Enhanced Oil Recovery Mechanism and Parameter Optimization of Huff-and-Puff Flooding with Oil Displacement Agents in the Baikouquan Oilfield

Abstract

1. Introduction

2. Experiments on ODA Performance

2.1. Experimental Materials and Instruments

2.2. Experimental Method

2.2.1. The IFT Test

2.2.2. Wettability Test

2.2.3. Emulsion Test

2.2.4. Relative Permeability Test

2.2.5. The Imbibition Experiment

2.2.6. Oil Displacement Experiment

- (1)

- Core preparation: Cylindrical core plugs were dried in an oven at 80 °C until a constant weight was reached, then cooled to room temperature in a desiccator.

- (2)

- Vacuum saturation: The dried cores were placed in a vacuum chamber and evacuated to a pressure below −0.08 MPa for at least 4 h to remove air from the pore spaces. Subsequently, formation brine was slowly introduced to saturate the cores under vacuum conditions, ensuring complete brine saturation.

- (3)

- Establishing initial oil saturation: After brine saturation, the cores were mounted in a core holder. Crude oil was injected at a constant flow rate of 0.02 mL/min until no more water was produced from the outlet.

- (4)

- Water/ODA flooding: The injection flow rate was maintained at 0.02 mL/min. Injection continued until the water cut reached 99% or 30 pore volumes (PV) were injected, whichever came first.

- (5)

- Backpressure and confining pressure: A backpressure of 1 MPa was applied at the outlet to stabilize flow and maintain liquid-phase continuity. A confining pressure of 12 MPa was maintained to mimic in situ stress and avoid bypass.

- (6)

- Pressure and production monitoring: Differential pressure across the core was continuously monitored using a precision pressure transducer. Oil and water production were recorded periodically throughout the flooding process.

- (7)

- Post-flooding analysis: At the end of the displacement test, the final oil recovery factor and residual oil saturation were calculated based on cumulative oil production [24].

