Optimization of Fracturing Sweet Spot in Deep Carbonate Reservoirs by Combining TOPSIS and AHP Algorithm

Abstract

1. Introduction

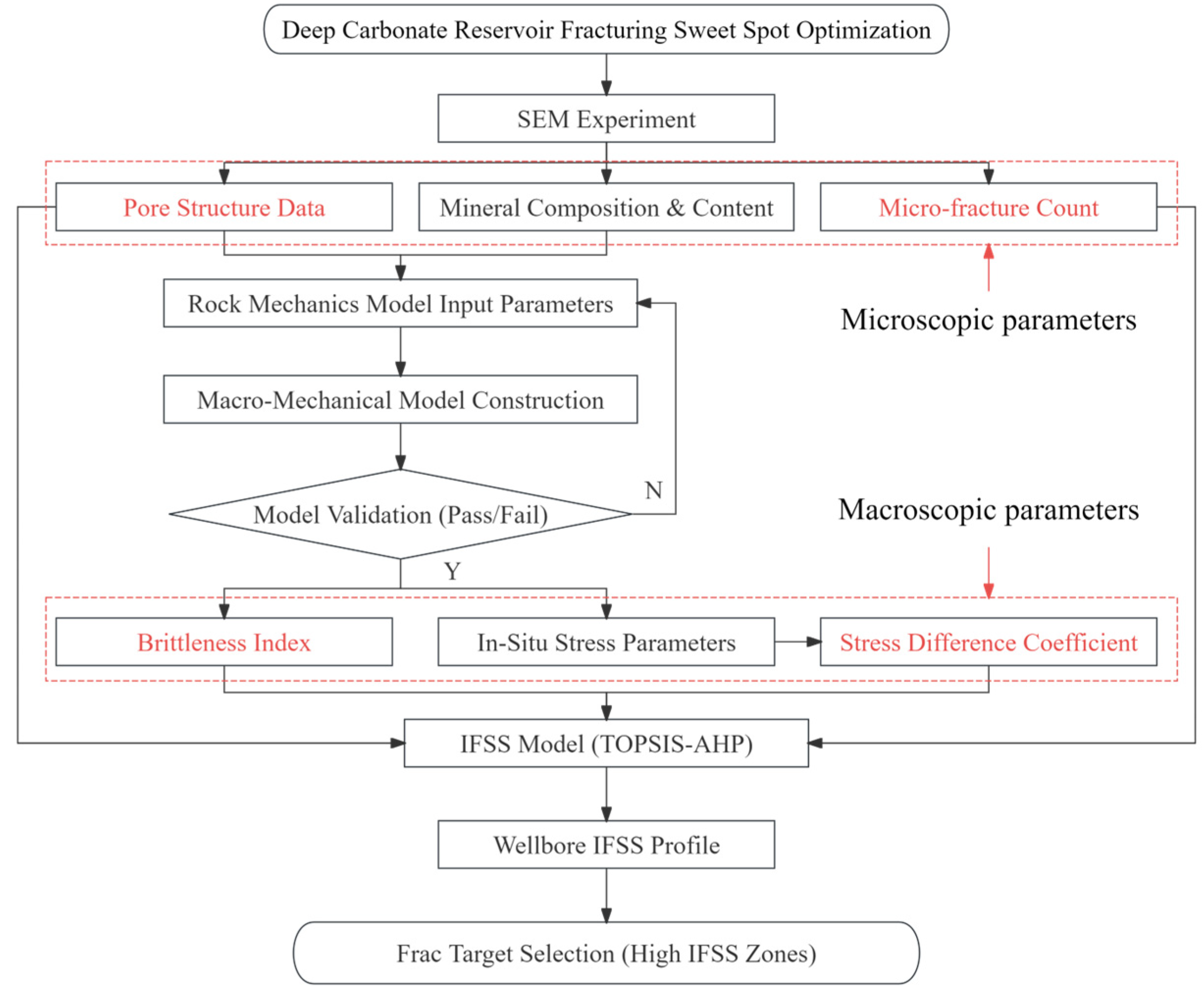

2. Methods for Obtaining Microscopic-Macroscopic Parameters

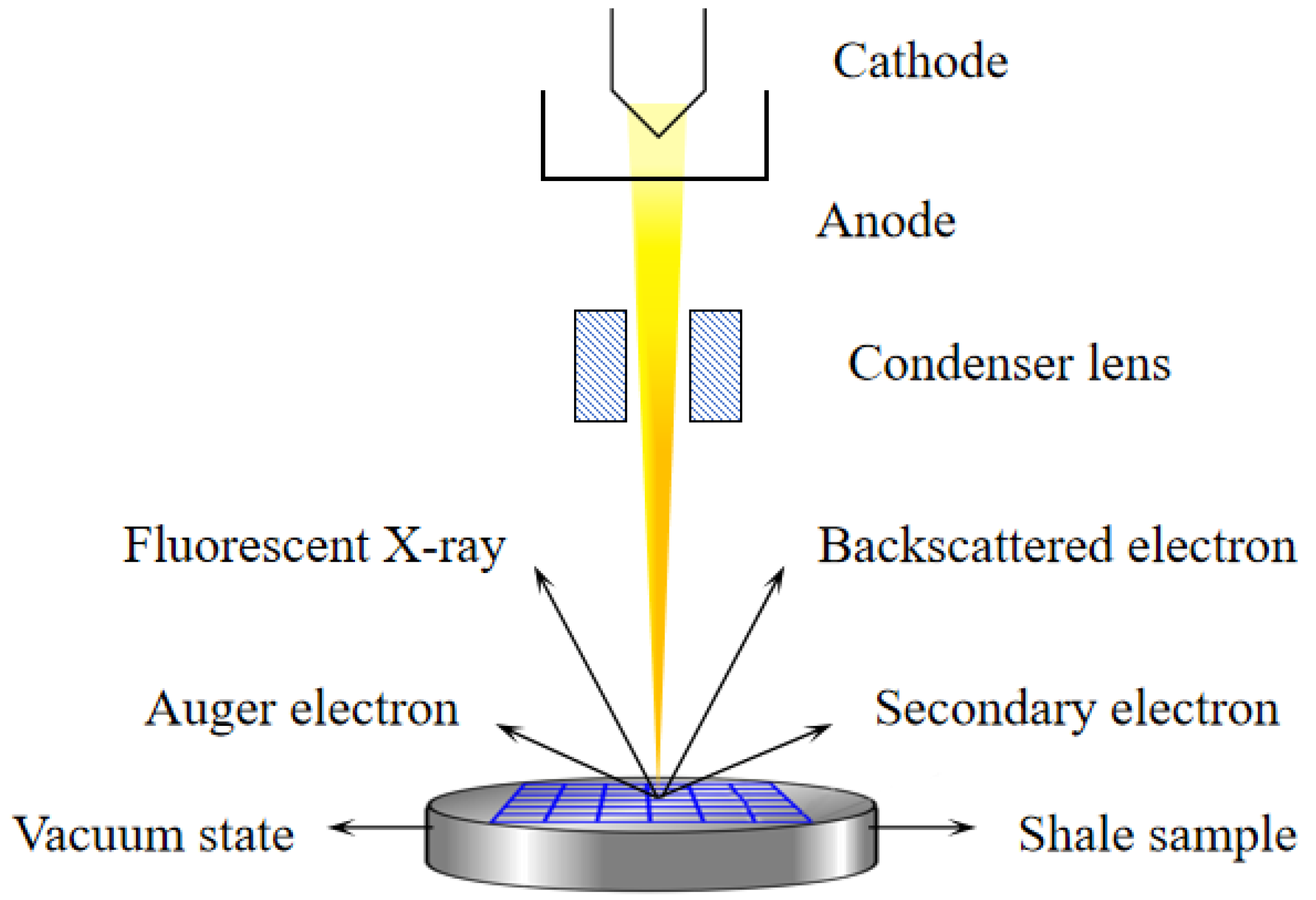

2.1. Methods for Obtaining Microscopic Parameters

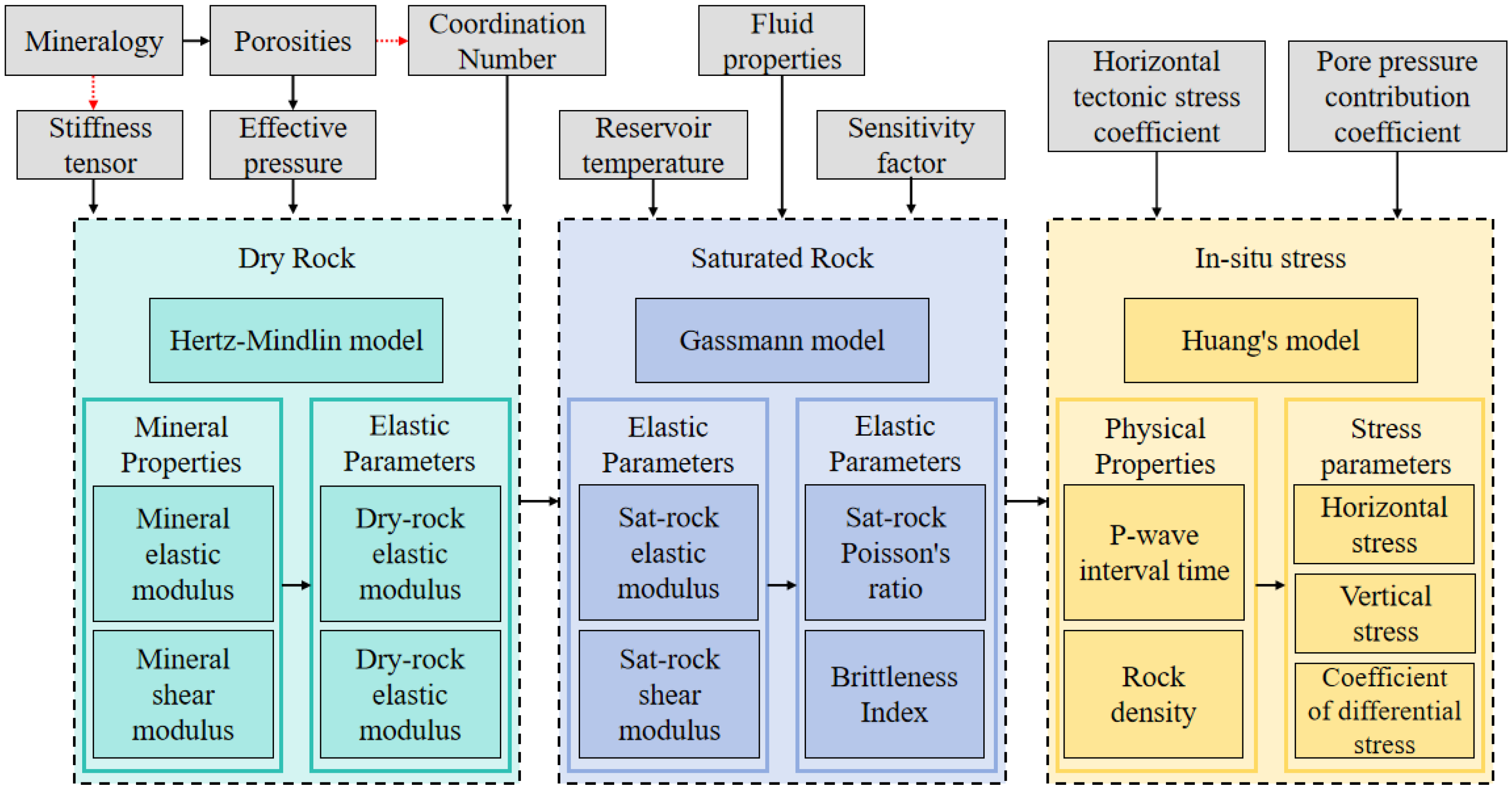

2.2. Macroscopic Rock Mechanics Parameter Calculation Model

2.2.1. Rock Mechanics Model

2.2.2. Model Verification

2.3. Fracturing Sweet Spot Index Model

2.3.1. Model Establishment

- (1)

- Positive indicator transformation: Unify the indicator types and convert all indicators into extremely large ones. That is, the larger the indicator value, the more favorable it is for the evaluation result. In the optimization of fracturing layers, four indicators obtained by RoqSCAN technology, namely the hole-to-surface ratio, the number of micro-fractures, the brittleness index, and the bidirectional stress difference coefficient, are mainly selected as evaluation indicators. Among them, the smaller the bidirectional stress difference coefficient, the more likely the artificial fractures are to turn, and the higher the complexity of the fracture network. Therefore, the bidirectional stress difference coefficient needs to be positively processed.

- (2)

- Standardization of positive indicators: Eliminate the influence of the dimensions of various indicators and standardize the positive indicators. Suppose there are n evaluation schemes and 4 evaluation indicators, then the forward matrix is:Its normalization matrix is denoted as Z, and the zij calculation formula for each element in the Z matrix is:

- (3)

- Construct the calculation formula for the fracturing sweet spot index: assuming there are n evaluation schemes and 4 evaluation indicators, then the normalized matrix Z is:

