Abstract

The aim of this study was to develop a scientifically substantiated recipe for the functional food granola using plant-derived ingredients selected for their nutritional value and functional properties. The proposed multi-component granola, comprised of a variety of cereals, fruits, and vegetables local to Kazakhstan, comprises ingredients including oats (Syrgalym variety), corn (Tatti-2012), rice (Barakat), buckwheat (Shortandinskaya 3), pumpkin (Karina), apple (Zailiyskiy), and cranberry (Ben Lear). The research methodology included an analysis of the chemical composition of ingredients, the development and testing of ten granola recipes, and an assessment of their nutritional and sensory value. Optimal formula No. 4 provided the following nutritional values per 100 g: protein—12.4 g; dietary fibre—6.8 g; vitamin C—22.3 mg; potassium—617.4 mg; and iron—4.7 mg. Statistical data processing was performed using the Pearson correlation coefficient and Student’s t-test (p < 0.05). The obtained correlation dependencies allowed the contribution of each component to the nutrient profiles to be determined. Sensory evaluation showed favourable taste and organoleptic characteristics of the recipes using fruit and berry components, especially apples and cranberries. The developed recipe can be recommended for inclusion in the diet of athletes, the elderly, and people with insufficient intake of vitamins and minerals. The results have practical value and contribute to the expansion of the range of healthy food products based on the agricultural potential of Kazakhstan. Prospects for further research include the development of specialised formulas for baby food and people with special dietary needs.

Keywords:

granola; recipe; functional ingredients; cranberry; nutritional value; whole grains; antioxidants 1. Introduction

Modern trends in nutrition reveal a steady growth of interest in functional food products aimed at preventing chronic diseases, improving well-being, and increasing the overall performance of the body [1,2]. In the context of an accelerated pace of life, there is a growing need for products that combine nutritional value, organoleptic properties, availability, and ease of preparation. Such products include granola, a dry multi-component breakfast that includes cereals, fruit, vegetable, and nut ingredients [3,4,5]. Despite the wide range of granolas on the market, the recipes usually contain standard components and rarely consider region-specific raw materials or the characteristics of target consumer groups. The use of local raw materials not only ensures economic efficiency but also opens up new opportunities for creating recipes with high nutrient and biological potential [6,7]. The combination of cereals (oats, rice, corn, and buckwheat) with fruit and vegetable components (pumpkin and apple) and berries (cranberry) forms the basis of a functional product enriched with vitamins, minerals, dietary fibre, and antioxidants. Previous studies have shown that each of these components has pronounced biological activity, but scientific data on their combined use in one product is limited [8,9,10].

Oats have a high content of β-glucans, which reduce cholesterol levels and the glycaemic index of the product [11,12]. Rice is a source of starch, phospholipids, and γ-oryzanol [13,14]. Corn contains bioavailable antioxidants and magnesium, which is involved in energy metabolism [15,16]. Buckwheat contains flavonoids and essential amino acids [17,18]. Pumpkin is a rich source of carotenoids and dietary fibre [19,20], and apples provide organic acids and polyphenols with antioxidant action [21,22]. Cranberries provide anthocyanins, proanthocyanidins, and vitamins C and K, which enhance immune response and reduce inflammatory processes [23,24,25]. However, these ingredients consumed in isolation do not provide the full potential of the complex interaction of nutrients. The focus of this work was the scientific justification of their combined use, aimed at enhancing biological activity and adapting the recipe to the needs of certain population groups like the elderly, athletes, and people with micronutrient deficiency [26,27].

Modern approaches to the creation of functional foods involve the use of local raw materials with high nutrient density and biological activity. The development of granola, a complex product that includes cereals, fruits, vegetables, and nuts, is a promising area, allowing for the creation of a product with high nutritional and physiological value that aligns with modern healthy eating trends [28,29].

Pumpkin is one of the most valuable components in terms of β-carotene content (4–5 times higher than in carrots), vitamins (A, B1, B2, B3, B6, B9, E, PP, and C), and minerals (K, Fe, Ca, P, and Mg), which makes it a functionally significant ingredient to maintain immunity and antioxidant protection [30,31,32]. Pectins and dietary fibre contained in pumpkin help improve digestion and normalise lipid metabolism [33,34].

Cranberries, as shown in several studies, are characterised by a high content of anthocyanins, catechins, vitamin C, iodine, iron, organic acids, and pectin. These compounds have antimicrobial and cardioprotective properties, and help reduce the activity of Helicobacter pylori, which is important in the prevention of diseases of the stomach and intestines [35,36,37]. In addition, cranberry consumption is associated with a decrease in blood pressure and an improvement in the lipid profile of the blood [38,39].

Apples are a source of soluble dietary fibre, sugars, organic acids, and more than 60 micro- and macroelements, including K, Fe, Ca, and Mg [40,41]. They have pronounced antioxidant activity and help normalise carbohydrate metabolism.

Nuts enrich the recipe with fats with a high content of mono- and polyunsaturated fatty acids, proteins with a high biological coefficient, vitamins E and group B, and Zn and Mg. Their inclusion in granola helps maintain cognitive function, reduce inflammation, and improve the blood lipid profile [42,43].

The combined use of these components in one recipe allows not only the nutritional and biological value of the product to be increased but also for a synergistic effect between antioxidants, dietary fibre, fatty acids, and vitamins to be achieved, which enhances the disease-preventive effect of granola. In addition, all the ingredients used are locally grown, which reduces logistical costs and increases the sustainability of the food chain [44,45].

Thus, the use of oats, rice, corn, buckwheat, pumpkin, cranberries, apples, and nuts within one functional product achieves a balanced ratio of macro- and micronutrients, corresponding to recommendations for the rational nutrition of various target groups of the population [46,47].

In this context, the aim of the study was to scientifically substantiate the composition of the granola recipe based on domestic plant components with a high content of biologically active substances and an optimal nutrient structure.

2. Materials and Methods

For the experimental studies, the following raw materials were used: oats of the Syrgalym variety, corn of the Tatti-2012 variety, rice of the Barakat variety, buckwheat of the Shortandinskaya 3 variety, pumpkin of the Karina variety, cranberries of the Ben Lear variety, and apple of the Zailiyskiy variety. Cranberries were gathered within the limits of the standards approved by the decision of local Maslikhats, taking into account the preservation of their populations and communities, as well as their places of growth.

Syrgalym is a Kazakhstani oat variety, bred by the method of individual selection from the world collection. The variety is included in the State Register of Breeding Achievements, approved for use in the Republic of Kazakhstan since 2020 for cultivation in the Almaty, Akmola, Zhambyl, North Kazakhstan, and Pavlodar regions. It is a mid-season variety, it is resistant to early spring frosts, and it has a vegetation period of 92–112 days. It weighs 32.0–39.2 g/1000 grains and has a grain protein content of 13.8%. The average yield of Syrgalym grain is 43.9 c/ha (centners per hectare).

The corn variety Tatti-2012 is mid–late-ripening (125–127 days), depending on the sewing time, and is approved for use in the Almaty, Zhambyl, and South Kazakhstan regions of the Republic of Kazakhstan. The grain is white and the flower scales are white to red. The grain yield at threshing is 20.7 c/ha (82%) and the weight of 1000 grains is 260 g. The variety is characterised by a grain explosiveness of 90–95%. Its protein and starch contents are 10.9% and 65.9%, respectively.

Barakat is a Kazakhstani rice variety produced in the Kyzylorda, Akmola, and North Kazakhstan regions. The variety is characterised by its large, elastic grains, aromatic and unique taste, delicate structure, and nutritional properties. It is rich in B vitamins, iron, phosphorus, magnesium, and dietary fibre. The yield of Barakat rice, in particular in the Kyzylorda region, averages about 50–53 c/ha, but may vary depending on specific conditions. In 2022, the average rice yield in Kyzylorda was recorded at 53 c/ha and, in 2023, 50.3 c/ha.

Shortandinskaya 3 is a Kazakhstani buckwheat variety developed for its tolerance to cultivation in various climatic conditions, and is mainly grown in the Kostanay, Pavlodar, and North Kazakhstan regions. Shortandinskaya 3 buckwheat is in demand among Kazakh farmers due to its high yield and adaptability to local conditions. The variety is characterised by large grains, which is one of its main advantages. Its potential yield can reach 33 c/ha, the grain is highly uniform (78.7–80.8%), and it has a high kernel yield (68.3–69.8%).

Karina is a mid–late-ripening pumpkin variety bred by the Kazakh Research Institute of Potato and Vegetable Growing. The plant is powerful, with long vines. The fruits are round-flattened and segmented, with thin skin, weighing 4–5 kg.

In Kazakhstan, mainly large-fruited cranberry varieties are grown, such as Ben Lear, Stevens, EarlyBlack, and Bergman. The variety Ben Lear is one of the earliest ripening, in late August. The fruits are large, up to 2.2 cm in diameter, of regular round shape, glossy, dark red with a blue waxy coating, sourish-cloying, and can remain on the bush all winter. The variety yields up to 1.5 kg/bush.

