Simulation, Optimization, and Techno-Economic Assessment of 100% Off-Grid Hybrid Renewable Energy Systems for Rural Electrification in Eastern Morocco

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Literature Review and Research Gap

1.3. Contribution

1.4. Paper Organization

2. Materials and Methods

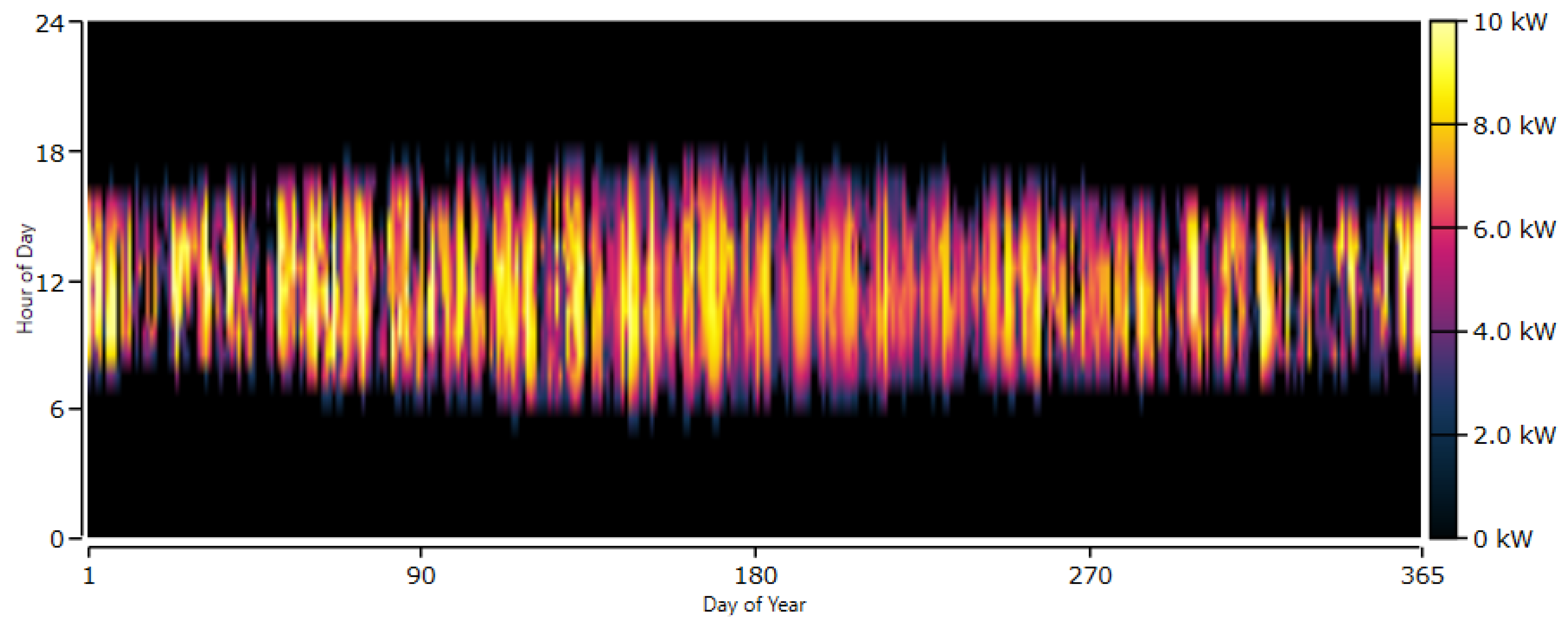

2.1. Site Description and Load Profile

