1. Introduction

Multilayer metal–polymer–metal (MPM) composites are gaining increasing attention due to their unique combination of properties that are not achievable by the individual constituent materials alone [

1]. These systems exhibit low specific weight, a high strength-to-weight ratio, enhanced flexural rigidity, and improved energy absorption, while the polymer interlayer provides additional vibration damping and thermal insulation. These advantages make MPM composites competitive compared to conventional sheet metals and promising for applications in the automotive, aerospace, shipbuilding, and other industries [

2]. The reduction in structural weight contributes to lower fuel consumption, thereby improving cost efficiency and reducing environmental impact.

The practical use of such composites is, however, associated with the need to develop reliable joining methods. The welding process of MPM systems is complicated by a number of specific factors, including differences in thermal conductivity and coefficients of thermal expansion of the layers, as well as the limited heat resistance of the polymer core. These features quite often lead to the formation of welding defects, such as porosity, delamination, and ack of fusion [

3]. Therefore, it is particularly important to carefully select welding parameters and heating conditions in order to minimize the risk of defects and prevent thermal damage to the polymer layer [

4].

Among modern technologies, a special place is occupied by laser welding, which is considered one of the most in-demand and rapidly developing methods for joining materials [

5,

6,

7]. Its features include high precision, localized heat input, a narrow heat-affected zone, and high processing speed, which makes it indispensable for creating strong and durable joints in complex structures [

8]. Laser welding is widely used for processing metallic and non-metallic materials, as well as composites, combining the advantages of high power and localized heating, which are difficult to achieve using traditional joining methods [

9,

10]. These features make laser welding particularly attractive for joining thin metals and multilayer MPM systems.

Studies on laser welding of both stainless and dual-phase steels showed that precise control of welding speed and pulse energy was critical for forming the desired microstructure and minimizing the heat-affected zone [

11,

12]. Laser welding of dual-phase steels under optimized conditions produced fusion zones with predominantly martensitic microstructures containing some bainite, while the ferrite fraction gradually increased in the heat-affected zones [

13,

14,

15]. Tensile and forming tests showed that the welded joints retained strength comparable to the base metal, with minimal reduction in ductility. Higher heat input modified the fusion zone microstructures, altering the proportions of martensite, bainite, and ferrite, which caused softening of both the fusion and heat-affected zones and reductions in yield strength, tensile strength, and elongation. All welded joints failed within the softened heat-affected zones, and the amount and distribution of tempered martensite affected void nucleation during tensile deformation [

16,

17]. These findings highlight the strong dependence of microstructure evolution on process parameters, which in turn governs the mechanical reliability of welded joints. The insights gained from monolithic steels provide a useful reference baseline when addressing more complex multilayer systems such as MPM composites.

It should be noted that conventional laser technologies that use standard Gaussian or top-hat intensity distribution profiles do not always ensure uniform heating of the weld zone. This can lead to overheating of the central part of the weld and insufficient heating of the peripheral areas, which is particularly critical when working with metal-polymer composites [

18,

19]. Localized excessive heat generation can cause degradation of the polymer layer, formation of microcracks, pores, or thermal decomposition of the binder material, which reduces the mechanical properties of the welded joint [

20].

To enhance energy control and prevent local overheating during laser welding, various beam shaping techniques have been proposed. Among these, diffractive optical elements (DOEs) are of particular interest, as they can modify the spatial intensity profile of the laser beam. By doing so, DOEs enable more precise control over heat input and help reduce thermal gradients in the weld zone [

21,

22], which is especially critical in the case of MPM composites. Studies suggest that DOE-based beam shaping can improve energy distribution, potentially reducing residual stresses and minimizing weld defects, such as pores, cracks, or poor fusion, which are often caused by uneven heating [

23]. However, most DOE-assisted investigations reported in the literature have so far focused on simple metallic weldments [

24,

25]. Their application in multilayer hybrid systems, particularly MPM composites with thermally sensitive polymer cores, remains largely unexplored. This gap underscores the need for systematic studies that evaluate whether concepts validated in metallic systems can be successfully translated to complex heterogeneous materials.

In this study, DOEs were not directly implemented during the welding process. However, their potential for enhancing energy distribution was evaluated based on experimental observations of weld quality and defect formation. The analysis specifically focused on the distribution of laser energy within the weld zone, its effect on the microstructure of the joint, and how better energy management could mitigate common welding issues. This allowed for an informed assessment of whether DOE-based beam shaping could significantly improve the quality and consistency of welds.

Previous studies have shown that DOE technology holds promise for optimizing laser processing of multilayer structures by achieving better control over heat input and energy distribution [

26]. Despite these promising results, the practical application of DOEs in the context of MPM composites welding is still in the exploratory phase [

27,

28]. The implementation of DOE in this field requires further research to fully understand how beam parameters, weld geometry, and the dynamics of microstructure formation interact in multilayer welding processes. Accordingly, the present work serves as a baseline investigation, establishing the structural response of the external metal layers in MPM joints under controlled two-sided pulse-periodic laser welding without advanced beam shaping. The results provide a reference framework for the future integration of DOEs or other optical energy control solutions.

