Stress-Barrier-Responsive Diverting Fracturing: Thermo-Uniform Fracture Control for CO2-Stimulated CBM Recovery

Abstract

1. Introduction

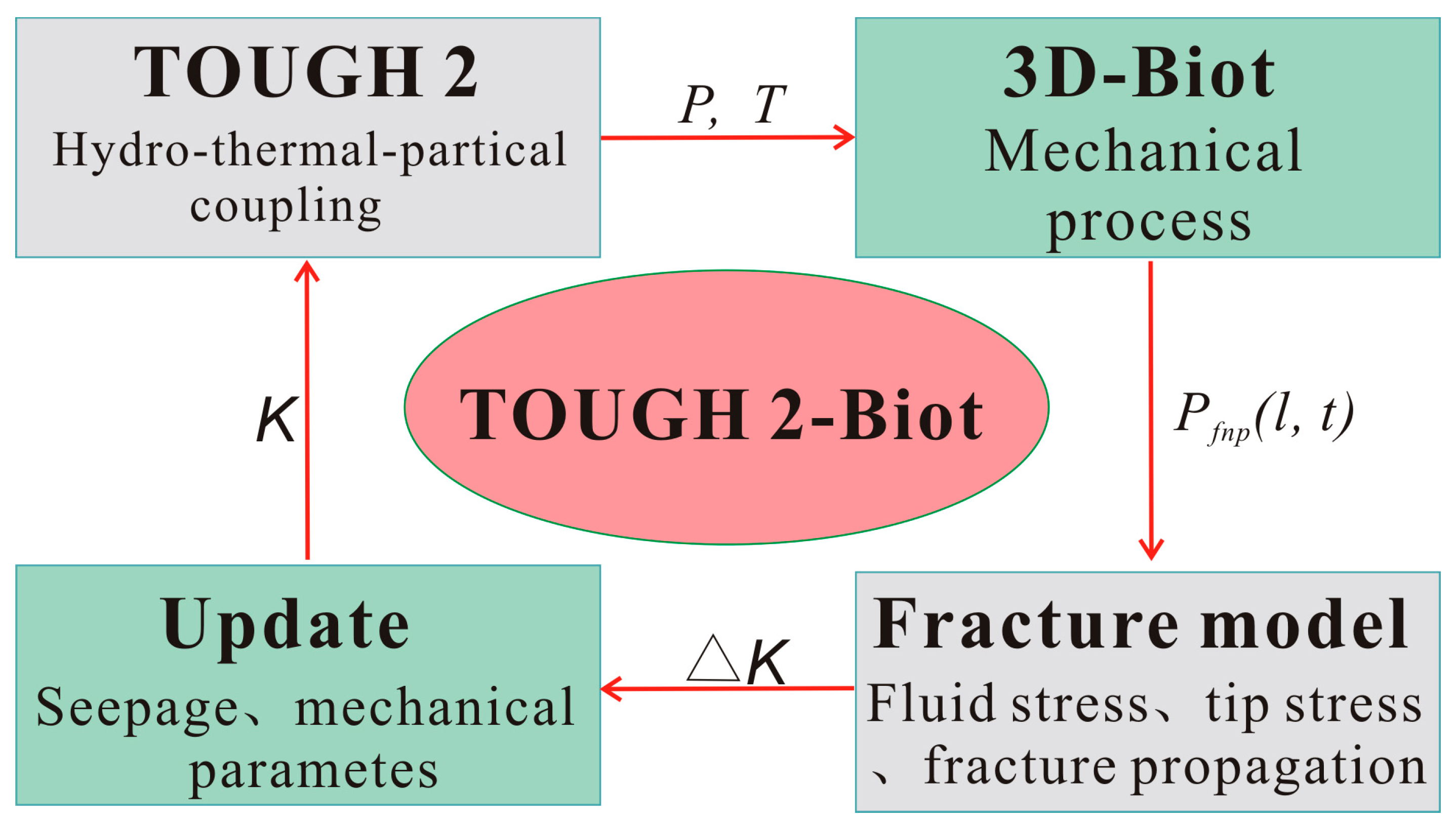

2. Methods

2.1. Fracture Propagation Model

2.1.1. Flow Equation of Fracturing Fluid in Fractures

2.1.2. Heat Transfer Model

2.1.3. Reservoir Stress Balance Model

2.1.4. Fracture Propagation Criterion

2.2. Numerical Model of Temporary Pugging Agent Transport

