Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review

Abstract

1. Introduction

2. NDT Techniques for Agricultural Products

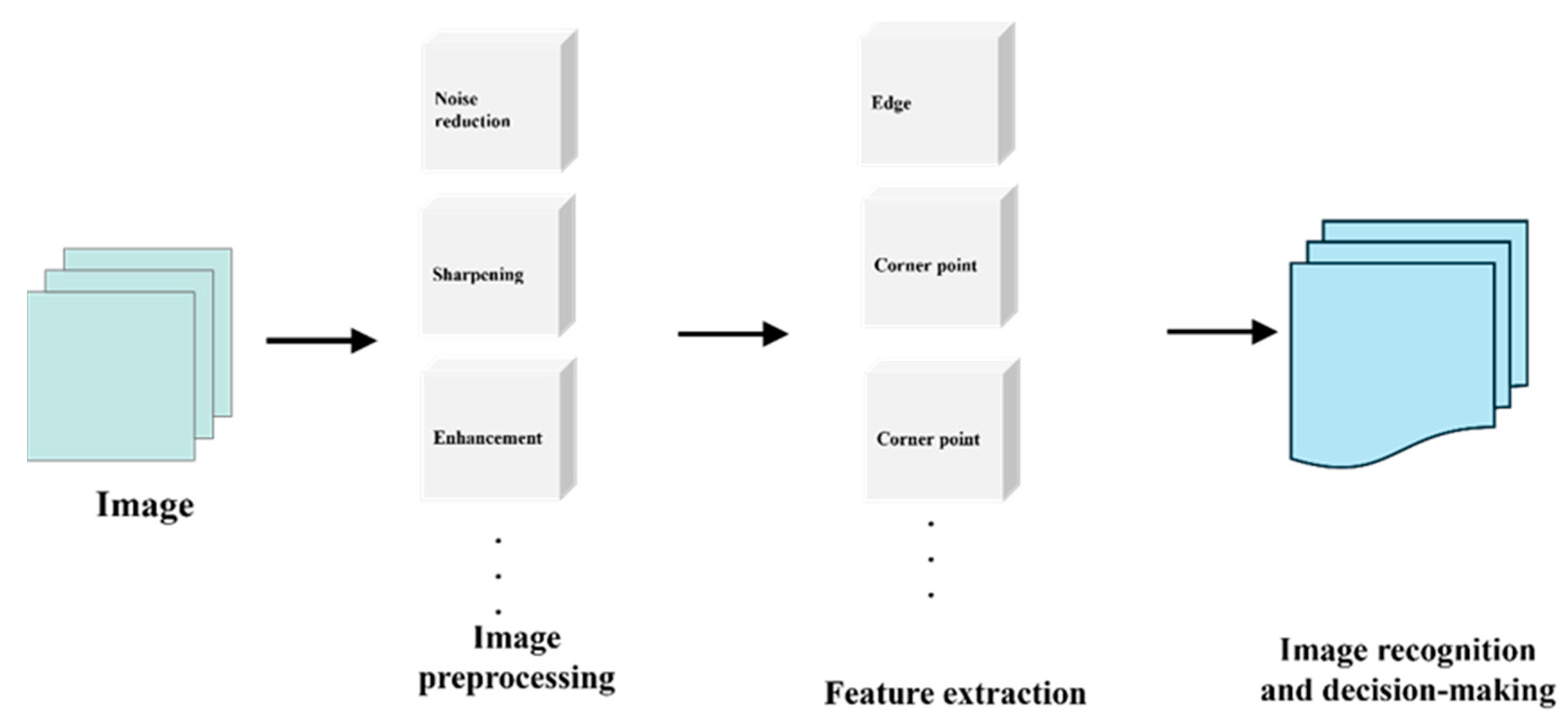

2.1. Computer Vision

2.2. Near-Infrared Spectroscopy

2.3. Hyperspectral Imaging

2.4. Computed Tomography

2.5. Electronic Nose

2.6. Other Techniques

3. Analysis of Agricultural Nondestructive Testing Tasks

4. Challenges and Future Directions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wassink, C.H.P. Innovation in Non Destructive Testing. Ph.D. Thesis, Technical University Delft, Delft, The Netherlands, 2012. [Google Scholar]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in applications of Non-Destructive Testing (NDT): A review. Adv. Mater. Process. Technol. 2022, 8, 2286–2307. [Google Scholar] [CrossRef]

- Prodhan, R.K.; Islam, M.M.; Fazle, A.B. Integration of Advanced NDT Techniques & Implementing QA/QC Programs in Enhancing Safety and Integrity in Oil & Gas Operations. Am. J. Interdiscip. Stud. 2022, 3, 1–35. [Google Scholar] [CrossRef]

- Zhao, Z. Review of non-destructive testing methods for defect detection of ceramics. Ceram. Int. 2021, 47, 4389–4397. [Google Scholar] [CrossRef]

- Gupta, N.; Gupta, A. Condition assessment of the structural elements of a reinforced concrete structure using non-destructive techniques. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012164. [Google Scholar] [CrossRef]

- Ni, P.; Niu, H.; Tang, Y.; Zhang, Y.; Zhang, W.; Liu, Y.; Lan, H. Bibliometrics and visual analysis of non-destructive testing technology for fruit quality. Horticulturae 2023, 9, 1091. [Google Scholar] [CrossRef]

- Wen, J.; Xu, G.; Zhang, A.; Ma, W.; Jin, G. Emerging technologies for rapid non-destructive testing of grape quality: A review. J. Food Compos. Anal. 2024, 133, 106446. [Google Scholar] [CrossRef]