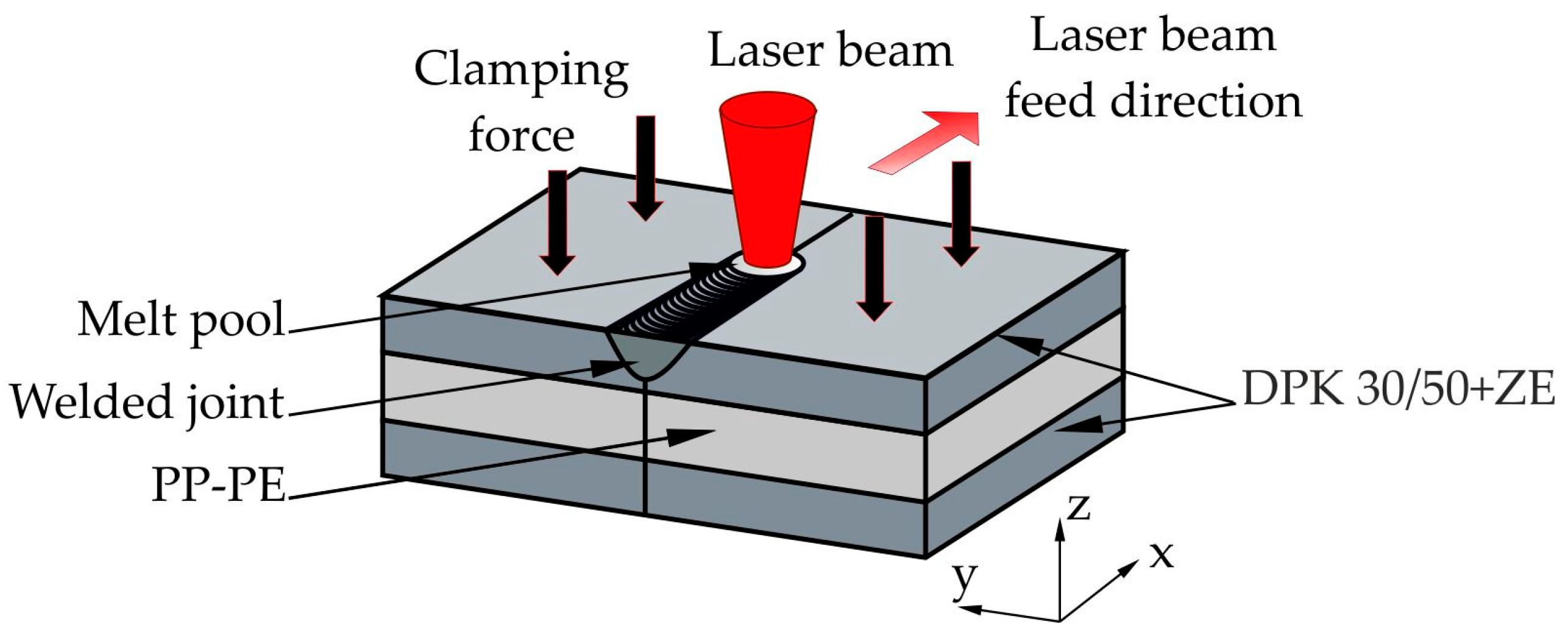

This study investigates two-sided pulsed-periodic laser welding of three-layered MPM composites using basic beam-shaping systems. The analysis focuses on thermal energy distribution, weld-seam morphology, and the conditions required to achieve defect-free joints. This approach helps to identify the practical capabilities and limitations of the process. The results serve as a starting point for further development of thermal management methods, particularly through the integration of optical energy control solutions, such as DOEs, which offer potential for enhancing spatial regulation of heat input and improving weld quality.

