1. Introduction

The strategic deployment involved in achieving peak carbon emissions and carbon neutrality has laid a solid policy foundation and created a favorable development environment for the adjustment of China’s energy structure [

1,

2]. Distributed photovoltaic systems featuring cleanliness, pollution-free operation, flexible scale adjustment, high system safety, and excellent peak-regulating performance have consequently become a core component of China’s renewable energy system in recent years [

3].

In power system research, the concept of “cluster”—defined as a logical aggregation of multiple functionally similar components—has been widely adopted to manage the complexity introduced by distributed energy integration. Reference [

4] pioneered the application of the cluster concept to power systems, defining it as a network structure integrating generation, storage, consumption, and distribution units to ensure grid stability. Building upon this, Reference [

5] specifically proposed a distributed energy cluster framework for distribution networks, emphasizing that clusters possess inherent power balance capabilities and intra-cluster communication functions, such as the capacity to coordinate power redistribution to mitigate voltage violations through internal power flow management. However, the continuous expansion of distributed photovoltaic integration into distribution networks has concurrently exposed significant technical challenges. These include difficulties in the local consumption of renewable energy, issues with power reverse flow, increased network losses, and violations of voltage limits [

6,

7]. Such problems not only undermine the operational reliability of distribution networks but also restrict the efficient utilization of new energy sources, making the development of systematic planning strategies an urgent priority [

8].

Current research addressing these challenges through cluster partitioning primarily focuses on two dimensions: evaluation metrics and methodological approaches. Regarding metrics, studies such as Reference [

9] utilize intra/inter-cluster electrical distance calculations, while Reference [

10] suggests incorporating factors like regulation costs, response characteristics, and geographic location. Common partitioning methods involve clustering and optimization algorithms, with References [

11,

12,

13] applying techniques like partitioning clustering, affinity propagation, and Fast Unfolding algorithms to distributed energy clustering, respectively. Furthermore, effective cluster partitioning for operational optimization must align with dispatch center requirements concerning new energy utilization efficiency and network loss control, necessitating pre-optimization of the DPV cluster output [

14]. Strategies have been proposed to optimize new energy output, such as coordinated dispatch for wind–solar–thermal-storage systems [

15], combining new energy consumption with economic costs using flexible resources [

16], and balancing grid operational economy with new energy utilization through energy-storage allocation [

17].

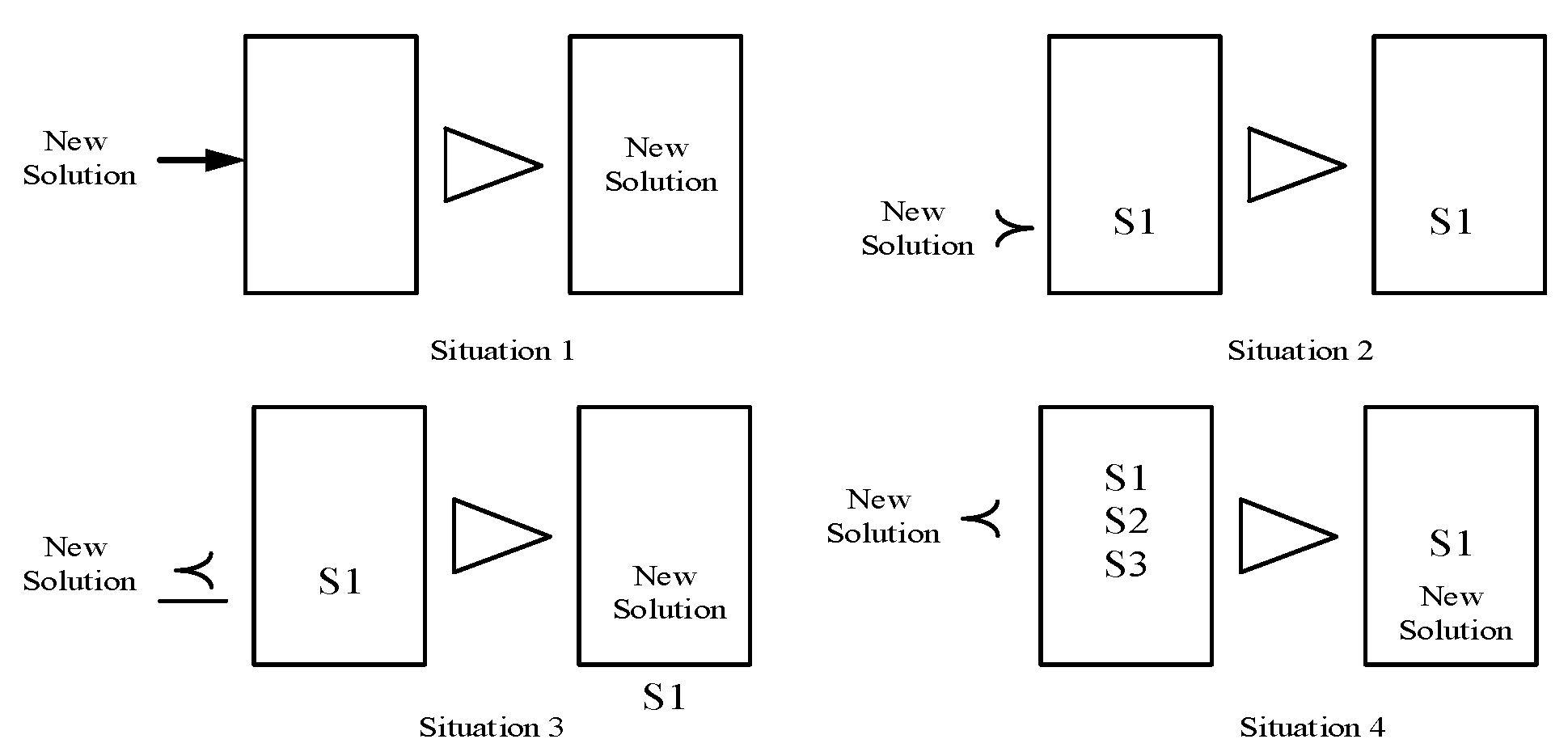

In recent years, a large number of studies have adopted bi-level optimization models for distribution network planning with DPV and ESS. Reference [

18] constructed a bi-level programming model considering the demand response of the user side. The upper layer selected the location and capacity of the distributed power supply, and the lower layer considered the operation of the energy-storage device, which realized the joint planning of the source and storage. In Reference [

19], the double-layer nested particle-swarm optimization algorithm was used to optimize the capacity and location of photovoltaic and energy storage with the goal of minimizing the annual comprehensive cost and network loss, which effectively improved the proportion of photovoltaic consumption. In Reference [

20], the cost objectives of the microgrid and distribution network are considered in the upper and lower layers, respectively, through the bi-level optimal configuration method, and the feasibility of the model is verified by practical examples. Based on time-of-use electricity price, a bi-level optimization model, with photovoltaic consumption rate and voltage deviation as the objectives, is established in [

21], and solved by parallel double quantum differential evolution algorithm. Overall, the existing studies address the joint planning of distributed photovoltaics and energy storage from various perspectives, effectively mitigating the adverse impacts of high PV penetration. However, most works neglect the role of cluster division and its correlation with network operation, leading to incomplete analysis and results. Hence, it is necessary to further investigate joint PV–storage optimization models that incorporate cluster division in both the planning and operation stages.