3. Experimental Results and Discussion

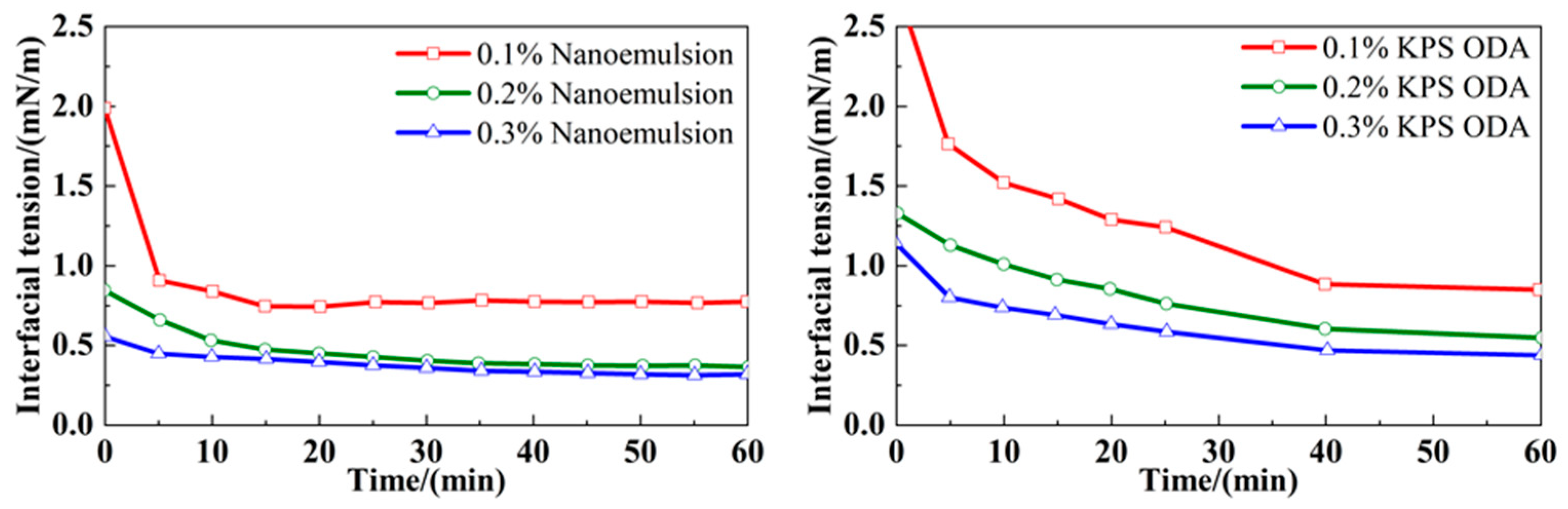

3.1. Effect of ODAs on Oil–Water IFT

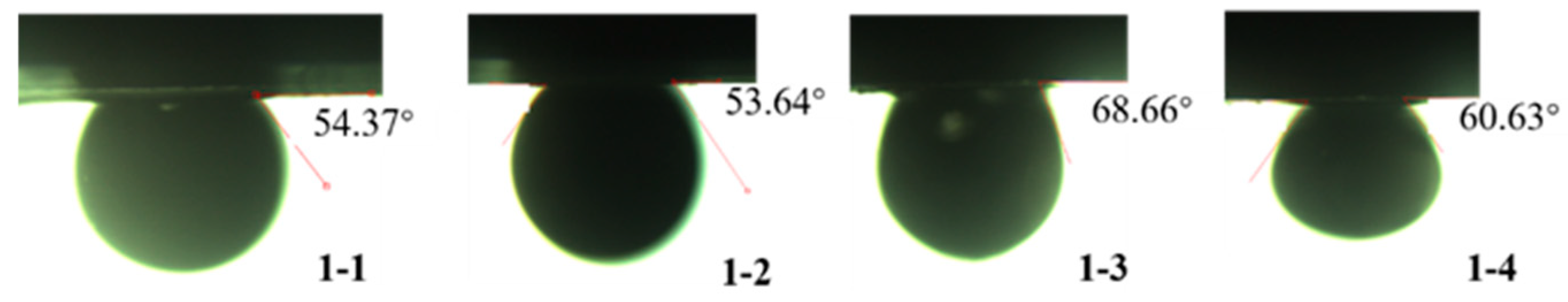

3.2. Effect of ODAs on Wettability

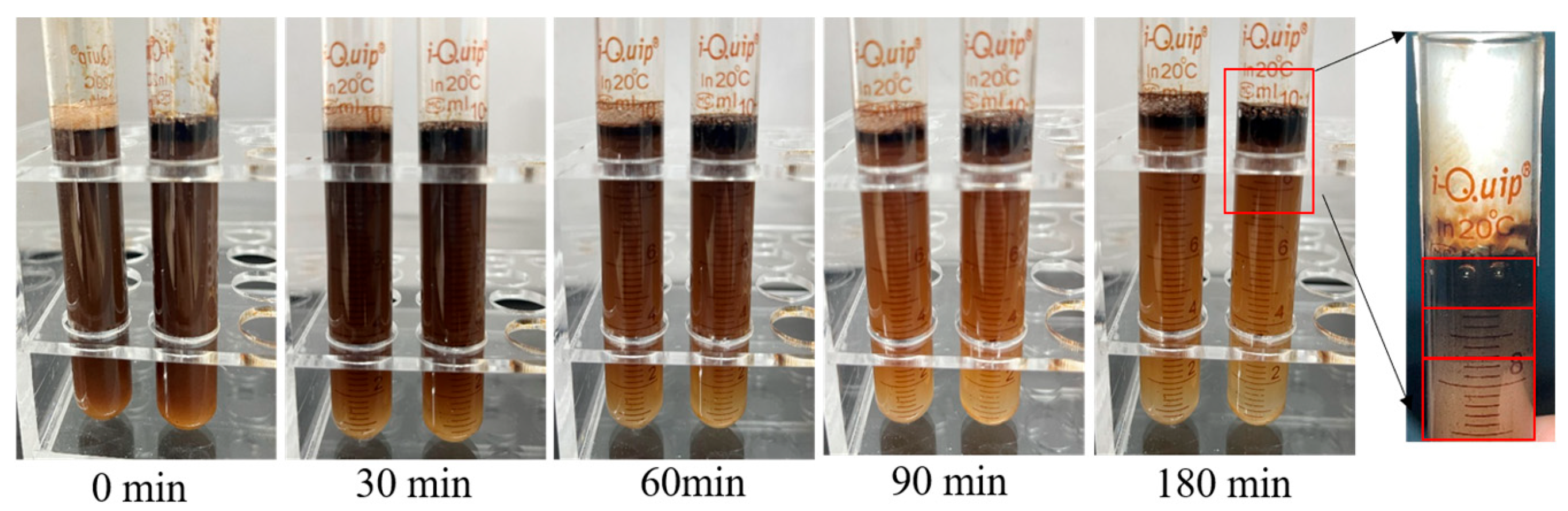

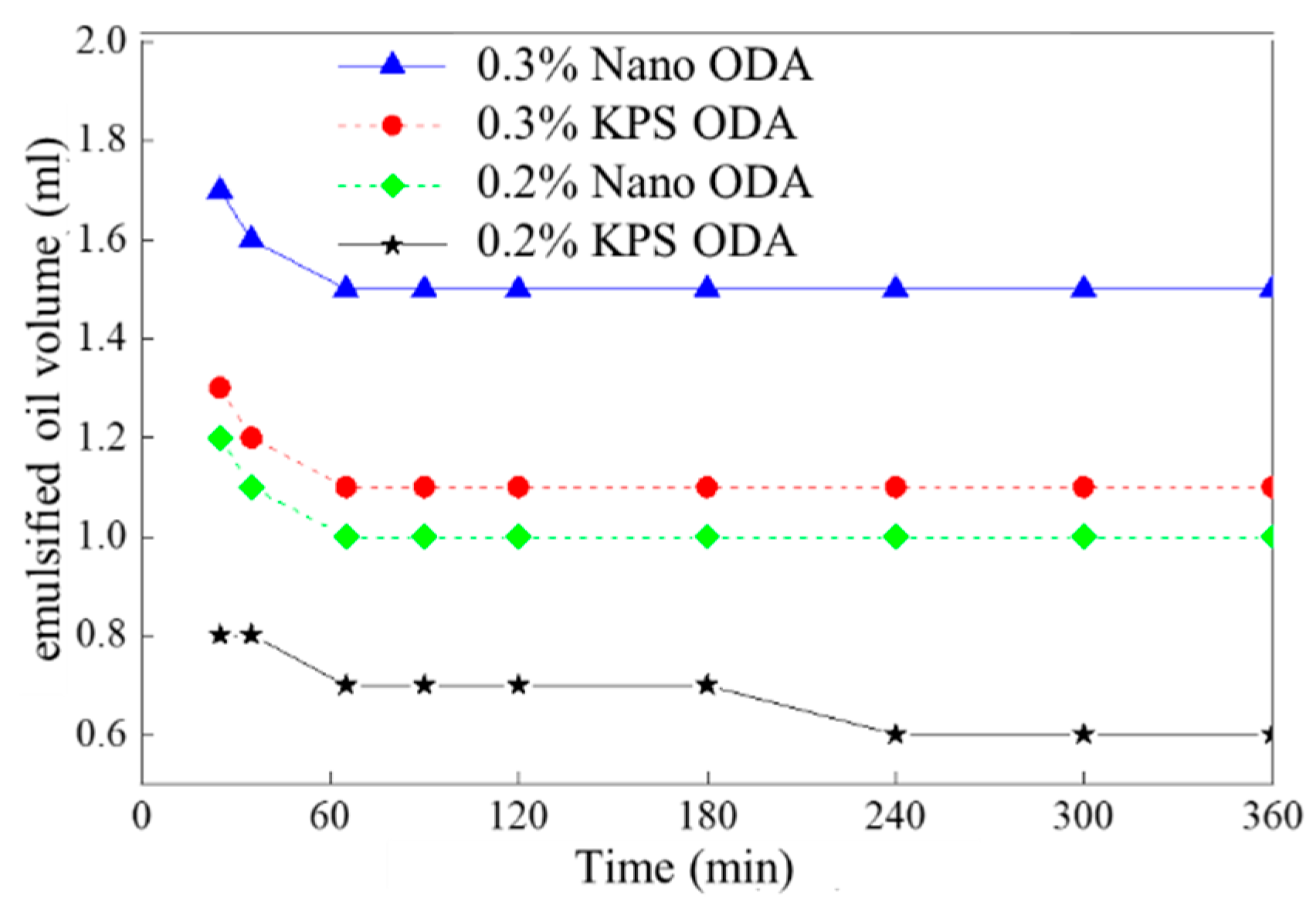

3.3. Emulsifying Efficiency of ODAs

3.4. Effect of ODAs on Oil–Water Relative Permeability

3.5. Effect of ODAs on Imbibition

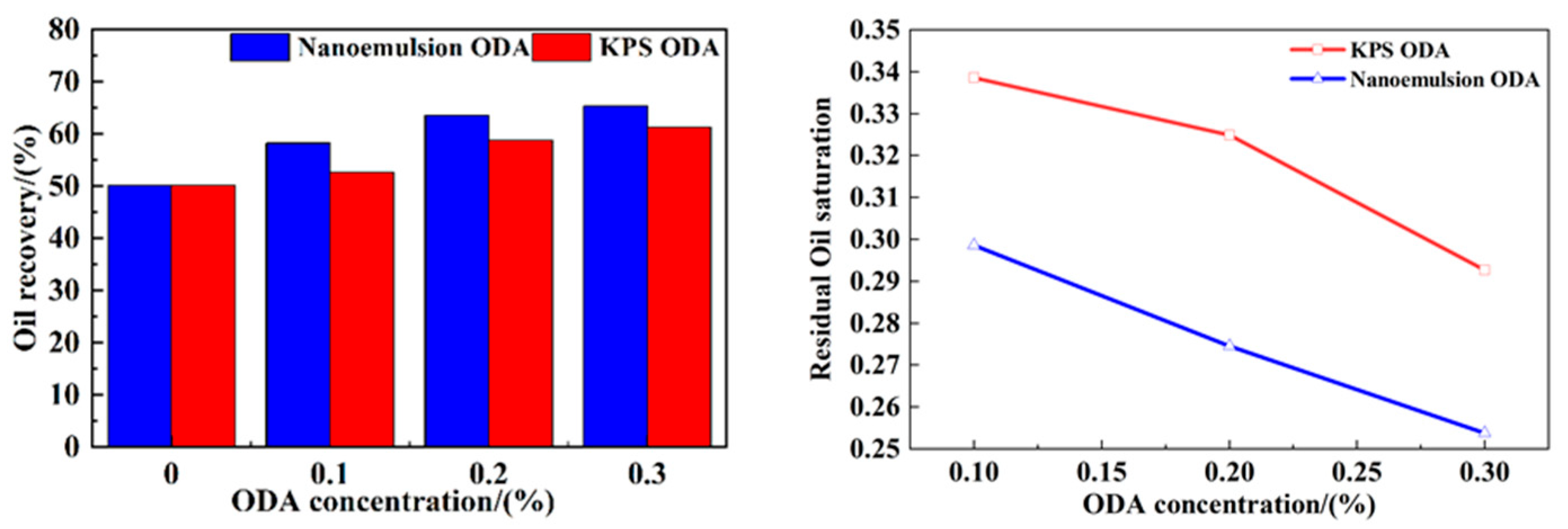

3.6. Effect of ODAs on Oil Recovery

4. Optimization of Huff-and-Puff Flooding Parameters

4.1. Model Setup

4.2. Simulation Results