3. Microstructural Characterization of the Welded Joint

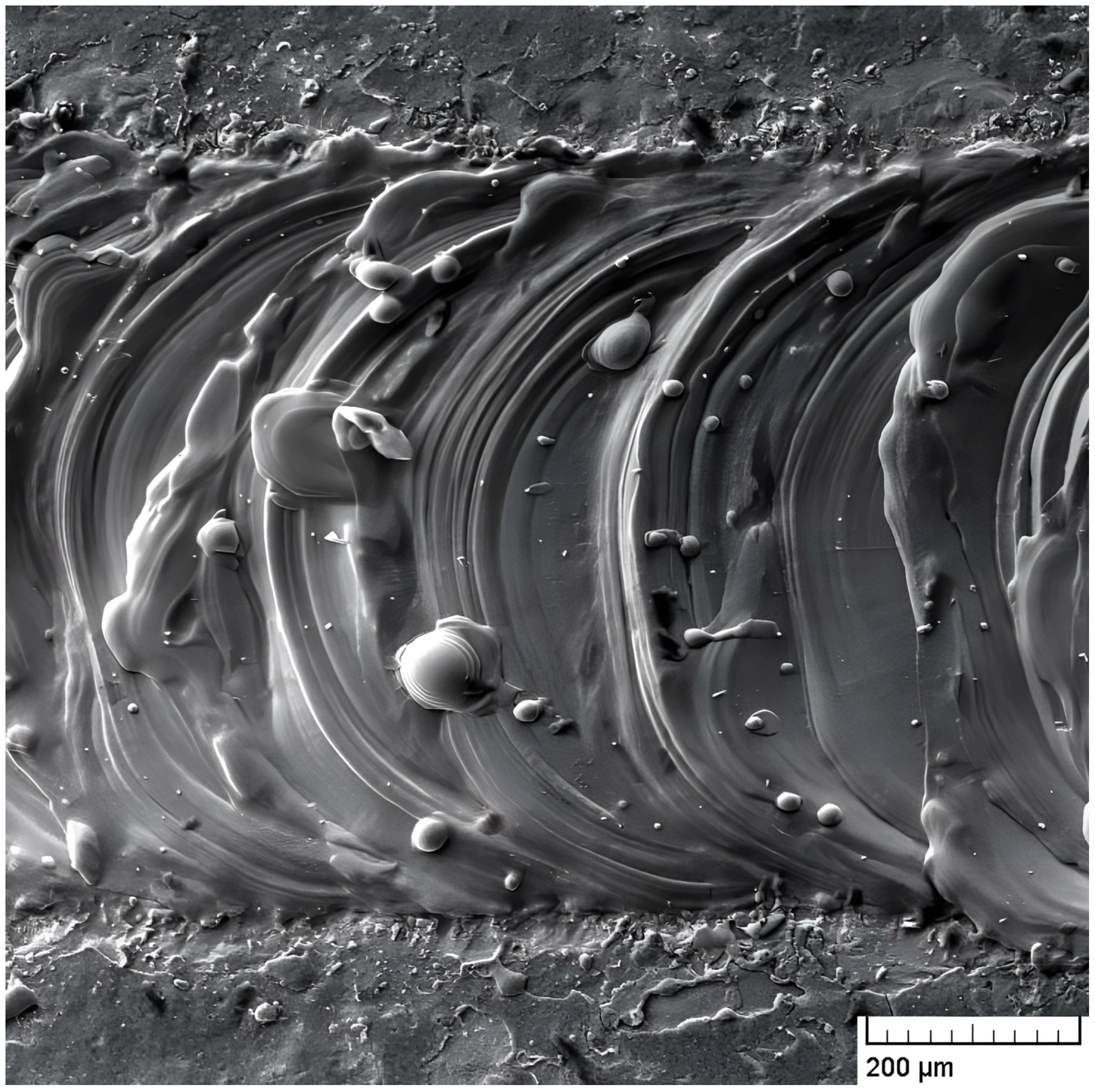

In pulsed laser welding, the weld seam is formed by the sequential overlapping of molten zones, each generated by an individual laser pulse [

36,

37]. Each new laser pulse partially remelts and overlaps the previously solidified region, resulting in a continuous and cohesive weld seam. The overlapping zones are critical for ensuring the structural integrity and mechanical strength of the welded joint. Adequate overlap is essential to prevent seam defects such as insufficient bonding or cracking.

Figure 2 provides a visual representation of the welded joint, showing the resulting weld morphology. The image allows for an assessment of the uniformity and precision of the weld, as well as potential defects or irregularities. The selected focal length and spot size, along with controlled laser parameters, contributed to achieving strong and reliable joints with minimal thermal distortion.

Microscopic examinations were conducted using a Neophot-30 microscope (Carl Zeiss Jena GmbH, Jena, Germany) on cross-section samples of the weld zone prepared with different surface treatments.

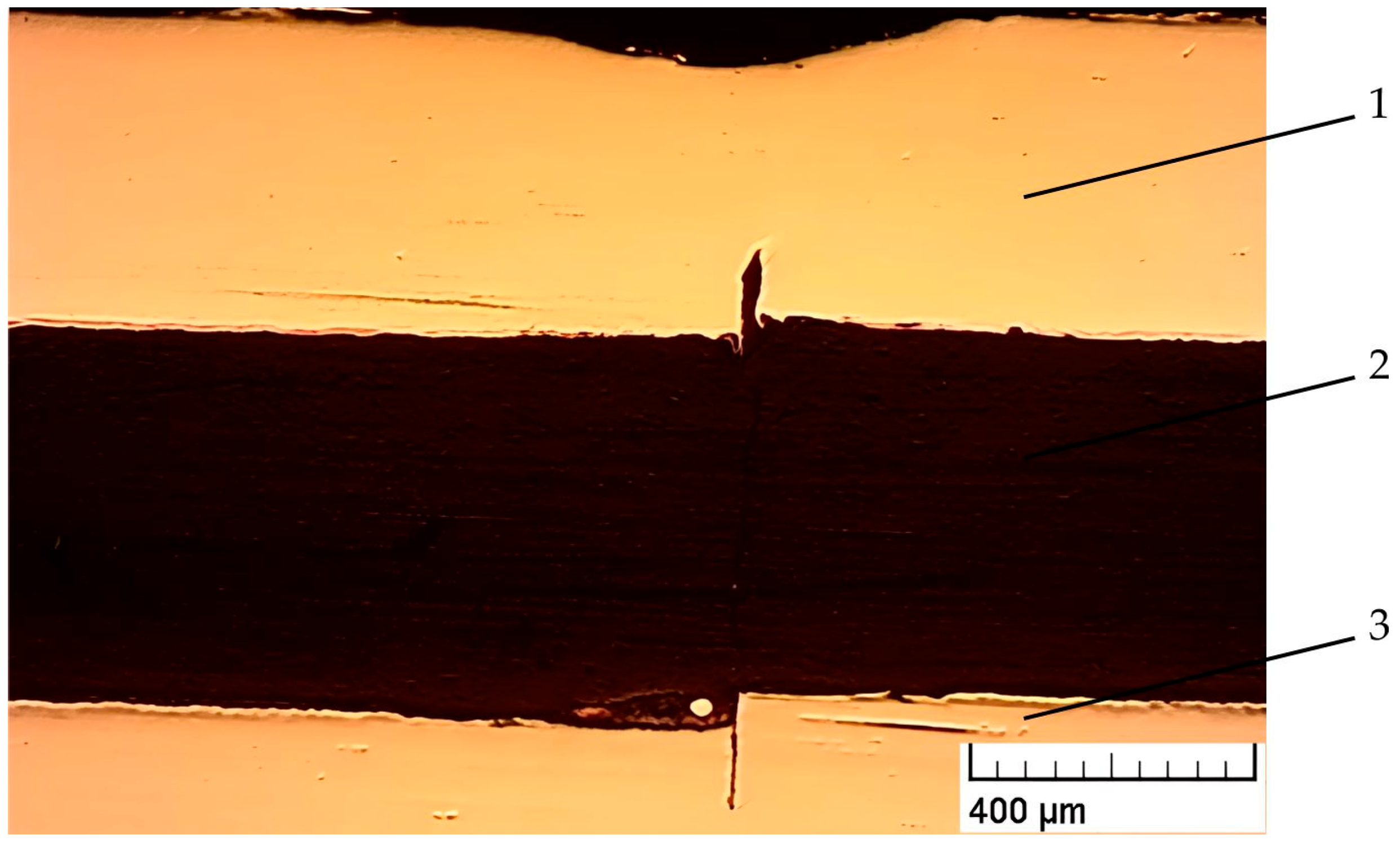

Figure 3 presents the view of an unetched cross-section of the welded MPM joint. This view allows visualization of the spatial arrangement of the layers, interlayer boundaries, and the absence of major macroscopic defects such as delamination, voids, or cracks. The integrity of the polymer layer is preserved, and the image provides an overall assessment of the joint quality without detailing the microstructure.