The granola formulae using multicomponent mixtures are shown in Table 1.

Table 1.

Granola formulations using multicomponent mixtures.

The addition of cranberry fruit concentrate to the granola formulation was carried out in accordance with the technical regulations of the Customs Union “Safety requirements for food additives, flavourings and technological aids” (TR CU 029/2012).

The sensory evaluation of granola was carried out in accordance with GOST ISO 6658:2017 “Sensory analysis—Methodology—General guidance” [48] and GOST 8756.1-2017 “Fruit and vegetable products—Methods for organoleptic evaluation” [49]:

- −

- GOST ISO 6658-2016—establishes the general methodology for conducting sensory analysis, including sampling and sample preparation, creating testing conditions, selecting and training assessors, and using standardised scales to evaluate product attributes (taste, smell, colour, texture, etc.).

- −

- GOST 8756.1-2017—regulates the procedure for sensory evaluation of fruit and vegetable products, including the determination of appearance, colour, odour, and taste according to established criteria, as well as recording the results using a point-based system in accordance with the standards for the specific product.

The panel consisted of 12 trained assessors (staff members of the Department of Technology of Grain Products and Processing Industries, ATU) with at least 3 years of experience in sensory evaluation of food products. Panellists were selected based on the following criteria: absence of diseases affecting taste and smell, no allergies to the tested ingredients, and consent to participate.

The evaluation was conducted in a specialised sensory laboratory at a temperature of (22 ± 2) °C, relative humidity of 60–70%, under diffuse daylight, with no extraneous odours or noise.

Each sample was coded with a random three-digit number and presented in randomised order in disposable cups (50 mL). The evaluation was performed in two replicates. Between samples, panellists rinsed their mouths with room-temperature drinking water.

The scoring was based on a five-point scale (from “1”—very poor to “5”—excellent) for four attributes: colour, taste, odour, and texture. The mean score for each attribute was calculated from all assessors’ results.

The granola protein content was determined according to GOST 10846-91 [50]. The method is based on the mineralisation of organic matter with sulfuric acid in the presence of a catalyst to form ammonium sulphate, the destruction of ammonium sulphate with alkali to release ammonia, and the distillation of ammonia with steam into a solution of sulfuric or boric acid, followed by titration.

The mass fraction of fat was determined according to GOST 29033-91 [51]. The essence of the method is to extract the crude fat from the product with a solvent, then to remove the solvent, and to dry and weigh the extracted fat.

The dietary fibre was determined according to GOST 31675-2012 [52] using a method based on sequential processing of the sample with acid and alkali solutions, ozonation, and quantitative determination of organic residue by weight. The crude dietary fibre content is expressed as a percentage by mass or in grams per 1 kg of dry matter.

The mass fraction of ash was determined according to GOST 25555.4-91 [53]. The method is based on dissolving ash in a titrated solution of hydrochloric acid and back titrating the ash solution in the presence of an indicator. The final test result is taken as the arithmetic mean of the results of two parallel determinations, the relative discrepancy between which should not exceed 5% (p < 0.05).

Chromatography methods, in particular high-performance liquid chromatography (HPLC), are widely used to determine the content of vitamins and other bioactive compounds such as vitamins A, E, and β-carotene in food products and biological samples. HPLC can be used in combination with spectrophotometric and fluorimetric detection for quantitative analysis.

HPLC with spectrophotometric detection is based on the ability of substances to absorb light in specific regions of the spectrum. For vitamins A and E, which have specific absorptions in the UV or visible region of the spectrum, spectrophotometric detection can be used. HPLC separates the components of the analysed mixture, and a detector determines the intensity of light absorption for each substance, which allows for quantitative assessment of the vitamin content.

HPLC with fluorimetric detection is used for substances that are capable of fluorescence; that is, emitting light after absorbing light of a certain wavelength. The advantage of the fluorimetric detector is its high sensitivity and selectivity, which allows for the determination of low concentrations of substances.

The advantages of using HPLC with light absorption detection and fluorimetric detection are high sensitivity and selectivity and the ability to analyse a wide range of substances. Moreover, modern HPLC systems can be automated, which simplifies analysis and increases productivity, and HPLC provides accurate and reproducible results, which is important for research and quality control. In general, HPLC with light absorption detection and fluorimetric detection is a powerful tool for the analysis of vitamins and other bioactive compounds in diverse sample types.

The β-carotene content was determined according to GOST R 54058-2010 [54]. The method is based on the extraction of carotenoids from a sample or sediment previously obtained by treating the sample with Carrez I and Carrez II solutions, followed by purification of the isolated preparation with petroleum ether and spectrophotometric determination of the mass concentration or mass fraction of carotenoids. The proportions of individual carotenoids (in the total carotenoid content) are determined by spectrophotometric measurement in fractions obtained from chromatographic separation of the extract.

The mass concentration of organic acids was determined according to GOST 32771-2014 [55]. The method is based on the determination of individual organic acids separated on a solid C18 column in reversed-phase chromatography. Identification and quantitative calculation of acid peaks are carried out at individual maxima of their light absorption in the UV region of the spectrum, and through comparison of the retention times in calibration solutions.

Vitamin A content was determined according to GOST R 54635-2011 [56]. Vitamin A is determined by separation using HPLC followed by fluorimetric detection. Quantitative analysis is carried out using an external standard method using the area or height of peaks of retinol, retinol acetate, and retinol palmitate. The content of B vitamins and vitamin C was determined according to GOST 31483-2012 [57]. This standard establishes a capillary electrophoresis method for determining the content of water-soluble vitamins B1 (thiamine chloride), B2 (riboflavin), B3 (pantothenic acid), B5 (nicotinic acid and nicotinamide), B6 (pyridoxine), B9 (folic acid), and C (ascorbic acid). Depending on the composition of the analysed sample and the accuracy of the measurements, two versions of the capillary electrophoresis method are used: capillary zone electrophoresis (herein referred to as CZE) or micellar electrokinetic chromatography (herein referred to as MEKC). CZE is not used to determine vitamin B5 in the form of nicotinamide or vitamin B2 (riboflavin) due to a large potential error, and MEKC is not used to determine vitamin B1 (thiamine chloride) for the same reason.

The content of vitamin E was determined according to GOST R 54634-2011 [58] by separating tocopherols using normal-phase or reversed-phase HPLC, followed by fluorimetric detection. If necessary, the extract is obtained after alkaline hydrolysis of the analysed sample. Quantitative analysis is carried out using the external standard method using the area or height of the tocopherol peaks.

GOST 33462-2015 [59] establishes a method for determining the mass concentrations of Na, K, Ca, and Mg using atomic absorption spectrometry with flame atomisation. The method is based on preliminary mineralisation of the sample with the addition of a chemical oxidizer (nitric acid) and measuring the absorption of radiation at the resonance wavelength of the atomic vapours formed by atomisation in an acetylene–oxygen flame of an atomic absorption spectrometer. Caesium chloride is added to prevent partial ionisation of metals in the flame when measuring Na and K (to modify the matrix), and lanthanum chloride when measuring Ca and Mg.

GOST 26657-97 [60] establishes photometric and titrimetric methods for determining the phosphorus content. The method consists of mineralisation of the sample by dry or wet ashing with the formation of salts of orthophosphoric acid, and subsequent photometric determination of phosphorus in the form of a yellow-coloured compound (a heteropoly acid formed in an acidic medium in the presence of vanadate and molybdate ions).

GOST 32343-2013 [61] uses atomic absorption spectrometry to determine the Ca, Cu, Fe, Mg, Mn, K, Na, and Zn contents. The method involves dissolving the analysed sample in hydrochloric acid, with ozonation in a muffle furnace at 550 ± 15 °C if necessary. Silicon compounds are removed by precipitation and filtration. Subsequently, the resulting mixture is atomised in an acetylene–air flame. The absorption of each element in the solution is compared to the absorption of the same element in a calibration solution.

Production of processed products—extracts and concentrates

Extracts from cranberry fruits were obtained by ultrasonic-assisted extraction (UAE) in an ultrasonic bath (Sapphire). Ultrasonic extraction extracts biologically active compounds from various sources, including plants, fruits, and vegetables, by exposing the extraction medium to ultrasonic waves. The extracts were concentrated by vacuum evaporation using an IKA RV-10 rotary evaporator.

In recent decades, modern, energy-saving, and environmentally friendly extraction methods have been actively developed, including ultrasonic and microwave processing, which allow high-quality extracts to be obtained. Ultrasonic extraction is especially attractive due to its simplicity, the availability of the equipment, and its low cost. The method is based on the effect of ultrasonic waves (at a frequency of >20 kHz), which contribute to a more effective release of active substances from plant materials. Ultrasonic activation significantly increases the yield of extractive substances [62,63]. Ethanol, in particular, is a widely used extractant for plant materials due to its ability to extract a wide range of compounds, including phenolic compounds, flavonoids, and organic acids.

The percentage of extractive substances (X) in terms of absolutely dry raw materials was calculated using Formula (1):

where

- −

- m is the mass of the dry residue (g);

- −

- m1 is the mass of raw materials (g);

- −

- W is the mass loss during drying of the raw materials (%).

