Abstract

Power engineering construction serves as the cornerstone of modern social development. Against the backdrop of new power system development, this study employs field investigations, case analysis, and expert discussions to conduct an in-depth analysis of the current status, existing problems, and characteristics of safety risk control in China’s power engineering construction during the 14th Five-Year Plan period. Through systematic analysis of 59 accident cases, 66 distinct causes are identified across 14 categories. Chi-squared testing quantitatively determines the top three risk factors: hollowing out of construction units’ own workforce (χ2 = 10.22), deficiencies in risk classification and hierarchical implementation (χ2 = 9.0), and inadequate hazard identification (χ2 = 6.25). Through brainstorming and expert discussions, 11 critical risks in China’s power engineering construction have been identified, and a set of countermeasures has been formulated. These include nine enterprise-level initiatives such as deepening engineering procurement construction management, improving training systems, optimizing bidding methods, and implementing management principles, along with four regulatory measures targeting the National Energy Administration of China and its regulatory agencies. This study innovates by combining quantitative chi-squared analysis with expert-derived countermeasures, offering a model for transitioning economies. While the sample size imposes limitations on generalizability, this research can significantly improve the intrinsic safety management level of power construction enterprises in China and provides valuable reference experience for similar transitioning countries developing energy infrastructure.

1. Introduction

Against the backdrop of rapid socioeconomic development, particularly accelerated industrialization and informatization, electricity demand continues to grow. As the impact of the greenhouse effect intensifies, the world is gradually transitioning toward a clean-energy era. In Latin America and the Caribbean, for example, 60% of electricity generation comes from renewable sources [1]. While most Southeast Asian countries still rely primarily on fossil fuels for power generation, the share of clean energy is also increasing under rapid expansion [2]. Specifically, in Vietnam, hydropower accounts for 35% of the electricity supply, and solar photovoltaics account for 10% [3]. Moreover, China is optimizing its energy structure and accelerating the development of clean energy [4]. Against this background, the construction of power infrastructure is of great significance [5], as it helps safeguard national energy security, promote energy transition, and achieve sustainable development [6], thereby contributing to the realization of carbon peak and carbon neutrality goals [7].

By the end of 2025, the installed capacity of grid-connected wind and solar power in State Grid’s (State Grid Corporation of China, Beijing, China) operating areas is projected to exceed 1.45 billion kilowatts, representing 3.2 times the level at the end of the 13th Five-Year Plan period (2016–2021) [8]. Additionally, during the 14th Five-Year Plan period, the renewable energy installed capacity reached 2.09 billion kilowatts by May 2025—doubling the 934 million kilowatts recorded at the end of the 13th Five-Year Plan. As of July 2025, China has commissioned 44 UHV transmission lines, with 4 more under construction. Notably, no major power safety accidents have occurred since the inception of the 14th Five-Year Plan period [9]. Moreover, the share of renewable energy in the global power mix has exceeded 50%, with solar energy continuing to dominate the path toward achieving net-zero plans [10]. Simultaneously, new onshore and offshore wind installations generated approximately 106 GW and 10.8 GW, respectively, bringing global cumulative onshore and offshore wind power capacity to 945 GW and 75 GW [11]. Furthermore, in 2023, renewables accounted for 30% of global electricity supply, while fossil fuels saw a modest decline to 60%, marking their lowest share in 50 years [12].

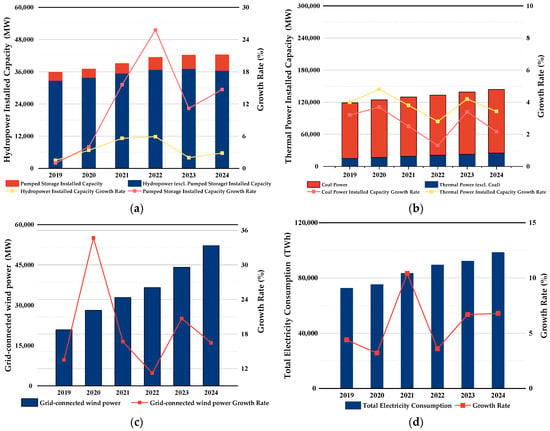

During the 14th Five-Year Plan period of China, investment in power engineering projects increased by 18.86% year on year. In 2024, China’s major power generation enterprises—comprising the five central state-owned power generation giants: China Energy Investment Corporation (Beijing, China), China Huaneng Group (Xiong’an New Area, China), China Huadian Corporation (Beijing, China), China Datang Corporation (Beijing, China), and State Power Investment Corporation (Beijing, China)—completed investment in power generation projects totaling CNY 1.1687 trillion, representing a year-on-year increase of 12.1% [13]. In 2023, the cumulative grid-connected capacity of wind and solar power reached 970 million kilowatts (970 GW), accounting for 34.04% of China’s total installed power generation capacity [14]. It is projected that by 2030, China’s total installed capacity of wind and solar power will exceed 1.2 billion kilowatts (1200 GW), constituting over 50% of the total installed capacity. The share of electricity generated from these sources is expected to rise to more than 25%. By 2060, the proportion of electricity generated from wind and solar power is anticipated to further increase to approximately 60% [15]. In the thermal power sector, the installed capacity in 2023 was 1.3779 billion kilowatts (1377.9 GW), representing 48.34% of the total installed capacity. In the hydropower sector, cumulative power generation reached 1004 billion kilowatt-hours (1004 TWh) by September 2024. Furthermore, by 2025, the cross-provincial and inter-regional power transmission capacity within the operating area of the State Grid Corporation of China (Beijing, China) is planned to reach 300 million kilowatts (300 GW). These developments highlight the significant progress China has achieved in power engineering construction across various domains, including new energy, hydropower, thermal power, and power transmission and transformation [16]. Relevant information is presented in Figure 1.

Figure 1.

Development trends in China’s power engineering construction. (a) Hydropower installed capacity and its increase, 2019–2024; (b) thermal power installed capacity and its increase, 2019–2024; (c) grid-connected wind power capacity and its growth rate, 2019–2024; (d) total electricity consumption of society and its growth rate, 2019–2024 [13,17,18].

As China’s power construction sector continues to expand, its safety risk management exhibits significant multidimensional complexity and systemic coordination requirements. Nationally, during China’s 15th Five-Year Plan Action Plan for Electric Power Work Safety (2026–2030), (1) large-scale hydropower stations and pumped storage projects will expand substantially [19], (2) wind power is developing rapidly [20,21]; and (3) photovoltaic capacity, particularly in offshore and distributed wind systems [22], is also growing swiftly, with active deployment nationwide. Though declining in proportion, thermal power will maintain a considerable installed capacity to ensure grid stability [15].

Various power generation entities and utility groups, serving as project implementers, possess the technical expertise, financial capacity, and extensive experience required for large-scale engineering projects. However, as renewable energy projects expand into remote regions, construction costs escalate while demanding substantial continuous investment in innovations such as energy storage. These pressures strain implementers’ resources and exacerbate the persistent shortage of construction and supervision personnel. Consequently, assigning safety responsibilities and implementing on-site safety controls become increasingly challenging. Regarding regulatory oversight, the National Energy Administration of China (NEA) and its regional branches leverage policy-making and supervisory powers to advance power planning. Yet, during the 15th Five-Year Plan period (2026–2030), the proliferation of power projects and emerging models like distributed energy [23] will significantly expand the regulatory scope and intensify workloads. Insufficient staffing may become apparent, while heightened demands for regulators’ technical expertise necessitate urgent capacity building.

Power engineering construction exhibits a distinctive high-risk profile involving operations at heights, high-voltage electrical work, heavy machinery operation, etc., resulting in persistently high accident rates. These incidents not only cause substantial direct economic losses but also trigger spillover effects leading to immeasurable indirect production capacity losses. (For instance, as documented in the NEA announcement [24], a turbine damage accident at a thermal power company in June 2024 incurred direct economic losses of CNY 7.1697 million; in March 2021, equipment failure at a wind farm owned by an energy company resulted in losses reaching CNY 4.45 million.) Safety risk management is crucial in power engineering construction, essential for implementing the Holistic Approach to National Security, safeguarding the economy and public welfare, ensuring personnel safety and project quality, and promoting social stability. The Holistic Approach to National Security emphasizes that development and security are dual imperatives requiring integrated management. It underscores that development serves as both the foundation and ultimate goal of security, while security provides the essential conditions and safeguards for development. However, the industry’s complex nature—involving multidisciplinary technology integration, dynamic environments, and varying risk profiles across project types—results in significant differences in safety management practices among enterprises. This poses major challenges for safety stratification, dynamic control, and managing critical risk projects.