Figure 4 presents the same weld region at a higher magnification after chemical etching, revealing detailed microstructural features such as phase distribution and transformations within the melting zone and HAZ. For etching, the cross-sections were electrolytically treated in a 20% aqueous NaOH solution at 3 V for 10 s, effectively revealing the ferrite-martensite microstructure without noticeably affecting the polymer–metal interface. Both figures clearly show the penetration depth of approximately 70% into the upper steel layer. The dark-brown region in the lower part of the joined outer sheets corresponds to a gap formed during welding; fusion is observed up to this zone.

In the cross section, the weld region was characterized by two distinct zones: the melting zone and the HAZ. In the melting zone, rapid heating and cooling cycles resulted in a fine-dispersed martensitic microstructure, indicating a high rate of solidification and minimal grain coarsening. No significant defects, such as cracks or voids, were observed, suggesting effective control of the thermal profile and energy distribution during welding. The HAZ displayed transient microstructures, which were influenced by the specific welding conditions and the thermal gradients generated during the laser-welding process. These microstructures exhibited characteristic variations in grain structure and phase transformations due to the localized heating and cooling. Notably, fibrous structures, often associated with excessive heat exposure and slow cooling rates, were absent, indicating that the thermal input was well-controlled, preventing the formation of undesirable microstructures that could negatively affect the mechanical properties of the joint.

This microstructural examination highlights the success of the welding parameters in achieving a uniform and high-quality weld. The absence of coarse-grained structures and defects, combined with the fine martensitic microstructure, suggests that the welding process provided the necessary heat input to create a strong and reliable joint while minimizing the risk of thermal degradation. The fusion-welded joint consisted of several distinct regions, each characterized by unique structural, compositional, and mechanical properties. Together, these distinct regions—weld seam, fusion zone, HAZ, and base metal—highlight the complex interplay of thermal processes during the laser welding of multi-layered materials. Microstructural modifications observed in the fusion and heat-affected zones, including grain growth and phase transformations induced by thermal gradients, are known to influence the mechanical properties of welded joints. Controlling heat input is thus critical to limit potential adverse effects.

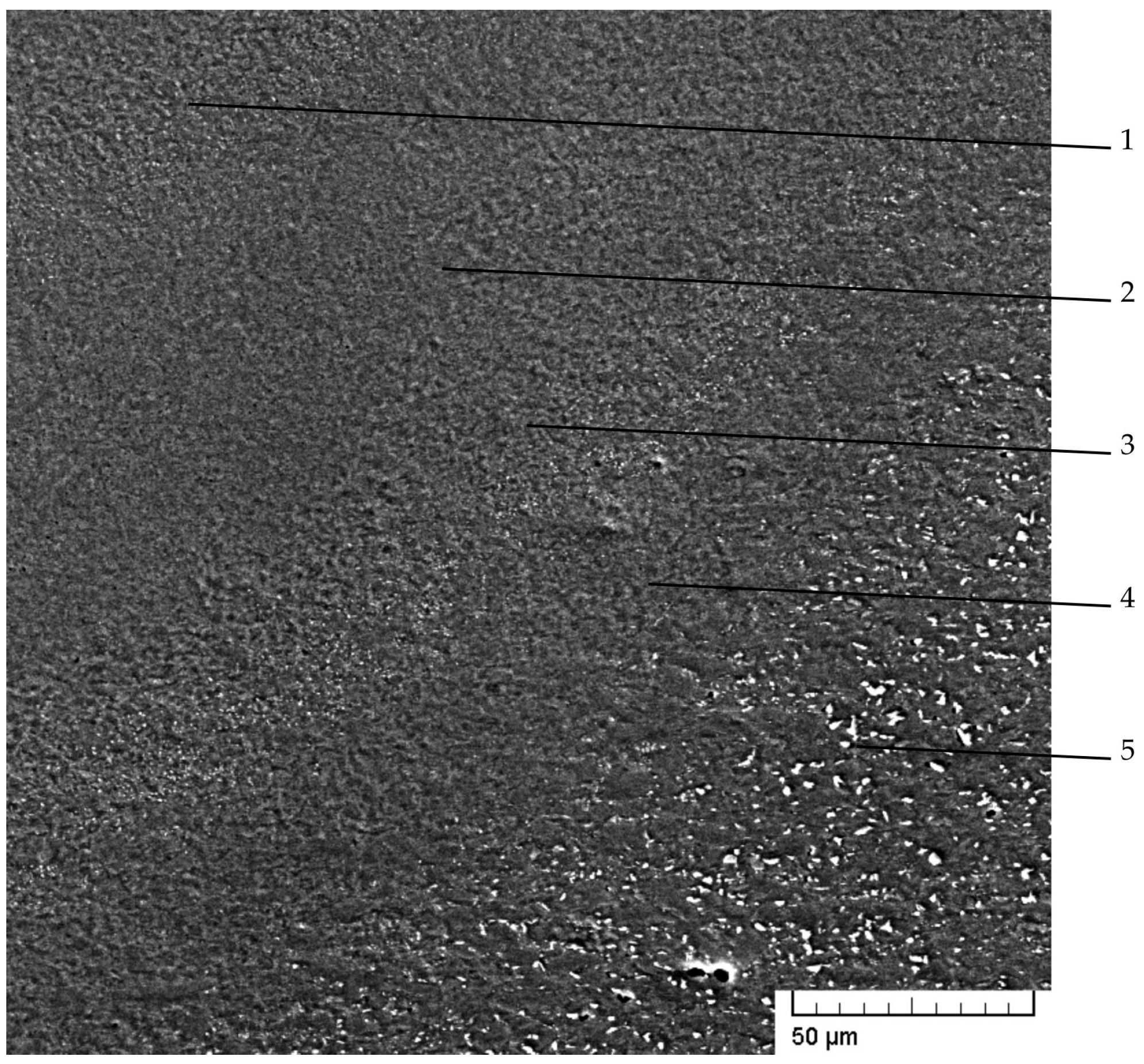

Each zone underwent different thermal histories, resulting in significant variations in microstructure and properties across the joint. The morphology of the laser-welded zones of the outer layers of the MPM samples made of DPK 30/50+ZE dual-phase steel was examined using the VEGA\SB scanning electron microscope (SEM, Tescan, a.s., Brno, Czech Republic).