The weight loss during drying (W) was calculated according to Formula (2):

where

- −

- m is the mass before drying (g);

- −

- m1 is the mass after drying (g).

Cranberries were subjected to ultrasonic extraction due to their high natural moisture content (up to 88–90%) and complex cellular structure, rich in pectins and phenolic compounds associated with cell walls. These structural features make it difficult to directly incorporate the fruit into the granola recipe in an unprocessed form as they worsen the texture and reduce the shelf life of the finished product. Moreover, traditional heat treatment can destroy heat-sensitive bioactive substances such as anthocyanins, flavonoids, and vitamin C.

The use of UAE facilitates the effective destruction of cell walls due to cavitation processes, which significantly increase the yield of target nutrients (phenolic compounds, vitamins, and organic acids) and help to provide a concentrate with high antioxidant activity. This approach allows the use of cranberries not as whole berries but as a concentrate in syrup, ensuring the uniform distribution of functional components throughout the product and improving sensory characteristics (taste, aroma, and homogeneity). Thus, ultrasonic extraction was used purposefully as a technologically and scientifically sound method for increasing the efficiency of extracting bioactive substances from cranberries.

The remaining ingredients, namely the oats, buckwheat, corn, rice, and pumpkin, due to their low moisture content and stable structure, were prepared using the standard methods of steaming, grinding, baking, and drying. These processes preserve the texture and nutritional value of the components without the need for preliminary extraction.

The process of obtaining granola consisted of the following operations:

- Preparation of ingredients: All components were cleaned, cut, and sorted by size so that all components were evenly baked.

- Mixing ingredients: Liquid components (syrup and oil) were added. This gives the mixture sweetness and improves the texture.

- Baking: Baking was carried out at a low temperature of 170–180 °C for 12–18 min to avoid burning the ingredients, to dry evenly, and to provide a crispy texture. The mixture was periodically stirred for uniform cooking.

- Cooling and packaging: After baking, the granola was cooled and packaged.

Each recipe was tested in 2 replicates.

Statistical analysis: To justify the optimal granola recipe composition aimed at achieving a balanced nutrient profile, a set of correlation and comparative analysis methods was used. The recipes were optimised based on an assessment of the contribution of individual ingredients to the content of key nutrients determined to be priority components in terms of functionality (protein, dietary fibre, vitamin C, iron, and potassium). The target optimisation contents per 100 g were as follows:

- −

- Protein content ≥ 10 g;

- −

- Dietary fibre ≥ 5 g;

- −

- Vitamin C ≥ 15 mg;

- −

- Iron ≥ 3 mg;

- −

- Potassium ≥ 400 mg.

These thresholds were determined based on adequate consumption standards and publications on the composition of functional foods. Correlation analysis was performed using the Pearson correlation coefficient (r) to determine the direction and degree of influence of the content of each ingredient on the level of the specified nutrients in 10 experimental samples (N = 10). The calculations allowed us to identify the ingredients with the greatest influence on the content of certain substances. The r values were interpreted using a generally accepted scale: |r| ≥ 0.7 for strong correlation, 0.3 < |r| < 0.7 for moderate, and |r| ≤ 0.3 for a weak or no relationship. The results were visualised as a heatmap, where the direction and strength of the relationship are presented using a colour scale (negative relationships in red, positive relationships in blue). To test the statistical significance of differences between the nutrient content of the base component (oat flakes) and the other ingredients, we used Student’s t-test for dependent samples. This approach allowed us to determine which ingredients make a reliable contribution to the fortification of the product. Statistical analysis was performed using Microsoft Excel 2016 and the Statistica package (TIBCO Software Inc., Palo Alto, CA, USA), and the significance level was set at p < 0.05. All results are presented in the form of tables containing t, p values, and interpretation of significance, which ensures the validity of decisions on the design of the recipes. Based on the data obtained, the formula that best meets the established criteria was determined to be recipe No. 4.

3. Results

The Department of Technology of Bread Products and Processing Industries of Almaty Technological University (Almaty, Kazakhstan) has conducted work on designing recipes for breakfast cereals, including granola, using cereal, fruit, and berry crops, and their processed products. Fortification (enrichment) is an important process that increases the nutrient content of food. This process can be a very cost-effective healthcare intervention. Fortifying foods with minerals (e.g., Ca and Fe), vitamins, and dietary fibre can effectively reduce and prevent diseases associated with nutritional deficiencies [64,65,66].

Table 2 shows an analysis of the chemical composition of the cereal, fruit, and berries cultivated in Kazakhstan. Cereals, fruits, and berries contain a small amount of protein and fat, but significantly more carbohydrates. The optimal combination of grain, fruit, and berries in complex recipes plays a key role in the creation of food products highly balanced in terms of essential nutrients, vitamins, minerals, and biologically active components. This approach ensures not only the nutritional value and physiological completeness of the finished product but also its functional focus, namely the prevention of nutrient deficiency conditions, the strengthening of the immune system, and improvement of metabolic processes. According to general literature sources, the types of plant materials used in this study, including grains (oats, corn, rice, and buckwheat), fruits (pumpkin and apple), and berries (cranberries), are not inferior to similar crops growing in the leading agricultural regions of the world in terms of their chemical composition, concentration of biologically active substances (polyphenols, antioxidants, dietary fibre, organic acids, and vitamins A, C, E, and group B), and their functional and technological characteristics. This demonstrates the high quality and competitiveness of Kazakhstani plant crops, which are capable of satisfying both the domestic food market needs and the export potential. In addition, the availability of environmentally friendly, affordable, and diverse plant materials in Kazakhstan justifies their effective use in the production of functional foods and dietary supplements aimed at improving public health, preventing chronic diseases, and creating a healthy eating culture. Thus, the development of recipes based on local grain, fruit, and vegetable components not only meets modern trends in the food industry but also contributes to the development of the agro-industrial complex, strengthening food security, and introducing innovative solutions in the production of products with specified properties.

Table 2.

Chemical composition of grain and fruit crops.

Dietary fibre, an indigestible component of the plant cell wall, plays an important role in human nutrition and health [67,68]. The content of dietary fibre in 100 g of the studied samples is 12.0 g in oat, 8.35 g in corn, 6.1 g in rice, 13.0 g in buckwheat, 2.17 g in pumpkin, 3.3 g in cranberries, and 1.51 g in apples. Along with proteins, fats, carbohydrates, and vitamins, an essential component of foods are minerals. Entering the body with food and water, each mineral element performs a special function in the body. They are integral to or activate the action of enzymes, hormones, and vitamins, and thus participate in all types of metabolism and affect immunity, haematopoiesis, and blood clotting. Only a varied diet ensures that the human body receives all the necessary minerals [69,70,71,72]. Minerals are divided into macro- and microelements depending on their content in the body. Seven elements are macroelements, including calcium, magnesium, phosphorus, sodium, potassium, sulphur, and chlorine. They are necessary for the formation of the skeleton and for the osmotic pressure of biological fluids. However, the body also needs microelements, the total amount of which is less than 0.01% of body weight. Among these are iron, copper, molybdenum, manganese, silicon, fluorine, vanadium, tin, arsenic, and selenium. In most cases, they are a component of enzymes, hormones, and vitamins. Thus, minerals are an irreplaceable component of food, and their long-term deficiency or excess in nutrition leads to metabolic disorders and diseases. According to WHO experts, among the most important for health are iodine and iron, the deficiency of which is a significant threat to global health, especially that of children and pregnant women in low-income countries [73].

Minerals and vitamins play a key role in substantiating the functional composition of granola as they determine its biological value and adaptation to the needs of various consumer groups. Among the mineral components, K, Ca, Mg, and Fe are particularly important as nutrients involved in the regulation of water-salt metabolism, muscle contractile function, haematopoiesis, and antioxidant protection.

As shown in Table 2, oats and buckwheat are distinguished by a high content of Mg and Fe, which makes them especially important for target groups with an increased need for these elements, including the elderly, athletes, and women of reproductive age. Corn and pumpkin enrich the product with K, and cranberries and apples, with vitamins C and E, enhance the antioxidant potential of the formulae.

The presence of vitamin C is especially important since it not only supports immunity and iron absorption but also helps stabilise other micronutrients [69,70,71]. At the same time, vitamin E, one of the key fat-soluble antioxidants, prevents lipid peroxidation and protects cell membranes [72,73]. The combined inclusion of components rich in these vitamins allows us to create a formula with a synergistic effect on cellular protection and restoration.

A comparative analysis of the nutrient profile of the ingredients (see Table 2) allowed us to identify formula No. 4 as the most balanced in terms of protein, dietary fibre, vitamin C, K, Mg, and Fe. This composition can be recommended for a wide range of consumers, including athletes and the elderly. The optimal contents of target nutrients in 100 g of the recipe are not less than 10 g protein, over 6 g dietary fibre, not less than 15 mg vitamin C, more than 300 mg K, and not less than 3 mg Fe. Thus, the recipe is based on critically important nutrients that provide the functional and disease-preventive properties of the product.