Despite existing advancements, research on decentralized solar–storage hybrid systems in distribution networks still exhibits notable limitations. Cluster partitioning metrics often focus excessively on electrical connectivity while neglecting critical aspects such as power balance and scale rationality, resulting in poor coordination between nodes within clusters. Additionally, insufficient integration between the planning and operational optimization phases hinders the ability to simultaneously address both economic efficiency and technical performance in the configuration of DPV and energy-storage systems. To address these gaps, this study proposes a comprehensive solution that tackles both the planning and operational challenges of distributed photovoltaic andenergy-storage systems in distribution networks. First, we develop a detailed cluster partitioning index that accounts for multiple factors: modularity based on electrical distance, active and reactive power balance metrics, and node affiliation for scale control. The Fast-Newman Algorithm is enhanced with a net-power constraint to achieve more rational clustering of the distribution network. Second, we propose a bi-level configuration model for the joint planning and operation of DPV and ESS systems. The first planning layer optimizes the siting and sizing of DPV and ESS units to minimize annualized costs, while the second operation layer refines ESS operation strategies, balancing multi-objective trade-offs such as voltage deviation suppression, loss reduction, and PV utilization maximization, using an adaptive multi-objective particle-swarm optimization algorithm.

To bridge the gap between planning and operation, we integrate the two via a bi-directional information flow: the planning layer proposes siting and sizing candidates, along with associated cost parameters, and the operation layer evaluates these candidates under voltage-deviation, network loss, and PV-utilization objectives, returning performance signals to guide subsequent planning iterations. This bi-level approach effectively closes the planning–operation gap, ensuring that investment decisions reflect both operational feasibility and benefits.

2. Metrics and Algorithms for Distribution Network Clustering

2.1. Cluster Division Principle

Incorporating distributed power sources into cluster divisions necessitates adaptation to dynamic operational conditions. To ensure the reliability and practicality of division outcomes, clusters must meet both logical and functional criteria. This paper explores the integration of high-penetration distributed photovoltaic systems into a typical distribution network through cluster division. In addition to the conventional logical and structural requirements, the uneven distribution of photovoltaic capacity necessitates the use of a power balance index to define clusters, thereby enhancing node coordination. Consequently, this investigation applies modularity depending on electrical distance and power balance aspects, whereas the scale index is integrated to limit the cluster size.

2.2. Cluster Division Indicators

2.2.1. Modularity Index Derived from Electrical Distance

The process of cluster division must consider the electrical connectivity between nodes. Electrical distance assesses the magnitude of electrical coupling between nodes, hence denoting the level of their electrical interconnection. Depending on its definition, electrical distance offers a quantitative assessment of the strength of electrical parameter linkages between nodes, making it a widely used metric for evaluating electrical coupling. Electrical distance is typically calculated using either impedance or sensitivity methods. However, as impedance is a static parameter reflecting fixed network configuration and fails to capture dynamic network characteristics, this paper employs sensitivity to compute electrical distance, using the following formulas:

It is assumed that there are

n nodes in the network, and the Euclidean distance is applied to define the electrical separation

eij between node

i and node

j:

Furthermore, to quantify intra-cluster cohesion and inter-cluster separation, modularity—a partitioning metric based on electrical distance—is introduced. First proposed by Girvan and Newman [

22], modularity quantifies the strength of community structures in complex networks. This metric inherently accounts for intra-cluster versus inter-cluster connection density, cluster size, and cluster count. Modularity is calculated as shown in Equation (5).

where

ρm is the modularity metric;

Aij is the weight of the edge connecting vertex

i and node

j;

m represents the total edge weight of the network graph;

S is the set of system nodes;

κi represents the weighted degree of centrality of node

i, defined as the summation of all edge weights incident to node

i; and

δ(

i,

j) is the cluster discrimination function.

The edge weight

Aij and electrical distance

eij satisfy the following relation:

where max (

eij) represents the largest element in the electrical distance matrix

eij.

And, the modularity index quantitatively measures the quality of cluster division in power networks. A higher modularity index signifies tighter electrical connections among nodes within a cluster and looser connections between clusters, indicating stronger structural strength and a more reasonable division plan. Therefore, maximizing the modularity ρm can lead to the optimal cluster division plan.

2.2.2. Cluster Power Balance Metrics

Functionally, the active balance degree is employed as a cluster division metric to minimize inter-cluster active power flows and maximize self-consumption capacity, thereby reducing solar power curtailment. A higher value signifies stronger supply–demand matching within clusters, which mitigates photovoltaic output uncertainty and volatility. The active balance degree is defined as follows:

where

Pk signifies the active power balance value of the c-th cluster;

Nk is the quantity of clusters

k;

Pk,t represents the net power balance for microgrid cluster

k during time interval

t;

T is the system simulation time period; and

φP is the active balance degree index of the cluster. Degree of active balance

φP aims to balance the net power complementary level between nodes in the network to achieve the effect of fully utilizing the cluster autonomy.

Likewise, the cluster reactive power balance degree metric is formulated as

In the formula,

φQ refers to the cluster reactive power balance index;

Qneed and

Qsup refer to the demand value of the reactive power and the maximum value of reactive power supply inside the cluster.

It should be noted that there is a fundamental distinction between the demand value of reactive power and the reactive power supply. Qneed is determined by the reactive requirements of loads within the cluster and represents an inflexible demand that must be satisfied to maintain voltage stability. In contrast, Qsup denotes the maximum available reactive power support from resources such as PV inverters, ESS inverters, and compensation devices, which are constrained by their technical limits. Therefore, the reactive power balance index reflects the extent to which internal resources can meet the demand, and the difference between Qneed and Qsup directly indicates the remaining reactive support that must be compensated externally.