2.2.1. Continuity (Mass Conservation) Equation

2.2.2. Momentum Conservation Equation

2.2.3. Turbulent Equation

2.2.4. Discrete Phase (Particle) Motion Equation

2.3. Model Calculation and Verification

2.3.1. Model Calculation

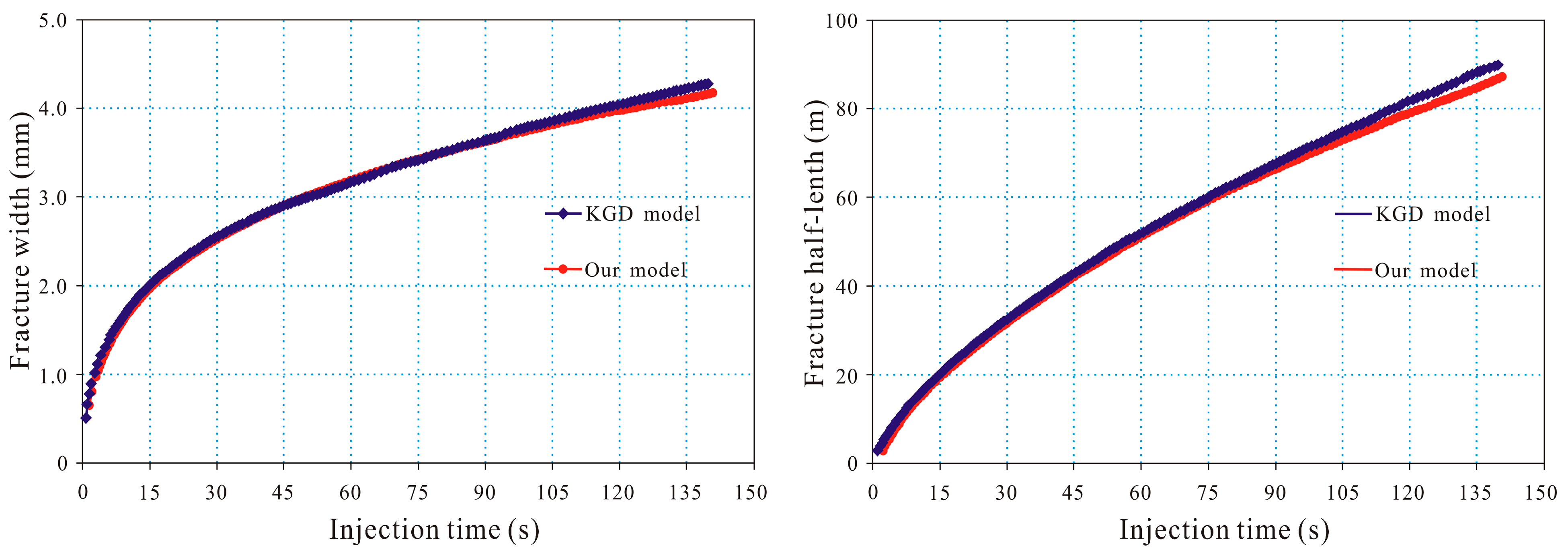

2.3.2. Model Verification

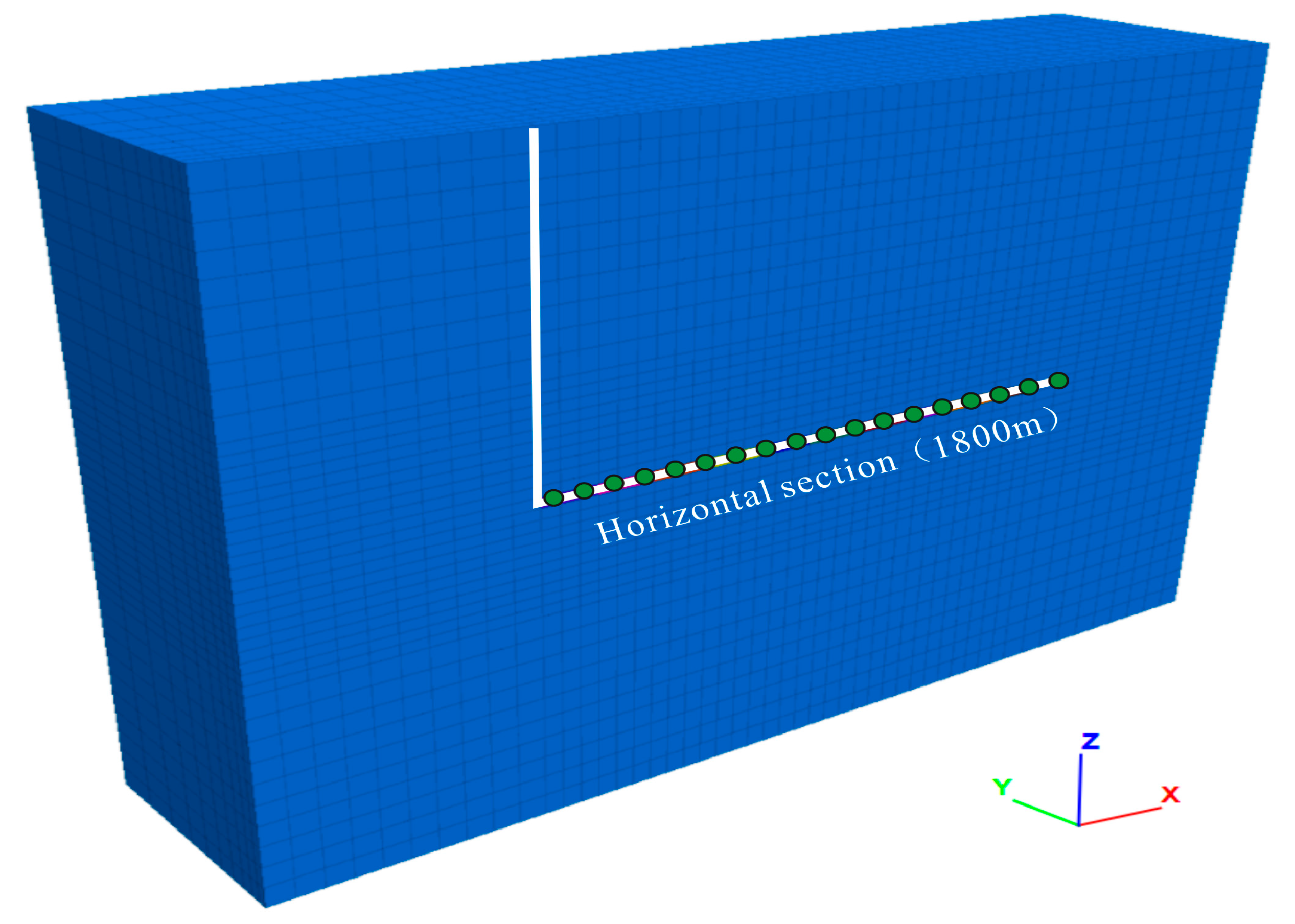

2.4. Construction of Numerical Models