- Mahanti, N.K.; Pandiselvam, R.; Kothakota, A.; Chakraborty, S.K.; Kumar, M.; Cozzolino, D. Emerging non-destructive imaging techniques for fruit damage detection: Image processing and analysis. Trends Food Sci. Technol. 2022, 120, 418–438. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, H.; Ji, W.; Yi, K.; Yang, S.; Mao, P.; Wang, Z.; Yu, H.; Li, M. Non-destructive testing of alfalfa seed vigor based on multispectral imaging technology. Sensors 2022, 22, 2760. [Google Scholar] [CrossRef]

- Halmshaw, R. Industrial Radiology: Theory and Practice; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1995; Volume 1. [Google Scholar] [CrossRef]

- Cosmi, F.; Bernasconi, A. Micro-CT investigation on fatigue damage evolution in short fibre reinforced polymers. Compos. Sci. Technol. 2013, 79, 70–76. [Google Scholar] [CrossRef]

- Sun, W.; Brown, S.; Leach, R. An Overview of Industrial X-Ray Computed Tomography. 2012. Available online: https://eprintspublications.npl.co.uk/5385/ (accessed on 9 July 2025).

- Chen, Y.; Kang, Y.; Feng, B.; Li, Y.; Cai, X.; Wang, S. Automatic defect identification in magnetic particle testing using a digital model aided De-noising method. Measurement 2022, 198, 111427. [Google Scholar] [CrossRef]

- Pollock, A.A. Acoustic emission inspection. In Nondestructive Evaluation of Materials; ASM International: Cleveland, OH, USA, 2018; pp. 360–379. [Google Scholar] [CrossRef]

- Xing, L.; Wang, Y.; Luo, R.; Zou, L. Application of computer vision technology in agricultural products and food inspection. J. Phys. Conf. Ser. 2021, 1915, 032045. [Google Scholar] [CrossRef]

- Brauer, H.; Ziolkowski, M.; Toepfer, H. Defect detection in conducting materials using eddy current testing techniques. Serbian J. Electr. Eng. 2014, 11, 535–549. [Google Scholar] [CrossRef]

- Czarnecki, M.A.; Morisawa, Y.; Futami, Y.; Ozaki, Y. Advances in molecular structure and interaction studies using near-infrared spectroscopy. Chem. Rev. 2015, 115, 9707–9744. [Google Scholar] [CrossRef] [PubMed]

- Sarawade, A.A.; Charniya, N.N. Infrared thermography and its applications: A review. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15–16 October 2018; pp. 280–285. [Google Scholar] [CrossRef]

- Patel, D.; Bhise, S.; Kapdi, S.; Bhatt, T. Non-destructive hyperspectral imaging technology to assess the quality and safety of food: A review. Food Prod. Process. Nutr. 2024, 6, 69. [Google Scholar] [CrossRef]

- Priyanka Handa, P.H.; Bhupinder Singh, B.S. Electronic nose and their application in food industries. Food Sci. Res. J. 2016, 7, 314–318. [Google Scholar] [CrossRef]

- Ahuja, S.; Kumar, M.; Kumar, P.; Gupta, V.; Singhal, R.; Yadav, A.; Singh, B. Metabolic and biochemical changes caused by gamma irradiation in plants. J. Radioanal. Nucl. Chem. 2014, 300, 199–212. [Google Scholar] [CrossRef]

- Chen, Z.; Jomdecha, C.; Xie, S. Eddy current testing. In Handbook of Advanced Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 2019; pp. 645–728. [Google Scholar] [CrossRef]

- AbdAlla, A.N.; Faraj, M.A.; Samsuri, F.; Rifai, D.; Ali, K.; Al-Douri, Y. Challenges in improving the performance of eddy current testing. Meas. Control 2019, 52, 46–64. [Google Scholar] [CrossRef]

- Zhang, H.; Li, D. Applications of computer vision techniques to cotton foreign matter inspection: A review. Comput. Electron. Agric. 2014, 109, 59–70. [Google Scholar] [CrossRef]

- Cortés, V.; Blasco, J.; Aleixos, N.; Cubero, S.; Talens, P. Monitoring strategies for quality control of agricultural products using visible and near-infrared spectroscopy: A review. Trends Food Sci. Technol. 2019, 85, 138–148. [Google Scholar] [CrossRef]

- Chandrasekaran, I.; Panigrahi, S.S.; Ravikanth, L.; Singh, C.B. Potential of near-infrared (NIR) spectroscopy and hyperspectral imaging for quality and safety assessment of fruits: An overview. Food Anal. Methods 2019, 12, 2438–2458. [Google Scholar] [CrossRef]

- Jung, H. Basic physical principles and clinical applications of computed tomography. Prog. Med. Phys. 2021, 32, 1–17. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, H.; John Martin, J.J.; Hou, M.; Cao, H.; Dong, Z.; Li, J.; Sun, C. Trends and Applications of Computed Tomography in Agricultural Non-Destructive Testing. Agriculture 2024, 14, 2329. [Google Scholar] [CrossRef]

- Wesoły, M.; Przewodowski, W.; Ciosek-Skibińska, P. Electronic noses and electronic tongues for the agricultural purposes. TrAC Trends Anal. Chem. 2023, 164, 117082. [Google Scholar] [CrossRef]