2.3.2. Fracking Sweet Spot Index Classification

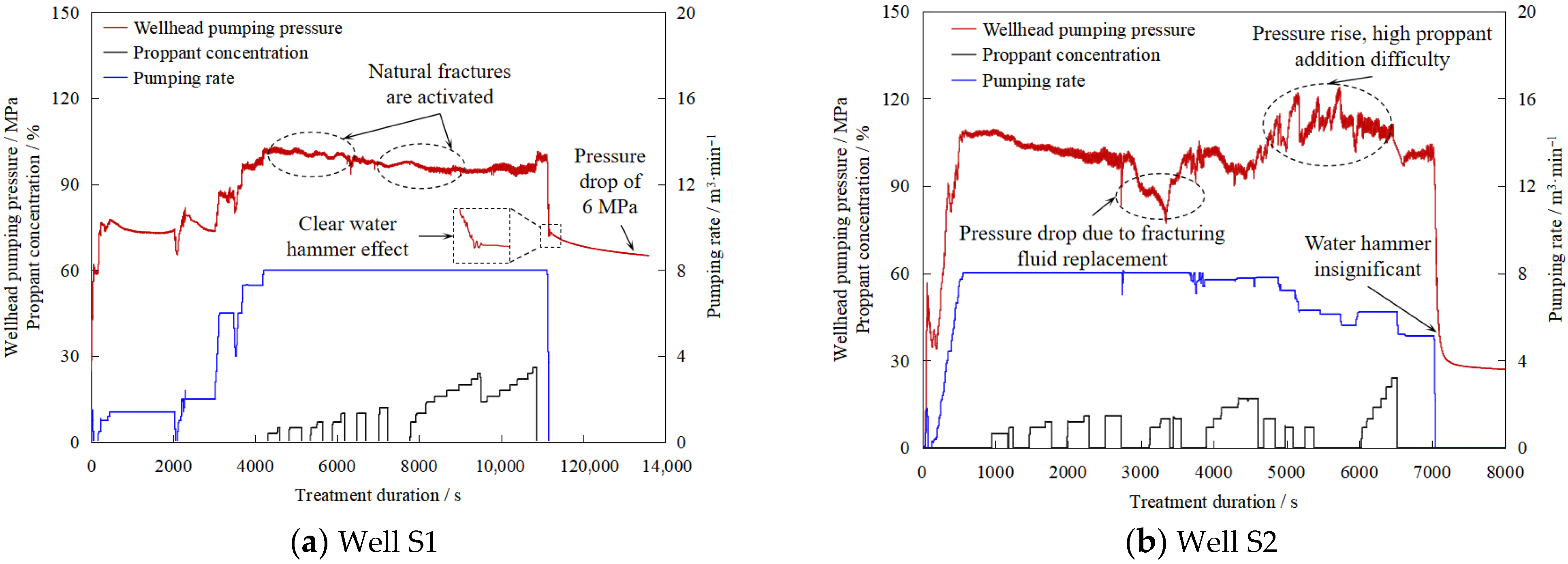

3. On-Site Practical Application

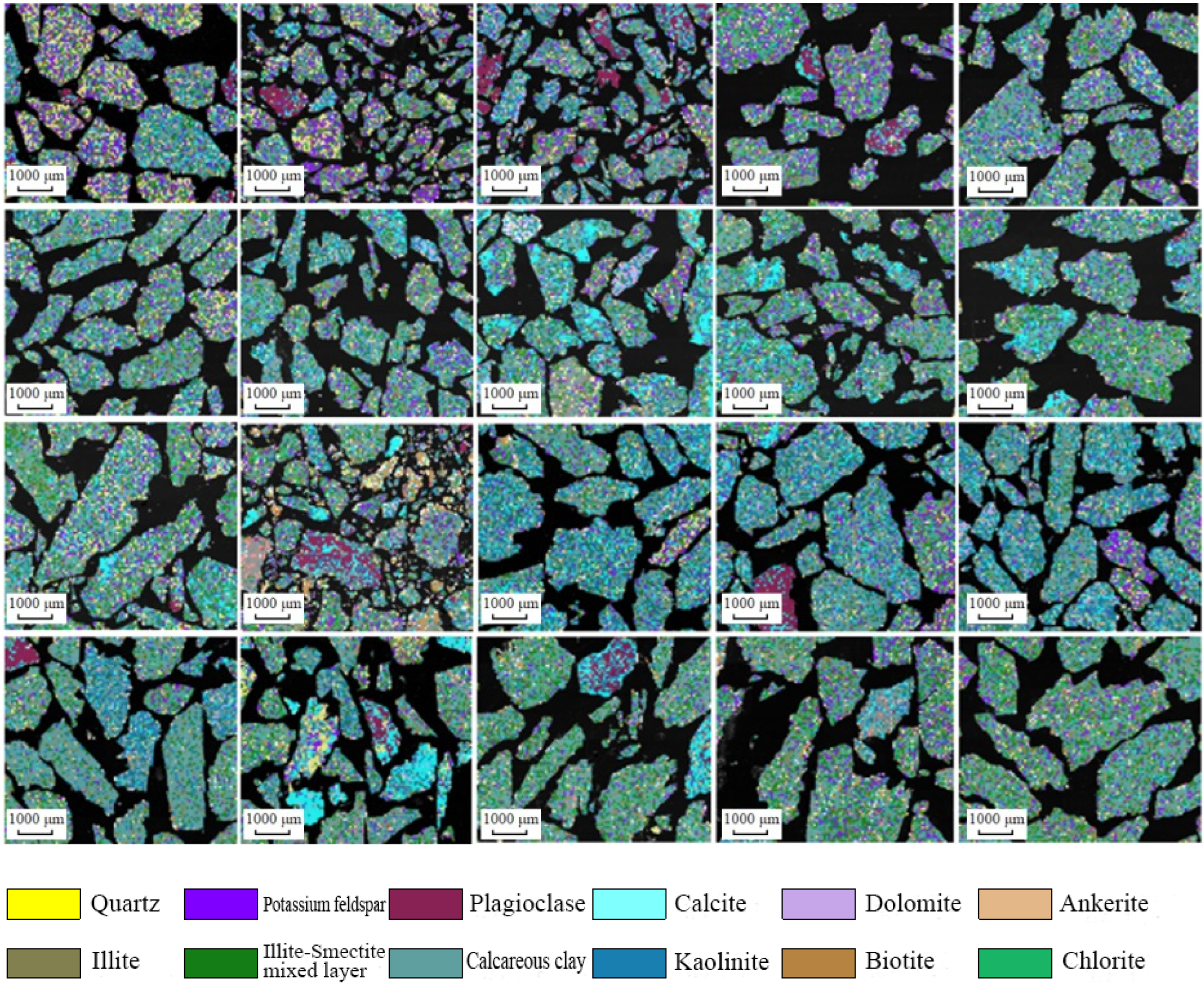

3.1. Cuttings Scanning Results and Analysis

3.1.1. Characteristics of Mineral Composition in Strata

3.1.2. Characteristics of Formation Pore Development

3.2. Analysis of Rock Mechanics Characteristics

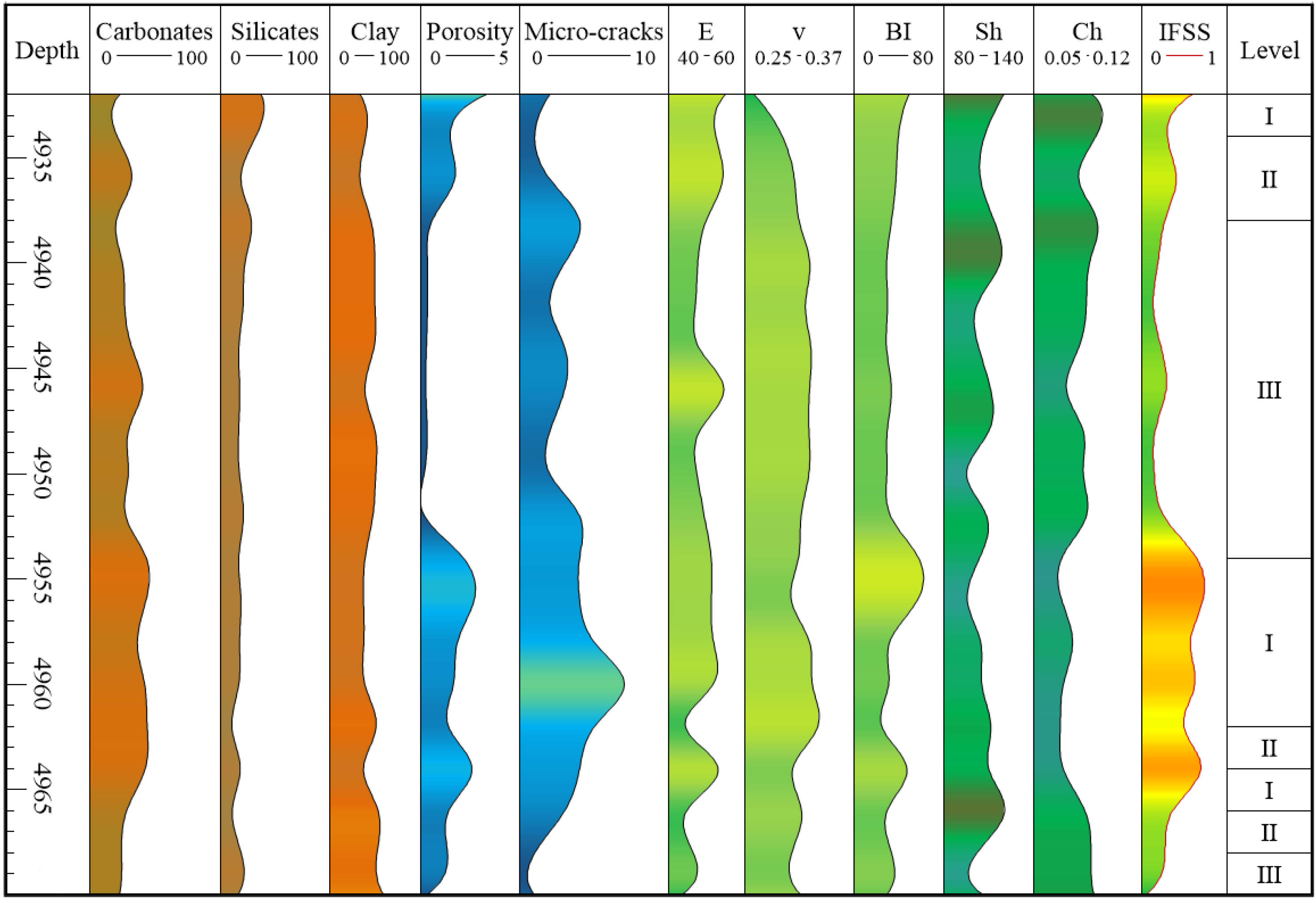

3.3. Interval Optimization Based on Fracturing Sweet Spot Index

4. Conclusions

- (1)

- In light of the characteristics of deep carbonate reservoirs in the Yingzhong Block of the Qaidam Basin, combined with automatic mineral identification scanning experiments, and considering the deep temperature-pressure coupling effect, a rock mechanics model based on mineral components is established. Upon verification, the correlation coefficient between the acoustic transit time calculated by the model and the actual logging acoustic transit time is 0.631, while the correlation coefficient for density is 0.817. The verification results demonstrate that this model can accurately characterize the mechanical and in situ stress properties of carbonate reservoirs under high-temperature and high-stress conditions, providing data support for the evaluation of formation fractionability.