Existing research on new power systems predominantly focuses on future development trajectories and application landscapes [25], or emphasizes economic feasibility assessments [26,27]. This study shifts scholarly attention to construction safety, specifically examining safety governance mechanisms in new power infrastructure construction. Through systematic analysis of historical accidents, we identify critical risk factors to provide targeted countermeasures for enhancing safety in future new power projects. The primary objective of this study is to establish a safety risk management and control system within the context of China’s power engineering construction. Specifically, this research aims to (1) diagnose and categorize safety risk management issues faced during the 14th Five-Year Plan period in power construction projects in China, and (2) conduct targeted countermeasure research on the identified safety risk management problems. This may enhance the intrinsic safety level of power engineering construction and provide critical technical and managerial support for achieving national energy transition and carbon neutrality goals.

2. Research Approach

2.1. Theoretical Framework

Risk is defined as the combination of the likelihood of a safety incident occurring and the severity of its consequences [28], typically categorized into low, medium, and high levels [29]. Common risk analysis methodologies include Failure Mode and Effects Analysis (FMEA) [30,31], Hazard and Operability Analysis (HAZOP) [30], Layer of Protection Analysis (LOPA) [32], Fault Tree Analysis (FTA) [33], and Event Tree Analysis (ETA) [31].

Risk management constitutes a systematic planning process for identifying, analyzing, responding to, and monitoring project risks. As an indispensable component of project management, effective implementation of enterprise risk management practices can shorten the duration of global economic recessions and mitigate their severity [10]. Regarding risk management models, the Systems-Theoretic Accident Model and Processes (STAMP) model provides a holistic perspective that treats systems as integrated wholes rather than isolated components [34].

When confronting inherent systemic risks and crises, High Reliability Organizations (HROs) serve as crucial entities for crisis prevention and mitigation through their repeatable, highly reliable behaviors and practices [35]. HROs maintain that hazardous accidents are “effectively inevitable”, and that systematic post-crisis reflection cannot fully eliminate dangers from high-risk systems [36].

Safety risk control refers to the process of selecting and implementing specific measures to “control” or “manage” identified risks within the safety risk management framework. Safety risk control refers to the process of selecting and implementing specific measures to “control” or “manage” identified risks within the safety risk management framework. Causality is the core element for effectively constructing a risk control system and represents a fundamental research question within safety science [37]. To effectively analyze the complex causal relationships in safety incidents, various analytical tools have been developed, as summarized in Table 1.

Among these, FTA is a systematic deductive analysis method. HAZOP identifies potential deviations in processes or operational procedures and their potentially hazardous consequences by systematically applying guide words [38]. System-Theoretic Process Analysis (STPA), based on systems theory, focuses on assessing risk, analyzing hazards, and delving into performance variability and interactions within complex systems [39]. The Decision-Making Trial and Evaluation Laboratory (DEMATEL) method addresses complex and comprehensive decision-making problems, enabling the identification of causal relationships among evaluation criteria [40]. Bayesian networks (BNs) are crucial tools for describing relationships between variables and outcomes, applicable to diagnosis, causal modeling, inference, and decision-making in safety risk analysis and control [41]. Bayesian Belief Networks (BBNs) are specifically used to explain causal relationships between risk factors and focal events [42].

To effectively process data, Cloud Modeling (CM) theory handles the fuzziness and randomness of probabilities inherent in human knowledge and the external environment [43]. Emerging blockchain technology further enhances data security [44] and has recently been applied within the safety management domain [45].

Regarding power engineering construction, Rasinojehdehi et al. [46] employed Data Envelopment Analysis and Support Vector Machine to conduct a comprehensive assessment of risks associated with solar power plants. Zhou et al. [47] applied the analytic hierarchy process to review and analyze global wind power accidents from 1980 to 2019. Albert et al. [48] conducted a quantitative study on safety risks in the construction of transmission and distribution lines. Kim et al. [49] classified and evaluated risks in nuclear power plant construction through a literature review and expert interviews, ultimately proposing a standardized risk classification system. Wang et al. [50] used expert interviews to categorize risks in nuclear power construction in China and proposed corresponding risk management measures.

Furthermore, the application of artificial intelligence (AI) in the construction industry is quite common [51]. For instance, Qi et al. [41] introduced AI combined with Bayesian networks to implement a data-driven approach for falls from height accidents, enabling effective predictive and diagnostic risk analysis. In the power construction industry, Wang et al. [52] utilized deep learning methods such as convolutional neural networks to identify component status and achieve proactive safety risk management. Cheng et al. [53] analyzed safety risk management in power engineering construction under big data settings using data preprocessing and visualization techniques. Okereke et al. [54] employed technologies such as machine learning, predictive analytics, and real-time data processing to achieve precise risk management in energy projects. Guang et al. [55] demonstrated the breadth and importance of AI model applications in power safety and emergency management.

Table 1.

Comparative analysis of safety risk methodologies.

Table 1.

Comparative analysis of safety risk methodologies.

| Method Model | Characteristics |

|---|---|

| FTA [31] | Top–down, deductive (backward method) risk assessment tool used to determine failures and contributing factors leading to adverse events in a system. |

| ETA [31] | Bottom–up, inductive risk analysis technique used to identify and assess potential accidents and their possible chains of related events. |

| HAZOP [31] | A technique used to identify system hazards to prevent adverse events. |

| FMEA [31] | Bottom–up, inductive (forward method) risk assessment tool that can be used to identify failure modes negatively impacting the entire system. |

| STAMP [56] | A novel qualitative and comprehensive accident causality model used to analyze accidents in systems. |

| STPA [56] | A proactive analysis method used to analyze potential causes of accidents during development to eliminate or control hazards. |

| Causal Analysis based on System Theory (CAST) [56] | A retrospective analysis method used to examine accidents/incidents and determine the contributing factors involved. |

2.2. Analytical Framework

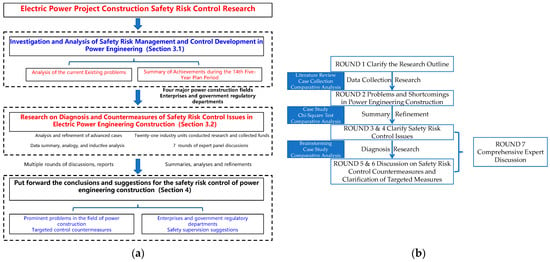

During the 14th Five-Year Plan period for power planning, rapid industry growth spurred a nationwide surge in power construction projects. However, significant unresolved challenges remain [57]. The participating institutions in this study include project owners, survey and design units, construction contractors, supervision agencies, and university teams—all possessing strong professional qualifications, familiarity with safety management characteristics, and the ability to accurately grasp the latest industry trends and cutting-edge technologies. This study engaged 39 experts exclusively from major state-owned enterprises, representing 20 top-tier Chinese power companies. More than 90% of the participants hold senior professional titles (professor-grade) with exceptional qualifications and comprehensive knowledge of safety management protocols. Their specialized expertise across the hydro, thermal, new energy, and transmission sectors significantly strengthened this research through multidisciplinary perspectives, ensuring both comprehensiveness and academic rigor. The present research’s framework is depicted in Figure 2.

Figure 2.

Research framework for safety risk management and control in power engineering construction. (a) Research framework; (b) Process flowchart of expert discussion.

- (1)

- Current Status Investigation

Through multiple methods including field investigations, literature reviews, case studies, analogical analysis, data analysis, expert elicitation, and brainstorming, information was collected. Building upon this foundation, accident case analyses were conducted, relevant policies and standards were researched, current status investigations and summarizations were performed, and exemplary case analyses were carried out.

- (2)

- Summary and Analysis

A summary and analysis of safety risk management and control in power engineering construction during the 14th Five-Year Plan period was performed. This encompassed analysis of key focal points and difficulties in the control, examination of current existing problems, and identification of deficiencies and shortcomings. The scope covered enterprises and government regulatory bodies across four major power construction sectors: hydropower (including pumped storage) engineering, thermal power engineering, new energy engineering, and power transmission and transformation engineering.