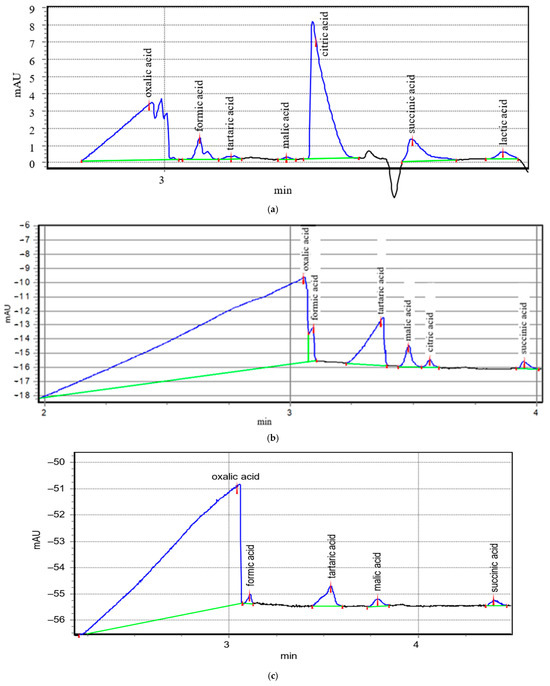

The work also determined the mass concentrations of organic acids in the studied raw materials, presented in Figure 1 and Figure 2.

Figure 1.

Organic acid content in fruit and berry crops: (a) Ben Lear cranberry; (b) Zailiyskiy apple; (c) Karina pumpkin.

Figure 2.

Organic acid content in grain crops: (a) Syrgalym oats; (b) Shortandinskaya 3 buckwheat.

Organic acids are a large group of biologically active compounds that perform important functions in plant metabolism. The main organic acids in food products include acetic, lactic, malic, citric, succinic, oxalic, and tartaric acids. Organic acids are intermediate metabolites that form during the oxidation of proteins and amino acids, fats, and carbohydrates. In the human body, they participate in maintaining the acid-base balance of the blood and other physiological fluids. Organic acids exhibit a wide range of biological activities in the human body, and they are characterised by their antiseptic and anti-inflammatory (salicylic and benzoic), choleretic (citric and malic), diaphoretic (salicylic), and antioxidant (ascorbic acid) properties, among others [74].

As part of a complex of flavouring substances, they participate in the formation of taste and aroma, which are among the main indicators of the quality of a food product. The presence of several organic acids in a product in combination with organic flavouring substances of other classes determines the formation of original taste sensations, often inherent exclusively to one specific type of food product [75]. From Figure 1 and Figure 2, it is clear that citric, malic, formic, tartaric, succinic, oxalic, and lactic acids are found in pumpkins, cranberries, and apples. Only malic and citric acids are found in oats, and malic, formic, tartaric, succinic, and oxalic acids are found in buckwheat. The effect of oxalic acid on the human body should be considered separately. Its excessive intake with food can lead to the development of urolithiasis caused by metabolic disorders and dysregulation of the acid-base balance. Thus, it is extremely important to control the content of organic acids in food products, especially oxalic acid.

An extract is a fraction obtained from a raw plant material using a liquid solvent (an extractant), purified from impurities and harmful substances. A principal advantage of extracts is that the properties of the original product are both preserved and enhanced because the extracted substances are in a concentrated form. In this work, an extract and concentrate were obtained from cranberry fruits for use as raw materials in the preparation of granola. To select the optimal extractant, the following aqueous solutions of ethyl alcohol were tested: 30, 40, 50, 60, 70, 80, and 96%. The results are presented in Table 3.

Table 3.

Effects of extractant on yield of cranberry extractive substances.

Table 3 shows that the optimal extractant is 70% ethyl alcohol, which provides the highest yield of extractive substances. This extractant was therefore applied in further extract development. The effect of extraction duration on the yield of extractive substances was also investigated (Table 4).

Table 4.

Effect of extraction duration on the yield of extractive substances using XX% EtOH.

It is evident from the data in Table 4 that the highest yield of extractive substances was obtained with an extraction duration of 45 min.

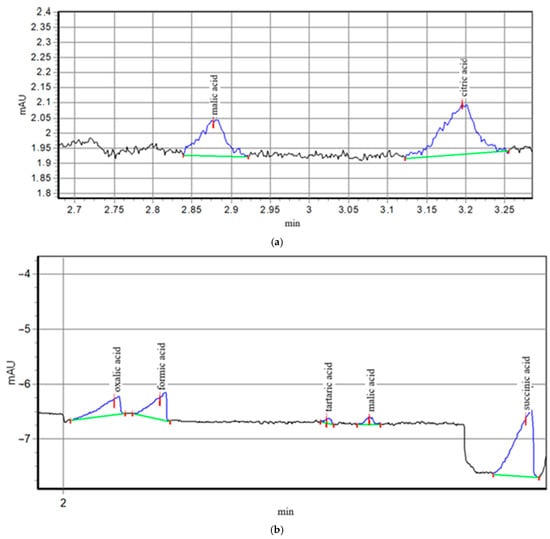

Based on the obtained results, a process was proposed for obtaining an alcohol extract and concentrate from cranberry fruits (Figure 3). The process for obtaining the extract and concentrate from the fruits consisted of the preparation of plant materials and extractant, grinding and sifting, extraction in an ultrasonic extractor, filtration, purification, concentration, pasteurisation, and packaging.

Figure 3.

Process scheme for obtaining extracts and concentrates from cranberry fruits.

To achieve the highest yield of extracted raw materials, we proposed UAE using ultrasonic wave frequency 40 kHz for 45 min at 50 °C, with concentration of the obtained extracts by vacuum evaporation using a rotary evaporator (IKA RV-10) at 40–50 °C and 800 mbar.

Granola is a dry instant breakfast, the peculiarity of which is its whole grains, flakes, or coarse cereals. This product is gaining popularity all over the world since, thanks to the ingredients included in the composition, granola is not only tasty and suitable for different segments of the population but also saturates the body with nutrients. Granola is based on oatmeal. However, the composition of the breakfast can be modified depending on consumer preferences. In addition, a mixture of cereals, dried fruits, nuts, honey, and other natural flavour components can be added to the product [76,77].

Various types of grain, as well as various fruits and berries and their processed products, are used as ingredients in the production of granola. To create a new range of such products, increasing attention is being paid to domestic products of natural origin, including fruits, berries, vegetables, grains, legumes, and oilseeds, as the main raw materials for healthy and functional nutrition. This is due to their availability, renewability, and consumer preferences across all groups of the population.

The rich plant resources of Kazakhstan present enormous opportunities for researchers searching for new biologically active substances and creating new valuable food products with original taste qualities and maximum health benefits [78,79].

Granola ingredients can include various grains such as oat, corn, rice, and buckwheat flakes, either individually or in combination [80,81]. Due to the proteins, vitamins, fats, and minerals present in all these grains, they are very valuable products in terms of nutrition [82,83]. They are often combined with fresh fruits, berries, or dried fruits to enrich them with ingredients with high nutritional value [84]. Fruits and berries are widely promoted as healthy foods, being a rich source of antioxidants, vitamins, and other bioactive plant compounds.

The process of preparing granola began with the selection of the main ingredients: grains, nuts, seeds, and dried fruits. The basis of granola was oat, corn, rice, and buckwheat flakes, which are rich in fibre and nutrients. Various nuts (almonds, walnuts, and cashews), seeds (pumpkin), dried fruits (raisins, dried apricots, dried apples, and cranberries), pumpkin, and syrup (containing cranberry concentrate, molasses, and sorbitol) were added.

The sensory evaluation was performed by a trained panel of 12 assessors (6 women and 6 men aged 22–45), selected based on preliminary sensory sensitivity testing. The tests were conducted in a sensory laboratory under controlled conditions (temperature 22 ± 1 °C, neutral lighting).

Each sample was evaluated based on four attributes: colour, taste, aroma, and texture (Table 5). Samples were presented in random order, in three replicates for each sample, with a 2 min interval between tastings. Still water and unsalted crackers were provided to cleanse the palate between evaluations.

Table 5.

Organoleptic evaluation of granolas using multicomponent mixtures.

A 5-point scale was used for scoring:

- 5—Excellent;

- 4—Good;

- 3—Satisfactory;

- 2—Poor;

- 1—Very poor (unsatisfactory).

Mean values and standard deviations were calculated for each attribute. One-way analysis of variance (ANOVA) followed by Tukey’s post hoc test was applied to determine the statistical significance of differences between samples, with a significance level of p < 0.05.

All the formulae had a pleasant, distinct taste and smell, with a slightly sweet cranberry aftertaste. When assessing the organoleptic characteristics, special attention was paid to the consistency of the product.