Figure 5 presents the welded joint in the metallographic cross-section of the MPM sample. On the prepared surface of the weld joint, after grinding, polishing, and etching, five distinct regions were identified: the melting zone; the incomplete melting zone, located at the periphery of the melting zone and adjacent to the HAZ; the normalizing zone; the incomplete recrystallization zone; and the base metallic material.

The weld seam was formed through crystallization of the molten material and exhibited a fine-grained cast structure. This structure is typically indicative of rapid cooling in the fusion zone, which promotes the formation of a solidified region with relatively uniform grain size. The rapid cooling also ensures the integrity of the weld bead by preventing excessive porosity or void formation. In the melting zone, laser exposure was accompanied by multiple cycles of rapid heating and cooling, which led to the formation of a finely dispersed martensitic structure. This structure results from high-speed solidification, which prevents excessive grain growth and promotes uniformity in the weld. No significant defects were observed, indicating effective control over the thermal distribution during the welding process.

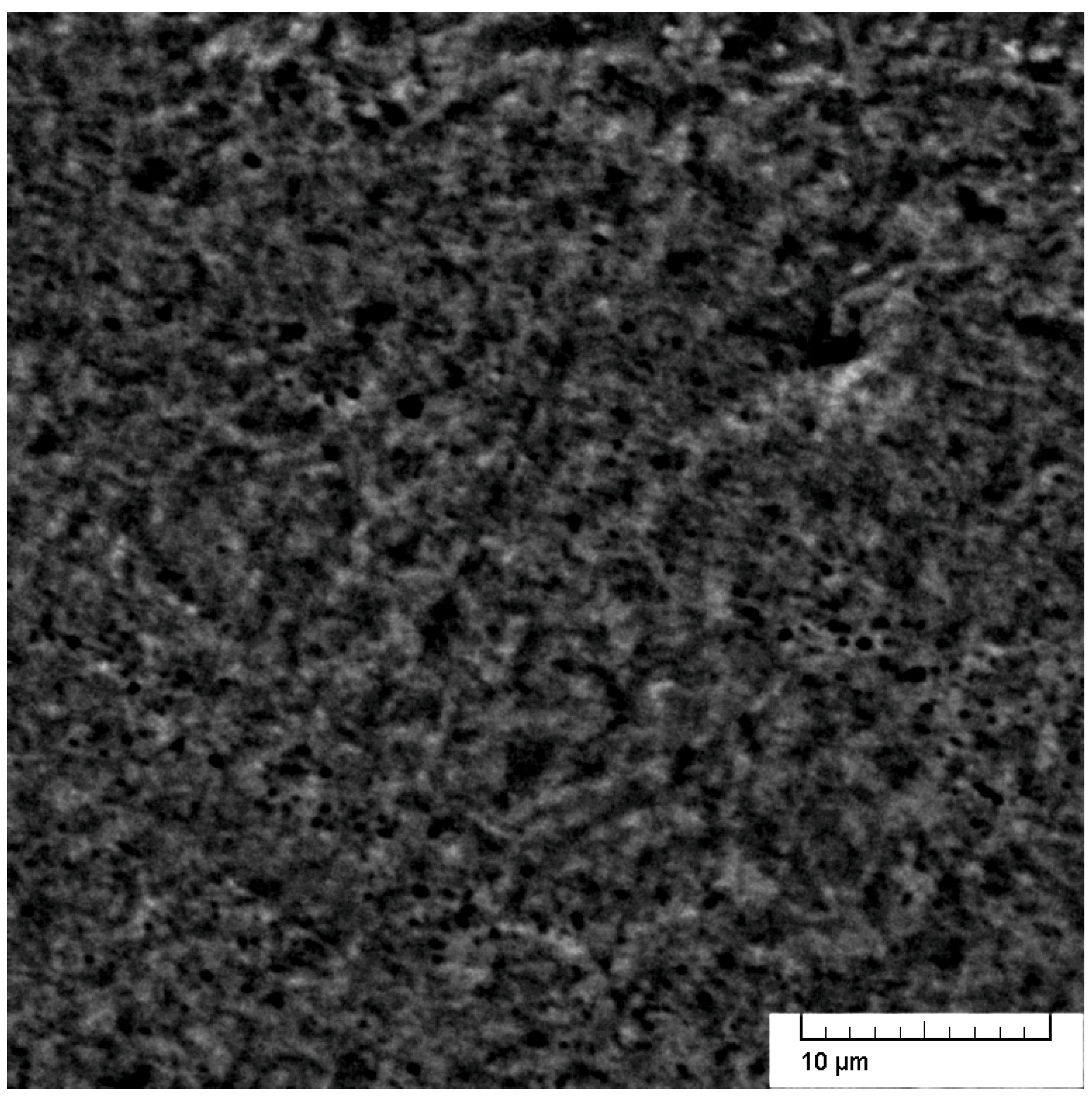

Figure 6 shows the melting zone. The microstructure exhibits a finely dispersed martensitic morphology, with highly refined and uniformly distributed grains. No evidence of porosity, microcracks, or coarse inclusions was observed, indicating uniform solidification and formation of a dense, homogeneous structure. The martensitic phase in this region is expected to provide increased hardness compared to the surrounding areas.

The incomplete melting zone, observed in the cross-section at the boundary between the melting zone and the adjacent base material, represents a region where only partial melting has occurred. Due to insufficient heat input, complete fusion was not achieved, leading to a microstructure that differs from both the fully melted and unaffected areas. This transition zone exhibits microstructural characteristics shaped by partial diffusion between solid and liquid phases, which may impact the overall mechanical integrity of the weld.