- (3)

- Diagnosis and Countermeasure Research

Through analysis and refinement of advanced cases, industry research diagnostics, multiple centralized discussions and expert consultations, and inductive analysis and distillation, research on the diagnosis of problems and countermeasures for safety risk management and control in power engineering construction was conducted. This yielded targeted management and control countermeasures for prominent issues in the power construction sector, along with safety supervision recommendations for enterprises and government regulatory bodies.

- (4)

- Strategy Consolidation

Conclusions and recommendations for safety risk management and control in power engineering construction were proposed, ultimately enhancing the inherent safety level of power engineering construction projects.

3. Investigation and Analysis of Safety Risk Management and Control Development in Power Engineering

3.1. Case Analysis of Accidents by Sector

Case studies were conducted on safety risk management and control in power engineering construction during the 14th Five-Year Plan period of China. Firstly, typical enforcement cases from the NEA’s power safety production supervision [58], typical violation cases reported by representative industry enterprises, and significant research-worthy typical cases provided by experts were collected. Then, the cases were compiled, organized, and categorized according to the type of violation (illegal/regulatory) and the severity of the incident. Among them, (1) as regards hydro (including pumped-storage) projects, 12 typical issues were identified, including 1 flooded powerhouse incident; (2) as regards thermal power projects, 11 typical issues were identified, resulting in 2 collapse accidents, 1 explosion, and 1 buried-alive accident; (3) as regards new energy projects, 31 typical issues were identified, leading to 1 structural collapse, 1 electrical injury incident, 3 component fall accidents, 1 fatal fall from height, 1 explosion, and 1 hoisting machinery injury; and (4) as regards transmission projects, five typical issues were identified, causing one fall from height incident and one significant collapse fatality.

Finally, the prominent issues identified across various sectors were summarized. These issues mainly concentrated on non-standard construction plan management, incomplete risk identification, inadequate safety protection, insufficient safety education and training, and deficiencies in safety cost management. Analysis and summarization were performed for four major sectors: hydropower (including pumped storage) engineering, thermal power engineering, new energy engineering, and power transmission and transformation engineering. Detailed information on the research cases can be found in Supplementary Material File S1. The analysis and summary of accident cases in the four major power construction fields are presented in Table 2.

Table 2.

Analysis and summary of accident cases in the four major power construction fields.

In the field of safety risk management and control for hydropower (including pumped storage) construction, some projects exhibited typical safety risk management and control problems. Analysis revealed that these problems reflected insufficient on-site management staffing, low competency levels among personnel, inadequate allocation of construction resources, and understaffing of supervision personnel on some projects. Concurrently, safety risk management and control were inadequate in some projects, manifested by the absence of comprehensive safety technical briefings covering operational risks and pre-control measures, and insufficient supervision of on-site risks and construction equipment.

In the field of thermal power construction safety risk management and control, some projects exhibited typical safety risk management and control problems. Analysis exposed that these problems reflected the superficial implementation of safety management systems in some projects, ineffective prevention of procedural violations, insufficient safety awareness among personnel coupled with inadequate training implementation, non-compliance with safety technical standards during construction, weak on-site safety management, and the absence of specific hazard controls for certain critical activities.

In the field of new energy construction safety risk management and control, some projects exhibited typical safety risk management deficiencies. Analysis indicated these problems reflected flaws in design and construction planning, ineffective implementation of special plans for critical/high-risk operations, and irrelevant safety training demonstrating insufficient awareness of risks associated with new technologies, processes, materials, and equipment. Furthermore, a significant disconnect between on-site execution and supervision resulted in failures to promptly identify and correct violations.

In the field of power transmission engineering construction and maintenance, some projects experienced typical safety incidents. Analysis revealed these problems reflected deficiencies in construction quality and equipment maintenance management, leading to failures in inherent safety measures; inadequate control over hazardous work procedures, poor safety awareness, and habitual violations among workers; and non-specific specialized skills training that failed to effectively mitigate safety risks.

The accident cases from the above four sectors were categorized according to the accident type and analyzed using the chi-squared test, with the chi-squared formula as shown below.

where denotes the chi-squared value, represents the observed frequency, and is the expected frequency. The Python code for calculating is provided in Supplementary Material File S2. The matrix of accident causation factors versus occurrence frequencies is presented below.

Table 3 is obtained based on the matrix R.

Table 3.

Proportion of accident causes and chi-squared values.

Analysis of the p-values in Table 3 reveals that the p-value for “Risk classification and hierarchical implementation” is 0.029 and that for “Hollowing out of construction units’ own workforce” is 0.017. Both values are below α (α = 0.05), indicating statistically significant issues. In contrast, the p-value for “Inadequate hazard identification” is 0.1, suggesting a marginally significant concern. Owing to the limited sample size, the number of cases is reduced and a sensitivity analysis is performed. Selection includes the first six accident cases from hydropower projects, the first five from thermal power projects, the first sixteen from new energy projects, and the first three from transmission and transformation projects, resulting in a total of thirty cases subjected to an additional round of chi-squared analysis. The results are shown in Supplementary Material File S3.

A significance level of α = 0.05 is again adopted for comparative analysis. The results indicate that, with the exception of “Insufficient equipment safety risk control”, “Inadequate safety production education and training”, and “Insufficient investment in safety resources”, which yield p-values greater than 0.05, all other items show p-values below 0.05, suggesting marginally significant issues.

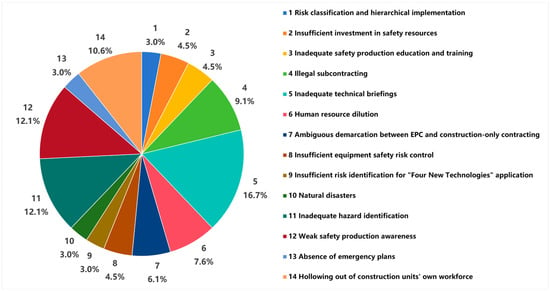

The discrepancy in the number of cases may influence the chi-squared test results. Therefore, future work will involve collaboration with relevant national authorities to acquire more cases and further enhance the reliability of the findings. To comparatively analyze the distribution of 14 risk factors across four sectors, Figure 3 was developed. It shows inadequate technical briefings as the most prevalent issue (16.7%), followed by inadequate hazard identification and weak safety production awareness (12.1% each), with hollowing out of construction units’ own workforce at 10.6%. While other risks show lower percentages, all may trigger cascading effects with severe safety implications. Collectively, these risks reflect multifaceted deficiencies in power engineering safety management, necessitating comprehensive review and targeted diagnostics to strengthen safety resilience.

Figure 3.

Summary of accident types in power engineering construction.

3.2. Problems and Deficiencies in Safety Risk Management and Control for Power Engineering Construction

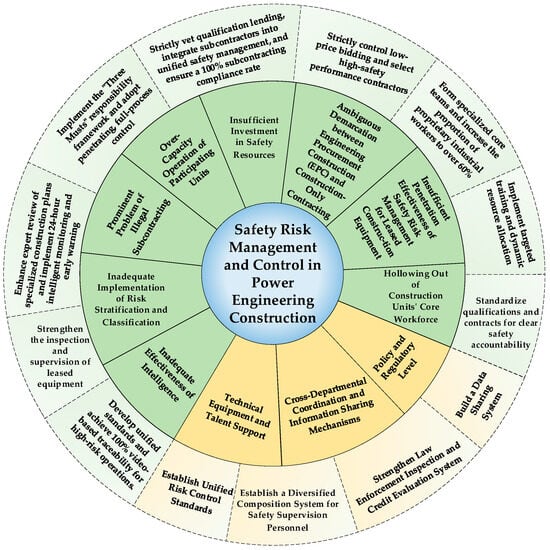

During the 14th Five-Year Plan period for power planning, the power construction industry experienced rapid development, leading to a sharp increase in the number of power construction projects in China. However, numerous significant issues persist that cannot be ignored. Through multiple discussions with experts, key problems have been summarized. These range from risk control management issues stemming from the ambiguous demarcation between EPC and construction-only contracting to human resource challenges resulting from participating units overextending their capacity; and from technical and safety hazards caused by the hollowing out of construction units’ own workforce to rampant irregularities such as insufficient investment in safety resources and illegal subcontracting. These problems pose a serious threat to the safety and quality of power construction projects and urgently require in-depth analysis and resolution. The summary is shown in Table 4.