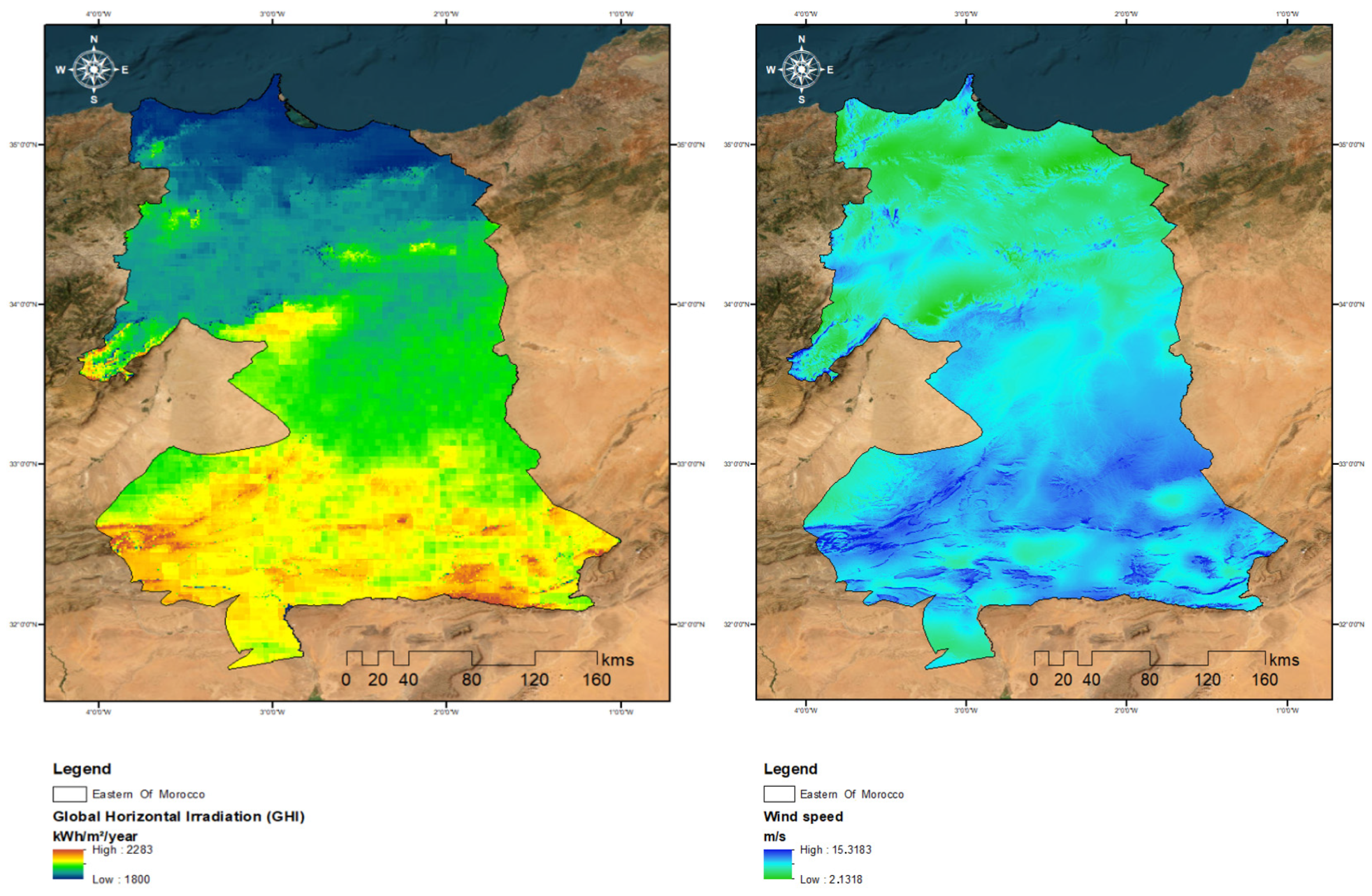

2.2. Resource Assessment

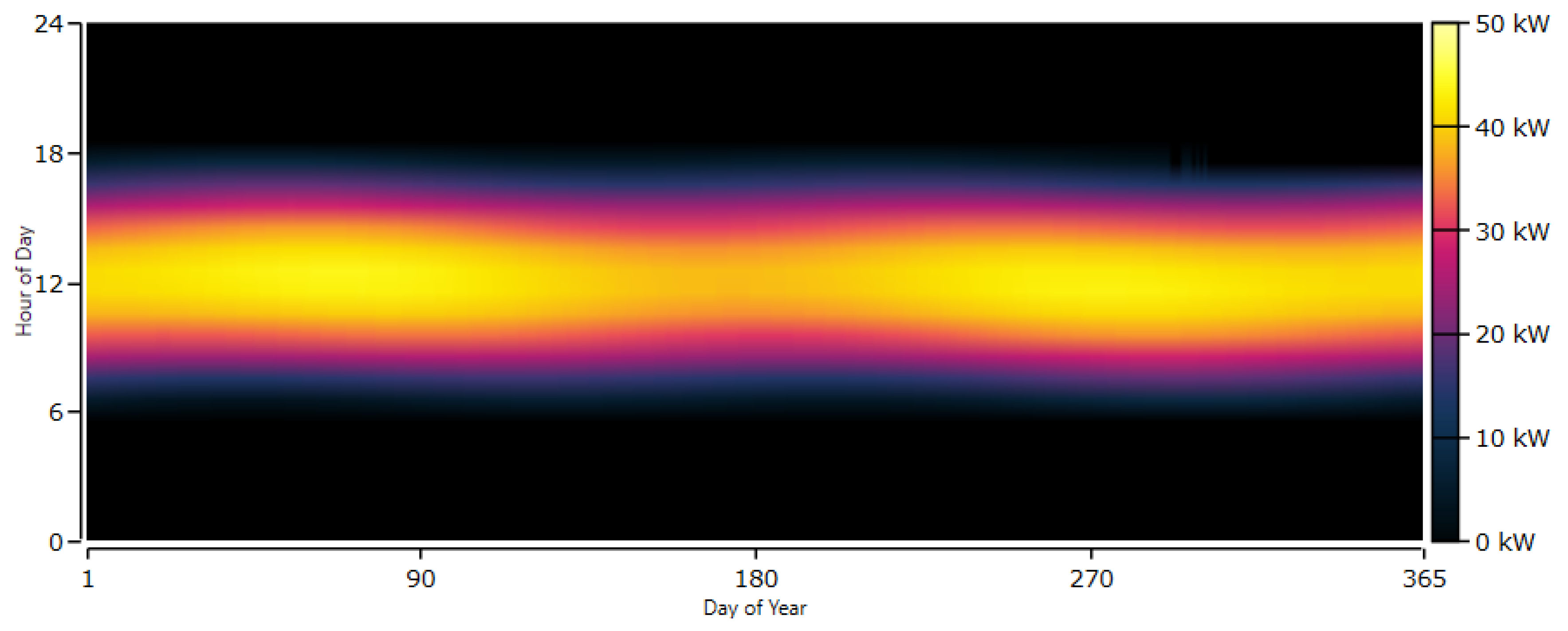

2.2.1. Solar Resource Assessment

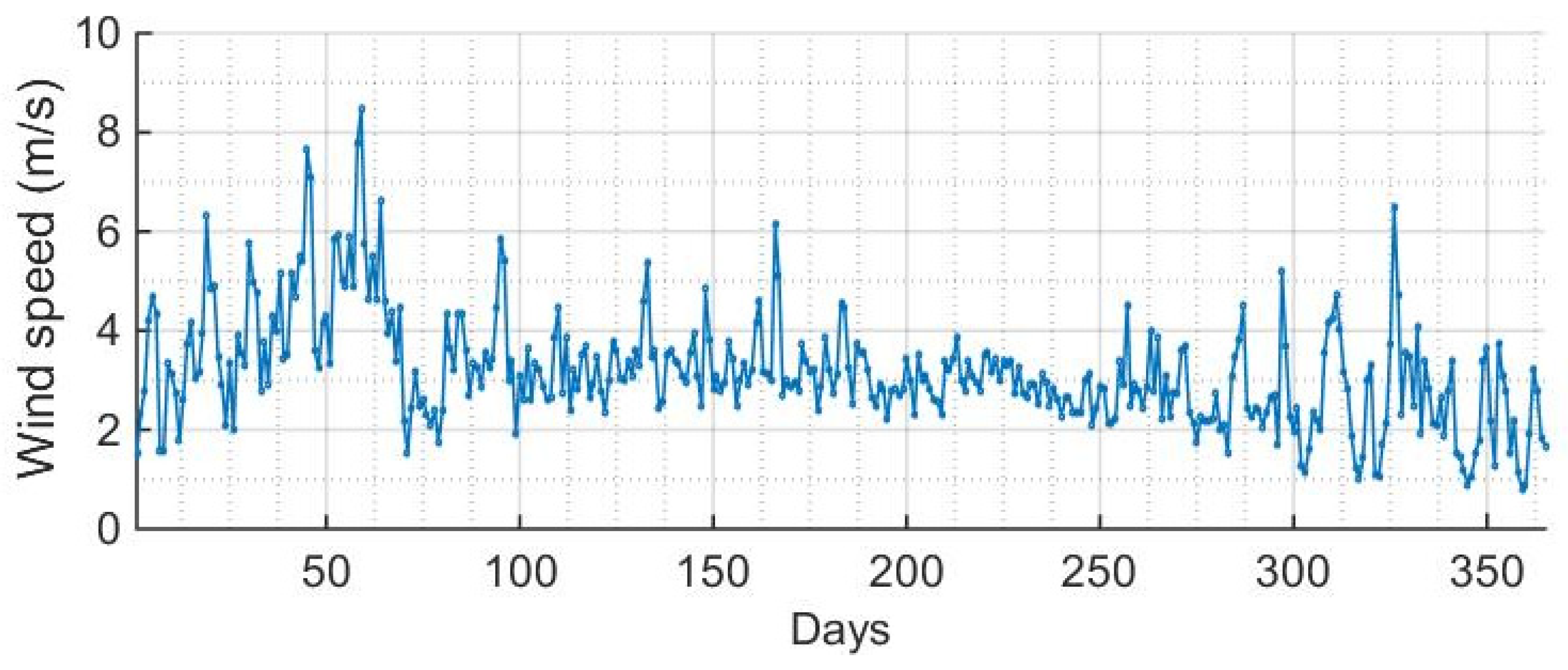

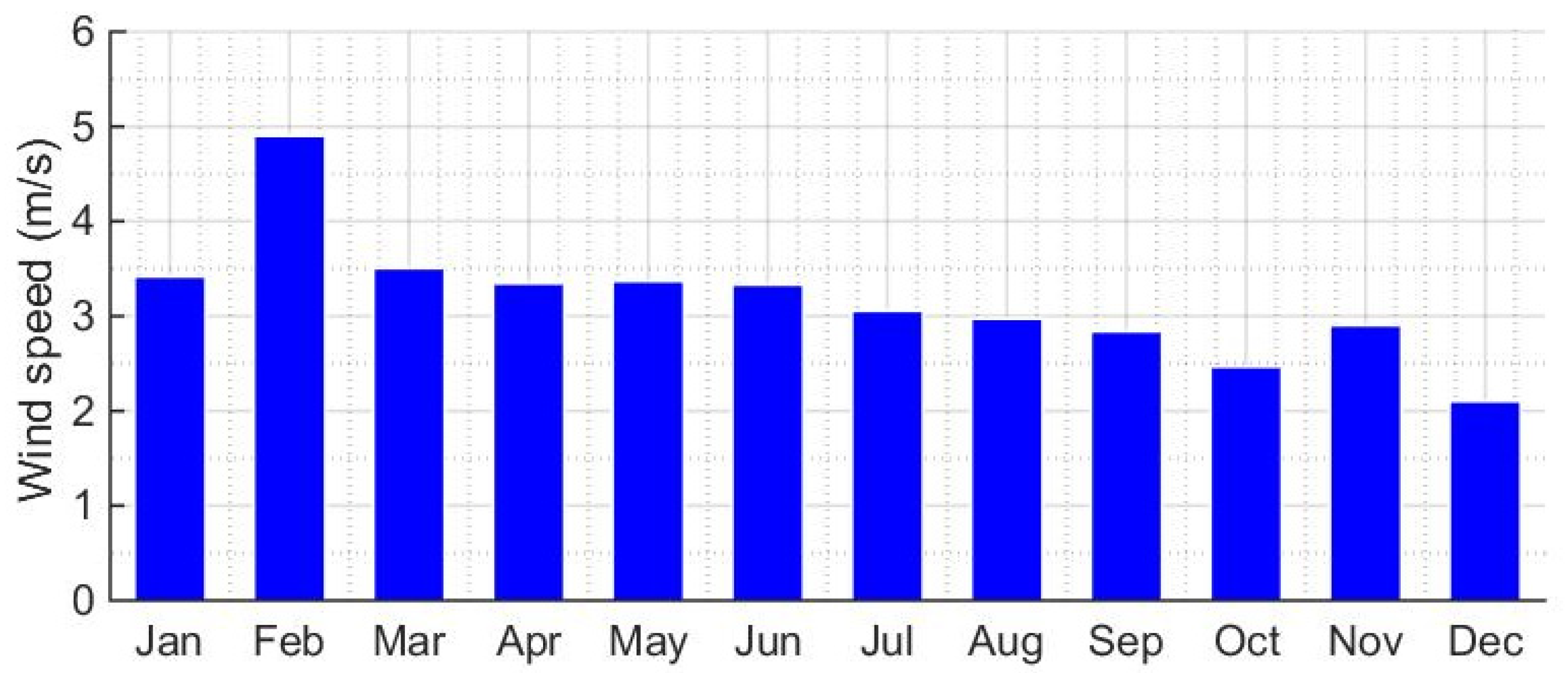

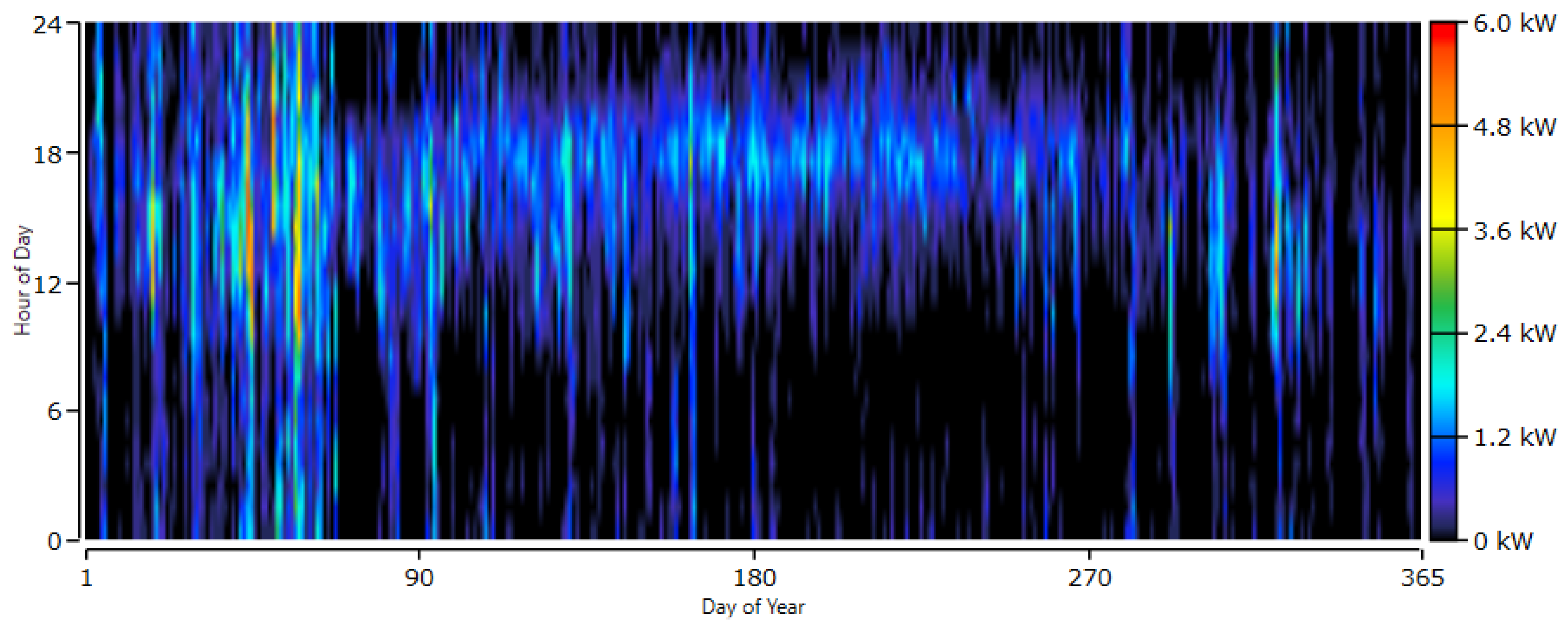

2.2.2. Wind Resource Assessment

2.3. Simulation Tools

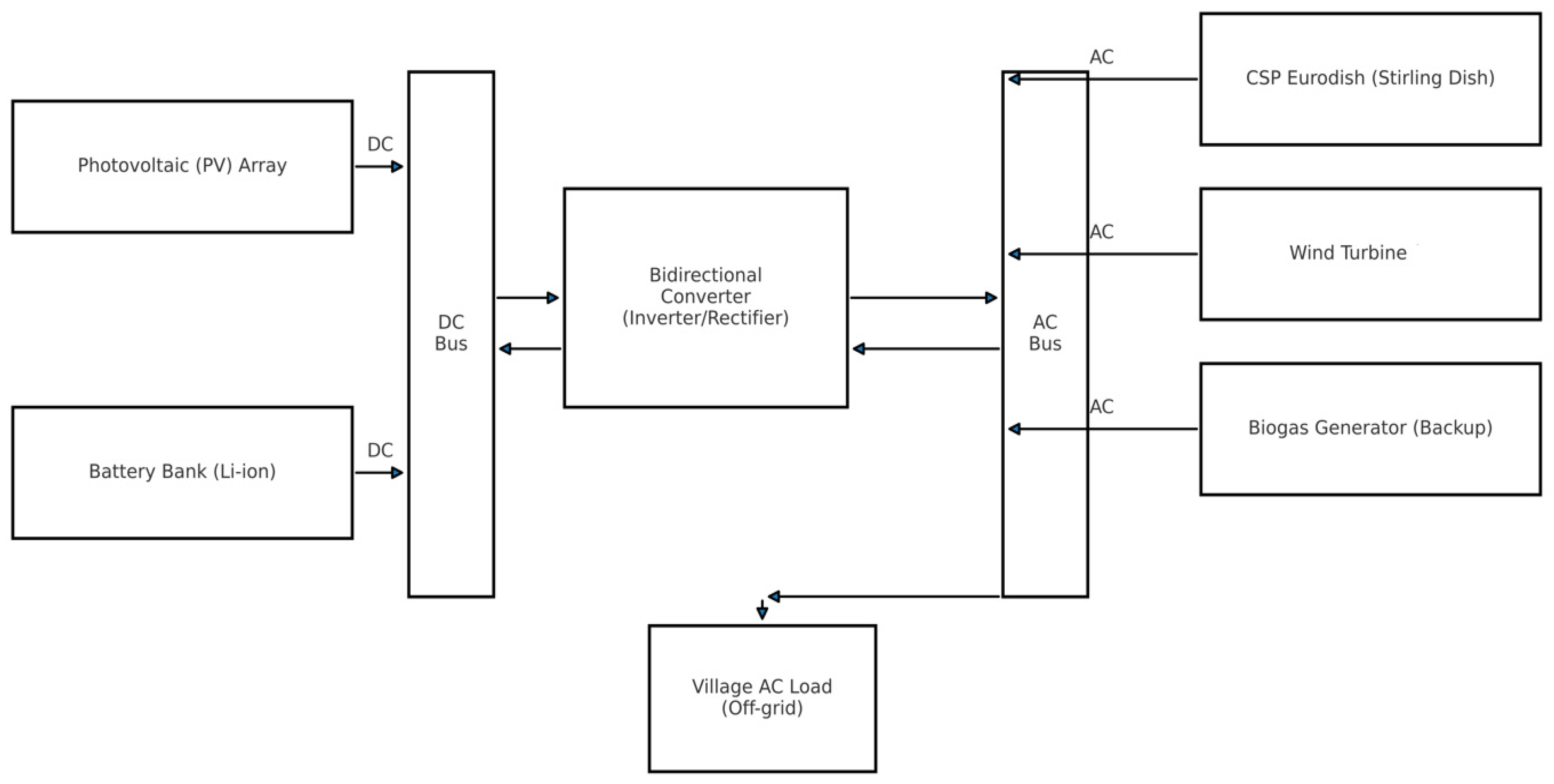