- Zhuang, J.; Jin, X.; Chen, Y.; Meng, W.; Wang, Y.; Yu, J.; Muthukumar, B. Drought stress impact on the performance of deep convolutional neural networks for weed detection in Bahiagrass. Grass Forage Sci. 2023, 78, 214–223. [Google Scholar] [CrossRef]

- Lopes, J.F.; da Costa, V.G.T.; Barbin, D.F.; Cruz-Tirado, L.J.P.; Baeten, V.; Barbon Junior, S. Deep computer vision system for cocoa classification. Multimed. Tools Appl. 2022, 81, 41059–41077. [Google Scholar] [CrossRef]

- Heydari, M.S.; Kolivand, M.; Al-Azzawi, M.; Kolivand, H. Intelligent augmented reality application for personalised rhinoplasty using machine learning. Intell. Robot. 2025, 5, 355–377. [Google Scholar] [CrossRef]

- Khan, A.I.; Al-Habsi, S. Machine learning in computer vision. Procedia Comput. Sci. 2020, 167, 1444–1451. [Google Scholar] [CrossRef]

- Szeliski, R. Computer Vision: Algorithms and Applications; Springer Nature: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, L.; Li, Y.; Li, J.; Liu, S.; Xie, X.; Xu, Y. Non-destructive classification of defective potatoes based on hyperspectral imaging and support vector machine. Infrared Phys. Technol. 2019, 99, 71–79. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Y.; Gu, Z.; Yang, S.X. Deep learning approaches for object recognition in plant diseases: A review. Intell. Robot. 2023, 3, 514–537. [Google Scholar] [CrossRef]

- Jin, X.; Han, K.; Zhao, H.; Wang, Y.; Chen, Y.; Yu, J. Detection and coverage estimation of purple nutsedge in turf with image classification neural networks. Pest Manag. Sci. 2024, 80, 3504–3515. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Hespeler, S.C.; Nemati, H.; Dehghan-Niri, E. Non-destructive thermal imaging for object detection via advanced deep learning for robotic inspection and harvesting of chili peppers. Artif. Intell. Agric. 2021, 5, 102–117. [Google Scholar] [CrossRef]

- Xu, Y.; Li, L.; Wang, Y.; Hu, Q. Novel non-destructive authentication of nine Dendrobium species using residual convolutional neural network relying on plant images and FT-NIR spectral information. Smart Agric. Technol. 2025, 11, 101027. [Google Scholar] [CrossRef]

- Yu, S.; Huan, K.; Liu, X. Application of quantitative non-destructive determination of protein in wheat based on pretreatment combined with parallel convolutional neural network. Infrared Phys. Technol. 2023, 135, 104958. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Tian, X.; Wang, L.; Dai, C.; Chang, X.; Ren, Y.; Yu, S.; Wang, C.; Han, F. Non-destructive quality monitoring of Shanxi vinegar production during the fumigation stage using computer vision, electronic nose and near-infrared spectroscopy assisted by machine learning. J. Food Compos. Anal. 2025, 146, 107908. [Google Scholar] [CrossRef]

- Ismail, N.; Malik, O.A. Real-time visual inspection system for grading fruits using computer vision and deep learning techniques. Inf. Process. Agric. 2022, 9, 24–37. [Google Scholar] [CrossRef]

- Rong, D.; Xie, L.; Ying, Y. Computer vision detection of foreign objects in walnuts using deep learning. Comput. Electron. Agric. 2019, 162, 1001–1010. [Google Scholar] [CrossRef]

- Blasco, J.; Aleixos, N.; Moltó, E. Machine vision system for automatic quality grading of fruit. Biosyst. Eng. 2003, 85, 415–423. [Google Scholar] [CrossRef]

- Du, Y.; Hu, Y.; San, L.; Tian, J. Research on potato appearance quality detection based on computer vision. In Proceedings of the 2019 5th International Conference on Control, Automation and Robotics (ICCAR), Beijing, China, 19–22 April 2019; pp. 286–289. [Google Scholar] [CrossRef]

- Soltani Firouz, M.; Sardari, H. Defect detection in fruit and vegetables by using machine vision systems and image processing. Food Eng. Rev. 2022, 14, 353–379. [Google Scholar] [CrossRef]

- Szczypiński, P.M.; Klepaczko, A.; Zapotoczny, P. Identifying barley varieties by computer vision. Comput. Electron. Agric. 2015, 110, 1–8. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, S.; Yin, H.; Han, X.; Xu, M.; Wang, W.; Zhang, Y.; Feng, X.; Liu, Y. Classification of oolong tea varieties based on computer vision and convolutional neural networks. J. Sci. Food Agric. 2024, 104, 1630–1637. [Google Scholar] [CrossRef]

- Manley, M. Near-infrared spectroscopy and hyperspectral imaging: Non-destructive analysis of biological materials. Chem. Soc. Rev. 2014, 43, 8200–8214. [Google Scholar] [CrossRef] [PubMed]

- Schneider dos Santos, R.; Rolim, S.B.A.; Hepp Pulgati, F. Application of visible and near infrared spectroscopy in non-destructive evaluation of cement materials. Int. J. Remote Sens. 2015, 36, 917–938. [Google Scholar] [CrossRef]

- Li, X.R. Non-destructive testing technology of sugar content in Huapi kumquat by near infrared spectroscopy. J. South. Agric. 2019, 50, 838–843. [Google Scholar]

- Zang, Y.; Wang, J.; Wu, X.; Chang, R.; Wang, Y.; Luo, H.; Zhong, Y.; Wu, Q.; Chen, Z.; Deng, M. The analysis and rapid non-destructive evaluation of Yongchuan Xiuya quality based on NIRS combined with machine learning methods. Processes 2023, 11, 2809. [Google Scholar] [CrossRef]