2.4.1. Modeling Geometric of Numerical Model

2.4.2. Boundary Conditions and Assignment Loading

3. Results and Analysis

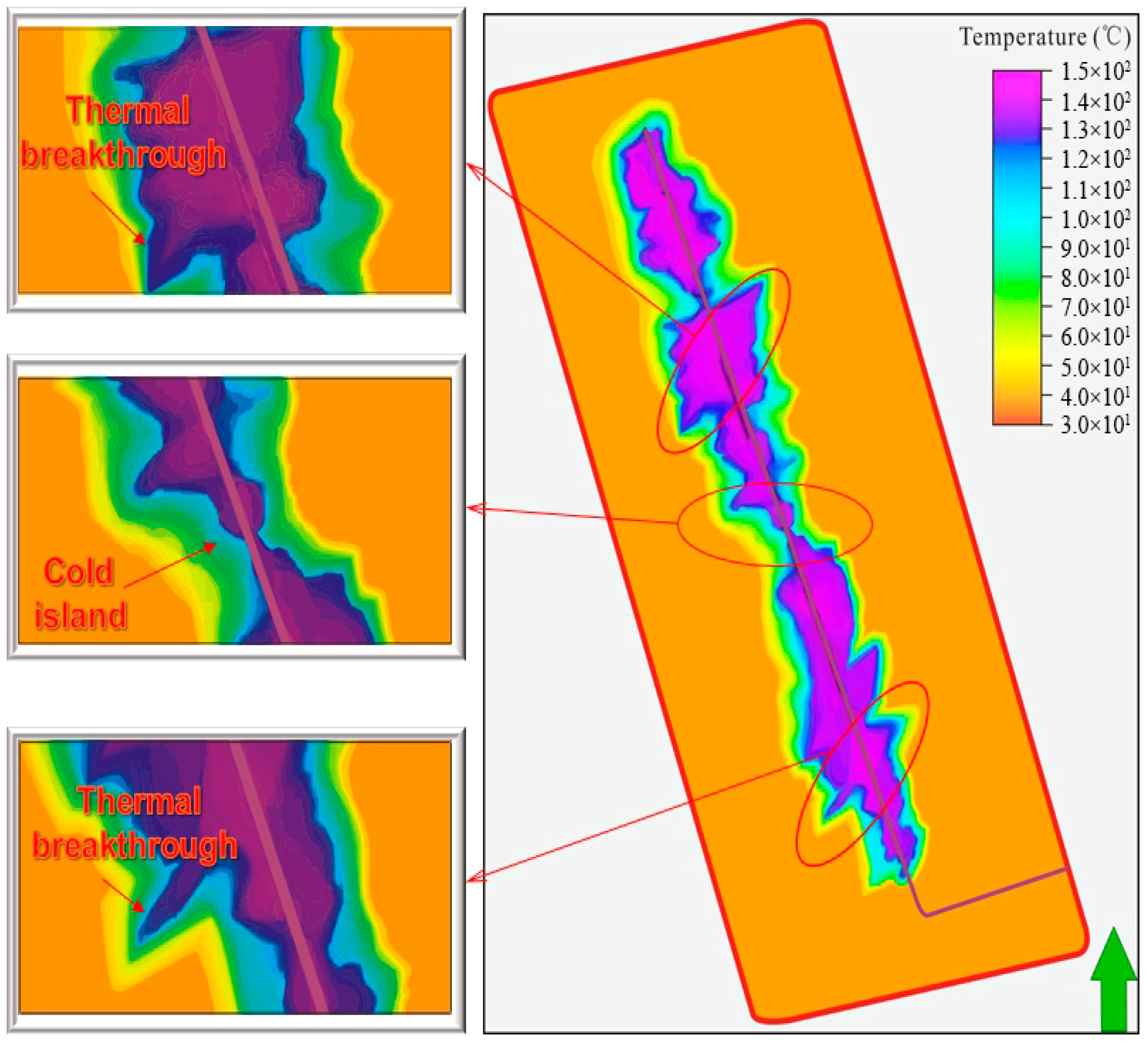

3.1. Thermal Field Evolution Under Anisotropic Fracture Growth with CO2 Stimulation

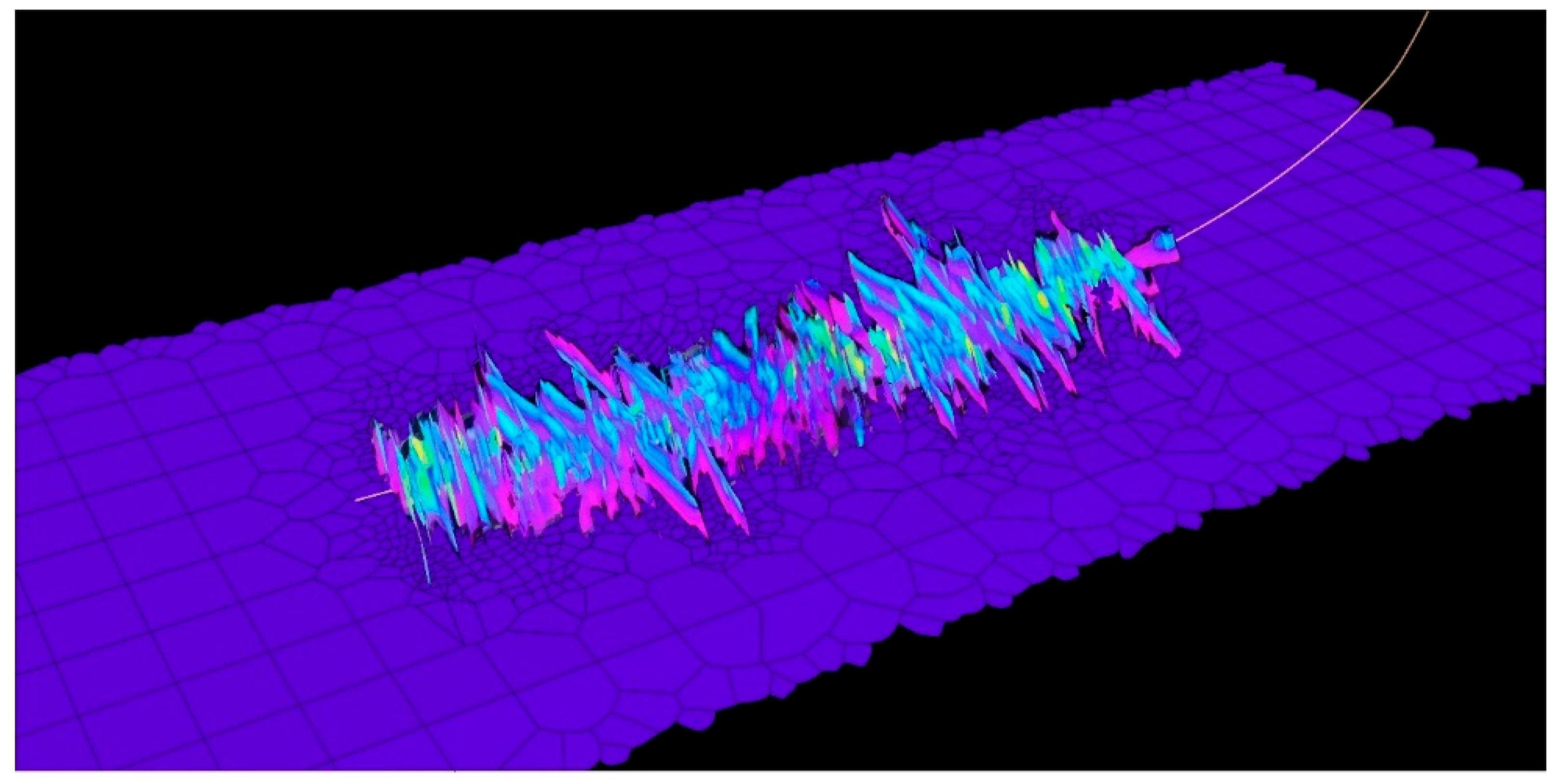

3.2. Temporary Plugging Simulation for CO2 Thermal-Drive Fracture Networks

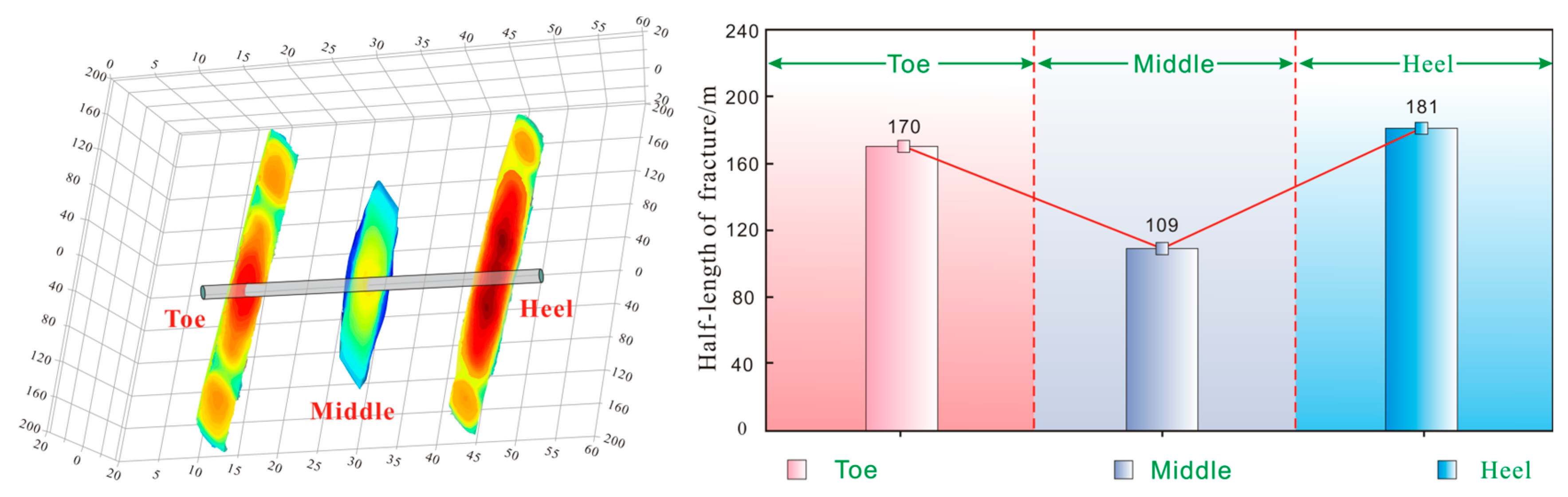