2.4. Hybrid Energy System Components

2.4.1. PV Module

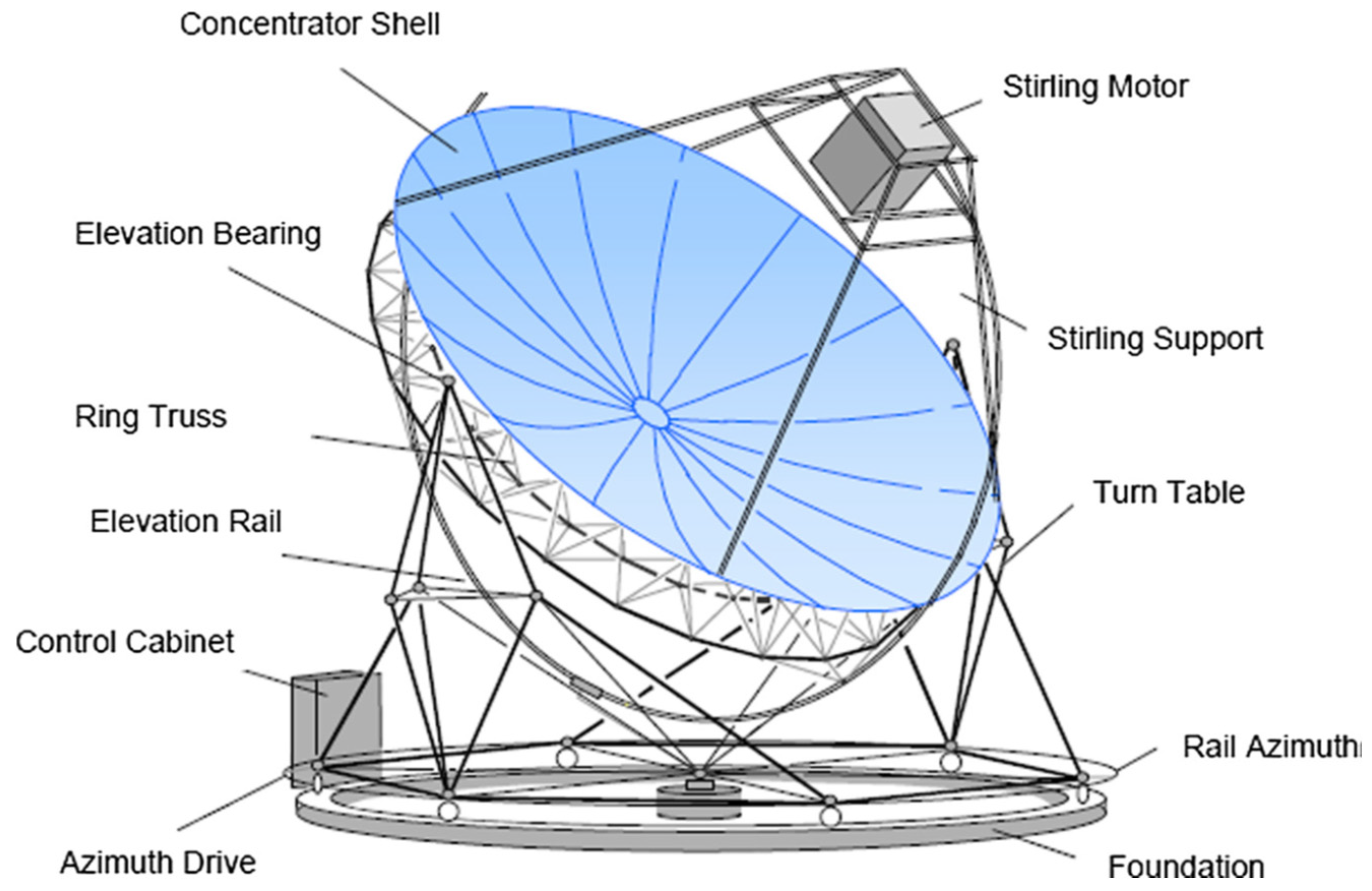

2.4.2. CSP-SD System

2.4.3. Wind Turbine

2.4.4. Biogas Generator

2.4.5. Battery System

3. Results and Discussion

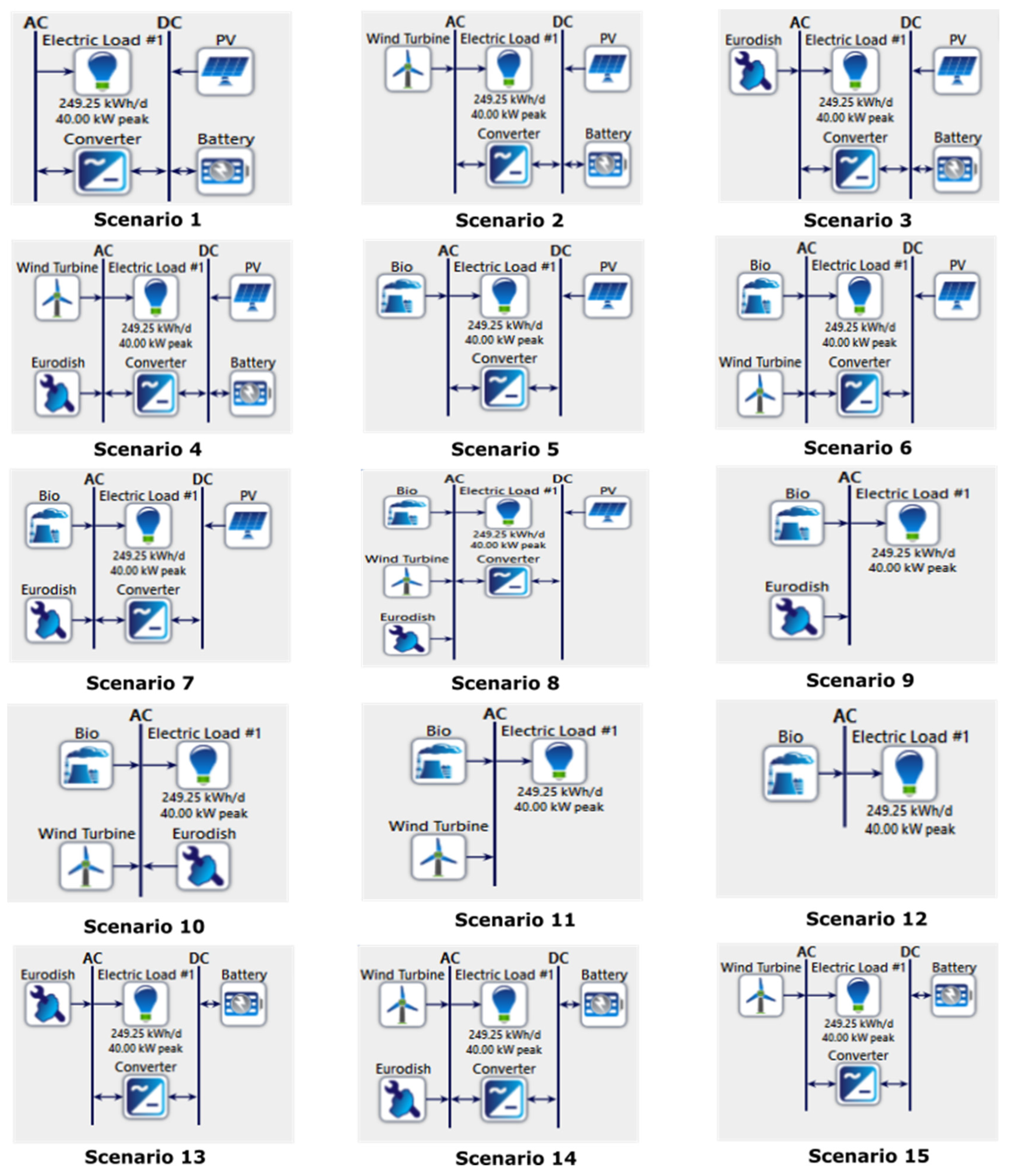

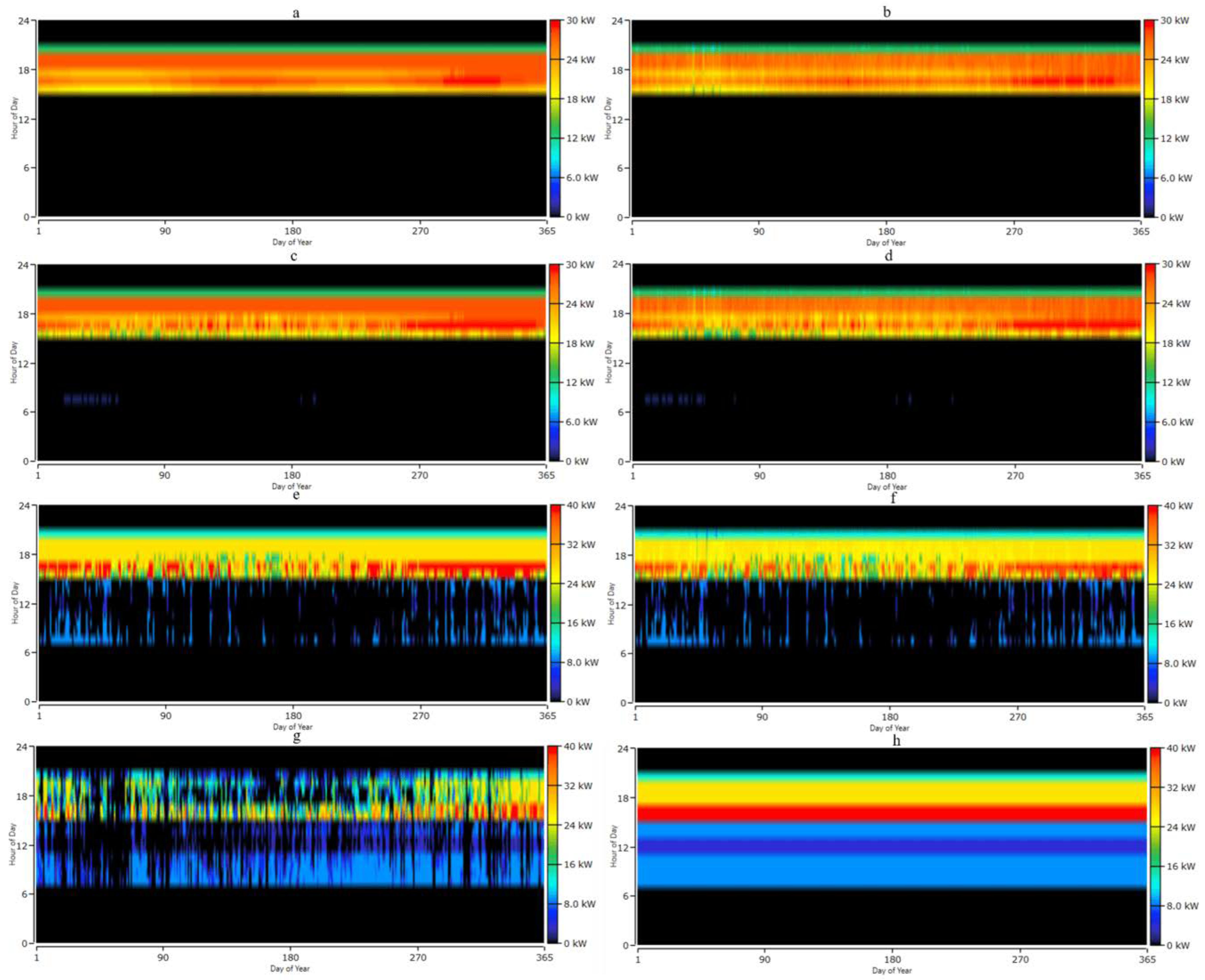

3.1. Optimization Results

3.2. Optimization Result Comparison and Analysis