- Pasquini, C. Near infrared spectroscopy: A mature analytical technique with new perspectives–A review. Anal. Chim. Acta 2018, 1026, 8–36. [Google Scholar] [CrossRef] [PubMed]

- Chávez-Angel, E.; Eriksen, M.B.; Castro-Alvarez, A.; Garcia, J.H.; Botifoll, M.; Avalos-Ovando, O.; Arbiol, J.; Mugarza, A. Applied Artificial Intelligence in Materials Science and Material Design. Adv. Intell. Syst. 2025, 7, 2400986. [Google Scholar] [CrossRef]

- Huan, K.; Chen, X.; Song, X.; Dong, W. Variable selection in near-infrared spectra: Application to quantitative non-destructive determination of protein content in wheat. Infrared Phys. Technol. 2021, 119, 103937. [Google Scholar] [CrossRef]

- Xiaobo, Z.; Jiewen, Z.; Povey, M.J.; Holmes, M.; Hanpin, M. Variables selection methods in near-infrared spectroscopy. Anal. Chim. Acta 2010, 667, 14–32. [Google Scholar] [CrossRef]

- Askarzadeh, A.; dos Santos Coelho, L.; Klein, C.E.; Mariani, V.C. A population-based simulated annealing algorithm for global optimization. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; pp. 004626–004633. [Google Scholar] [CrossRef]

- Carlomagno, G.; Capozzo, L.; Attolico, G.; Distante, A. Non-destructive grading of peaches by near-infrared spectrometry. Infrared Phys. Technol. 2004, 46, 23–29. [Google Scholar] [CrossRef]

- Stella, E.; Moscetti, R.; Haff, R.P.; Monarca, D.; Cecchini, M.; Contini, M.; Massantini, R. Recent advances in the use of non-destructive near infrared spectroscopy for intact olive fruits. J. Near Infrared Spectrosc. 2015, 23, 197–208. [Google Scholar] [CrossRef]

- Tan, B.; You, W.; Huang, C.; Xiao, T.; Tian, S.; Luo, L.; Xiong, N. An intelligent near-infrared diffuse reflectance spectroscopy scheme for the non-destructive testing of the sugar content in cherry tomato fruit. Electronics 2022, 11, 3504. [Google Scholar] [CrossRef]

- Du, Z.; Zeng, X.; Li, X.; Ding, X.; Cao, J.; Jiang, W. Recent advances in imaging techniques for bruise detection in fruits and vegetables. Trends Food Sci. Technol. 2020, 99, 133–141. [Google Scholar] [CrossRef]

- Ang, K.L.-M.; Seng, J.K.P. Big data and machine learning with hyperspectral information in agriculture. IEEE Access 2021, 9, 36699–36718. [Google Scholar] [CrossRef]

- Signoroni, A.; Savardi, M.; Baronio, A.; Benini, S. Deep learning meets hyperspectral image analysis: A multidisciplinary review. J. Imaging 2019, 5, 52. [Google Scholar] [CrossRef]

- Ali, U.M.E.; Hossain, M.A.; Islam, M.R. Analysis of PCA based feature extraction methods for classification of hyperspectral image. In Proceedings of the 2019 2nd International Conference on Innovation in Engineering and Technology (ICIET), Dhaka, Bangladesh, 23–24 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Q.; Jia, W.; Lin, Y.; Bi, L.; Chen, D.; Lv, C. Application of Hyperspectral Imaging Technology in Nondestructive Testing of Core Chemical Components of Fruits. J. Agric. Food Chem. 2025, 73, 15480–15490. [Google Scholar] [CrossRef]

- Benelli, A.; Cevoli, C.; Ragni, L.; Fabbri, A. In-field and non-destructive monitoring of grapes maturity by hyperspectral imaging. Biosyst. Eng. 2021, 207, 59–67. [Google Scholar] [CrossRef]

- Vigneau, N.; Ecarnot, M.; Rabatel, G.; Roumet, P. Potential of field hyperspectral imaging as a non destructive method to assess leaf nitrogen content in Wheat. Field Crops Res. 2011, 122, 25–31. [Google Scholar] [CrossRef]

- Schulz, R.A.; Stein, J.A.; Pelc, N.J. How CT happened: The early development of medical computed tomography. J. Med. Imaging 2021, 8, 052110. [Google Scholar] [CrossRef]

- Du, Z.; Hu, Y.; Ali Buttar, N.; Mahmood, A. X-ray computed tomography for quality inspection of agricultural products: A review. Food Sci. Nutr. 2019, 7, 3146–3160. [Google Scholar] [CrossRef]

- Kotwaliwale, N.; Singh, K.; Kalne, A.; Jha, S.N.; Seth, N.; Kar, A. X-ray imaging methods for internal quality evaluation of agricultural produce. J. Food Sci. Technol. 2014, 51, 1–15. [Google Scholar] [CrossRef]

- Michail, C.; Liaparinos, P.; Kalyvas, N.; Kandarakis, I.; Fountos, G.; Valais, I. Radiation detectors and sensors in medical imaging. Sensors 2024, 24, 6251. [Google Scholar] [CrossRef]

- Mooney, S.J.; Pridmore, T.P.; Helliwell, J.; Bennett, M.J. Developing X-ray computed tomography to non-invasively image 3-D root systems architecture in soil. Plant Soil 2012, 352, 1–22. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, R.; Luo, G.; Wu, J. Three-dimensional reconstruction of light microscopy image sections: Present and future. Front. Med. 2015, 9, 30–45. [Google Scholar] [CrossRef] [PubMed]