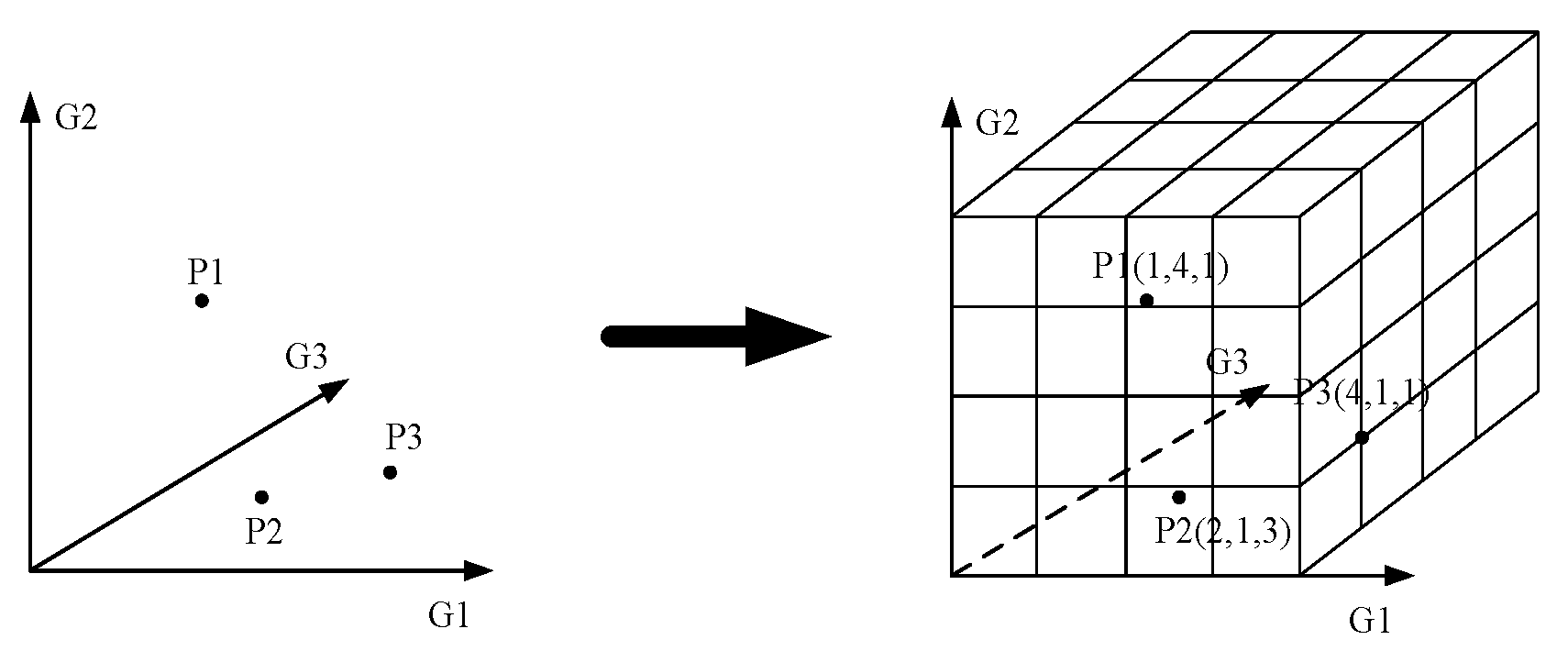

2.2.3. Node Affiliation Metrics

Balanced sub-cluster sizing significantly impacts subsequent optimization and control feasibility. Size-uniform clusters reduce optimization model complexity, accelerate solution times, and maintain consistent mathematical dimensionality in cluster architectures. Consequently, appropriate cluster sizing is essential for operational efficacy. The

αP indicates the strength of mutual influence among nodes within a sub-zone, which helps balance the number of nodes and photovoltaic installations. The range of values is [0, 1), with a larger

αP signifying a more rational sub-zone. The

βP represents the strength of mutual influence between different nodes within a sub-zone, preventing the unreasonable sub-zone configurations that occur due to imbalanced node and photovoltaic installation numbers. The value interval is (0, 1], with a lower

βP denoting a more rational sub-zone. To evaluate post-partition size distribution, this work proposes the scale sensitivity index

φM.

where

n represents the cardinality of the partition set; Φ

k denotes the bus set in control area

k;

Rk represents the count of nodes in cluster

k; and

N represents the total number of nodes.

2.2.4. Comprehensive Performance Indicators

Both the modularity and the power balance indices range between 0 and 1. Higher modularity values indicate stronger intra-cluster electrical coupling. Similarly, a higher active power balance index reflects minimized net power exchange with external clusters and enhanced self-consumption capability. To holistically evaluate cluster performance, we propose the following comprehensive index formula:

In the formula,

ω1,

ω2,

ω3, and

ω4 are the weights of degree index, active power balance index, reactive power balance index, and node membership function, which satisfy 0 ≤

ω1,

ω2,

ω3,

ω4 ≤ 1, and the sum of them is 1.

During cluster delineation, decision-makers may assign varying weights to each performance indicator according to specific operational priorities. This flexibility enables tailored partitioning outcomes aligned with distinct optimization objectives. In this study, the weights (

ω1,

ω2,

ω3, and

ω4) are determined using the analytic hierarchy process (AHP) [

23], which combines expert judgment and pairwise comparison to reflect the relative importance of modularity, active power balance, reactive power balance, and node scale uniformity. For the case study, an equal weighting scheme (

ω1 =

ω2 =

ω3 =

ω4 = 1/4) is adopted to ensure fairness among different indicators and to avoid bias toward a single criterion. To validate the robustness of this choice, a sensitivity analysis was conducted by varying the weights within ±20%. As shown in

Table 1, the equal-weight scheme yields the highest comprehensive index

φ, while other perturbed weight combinations result in only minor decreases (within 2%). This confirms that the equal-weight approach is both reasonable and practical, while the framework remains flexible to accommodate different weighting strategies in future applications, depending on operator priorities.

2.3. Distribution Network Clustering Method

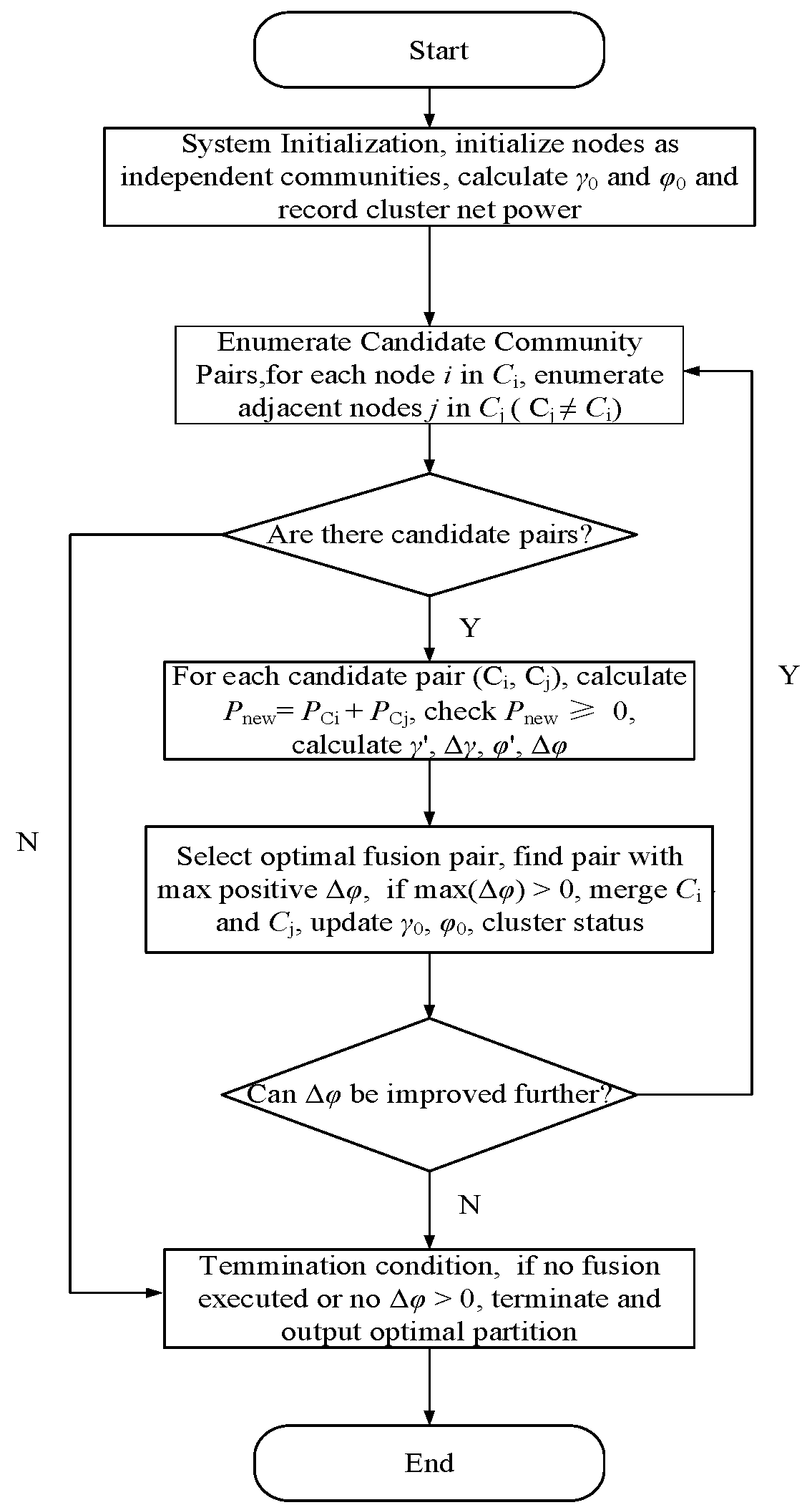

The cluster partitioning adopts an improved fast-Newman community detection (FN-CD) algorithm that selects fusion pairs. The complete algorithm procedure is presented in

Figure 1, with implementation details as follows:

Step 1: System Initialization: Treat each node as an independent community. Calculate the comprehensive electrical distance γ0 (an overall indicator reflecting the strength of electrical association between clusters under the initial partition, calculated by integrating parameters such as branch impedance and voltage sensitivity; smaller values indicate tighter electrical connections between clusters) and the comprehensive index φ0. Meanwhile, record the nodes contained in each community and their net power (based on node load and distributed PV output).