4.2.1. Injection Volume

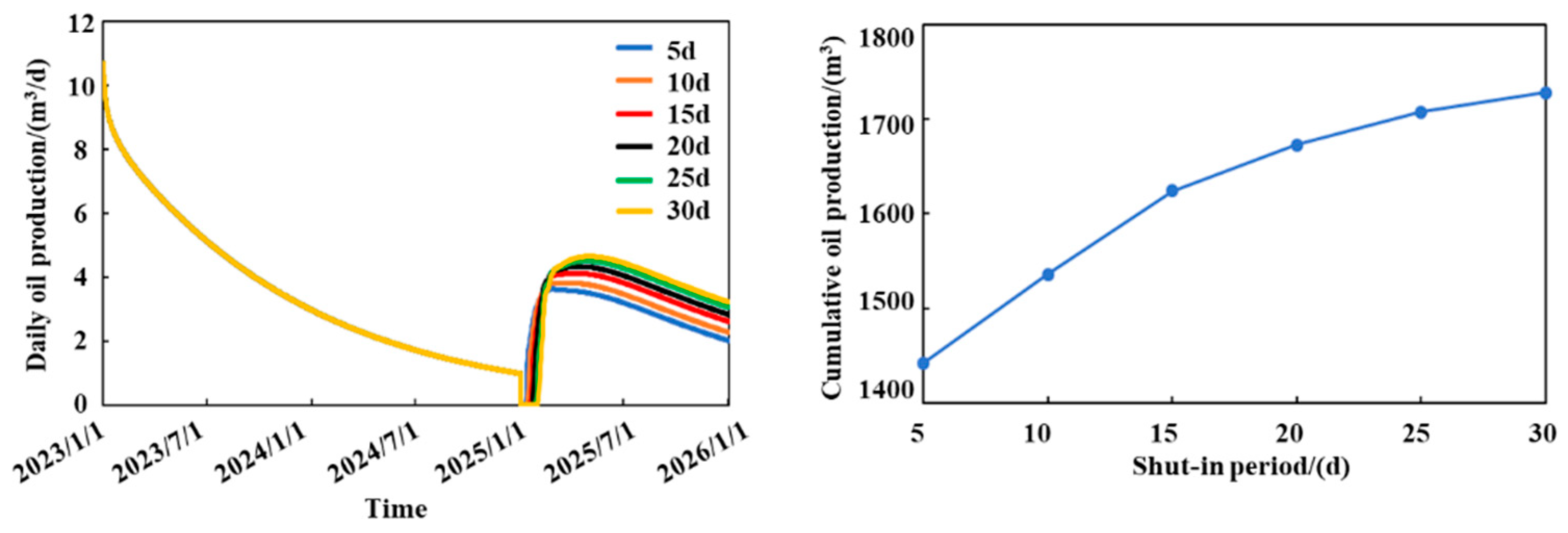

4.2.2. Shut-In Period

4.2.3. Huff-and-Puff Flooding Cycle

5. Discussions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, W.; Zhi, H.; Li, J. Analysis of water flooding mechanism and development effect after water breakthrough in Ansete low permeability oilfield. Exp. Petr. Geol. 1999, 3, 256–260. [Google Scholar]

- Thomas, A.; Kumar, A.; Rodrigues, K.; Sinclair, R.; Lackie, C.; Galipeault, A.; Blair, M. Understanding water flood response in tight oil formations: A case study of the lower Shaunavon. In Proceedings