- Donis-Gonzalez, I.R.; Guyer, D.E.; Pease, A.; Barthel, F. Internal characterisation of fresh agricultural products using traditional and ultrafast electron beam X-ray computed tomography imaging. Biosyst. Eng. 2014, 117, 104–113. [Google Scholar] [CrossRef]

- Hughes, N.; Askew, K.; Scotson, C.P.; Williams, K.; Sauze, C.; Corke, F.; Doonan, J.H.; Nibau, C. Non-destructive, high-content analysis of wheat grain traits using X-ray micro computed tomography. Plant Methods 2017, 13, 76. [Google Scholar] [CrossRef]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Charoenlarpnopparut, C.; Suksompong, P. Classification and pattern recognition algorithms applied to E-Nose. In Proceedings of the 2015 2nd International Conference on Electrical Information and Communication Technologies (EICT), Khulna, Bangladesh, 10–12 December 2015; pp. 44–48. [Google Scholar] [CrossRef]

- Rabehi, A.; Helal, H.; Zappa, D.; Comini, E. Advancements and prospects of electronic nose in various applications: A comprehensive review. Appl. Sci. 2024, 14, 4506. [Google Scholar] [CrossRef]

- Lelono, D.; Triyana, K.; Hartati, S.; Istiyanto, J.E. Classification of Indonesia black teas based on quality by using electronic nose and principal component analysis. AIP Conf. Proc. 2016, 1755, 020003. [Google Scholar] [CrossRef]

- Tazi, I.; Isnaini, N.L.; Mutmainnah, M.; Ainur, A. Principal component analysis (PCA) method for classification of beef and pork aroma based on electronic nose. Indones. J. Halal Res. 2019, 1, 5–8. [Google Scholar] [CrossRef]

- Liu, W.; Liu, P.; Han, F.; Xiao, Y. Research on electronic nose for compound malodor recognition combined with artificial neural network and linear discriminant analysis. J. Intell. Fuzzy Syst. 2023, 44, 6991–7008. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, B.; Yang, J.; Zhou, J.; Xu, Y. Linear discriminant analysis. Nat. Rev. Methods Primers 2024, 4, 70. [Google Scholar] [CrossRef]

- Hanif, S.; Wijaya, D.R.; Wikusna, W. K-nearest neighbors algorithm for prediction shelf life of rice based on electronic nose dataset. In Proceedings of the 2021 IEEE Asia Pacific Conference on Wireless and Mobile (APWiMob), Bandung, Indonesia, 8–10 April 2021; pp. 116–120. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, X.; Miao, J.; Wang, Y.; Luo, Z.; Li, G. Conformal prediction based on k-nearest neighbors for discrimination of ginsengs by a home-made electronic nose. Sensors 2017, 17, 1869. [Google Scholar] [CrossRef]

- Mohareb, F.; Papadopoulou, O.; Panagou, E.; Nychas, G.-J.; Bessant, C. Ensemble-based support vector machine classifiers as an efficient tool for quality assessment of beef fillets from electronic nose data. Anal. Methods 2016, 8, 3711–3721. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Liu, T.; Liu, Y. Prediction of total viable counts on chilled pork using an electronic nose combined with support vector machine. Meat Sci. 2012, 90, 373–377. [Google Scholar] [CrossRef]

- Astuti, S.D.; Wicaksono, I.R.; Soelistiono, S.; Permatasari, P.A.D.; Yaqubi, A.K.; Susilo, Y.; Putra, C.D.; Syahrom, A. Electronic nose coupled with artificial neural network for classifying of coffee roasting profile. Sens. Bio-Sens. Res. 2024, 43, 100632. [Google Scholar] [CrossRef]

- Sabilla, S.I.; Sarno, R.; Siswantoro, J. Estimating gas concentration using artificial neural network for electronic nose. Procedia Comput. Sci. 2017, 124, 181–188. [Google Scholar] [CrossRef]

- Rayappan, J.B.B.; Kulandaisamy, A.J.; Ezhilan, M.; Srinivasan, P.; Mani, G.K. Developments in electronic noses for quality and safety control. Adv. Food Diagn. 2017, 63–96. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y. Electronic nose and its application in the food industry: A review. Eur. Food Res. Technol. 2024, 250, 21–67. [Google Scholar] [CrossRef]

- Wasilewski, T.; Migoń, D.; Gębicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef]

- Eamsa-Ard, T.; Swe, M.M.; Seesaard, T.; Kerdcharoen, T. Development of electronic nose for evaluation of fragrance and human body odor in the cosmetic industry. In Proceedings of the 2018 IEEE 7th Global Conference on Consumer Electronics (GCCE), Nara, Japan, 9–12 October 2018; pp. 363–364. [Google Scholar] [CrossRef]

- Beghi, R.; Buratti, S.; Giovenzana, V.; Benedetti, S.; Guidetti, R. Electronic nose and visible-near infrared spectroscopy in fruit and vegetable monitoring. Rev. Anal. Chem. 2017, 36, 20160016. [Google Scholar] [CrossRef]

- Singh, S.; Gaur, S. Development of rapid and non-destructive electric nose (E-nose) system for shelf life evaluation of different edible seeds. Food Chem. 2023, 426, 136562. [Google Scholar] [CrossRef]

