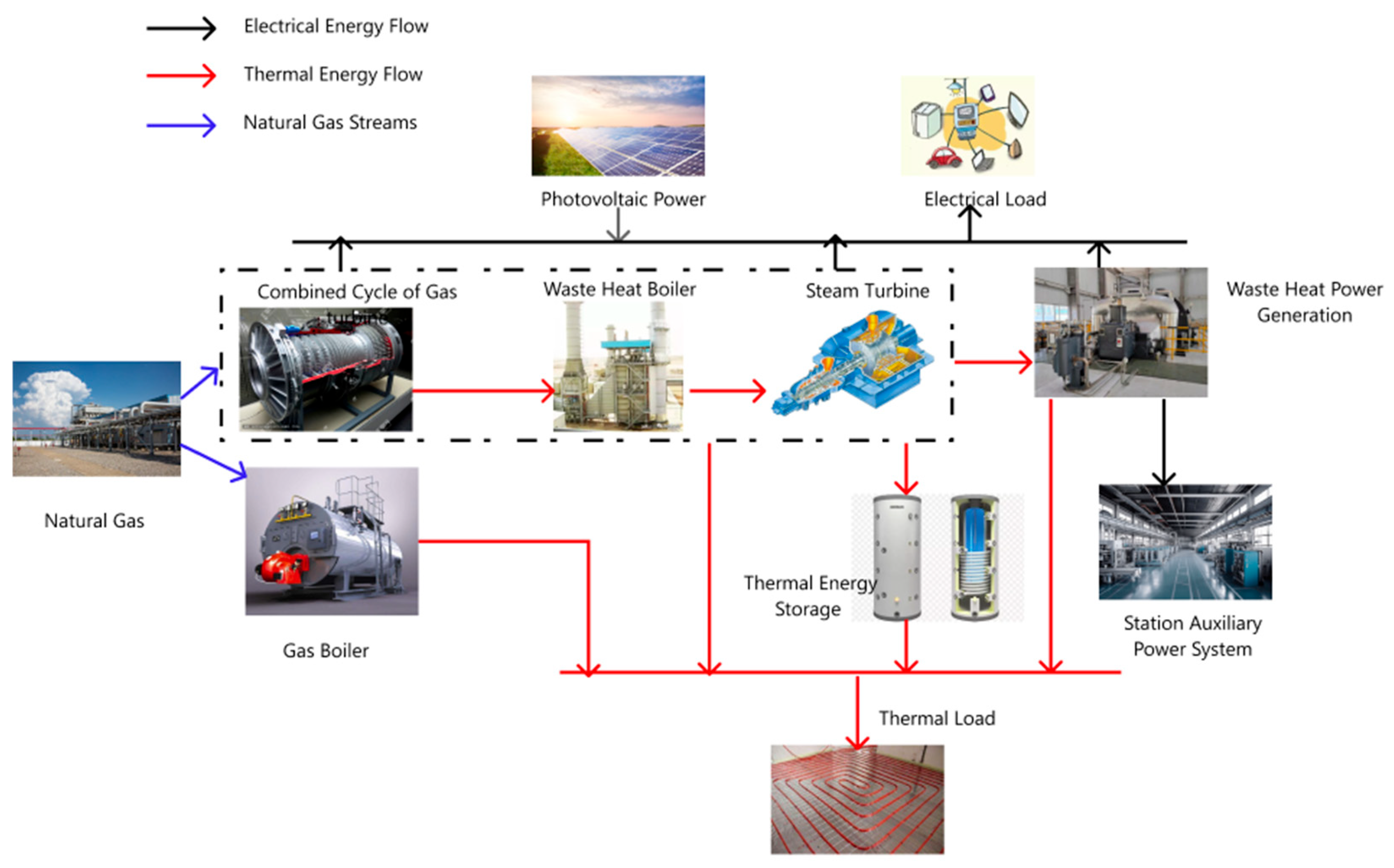

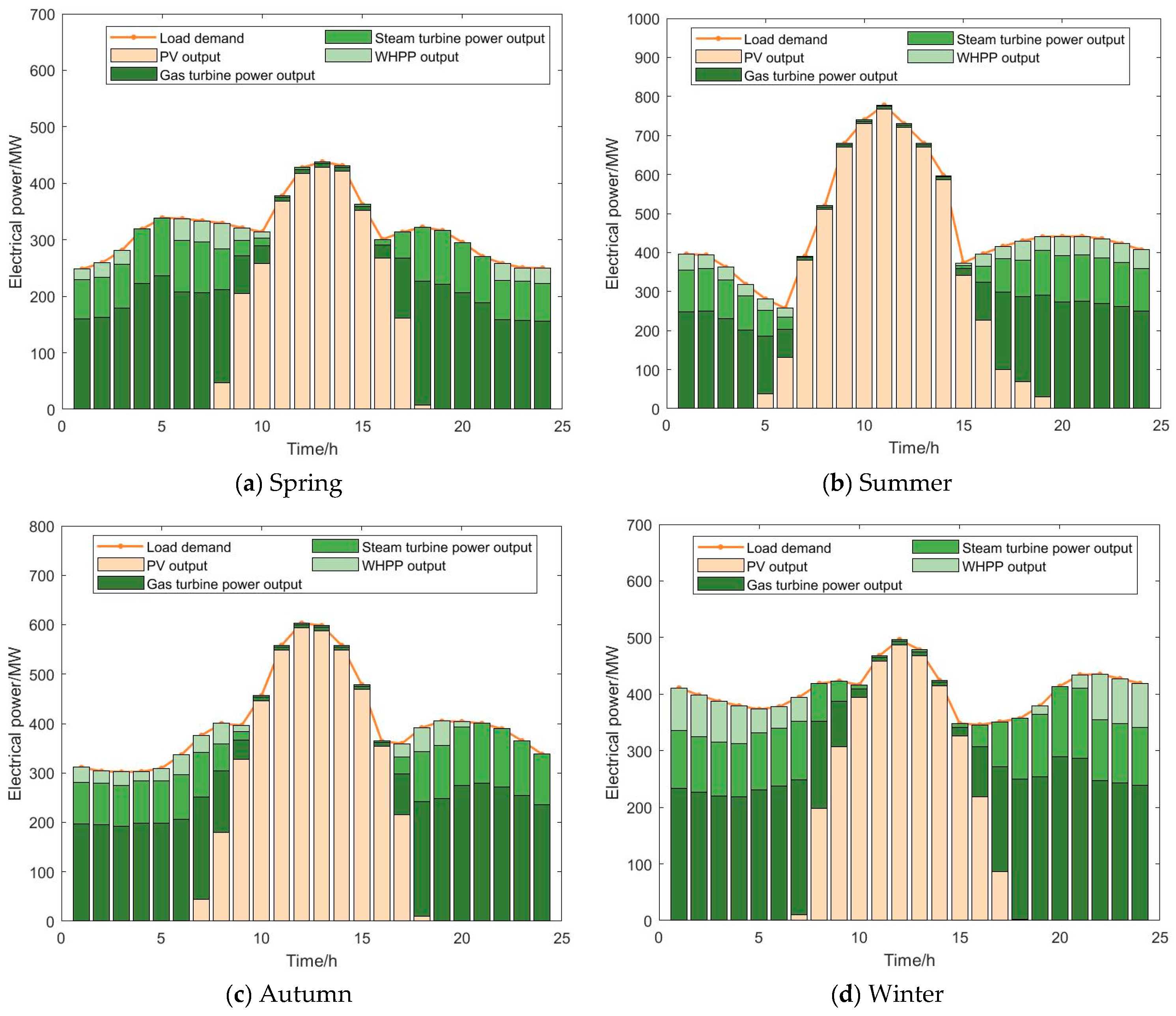

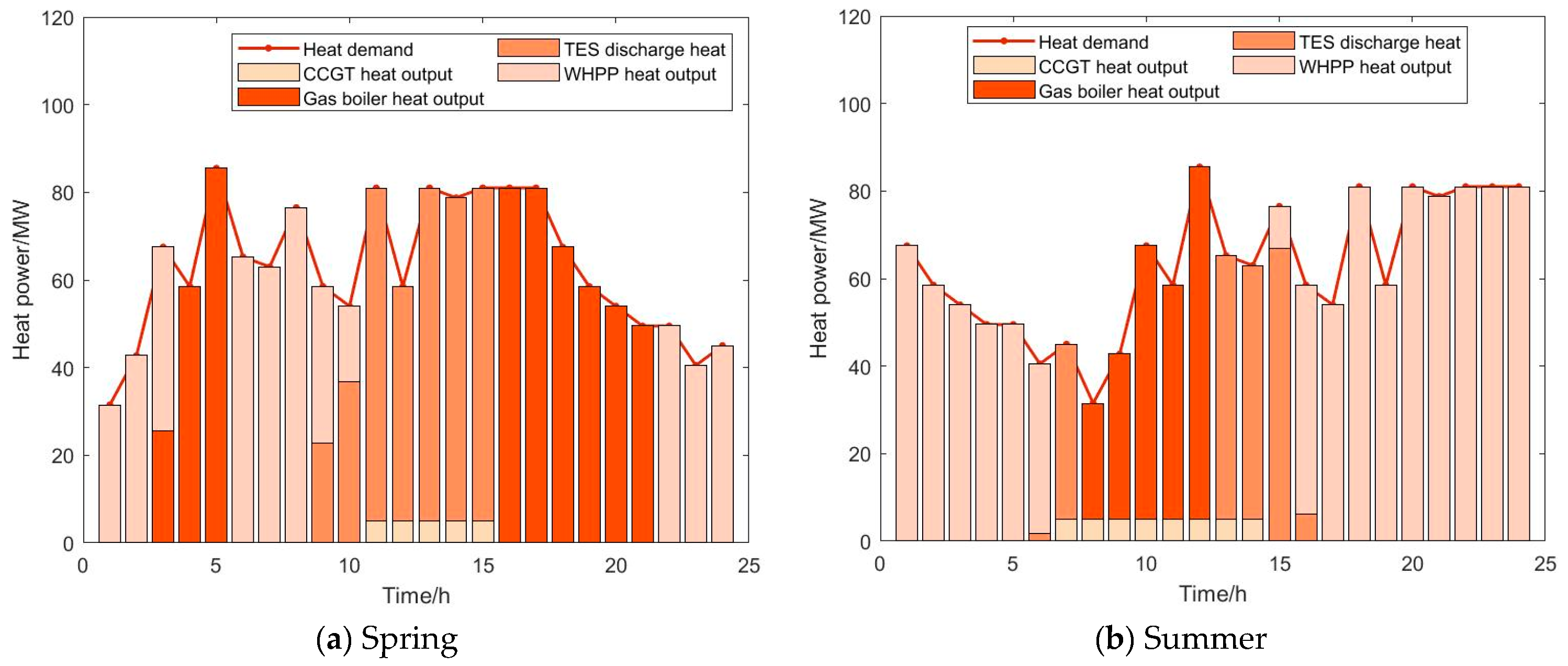

The complementary nature of different energy sources can help balance energy supply and demand, as well as improve the utilization rate of renewable energy. Constructing and operating energy systems independently reduces energy efficiency. Moreover, the combined cycle of gas turbine (CCGT) unit is seen as playing a critical role in contributing to the system operational flexibility and economy due to its fast starting speed, high thermal efficiency, and low pollution. Based on this, combining CCGT units, photovoltaic power (PV) station, and thermal energy storage (TES) could improve the utilization efficiency of renewable energy and reliable power supply capability of the energy system, by using the complementary characteristics and the flexible adjustment capability of energy coupling components.