Table 4.

Compilation of challenges in safety risk management and control for power engineering construction.

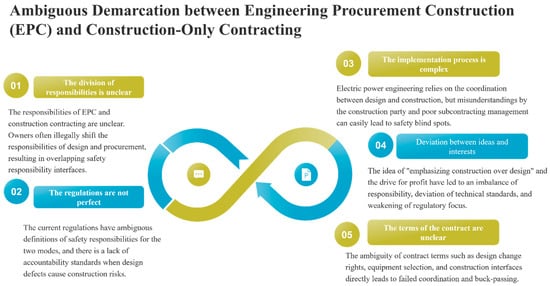

3.2.1. Ambiguous Demarcation Between EPC and Construction-Only Contracting

The current surge in power construction projects highlights the ambiguous demarcation between EPC and construction-only contracting. The core conflict stems from three factors: unclear responsibility division, imperfect regulations, and implementation complexity. EPC contractors bear full-chain responsibility for design–procurement–construction, while construction-only contractors are solely responsible for construction according to the drawings provided. In practice, owners frequently transfer design/procurement responsibilities to construction contractors in violation of contractual agreements, resulting in overlapping safety responsibility interfaces. Existing regulations offer vague delineation of safety responsibilities for the two models and lack standards for assigning liability when design defects cause construction risks. Power engineering heavily relies on design-construction coordination, yet deviations in the construction party’s understanding of design intent create safety blind spots. Critically, ambiguous contract clauses regarding design change authority, equipment selection, and construction interfaces directly trigger coordination failures and procedural buck-passing. This confusion over safety risk ownership and schedule risks severely undermines project execution efficiency, as shown in Figure 4.

Figure 4.

Ambiguous demarcation between EPC and construction-only contracting.

3.2.2. Over-Capacity Operation of Participating Units

Power engineering construction faces dual challenges: human resource supply–demand imbalance and structural disparity. Firstly, the rapid expansion of infrastructure scale contrasts sharply with a shrinking construction workforce, creating a pronounced “scissors gap”. The total personnel supply is insufficient, and the extended training cycle for new-generation skilled workers results in deficiencies in both quantity and quality. Secondly, the workforce structure exhibits generational fragmentation, marked by a rising proportion of aging workers alongside the upgraded career expectations of younger workers. The steadily declining proportion of highly skilled workers compels a “compensate quantity for quality” approach, normalizing illegal approvals for high-risk operations. Compounding this, the breakdown of mentorship-based skill transmission has created a vicious cycle: novices lack practical experience, further diminishing safety control effectiveness.

3.2.3. Hollowing Out of Construction Units’ Core Workforce

The “hollowing out” of industrial workers is increasingly severe. The loss of in-house technical expertise and critical shortage of on-site technical supervisors proficient in corporate standards have significantly eroded construction process standardization. With corporate-owned workers largely absent, most on-site tasks depend on migrant labor. Constraints arising from their educational levels, professional backgrounds, and job instability result in safety awareness [59] and skill levels that fall short of current industry requirements.

The practice of “one person holding multiple positions” in critical roles is pervasive on site. Insufficient reserves of core technical personnel render emergency deployment capabilities inadequate for project demands. Similarly, in-house safety management personnel are chronically understaffed and often forced to juggle multiple roles with fragmented focus, severely limiting their capacity for comprehensive, site-wide supervision. The hollowing out of the core workforce fosters complex on-site personnel structures and heightened communication barriers. Moreover, diminished team cohesion encourages blame-shifting when problems arise, preventing unified responses to emergent construction risks and ultimately obstructing the implementation of effective risk control measures.

3.2.4. Insufficient Investment in Safety Resources

Due to intense market competition and bid price constraints imposed by project owners, low-price bidding has become prevalent. This leads to reductions in construction enterprises’ allocation of management and construction resources, resulting in insufficient configuration of safety management resources. Examples include an inadequate number of safety management personnel, low competency levels among assigned personnel, and insufficient investment in safety protection equipment and facilities that fail to meet construction safety requirements. Consequently, on-site safety management is deficient, and safety protections are lacking [60]. Additionally, some supervision project departments face issues such as insufficient staffing of supervisors and key personnel lacking corresponding qualification certificates. Furthermore, the recruitment of operational personnel prioritizes wage levels over skill constraints. Figure 5 presents the issue of insufficient investment in safety resources.

Figure 5.

Insufficient investment in safety resources.

3.2.5. Prominent Problem of Illegal Subcontracting

In power engineering construction, the ambiguity in the work scope list and the unclear definition of main works easily lead to illegal subcontracting, cost overruns, schedule delays, and disputes over rights and responsibilities. Subcontracting main works significantly impairs the project’s risk management capability. Various covert methods are employed to achieve “professional subcontracting under the guise of labor subcontracting”. Subcontractors further subcontract the works they have contracted, resulting in severe multi-tiered subcontracting. This causes progressive attenuation of the management chain and the attenuation of primary safety responsibility (buck-passing of responsibilities between general and subcontractors). Moreover, construction units lack unified standards and effective measures for managing the safety of subcontracting teams. Subcontracting teams themselves have an unsound safety management system. Labor units lack corresponding construction capabilities and management experience, personnel safety training is inadequate, and frequent violations during construction easily cause safety accidents and quality issues.

3.2.6. Inadequate Implementation of Risk Stratification and Classification

Enterprises lack a standardized process for reporting major risks by level. They fail to establish a safety risk database categorized by risk type and severity level for dynamic management. Furthermore, they neglect to regularly organize production safety management personnel, professional technicians, and other relevant staff to identify major hazards within their operations, resulting in insufficient registration of identified risks.

The risk management and control system within construction projects are disorganized. Work teams lack effective mechanisms to strengthen risk awareness. Safety concepts are inadequately integrated into operational procedures during daily tasks, and “three violations” (violations of regulations, discipline, and operational procedures) persist unchecked due to complacency at the grassroots level and the absence of effective violation correction. Safety responsibility implementation is superficial. “Safety First” remains merely a slogan. The responsibility chain attenuates progressively, and relevant personnel lack the initiative to resolve production safety problems.

Leaders demonstrate insufficient safety knowledge and skills, remaining unfamiliar with the latest safety regulations, standards, and technologies. Personnel authorizing critical and major risk operations lack the requisite professional expertise. The approval process is flawed; supervision and scrutiny are lax, and the “prepare-review-approve” workflow is not strictly followed. Expert argumentation becomes perfunctory, rendering recommendations ineffective under special conditions. Concurrently, construction personnel lack sufficient understanding of the critical and major risk operation approval process and its importance. Instances of performing work first and seeking approval later, or bypassing approval altogether, occur frequently. Workers take arbitrary procedural shortcuts, and monitors fail to conduct mandatory on-site supervision, making timely correction of violations difficult.

The safety responsibility assessment mechanism is imperfect, failing to dispel the misconception that “safety is exclusively the safety department’s responsibility”. Technical and production personnel do not prioritize the implementation of safety risk control measures.

3.2.7. Insufficient Penetration Effectiveness of Safety Risk Management for Leased Construction Equipment

To alleviate financial and management pressure, construction units increasingly adopt light-asset operation models. Their willingness to invest in equipment is low, and they prefer leasing to reduce costs. This directly results in a lack of owned equipment and excessive reliance on leasing, leading to poor equipment management that undermines safety risk control.

Leased equipment is frequently aging and prone to faults, with performance often mismatched to project requirements. Daily maintenance is typically inadequate, significantly increasing operational risks. Under the subcontracting model, equipment management responsibility boundaries are often blurred. The practice of “managing through leasing” leads to suspended maintenance responsibility and unclear primary safety responsibility. A fault-tracing system for leased equipment is absent, severely hindering accountability investigations for mechanical accidents. The circulation of special equipment “in suboptimal condition” is normalized, and the completeness rate of maintenance records transferred between subcontracting teams is consistently insufficient.