Step 2: Candidate Community Pair Evaluation: Iterate over all neighboring community pairs (Cᵢ, Cⱼ) and perform the following operations. (a.) Compute the merged net power: Pnew = PCi + PCj. (b.) In the net power constraint check, if Pnew < 0, skip this candidate pair. (c.) Simulate merging Cᵢ and Cⱼ into a new community Cᵢⱼ. (d.) Calculate the new comprehensive index φ′ under the updated partition. (e.) Compute the comprehensive index gain, Δφ = φ′ − φ0.

Step 3: Select the Best Merge: From all candidate pairs that satisfy the net power constraint, select the community pair with the maximum Δφ. If max (Δφ) > 0, formally merge the selected pair and update the community structure, net power, and network indicators (γ0 = γ′, φ0 = φ′).

Step 4: Termination Check: If no feasible community pair exists that yields Δφ > 0, the algorithm terminates and returns the current partition with the highest comprehensive index.

Step 5: Output: Return the final community partition result.

Figure 1.

Flow chart of the cluster partition algorithm.

Figure 1.

Flow chart of the cluster partition algorithm.

The pseudocode of the algorithm is shown in Algorithm 1.

| Algorithm 1. Improved Fast-Newman Community Detection (FN-CD) Algorithm |

Input: Distribution network graph G (N, E)

Output: Optimal community partition C*

Step 1: Initialization

Treat each node as an independent community

Compute initial comprehensive electrical distance γ0

Compute initial comprehensive index φ0

Record nodes and net power of each community

Step 2: Candidate Community Pair Evaluation

For each neighboring community pair (Ci, Cj):

a. Compute merged net power P_new = PCi + PCj

b. If Pnew < 0, skip this pair

c. Simulate merge to form Cij

d. Calculate new comprehensive index φ′

e. Compute index gain Δφ = φ′ − φ0

Step 3: Best Merge Selection

From feasible pairs, select (Ci, Cj) with maximum Δφ

If max (Δφ) > 0:

Perform formal merge of (Ci, Cj)

Update community structure, net power, γ0 ← γ′, φ0 ← φ′

Step 4: Termination Check

If no feasible pair yields Δφ > 0, terminate

Return the partition with maximum φ

Step 5: Output

Return final optimal community partition C* |

The FN-CD algorithm is selected in this study because it maximizes modularity while maintaining relatively low computational complexity, which makes it suitable for large-scale and sparse distribution networks. Compared with K-means, spectral clustering, or affinity propagation methods, the FN-CD algorithm does not require predefining the number of clusters and is capable of automatically detecting community structures that align with electrical connectivity. This property is particularly valuable in distribution systems, in which the underlying network topology and electrical distance dictate natural groupings.

In the implementation, each node is initially treated as an independent cluster, and the modularity index is calculated based on electrical distance. Candidate cluster pairs are then iteratively merged according to the maximum improvement in the comprehensive index, while a net power balance constraint is applied to ensure that each merged cluster maintains a feasible active power exchange. The algorithm terminates when no further positive modularity gain can be achieved, and the division with the highest comprehensive index is selected as the final clustering result. This process ensures that the derived clusters exhibit strong intra-cluster electrical coupling, balanced power distribution, and rational scale, thereby providing a solid foundation for subsequent optimization and control.

4. Practical Examples of the System and Result Analysis

4.1. Example Overview and Parameters

The configuration of energy storage in the cluster can improve the self-healing ability of the system, and the nodes in the cluster have high degrees of coupling and strong correlation. The cluster configuration energy storage divided by the cluster comprehensive division index can effectively coordinate the planning. An example of the analysis was conducted using the IEEE 33-node test system to verify its effectiveness and rationality. The simulation environment is based on Matlab2021a software. A comparison of modularity index grounded in electrical distance and cluster division considering multiple cluster division indicators, the cluster division algorithm adopts the improved FN-CD cluster division algorithm proposed. The weight of the cluster comprehensive division index is

ω1 =

ω2 =

ω3 =

ω4 = 1/4, and the cluster division result is presented in

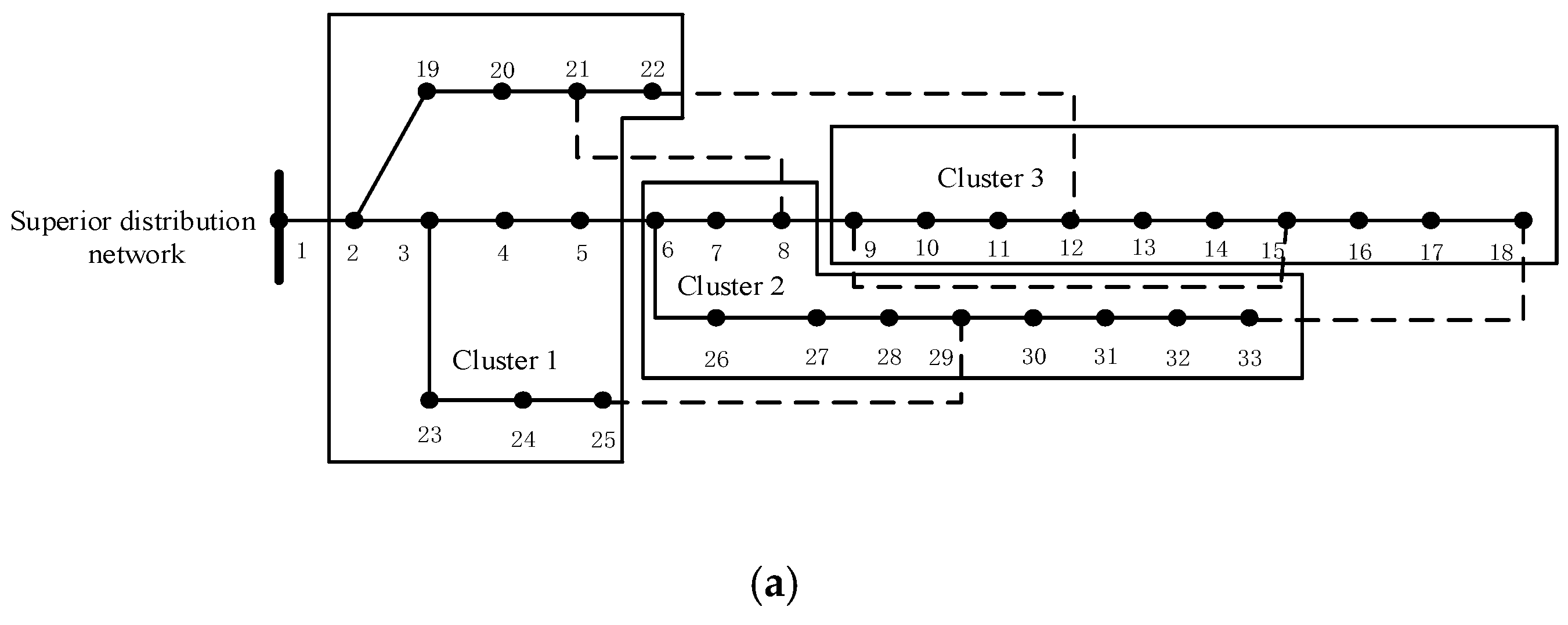

Figure 6.