3.2.1. Mechanisms Governing Asymmetric Propagation in Hydraulic Fracture Networks

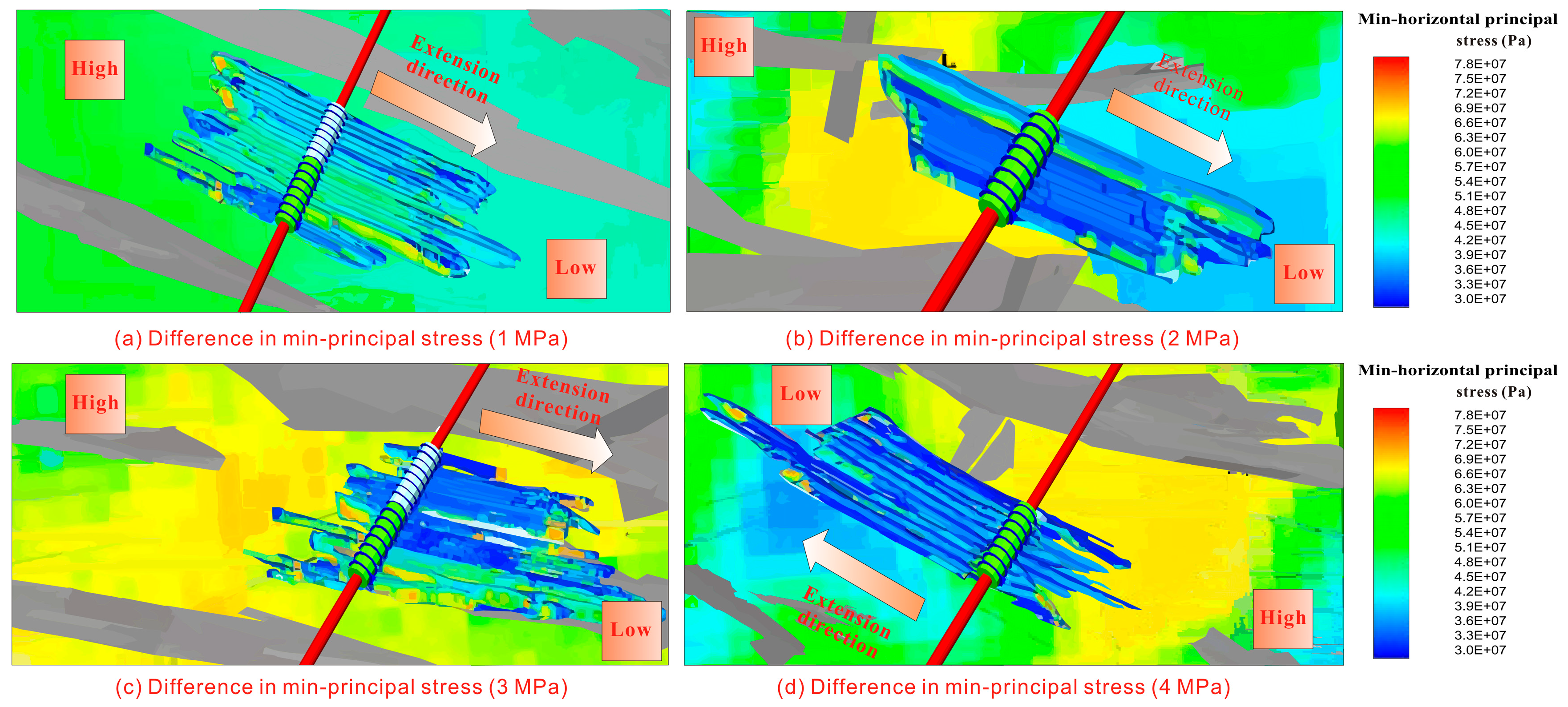

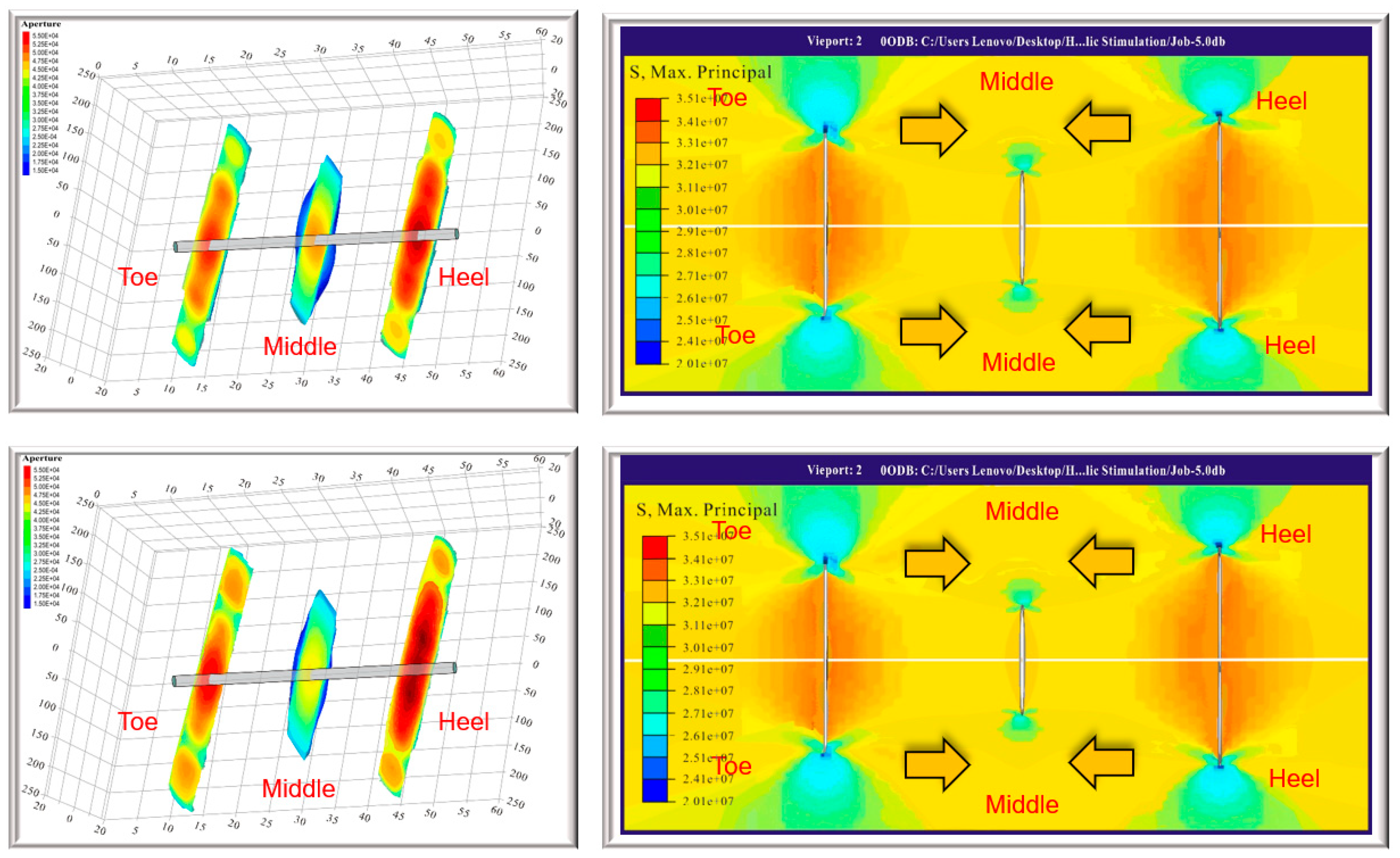

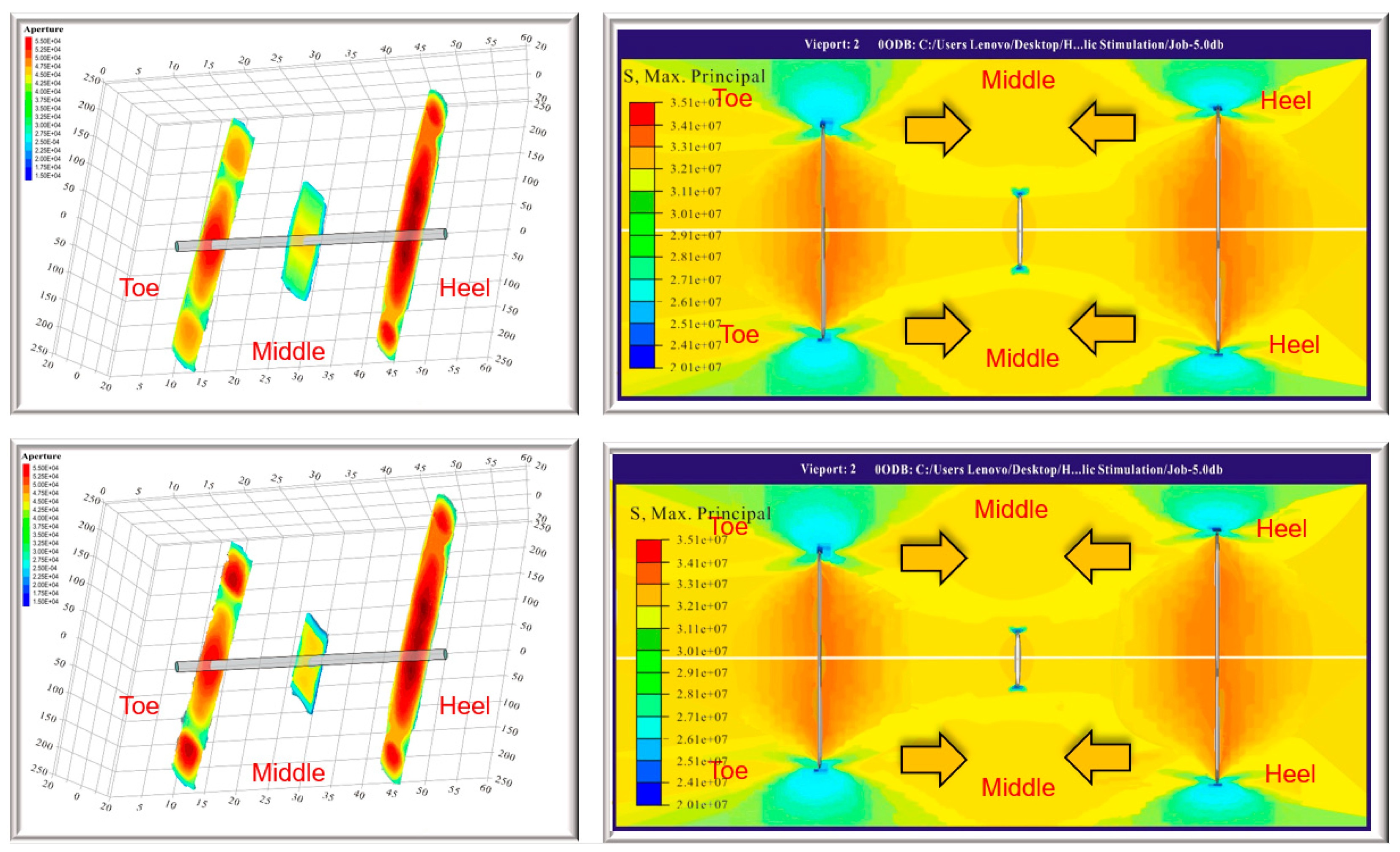

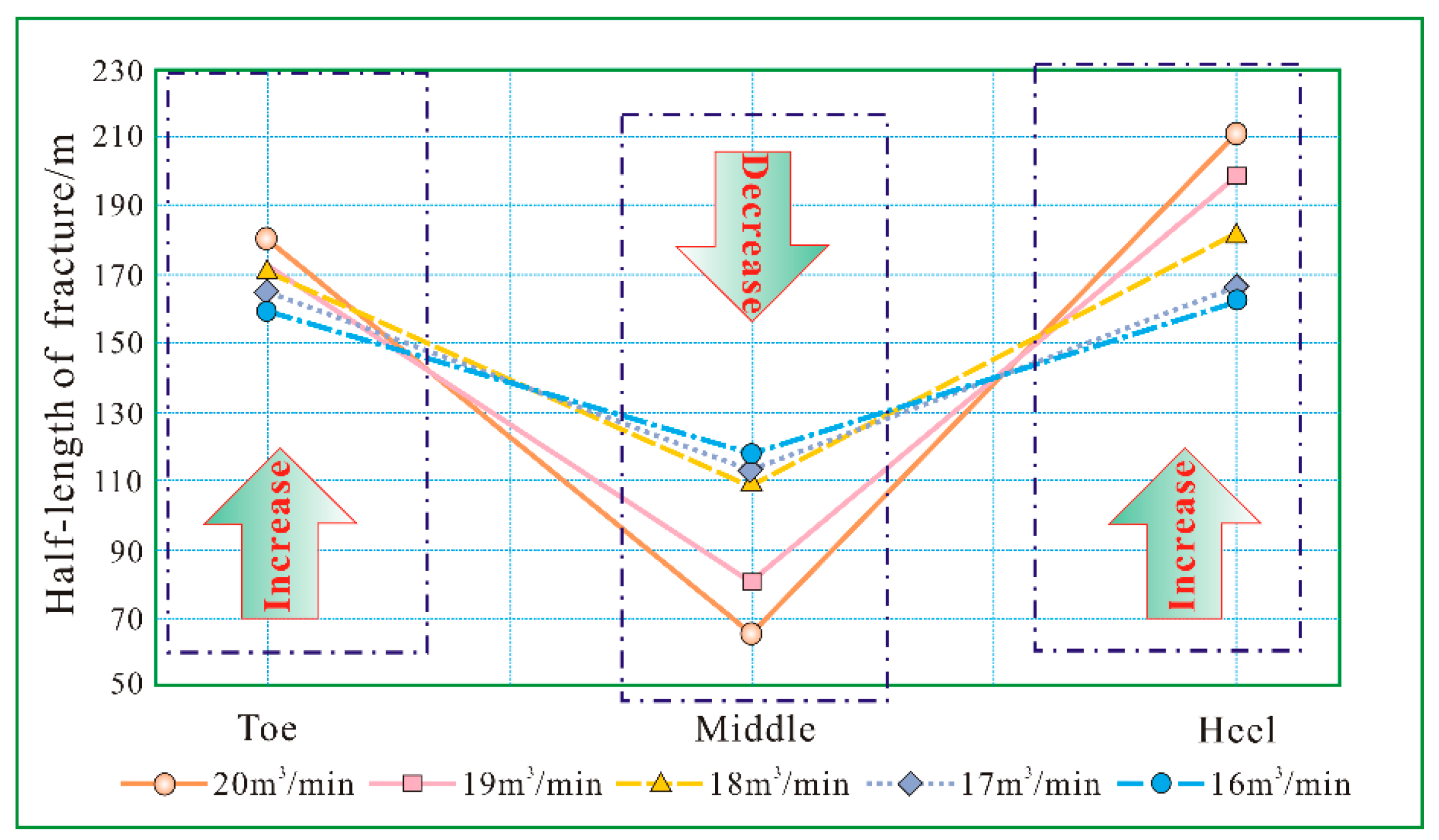

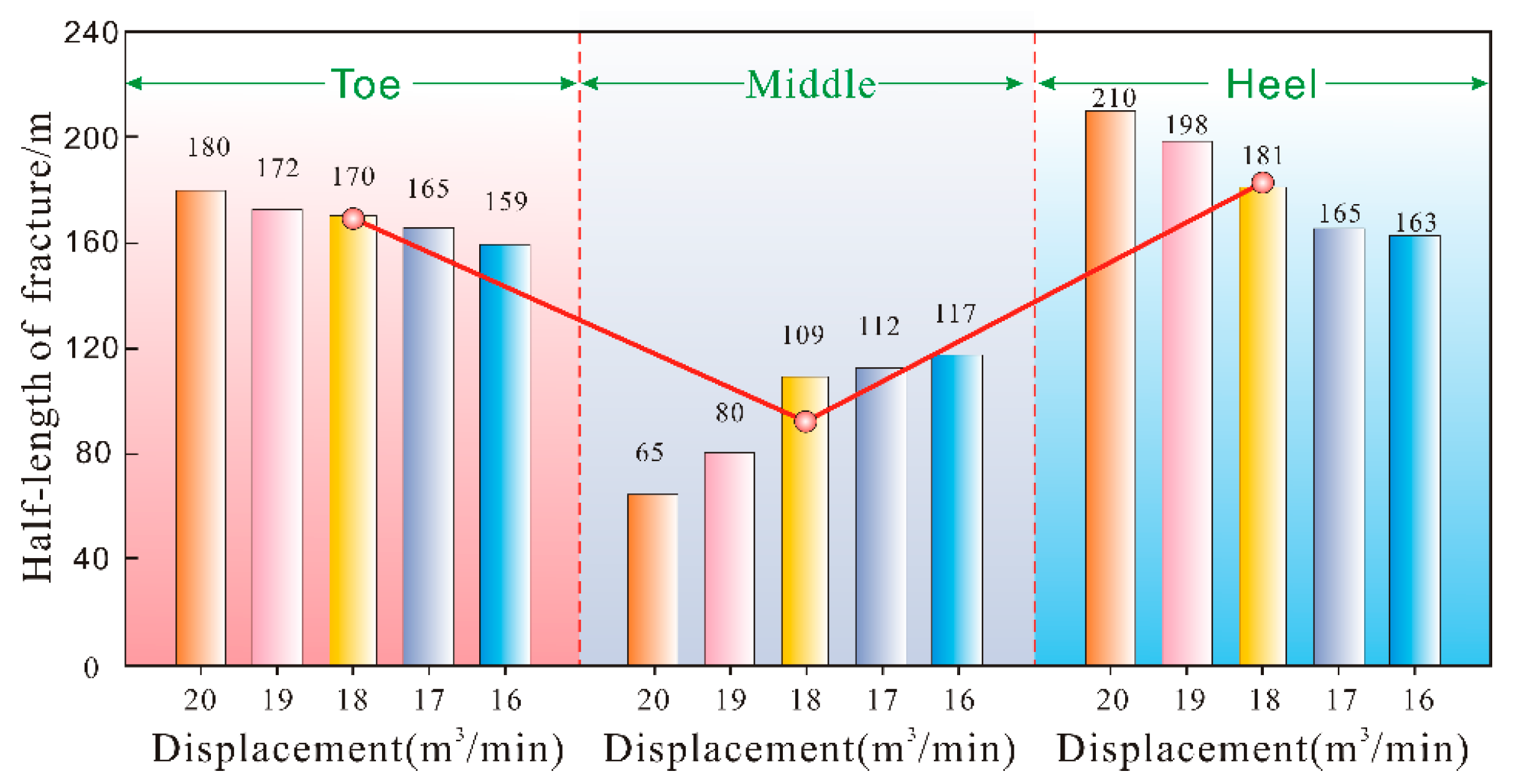

Stress Shadow Response to Differential Injection Displacements

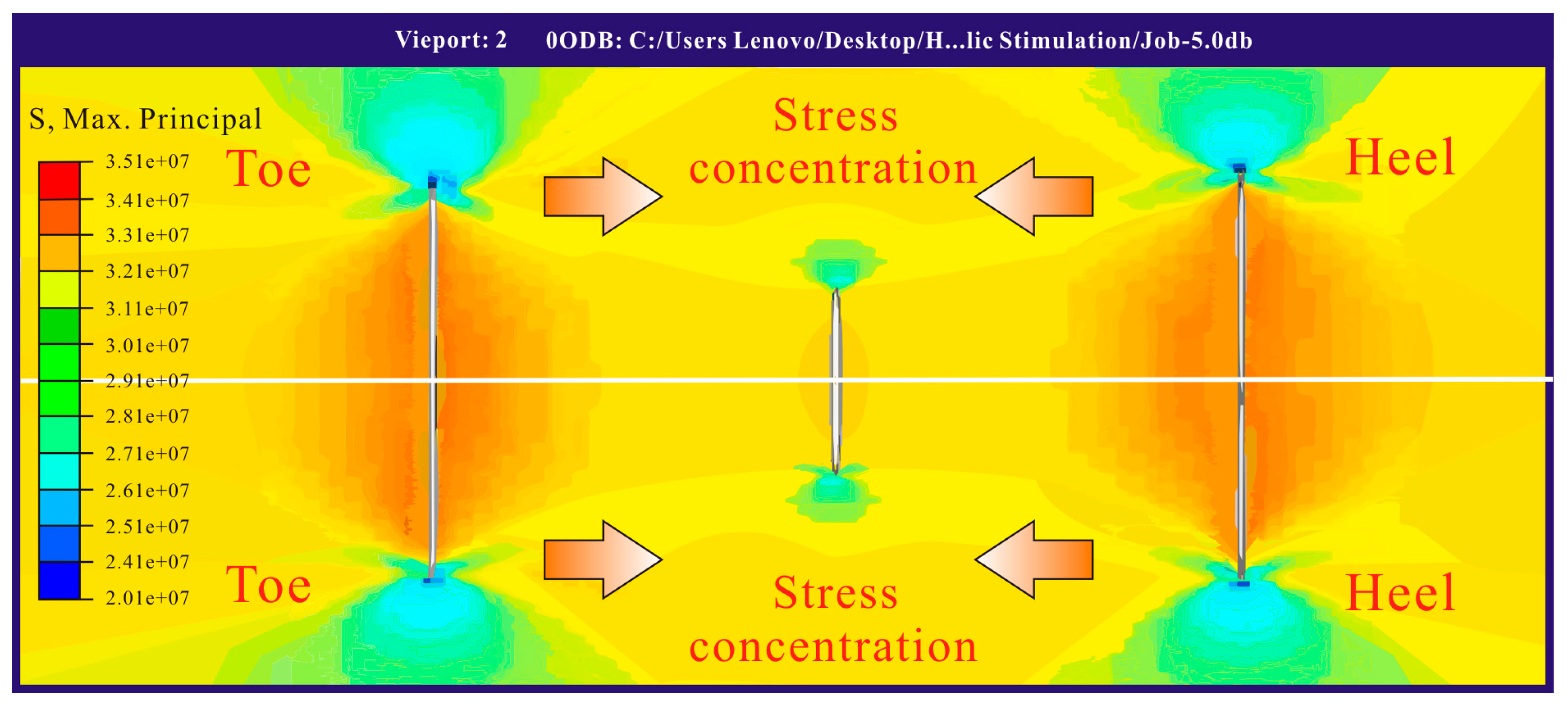

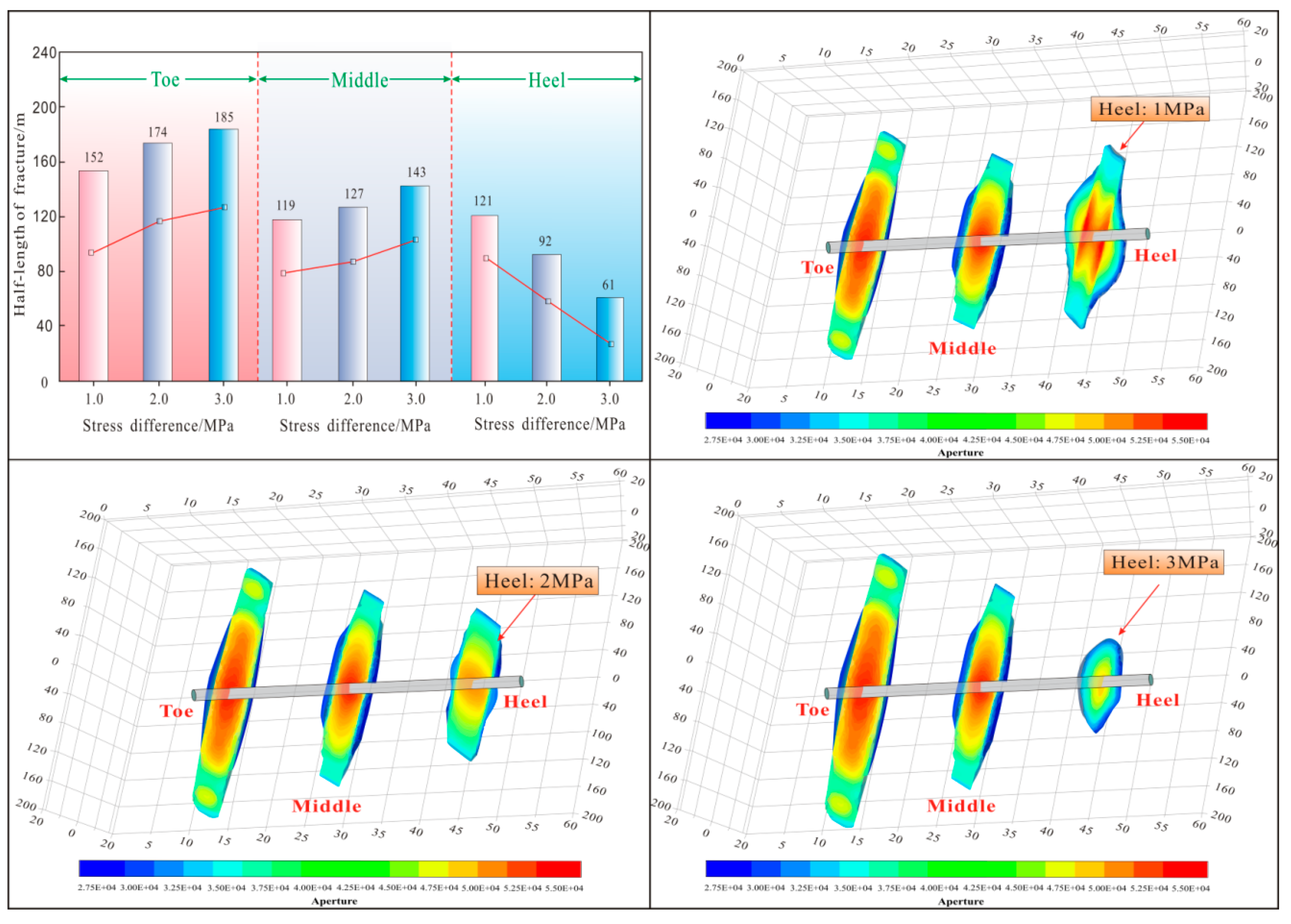