- (2)

- The porosity and the number of micro-fractures in the scanning results are selected as the microscopic physical property indicators affecting the fracturing sweet spot, and the brittleness index and the bidirectional stress difference coefficient calculated by the rock mechanics model are selected as the macroscopic mechanical indicators. A multi-factor fusion fracturing sweet spot prediction model fracability considering reservoir physical properties, mechanical properties and stress states was established by using the TOPSIS-AHP joint algorithm, and the fracturing sweet spots of deep carbonate reservoirs were divided into three levels: IFSS ≥ 0.50 belongs to Class I desserts, 0.35 ≤ IFSS < 0.50 belongs to Class II desserts, and IFSS < 0.35 belongs to Class III desserts.

- (3)

- The formation evaluation technology based on the fracturing sweet spot index was successfully applied to the test oil Wells in the study work area. By using this method for fracturing section selection, the stimulation operation pressure was reduced by 11.6%, and the sand addition success rate was increased by 24%, effectively improving the fracturing effect of deep oil Wells. This research has positive guiding significance for the benefit development of deep carbonate reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Z.L.; Ma, Y.S.; Zhu, D.Y.; Duan, T.Z.; Geng, J.H.; Zhang, J.T.; Ding, Q.; Qian, Y.X.; Wo, Y.J.; Gao, Z.Q. Theoretical and technological progress and research direction of deep and ultra-deep carbonate reservoirs. Oil Gas Geol. 2021, 42, 533–546. [Google Scholar] [CrossRef]

- Shao, X.P.; Guan, S.W.; Jin, J.Q.; Shen, Y.; Meng, Q.Y.; Wang, L.N.; Wang, P. Differences in structural characteristics and control factors of Yingxiong Range structural belt in the western Qaidam Basin. Pet. Geol. Recovery Effic. 2018, 25, 67–72. [Google Scholar] [CrossRef]

- Huang, J.L. Shale gas accumulation conditions and favorable zones of Silurian Longmaxi Formation in south Sichuan Basin, China. J. China Coal Soc. 2012, 37, 782–787. [Google Scholar]

- Li, H.Y.; Zhou, C.C.; Li, C.X.; Li, C.L.; Shi, Y.J.; Wang, C.S. Logging Evaluation and Application of Brittleness Index in Tight Sandstone Reservoir—A case study of Chang -7 tight sandstone reservoir in Longdong area of Ordos basin. Xinjiang Pet. Geol. 2014, 35, 593–597. [Google Scholar]

- Yang, H.W. Quantitative evaluation of shale fracability based on logging data. Fault-Block OilGas Field 2017, 24, 382–386. [Google Scholar]

- Zhai, W.B.; Li, J.; Zhou, Y.C.; Huang, T.; Song, X. New evaluation method of shale reservoir fracability based on logging data. Lithol. Reserv. 2018, 30, 112–123. [Google Scholar]

- Lin, Y.; Li, C.M.; Gu, W.; Luo, W.J.; Wang, Z.Y.; Yu, Z.; Zhang, J.; Bie, J.; Li, W.Q. Seismic fine characterization of deep carbonate fractured-vuggy reservoir: Case study of the 4th Member of Sinian Denying Formation in Anyue Gas Field, Sichuan Basin. Nat. Gas Geosci. 2020, 31, 1792–1801. [Google Scholar] [CrossRef]

- Feng, X.Y.; Zhang, C.J.; Xie, G.Q.; Guo, D.L.; Liu, Y. Evaluation techniques and applications of sweet spots in shale oil engineering in the Qaidam Basin. Nat. Gas Oil 2023, 41, 63–69. [Google Scholar]

- Zhu, J.Y.; Tan, Z.J.; Zhang, G.Q.; Li, D. A comprehensive lithology identification technology for the buried-hill reservoirs with complex lithology in the Bohai Sea. Oil Drill. Prod. Technol. 2018, 40, 62–65. [Google Scholar]

- Ashton, T.; Vinh Ly, C. Portable Technology Puts Real-time Automated Mineralogy On The Well Site. In Proceedings of the SPE Unconventional Resources Conference and Exhibition-Asia Pacific, Brisbane, Australia, 11–13 November 2013. [Google Scholar] [CrossRef]

- Oliver, G.; Spence, G.; Davis, A.; Stolyarov, S. Advanced cuttings analysis provides improved completion design, efficiency and well production. Unconv. Carbon Capture Storage 2016, 34, 69–76. [Google Scholar] [CrossRef]

- El Sherbeny, W.; Nuic, I.; Madkour, A. Significance of advanced cuttings evaluation (ACE) technologies for Chemostratigraphy purposes while drilling; technology overview & applications. In Proceedings of the SPE North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–16 September 2015. [Google Scholar]