In

Figure 6a, when the modularity index rooted in electrical distance serves for cluster division, it only considers the structure between nodes for cluster division, dividing into three clusters with a relatively average number of nodes in each cluster, which reflects the strong structure within the clusters and centers around the electrical coupling intensity among nodes. However, the cluster scale is large and the regional span is large. When classifying distribution network clusters based on comprehensive performance indicators, a total of four clusters were identified, making the scale distribution of the clusters more reasonable. Under the premise of having a strong structural structure, it also has good power matching within its cluster.

In

Figure 6, branch 1–2 is the main network connection branch; branches 4–5, 12–13, and 6–26 are inter-group branches; the dotted line is the tie-line. When integrating DPV, the power factor is set to 0.89 (lagging) under normal operation, meaning the inverters are capable of injecting reactive power to support the grid voltage. It is noteworthy that modern PV and ESS inverters can provide reactive power support and operate with a variable power factor. While the base case in this study assumes a fixed power factor to simplify the initial analysis, the proposed framework is capable of incorporating variable power factor control as an additional decision variable in the operational layer to further minimize voltage deviations. Reactive power compensation devices are connected at nodes 17 and 32, with capacities of 0.40 Mvar and 0.60 Mvar, respectively. Except for node 1, which is a power source, all nodes are load nodes.

At the planning level, particles are randomly generated for the location and capacity of the DPV and ES. In this example, four DPV units and four ES units are connected. The typical daily load curve is presented in

Figure 7, and the PV output is based on a typical scenario from a specific location, as illustrated in

Figure 8.

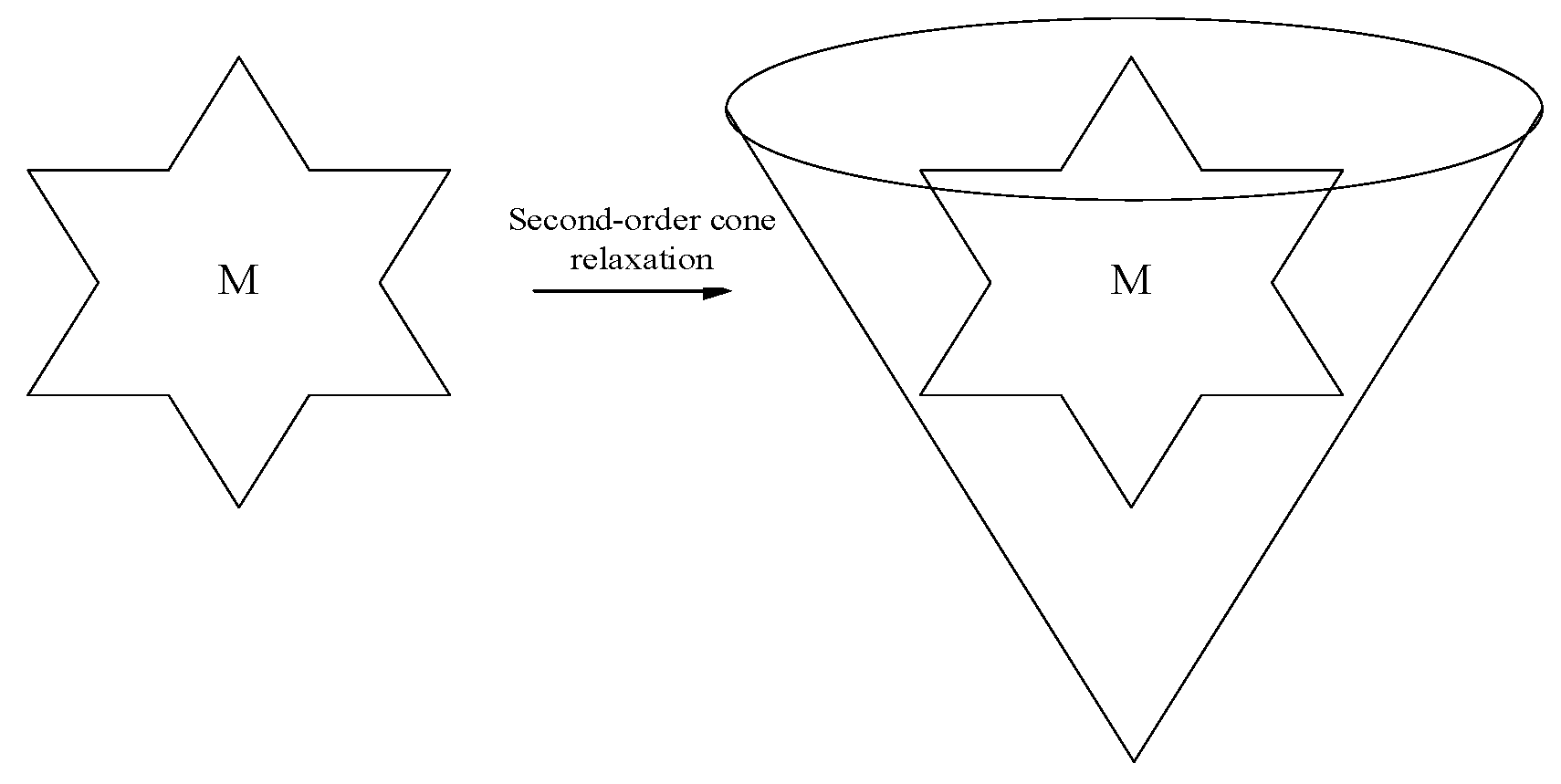

The system-related parameters are set as below: the DPV access nodes selected are 8, 14, 15, 19, and 24, with a maximum light rejection rate of 10%. The energy-storage nodes are chosen based on the system cluster division positions. The first-level particle population size is assigned a value of one hundred, with a maximum iteration count of one hundred, and the individual factor and learning factor are both set to 1.5. For the second-level multi-objective adaptive grid particle-swarm optimization algorithm, the inertia weight is set to 0.85, the population size is one hundred, the maximum iteration count is 100, the external archive limit is one hundred, the individual factor is 1.5, and the group factor is 2. When solving with the second-order cone hybrid algorithm, the planning layer parameters remain the same as above. The second-level multi-objectives use the AHP method to determine the multi-objective weights, and the daily scheduling strategy for the ESS is solved using second-order cone programming. The planning layer still utilizes the IPSO algorithm, while the second-level operational layer employs the Gurobi commercial solver for the solution.

In this paper, the distribution network system model implements the time-sharing electricity purchase price and sale price shown in

Table 4 below. The unit electricity policy subsidy is 0.10 USD/(kW-h).

The parameters relating to DPV and energy storage are presented in

Table 5 and

Table 6.