3.2.8. Inadequate Effectiveness of Intelligence

The development of smart construction sites faces a series of constraints. Technically, equipment and standards from different vendors vary, system compatibility is poor, and data silos are prominent, hindering data flow and integration. Cost-wise, development requires significant funds for equipment procurement and operation/maintenance, placing heavy pressure on small and medium enterprises. Budget limitations restrict the application of high-end technologies. In terms of environmental adaptability, network coverage in mountainous areas and hardware deployment in complex geographical environments like hydropower stations are difficult. Existing technologies lack adaptability in high-risk zones. Regarding personnel, smart construction sites urgently require interdisciplinary professionals skilled in both engineering management and digital technology. However, such personnel are scarce within the industry, and the training system is inadequate, making it difficult to meet development needs, as shown in Figure 6.

Figure 6.

Inadequate effectiveness of intelligence.

3.3. Problems and Deficiencies in Industry Supervision and Management of Safety Risk Control

Amid rapid technological advancement and increasingly complex, dynamic safety landscapes, enterprise safety management faces unprecedented dual pressures: severe challenges from constantly emerging new risks, alongside opportunities where emerging technologies and concepts provide powerful momentum for safety management innovation. From a safety risk supervision perspective, actively embracing new technologies and concepts to comprehensively innovate risk control methodologies has become critical for steady industry progression within this complex environment.

3.3.1. Policy and Regulatory Level

The existing regulatory system often lags behind industry and technological developments, particularly regarding applications of new technologies, processes, materials, and equipment (“Four New Technologies”). Key provisions frequently suffer from ambiguous wording or unclear definitions. Concurrently, the pace of regulatory updates fails to match market evolution, hindering the timely integration of emerging safety risks into the legal framework. Compounding these issues, some regulatory bodies—constrained by resource limitations and inadequate enforcement mechanisms—demonstrate insufficient oversight capacity, failing to effectively curb corporate violations and non-compliant behaviors.

3.3.2. Cross-Departmental Coordination and Information Sharing Mechanisms

Efficient inter-departmental coordination mechanisms are notably deficient among regulatory bodies. Ambiguous responsibility delineation frequently yields overlapping jurisdictions or critical gaps, actively fostering regulatory buck-passing. Moreover, information sharing encounters systemic barriers including incompatible data formats and conflicting confidentiality protocols. This fragmentation disperses regulatory resources, impedes critical information flow, hinders synergistic oversight capacity, and ultimately compromises effectiveness in managing complex safety risks.

3.3.3. Technical Equipment and Expert Support

Technical equipment and expert support face dual dilemmas. Regulatory bodies have limited investment in safety technical equipment; outdated and obsolete devices struggle to meet modern supervision demands. Simultaneously, a severe shortage of professional safety supervision personnel exists, making it difficult to cope with the complexity and challenges of safety risk supervision.

4. Countermeasures for Safety Risk Management and Control in Power Engineering

Building upon a systematic synthesis of identified issues and in-depth case analysis, this chapter establishes a scientifically rigorous framework for safety risk control measures.

4.1. Countermeasures for Safety Risk Management and Control in Power Engineering Construction

4.1.1. Countermeasures for Ambiguous Demarcation Between EPC and Construction-Only Contracting

To enhance construction project management, multiple approaches can be adopted. Regarding the EPC management model, the industry should establish an engineering safety management capability model, conduct assessments of construction safety management capabilities, cultivate safety risk control capabilities, and simultaneously refine qualification regulations for EPC contractors by referencing management practices from other industries. In terms of contract management, standardized subcontract template agreements need to be developed, clearly defining the safety responsibilities, rights, and obligations of both parties. Supervision during contract execution must be strengthened to ensure strict contract compliance. During the project bidding stage, strict qualification reviews of participating subcontracting units should be conducted.

4.1.2. Countermeasures for Over-Capacity Operation of Participating Units

To address the over-capacity operation of participating units, measures can be implemented in three areas. Training: establish targeted personnel cultivation mechanisms in collaboration with universities and institutions, develop training programs for newcomers encompassing theory, practical skills, and safety regulations, and invite experienced workers to teach. Planning: scientifically allocate personnel based on project scale and difficulty, develop optimization models, establish dynamic deployment mechanisms, build an electronic archive database linking key information, and utilize blockchain to ensure information authenticity, thereby optimizing resources. Resource allocation: utilize project management tools to rationally allocate resources according to project progress and risk status, ensuring efficient resource utilization and promoting smooth, safe construction. To address safety hazards arising from schedule compression, mandatory dynamic safety assessments should be implemented alongside increased deployment of dedicated safety officers. Modular construction techniques should be adopted to reduce high-risk operations, complemented by intelligent monitoring systems. Additionally, establishing ‘safety buffer periods’ and enhancing overtime insurance coverage will ensure alignment between safety investments and accelerated timelines.

4.1.3. Countermeasures for Hollowing Out of Construction Units’ Own Workforce

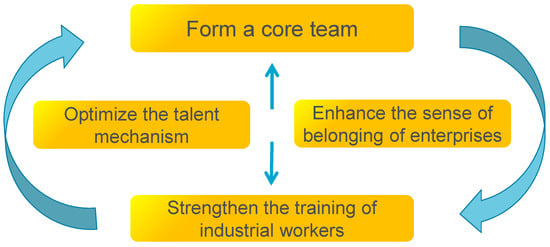

To address the hollowing out of construction units’ own workforce, the following countermeasures can be adopted: Carefully select personnel with rich engineering experience, an understanding of safety control, and leadership abilities to form core work teams and safety control core teams encompassing professionals in engineering technology, safety management, and other fields, providing professional support for safety decision-making, risk assessment, and control. Optimize personnel recruitment and retention mechanisms, improve the compensation of industrial workers, enhance the working and career development environments, establish skill advancement pathways, and conduct corporate cultural activities to enhance a sense of belonging. Strengthen the development of the industrial workforce, encourage construction units to cultivate their own workers, increase the proportion of own workers to over 60%, and cultivate or select long-term partners with their own industrial teams, laying the foundation for personnel cultivation and professional capability enhancement. Improve team building, refine team management systems, formulate safety standardization compliance standards, and use exemplary core teams as benchmarks to promote the comprehensive coverage of standardized team construction. The countermeasures for the hollowing out of construction units’ own workforce are described in Figure 7.

Figure 7.

Countermeasures for hollowing out of construction units’ own workforce.

4.1.4. Countermeasures for Insufficient Safety Investment

To address insufficient safety investment in power engineering, solutions can be approached from the following aspects.

Government level: Strengthen regulatory oversight, further refine regulations related to safety investment, clearly define the responsibilities of construction and contracting units regarding the proportion of safety funds allocated and their usage scope, strictly prohibit bidders from bidding below cost or using fraudulent means to win bids, and flexibly employ methods such as regular inspections and unannounced spot checks.

Construction unit level: Standardize tender document settings and avoid unreasonably raising design performance thresholds or adding other barriers beyond national qualification limits that restrict qualified and capable construction units from participating in bidding. During the project bidding phase, standardize project organizational forms, improve bidding evaluation methods, establish a reasonable low-price review mechanism, resolutely eliminate the phenomena of low-price winning bids and qualification lending, strengthen the setting and review of safety conditions during the bidding stage, establish scientific criteria for evaluating corporate safety compliance capabilities, and select the best construction teams with outstanding safety records and strong safety control capabilities to participate in project construction.

Clearly define the scope of expenditures for improving, retrofitting, and maintaining safety protection facilities and equipment (excluding initial investments in safety facilities required by the “Three Simultaneities” (the safety facilities of construction projects shall be designed, constructed, and put into operation and use simultaneously with the main project).

4.1.5. Countermeasures for Prominent Illegal Subcontracting Problem

To address the prominent issue of illegal subcontracting, countermeasures can be taken in areas such as qualification review, team management, subcontracting definition, and crackdowns on illegality.

Qualification review: Establish a robust subcontractor qualification review mechanism and capability assessment system, conduct on-site inspections of subcontracting teams’ personnel, equipment, and performance, and eliminate qualification lending practices; construction units implementing labor subcontracting must ensure the labor subcontractor possesses corresponding qualifications, and the construction unit bears primary responsibility for on-site production safety.

In terms of team management: construction units must integrate subcontracting teams into a unified safety management system, conduct regular safety training and inspections [61], and must be urged to improve their safety management systems and standardize construction behavior.