- Yang, G.; Zhang, S.; Zheng, H.; Tian, G. Analysis of Cuttings’ Minerals for Multistage Hydraulic Fracturing Optimization in Volcanic Rocks. ACS Omega 2020, 5, 14868–14878. [Google Scholar] [CrossRef]

- Duan, Y.T.; Feng, X.T.; Li, X. Study on the influence of mesomineral bands of shale on its macro failure Mode. Chin. J. Rock Mech. Eng. 2021, 40, 43–52. [Google Scholar] [CrossRef]

- Ly, C.V.; Oliver, G.M.; Spence, G.; Centurion, S.; Jackson, C.E.; Hearn, F.P.; Palomarez, V. Cross Correlation of Logging Data with SEM-Based Mineralogical and Textural Well Data: A New Tool for Optimized Completion Design. In Proceedings of the SPE Russian Oil and Gas Exploration & Production Technical Conference and Exhibition, Moscow, Russia, 14–16 October 2014. [Google Scholar] [CrossRef]

- Yang, W.; Wang, B.; Yao, J.; Jing, W.; Zhang, X. Experimental study on mechanical properties of carbonate rocks under real-time high temperature and heat treatment under triaxial compression. Chin. J. Rock Mech. Eng. 2024, 43, 1347–1358. [Google Scholar]

- Wang, J.B.; Feng, M.G.; Yan, W.; Liu, S. Influence factors and evaluation methods for shale reservoir fracability in Jiaoshiba Area. Fault-Block Oil Gas Field 2016, 2, 216–220. [Google Scholar]

- Zhang, M.L.; Zhang, J.P.; Tang, Z.Y.; Li, M.Q.; Xu, Y.M.; Luo, W.J.; Peng, Y.; Jiang, R. Preferential selection of favorable development areas of tight sandstone gas reservoir in the second Member of Xujiahe Formation in Anyue gas field of central Sichuan Basin. Fault-Block Oil Gas Field 2022, 29, 171–177. [Google Scholar]

- Zhang, J.; Liang, C. Application of TOPSIS Model Based on Gray Correlation Coefficient Matrix in the Evaluation of Water Environmental Quality. J. Sichuan Univ. 2009, 41, 97–101. [Google Scholar]

- Liu, Y.T.; Sun, B.L.; Yu, Y.S. Fuzzy recognition and quantitative calculation method for large pore channels. Oil Drill. Prod. Technol. 2003, 25, 054–059. [Google Scholar]

- Jin, X.; Shah, S.N.; Roegiers, J.C.; Zhang, B. An integrated petrophysics and geomechanics approach for fracability evaluation in shale reservoirs. SPE J. 2015, 20, 518–526. [Google Scholar] [CrossRef]

- Li, Z.H.; Deng, P.; Yang, C.H.; Guo, Y.T.; Hou, L.F. Study on mechanical properties and compressibility evaluation of carbonate reservoir. J. Guangxi Univ. 2019, 44, 1450–1460. [Google Scholar]

- Xiao, Z.H.; Liu, J.S.; Chen, Y.G. Analysis of Fracturing Operation Curve Characteristics and Their Applications. Pet. Geol. Eng. 2008, 22, 99–102. [Google Scholar]

- Huang, J.; Gong, Y.G.; Xu, Y.T.; Guo, B.M.; Zhang, B.K. The Application of G Function in Bohai Oilfield Frac-pack Treatment. Dffshore Oil 2019, 39, 57–61. [Google Scholar]

| Parameter Name | Parameter Value | Unit |

|---|---|---|

| Elastic modulus of quartz minerals Eq | 7.85 × 104 | MPa |

| Elastic modulus of calcite mineral Ec | 5.80 × 104 | MPa |

| Elastic modulus of feldspar minerals Ea | 4.5 × 104 | MPa |

| Percentage of quartz mineral content fq | 5.7~13.1 | % |

| Percentage of calcite mineral content fc | 16.0~25.3 | % |

| Percentage of plagioclase mineral content fa | 8.6~17.8 | % |

| Particle contact coefficient C | 9.0 | Dimensionless |

| Total porosity φ | 1.82 | % |

| Porosity of non-flowable fluids φs | 0.58 | % |

| Effective formation pressure peff | 54.9 | MPa |

| Rock stiffness tensor M | 0.82 | MPa |

| Density of pure rock ρm | 2.65 | g/cm3 |

| Influencing Factors | Arithmetic Mean Method | Geometric Mean Method | Eigenvalue Method | Comprehensive Weight |

|---|---|---|---|---|

| Brittleness Index | 0.3855 | 0.3855 | 0.3856 | 0.3855 |

| Pore-to-Surface Ratio | 0.2773 | 0.2774 | 0.2773 | 0.2773 |

| Number of Micro-fractures | 0.1962 | 0.1961 | 0.1961 | 0.1961 |

| Difference in Horizontal Biaxial Stresses | 0.1411 | 0.1409 | 0.1410 | 0.1410 |

| Mineral Classification | Main Mineral Names | Main Mineral Content Range (%) | Average Value of Major Minerals (%) | Total Average Value (%) |