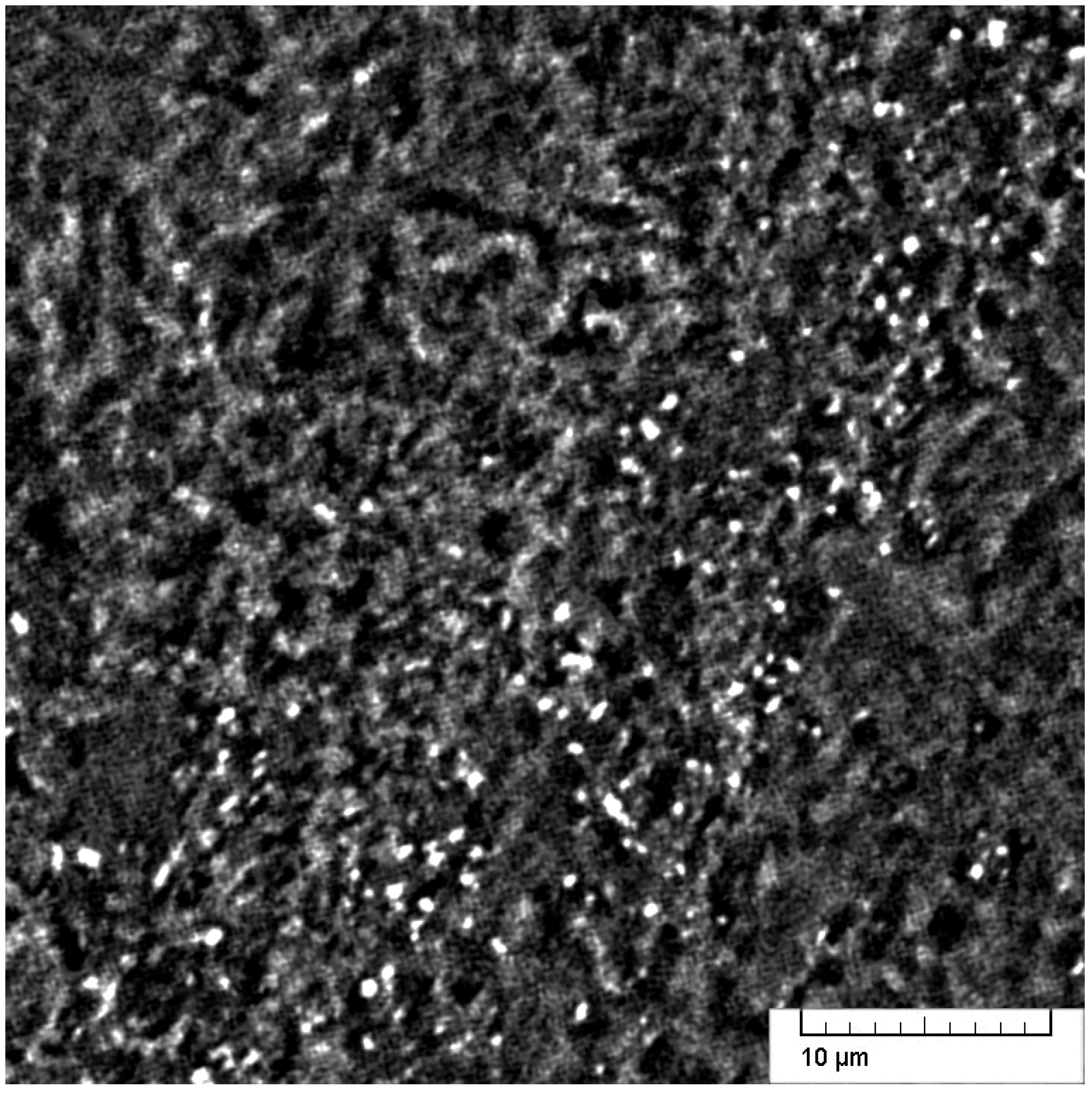

Figure 7 presents the incomplete melting zone, the normalizing zone, and part of the incomplete recrystallization zone. The incomplete melting zone is characterized by transformed grains resulting from incomplete fusion and solidification, with partial homogenization. The normalizing zone exhibits a refined microstructure with relatively uniform and smaller grains, formed under moderate thermal exposure followed by controlled cooling. In the incomplete recrystallization zone, the original ferritic–martensitic matrix is partially preserved, with only limited recrystallization, leaving some features of the base morphology visible. The gradual transition across these zones reflects the microstructural heterogeneity produced by local thermal gradients during laser welding.

In the HAZ, the base material underwent microstructural transformations depending on its proximity to the weld seam. Areas closer to the seam experienced elevated temperatures, leading to partial recrystallization or even grain coarsening, which may reduce the material’s strength in these regions. Notably, no fibrous structures, were observed, which are typically associated with prolonged exposure to high temperatures and slow cooling rates. This absence indicates that the thermal input was well-controlled, preventing the formation of undesirable microstructures that could compromise the mechanical properties of the joint. In contrast, signs of normalizing were observed in some areas, where the material was subjected to a moderate thermal cycle, resulting in a refined microstructure (

Figure 6). Additionally, regions of incomplete recrystallization were found, where the thermal gradients and cooling rates led to only partial recovery of the original structure without full recrystallization. These regions may also influence the mechanical performance of the joint. The observed weld joint morphology underscores the importance of precise thermal management when welding DPK 30/50+ZE dual-phase steel. Careful control of heat input and cooling rates is essential to avoid the formation of brittle phases, such as coarse martensite or needle-like ferrite, and to encourage the development of beneficial microstructures, such as refined bainite or tempered martensite, which enhance the strength and ductility of the weld joint.