As regards the definition of subcontracting: construction units should clearly define the boundaries of main works and undertake main works construction themselves. When subcontracting non-main professional works, subcontract agreements must clearly define the safety responsibilities and obligations of both parties. The construction unit performs supervision and management duties. The EPC contractor performs the construction unit’s production safety management duties and bears joint management liability. The supervision unit dynamically verifies the construction capability of subcontractors. The construction unit arranges dedicated personnel for full-process supervision of critical procedures. Simultaneously, illegal subcontracting should be severely cracked down on by organizing specialized supervision and inspection campaigns, establishing reporting platforms, increasing penalties to form an effective deterrent, ensuring a 100% rate of standardized professional subcontracting management, and guaranteeing construction quality and safety.

4.1.6. Countermeasures for Inadequate Implementation of Risk Stratification and Classification

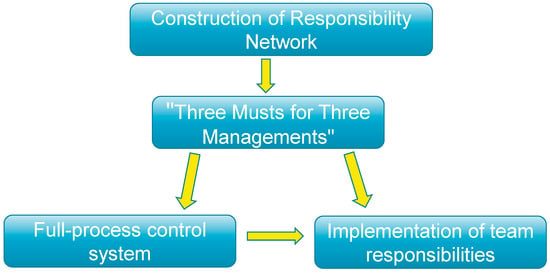

To solve the problem of inadequate implementation of risk stratification and classification, the following series of countermeasures can be adopted. Firstly, optimize the line management model by clearly delineating the safety management responsibilities of each department and position, constructing a rigorous safety management responsibility network that horizontally covers all departments and vertically extends to every position. Simultaneously, strengthen communication and collaboration between departments and establish a regular safety work coordination meeting system. Comprehensively implement the “Three Controls and Three Musts” principle (safety production supervision requires that safety must be supervised in industrial management, in business management, and in production and operation management), and actively explore new “penetration-style” management models. Relying on information technology, focus on the four core elements of “controlling plans, teams, personnel, and the site”, clarify control responsibilities, and build a full-process control system encompassing “pre-control, in-process supervision, and post-evaluation” to achieve comprehensive management. Construction team (work team) leaders must effectively implement production safety responsibilities, undertake daily safety management work, and bear direct management responsibility for the safety and health of construction personnel during operations. They are required to organize safety learning, conduct safety education, inspect on-site safety measures, organize safety activities, perform risk identification and pre-control, hold “pre-shift meetings”, identify hazards, supervise the use of protective equipment, and conduct safety technical briefings. Personnel without briefings or signatures are strictly prohibited from starting work. Countermeasures for the inadequate implementation of risk stratification and classification are presented in Figure 8.

Figure 8.

Countermeasures for inadequate implementation of risk stratification and classification.

4.1.7. Countermeasures for Problems in Critical and Major Risk Operations and Above

Strengthen training for approval personnel, regularly organize their participation in regulation and standard training and assessments, and invite experts for case analysis explanations to enhance risk assessment capabilities. Simultaneously, strengthen awareness among construction personnel through specialized training and publicity campaigns, emphasizing the approval process and its importance, establish a reporting mechanism, and impose strict penalties for violations. For the approval process, establish an expert database for critical and major risk operation approvals and formulate standardized approval procedures to improve approval quality. For hazardous sub-projects and tasks such as deep foundation excavation, high slope support, and large equipment lifting, construction units must formulate detailed and scientific specialized construction plans. Upon completion of the plan, organize a rigorous review and verification by authoritative industry experts to ensure the plan is technically and safety-feasible and aligns with the project reality. Additionally, utilize advanced technologies like displacement monitoring and stress monitoring to implement 24 h real-time dynamic monitoring of critical and major risk projects. Establish a robust early-warning mechanism with reasonable threshold values. Once the monitoring data exceeds the thresholds, the system promptly and accurately issues warnings and initiates emergency measures to contain safety risks at the initial stage.

4.1.8. Countermeasures for Insufficient Penetration in Risk Control of Leased Construction Equipment

The industry should accelerate specialized research to establish a risk control model under the “lease instead of management” mode for construction equipment, conduct efficacy assessments of risk management for leased construction equipment, and strengthen the risk management responsibilities of construction units, EPC contractors, and equipment suppliers. Government departments should formulate management regulations for the equipment leasing market, establish an access system for leased equipment, strengthen testing and supervision of leased equipment, conduct regular random inspections of leased equipment, and remove unqualified equipment.

Utilize IoT technology to transmit real-time equipment operational data to monitoring platforms for real-time monitoring and analysis of operational parameters, fault alarms, etc. Establish equipment health records, predict failure cycles based on big data, and achieve predictive maintenance.

4.1.9. Countermeasures for Inadequate Effectiveness of Smart Construction Site Development

Promote cross-domain technology integration (e.g., power large models, AI), and accelerate the formulation of industry-wide unified standards. Optimize the cost–benefit model by promoting low-cost, high-efficiency solutions such as shared platforms and lightweight applications to lower the transformation threshold for SMEs. Develop customized smart construction site solutions tailored to different project types (e.g., thermal power, wind power, UHV) to enhance adaptability in complex scenarios. Collaborate with universities and enterprises to establish training bases for cultivating professionals with engineering and digital skills; deepen the advancement of smart construction site development to achieve video collection of safety briefings for all critical and major risk projects and high-risk operations, video archiving of key processes and construction sequences, and video traceability; promote cross-domain technology integration, accelerate the formulation of industry-wide unified standards for smart construction sites, and develop specialized smart construction site solutions for different project types.

Section 4.1 proposes management and control countermeasures for safety risk management and control in power engineering construction, which are summarized in Table 5.

Table 5.

Countermeasures for safety risk management and control in power engineering construction.

4.2. Regulatory Countermeasures for the NEA and Its Dispatched Agencies

4.2.1. Standard Quantification: Establish Unified Risk Control Standards

In the field of power engineering construction, the state strengthens safety risk control through standard quantification by formulating scientific quantitative standards for risk classification. Based on indicators such as the likelihood of accidents and the severity of consequences, risks are classified into major, significant, and general levels. Control measures and responsible entities for each level are clearly defined. A dynamic assessment mechanism is established to regularly update standards to adapt to technological developments and changes in the construction environment, ensuring the precision and operability of risk classification and control.

4.2.2. Market Supervision: Strengthen Law Enforcement Inspection and Credit Evaluation System

The NEA and its dispatched agencies strengthen supervision and law enforcement regarding enterprises’ implementation of the dual prevention mechanism, conduct regular safety inspections, and incorporate safety credit into the market access and bidding system, establishing an “incentivizing compliance and penalizing non-compliance” mechanism [62]. Explicitly prohibit bidders from bidding with quotations below cost, establish a reasonable low-price review mechanism to eliminate the phenomenon of low-price winning bids; incorporate safety credit into the market access and bidding system, strengthen the setting and review of safety conditions during the bidding stage, establish criteria for evaluating corporate safety compliance capabilities, and select construction teams with outstanding safety records and strong control capabilities through EPC model research and safety management capability assessment; and strengthen qualification reviews of subcontracting units during the bidding stage, strictly eliminate qualification lending, and ensure construction units possess corresponding safety qualifications and compliance capabilities. Prior to project commencement, the project owner must develop a dedicated safety plan approved through formal risk assessment, explicitly defining construction safety risk mitigation measures. The owner bears overarching safety management responsibility and shall legally procure qualified contractors through competitive bidding. The contractor assumes primary responsibility for site safety execution, including safety budget implementation and field management. The supervision entity conducts independent safety oversight. All parties must execute a legally binding safety protocol clarifying liability demarcation and undergo regular inspections by energy regulatory authorities, ensuring safety accountability permeates the project life-cycle. Through these measures, safety risks are prevented at the source, compelling enterprises to implement their primary responsibilities.

4.2.3. Information Platform Construction: Build a Data-Sharing System

In terms of information platform construction, the state promotes the establishment of a nationwide power engineering safety risk control information platform. Enterprises are required to input data such as risk lists and hidden danger rectifications in real time. Big data analysis technology is leveraged to achieve dynamic risk monitoring and intelligent early warning. Simultaneously, data-sharing channels between regulatory authorities, enterprises, and third-party institutions are opened up, enhancing regulatory efficiency and providing data support for scientific decision-making, thereby driving the digital and refined transformation of safety risk control.

4.2.4. Establish a Diversified Composition System for Safety Supervision Personnel

It is recommended to establish a diversified composition system based on a “core team + flexible supplementation” model. Create an industry expert sharing pool and university–enterprise cooperation platforms. Strengthen resource coordination through intelligent scheduling of industry expert databases, university internship placements, and targeted cultivation, enabling flexible supplementation.