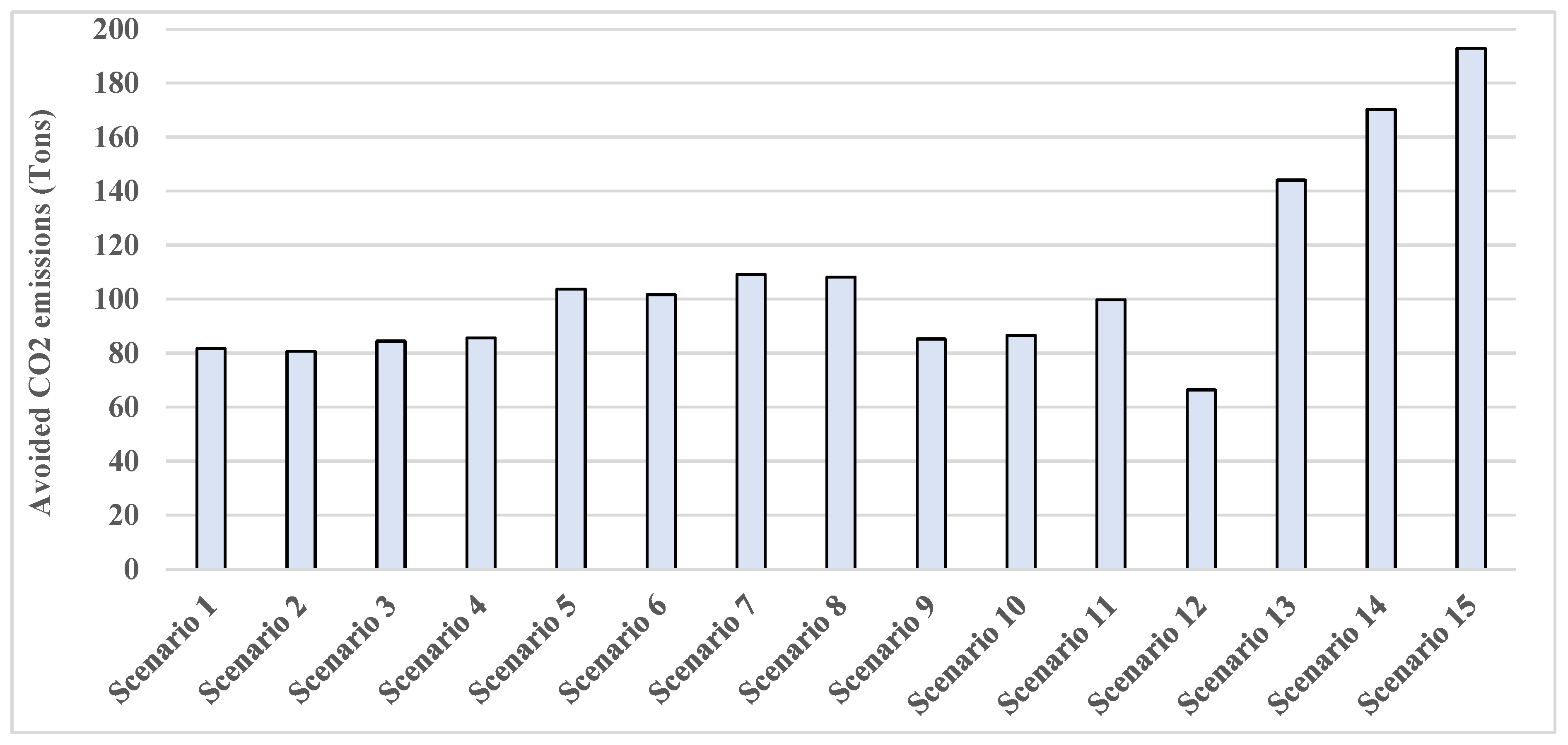

3.3. Environmental Impact

3.4. Result Validation

| Location | HRES Configuration | LCOE (USD/kWh) | Reference |

|---|---|---|---|

| Sidhwanbet, Punjab, India | PV/biomass/battery | 0.362 | [26] |

| Koh Samui Island, Thailand | PV/wind/fuel cell/battery | 0.309 | [27] |

| Arandun, Nigeria | PV/CSP/hydropower/battery | 0.26 | [28] |

| North-East India | PV/fuel cell | 0.509–0.689 | [32] |

| Pirthala, Haryana, India | PV/hydropower/battery | 0.782 | [53] |

| Countryside area in Egypt | PV/wind/fuel cell | 0.47 | [54] |

| Countryside region in Turkey | PV/wind/fuel cell | 0.55 | [55] |

| Gobardhanpur village, India | PV/biomass/wind/battery PV/biomass | 0.278 0.455 | [56] |