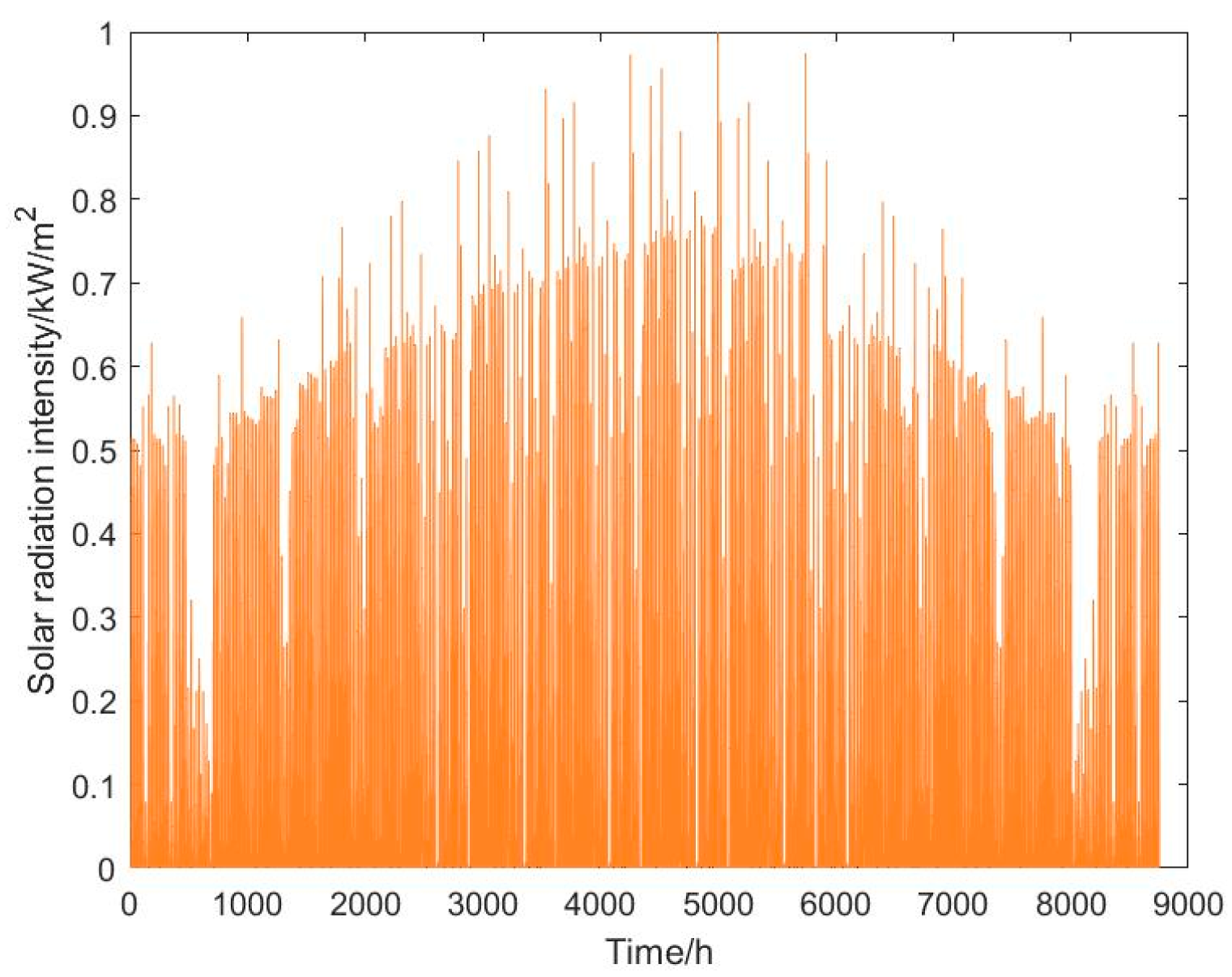

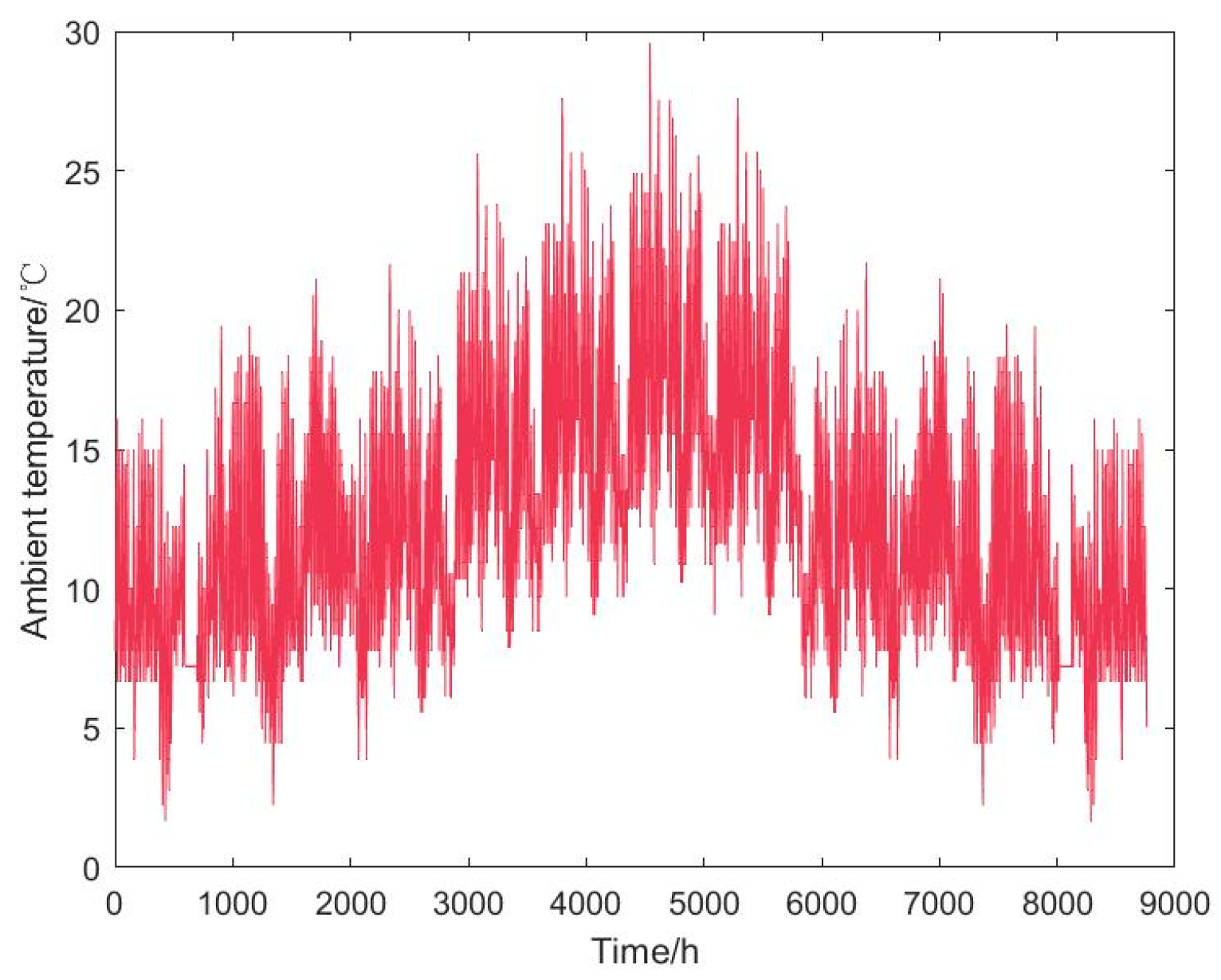

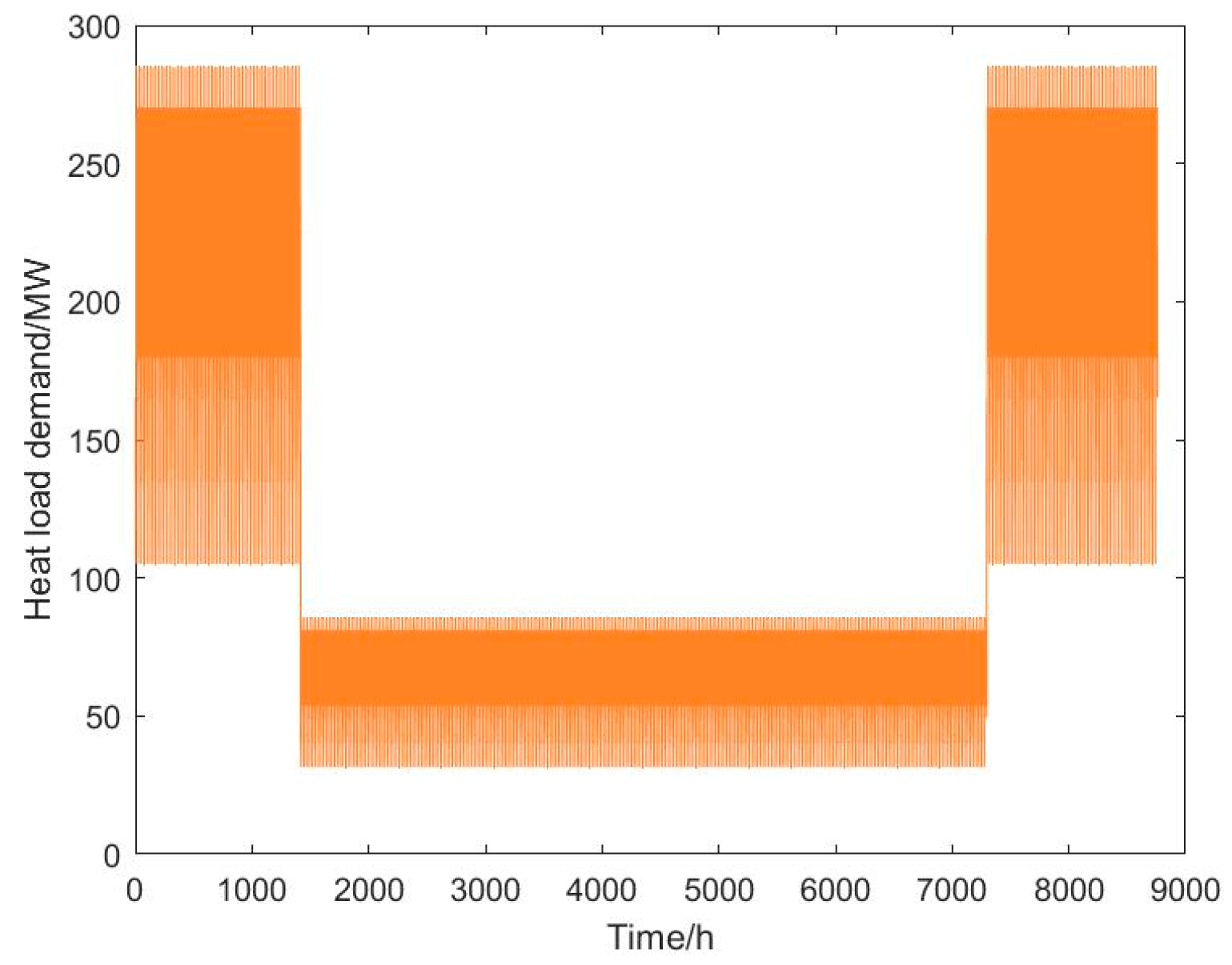

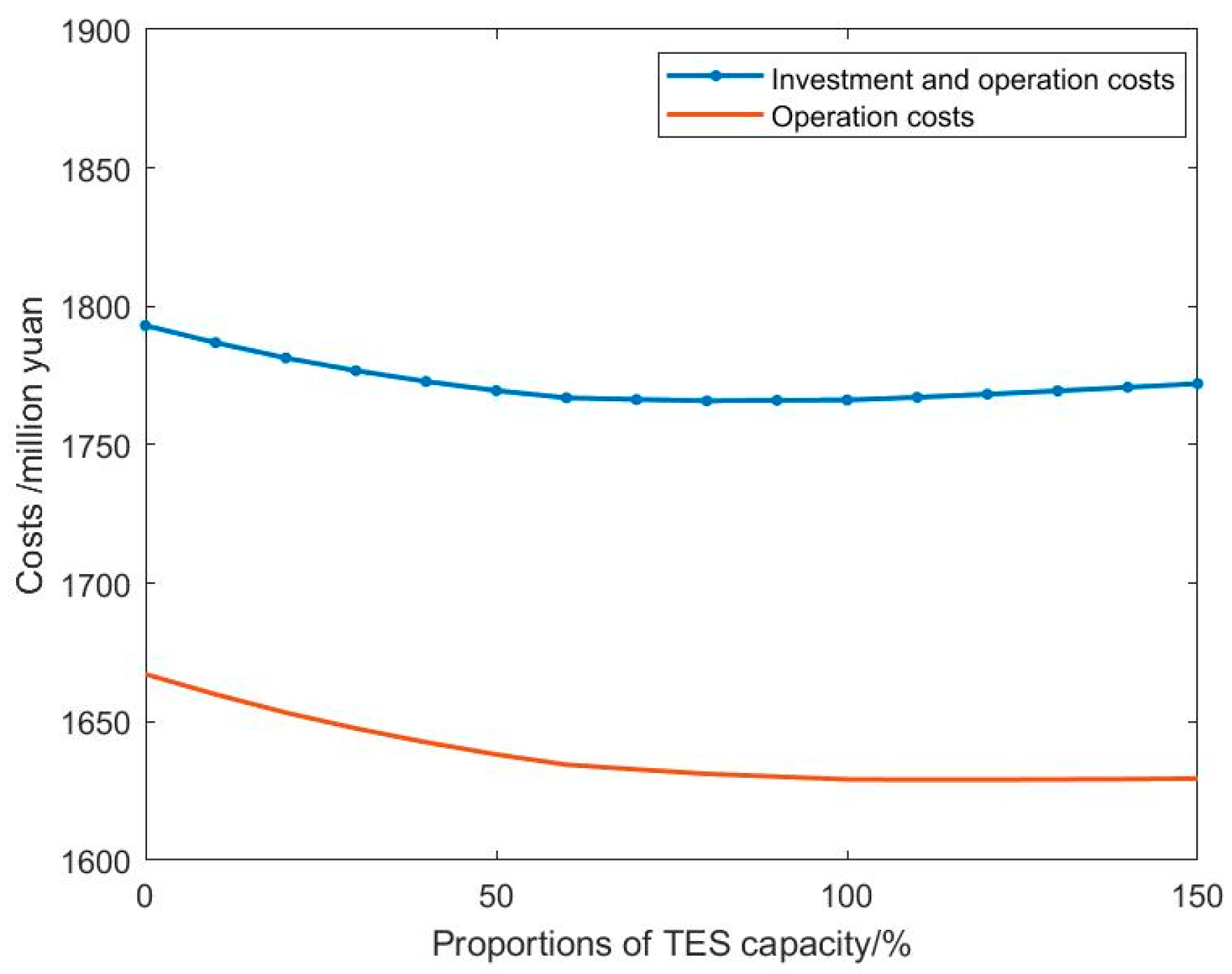

However, the CCGT system is composed of multiple components, including a gas turbine, a waste heat boiler, a steam turbine, and waste heat power generation (WHPP). Due to participating in the peak load regulation of the power grid, the gas turbine would decrease output and its thermal efficiency correspondingly during the partial load operation status of the CCGT units. In addition, the PV stations, TES, and gas boiler contained in the multi-energy complementary system (MECS) increase the complexity of system operation and provide more operational flexibility. Moreover, the seasonal fluctuation of load demand increases the difficulty of balancing supply and demand, which brings more uncertainty to the planning of PV station and TES. Therefore, it is urgent to optimize the capacity of PV and TES from a holistic perspective, considering the load uncertainty, to improve the economy of the CCGT and the energy supply efficiency of MECS.

Reasonable planning and configuration scheme of energy supply equipment play a crucial role in improving power supply reliability and economy of the system [

1]. Energy storage technology has been studied widely due to its advantages in promoting renewable energy consumption and increasing regulation flexibility [