4.2. Case Results and Case Comparison Analysis

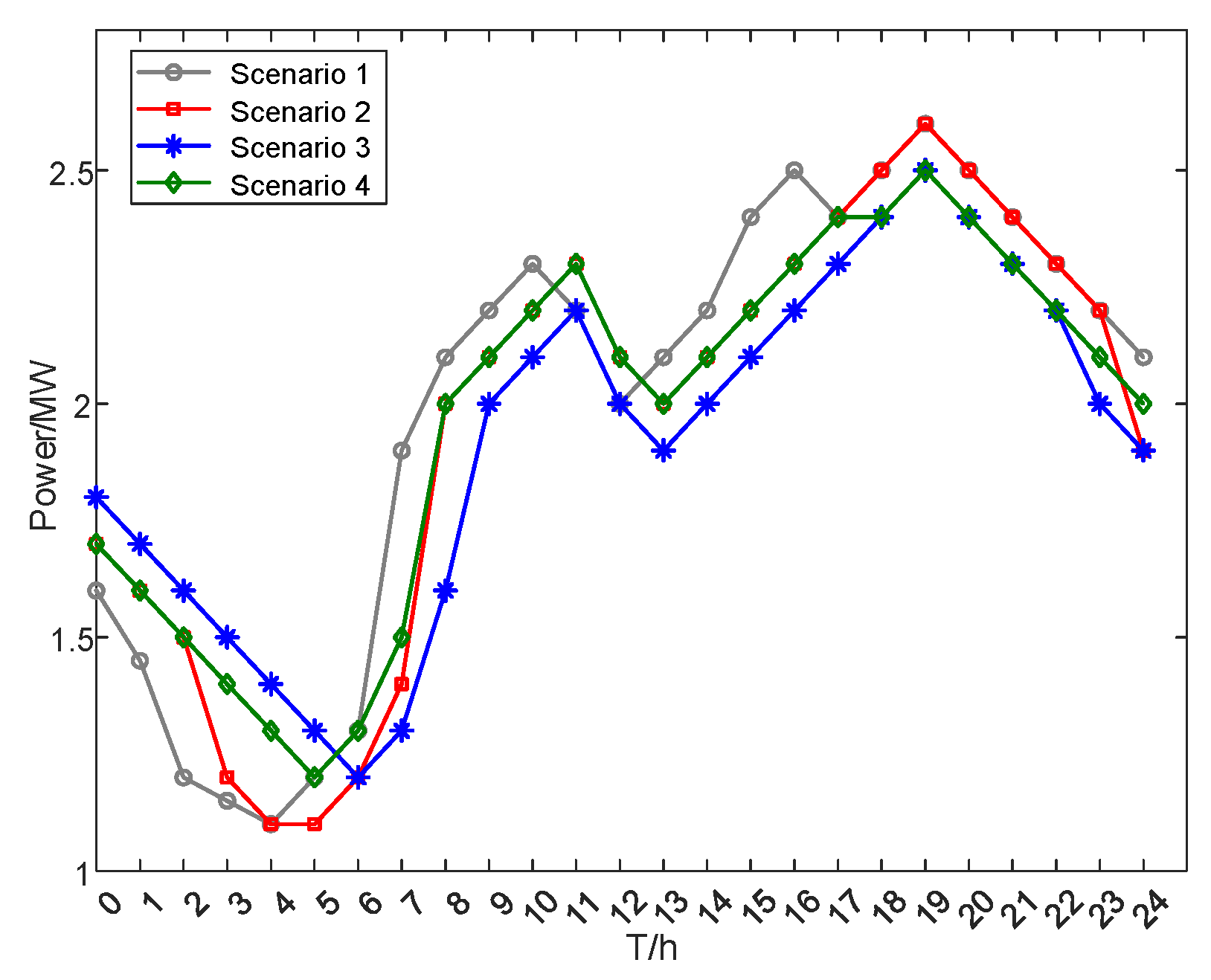

To reasonably validate the model and solution method of this chapter, four scenarios can be set for comparative analysis:

- (1)

Scenario 1: No consideration of DPV or energy-storage access (not planned);

- (2)

Scenario 2: Consider the access of DPV, but not the access of energy storage;

- (3)

Scenario 3: Considering the access of DPV and ESS, the joint access of DPV + ESS is considered, and the double-layer improved algorithm is applied to solve it;

- (4)

Scenario 4: Considering the integration of DPV and ESS, the DPV + ESS joint access is implemented using an improved hybrid algorithm that combines particle-swarm optimization with second-order cone programming.

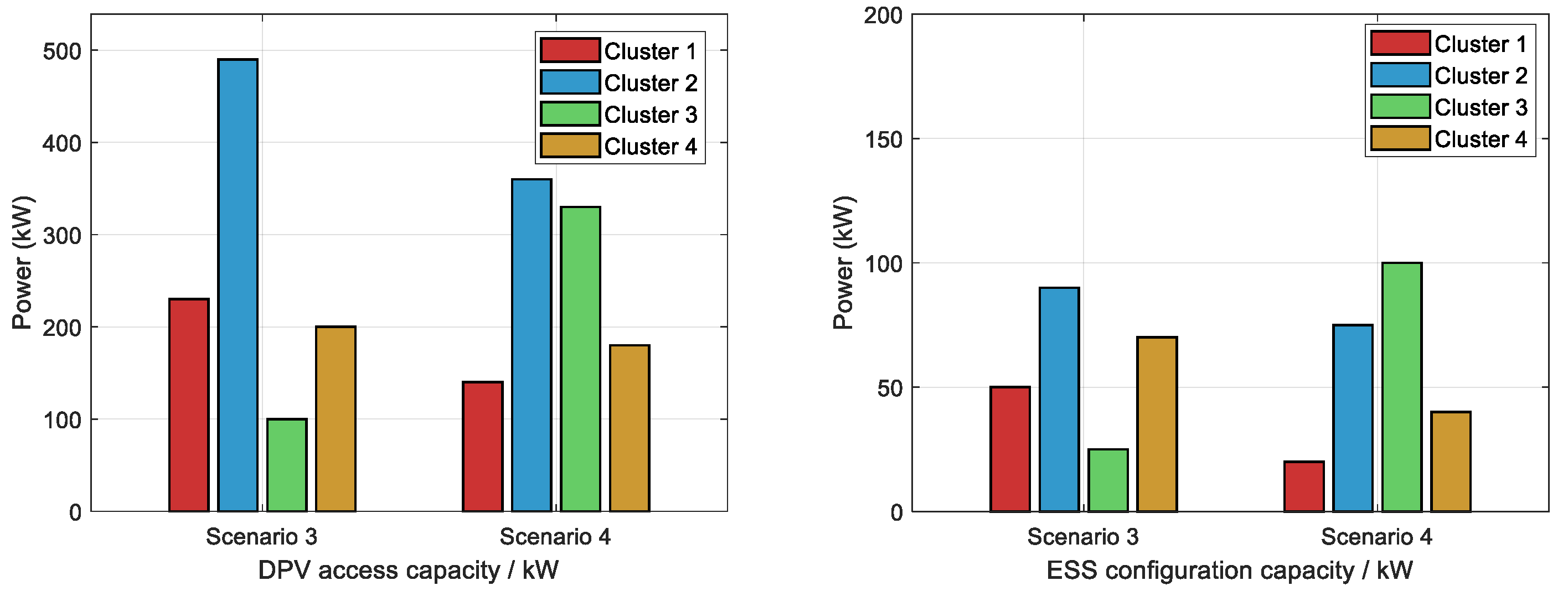

According to the two-layer model and the two-layer adaptive grid particle-swarm optimization algorithm as well as the second-order cone programming hybrid algorithm constructed in this paper, the planning scheme of each scene can be obtained, as shown in

Table 7 and

Figure 9.

It can be seen from

Table 6 that when ESS is not configured in Scenario 2, the access power of the DPV is 580 kW, while in Scenario 3 and Scenario 4, the access power values for the DPV are 1022 kW and 1000 kW, respectively. Therefore, it can be seen that the configuration of energy storage can increase the proportion of distributed photovoltaic consumption, which can effectively improve the DPV consumption capacity. The DPV and ESS power values for each cluster access in Scenario 3 and Scenario 4 are shown in

Figure 9. In Scenario 3, the ESS power is 228 kW and the capacity is 941 kWh. In Scenario 4, the ESS power is 217 kW and the capacity is 841 kW·h. Therefore, in the two-layer model constructed in this paper, the energy-storage ratio of the Scenario 3 photovoltaic configuration is about 22.31%, and the energy-storage ratio of the Scenario 4 photovoltaic configuration is about 21.70%. This provides some theoretical support for the current level of construction of photovoltaic energy-storage capacity on a national scale.