- Adebayo, S.E.; Hashim, N.; Abdan, K.; Hanafi, M. Application and potential of backscattering imaging techniques in agricultural and food processing—A review. J. Food Eng. 2016, 169, 155–164. [Google Scholar] [CrossRef]

- Pham, T.T.; Nguyen, T.B.; Dam, M.S.; Nguyen, L.L.; Baranyai, L. A Review of the Application of the Laser-Light Backscattering Imaging Technique to Agricultural Products. Agriculture 2024, 14, 1782. [Google Scholar] [CrossRef]

- Sanchez, P.D.C.; Hashim, N.; Shamsudin, R.; Nor, M.Z.M. Laser-light backscattering imaging approach in monitoring and classifying the quality changes of sweet potatoes under different storage conditions. Postharvest Biol. Technol. 2020, 164, 111163. [Google Scholar] [CrossRef]

- Mozaffari, M.; Sadeghi, S.; Asefi, N. Prediction of the quality properties and maturity of apricot by laser light backscattering imaging. Postharvest Biol. Technol. 2022, 186, 111842. [Google Scholar] [CrossRef]

- Mukhtar, S.; Arbabi, A.; Viegas, J. Advances in Spectral Imaging: A Review of Techniques and Technologies. IEEE Access 2025, 13, 35848–35902. [Google Scholar] [CrossRef]

- Boelt, B.; Shrestha, S.; Salimi, Z.; Jørgensen, J.R.; Nicolaisen, M.; Carstensen, J.M. Multispectral imaging–a new tool in seed quality assessment? Seed Sci. Res. 2018, 28, 222–228. [Google Scholar] [CrossRef]

- Chen, I.-T.; Lin, H.-Y. Detection, Counting and Maturity Assessment of Cherry Tomatoes using Multi-spectral Images and Machine Learning Techniques. In Proceedings of the 15th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications, Valletta, Malta, 27–29 February 2020; pp. 759–766. [Google Scholar] [CrossRef]

- Dong, P.; Wang, M.; Li, K.; Qiao, H.B.; Zhao, Y.Y.; Bacao, F.; Shi, L.; Guo, W.; Si, H.P. Research on the Identification of Wheat Fusarium Head Blight Based on Multispectral Remote Sensing from UAVs. Drones 2024, 8, 445. [Google Scholar] [CrossRef]

- Abdelsalam, A.M.; Sayed, M.S. Real-time defects detection system for orange citrus fruits using multi-spectral imaging. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Crcuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Tian, H.; Wang, T.; Liu, Y.; Qiao, X.; Li, Y. Computer vision technology in agricultural automation—A review. Inf. Process. Agric. 2020, 7, 1–19. [Google Scholar] [CrossRef]

- Naik, S.; Patel, B. Machine vision based fruit classification and grading-a review. Int. J. Comput. Appl. 2017, 170, 22–34. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Mao, H.; Abomohra, A.E.-F. Applications of non-destructive technologies for agricultural and food products quality inspection. Sensors 2019, 19, 846. [Google Scholar] [CrossRef] [PubMed]

- Ravikanth, L.; Jayas, D.S.; White, N.D.; Fields, P.G.; Sun, D.-W. Extraction of spectral information from hyperspectral data and application of hyperspectral imaging for food and agricultural products. Food Bioprocess Technol. 2017, 10, 1–33. [Google Scholar] [CrossRef]

- Wei, G.; Dan, M.; Zhao, G.; Wang, D. Recent advances in chromatography-mass spectrometry and electronic nose technology in food flavor analysis and detection. Food Chem. 2023, 405, 134814. [Google Scholar] [CrossRef]

- Wang, B.; Sun, J.; Xia, L.; Liu, J.; Wang, Z.; Li, P.; Guo, Y.; Sun, X. The applications of hyperspectral imaging technology for agricultural products quality analysis: A review. Food Rev. Int. 2023, 39, 1043–1062. [Google Scholar] [CrossRef]

- Li, J.; Huang, W.; Zhao, C. Machine vision technology for detecting the external defects of fruits—A review. Imaging Sci. J. 2015, 63, 241–251. [Google Scholar] [CrossRef]

- Zhang, W.; Pan, L.; Tu, S.; Zhan, G.; Tu, K. Non-destructive internal quality assessment of eggs using a synthesis of hyperspectral imaging and multivariate analysis. J. Food Eng. 2015, 157, 41–48. [Google Scholar] [CrossRef]

- Patel, K.K.; Pathare, P.B. Principle and applications of near-infrared imaging for fruit quality assessment—An overview. Int. J. Food Sci. Technol. 2024, 59, 3436–3450. [Google Scholar] [CrossRef]

- Magwaza, L.S.; Opara, U.L. Investigating non-destructive quantification and characterization of pomegranate fruit internal structure using X-ray computed tomography. Postharvest Biol. Technol. 2014, 95, 1–6. [Google Scholar] [CrossRef]

- Nakariyakul, S.; Casasent, D.P. Classification of internally damaged almond nuts using hyperspectral imagery. J. Food Eng. 2011, 103, 62–67. [Google Scholar] [CrossRef]

- Jha, S.; Narsaiah, K.; Jaiswal, P.; Bhardwaj, R.; Gupta, M.; Kumar, R.; Sharma, R. Nondestructive prediction of maturity of mango using near infrared spectroscopy. J. Food Eng. 2014, 124, 152–157. [Google Scholar] [CrossRef]