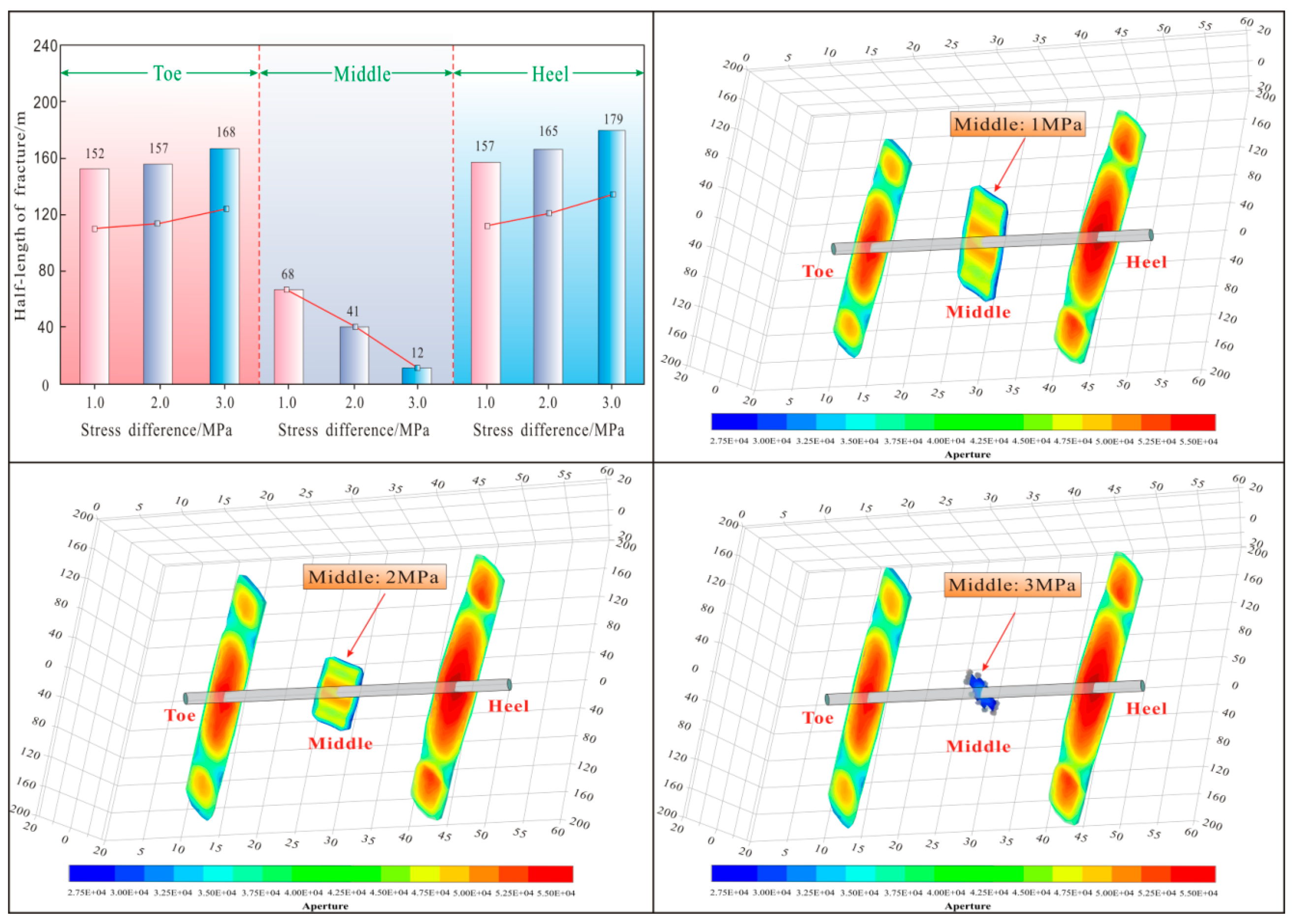

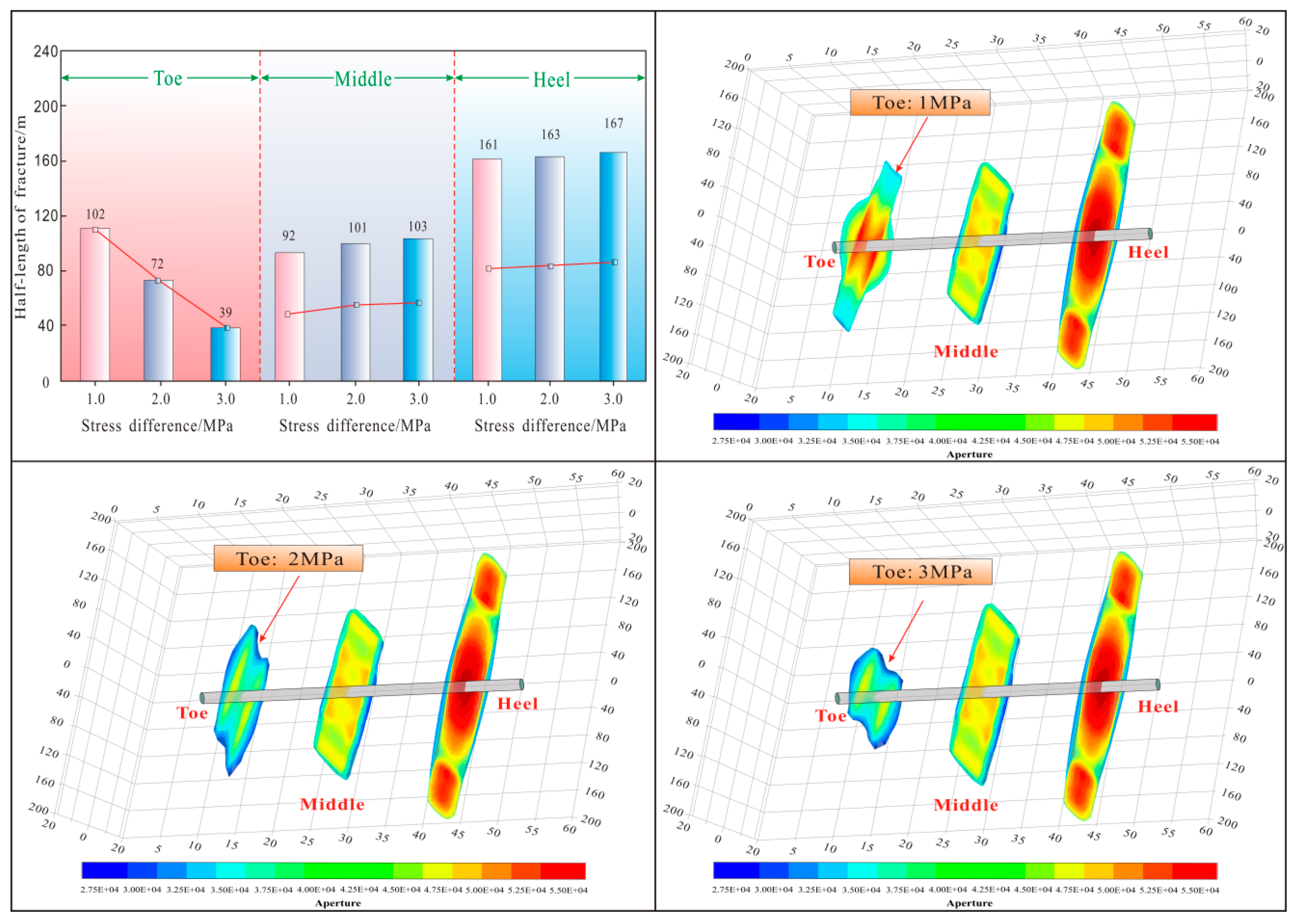

Intra-Stage Stress Heterogeneity Shielding Effect

3.2.2. Diverter Particle Migration and Efficiency

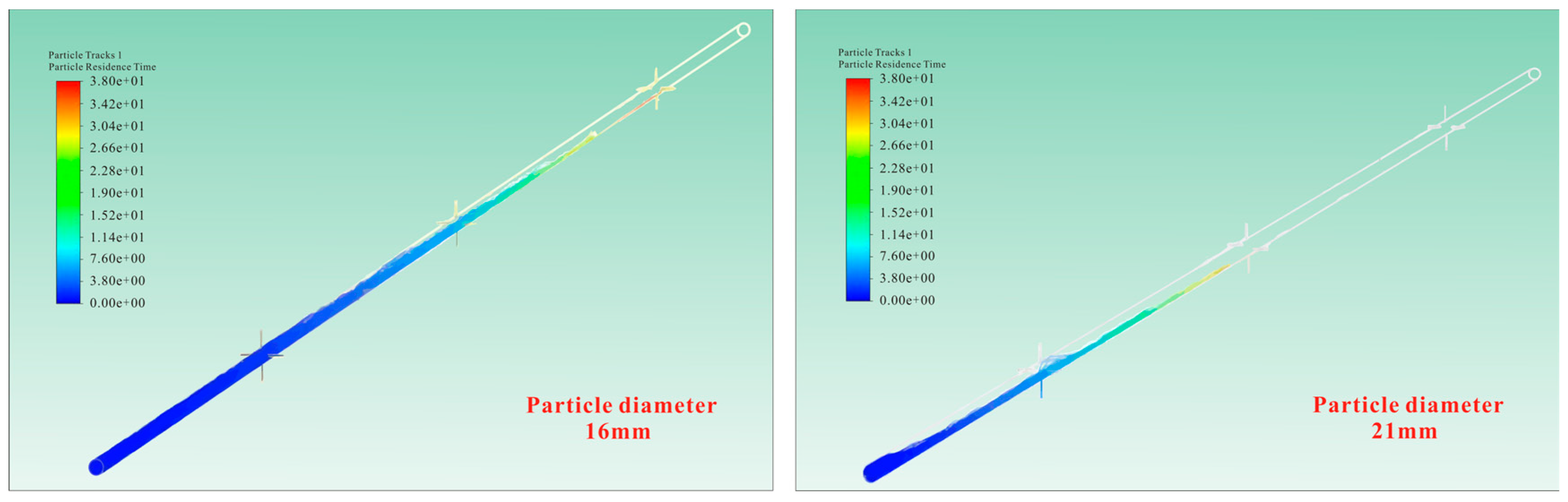

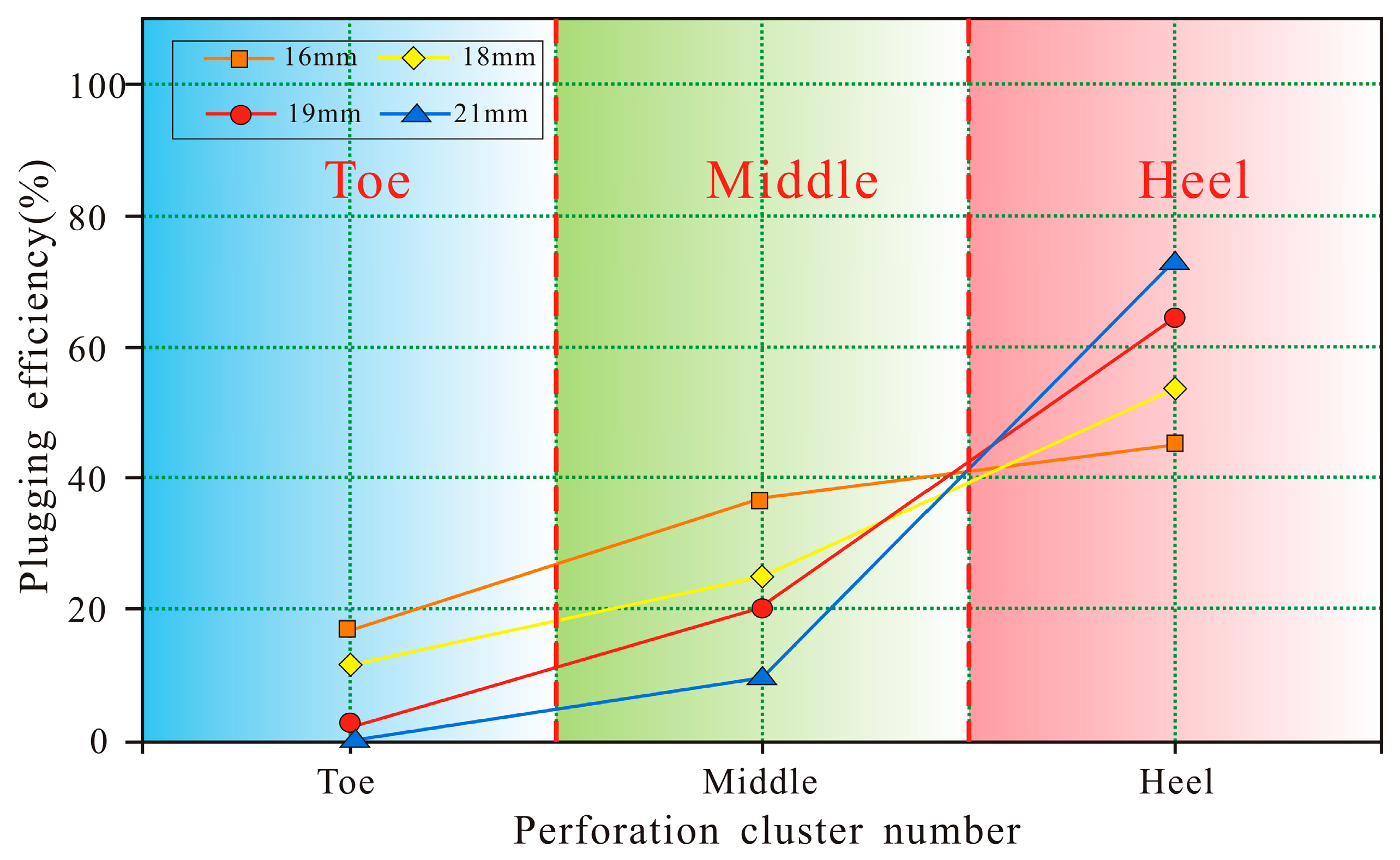

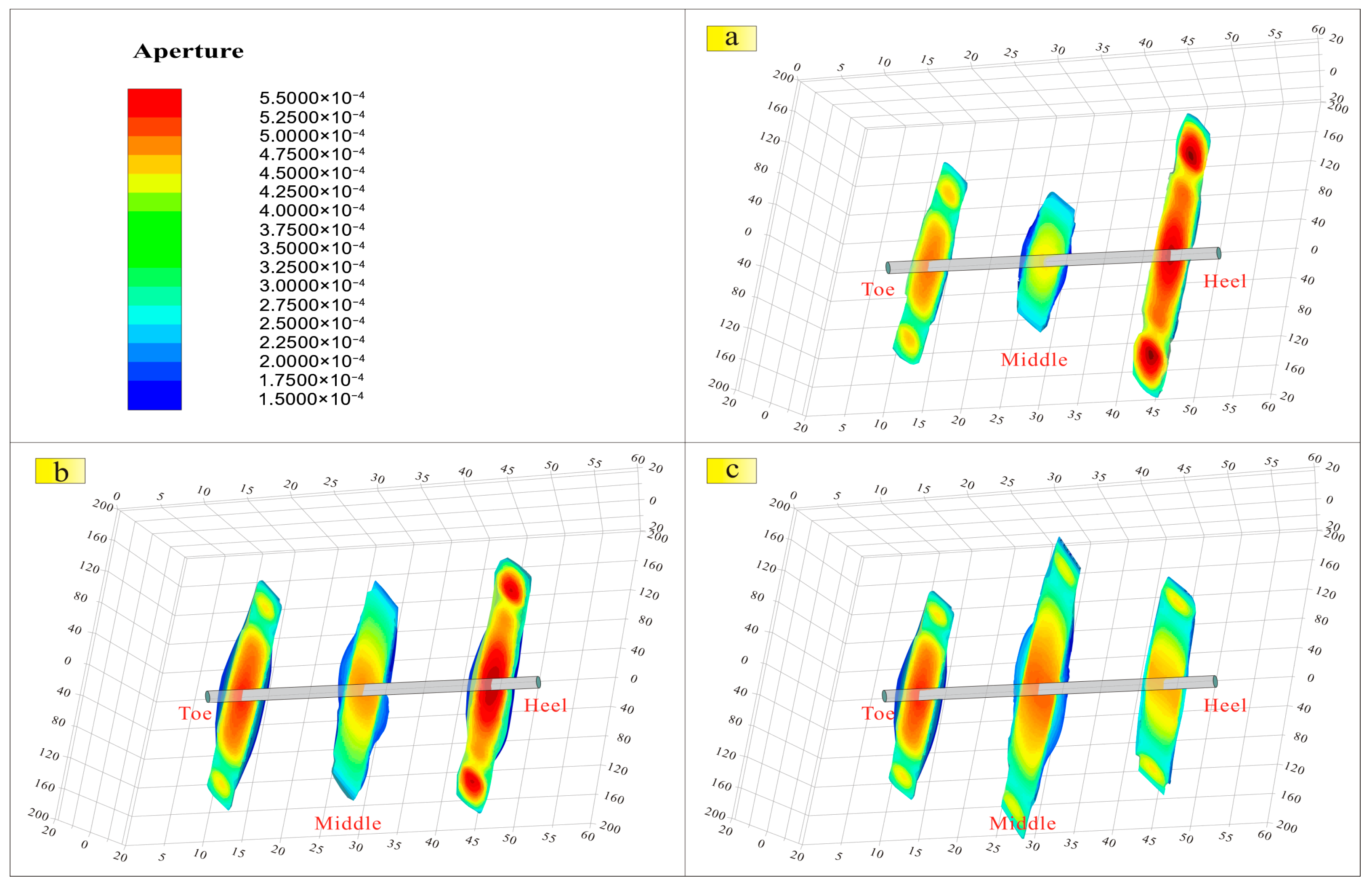

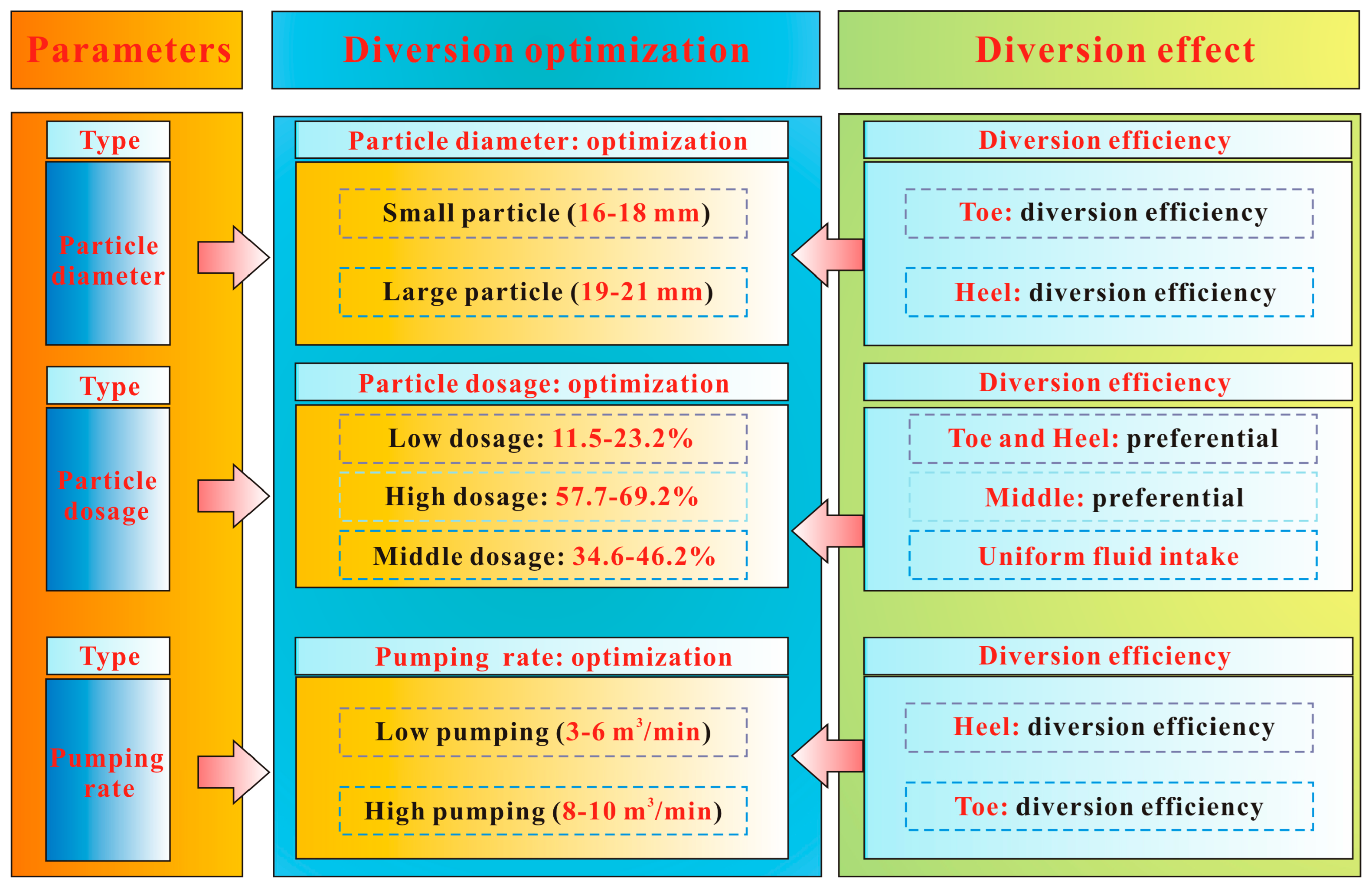

Effect of Diverters’ Particle Size on Fracture Plugging Efficiency

