A Power-Law-Based Predictive Model for Proppant Settling Velocity in Non-Newtonian Fluid

Abstract

1. Introduction

2. Materials and Methods

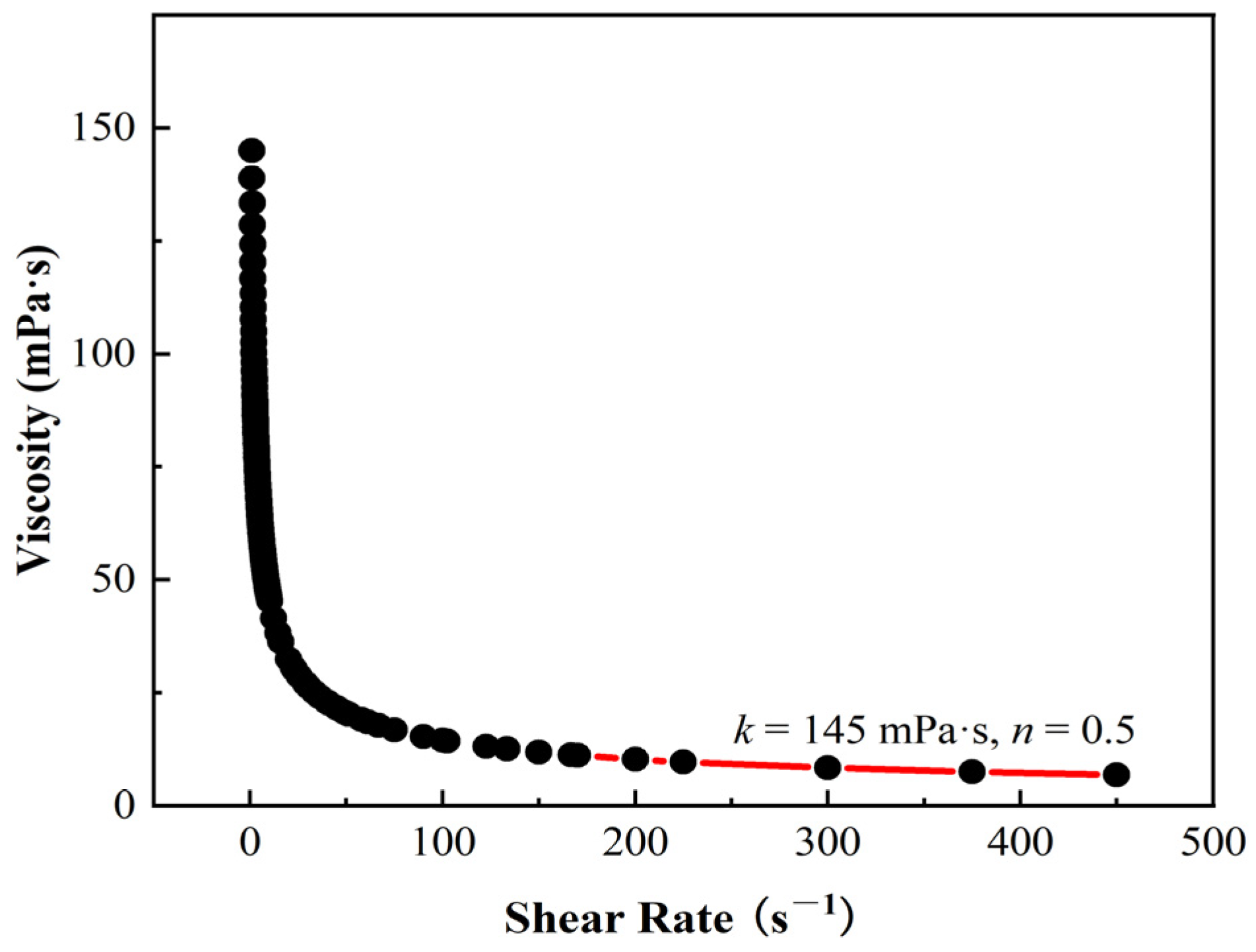

2.1. Rheology of Fluid Used in This Study

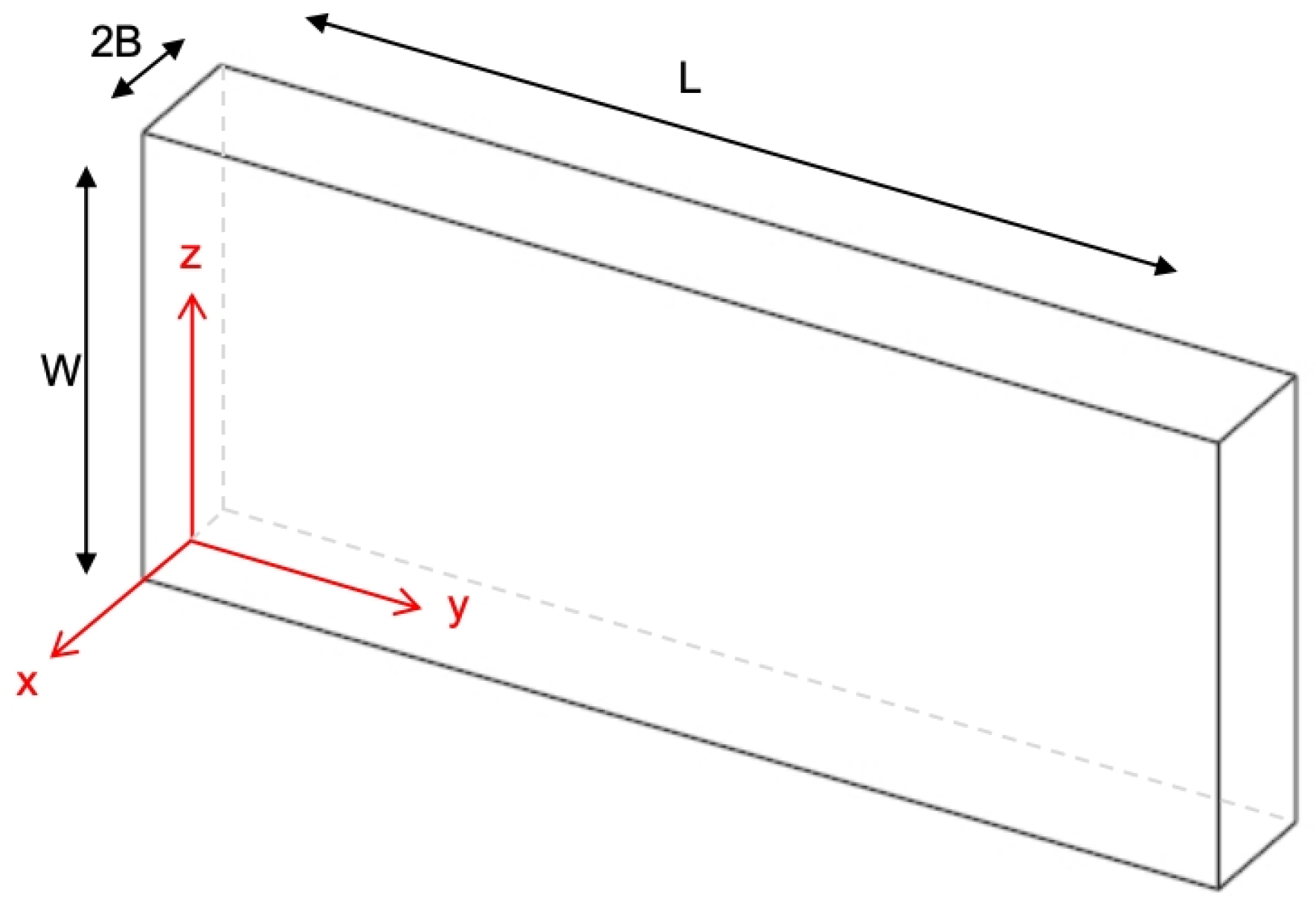

2.2. Shear Rate of Non-Newtonian Fluid Within a Hydraulic Fracture