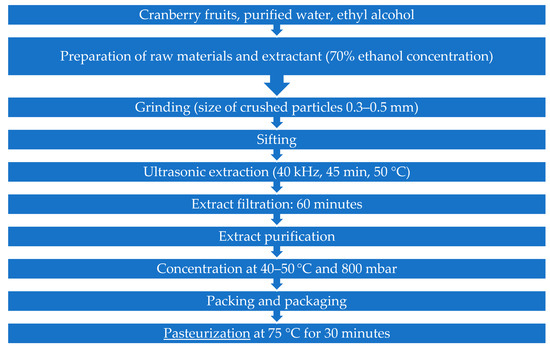

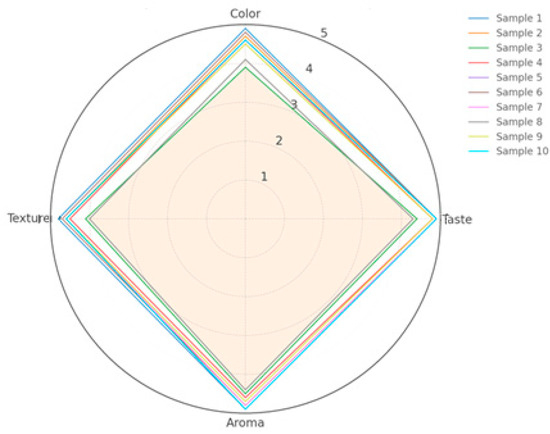

For a visual representation of the comparative characteristics of sensory attributes across the samples, a spider (radar) chart (Figure 4) was constructed, showing the mean values for each attribute.

Figure 4.

Sensory evaluation of granola samples (1–5: 5-point scale).

The chemical profile of the experimental granola recipes varied according to their composition (Table 6). Based on the chemical profile of the formulae, a colour map of the correlation matrix between the ingredients and their chemical parameters is presented in Table 7.

Table 6.

Contents and chemical profiles of experimental granola formulae using multicomponent mixtures.

Table 7.

Colour map of the correlation matrix (r) between the ingredients and the chemical composition of granola (n = 10).

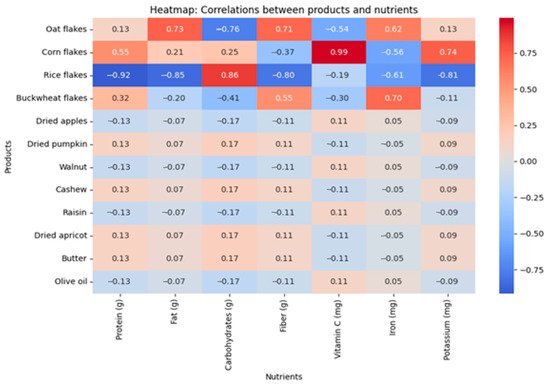

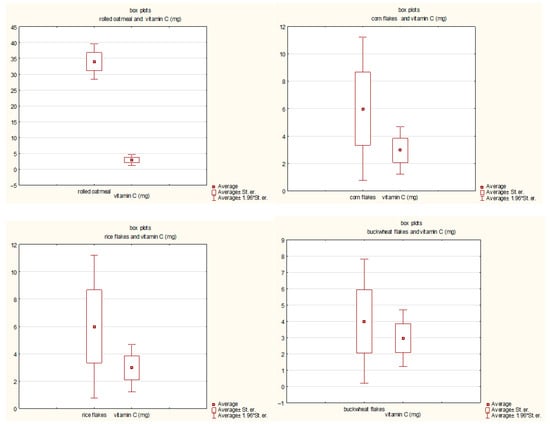

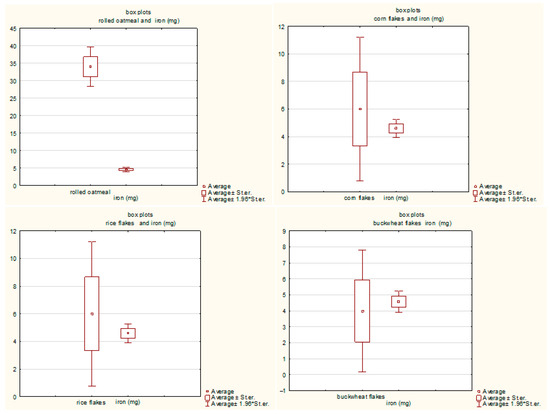

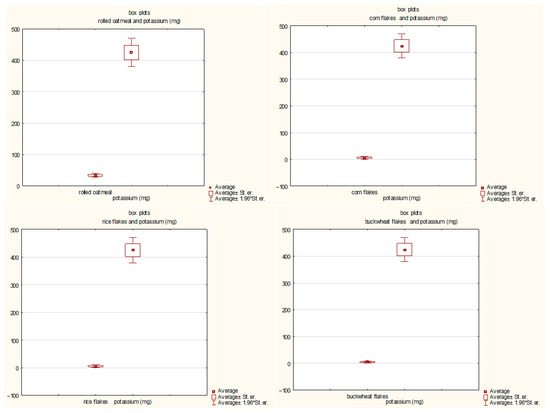

Table 7 shows a heat map of colour correlations (granola; n = 10; r ≥ 1) between the ingredients of the mixture (mainly cereals, nuts, dried fruits, and oils) and their nutritional constituents (proteins, fats, carbohydrates, dietary fibre, vitamin C, iron, and potassium). In the heat map, red shades are a negative correlation (the ingredient lowers the nutrient content), blue shades are a positive correlation (the ingredient increases the nutrient content), and grey represents missing data.

The correlation analysis shows that oat flakes have a strong positive correlation with the content of fats (r = 0.73) and dietary fibre (r = 0.71), rice flakes with carbohydrates (r = 0.86), corn flakes with vitamin C (r = 0.99), and buckwheat flakes with iron (r = 0.70). This confirms the key role of cereal components in the nutrient profile of granola. The high correlation between corn flakes and vitamin C is probably due to product fortification.

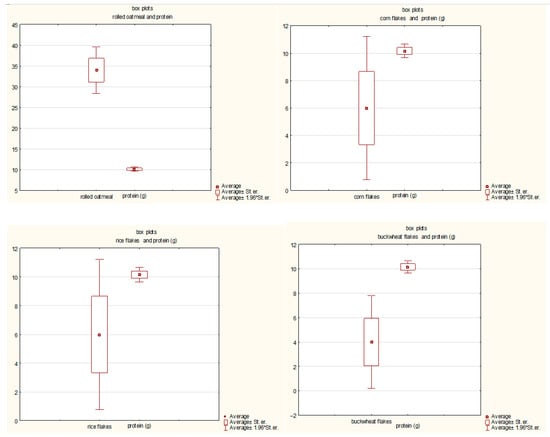

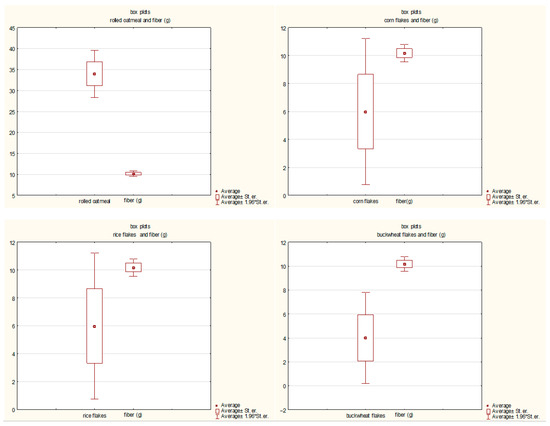

Fruits, nuts, and oils showed predominantly weak or moderate correlation with the main nutrients, which may be due to their lower variability in the composition of mixtures or a relatively small contribution to the overall chemical profile. The results of Student’s t-test (Appendix A, Table A1) show statistically significant differences (p < 0.05) for most of the studied parameters between oat flakes and the other ingredients, including the content of protein, fat, carbohydrates, dietary fibre, potassium, and sodium. This indicates a significant impact of oat flakes on the nutritional value of the product.

Based on a comprehensive analysis of the chemical composition of the formulae (Table 6), the correlation between the nutrients (Table 7), and the results of statistical processing of the differences between the formulae (Appendix A, Table A1), the most balanced granola formula was determined to be No. 4. This option is distinguished by an optimal ratio of key food components, including protein, dietary fibre, vitamin C, potassium, and iron. This recipe can be recommended for a wide range of consumers as a complete functional food product. It is especially suitable for the elderly due to the high content of dietary fibre, which helps normalise digestion, and iron, which is necessary for the prevention of anaemia. Recipe No. 4 is also suitable for athletes, since it provides an increased protein content (important for the restoration of muscle tissue) and potassium, which maintains electrolyte balance and the functioning of the cardiovascular system during physical exertion.

Alternative formulae can be offered to meet the individual needs of different target groups:

- −

- No. 2 and No. 7, with increased protein content and energy value, are optimal for people leading an active lifestyle and playing sports;

- −

- No. 5 and No. 9 can be aimed at replenishing the mineral balance for populations on diets, with microelement deficiency, or during the recovery period after illness.

Thus, the developed range of formulae provides flexible solutions in the field of functional nutrition, focused on the specific needs of consumers.

To enhance the clarity of the correlation matrix (Table 7), a colour heat map was constructed (Figure 5), where the colour intensity reflects the strength and direction of the correlation between ingredients and nutrients.