of the SPE/CSUR Unconventional Resources Conference, Calgary, AB, Canada, 30 September–2 October 2014. SPE-171671-MS. [Google Scholar] [CrossRef]

- Wang, T. Influencing factors and analysis of carbon dioxide flooding effect. China Petrol. Chem. Ind. 2008, 24, 30–33. [Google Scholar]

- Shang, Q. Sensitivity analysis of CO2 flooding oil well productivity and influencing factors. Petr. Dril. Tech. 2011, 39, 83–88. [Google Scholar]

- Wang, H.; Chen, Z.; Zhang, L. Discussion on injection huff and puff development model of water-wet sandstone reservoir. Petrol. Explor. Dev. 2004, 5, 86–88. [Google Scholar]

- Li, G.; Zhang, S. Study on capillary imbibition effect of low permeability sandstone simulated by quartz glass. J. Chongqing Univ. Sci. Technol. (Nat. Sci.) 2010, 12, 1–3+7. [Google Scholar]

- Sheng, J. What type of surfactants should be used to enhance spontaneous imbibition in shale and tight reservoirs? J. Petrol. Sci. Eng. 2017, 159, 635–643. [Google Scholar] [CrossRef]

- Standnes, D.; Austad, T. Wettability alteration in chalk: Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J. Petrol. Sci. Eng. 2000, 28, 123–143. [Google Scholar] [CrossRef]