2,

3]. A planning and operation framework of solar energy-based renewable energy communities is proposed in [

4] based on the multi-objective optimization theory. In [

5], the combination of transportation, natural gas, and active distribution networks is considered via building a novel optimal planning model, and the optimal investment and operational strategies of the multi-energy system are developed. A co-expansion planning method of integrated electricity and natural gas is studied in [

6] while considering the economy and safety of system operation, and the uncertainty of supply and demand is modeled by the information-gap decision theory technique. Integrated energy systems’ structure and component capacity are optimized to reduce the fluctuation of the source and load in [

7] based on the synergistic effects of multiple energy resources. In [

8], carbon emission reduction in integrated energy systems is introduced in the capacity optimization configuration model, and the operation characteristics of energy conversion and storage devices are analyzed and modeled.

The randomness and volatility of the load directly influence the effectiveness of the energy supply system planning scheme. Uncertainty modeling is a critical component in energy system optimization research. Scenario analysis is commonly used to model the uncertainty of parameters in an optimization problem [

9]. Uncertainties of wind speed are modeled in [

10] via a transfer learning-based scenario generation method, and the correlation of multiple wind farms is described. The temporal and spatial correlation model of wind and solar energy resources is constructed in [

11], and the proposed method is validated in Indian. The multiple scenarios of PV output are built in [

12] to study the effect of the number of PV stations and storage batteries on system reliability and cost. The Monte Carlo simulation method is used in [

13] to generate the scenarios of wind power and load. The Latin hypercube sampling method is adopted in [

14] to reflect the forecast errors of wind and PV plants’ output. Similarly, Latin hypercube sampling is combined with K-means in [

15] to generate the scenarios of sources and loads. The probability distribution is established to describe the stochasticity and uncertainty of the wind power in [

16]. Scenarios with uncertainty and randomness are established to represent the randomness and volatility of the load based on probability theory. The Markov Chain method and the Monte Carlo method are combined in [

17] to simulate time series output scenarios of wind power. The sequential sampling method is used in [

18] to generate the time series output of wind power by counting the probability distribution of multiple wind power outputs. The above research mainly adopts probability models based on statistical theory to build scenarios of parameter uncertainty. And the selection of probability models has a great impact on the efficiency and effectiveness of scenarios. However, in reality, the load curve on weekdays is quite different from that on weekends or holidays, and it shows seasonal characteristics, which means that there are multiple “peaks” or “patterns” in the data distribution. And the electrical load pattern is significantly influenced by many external factors, such as temperature, humidity, weather type, user energy consumption behavior, and so on. Moreover, the load has obvious diurnal, weekly, and seasonal periodicity, and the loads at adjacent time points are highly correlated. These show that the electrical load characteristics are high-dimensional, multimodal, and time series coupled. It is difficult to know the probability distribution of the load in advance and describe the load with a specific single probability distribution. To solve this problem, Generative Adversarial Networks (GANs) are introduced to generate uncertainty scenarios. Unlike statistical simulation methods, GANs have the advantage of not knowing the distribution in advance and generating a large number of samples quickly.