Figure 5.

Colour heat map.

The results obtained during the study confirm the significance of the development of functional food products, taking into account the nutrient profile of the components. Analysis of the chemical composition demonstrated statistically significant differences in the content of key nutrients between oat flakes and the other ingredients included in the granola formulae. These differences primarily concern the levels of carbohydrates, protein, dietary fibre, and minerals, which play an important role in meeting the physiological needs of the body. The identified features confirm the need for an integrated approach to the formulation of functional product recipes, since each component contributes to improving the nutritional and biological value of the final product. Thus, oat flakes provide a source of slowly digestible carbohydrates and β-glucans, which help reduce cholesterol levels and normalise the glycaemic profile. At the same time, components such as buckwheat, corn, or apples add variety to the amino acid composition, enriching the product with vitamins, antioxidants, and organic acids. Pumpkin and cranberry, due to their high contents of carotenoids, vitamin C, and polyphenolic compounds, enhance the antioxidant potential of the mixture.

Thus, combining components with different chemical compositions provides granola recipes optimised for the specific nutritional needs of various target groups, including children, the elderly, athletes, and people with increased mental or physical stress. Detailed compositional differences and their contribution to the final nutritional value are presented in Appendix B, Appendix C, Appendix D, Appendix E and Appendix F, serving as a basis for the rational design of recipes in the field of functional nutrition.

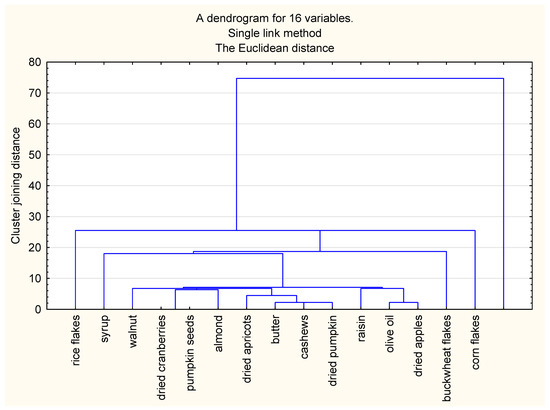

Figure 6 shows a dendrogram created on the basis of hierarchical cluster analysis of 16 variables (ingredients). This multivariate statistical analysis method identifies data structure and similarity between observations. The single linkage method defines the distance between two clusters as the minimum distance between any two points from different clusters. This leads to the so-called chaining effect, where elements can form long linear clusters even with weak connections.

Figure 6.

Dendrogram for creating hierarchical cluster analysis.

As a result, the main cluster is formed in the middle part of the tree, where most of the ingredients are combined. This can be the main set of components used in formulating a recipe. In addition, the set can be divided into groups of 3–4 large clusters, which can help in formulating different recipes (for example, with an emphasis on cereals, nuts, dried fruits, and fats) and optimising the composition of the product by replacing ingredients in a cluster (for example, replacing raisins with cranberries).

4. Discussion

An analysis of the literature and market trends indicates a high demand for dry cereal breakfasts among various age groups, from children to adults. This category of products includes granola, muesli, corn flakes, and puffed cereal mixes, which are easy to eat, quick to prepare, and have high nutritional and energy value. The popularity of these products is due not only to the accelerating pace of life and limited time for cooking, but also to the increased level of consumer awareness about the impact of nutrition on health, disease prevention, and maintaining vitality [85,86].

Modern consumers have dual but interrelated demands. On the one hand, there is a desire for healthy eating and the inclusion of foods with a high concentration of biologically active substances (vitamins, minerals, and dietary fibre) in the diet. On the other hand, there is a preference for products that provide a quick energy response and are easy to consume. Research confirms that granola-type products effectively satisfy both needs, being a source of slow carbohydrates, dietary fibre, and phytonutrients [87].

However, the scientific literature emphasises that the nutritional value of granola largely depends on the recipe composition and the raw materials used. According to general literature data, granola is conventionally divided into three main structural elements, including a cereal base, additives (e.g., fruit, vegetable, and nut derivatives), and connecting components (e.g., syrups, molasses, and natural extracts) [88].

Oat flakes are traditionally used as a base for granola due to their high content of soluble dietary fibre, in particular β-glucans, which have a proven hypocholesterolaemia effect [5,89]. However, recent years have seen a growing interest in using other grain crops as a cereal base (corn, buckwheat, rice, or millet) to increase nutrient diversity and to meet the various needs of target groups. For example, buckwheat is known for its high content of rutin and iron, rice for its readily digestible carbohydrates and hypoallergenicity, and corn for its antioxidants and food pigments [90,91].

The results of this study showed that the use of multicomponent mixtures including oats, corn, buckwheat, and rice can significantly expand the amino acid and mineral profile of the finished product. This is consistent with the data of other researchers, indicating the importance of grain diversity in the creation of functional products aimed at maintaining intestinal health, the immune system, and carbohydrate metabolism [89,90,91].

At the same time, in comparison with traditional commercial granolas, the proposed formulae have a lower content of simple sugars and saturated fats, which is an advantage in terms of preventing metabolic disorders. However, the limitation of this approach may be the increased cost of some components, as well as the need to standardise natural syrups (e.g., from cranberries) to ensure stable product quality in industrial production.

The production of cranberry concentrate using ultrasound-assisted extraction (UAE) confirmed the high efficiency of this method. UAE is an advanced technology that facilitates a more effective release of bioactive compounds from plant materials due to the cavitation effect, which improves the penetration of the solvent into cellular structures [92,93]. Numerous studies have shown that this method allows for the extraction of the total amount of phenolic substances with high antioxidant activity (e.g., up to 54.4 mg HAE/g), significantly exceeding the efficiency of traditional extraction methods [94].

The main factors affecting the efficiency of UAE are temperature, ultrasound power and frequency, extraction time, and the ratio of solid and liquid phases [95,96]. According to the results of other authors, temperatures above 50 °C can cause the degradation of heat-sensitive components, including polyphenols, and frequencies above 40 kHz can reduce the extraction efficiency due to instability of cavitation bubbles [97,98]. In our study, the extraction parameter values of 40 kHz, 50 °C, and 45 min were selected to optimise the yield of valuable compounds. Concentration was carried out by vacuum evaporation (40–50 °C, 800 mbar), which allowed the preservation of heat-sensitive nutrients, including vitamin C and anthocyanins.

The results of the sensory evaluation of granola samples produced using various multicomponent mixtures demonstrated that the product’s composition directly influences its organoleptic characteristics. The highest scores for taste, aroma, and texture were recorded for samples No. 1, 2, 5, 6, 7, and 10. This may be attributed to the optimal balance of ingredients that provide a harmonious flavour and pleasant texture. For example, the addition of natural sweeteners combined with berry ingredients contributed to the formation of a pronounced yet not overly intense aroma, which had a positive impact on the overall perception of the product.

A comparative analysis with data from the scientific literature [99,100,101] confirms that the presence of high-quality cereal flakes, nuts, and dried fruits in specific proportions improves the flavour profile and texture of finished products. Furthermore, studies have shown that incorporating dietary fibre and protein sources into the formulation enhances the perception of the product as more “filling” and nutritious, which is important for health-conscious consumers.

Statistical analysis (ANOVA with Tukey’s test, p < 0.05) revealed significant differences among the samples across all four sensory attributes. The most notable differences were observed in “taste” and “texture”, confirming the high sensitivity of these parameters to recipe variations. The radar chart based on the mean values clearly demonstrates the superiority of samples with an optimal balance of dry and moist components compared to less balanced variants.

The results suggest a possible correlation between sweetness level and aroma perception, as well as between the fat content (nuts, seeds) and texture scores. These findings are consistent with published research on breakfast cereals and snack products, which emphasise the importance of selecting components with regard to their interactions during thermal processing [102,103].

Thus, sensory analysis confirmed that adjusting the ratio of core ingredients and incorporating functional additives can be used to deliberately improve the organoleptic profile of granola, enhancing its competitiveness in the market.

A comparative analysis of the chemical composition of the granola formulae showed that recipe No. 4 was the most balanced in terms of protein (12.4 g/100 g), dietary fibre (6.8 g/100 g), vitamin C (22.3 mg/100 g), and minerals (potassium, iron, magnesium, and zinc). These data are comparable with results from similar studies on the creation of functional cereal mixtures and confirm the possibility of targeted regulation of the granola composition depending on the needs of various demographic groups.

Notably, recipes No. 2 and No. 7, which have an increased content of protein and energy, can be recommended for sports nutrition, while recipes No. 5 and No. 9 can be recommended for groups with a need for additional micronutrients. This approach corresponds to modern principles of personalised nutrition, which are increasingly reflected in scientific and applied dietetics.

Considering the recommendations of the WHO and FAO on the prevention of chronic non-communicable diseases through food, the developed formulae correspond to the current trend of enriching the diet with dietary fibre, vitamins, and antioxidants, while remaining technologically suitable for industrial production.