- Salehi, M.; Johnson, S.; Liang, J. Mechanistic study of wettability alteration using surfactants with applications in naturally fractured reservoirs. Langmuir 2008, 24, 14099–14107. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Xiang, D. Study on the mechanism of injection huff and puff oil recovery. Petrol. Geol. Rec. Effi. 2004, 5, 39–40+43. [Google Scholar]

- Hendraningrat, L.; Torsæter, O. A study of water chemistry extends the benefits of using silica-based nanoparticles on enhanced oil recovery. Appl. Nanosci. 2016, 6, 83–95. [Google Scholar] [CrossRef]

- Foster, W. A low-tension waterflooding process. J. Petrol. Technol. 1973, 25, 205–210. [Google Scholar] [CrossRef]

- Youssif, M.; El-Maghraby, R.; Saleh, S.; Elgibaly, A. Silica nanofluid flooding for enhanced oil recovery in sandstone rocks. Egypt J. Pet. 2018, 27, 105–110. [Google Scholar] [CrossRef]

- Wellington, S.; Richardson, E. Low surfactant concentration enhanced waterflooding. SPE J. 1997, 2, 389–405. [Google Scholar] [CrossRef]

- Gao, T. Injection huff mechanism and application of tight reservoir in Yanchang Oilfield. Spec. Oil Gas Res. 2018, 25, 134–137. [Google Scholar]

- Liu, L. Numerical Simulation of Imbibition Production in Fractured Reservoirs. Master's Thesis, Southwest Petroleum University, Chengdu, China, 2006. [Google Scholar]

- Kaul, S.; Putra, E.; Schechter, D. Simulation of spontaneous imbibition using Rayleigh-Ritz finite element method—A discrete fracture approach. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 8–10 June 2004. PETSOC-2004-228. [Google Scholar]

- Nguyen, V. A dynamic network model for imbibition. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26 September 2004. SPE-90365-MS. [Google Scholar] [CrossRef]

- Zhu, Y. Study on Oil Recovery by Nano-Active Water Huff and Puff After Fracturing in Tight Reservoirs. Master's Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- SY/T 5370-2018; Test Method for Surface Tension and Interfacial Tension. China Petroleum Industry Publishing House: Beijing, China, 2019.

- SY/T 5153-2017; Test Method of Reservoir Rock Wettability. China Petroleum Industry Publishing House: Beijing, China, 2017.

- Q/SY17583-2018; Technical Specification for Surfactants Used in Binary Composite Flooding. China Petroleum Industry Publishing House: Beijing, China, 2018.

- GB/T 28912-2012; Test Method for Two Phase Relative Permeability in Rock. China Standards Press: Beijing, China, 2012.

- Green, D.W.; Willhite, G.P. Enhanced Oil Recovery; Society of Petroleum Engineers: Richardson, TX, USA, 2018. [Google Scholar] [CrossRef]

- Bui, T.; Frampton, H.; Huang, S.; Collins, I.; Striolo, A.; Michaelides, A. Water/oil interfacial tension reduction—An interfacial entropy driven process. Phys. Chem. Chem. Phys. 2021, 44, 25075–25085. [Google Scholar] [CrossRef] [PubMed]

- Najimi, S.; Nowrouzi, I.; Khaksar, A.; Mohammadi, A. Experimental study of the performances of commercial surfactants in reducing interfacial tension and wettability alteration in the process of chemical water injection into carbonate reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1551–1563. [Google Scholar] [CrossRef]

- Liang, T.; Hou, J.; Qu, M.; Xi, J.; Raj, I. Application of nanomaterial for enhanced oil recovery. Petrol. Sci. 2022, 19, 882–899. [Google Scholar] [CrossRef]

- Rosen, M.; Kunjappu, J. Surfactants and Interfacial Phenomena, 4th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Dang, H.; Wang, X.; Duan, W. Research on imbibition displacement of fractured low permeability reservoir in Ordos Basin. Fault Block Oil Gas Field 2017, 24, 687–690. [Google Scholar]