In dual-phase steels such as DPK 30/50, careful control of heat input is essential, as it influences the final balance between ferrite and martensite in the HAZ and affects grain morphology. These microstructural changes directly impact mechanical performance, including strength and ductility. Moderate thermal exposure, such as in the normalizing zone, typically leads to grain refinement and a more uniform phase distribution, which are associated with improved toughness and structural integrity [

38,

39]. This refined microstructure, resulting from controlled cooling and recrystallization, ensures that the material maintains its desirable balance of hardness and ductility.

In contrast, the incomplete recrystallization area retained a structure closely resembling the original ferritic matrix, with only minor reductions in pearlitic grain size. This zone, which underwent insufficient thermal cycling, exhibited a microstructure that was not fully homogenized. While the base ferritic structure remained intact, the limited recrystallization hindered the full potential for improving material properties in these regions. Although recrystallization was limited, the area retained enough structural integrity to avoid significant degradation of mechanical performance.

Figure 8 shows the base metallic material. The structure corresponds to the ferritic–martensitic morphology typical of DPK 30/50+ZE dual-phase steel prior to welding. Ferrite grains form the light matrix, while martensite islands are dispersed within it. The phases are evenly distributed, and no thermal alteration is observed. This microstructure serves as a reference state for comparison with the heat-affected and fusion zones, allowing assessment of the extent of microstructural changes caused by welding.

These microstructural variations across the weld region (

Figure 5,

Figure 6,

Figure 7 and

Figure 8) highlight the critical role of precise thermal management in welding dual-phase steels. Achieving the optimal balance between heat input and cooling rates is key to avoiding undesirable phase transformations, such as the formation of brittle needle ferrite, while also promoting beneficial microstructural changes, such as grain refinement in the normalizing zone. This careful control of thermal processes is essential to optimize weld quality, ensuring the joint maintains both strength and ductility, with minimal risk of cracking or other failure modes.

MPM samples with a width of 16.2 mm were prepared for tensile testing of the welded joints. Tests were conducted on a Shimadzu AGS-100kNX universal testing machine (Shimadzu Europa GmbH, Duisburg, Germany) at a crosshead speed of 1.5 mm/min. The average maximum tensile force obtained from three samples was 3.78 ± 0.12 kN, with a corresponding elongation of 0.6 ± 0.05 mm. The tensile strength of the welded zone reached approximately 470 MPa, which is about 80% of the ultimate tensile strength (UTS) of the base galvanized steel (580 MPa). This indicates that the laser-welding process preserves a significant portion of the mechanical integrity of the base material, which is a promising outcome for multilayer composites.

Fracture consistently occurred in the HAZ, slightly offset from the fusion line. This suggests local microstructural softening due to thermal exposure. The limited elongation (less than 1 mm) can be attributed to several factors. Rapid thermal cycles inherent in pulsed laser welding may induce local phase transformations or the formation of harder, brittle microstructures, which reduce plasticity. Incomplete penetration into the outer metal layer may also cause localized stress concentrations under mechanical load, further restricting ductility.

The consistency in mechanical test results (tensile force deviation ±0.12 kN) demonstrates high process stability. Thermal gradients formed during welding lead to HAZ formation, where microstructural changes occur. The combination of these effects, while limiting ductility, does not compromise structural strength, as evidenced by the residual tensile strength of ~470 MPa.

These results confirm the structural soundness of the joints, making the technique suitable for moderate-load applications, such as automotive body structures. Further optimization of thermal management and HAZ control could enhance the ductility and overall performance of the welded joints.

4. Considerations for Energy Distribution Optimization

One of the critical aspects of pulse-periodic laser welding is the precise control of heat input and energy distribution throughout the welding process. Variations in key parameters, such as pulse energy, pulse duration, and pulse frequency, can profoundly influence important characteristics of the weld, including weld depth, defect formation, and the development of residual stresses. Each of these parameters must be carefully adjusted and optimized to ensure consistent, high-quality results, as they directly affect both the structural integrity and the mechanical properties of the welded joint.

Traditional welding techniques, such as defocused laser-beam welding [

40], are employed to redistribute laser energy across the joint area, with the aim of improving overall joint formation. While these methods can help enhance heat distribution, they also come with inherent challenges. For example, defocusing the laser beam can cause instability in weld depth, leading to inconsistent penetration and, in some cases, incomplete fusion. Furthermore, these approaches generally result in higher energy consumption, as they require more laser power to achieve the necessary penetration and desired weld quality when compared to focused laser systems.

To address these challenges and achieve more reliable results, advanced optical systems are essential in ensuring uniform energy distribution across the weld zone. These systems enable precise control over the heat input, minimizing the risk of defects such as excessive HAZ, material distortion, or microstructural imperfections. Technologies like variable-focus optics, spatial filters, and beam-shaping optics are particularly effective in maintaining a consistent energy distribution. These innovations improve the stability of the welding process by offering fine-tuned control over the energy delivery, which, in turn, enhances the mechanical properties of the welded joint.

The use of modern optical technologies enables more efficient control of energy input, which in turn allows for precise management of the welding process and minimizes the likelihood of defects. By controlling the spatial characteristics of the laser beam, this approach not only improves the accuracy and efficiency of the process but also enhances its adaptability to various materials and joint configurations, resulting in superior welds with improved structural integrity.

Although traditional methods of energy redistribution and beam shaping used in this study have certain limitations, such as challenges in precise energy distribution and limited flexibility, the results indicate that more advanced beam-shaping techniques could significantly improve the laser-welding process. Unlike conventional methods, these advanced techniques can enable more effective control over the laser spot’s shape and intensity, ensuring more uniform heat distribution. This helps minimize defects such as weld asymmetry, overheating, or insufficient peripheral heating.

The ability to dynamically adjust the laser-beam profile would allow for more precise thermal control in the weld zone. This is particularly important for welding multi-layer materials, such as MPM, where avoiding weld asymmetry caused by local overheating or inadequate peripheral heating is crucial. By ensuring more uniform energy distribution, these advanced techniques could strongly reduce the risk of thermal defects, such as excessive heating in one part of the weld or insufficient penetration in others.