Thus, the proposed granola recipes have the potential to be complete functional products that help correct nutritional deficiencies and improve health. A promising direction for future research may be the clinical evaluation of the bioavailability of included nutrients and the development of specialised formulae aimed at people with special needs (e.g., diabetics, the elderly, children, and vegetarians).

The developed granola recipe composition using multi-component mixtures and cranberry concentrate has high potential for industrial implementation in the functional and health food sector. The resulting recipes can be adapted for production at food industry enterprises of various sizes, from craft- to large-scale. The use of local raw materials contributes to reducing the cost of finished products and to increasing the added value of agricultural products in Kazakhstan.

The possible industrial applications are as follows.

- A line of functional breakfasts and snacks for various age and dietary groups (including the elderly and athletes);

- Production of specialised nutrition products aimed at preventing micronutrient deficiency (Fe, Mg, K, vitamin C, etc.);

- Export-oriented products labelled “functional food” and “clean label”, attractive to the international market due to their natural composition and the absence of synthetic additives;

- Development of contract manufacturing, including private label releases for retailers interested in domestically produced functional products.

However, the study has a number of limitations, including the following:

- −

- no studies were conducted on the shelf life and stability of the product during long-term storage, which limits its immediate industrial use without additional testing;

- −

- there are no data on the bioavailability and metabolic assimilation of key nutrients in the body, which requires in-depth clinical and dietary studies;

- −

- the prototypes were manufactured in laboratory conditions, so a scaling calculation is needed that considers the change in properties when switching to industrial equipment (ovens, mixers, etc.);

- −

- the presence of allergenic components (e.g., apples, buckwheat, and cranberries) is possible, which requires a separate study of the composition for hypoallergenicity, with a subsequent clarification of target consumer groups;

- −

- the use of sorbitol requires dosage control, considering the possible laxative effect when exceeding the recommended consumption rates.

Overall, the results of the study confirm the possibility of industrial production of a new category of functional product, granola, adapted to the nutritional needs of the population, taking advantage of local agro-food resources. Future studies will be aimed at developing hypoallergenic, diabetic, and children’s formulae, as well as assessing the effect of the product on the biochemical parameters of the body in clinical conditions.

5. Conclusions

The aim of this study was to scientifically substantiate and develop a recipe for a functional product, granola, based on domestic plant materials selected according to the criterion of high nutritional value, with the addition of cranberry concentrate as a source of biologically active substances.

Within the framework of the study, the choice of ingredients was substantiated based on the chemical composition and target nutrient content, the nutritional value and sensory characteristics of the experimental samples were assessed, and the composition of the recipe was optimised using statistical analysis methods (Pearson correlation coefficient and Student’s t-test).

A granola formula was proposed with an increased content of protein (up to 12.4 g/100 g), dietary fibre (up to 6.8 g/100 g), vitamin C (up to 22.3 mg/100 g), and minerals (K, Mg, Fe, and Zn), balanced in terms of the needs of the elderly and athletes.

The sensory evaluation of granola showed that the product’s composition directly affects its organoleptic properties. Samples No. 1, 2, 5, 6, 7, and 10 received the highest scores for taste, aroma, and texture, which is associated with an optimal balance of ingredients. The addition of natural sweeteners and berry components provided a harmonious flavour and pleasant texture. Statistical analysis (ANOVA, p < 0.05) revealed significant differences between the samples, especially in “taste” and “texture.” These results confirm that adjusting the ingredient ratios and using functional additives can improve the organoleptic profile of granola and enhance its market competitiveness.

The practical significance of the study lies in the development of a technologically viable product with specified functional properties. The use of cranberry concentrate syrup as a binding component gave the product improved organoleptic properties and enhanced its antioxidant potential.

The study represents the first development in Kazakhstan of a multi-component granola recipe based on a complex of local agricultural crops, adapted to the requirements of target groups and modern trends in functional nutrition. The limitations of the study include a lack of clinical validation of the nutrient effects, as well as the use of data from the literature to evaluate individual ingredients. This requires additional study in the next stages of development.

Prospects for further research include a study of the bioavailability of key nutrients and their interactions in the product matrix; the development of specialised recipes for children, people with diabetes, and allergies; conducting extended sensory testing and consumer panels; and testing the product in industrial production conditions.

Thus, the developed granola formulae represent a scientifically and practically substantiated approach to the formation of new functional products using the potential of local raw materials, aimed at improving the health of the population and expanding the range of the domestic food industry.

Author Contributions

Conceptualization, Z.M. and M.B. (Makpal Baigaiypkyzy); data curation, T.A. and M.B. (Makpal Baigaiypkyzy); formal analysis, A.A. and T.A.; funding acquisition, A.K.; investigation, M.B. (Meruyet Baiysbayeva) and A.S.; methodology, G.I. and D.S.; resources, A.S. and D.S.; software, M.B. (Meruyet Baiysbayeva) and G.I.; writing—review and editing, Z.M., G.I. and A.K. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan for their financial support (grant for young scientists for 2024–2026: No. AP22786450 “Development of technology of functional breakfast cereals (granola, snacks) based on multicomponent mixtures and biologically active additives”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author. Additional files are provided in Appendix A, Appendix B, Appendix C, Appendix D, Appendix E and Appendix F.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

t-test results for dependent samples in comparison of oatmeal with granola components by main nutrients.

Table A1.

t-test results for dependent samples in comparison of oatmeal with granola components by main nutrients.

| Variable | t-Test for Dependent Samples (Granola) (p < 0.05000) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average | Std. off | N | Different | Std. off diff | t | cc | p | To Entrust. −95.000% | To Entrust. +95.000% | |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | 23.840 | 9.00123 | 8.3754 | 9 | 0.000015 | 17.401 | 30.279 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 29.082 | 8.65118 | 10.6304 | 9 | 0.000002 | 22.893 | 35.271 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −22.101 | 10.43571 | −6.6972 | 9 | 0.000089 | −29.566 | −14.636 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | 23.818 | 8.38141 | 8.9865 | 9 | 0.000009 | 17.822 | 29.814 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 31.041 | 10.82712 | 9.0661 | 9 | 0.000008 | 23.296 | 38.786 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 29.415 | 8.44640 | 11.0128 | 9 | 0.000002 | 23.373 | 35.457 |

| Oatmeal flake | 34.0000 | 9.06765 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −391.019 | 72.58491 | −17.0354 | 9 | 0.000000 | −442.943 | −339.095 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −4.160 | 8.01872 | −1.6405 | 9 | 0.135311 | −9.896 | 1.576 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 1.082 | 8.33070 | 0.4107 | 9 | 0.690884 | −4.877 | 7.041 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| carbohydrates (g) | 56.1010 | 1.73064 | 10 | −50.101 | 8.18044 | −19.3673 | 9 | 0.000000 | −55.953 | −44.249 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −4.182 | 8.85320 | −1.4938 | 9 | 0.169441 | −10.515 | 2.151 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 3.041 | 5.67644 | 1.6941 | 9 | 0.124489 | −1.020 | 7.102 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 1.415 | 9.07913 | 0.4928 | 9 | 0.633921 | −5.080 | 7.910 |

| Corn flake | 6.0000 | 8.43274 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −419.019 | 67.20010 | −19.7180 | 9 | 0.000000 | −467.091 | −370.947 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −4.160 | 9.17908 | −1.4332 | 9 | 0.185622 | −10.726 | 2.406 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 1.082 | 8.93063 | 0.3831 | 9 | 0.710517 | −5.307 | 7.471 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −50.101 | 6.99743 | −22.6416 | 9 | 0.000000 | −55.107 | −45.095 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| dietary fiber (g) | 10.1820 | 1.00951 | 10 | −4.182 | 9.25810 | −1.4284 | 9 | 0.186936 | −10.805 | 2.441 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 3.041 | 9.37608 | 1.0256 | 9 | 0.331837 | −3.666 | 9.748 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 1.415 | 9.12795 | 0.4902 | 9 | 0.635713 | −5.115 | 7.945 |

| Rice flake | 6.0000 | 8.43274 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −419.019 | 80.20659 | -16.5205 | 9 | 0.000000 | −476.395 | −361.643 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −6.160 | 5.93857 | −3.2802 | 9 | 0.009526 | −10.408 | −1.912 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −0.918 | 6.29096 | −0.4615 | 9 | 0.655425 | −5.418 | 3.582 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| carbohydrates (g) | 56.1010 | 1.73064 | 10 | −52.101 | 7.02959 | −23.4378 | 9 | 0.000000 | −57.130 | −47072 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −6.182 | 5.65324 | −3.4581 | 9 | 0.007183 | −10.226 | −2.138 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 1.041 | 7.48508 | 0.4398 | 9 | 0.670454 | −4.314 | 6.396 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −0.585 | 5.44951 | −0.3395 | 9 | 0.742045 | −4.483 | 3.313 |