- Li, Y.; Li, M.; Xu, H.; Yang, F.; Yan, M.; Tao, T. Surfactant flooding technology in ultra-low permeability reservoir. Liaoning Chem. Ind. 2020, 49, 804–806. [Google Scholar]

- Zhang, J.; Wang, M.; Wu, J. Study on synthesis and pressure flooding technology of a new nano imbibition agent. Appl. Chem. Ind. 2021, 50, 1239–1244. [Google Scholar]

- Liu, C.; Wang, Y.; Yu, H. Laboratory study on surfactant flooding system in low permeability reservoir. Oil Gas Chem. Ind. 2011, 40, 486–489. [Google Scholar]

- Cui, Z. Research on the Influence of Wettability of Low Permeability Reservoir on oil Recovery. Master’s Thesis, Daqing Petrol. Inst., Daqing, China, 2009. [Google Scholar]

- Phukan, R.; Saha, R.; Mazumdar, P. Adsorption behavior of surfactants on sandstone reservoir rocks with carbonate cements and its influence on wettability alteration. J. Surfactants Deterg. 2024, 27, 392–408. [Google Scholar] [CrossRef]

- Li, N.; Wang, H.; Li, J. Research status and development trend of surfactants for oil displacement. Guangdong Chem. Ind. 2012, 39, 98–99+127. [Google Scholar]

- Ratanpara, A.; Kim, M. Wettability alteration mechanisms in enhanced oil recovery with surfactants and nanofluids: A review with microfluidic applications. Energies 2023, 16, 8003. [Google Scholar] [CrossRef]

- Malode, G.; Ande, S.; Chavhan, S.; Bartare, S.; Malode, L.; Manwar, J.; Bakal, R. A critical review on nanoemulsion: Advantages, techniques and characterization. World J. Adv. Res. Rev. 2021, 11, 462–473. [Google Scholar] [CrossRef]

- Jalilian, M.; Tabzar, A.; Ghasemi, V.; Mohammadzadeh, O.; Pourafshary, P.; Rezaei, N.; Zendehboudi, S. An experimental investigation of nanoemulsion enhanced oil recovery: Use of unconsolidated porous systems. Fuel 2019, 251, 754–762. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Wu, H.; Ding, Z.; Yuan, S.; Bai, H.; Yao, E.; Zhou, F. Development and performance evaluation of nonionic surfactant-stabilized nanoemulsion for enhanced oil recovery applications in tight reservoir. Phys. Fluids 2024, 36, 032015. [Google Scholar] [CrossRef]

- Ding, X.; Zhou, D.; Wu, K.; Li, S.; He, Y.; Yu, B.; Chen, L. Performance evaluation and application of nanoemulsion imbibition oil-displacing agent. Oilfield Chem. 2022, 39, 651–657. [Google Scholar]

- Morrow, N.R.; Mason, G. Recovery of oil by spontaneous imbibition. Curr. Opin. Colloid Interface Sci. 2001, 6, 321–337. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, J.; Liu, H. Optimization of cyclic water injection parameters in low-permeability reservoirs: Understanding the marginal returns of injection volume. J. Pet. Sci. Eng. 2021, 198, 108209. [Google Scholar]

- Kukharova, T.; Maltsev, P.; Novozhilov, I. Development of a control system for pressure distribution during gas production in a structurally complex field. Appl. Syst. Innov. 2025, 8, 51. [Google Scholar] [CrossRef]

| Core Number | Length (cm) | Diameter (cm) | Permeability (mD) | Porosity (%) | Experimental Purpose | |