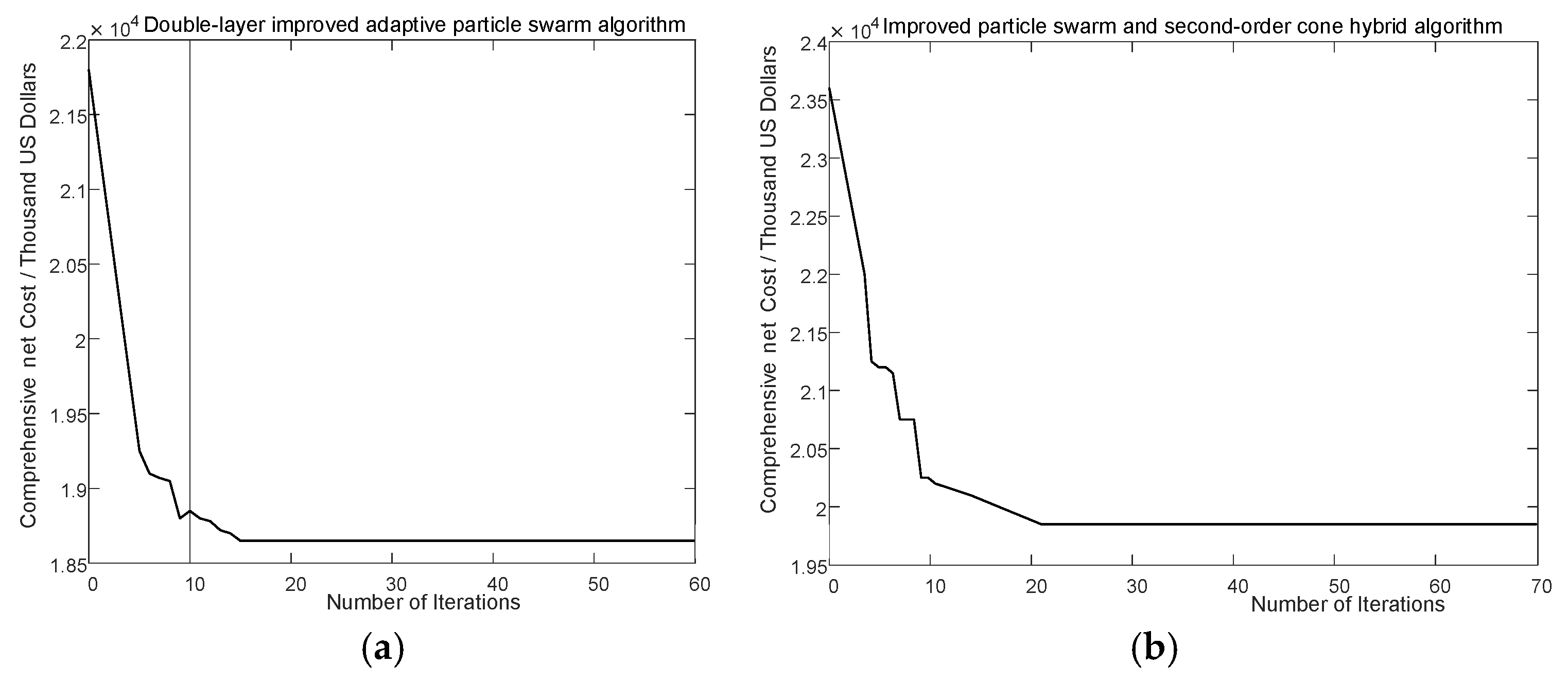

The integrated energy storage and distributed photovoltaic (DPV) capacities are both larger. This configuration leads to a more effective utilization of resources, resulting in superior system performance. Two different solving algorithms are used. Because in the second, multi-objective layer, each iteration cycle produces different Pareto solution sets, the second layer is normalized by the TOPSIS method and passed to the first layer. The first layer calls the second layer to transfer the results. The final annual comprehensive cost iteration curve is demonstrated by

Figure 10:

According to the results, the convergence speed is faster, and the annual comprehensive net cost is USD 18,388.6 thousand. In contrast, when the improved PSO and second-order cone hybrid algorithm are used, the annual comprehensive net cost is USD 19,798.1 thousand. Therefore, the algorithm proposed in this paper exhibits a faster convergence rate when solving this two-layer model, thereby enhancing the computational efficiency of the model. Therefore, compared with the second-order cone hybrid algorithm, the two-layer improved adaptive grid particle-swarm algorithm proposed demonstrates certain advantages. This is due to the application of multi-objective compromise solution in the second layer of the improved two-layer adaptive grid particle-swarm algorithm, while the second layer of the second-order cone hybrid algorithm uses the analytic hierarchy process to normalize the multi-objective.