- Wendel, A.; Underwood, J.; Walsh, K. Maturity estimation of mangoes using hyperspectral imaging from a ground based mobile platform. Comput. Electron. Agric. 2018, 155, 298–313. [Google Scholar] [CrossRef]

- Tyagi, P.; Semwal, R.; Sharma, A.; Tiwary, U.S.; Varadwaj, P. E-nose: A low-cost fruit ripeness monitoring system. J. Agric. Eng. 2023, 54. [Google Scholar] [CrossRef]

- Feng, L.; Zhu, S.; Zhang, C.; Bao, Y.; Gao, P.; He, Y. Variety identification of raisins using near-infrared hyperspectral imaging. Molecules 2018, 23, 2907. [Google Scholar] [CrossRef]

- Li, C.; Li, L.; Wu, Y.; Lu, M.; Yang, Y.; Li, L. Apple variety identification using near-infrared spectroscopy. J. Spectrosc. 2018, 2018, 6935197. [Google Scholar] [CrossRef]

- Nazarloo, A.S.; Sharabiani, V.R.; Gilandeh, Y.A.; Taghinezhad, E.; Szymanek, M. Evaluation of different models for non-destructive detection of tomato pesticide residues based on near-infrared spectroscopy. Sensors 2021, 21, 3032. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, K.; Zhao, B.; Zhang, M.; Gong, C.; Wan, H.; Wang, Y.; Yang, Z. A novel electronic nose for the detection and classification of pesticide residue on apples. RSC Adv. 2021, 11, 20874–20883. [Google Scholar] [CrossRef]

- Jin, P.; Fu, Y.; Niu, R.; Zhang, Q.; Zhang, M.; Li, Z.; Zhang, X. Non-destructive detection of the freshness of air-modified mutton based on near-infrared spectroscopy. Foods 2023, 12, 2756. [Google Scholar] [CrossRef] [PubMed]

- Qi, L.; Zhao, M.-c.; Li, Z.; Shen, D.-H.; Lu, J. Non-destructive testing technology for raw eggs freshness: A review. SN Appl. Sci. 2020, 2, 1113. [Google Scholar] [CrossRef]

- Wang, M.; Gao, F.; Wu, Q.; Zhang, J.; Xue, Y.; Wan, H.; Wang, P. Real-time assessment of food freshness in refrigerators based on a miniaturized electronic nose. Anal. Methods 2018, 10, 4741–4749. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Zhou, X.; Cheng, J. Study on Rapid Non-Destructive Detection Method of Corn Freshness Based on Hyperspectral Imaging Technology. Molecules 2024, 29, 2968. [Google Scholar] [CrossRef] [PubMed]

| Method | Principle | References |

|---|---|---|

| Radiographic Testing (RT) | Detects defects by measuring attenuation patterns of radiation passing through objects | [10] |

| Computed Tomography (CT) | Uses X-ray scanning from multiple angles to reconstruct cross-sectional images, revealing internal structures and density distributions | [11,12] |

| Magnetic Particle Detection (MPD) | Identifies defects through magnetic particles attracted to leakage magnetic fields | [13] |

| Acoustic Emission (AE) | Monitors stress waves generated during material deformation or damage to detect internal defects or structural changes | [14] |

| Computer Vision (CV) | Acquires images through sensors and analyzes them computationally after converting images into numerical matrices | [15] |

| Eddy Current Testing (ECT) | Detects defects in conductive materials using electromagnetic induction phenomena | [16] |

| Near-Infrared Spectroscopy (NIRS) | Analyzes how materials respond to near-infrared light to determine internal composition or quality attributes | [17] |

| Infrared Thermography (IRT) | Detects temperature distributions and thermal conditions of objects through infrared radiation | [18] |

| Hyperspectral Imaging (HSI) | Creates hypercubes containing spatial and spectral features from multiple wavelength images | [19] |

| Electronic Nose (EN) | Simulates human olfaction to distinguish complex gaseous components through sensor arrays | [20] |

| Detection Task | Target or Application Example | References |

|---|---|---|

| Sorting and grading | Automatic grading and sorting based on external quality, such as sorting fruits and vegetables | [43] |

| Foreign object detection | Detection of foreign materials within agricultural products, such as cotton (Gossypium spp.) and walnut (Juglans regia L.) contamination | [24,44] |

| Defect detection and quality assessment | Detection of external defects and quality evaluation during agricultural production processes, such as fruit and vegetable quality control | [45,46,47] |

| Variety identification | Accurate classification and differentiation of agricultural product varieties from images, such as barley (Hordeum vulgare vulgare L.) and tea (Camellia sinensis) leaves varieties | [48,49] |

| Method | Basic Principles | Advantages | Disadvantages |

|---|---|---|---|

| Manual selection | Removing variables with poor-quality information manually | Simple and easy to perform | Risk of discarding informative variables inadvertently |

| Univariate linear regression | Selects variables based on individual linear relationships | Simplicity | Selected variables may lack robustness and acceptance |

| Multiple linear regression | Uses multiple wavelengths to isolate individual absorbers and normalize baselines | Combines multiple wavelength data efficiently | Inconsistent performance under varying noise conditions |

| Successive projections algorithm (SPA) | Uses vector-space projections to obtain subsets with minimal collinearity | Simplicity of computation and implementation | May select variables with low signal-to-noise ratios |

| Uninformative variable elimination (UVE) | Variable selection based on the stability of regression coefficients | Removes irrelevant variables and prevents overfitting | Typically selects numerous variables; latent variables often required |