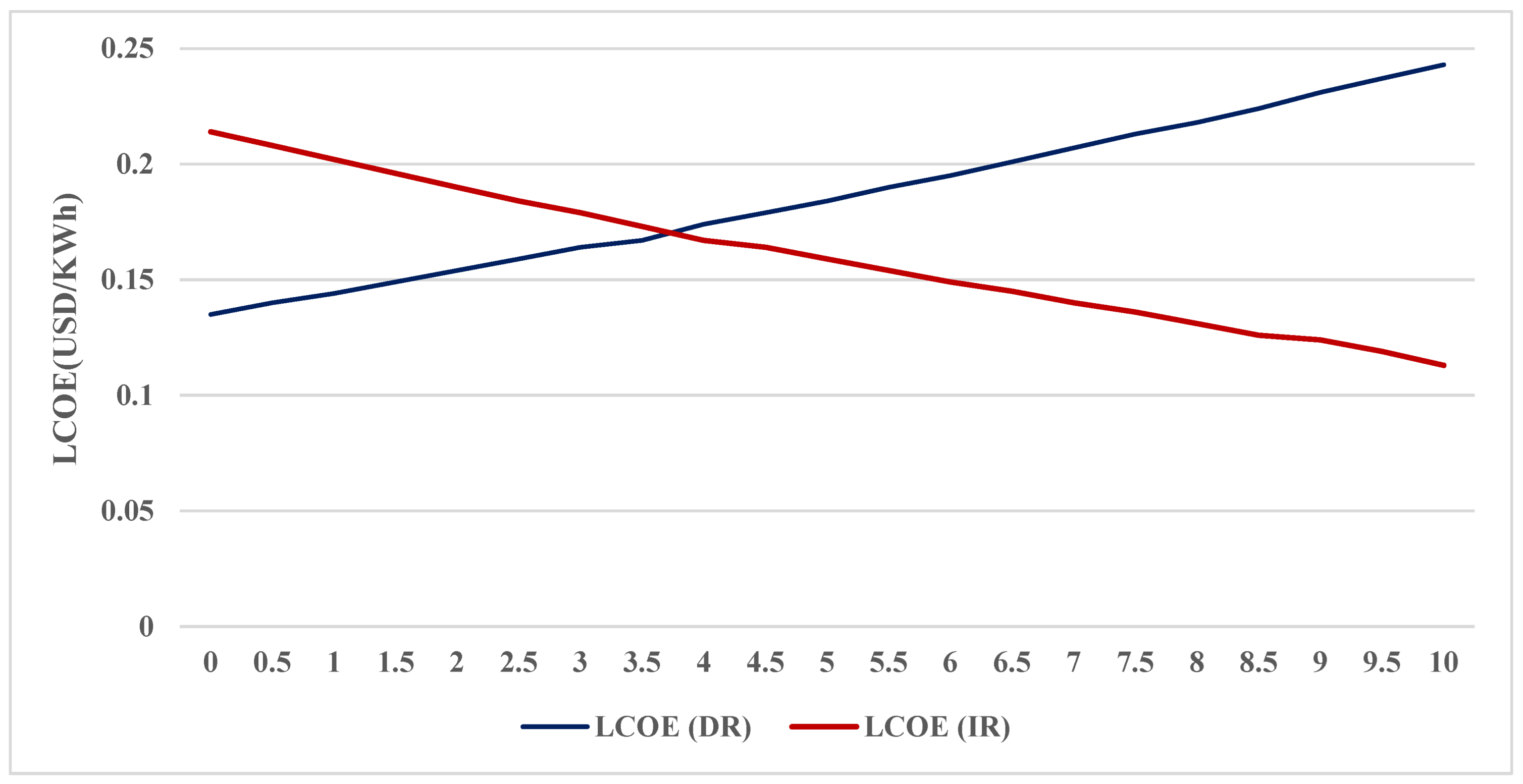

3.5. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HRES | Hybrid Renewable Energy System |

| RE | Renewable Energy |

| PV | Photovoltaic |

| CSP | Concentrating Solar Power |

| SD | Stirling Dish |

| LCOE | Levelized Cost of Energy |

| SoC | State of Charge |

| CO2 | Carbon Dioxide |

| GHI | Global Horizontal Irradiance |

| DNI | Direct Normal Irradiance |

| NPC | Net Present Cost |

| CRF | Capital Recovery Factor |

References

- Saleem, S.; Farhan, M.; Raza, S.; Awan, F.G.; Butt, A.D.; Safdar, N. Power Factor Improvement and MPPT of the Grid-Connected Solar Photovoltaic System Using Nonlinear Integral Backstepping Controller. Arab. J. Sci. Eng. 2023, 48, 6453–6470. [Google Scholar] [CrossRef]

- Guchhait, R.; Sarkar, B. Increasing Growth of Renewable Energy: A State of Art. Energies 2023, 16, 2665. [Google Scholar] [CrossRef]

- Yolcan, O.O. World energy outlook and state of renewable energy: 10-Year evaluation. Innov. Green Dev. 2023, 2, 100070. [Google Scholar] [CrossRef]

- Deshmukh, M.K.G.; Sameeroddin, M.; Abdul, D.; Sattar, M.A. Renewable energy in the 21st century: A review. Mater. Today Proc. 2023, 80, 1756–1759. [Google Scholar] [CrossRef]

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- World Energy Outlook 2023—Analysis—IEA. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 29 April 2025).

- Jacobson, M.Z.; Delucchi, M.A.; Bauer, Z.A.F.; Goodman, S.C.; Chapman, W.E.; Cameron, M.A.; Bozonnat, C.; Chobadi, L.; Clonts, H.A.; Enevoldsen, P.; et al. 100% Clean and Renewable Wind, Water, and Sunlight All-Sector Energy Roadmaps for 139 Countries of the World. Joule 2017, 1, 108–121. [Google Scholar] [CrossRef]

- Renewable Energy—Powering a Safer Future|United Nations. Available online: https://www.un.org/en/climatechange/raising-ambition/renewable-energy (accessed on 29 April 2025).

- Achin Jain, A.J.; Vanita Jain, V.J. Renewable Energy Sources for Clean Environment: Opinion Mining. AJW Asian J. Water Environ. Pollut. 2019, 16, 9–14. [Google Scholar] [CrossRef]

- Achieving Net-Zero Emissions by 2050—World Energy Outlook 2020—Analysis—IEA. Available online: https://www.iea.org/reports/world-energy-outlook-2020/achieving-net-zero-emissions-by-2050 (accessed on 29 April 2025).

- Renewable Energy Target Setting. Available online: https://www.irena.org/publications/2015/Jun/Renewable-Energy-Target-Setting (accessed on 1 May 2025).

- Rubino, A.; Öztürk, I.; Lenzi, V.; Campi, M.T.C. (Eds.) Regulation and Investments in Energy Markets: Solutions for the Mediterranean, 1st ed.; Elsevier: Waltham, MA, USA, 2015. [Google Scholar]

- Moudene, K.; El-Oud, R.; Ejbari, R.; Amedjar, A. Renewable Energy and Economic Growth in Morocco. JHRSS J. Hum. Resour. Sustain. Stud. 2023, 11, 401–413. [Google Scholar] [CrossRef]

- Nakach, I.; Mouhat, O.; Shamass, R.; El Mennaouiy, F. Review of strategies for sustainable energy in Morocco. Polityka Energetyczna—Energy Policy J. 2023, 26, 65–104. [Google Scholar] [CrossRef]

- Renewable Energy in Morocco|EcoMENA. Available online: https://www.ecomena.org/renewable-energy-in-morocco/ (accessed on 2 May 2025).