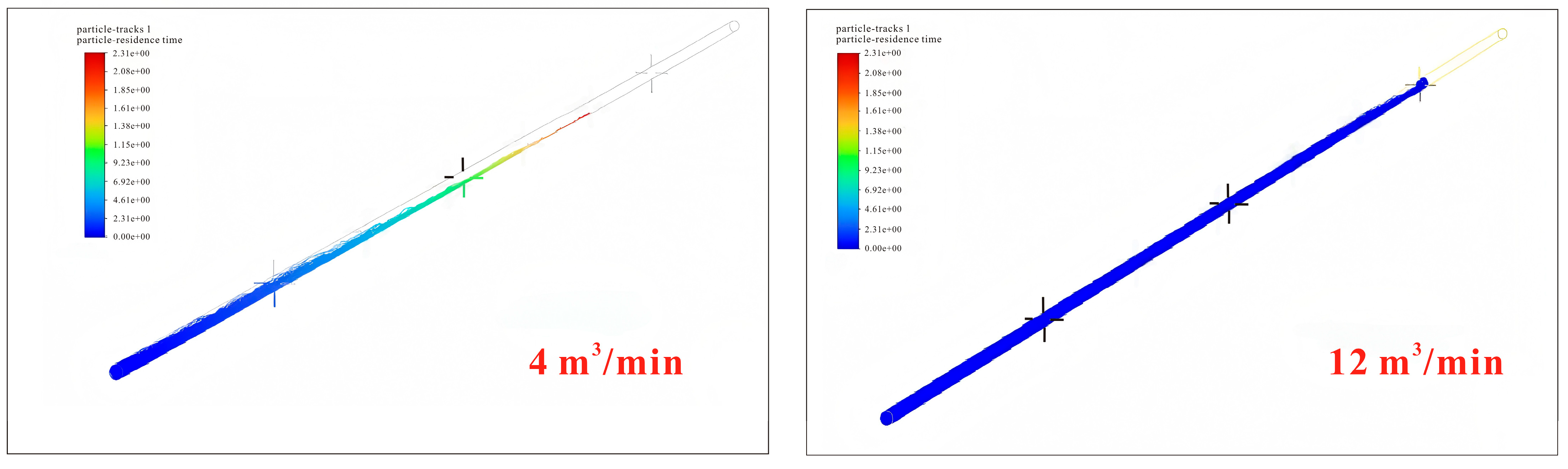

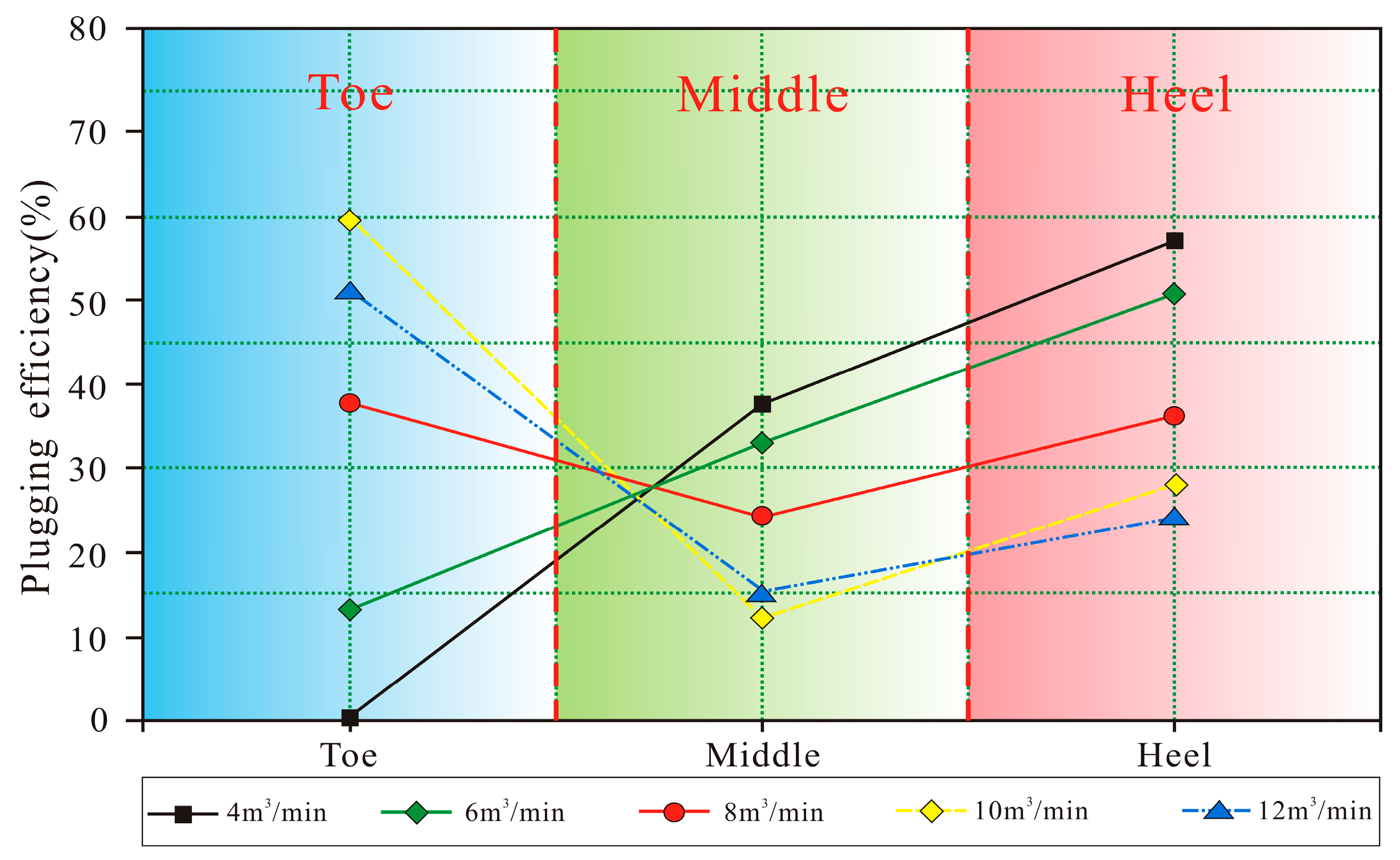

Effect of Pumping Displacements on Fracture Plugging Efficiency

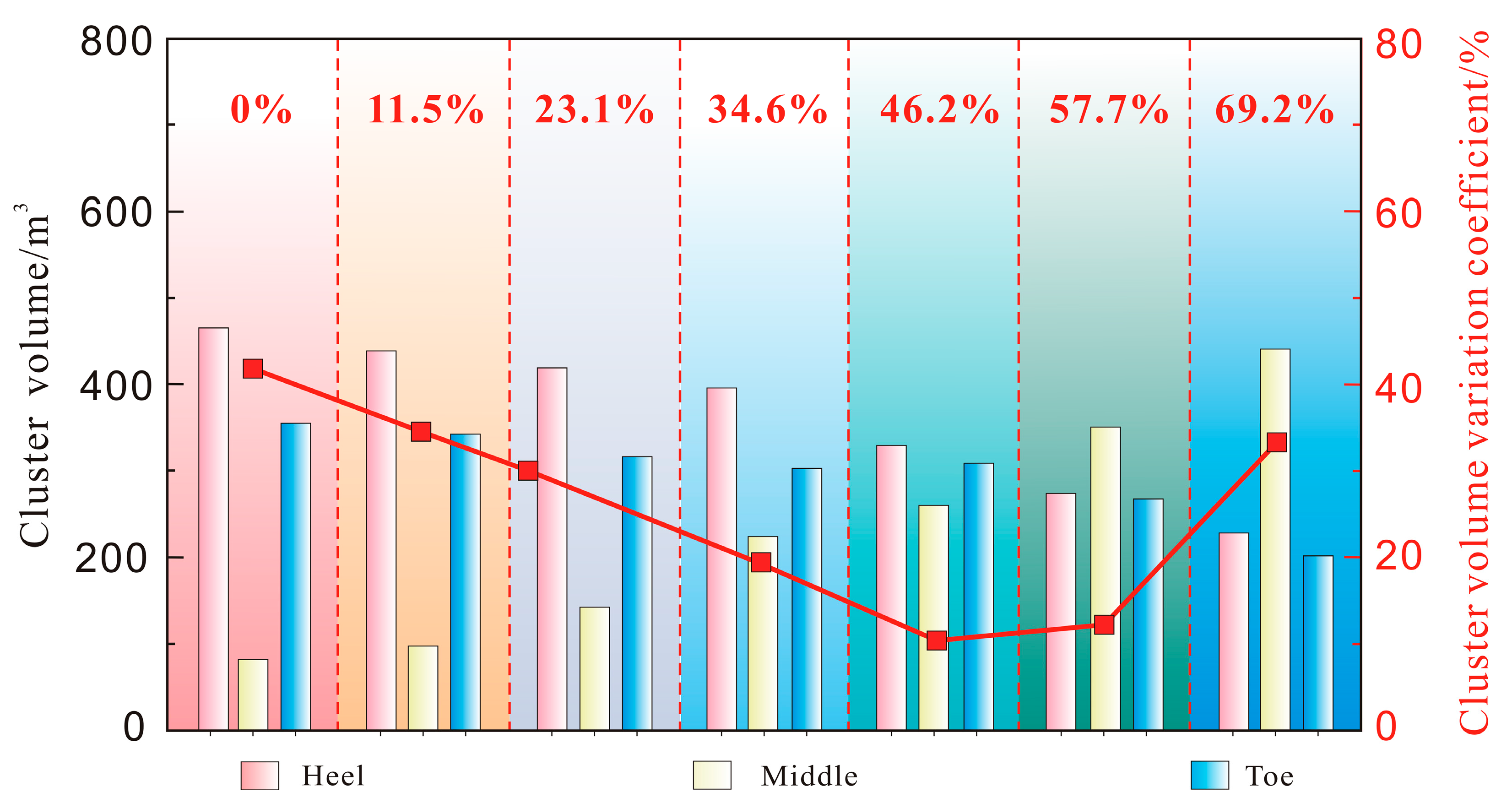

Effect of Diverting Particle Concentration on Fracture Plugging Efficiency

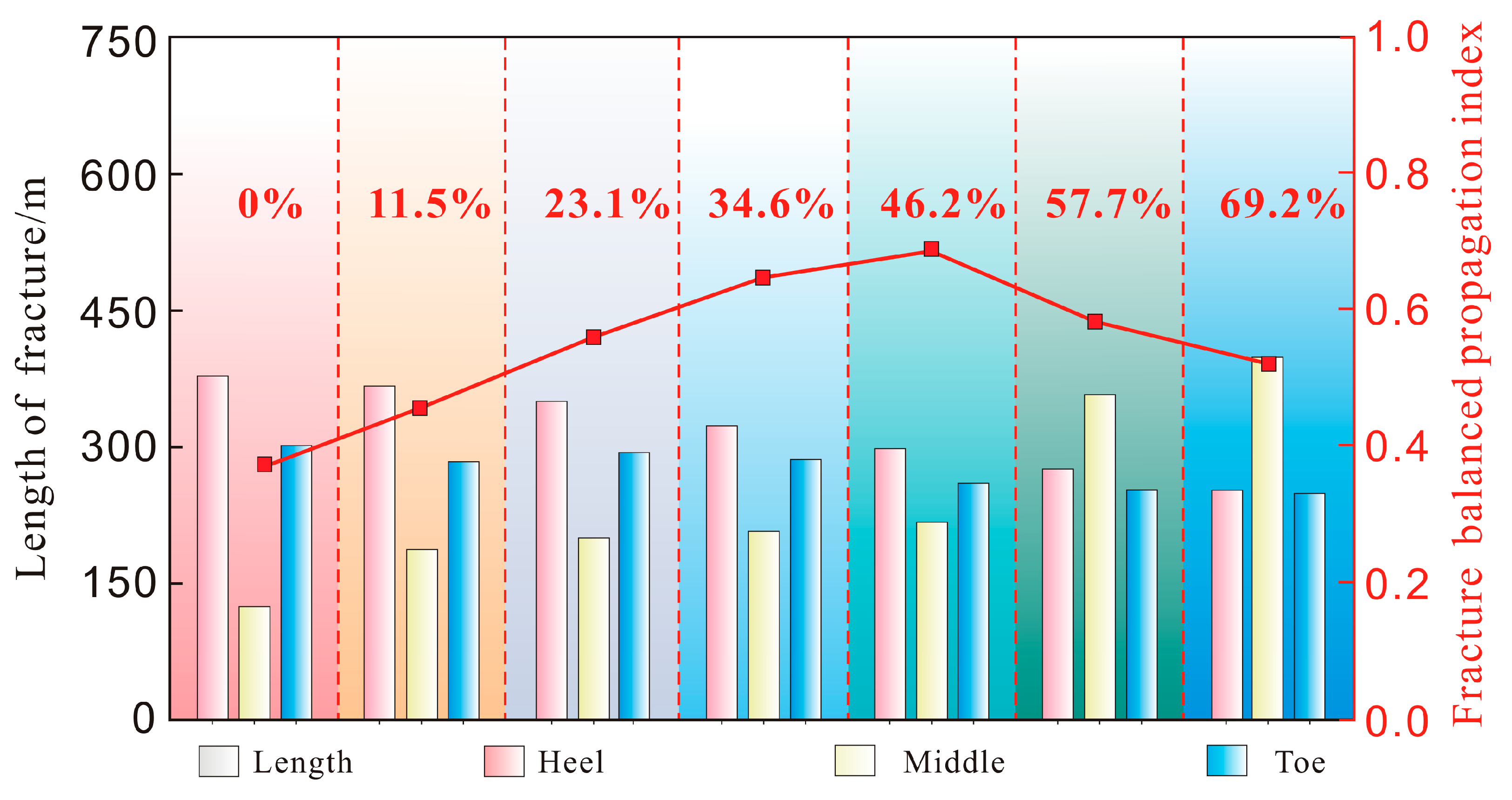

3.2.3. Optimizing Diverting Particle Efficiency Through Perforation Cluster Parametric