Section 4.2 proposes regulatory countermeasures for the NEA and its dispatched agencies, with the content summarized in Figure 9.

Figure 9.

Regulatory countermeasures for the NEA and its dispatched agencies.

5. Conclusions and Future Directions

5.1. Conclusions

This study is grounded in the unique context of China’s “new-type power systems” initiative. It focuses on the complex safety management challenges arising from the surge in power engineering construction during the 14th Five-Year Plan period—a period of strategic significance in the global energy transition. The safety construction risk issues and countermeasures in electric power engineering are summarized in Figure 10.

Figure 10.

Summary of safety construction risk issues and countermeasures in electric power engineering.

This study synthesizes 59 accident cases from China’s four major power construction entities, classifying accident causation through case analysis and expert deliberations into 14 categories comprising 66 risk factors. Chi-squared testing quantitatively identifies the top three significant risk factors: hollowing out of construction units’ own workforce, deficiencies in risk classification and hierarchical implementation, and inadequate hazard identification. Through multiple rounds of discussions with 39 industry experts, 11 critical issues are distilled, including ambiguous demarcation between EPC and construction-only contracting, over-capacity operation of participating units, hollowing out of construction units’ own workforce, and policy and regulatory level deficiencies.

To elevate the safety standards in China’s power engineering construction, countermeasures addressing these issues are developed via brainstorming and expert consultations, yielding nine enterprise-level initiatives—such as deepening general contracting management, improving training systems, optimizing bidding methods, and implementing management principles—alongside four regulatory measures targeting the National Energy Administration and supervisory agencies: formulating unified standards, strengthening law enforcement and credit evaluation, building an information platform, and establishing a diversified supervision personnel system. Collectively, these measures aim to holistically enhance the intrinsic safety of power construction projects. This research fills the application gap in “high-growth, multi-business-form” scenarios, providing reference recommendations for similar transforming countries.

5.2. Research Limitations and Future Directions

This study systematically explores the current status, problems, and countermeasures of safety risk management and control in power engineering construction during the 14th Five-Year Plan period, but it still has the following limitations:

(1) The research depth focuses closely on China’s policy environment (e.g., the 14th Five-Year Plan period for power projects) and regulatory framework (e.g., the NEA system). Conclusions drawn from 59 domestic cases are not systematically compared with practices in other countries. Regarding accident cases from power engineering projects during China’s 14th Five-Year Plan period, the publicly available data is inherently limited, partly due to the confidentiality surrounding certain incidents. While the identified core issues (such as ambiguity in EPC contractors’ responsibilities and subcontracting risks) are common, their manifestations and solutions may vary significantly due to differences in regulations, markets, and cultures.

(2) This research is strictly confined to the four major fields of power engineering (hydropower/pumped storage, thermal power, new energy, power transmission and transformation). Strategies proposed for industry-specific risks (e.g., intelligent monitoring for specialized operations at remote new energy projects or ultra-large hydropower projects) may not be directly transferable to other infrastructure sectors (e.g., construction, transportation, petrochemicals) due to unique technical specifications and supply chains.

This study proposes 14 core countermeasures for safety risk management in China’s power engineering construction. Effective implementation requires synergistic efforts between enterprises and regulatory authorities to enhance safety in clean energy infrastructure development. Future work will focus on the following aspects:

(1) Future work will include collaboration with relevant national authorities to obtain additional case data. In follow-up studies, data will be gathered from pilot projects that implement the research outcomes. Methods such as Monte Carlo simulation or Bayesian networks will be applied to quantify the potential effectiveness of individual countermeasures and estimate the overall reduction in accident rates.

(2) Developing intelligent risk prediction tools utilizing machine learning for dynamic early-warning systems, while leveraging blockchain technology to strengthen credential verification and historical incident record-keeping. An AI-driven countermeasure repository will be established to automatically generate incident response protocols.

(3) Conducting cross-national policy benchmarking with validation in extreme environments (high-temperature/humidity, desert/strong-wind scenarios). This will facilitate the adaptation of China’s methodology for projects across Southeast Asia, Latin America, and the Middle East, catalyzing the transition of China’s expertise from “localized solutions” to “global standards”, thereby advancing carbon-neutral transitions in energy infrastructure safety.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/pr13092789/s1, Supplementary Material File S1: Accident cases in hydropower (including pumped storage) engineering, thermal power engineering, new energy engineering, and transmission and transformation engineering. Supplementary Material File S2: Python code for calculation. Supplementary Material File S3: Results of the chi-squared analysis with a reduced number of cases.

Author Contributions

Conceptualization, X.Z. and J.Z.; methodology, X.Z. and J.Z.; validation, C.L. and F.H.; formal analysis, X.Z. and J.Z.; investigation, X.Z., Y.X., C.L. and J.Z.; resources, X.Z. and F.H.; data curation, X.Z. and F.H.; writing—original draft preparation, X.Z. and F.H.; writing—review and editing, X.Z. and F.H.; supervision, X.Z. and F.H.; project administration, X.Z. and F.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All analysis code and processed anonymized data for this study are available in the main text and Supplementary Materials, ensuring complete reproducibility of our results. Further inquiries can be directed to the corresponding author.

Acknowledgments

We also extend our thanks to the members of our research group. Their lively discussions, hard-working attitudes, and willingness to share knowledge have created a positive and productive research environment.

Conflicts of Interest

Authors Xiaoli Zhu, Jingyi Zhao, Yi Xiang, and Chen Li are employed by the company Hubei Anyuan Safety & Environmental Protection Technology Co., Ltd. Author Fan Hu is employed by the company China University of Geosciences (Wuhan). The authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

Nomenclature

| UHV | Ultra-High Voltage |

| GW | Gigawatt |

| TWh | Tera Watt Hour |

| NEA | National Energy Administration |

| CNY | Chinese Yuan |

| FMEA | Failure Mode and Effects Analysis |

| HAZOP | Hazard and Operability Analysis |

| LOPA | Layer of Protection Analysis |

| FTA | Fault Tree Analysis |

| ETA | Event Tree Analysis |

| STAMP | Systems-Theoretic Accident Model and Processes |

| HROs | High Reliability Organizations |

| STPA | System-Theoretic Process Analysis |

| CAST | Causal Analysis based on System Theory |

| DEMATEL | Decision-Making Trial and Evaluation Laboratory |

| BN | Bayesian Network |

| BBN | Bayesian Belief Network |

| CM | Cloud Modeling |

| EPC | Engineering Procurement Construction |

| AI | Artificial Intelligence |

References

- IEA. Latin America Energy Outlook 2023. Available online: https://www.iea.org/reports/latin-america-energy-outlook-2023 (accessed on 16 August 2025).

- IEA. Southeast Asia Energy Outlook 2024. Available online: https://www.iea.org/reports/southeast-asia-energy-outlook-2024 (accessed on 16 August 2025).

- IEA. Achieving a Net Zero Electricity Sector in Viet Nam. Available online: https://www.iea.org/reports/achieving-a-net-zero-electricity-sector-in-viet-nam (accessed on 20 August 2025).

- Yue, B.; Guo, C.; Guo, Y.; Feng, B.; Ding, X.; Wang, S. Review on the Development of Carbon Transaction in China and Analysis on the Participation Strategy of Electric Power Industry. In Proceedings of the 2021 IEEE Sustainable Power and Energy Conference (iSPEC), Nanjing, China, 23–25 December 2021; pp. 717–724. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Ma, H.; He, Y.; Wang, H.; Zhang, H. Reliability Evaluation Method for Underground Cables Based on Double Sequence Monte Carlo Simulation. Processes 2025, 13, 505. [Google Scholar] [CrossRef]

- Kang, C.; Yao, L. Key Scientific Issues and Theoretical Research Framework for Power Systems with High Proportion of Renewable Energy. Autom. Electr. Power Syst. 2017, 41, 2–11. [Google Scholar] [CrossRef]

- Shu, Y.; Chen, G.; He, J.; Zhang, F. Building a New Electric Power System Based on New Energy Sources. Strateg. Study CAE 2021, 23, 61–69. [Google Scholar] [CrossRef]

- NEWS, S.G. Development Achievements of State Grid During the 14th Five Year Plan Period. Available online: http://www.chinapower.com.cn/dww/jdxw/20250808/282462.html (accessed on 10 August 2025).