- El Mokhi, C.; Choukai, O.; Hachimi, H.; Errouhi, A.A. Assessment and optimization of photovoltaic systems at the University Ibn Tofail according to the new law on renewable energy in Morocco using HOMER Pro. Energy Harvest. Syst. 2023, 10, 55–69. [Google Scholar] [CrossRef]

- El-Maaroufi, A.; Daoudi, M.; Laamara, R.A. Techno-economic analysis of a PV/WT/biomass off-grid hybrid power system for rural electrification in northern Morocco using HOMER. Renew. Energy 2024, 231, 120904. [Google Scholar] [CrossRef]

- Ennemiri, N.; Berrada, A.; Emrani, A.; Abdelmajid, J.; El Mrabet, R. Optimization of an off-grid PV/biogas/battery hybrid energy system for electrification: A case study in a commercial platform in Morocco. Energy Convers. Manag. X 2024, 21, 100508. [Google Scholar] [CrossRef]

- Ladide, S.; Fathi, A.E.; Bendaoud, M.; Hihi, H.; Faitah, K. Hybrid Renewable Power Supply for Typical Public Facilities in Six Various Climate Zones in Morocco. IJRER Int. J. Renew. Energy Res. 2019, 9, 893–912. [Google Scholar] [CrossRef]

- Bari, Z.; Yakhlef, M.B. Optimal sizing of Hybrid Renewable Energy System a case study in Morocco. Int. J. Math. Comput. Methods 2017, 2, 300–306. Available online: https://www.iaras.org/home/caijmcm/optimal-sizing-of-hybrid-renewable-energy-system-a-case-study-in-morocco (accessed on 29 April 2025).

- Mahdavi, M.; Jurado, F.; Ramos, R.A.V.; Awaafo, A. Hybrid biomass, solar and wind electricity generation in rural areas of Fez-Meknes region in Morocco considering water consumption of animals and anaerobic digester. Appl. Energy 2023, 343, 121253. [Google Scholar] [CrossRef]

- Ladide, S.; Fathi, A.E.; Bendaoud, M.; Hihi, H.; Faitah, K. Flexible design and assessment of a stand-alone hybrid renewable energy system: A case study Marrakech, Morocco. IJRER Int. J. Renew. Energy Res. 2019, 9, 2003–2022. [Google Scholar] [CrossRef]

- Purlu, M.; Beyarslan, S.; Türkay, B.E. On-Grid and Off-Grid Hybrid Renewable Energy System Designs with HOMER: A Case Study of Rural Electrification in Turkey. TEPES Turk. J. Electr. Power Energy Syst. 2022, 2, 75–84. [Google Scholar] [CrossRef]

- Li, C.; Zhou, D.; Zhang, L.; Shan, Y. Exploration on the feasibility of hybrid renewable energy generation in resource-based areas of China: Case study of a regeneration city. Energy Strategy Rev. 2022, 42, 100869. [Google Scholar] [CrossRef]

- Kapen, P.T.; Nouadje, B.A.M.; Chegnimonhan, V.; Tchuen, G.; Tchinda, R. Techno-economic feasibility of a PV/battery/fuel cell/electrolyzer/biogas hybrid system for energy and hydrogen production in the far north region of cameroon by using HOMER pro. Energy Strategy Rev. 2022, 44, 100988. [Google Scholar] [CrossRef]

- Kumar, R.; Channi, H.K. A PV-Biomass off-grid hybrid renewable energy system (HRES) for rural electrification: Design, optimization and techno-economic-environmental analysis. J. Clean. Prod. 2022, 349, 131347. [Google Scholar] [CrossRef]

- Chaichan, W.; Waewsak, J.; Nikhom, R.; Kongruang, C.; Chiwamongkhonkarn, S.; Gagnon, Y. Optimization of stand-alone and grid-connected hybrid solar/wind/fuel cell power generation for green islands: Application to Koh Samui, southern Thailand. Energy Rep. 2022, 8, 480–493. [Google Scholar] [CrossRef]

- Odetoye, O.A.; Olulope, P.K.; Olanrewaju, O.M.; Alimi, A.O.; Igbinosa, O.G. Multi-year techno-economic assessment of proposed zero-emission hybrid community microgrid in Nigeria using HOMER. Heliyon 2023, 9, e19189. [Google Scholar] [CrossRef]

- Mbasso, W.F.; Naoussi, S.R.D.; Molu, R.J.J.; Saatong, K.T.; Kamel, S. Technical assessment of a stand-alone hybrid renewable system for energy and oxygen optimal production for fishes farming in a residential building using HOMER pro. Clean. Eng. Technol. 2023, 17, 100688. [Google Scholar] [CrossRef]

- Irshad, A.S.; Ahmadullah, A.B.; Kamal, K.; Haidari, N.; Qanit, A.; Osmani, J.A.; Elias, S. Optimization of coal sustainability via hybrid renewable integration: A PVsyst-HOMER Synergistic framework for sustainable energy transitions. Energy Convers. Manag. X 2025, 27, 101110. [Google Scholar] [CrossRef]

- Chisale, S.W.; Eliya, S.; Taulo, J. Optimization and design of hybrid power system using HOMER pro and integrated CRITIC-PROMETHEE II approaches. Green Technol. Sustain. 2023, 1, 100005. [Google Scholar] [CrossRef]

- Pal, P.; Mukherjee, V. Off-grid solar photovoltaic/hydrogen fuel cell system for renewable energy generation: An investigation based on techno-economic feasibility assessment for the application of end-user load demand in North-East India. Renew. Sustain. Energy Rev. 2021, 149, 111421. [Google Scholar] [CrossRef]

- Mouaky, A.; Rachek, A. Energetic, exergetic and exergeoeconomic assessment of a hybrid solar/biomass poylgeneration system: A case study of a rural community in a semi-arid climate. Renew. Energy 2020, 158, 280–296. [Google Scholar] [CrossRef]

- Gueymard, C.A. Clear-sky irradiance predictions for solar resource mapping and large-scale applications: Improved validation methodology and detailed performance analysis of 18 broadband radiative models. Sol. Energy 2012, 86, 2145–2169. [Google Scholar] [CrossRef]

- Gueymard, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Ammari, N.; Merrouni, A.A.; Mendyl, A.; Chaabelasri, E.; Weidinger, T. Energy, Economic and Environmental (3E) Analysis for an Optimal CSP Technology Integration in Morocco. Energies 2024, 17, 3020. [Google Scholar] [CrossRef]

- Ackermann, T. Wind Power in Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Duman, A.C.; Güler, Ö. Techno-economic analysis of off-grid PV/wind/fuel cell hybrid system combinations with a comparison of regularly and seasonally occupied households. Sustain. Cities Soc. 2018, 42, 107–126. [Google Scholar] [CrossRef]

- Lamnadi, M.; Trihi, M.; Boulezhar, A. Study of a hybrid renewable energy system for a rural school in Tagzirt, Morocco. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016; pp. 381–386. [Google Scholar] [CrossRef]

- Boqtob, O.; El Moussaoui, H.; El Markhi, H.; Lamhamdi, T. Optimal sizing of grid connected microgrid in Morocco using Homer Pro. In Proceedings of the 2019 International Conference on Wireless Technologies, Embedded and Intelligent Systems (WITS), Fez, Morocco, 3–4 April 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Choukri, N.E.; Touili, S.; Azzaoui, A.; Merrouni, A.A. Techno-economic analysis for a 100% renewable hybrid energy systems integration in a research facility in Morocco. iScience 2025, 28, 113132. [Google Scholar] [CrossRef]

- El-Houari, H.; Allouhi, A.; Rehman, S.; Buker, M.S.; Kousksou, T.; Jamil, A.; El Amrani, B. Feasibility evaluation of a hybrid renewable power generation system for sustainable electricity supply in a Moroccan remote site. J. Clean. Prod. 2020, 277, 123534. [Google Scholar] [CrossRef]