The findings of this study highlight the potential of advanced beam-shaping techniques to enhance the laser-welding process and suggest the need for further exploration and development of such technologies. Incorporating these techniques into future welding processes could improve weld quality and extend the range of materials and joint geometries that can be effectively welded.

Additionally, the research emphasizes the critical role of precise thermal management in the laser welding of MPM composites. While conventional methods such as focal adjustment and pulse parameter tuning are effective for controlling heat input and ensuring weld quality, they are limited by their lack of flexibility and precision. Advanced beam-shaping technologies present a promising opportunity for refining the welding process. By enabling more controlled and dynamic adjustments to the laser-beam profile, these innovations could enhance heat distribution, reduce defects, and improve the overall stability of the welding process.

Future research should focus on exploring the integration of advanced beam-shaping systems into real-time beam modulation. This could improve the adaptability of the welding process, allowing for more consistent and reliable welds, particularly when working with complex multi-material structures such as MPM composites. Investigating these advanced applications could lead to substantial advancements in both the efficiency and the quality of laser welding, making it more versatile and effective for a wider range of materials and joint configurations.

5. Discussion

The results of this study confirm the effectiveness of two-sided pulse-periodic laser welding for MPM composites. Key factors influencing weld quality include laser parameters, heat distribution strategies, and energy input control. Precise adjustment of pulse energy and duration, as well as beam focus, significantly impact weld joint formation, achieving desired penetration depth while minimizing defects such as overheating, asymmetry, and polymer degradation.

The polypropylene–polyethylene interlayer in the MPM composite is characterized by a low melting point and a relatively low thermal degradation threshold. During laser welding, the primary objective is to limit thermal exposure to the polymer in order to prevent its degradation. This is achieved by establishing a steep temperature gradient from the weld zone to the polymer layer. Such a thermal regime is maintained through precise adjustment of the laser pulse parameters—energy, duration, and frequency.

Special attention was given to energy distribution strategies. Experiments were conducted with various laser parameters, including adjustments to focus and energy delivery. The results showed that the best welds were achieved by carefully selecting pulse energy, ensuring the desired penetration depth without overheating or significant expansion of the heat-affected zone.

It is well known that pulse-periodic laser welding involves steep thermal gradients caused by rapid local heating and cooling, which contribute to the development of residual stresses. Although direct measurements were not conducted in this study, the absence of cracks or defects and the observed joint integrity suggest that these stresses likely remain within acceptable limits. The mechanical test results demonstrate that the welded joints retain approximately 80% of the base metal’s tensile strength, indicating that pulsed-periodic laser welding provides structurally reliable joints in MPM composites. The consistent failure location in the heat-affected zone, rather than in the fusion zone, implies that metallurgical bonding at the interface is robust.

Further improvements can be anticipated with the integration of advanced beam-shaping technologies such as DOEs [

41]. DOEs offer significant advantages, including greater flexibility in shaping laser spot intensity profiles and enhancing the adaptability of the welding process without the need for complex mechanical components. These elements can be tailored to meet specific application requirements, and when integrated with a coordinate positioning system, they can dynamically adjust the laser beam. This allows the system to efficiently execute a variety of welding tasks across different materials and joint configurations.

The primary advantage of DOEs lies in their ability to shape power and energy density profiles [

42], offering new opportunities to control the properties of welded joints, particularly in MPM sandwich panels. The dynamic adjustability of the DOE position, including capabilities such as rotation, oscillation, and shifting, enables the creation of varying laser processing conditions with adjustable spatial-energy distribution. By selectively switching between different regions of the DOE, the laser spot shape can be altered, with the microrelief at the boundaries between regions changing either discretely or continuously. This level of control ensures more efficient and customized welding solutions, improving precision and stability in the welding process.

In precision welding of micro and mesoscale components, challenges such as overheating in the central region and insufficient heating in the peripheral zones of the weld area can arise. To mitigate these issues, adjusting the intensity distribution by concentrating more energy at the periphery allows for a more uniform heat distribution. This reduces the risk of localized overheating and ensures adequate energy delivery to the edges of the weld [

43]. The intensity ratio between the center and the periphery can be tailored to meet the specific requirements of each stage of the welding process. Integrating real-time control systems and automatic feedback mechanisms will significantly improve process precision, enabling dynamic adjustments as conditions evolve. This approach ensures consistent and high-quality welds, even across a diverse range of materials and joint configurations, making it particularly effective for precision welding applications.

6. Conclusions

This study investigated two-sided pulsed-periodic laser welding of three-layer MPM composites consisting of galvanized dual-phase steel (DPK 30/50+ZE) and a PP-PE polymer core. Welding was performed using a standard Nd:YAG laser system with basic beam-shaping optics. The process achieved up to 70% penetration into the outer steel layer, forming defect-free or minimally defective welds while preserving the integrity of the polymer core.

Microscopic analysis revealed clearly defined melting and HAZ, with martensitic transformation in the melting zone and transitional structures in the HAZ. The absence of cracks, porosity, or other major defects confirms stable thermal conditions during welding. The tensile strength of the joints reached approximately 470 MPa (80% of base metal UTS), confirming high structural integrity. Further investigations into microhardness distribution are planned to better understand local mechanical property changes across the weld zone.

The results highlight the role of pulse parameters—energy, duration, frequency—and controlling spatial heat distribution to ensure high-quality welds. Although this study used standard optics, it identified key process limitations and pointed to the potential benefits of advanced beam-shaping tools. In particular, DOEs and dynamically adjustable beam profiles offer promising opportunities for further improving weld quality through enhanced control of energy input and distribution.

Future research should focus on developing dynamic, real-time control systems that incorporate advanced beam-shaping techniques. This could lead to significant improvements in laser-welding efficiency, weld quality, and the range of materials and joint configurations that can be effectively welded. By refining these technologies, it may be possible to further optimize the laser-welding process, resulting in more reliable and durable welded joints, particularly in complex composite structures.