- The State Council Information Office Held a Series of Themed Press Conferences on “High Quality Completion of the 14th Five Year Plan” to Introduce the Achievements of Economic and Social Development During the 14th Five Year Plan Period. Available online: https://www.gov.cn/lianbo/fabu/202507/content_7031379.htm (accessed on 10 August 2025).

- Narayan, P.; Kar, S.; Jha Kumar, N. Enterprises’ Perspective in Managing Risks in Developing Renewable Power Projects: Case of Solar Power Projects. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2025, 17, 05025006. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, H.; Xu, H.; Li, Z.; Tian, X.; Fang, S.; Wang, J.; Xie, C.; Yang, D. A Hierarchical Analysis Method for Evaluating the Risk Factors of Pile Foundation Construction for Offshore Wind Power. Sustainability 2024, 16, 7906. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2024. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 10 August 2024).

- National Energy Administration. National power industry statistics for 2024. Available online: https://www.nea.gov.cn/20250121/097bfd7c1cd3498897639857d86d5dac/c.html (accessed on 10 August 2025).

- Wang, Q.; Huang, Y.; Zhu, Y.; Liu, J.; Du, Z. Development direction, technical issues, and key construction tasks for new power system. Renew. Energy Syst. Equip. 2025, 1, 1–7. [Google Scholar] [CrossRef]

- Tong, J.; Liu, W.; Mao, J.; Ying, M. Role and Development of Thermal Power Units in New Power Systems. IEEE J. Radio Freq. Identif. 2022, 6, 837–841. [Google Scholar] [CrossRef]

- Wang, K.; Niu, D.; Yu, M.; Liang, Y.; Yang, X.; Wu, J.; Xu, X. Analysis and Countermeasures of China’s Green Electric Power Development. Sustainability 2021, 13, 708. [Google Scholar] [CrossRef]

- National Energy Administration. The Grid Connection and Operation of Renewable Energy in 2024. Available online: https://www.nea.gov.cn/20250221/e10f363cabe3458aaf78ba4558970054/c.html (accessed on 10 August 2025).

- China Electricity Council. Available online: https://cec.org.cn/index.html (accessed on 10 August 2025).

- Bai, J.; Che, C.; Liu, X.; Wang, L.; He, Z.; Xie, F.; Dou, B.; Guo, H.; Ma, R.; Zou, H. Fault Diagnosis of Pumped Storage Units—A Novel Data-Model Hybrid-Driven Strategy. Processes 2024, 12, 2127. [Google Scholar] [CrossRef]

- Yao, J.; Yao, F. Status Quo, Development and Utilization Efficiencies of Wind Power in China. Processes 2021, 9, 2133. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Xie, D.; Zhang, Y. Intelligent Selective Aggregation Method for Offshore Wind, Thermal Power, and Energy Storage Systems Based on Set Theory. In Proceedings of the 2024 4th Power System and Green Energy Conference (PSGEC), Shanghai, China, 22–24 August 2024; pp. 153–157. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H. Overview of the development of offshore wind power generation in China. Sustain. Energy Technol. Assess. 2022, 53, 102766. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, Y.; Ning, H.; Li, P.; Cen, B.; Zhao, H.; Zou, H. Research on Power Quality Control Methods for Active Distribution Networks with Large-Scale Renewable Energy Integration. Processes 2025, 13, 1469. [Google Scholar] [CrossRef]

- National Energy Administration. Available online: https://www.nea.gov.cn/sjzz/aqs/index.htm (accessed on 10 August 2025).

- Jayabal, R. Towards a carbon-free society: Innovations in green energy for a sustainable future. Results Eng. 2024, 24, 103121. [Google Scholar] [CrossRef]

- Park, J.; Kang, S.; Kim, S.; Kim, H.; Cho, H.-S.; Lee, J.H. Enhancing the economic viability and reliability of renewables based electricity supply through Power-to-Gas-to-Power with green hydrogen. Energy Convers. Manag. 2024, 310, 118485. [Google Scholar] [CrossRef]

- Javanshir, N.; Pekkinen, S.; Santasalo-Aarnio, A.; Syri, S. Green hydrogen and wind synergy: Assessing economic benefits and optimal operational strategies. Int. J. Hydrogen Energy 2024, 83, 811–825. [Google Scholar] [CrossRef]

- IEC 61511; Functional Safety–Safety Instrumented Systems for the Process Industry Sector–Part 2: Guidelines for the Application of IEC 61511-1. International Electrotechnical Commission: Geneva, Switzerland, 2003.

- Zhang, J.; Ren, H.; Ren, H.; Chai, Y.; Liu, Z.; Liang, X. Comprehensive Review of Safety Studies in Process Industrial Systems: Concepts, Progress, and Main Research Topics. Processes 2023, 11, 2454. [Google Scholar] [CrossRef]

- Giardina, M.; Morale, M. Safety study of an LNG regasification plant using an FMECA and HAZOP integrated methodology. J. Loss Prev. Process Ind. 2015, 35, 35–45. [Google Scholar] [CrossRef]

- Altabbakh, H.; AlKazimi, M.A.; Murray, S.; Grantham, K. STAMP–Holistic system safety approach or just another risk model? J. Loss Prev. Process Ind. 2014, 32, 109–119. [Google Scholar] [CrossRef]

- Willey, R.J. Layer of Protection Analysis. Procedia Eng. 2014, 84, 12–22. [Google Scholar] [CrossRef]

- Collong, S.; Kouta, R. Fault tree analysis of proton exchange membrane fuel cell system safety. Int. J. Hydrogen Energy 2015, 40, 8248–8260. [Google Scholar] [CrossRef]

- Ceylan, B.O.; Karatuğ, Ç.; Akyuz, E.; Arslanoğlu, Y.; Boustras, G. A system theory (STAMP) based quantitative accident analysis model for complex engineering systems. Saf. Sci. 2023, 166, 106232. [Google Scholar] [CrossRef]

- Grabowski, M.; Roberts, K. Reliability seeking virtual organizations: Challenges for high reliability organizations and resilience engineering. Saf. Sci. 2019, 117, 512–522. [Google Scholar] [CrossRef]

- Cummings, L. Normal Accidents: Living with High-Risk Technologies. JSTOR 1984, 29, 630–632. [Google Scholar] [CrossRef]

- Niu, Y.; Fan, Y.; Gao, Y.; Li, Y. A causal inference method for improving the design and interpretation of safety research. Saf. Sci. 2023, 161, 106082. [Google Scholar] [CrossRef]

- Durukan, O.; Akyuz, E.; Destanoğlu, O.; Arslanoğlu, Y.; Sezer, S. Quantitive HAZOP and DS evidence theory-fault tree analysis approach to predict fire and explosion risk in inert gas system on-board tanker ship. Ocean. Eng. 2024, 308, 118274. [Google Scholar] [CrossRef]

- Kaya, G.K.; Bovell, D.; Sujan, M.; Braithwaite, G. Large language models powered system safety assessment: Applying STPA and FRAM. Saf. Sci. 2025, 191, 106960. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, E. A fuzzy DEMATEL method to evaluate critical operational hazards during gas freeing process in crude oil tankers. J. Loss Prev. Process Ind. 2015, 38, 243–253. [Google Scholar] [CrossRef]

- Qi, H.; Zhou, Z.; Manu, P.; Li, N. Falling risk analysis at workplaces through an accident data-driven approach based upon hybrid artificial intelligence (AI) techniques. Saf. Sci. 2025, 185, 106814. [Google Scholar] [CrossRef]

- Elidolu, G.; Sezer, S.I.; Akyuz, E.; Aydin, M.; Gardoni, P. A comprehensive risk analysis for cargo leakage pollution at tanker ship manifold under cloud modelling and Bayesian belief network approach. Mar. Pollut. Bull. 2025, 219, 118238. [Google Scholar] [CrossRef]

- Li, F.; Zhang, L.; Dong, S.; Xu, L.; Zhang, H.; Chen, L. Risk assessment of bolt-gasket-flange connection (BGFC) failures at hydrogen transfer stations based on improved FMEA. Int. J. Hydrogen Energy 2024, 50, 700–716. [Google Scholar] [CrossRef]