To solve the above issues, this paper proposes a stochastic programming model to optimally configure the capacity of PV station and TES, considering the load demand uncertainty in the MECS including CCGT units, gas boiler, PV station, and TES. And the uncertainty of load demand in four seasons is modeled via the GANs, which could learn the correlation, seasonality, and multimodality of load time series based on the historical data, and efficiently generate a number of load scenarios according to the distribution characteristics of historical load. In addition, to decrease the computation costs of the stochastic optimization model, the Fuzzy C-means clustering method is adopted to reduce the load scenarios. The highlights of the paper are listed below.

- (1)

To utilize the complementation of multi-energy carriers and the flexible adjustment capability of energy components, a stochastic optimization model for optimally configuring the capacity of the PV station and TES is proposed in this paper.

- (2)

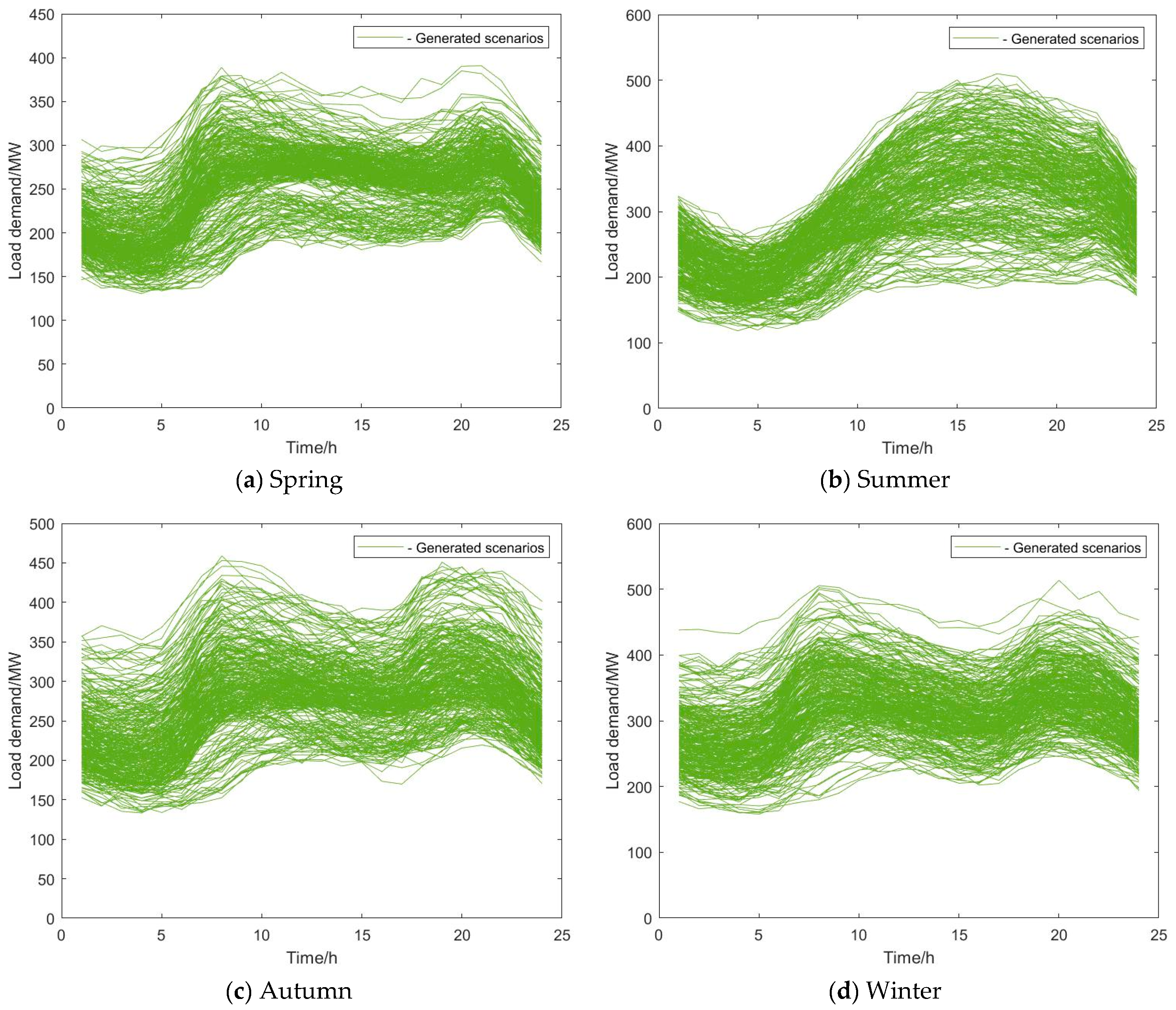

The load demand uncertainty is modeled via GANs, which capture the temporal correlation of load time series. And the load demand scenarios in spring, summer, autumn, and winter are generated separately, which reflects the influence of seasons on the electricity consumption behavior of users.

4. Uncertainty Modeling

In this work, a set of possible scenarios is generated based on the GANs for describing the uncertainty of load demand in four seasons. GANs are one of the machine learning methods for learning the latent distribution of historical data. They could discover the potential correlations via continuously learning the patterns of training data and generate new data sets with similar features. It is widely used for data generation when the real data are insufficient.