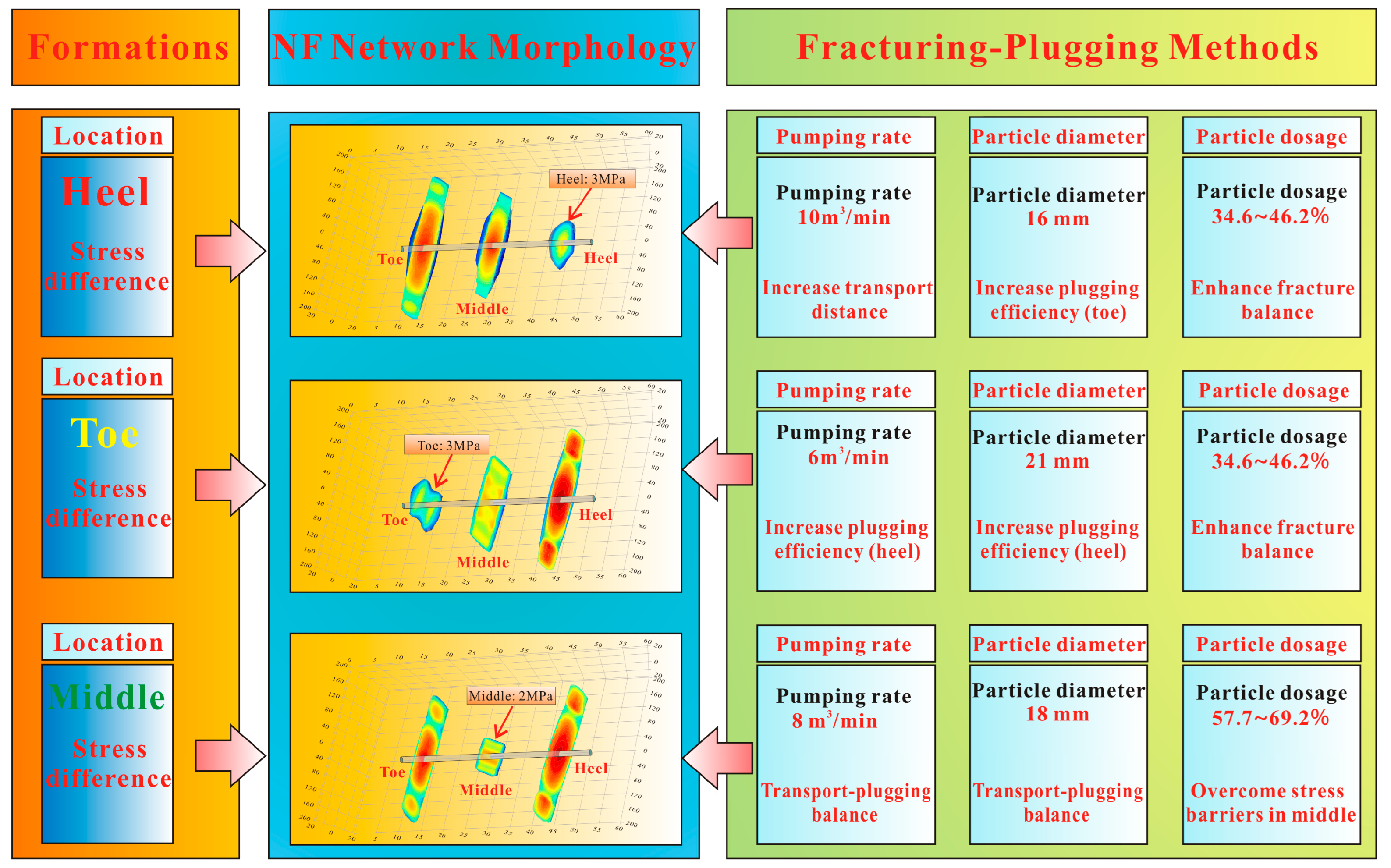

3.3. The Stress-Barrier-Responsive Diverting Fracturing Technology for CTD

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; Su, X.B.; Su, L.N.; Guo, H.Y.; Song, J.X.; Zhu, Z.L. Theory and application of pseudo-reservoir hydraulic stimulation for coalbed methane indirect extraction in horizontal well: Part 2, application. Nat. Resour. Res. 2020, 29, 3895–3915. [Google Scholar]