| Buckwheat flake | 4.0000 | 6.14636 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −421.019 | 74.19368 | −17.9446 | 9 | 0.000000 | −474.094 | −367.944 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −7.660 | 2.85578 | −8.4821 | 9 | 0.000014 | −9.703 | −5.617 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −2.418 | 2.73954 | −2.7911 | 9 | 0.021015 | −4.378 | −0.458 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −53.601 | 3.38962 | −50.0059 | 9 | 0.000000 | −56.026 | −51.176 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −7.682 | 2.92256 | −8.3121 | 9 | 0.000016 | −9.773 | −5.591 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | −0.459 | 3.61429 | −0.4016 | 9 | 0.697350 | −3.045 | 2.127 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −2.085 | 2.79334 | −2.3604 | 9 | 0.042575 | −4.083 | −0.087 |

| Apple, dried | 2.5000 | 2.63523 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −422.519 | 73.53975 | −18.1687 | 9 | 0.000000 | −475.126 | −369.912 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −8.160 | 2.15766 | −11.9593 | 9 | 0.000001 | −9.703 | −6.617 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −2.918 | 2.14594 | −4.3000 | 9 | 0.001991 | −4.453 | −1.383 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −54.101 | 2.48989 | −68.7109 | 9 | 0.000000 | −55.882 | −52.320 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −8.182 | 2.23637 | −11.5696 | 9 | 0.000001 | −9.782 | −6.582 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | −0.959 | 3.68417 | −0.8231 | 9 | 0.431693 | −3.594 | 1.676 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −2.585 | 2.41097 | −3.3905 | 9 | 0.007992 | −4.310 | −0.860 |

| Pumpkin, dried | 2.0000 | 2.10819 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −423.019 | 73.07889 | −18.3049 | 9 | 0.000000 | −475.296 | −370.742 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | 1.840 | 0.80962 | 7.1868 | 9 | 0.000052 | 1.261 | 2.419 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 7.082 | 0.58172 | 38.4985 | 9 | 0.000000 | 6.666 | 7.498 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −44.101 | 1.73064 | −80.5829 | 9 | 0.000000 | −45.339 | −42.863 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | 1.818 | 1.00951 | 5.6949 | 9 | 0.000296 | 1.096 | 2.540 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 9.041 | 2.79122 | 10.2429 | 9 | 0.000003 | 7.044 | 11.038 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 7.415 | 1.06848 | 21.9455 | 9 | 0.000000 | 6.651 | 8.179 |

| Syrup | 12.0000 | 0.00000 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −413.019 | 73.24616 | −17.8314 | 9 | 0.000000 | −465.416 | −360.622 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −3.660 | 1.86784 | −6.1964 | 9 | 0.000160 | −4.996 | −2.324 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 1.582 | 1.72387 | 2.9020 | 9 | 0.017537 | 0.349 | 2.815 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −49.601 | 2.53478 | −61.8800 | 9 | 0.000000 | −51.414 | −47.788 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −3.682 | 1.96616 | −5.9220 | 9 | 0.000223 | −5.089 | −2.275 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 3.541 | 3.04755 | 3.6743 | 9 | 0.005121 | 1.361 | 5.721 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 1.915 | 1.86324 | 3.2501 | 9 | 0.009995 | 0.582 | 3.248 |

| Walnut | 6.5000 | 1.58114 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −418.519 | 73.41110 | −18.0282 | 9 | 0.000000 | −471.034 | −366.004 |

| Almond | 3.0000 | 0.00000 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −7.160 | 0.80962 | −27.9660 | 9 | 0.000000 | −7.739 | −6.581 |

| Almond | 3.0000 | 0.00000 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −1.918 | 0.58172 | −10.4264 | 9 | 0.000003 | −2.334 | −1.502 |

| Almond | 3.0000 | 0.00000 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −53.101 | 1.73064 | −97.0280 | 9 | 0.000000 | −54.339 | −51.863 |

| Almond | 3.0000 | 0.00000 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −7.182 | 1.00951 | −22.4976 | 9 | 0.000000 | −7.904 | −6.460 |

| Almond | 3.0000 | 0.00000 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 0.041 | 2.79122 | 0.0465 | 9 | 0.963966 | −1.956 | 2.038 |

| Almond | 3.0000 | 0.00000 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −1.585 | 1.06848 | −4.6910 | 9 | 0.001135 | −2.349 | −0821 |

| Almond | 3.0000 | 0.00000 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −422.019 | 73.24616 | −18.2199 | 9 | 0.000000 | −474.416 | −369.622 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −5.160 | 0.80962 | −20.1543 | 9 | 0.000000 | −5.739 | −4.581 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 0.082 | 0.58172 | 0.4458 | 9 | 0.666300 | −0.334 | 0.498 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −51.101 | 1.73064 | −93.3735 | 9 | 0.000000 | −52.339 | −49.863 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −5.182 | 1.00951 | −16.2326 | 9 | 0.000000 | −5.904 | −4.460 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 2.041 | 2.79122 | 2.3123 | 9 | 0.046061 | 0.044 | 4.038 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 0.415 | 1.06848 | 1.2282 | 9 | 0.250509 | −0.349 | 1.179 |

| Pumpkin seeds | 5.0000 | 0.00000 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −420.019 | 73.24616 | −18.1336 | 9 | 0.000000 | −472.416 | −367.622 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| Proteins (r) | 10.1600 | 0.80962 | 10 | −8.660 | 1.67993 | −16.3015 | 9 | 0.000000 | −9.862 | −7.458 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −3.418 | 1.64471 | −6.5718 | 9 | 0.000103 | −4.595 | −2.241 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −54.601 | 2.13661 | −80.8119 | 9 | 0.000000 | −56.129 | −53.073 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −8.682 | 1.78113 | −15.4143 | 9 | 0.000000 | −9.956 | −7.408 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | −1.459 | 3.36069 | −1.3729 | 9 | 0.203030 | −3.863 | 0.945 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −3.085 | 1.95234 | −4.9969 | 9 | 0.000742 | −4.482 | −1.688 |

| Cashews | 1.5000 | 1.58114 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −423.519 | 73.11504 | −18.3175 | 9 | 0.000000 | −475.822 | −371.216 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −6.160 | 4.39570 | −4.4315 | 9 | 0.001644 | −9.304 | −3.016 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −0.918 | 4.29787 | −0.6754 | 9 | 0.516371 | −3.993 | 2.157 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −52.101 | 4.82212 | −34.1671 | 9 | 0.000000 | −55.551 | −48.651 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| dietary fiber (g) | 10.1820 | 1.00951 | 10 | −6.182 | 4.44087 | −4.4021 | 9 | 0.001715 | −9.359 | −3.005 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 1.041 | 4.78468 | 0.6880 | 9 | 0.508786 | −2.382 | 4.464 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −0.585 | 4.29722 | −0.4305 | 9 | 0.676961 | −3.659 | 2.489 |

| Raisin | 4.0000 | 4.21637 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −421.019 | 73.76054 | −18.0500 | 9 | 0.000000 | −473.784 | −368.254 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −6.660 | 3.67271 | −5.7344 | 9 | 0.000282 | −9.287 | −4.033 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | −1.418 | 3.69302 | −1.2142 | 9 | 0.255565 | −4.060 | 1.224 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −52.601 | 3.79950 | −43.7792 | 9 | 0.000000 | −55.319 | −49.883 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −6.682 | 3.71770 | −5.6837 | 9 | 0.000300 | −9.341 | −4.023 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 0.541 | 4.87269 | 0.3511 | 9 | 0.733594 | −2.945 | 4.027 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | −1.085 | 3.89223 | −0.8815 | 9 | 0.400966 | −3.869 | 1.699 |

| Apricot, dried | 3.5000 | 3.68932 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −421.519 | 72.99316 | −18.2614 | 9 | 0.000000 | −473.735 | −369.303 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −5.160 | 0.80962 | −20.1543 | 9 | 0.000000 | −5.739 | −4.581 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| fat (g) | 4.9180 | 0.58172 | 10 | 0.082 | 0.58172 | 0.4458 | 9 | 0.666300 | −0.334 | 0.498 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| carbohydrates (d) | 56.1010 | 1.73064 | 10 | −51.101 | 1.73064 | −93.3735 | 9 | 0.000000 | −52.339 | −49.863 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| dietary fibre (g) | 10.1820 | 1.00951 | 10 | −5.182 | 1.00951 | −16.2326 | 9 | 0.000000 | −5.904 | −4.460 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| vitamin C (mg) | 2.9590 | 2.79122 | 10 | 2.041 | 2.79122 | 2.3123 | 9 | 0.046061 | 0.044 | 4.038 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| iron (mg) | 4.5850 | 1.06848 | 10 | 0.415 | 1.06848 | 1.2282 | 9 | 0.250509 | −0.349 | 1.179 |

| Cranberry, dried | 5.0000 | 0.00000 | ||||||||

| potash (mg) | 425.0190 | 73.24616 | 10 | −420.019 | 73.24616 | −18.1336 | 9 | 0.000000 | −472.416 | −367.622 |

| Creame master | 2.5000 | 2.63523 | ||||||||

| proteins (g) | 10.1600 | 0.80962 | 10 | −7.660 | 2.65412 | −9.1266 | 9 | 0.000008 | −9.559 | −5.761 |

| Creame master | 2.5000 | 2.63523 | ||||||||