GANs usually consist of a generative model and a discriminative model. The generative model would artificially synthesize data samples according to the real data samples to deceive the discriminative model. The discriminative model would learn to identify whether samples are real or synthetic by using neural networks. The generative model and discriminative model continuously improve their own generation and discrimination capabilities through mutual training. And the learning optimization process is to find the Nash equilibrium between them [

23].

In the generative model, random noise is received and sampled by neural networks during the training process, and the generated sample data are obtained after a large number of iterations of learning.

In the discriminative model, the model inputs are the real samples from the training set and sample data generated by the generative model. And these input data are sampled by neural networks to determine the probability that the data comes from the real training samples. The confrontation between the generative model and discriminative model forms a minimax game problem, expressed as follows:

where D and G are weight parameterizations from two different deep neural networks.

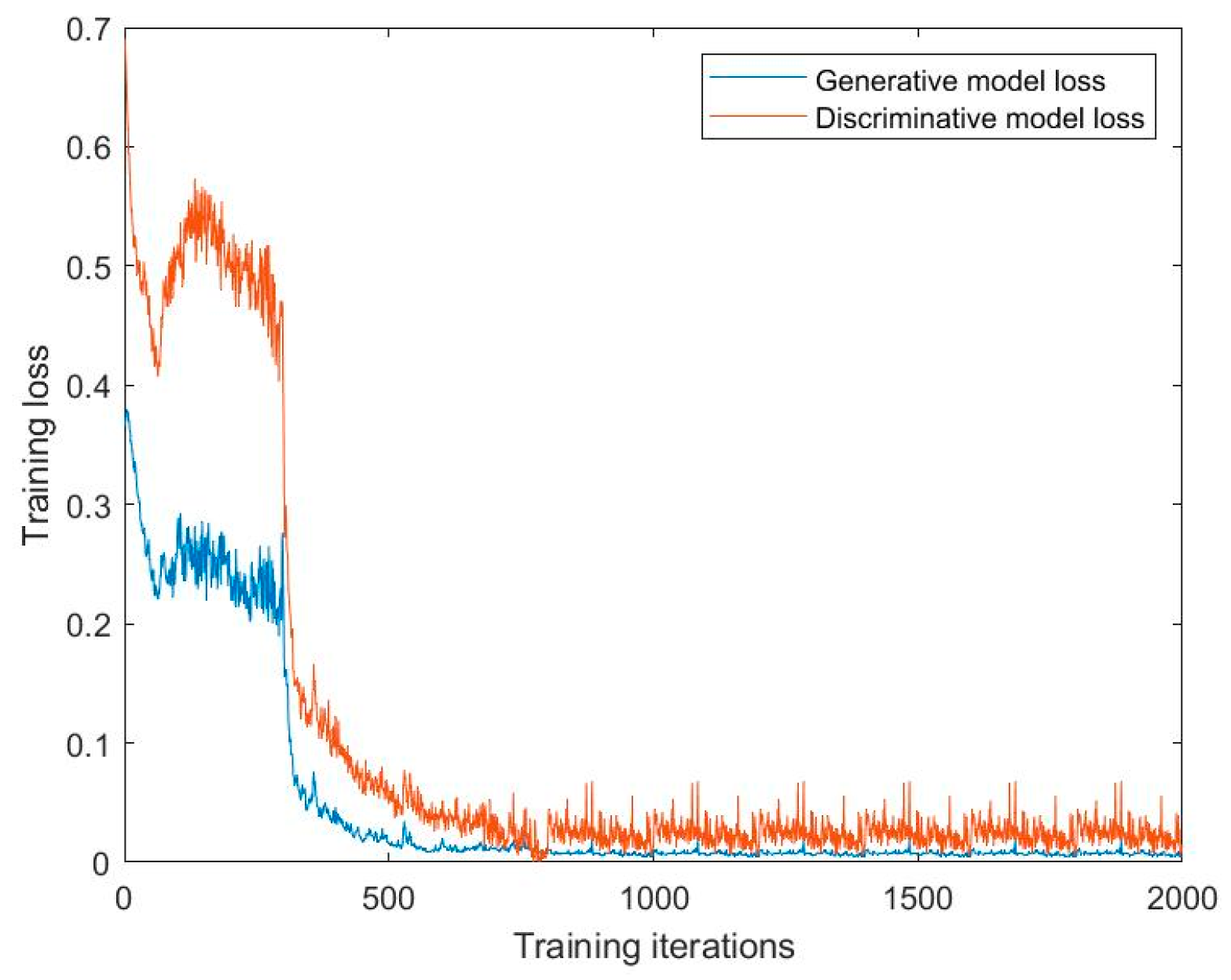

In the initial stage of training, there is a significant difference between the generated data and the actual data. The discriminative model has a higher success rate in distinguishing the generated data and the actual data. At this stage, the loss function of the generative model is larger and the loss function of the discriminative model is smaller. As the training process develops, the generative model and the discriminative model constantly compete until converging to a dynamic equilibrium state.

Based on the above GANs approach, the load demand scenario is built considering the temporal correlation of the load time series. And as the electricity consumption behavior of users is influenced by seasons, the load demand scenarios in four seasons are generated separately.