- Singh, A.; Baredar, P. Techno-economic assessment of a solar PV, fuel cell, and biomass gasifier hybrid energy system. Energy Rep. 2016, 2, 254–260. [Google Scholar] [CrossRef]

- Bravo, Y.; Carvalho, M.; Serra, L.M.; Monné, C.; Alonso, S.; Moreno, F.; Muñoz, M. Environmental evaluation of dish-Stirling technology for power generation. Sol. Energy 2012, 86, 2811–2825. [Google Scholar] [CrossRef]

- Hafez, A.Z.; Soliman, A.; El-Metwally, K.A.; Ismail, I.M. Solar parabolic dish Stirling engine system design, simulation, and thermal analysis. Energy Convers. Manag. 2016, 126, 60–75. [Google Scholar] [CrossRef]

- Touili, S.; Merrouni, A.A.; El Hassouani, Y.; Amrani, A.; Rachidi, S. Analysis of the yield and production cost of large-scale electrolytic hydrogen from different solar technologies and under several Moroccan climate zones. Int. J. Hydrogen Energy 2020, 45, 26785–26799. [Google Scholar] [CrossRef]

- Babu, M.K.; Ray, P. Sensitivity analysis; optimal design, cost and energy efficiency study of a hybrid forecast model using HOMER pro. J. Eng. Res. 2023, 11, 100033. [Google Scholar] [CrossRef]

- Mahdavi, M.; Vera, D. Importance of renewable energy sources and agricultural biomass in providing primary energy demand for Morocco. Int. J. Hydrogen Energy 2023, 48, 34575–34598. [Google Scholar] [CrossRef]

- Mana, A.A.; Allouhi, A.; Ouazzani, K.; Jamil, A. Feasibility of agriculture biomass power generation in Morocco: Techno-economic analysis. J. Clean. Prod. 2021, 295, 126293. [Google Scholar] [CrossRef]

- Allouhi, A.; Saadani, R.; Buker, M.S.; Kousksou, T.; Jamil, A.; Rahmoune, M. Energetic, economic and environmental (3E) analyses and LCOE estimation of three technologies of PV grid-connected systems under different climates. Sol. Energy 2019, 178, 25–36. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Lashari, A.A.; Leghari, Z.H.; Memon, Z.A. Techno-enviro-economic assessment of a stand-alone parabolic solar dish stirling system for electricity generation. Int. J. Energy Res. 2021, 45, 10250–10270. [Google Scholar] [CrossRef]

- Lund, C.; Biswas, W. A Review of the Application of Lifecycle Analysis to Renewable Energy Systems. Bull. Sci. Technol. Soc. 2008, 28, 200–209. [Google Scholar] [CrossRef]

- Kumar, P.; Channi, H.K.; Kumar, R.; Prakash, C.; Bhowmik, A.; Pandey, S.; Singh, A.K.; Ali, M.M.; Soudagar, M.E.M. Efficient integration of photo voltaic and hydro energy technologies for sustainable power generation in rural areas: A case study. Mater. Sci. Energy Technol. 2024, 7, 297–308. [Google Scholar] [CrossRef]

- Samy, M.M.; Barakat, S.; Ramadan, H.S. Techno-economic analysis for rustic electrification in Egypt using multi-source renewable energy based on PV/wind/FC. Int. J. Hydrogen Energy 2020, 45, 11471–11483. [Google Scholar] [CrossRef]

- Wang, Y.; He, X.; Liu, Q.; Razmjooy, S. Economic and technical analysis of an HRES (Hybrid Renewable Energy System) comprising wind, PV, and fuel cells using an improved subtraction-average-based optimizer. Heliyon 2024, 10, e32712. [Google Scholar] [CrossRef]

- Roy, D.; Shivaprasad, K.V.; Wang, Y.; Roskilly, A.P. Techno-economic feasibility assessment for a standalone hybrid energy system integrating renewable energy sources. Clean. Eng. Technol. 2025, 28, 101045. [Google Scholar] [CrossRef]

| Properties | Specifications |

|---|---|

| Brand name | AWS HC 5.1 kW wind turbine |

| Rated capacity (kW) | 5.1 |

| Number of blades | 3 |

| Rotor diameter (m) | 5.24 |

| Hub height (m) | 12 |

| Lifetime | 25 years |

| Properties | Specifications |

|---|---|

| Nominal capacity (kWh) | 1 kWh |

| Nominal capacity (Ah) | 167 Ah |

| Nominal voltage | 7 V |

| Maximum discharge current | 500 A |

| Maximum charge current | 167 A |

| Lifetime | 15 years |

| Scenario | PV (kW) | Wind (kW) | Eurodish (kW) | Biomass (kW) | Battery (Number) | Converter (kW) | Energy Production (kWh) | Excess Energy (kWh) | LCOE (USD/kWh) |

|---|---|---|---|---|---|---|---|---|---|

| 1: PV/Battery | 48.8 | 213 | 43.8 | 117,454 | 10,363 | 0.184 | |||

| 2: PV/Wind/Battery | 46.6 | 5.1 | 212 | 41.1 | 115,761 | 9114 | 0.187 | ||

| 3: PV/Eurodish/Battery | 42.6 | 10 | 219 | 41.1 | 120,636 | 15,407 | 0.214 | ||

| 4: PV/Wind/Eurodish/Battery | 41.7 | 5.1 | 10 | 228 | 40.7 | 122,083 | 17,212 | 0.220 | |

| 5: PV/Biomass | 38.7 | 30 | 22.2 | 146,413 | 51,259 | 0.300 | |||

| 6: PV/Wind/Biomass | 36.2 | 5.1 | 30 | 37.7 | 143,346 | 48,439 | 0.314 | ||

| 7: PV/Eurodish/Biomass | 34.5 | 10 | 30 | 16.7 | 153,615 | 60,290 | 0.332 | ||

| 8: PV/Wind/Eurodish/Biomass | 32.8 | 5.1 | 10 | 30 | 31.3 | 152,003 | 58,838 | 0.342 | |

| 9: Eurodish/Biomass | 30 | 40 | 117,249 | 26,272 | 0.472 | ||||

| 10: Wind/Eurodish/Biomass | 5.1 | 30 | 40 | 119,057 | 28,081 | 0.474 | |||

| 11: Wind/Biomass | 127.5 | 40 | 136,331 | 45,355 | 0.572 | ||||

| 12: Biomass | 40 | 90,976 | 0 | 0.602 | |||||

| 13: Eurodish/Battery | 110 | 732 | 65.1 | 198,984 | 94,029 | 0.739 | |||

| 14: Wind/Eurodish/Battery | 96.9 | 90 | 627 | 55.4 | 234,306 | 135,358 | 0.759 | ||

| 15: Wind/Battery | 357 | 1404 | 54.9 | 263,427 | 168,236 | 1.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choukri, N.E.; Touili, S.; Azzaoui, A.; Alami Merrouni, A. Simulation, Optimization, and Techno-Economic Assessment of 100% Off-Grid Hybrid Renewable Energy Systems for Rural Electrification in Eastern Morocco. Processes 2025, 13, 2801. https://doi.org/10.3390/pr13092801

Choukri NE, Touili S, Azzaoui A, Alami Merrouni A. Simulation, Optimization, and Techno-Economic Assessment of 100% Off-Grid Hybrid Renewable Energy Systems for Rural Electrification in Eastern Morocco. Processes. 2025; 13(9):2801. https://doi.org/10.3390/pr13092801

Chicago/Turabian StyleChoukri, Noure Elhouda, Samir Touili, Abdellatif Azzaoui, and Ahmed Alami Merrouni. 2025. "Simulation, Optimization, and Techno-Economic Assessment of 100% Off-Grid Hybrid Renewable Energy Systems for Rural Electrification in Eastern Morocco" Processes 13, no. 9: 2801. https://doi.org/10.3390/pr13092801

APA StyleChoukri, N. E., Touili, S., Azzaoui, A., & Alami Merrouni, A. (2025). Simulation, Optimization, and Techno-Economic Assessment of 100% Off-Grid Hybrid Renewable Energy Systems for Rural Electrification in Eastern Morocco. Processes, 13(9), 2801. https://doi.org/10.3390/pr13092801