- Mu, F.Y.; Zhong, W.Z.; Zhao, X.L.; Che, C.B.; Chen, Y.P.; Zhu, J. Strategies for the development of CBM gas industry in China. Nat. Gas Ind. B 2015, 2, 383–389. [Google Scholar] [CrossRef]

- Crosdale, P.J.; Beamish, B.B.; Valix, M. Coalbed methane sorption related to coal composition. Int. J. Coal Geol. 1998, 35, 147–158. [Google Scholar] [CrossRef]

- Gu, J.Y.; Zhang, B.; Guo, M.Q. Deep coalbed methane enrichment rules and its exploration and development prospect in Linxing Block. J. China Coal Soc. 2016, 41, 72–79. [Google Scholar]

- Hou, S.H.; Wang, X.M.; Wang, X.J.; Yuan, Y.; Zhuang, X. Geological controls on gas saturation in the yan chuan nan coalbed methane field, southeastern Ordos basin, China. Mar. Pet. Geol. 2016, 78, 254–270. [Google Scholar] [CrossRef]

- Zhu, Q.; Du, X.; Zhang, T.; Yu, H.; Liu, X. Investigation into the variation characteristics and influencing factors of coalbed methane gas content in deep coal seams. Sci. Rep. 2024, 14, 18813. [Google Scholar] [CrossRef]

- Hou, X.; Liu, S.; Zhu, Y.; Yang, Y. Evaluation of gas contents for a multi-seam deep coalbed methane reservoir and their geological controls: In Situ direct method versus indirect method. Fuel 2020, 265, 116917. [Google Scholar] [CrossRef]

- Han, S.; Sang, S.; Liang, J.; Zhang, J. Supercritical CO2 adsorption in a simulated deep coal reservoir environment, implications for geological storage of CO2 in deep coals in the southern Qinshui Basin, China. Energy Sci. Eng. 2019, 7, 488–500. [Google Scholar] [CrossRef]

- Fathi, E.; Akkutlu, I.Y. Multi-component gas transport and adsorption effects during CO2 injection and enhanced shale gas recovery. Int. J. Coal Geol. 2014, 123, 52–61. [Google Scholar] [CrossRef]

- Bai, B.; Chen, M.; Jin, Y.; Wei, S.M.; Zheng, H.Y. The thermoporoelastic coupling analysis of wellbore stability in shale formation under supercritical CO2 drilling conditions. J. Pet. Sci. Eng. 2023, 220, 111146. [Google Scholar] [CrossRef]

- Ottiger, S.; Pini, R.; Storti, G.; Mazzotti, M.; Bencini, R.; Quattrocchi, F. Adsorption of pure carbon dioxide and methane on dry coal from the Sulcis coal province (SW Sardinia, Italy). Environ. Prog. 2010, 25, 355–364. [Google Scholar] [CrossRef]

- Xia, T.; Zhou, F.; Gao, F.; Kang, J.; Liu, J.; Wang, J. Simulation of coal self-heating processes in underground methane-rich coal seams. Int. J. Coal Geol. 2015, 141, 1–12. [Google Scholar] [CrossRef]

- Pini, R.; Ottiger, S.; Burlini, L.; Storti, G.; Mazzotti, M. Sorption of carbon dioxide, methane and nitrogen in dry coals at high pressure and moderate temperature. Int. J. Greenh. Gas Control 2010, 4, 90–101. [Google Scholar] [CrossRef]

- Billemont, P.; Coasne, B.; De, W.G. Adsorption of carbon dioxide, methane, and their mixtures in porous carbons: Effect of surface chemistry, water content, and pore disorder. Langmuir 2013, 29, 3328–3338. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Saipeng, H.; Jian, H.; Liu, X.; Huang, L.; Fang, C. Numerical Simulation of the Effect of Injected CO2 Temperature and Pressure on CO2-Enhanced Coalbed Methane. Appl. Sci. 2020, 10, 1385. [Google Scholar] [CrossRef]

- Fang, H.H.; Sang, S.X.; Liu, S.Q. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery. J. Pet. Sci. Eng. 2019, 181, 106177. [Google Scholar] [CrossRef]

- Ma, T.R.; Rutqvist, J.; Oldenburg, C.M.; Liu, W. Coupled thermal-hydrological-mechanical modeling of CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2017, 179, 81–91. [Google Scholar] [CrossRef]

- Liu, H.H.; Sang, S.X.; Xue, J.H.; Wang, G.; Xu, H.; Ren, B. Characteristics of an in-situ stress field and its control on coal fractures and coal permeability in the Gucheng Block, southern Qinshui basin, China. J. Nat. Sci. Eng. 2016, 36, 1130–1139. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Tang, D.; Mathews, J.P.; Zhai, Y.; Hou, W. The impact of the coal macrolithotype on reservoir productivity, hydraulic fracture initiation and propagation. Fuel 2019, 239, 471–483. [Google Scholar] [CrossRef]

- Zhang, D.; Yi, L.P.; Yang, Z.Z.; Zhang, J.Q.; Chen, G.; Yang, R.Y.; Li, X.G. A phase-field model for simulating the propagation behavior of mixed-mode cracks during the hydraulic fracturing process in fractured reservoirs. Appl. Math. Mech. 2024, 45, 911–930. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, D.; Xu, H.; Li, S.; Tao, S. The impact of coal macrolithotype on hydraulic fracture initiation and propagation in coal seams. J. Nat. Gas Sci. Eng. 2018, 56, 299–314. [Google Scholar] [CrossRef]

- Pei, P.; Ling, K.; He, J.; Liu, Z. Shale gas reservoir treatment by a CO2-based technology. J. Nat. Gas Sci. Eng. 2015, 26, 1595–1606. [Google Scholar] [CrossRef]

- Rexer, T.F.T.; Benham, M.J.; Aplin, A.C.; Thomas, K.M. Methane adsorption on shale under simulated geological temperature and pressure conditions. Energy Fuels 2013, 27, 3099–3109. [Google Scholar] [CrossRef]

- Zhou, F.; Hussain, F.; Cinar, Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation. Int. J. Coal Geol. 2013, 116, 53–62. [Google Scholar] [CrossRef]

- Liu, X.; Wu, C.; Zhao, K. Feasibility and applicability analysis of CO2-ECBM based on CO2-H2O-coal interactions. Energy Fuels 2017, 31, 9268–9274. [Google Scholar] [CrossRef]

- Chalmers, G.R.L.; Bustin, R.M. On the effects of petrographic composition on coalbed methane sorption. Int. J. Coal Geol. 2007, 69, 288–300. [Google Scholar] [CrossRef]

- Lu, J.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Kurz, B.; Smith, S. Advancing CO2 enhanced oil recovery and storage in unconventional oil play—Experimental studies on Bakken shales. Appl. Energy 2017, 208, S0306261917314654. [Google Scholar] [CrossRef]

- Charoensuppanimit, P.; Mohammad, S.A.; Robinson, R.L.; Gasem, K.A.M. Modeling the temperature dependence of supercritical gas adsorption on activated carbons, coals and shales. Int. J. Coal Geol. 2015, 138, 113–126. [Google Scholar] [CrossRef]

- Charrière, D.; Pokryszka, Z.; Behra, P. Effect of pressure and temperature on diffusion of CO2 and CH4 into coal from the Lorraine basin. Int. J. Coal Geol. 2010, 81, 373–380. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Sang, S.; Liu, D.; Wang, M.; Liu, S. Dynamic characterization of multiphase methane during CO2-ECBM: An NMR relaxation method. Fuel 2022, 324, 124526. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Yang, W.; Hong, Y.; Wang, Z. A fully coupled electromagnetic-thermal-mechanical model for coalbed methane extraction with microwave heating. J. Nat. Gas Sci. Eng. 2017, 46, 830–844. [Google Scholar] [CrossRef]

- Teng, T.; Zhao, Y.; Gao, F.; Wang, J.G.; Wang, W. A fully coupled thermo-hydro-mechanical model for heat and gas transfer in thermal stimulation enhanced coal seam gas recovery. Int. J. Heat Mass Transf. 2018, 125, 866–875. [Google Scholar] [CrossRef]

- Weng, X.; Kresse, O.; Cohen, C. Modeling of Hydraulic-Fracture-Network Propagation in a Naturally Fractured Formation. SPE Prod. Oper. 2011, 26, 368–380. [Google Scholar]

- Cohen, C.; Kresse, O.; Weng, X. Stacked Height Model to Improve Fracture Height Growth Prediction, and Simulate Interactions with Multilayer DFNs and Ledges at Weak Zone Interfaces. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2017. SPE-184876-MS. [Google Scholar]

- Ren, X.; Zhou, L.; Zhou, J.; Lu, Z.; Su, X. Numerical Analysis of Heat Extraction Efficiency in a Multilateral-Well Enhanced Geothermal System Considering Hydraulic Fracture Propagation and Configuration. Geothermics 2020, 87, 101834. [Google Scholar] [CrossRef]

- Crouch, S. Solution of Plane Elasticity Problems by the Displacement Discontinuity Method. I. Infinite Body Solution. Int. J. Numer. Methods Eng. 1976, 10, 301–343. [Google Scholar] [CrossRef]

- Mukherjee, S. Boundary Element Methods in Solid Mechanics—A Tribute to Frank Rizzo; George Allen & Unwin: London, UK, 1983; pp. 97–99. [Google Scholar]

- He, P. Simulation Study on Inter-Well Fractures During Simultaneous Fracturing. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2016. [Google Scholar]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

| Category | Parameter | Value | Acquisition Approach |

|---|---|---|---|

| Coal properties | Tensile strength (MPa) | 2.29 | Experimental value |

| Elasticity modulus (GPa) | 4.87 | Experimental value | |

| Poisson’s ratio | 0.25 | Experimental value | |

| Cohesive strength (MPa) | 0.418 | Experimental value | |

| Friction angle (°) | 18.13 | Experimental value | |

| Reservoir Properties | Initial pore pressure (MPa) | 7.85 | Field data |

| Permeability (mD) | 0.15 | Experimental value | |

| Porosity (%) | 3 | Experimental value | |

| Density (g/cm3) | 1.53 | Experimental value | |

| Geostress distribution | Minimum horizontal stress (MPa) | 14.47 | Field data (well testing) |

| Maximum horizontal stress (MPa) | 20.53 | Field data (well testing) | |

| Vertical stress (MPa) | 18.21 | Field data (well testing) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhen, H.; Gao, E.; Li, S.; Ge, T.; Wei, K.; Liu, Y.; Wang, A. Stress-Barrier-Responsive Diverting Fracturing: Thermo-Uniform Fracture Control for CO2-Stimulated CBM Recovery. Processes 2025, 13, 2855. https://doi.org/10.3390/pr13092855

Zhen H, Gao E, Li S, Ge T, Wei K, Liu Y, Wang A. Stress-Barrier-Responsive Diverting Fracturing: Thermo-Uniform Fracture Control for CO2-Stimulated CBM Recovery. Processes. 2025; 13(9):2855. https://doi.org/10.3390/pr13092855

Chicago/Turabian StyleZhen, Huaibin, Ersi Gao, Shuguang Li, Tengze Ge, Kai Wei, Yulong Liu, and Ao Wang. 2025. "Stress-Barrier-Responsive Diverting Fracturing: Thermo-Uniform Fracture Control for CO2-Stimulated CBM Recovery" Processes 13, no. 9: 2855. https://doi.org/10.3390/pr13092855

APA StyleZhen, H., Gao, E., Li, S., Ge, T., Wei, K., Liu, Y., & Wang, A. (2025). Stress-Barrier-Responsive Diverting Fracturing: Thermo-Uniform Fracture Control for CO2-Stimulated CBM Recovery. Processes, 13(9), 2855. https://doi.org/10.3390/pr13092855