| Simulated annealing (SA) | Probabilistic global optimization inspired by physical annealing processes [58] | Escapes local minima, seeking global optimum | Computationally intensive; may not guarantee optimal subset |

| Artificial neural networks (ANN) | Mimics human brain learning; adapts through training data | High flexibility; suitable for complex relationships | Difficult interpretation; prone to overfitting; data-intensive |

| Genetic algorithms (GA) | Probabilistic heuristic optimization inspired by natural selection theory | Explores multiple subsets thoroughly; finds near-optimal solutions | Slow convergence; sensitivity to initial parameters |

| Interval selection methods | Based on continuity characteristics of molecular spectra bands | Maintains spectral wavelength continuity | High complexity in optimization |

| Method | Technical Characteristics | Practical Examples |

|---|---|---|

| Principal Component Analysis (PCA) | Extracts principal features rapidly by ranking components in descending order | [80,81] |

| Linear Discriminant Analysis (LDA) | Requires continuous independent variables; suitable for linear classification | [82,83] |

| K-Nearest Neighbor (KNN) | Simple and intuitive; sensitive to outliers | [84,85] |

| Support Vector Machines (SVMs) | Identifies optimal hyperplanes maximizing margins between classes; effective with small datasets | [86,87] |

| Artificial Neural Networks (ANNs) | Mimics human brain functions through iterative learning; suitable for nonlinear data | [88,89] |

| Method | Accuracy | Adoption Trend | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Computer Vision (CV) | Up to 96.7% and 93.8% classification accuracy were achieved during real-time testing on actual samples of apples (Malus domestica) and bananas (Musa spp.) [43] | Widely used in commercial sorting and grading lines | Nondestructive, rapid, high accuracy, low cost | Requires large-scale datasets for generalization; lower accuracy for objects difficult to distinguish from backgrounds; sensitive to lighting conditions | [105,106] |

| Near-Infrared Spectroscopy (NIRS) | 82.5% classification accuracy for peach (Prunus persica) maturity [59] | Portable devices increasingly adopted in field and industry | Minimal or no sample preparation required; rapid; suitable for online quality control systems | Dependent on chemometric modeling for information extraction; challenging to establish universally robust models; requires careful parameter tuning | [107] |

| Hyperspectral Imaging (HSI) | Qualitative defect detection reported; accuracy not quantified [19] | Primarily research; gradual adoption in high-value crops | Non-invasive, no sample preparation needed; high accuracy even for visually similar samples | High equipment cost; large data volumes; longer processing times; environmental conditions can affect results | [108] |

| Computed Tomography (CT) | Qualitative defect detection reported; accuracy not quantified [75] | Industrial adoption limited by cost/throughput | High resolution; 3D imaging capability; objective and non-invasive analysis | High equipment cost; relatively slow processing; technically demanding operation | [28] |

| Electronic Nose (EN) | Shelf-life estimation of edible seeds; accuracy not quantified | Portable systems in niche commercial use | Rapid and convenient; effective for distinguishing complex gas compositions | Difficulty in accurately identifying single aromatic compounds | [95,109] |

| Detection Task | Detect the Target | Commonly Used Methods | Product Type | Application Examples |

|---|---|---|---|---|

| External Quality Inspection | Shape, color, size, and surface defects; suitable for grading and sorting of fruits and vegetables | Computer vision, hyperspectral imaging | Fruits, Root vegetables, Cereals, Legumes | [47,110,111] |

| Internal Quality Inspection | Evaluate the quality indicators of agricultural products such as internal components and defects | Hyperspectral imaging, near-infrared spectroscopy | Fruits, Root vegetables | [112,113] |

| Internal Defect Detection | Internal structural defects such as decay, cracks, or voids | Computed tomography, hyperspectral imaging | Root vegetables, Fruits | [114,115] |

| Ripeness Evaluation | Ripeness classification of fruits | Hyperspectral imaging, near-infrared spectroscopy, electronic nose (Fruits with volatile organic compounds) | Fruits, Cereals | [116,117,118] |

| Variety Identification | Identification and classification of different varieties and origins | Hyperspectral imaging, computer vision, near-infrared spectroscopy | Fruits, Root vegetables, Cereals, Legumes | [48,119,120] |

| Pesticide or Contaminant Detection | Rapid detection of pesticide residues or contaminants (e.g., heavy metals) on or within products | Electronic nose, near-infrared spectroscopy | Fruits, Root vegetables, Cereals | [121,122] |

| Freshness Detection | Freshness evaluation of agricultural products including meat, fruits, vegetables, eggs, etc. | Near-infrared spectroscopy, hyperspectral imaging, electronic nose, computer vision | Fruits, Root vegetables, Eggs, Meat | [123,124,125,126] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Yin, H.; Gu, F.; Duan, Y.; Zhuang, W.; Han, K.; Jin, X. Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review. Processes 2025, 13, 2674. https://doi.org/10.3390/pr13092674

Li M, Yin H, Gu F, Duan Y, Zhuang W, Han K, Jin X. Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review. Processes. 2025; 13(9):2674. https://doi.org/10.3390/pr13092674

Chicago/Turabian StyleLi, Mian, Honglian Yin, Fei Gu, Yanjun Duan, Wenxu Zhuang, Kang Han, and Xiaojun Jin. 2025. "Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review" Processes 13, no. 9: 2674. https://doi.org/10.3390/pr13092674

APA StyleLi, M., Yin, H., Gu, F., Duan, Y., Zhuang, W., Han, K., & Jin, X. (2025). Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review. Processes, 13(9), 2674. https://doi.org/10.3390/pr13092674