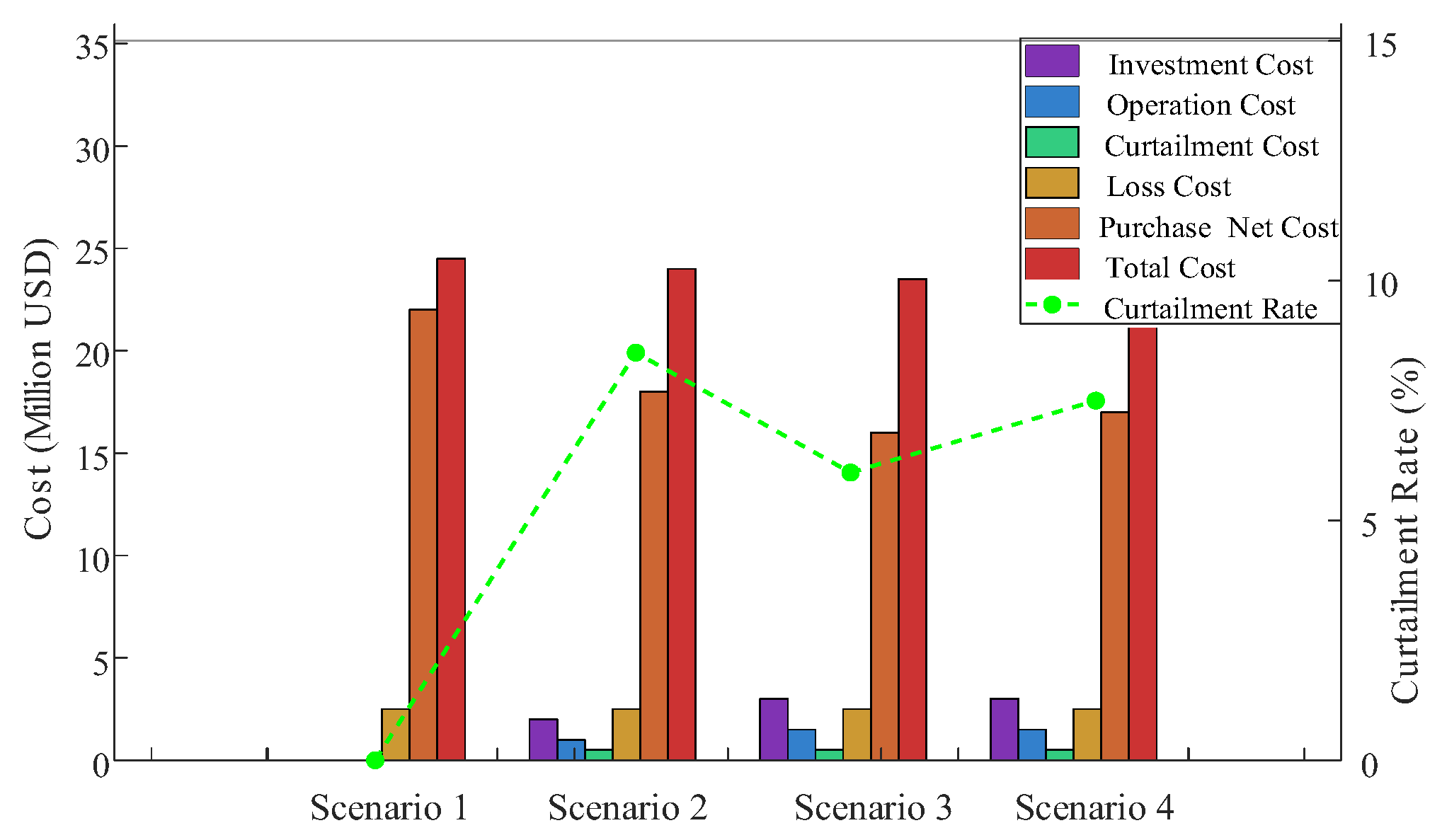

4.3. Economic Criteria Analysis

The comparison of economic indicators is shown in

Figure 11 and

Table 8. In Scenario 1, the net costs of distributed photovoltaic and energy storage are not involved. It only includes the network loss cost of the distribution network and the cost of purchasing electricity from the main grid. In the second scenario, the investment, operation, and maintenance costs of DPV are added. Owing to the integration of DPV and other renewable energy sources, the cost of purchasing electricity from the first-level power grid is reduced. In the third scenario, considering the joint access of DPV and energy storage, because ESS access increases the proportion of DPV consumption, the investment cost is up to USD 1748.3 thousandin the four scenarios. The cost of procuring the electricity grid is USD 4931.2 thousand and 1987.1 thousand lower than those of Scenario 1 and 2, respectively.

Comparing the annual comprehensive net cost under the four scenarios, the annual comprehensive net cost of Scenario 3 is the lowest; the annual comprehensive net cost of Scenario 3 sees reductions of 22.68% and 10.86% compared to those of Scenarios 1 and 2, respectively. Compared with Scenarios 3 and 4, the total economic cost of the proposed method is 6.6% lower than that of Scenario 4. The light rejection rates of Scenarios 2, 3, and 4 are 8.73%, 6.21%, and 7.52%, respectively. Therefore, the rational allocation of ESS is able to effectively reduce the photovoltaic curtailment rate and boost the absorption of new energy.

Comparing the four scenarios, Scenario 2 accesses DPV; compared with Scenario 1, the cost of network loss is smaller, which is conducive to reducing network loss. Comparing Scenarios 2 and 1, the annual network loss cost of DPV + ESS joint planning is reduced by USD 467.7 thousandand USD 760.9 thousand, respectively. Therefore, the coordinated integration can efficiently mitigate the network losses. Comparing Scenario 3 with the Scenario 4, it can be seen that the algorithm can increase the proportion of photovoltaic consumption to a greater extent, thus verifying its superiority in solving the double-layer model. Based on the analysis of economic indicators, it is necessary to reasonably configure DPV and ESS.

4.4. Configuration Energy Storage Peak Shaving Effect and Demand Response Analysis

To verify the effectiveness of low-storage and high-level peak load shifting following energy-storage configuration, the power of ESS and the time-of-use electricity price change curve in Scenario 3 are shown in the following,

Figure 12:

In

Figure 12, it can be observed that charging is carried out from one to seven in the morning, in the low load period, and discharging is carried out from seven to eleven in the evening, in the peak load period. Therefore, by optimizing the power of ESS, the fluctuation of DPV output can be improved. By virtue of satisfying the two-layer model, the operation law of low storage and high level is followed, and the rational allocation of energy storage within the system, combined with the demand-side response, can verify the effectiveness of peak shaving and valley filling.

The system configuration of the energy storage and the consideration of demand response have effectively improved the peak–valley load difference, as shown in

Table 9 and

Figure 13. Comparing Scenario 2 with Scenario 1, the peak and valley loads in Scenario 1 are 2.6143 MW and 1.1322 MW, respectively, while in Scenario 2, they are 2.5637 MW and 1.1823 MW, respectively. The peak–valley difference has decreased from the original 1.4821 MW to 1.3814 MW. This reflects the fact that the consideration of the demand response of time-of-use electricity prices and the integration of DPV can improve the operational performance of the distribution network. Scenario 3 is designed with a reasonable configuration of energy storage and the coordination of demand response under time-of-use electricity pricing; comparing Scenario 3and Scenario 1, the peak and valley load values in Scenario 3 are 2.4421 MW and 1.2587 MW respectively, and the peak–valley difference has been reduced from the original 1.4821 MW to 1.1834 MW. Comparing Scenario 3 and Scenario 2, the peak–valley difference of the load has decreased from 1.3814 MW to 1.1834 MW. Therefore, by the configuration of the energy storage, the peak–valley difference of the load has decreased. Effective configuration of energy storage can achieve the peak shaving and valley filling of the load.

Comparing Scenario 3 and Scenario 4, the peak and valley values for the load in Scenario 3 are 2.4421 MW and 1.2587 MW, respectively, and the peak and valley values of the load in Scenario 4 are 2.4932 MW and 1.2135 MW, respectively; the difference between the peak and the valley of load is reduced from 1.2797 MW to 1.183 MW. The comparison between Scenario 3 and Scenario 4 shows the superiority of this algorithm in solving this two-layer optimization model.

5. Conclusions and Future Work

This study proposes a cluster-based bi-level optimization framework for the coordinated planning and operation of DPV and ESS in active distribution networks. By integrating electrical distance, power balance, and scale rationality into a comprehensive cluster partition index and applying an improved FN-CD algorithm, the method achieves rational partitioning with strong intra-cluster coupling and balanced sizes. On this basis, a two-layer optimization model jointly optimizes siting, sizing, and operational strategies.

Simulation results on the IEEE 33-node system highlight the quantitative advantages of the proposed method. Compared with the hybrid SOCP approach, the annual comprehensive net cost is reduced by 6.6%, the load peak–valley difference is decreased by 22.6%, and the PV utilization rate is improved by 28.9%, while voltage deviations remain below 6.3%. These outcomes demonstrate that the proposed framework can provide both economic and technical benefits for the operation of the distribution network.

The operative boundaries of the proposed method should also be noted. The current model is designed for radial distribution networks under balanced three-phase steady-state conditions and relies on accurate system data, including line parameters, load demand, and PV generation profiles. Although the cluster-based decomposition improves scalability, further algorithmic acceleration may be required to handle very large networks efficiently. In addition, unbalanced conditions, harmonic distortions, and transient dynamics are not explicitly modeled in the present work.

Future research directions are therefore essential. First, the cluster-based decomposition is inherently suitable for large-scale networks, but practical implementation will face challenges such as inter-cluster coordination complexity, higher requirements for high-quality data, and the need for reliable, low-latency communication infrastructures. Second, sudden load variations, renewable intermittency, and fault events will require more advanced stability assessments, including electromagnetic transient (EMT) validation, which remains beyond the current scope. Third, while the bi-level optimization framework could in principle be simplified for scenarios involving only active or only reactive power transfer, its advantages are more evident in complex cases involving multiple objectives such as voltage regulation, loss minimization, and PV utilization enhancement.

To further adapt the framework for real-time operation in high-voltage distribution networks, significant modifications are necessary. These include shifting the optimization time scale from long-term planning to short-term operation through model predictive control (MPC), employing linearization or convex relaxation of AC optimal power flow (ACOPF) for computational tractability, and performing hardware-in-the-loop (HIL) validation. Additionally, robust cybersecurity measures must be considered to ensure secure and reliable deployment under realistic conditions.