|---|---|---|---|---|---|---|

| 1-1 | 1.24 | 2.49 | 1.15 | 15.32 | Wettability test | Oil saturated |

| 1-2 | 1.25 | 2.50 | 1.15 | 15.32 | Water flooded | |

| 1-3 | 1.24 | 2.50 | 1.15 | 15.32 | Nano ODA flooded | |

| 1-4 | 1.23 | 2.50 | 1.15 | 15.32 | KPS ODA flooded | |

| 2 | 5.01 | 2.49 | 1.24 | 15.61 | Relative permeability test | Water |

| 3 | 5.00 | 2.50 | 0.98 | 13.12 | Nano ODA | |

| 4 | 4.99 | 2.50 | 1.42 | 15.28 | KPS ODA | |

| 5 | 5.00 | 2.49 | 0.98 | 14.62 | Imbibition test | Water+ Nano ODA |

| 6 | 5.01 | 2.49 | 1.15 | 16.15 | Nano ODA | |

| 7 | 5.00 | 2.50 | 1.02 | 14.24 | Water + KPS ODA | |

| 8 | 4.98 | 2.49 | 0.90 | 12.49 | KPS ODA | |

| 9 | 4.97 | 2.50 | 1.12 | 13.82 | Displacement test | Water |

| 10 | 4.99 | 2.49 | 1.25 | 14.53 | 0.1% Nano ODA | |

| 11 | 5.01 | 2.49 | 1.32 | 15.10 | 0.2% Nano ODA | |

| 12 | 5.00 | 2.49 | 1.28 | 13.94 | 0.3% Nano ODA | |

| 13 | 4.98 | 2.49 | 1.25 | 14.25 | 0.1% KPS ODA | |

| 14 | 4.99 | 2.50 | 1.38 | 16.18 | 0.2% KPS ODA | |

| 15 | 5.00 | 2.49 | 1.32 | 15.47 | 0.3% KPS ODA | |

| Number | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| ODA type | Nano ODA | Nano ODA | KPS ODA | KPS ODA |

| Concentration | 0.2% | 0.3% | 0.2% | 0.3% |

| Emulsifying efficiency | 53.0% | 68% | 32% | 57% |

| Injected Fluid (Core Number) | Oil Relative Permeability Under Water Saturation of 0.5 | Residual Oil Saturation (%) |

|---|---|---|

| Water (2#) | 0.222 | 0.378 |

| 0.2% Nano ODA (3#) | 0.369 | 0.325 |

| 0.2% KPS ODA (4#) | 0.285 | 0.346 |

| Core Number | Fluid Type | Core Mass (g) | Saturated Oil Mass (g) | Core Mass After Imbibition (g) | Imbibition Efficiency (%) |

|---|---|---|---|---|---|

| 5# | Water + 0.2% Nano ODA | 49.61 | 2.37 | 51.34 (4 d) | 26.98 |

| 51.31 (5 d–8 d) | 28.00 | ||||

| 6# | 0.2% Nano ODA | 48.77 | 2.68 | 50.79 (8 d) | 24.55 |

| 7# | Water + 0.2% KPS ODA | 49.22 | 2.25 | 50.83 (4 d) | 28.01 |

| 50.82 (5 d–8 d) | 28.91 | ||||

| 8# | 0.2% KPS ODA | 48.15 | 2.07 | 49.68 (8 d) | 25.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Mou, J.; Xue, K.; Yi, X.; Liu, H.; Gao, B. Enhanced Oil Recovery Mechanism and Parameter Optimization of Huff-and-Puff Flooding with Oil Displacement Agents in the Baikouquan Oilfield. Processes 2025, 13, 3098. https://doi.org/10.3390/pr13103098

Tian H, Mou J, Xue K, Yi X, Liu H, Gao B. Enhanced Oil Recovery Mechanism and Parameter Optimization of Huff-and-Puff Flooding with Oil Displacement Agents in the Baikouquan Oilfield. Processes. 2025; 13(10):3098. https://doi.org/10.3390/pr13103098

Chicago/Turabian StyleTian, Hui, Jianye Mou, Kunlin Xue, Xingyu Yi, Hao Liu, and Budong Gao. 2025. "Enhanced Oil Recovery Mechanism and Parameter Optimization of Huff-and-Puff Flooding with Oil Displacement Agents in the Baikouquan Oilfield" Processes 13, no. 10: 3098. https://doi.org/10.3390/pr13103098

APA StyleTian, H., Mou, J., Xue, K., Yi, X., Liu, H., & Gao, B. (2025). Enhanced Oil Recovery Mechanism and Parameter Optimization of Huff-and-Puff Flooding with Oil Displacement Agents in the Baikouquan Oilfield. Processes, 13(10), 3098. https://doi.org/10.3390/pr13103098