|---|---|---|---|---|

| Silicates | Quartz | 5.2–18.7 | 8.90 | 19.8 |

| Potassium feldspar | 0.25–1.81 | 0.61 | ||

| Plagioclase | 3.36–21.40 | 10.31 | ||

| Carbonates | Calcite | 16.8–37.6 | 26.80 | 30.2 |

| Dolomite | 0.05–3.92 | 1.00 | ||

| Iron dolomite | 1.18–3.76 | 2.40 | ||

| Clay minerals | Imon mixed floor | 4.99–20.42 | 11.66 | 44.7 |

| Illite | 3.99–17.22 | 10.17 | ||

| Calcareous clay | 14.33–33.81 | 22.82 | ||

| Kaolinite | 0–0.16 | 0.05 | ||

| Accessory minerals | Anhydrite | 0.08–13.32 | 2.74 | 5.3 |

| Hematite | 0–0.07 | 0.02 | ||

| Pyrite | 0.37–1.03 | 0.63 | ||

| Siderite | 0–0.11 | 0.03 |

| Value Range | E (GPa) | v | BI (%) | σh (MPa) | Ch |

|---|---|---|---|---|---|

| Max | 54.89 | 0.330 | 48.89 | 109.5 | 0.067 |

| Min | 43.15 | 0.261 | 25.06 | 108.3 | 0.090 |

| Average | 49.51 | 0.311 | 33.03 | 108.9 | 0.079 |

| Depth (m) | BI (%) | Microcrack / | Porosity (%) | Ch / | IFSS | Level |

|---|---|---|---|---|---|---|

| 4932 | 48.89 | 2 | 3.2996 | 0.088 | 0.590 | I |

| 4934 | 39.63 | 1 | 1.4956 | 0.090 | 0.301 | II |

| 4936 | 37.42 | 2 | 1.7216 | 0.079 | 0.401 | II |

| 4938 | 33.45 | 4 | 0.5802 | 0.091 | 0.270 | III |

| 4940 | 29.22 | 3 | 0.3551 | 0.086 | 0.188 | III |

| 4942 | 30.01 | 2 | 0.3569 | 0.084 | 0.133 | III |

| 4944 | 29.10 | 3 | 0.3039 | 0.079 | 0.225 | III |

| 4946 | 33.44 | 3 | 0.2709 | 0.071 | 0.285 | III |

| 4948 | 29.68 | 2 | 0.3376 | 0.082 | 0.154 | III |

| 4950 | 29.36 | 2 | 0.1854 | 0.082 | 0.145 | III |

| 4952 | 32.64 | 4 | 0.2089 | 0.084 | 0.259 | III |

| 4954 | 57.49 | 4 | 2.1675 | 0.068 | 0.636 | I |

| 4956 | 56.42 | 4 | 2.6979 | 0.068 | 0.712 | I |

| 4958 | 31.79 | 5 | 1.8582 | 0.075 | 0.568 | I |

| 4960 | 30.94 | 7 | 1.6563 | 0.069 | 0.619 | I |

| 4962 | 25.06 | 5 | 1.4142 | 0.067 | 0.492 | II |

| 4964 | 47.17 | 4 | 2.594 | 0.069 | 0.687 | I |

| 4966 | 29.67 | 3 | 1.4265 | 0.083 | 0.361 | II |

| 4968 | 33.46 | 1 | 1.3609 | 0.087 | 0.273 | III |

| 4970 | 28.83 | 1 | 0.2899 | 0.089 | 0.047 | III |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xie, G.; Zheng, H.; Ma, X.; Ren, G.; Feng, X.; Zhao, W.; Ma, H.; Lei, F. Optimization of Fracturing Sweet Spot in Deep Carbonate Reservoirs by Combining TOPSIS and AHP Algorithm. Processes 2025, 13, 2777. https://doi.org/10.3390/pr13092777

Liu Y, Xie G, Zheng H, Ma X, Ren G, Feng X, Zhao W, Ma H, Lei F. Optimization of Fracturing Sweet Spot in Deep Carbonate Reservoirs by Combining TOPSIS and AHP Algorithm. Processes. 2025; 13(9):2777. https://doi.org/10.3390/pr13092777

Chicago/Turabian StyleLiu, Yong, Guiqi Xie, Honglin Zheng, Xinfang Ma, Guangcong Ren, Xinyuan Feng, Wenkai Zhao, He Ma, and Fengyu Lei. 2025. "Optimization of Fracturing Sweet Spot in Deep Carbonate Reservoirs by Combining TOPSIS and AHP Algorithm" Processes 13, no. 9: 2777. https://doi.org/10.3390/pr13092777

APA StyleLiu, Y., Xie, G., Zheng, H., Ma, X., Ren, G., Feng, X., Zhao, W., Ma, H., & Lei, F. (2025). Optimization of Fracturing Sweet Spot in Deep Carbonate Reservoirs by Combining TOPSIS and AHP Algorithm. Processes, 13(9), 2777. https://doi.org/10.3390/pr13092777