2.3. Model of Particle Settling in Newtonian Fluids (Stokes’ Law)

2.4. Description of the Simulation Model

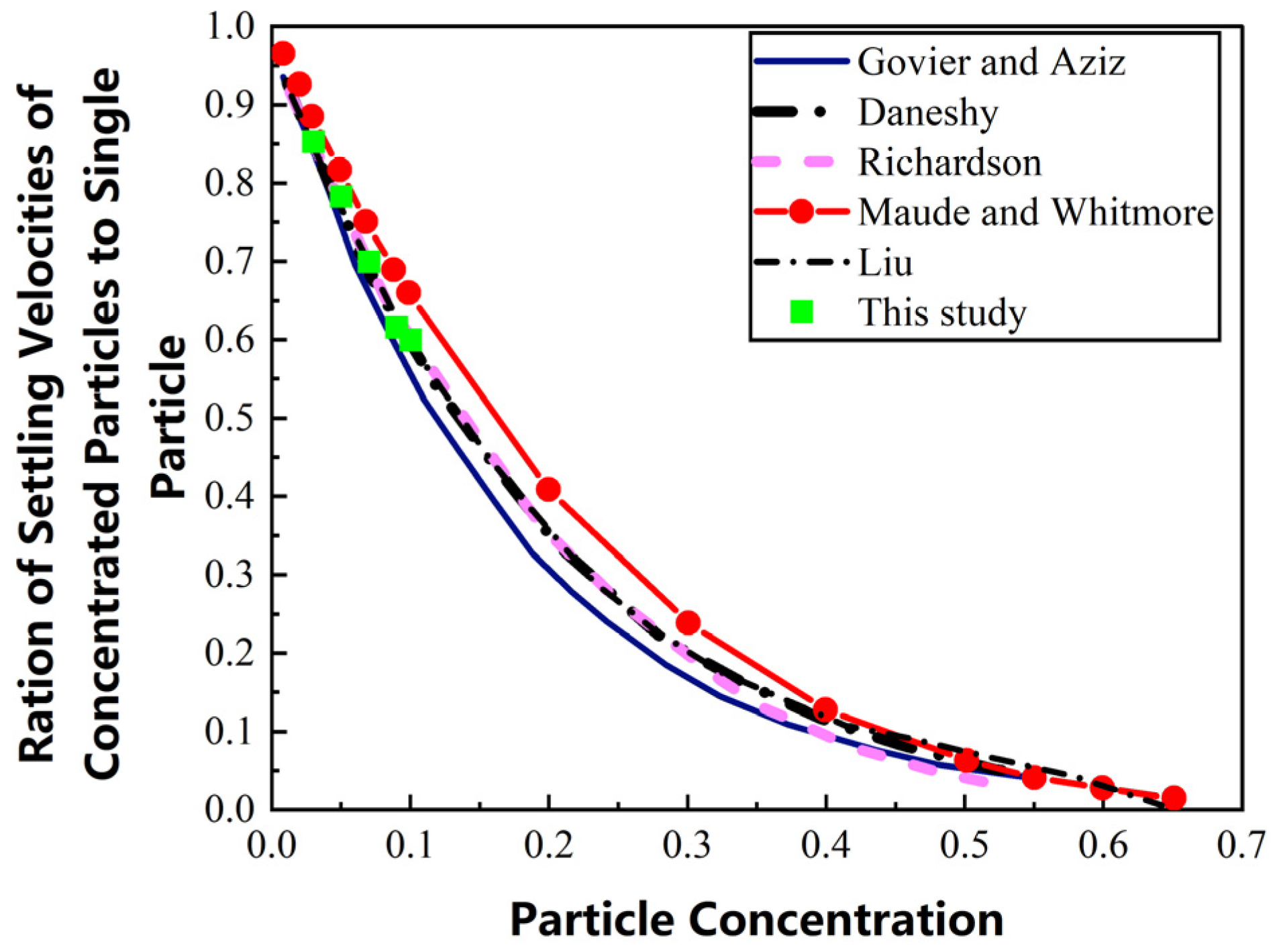

2.5. Validation of the Predictive Model for Proppant Settling Velocity and Design of the Simulation Cases

3. Results and Discussion

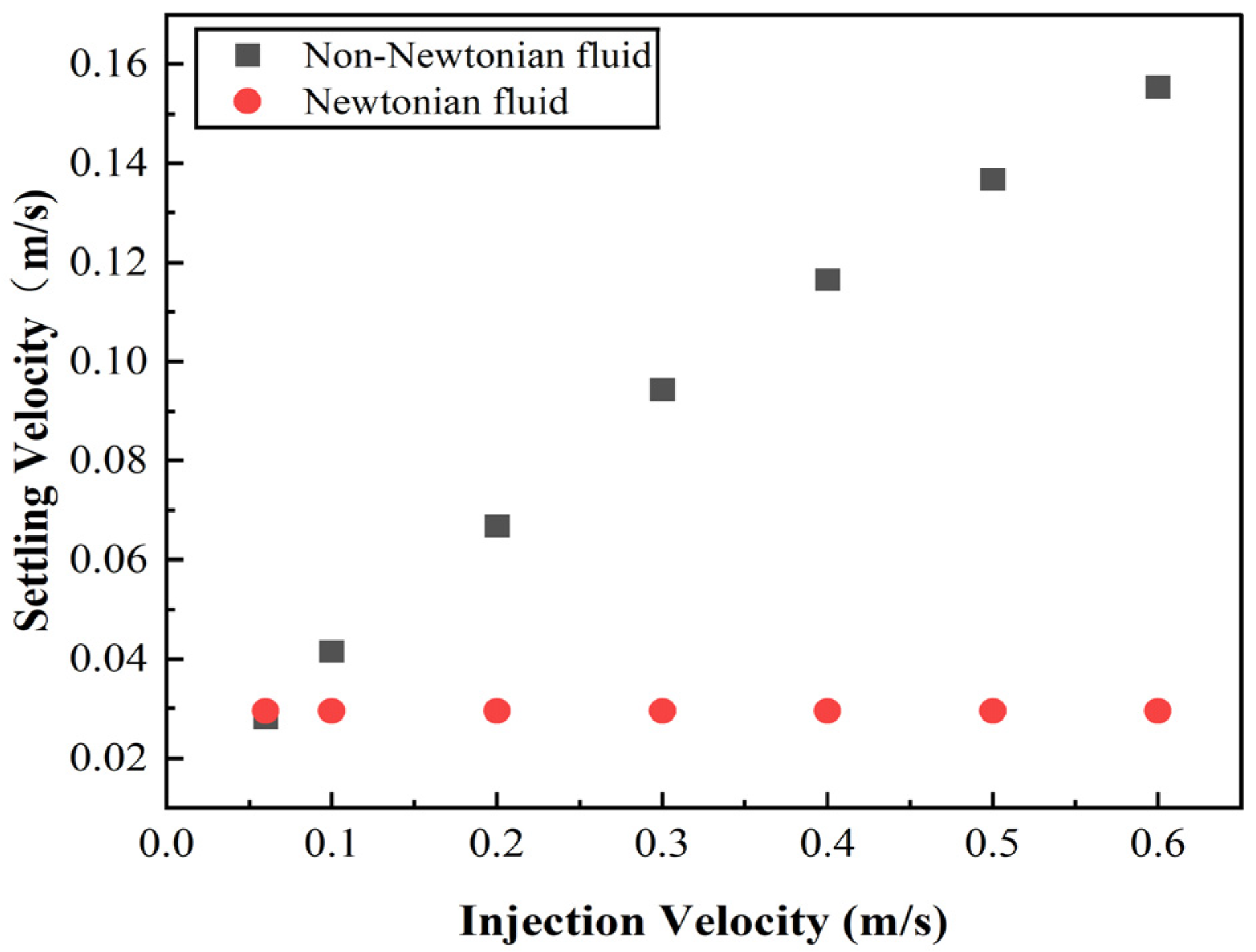

3.1. Influence of Particle Settling Velocity in the Newtonian Fluid

3.2. Influence of Particle Settling Velocity in the Non-Newtonian Fluid

4. Conclusions

- Newtonian fluids: The proppant settling velocity is primarily governed by the fluid viscosity and particle diameter. Higher viscosity significantly enhances the drag force, reduces the settling velocity of proppants, and thus improves the proppant suspension capacity. Conversely, larger particle diameters accelerate settling due to the increased gravitational force. These observations align with Stokes’ law, validating the foundational principles of particle dynamics in the Newtonian fluid;

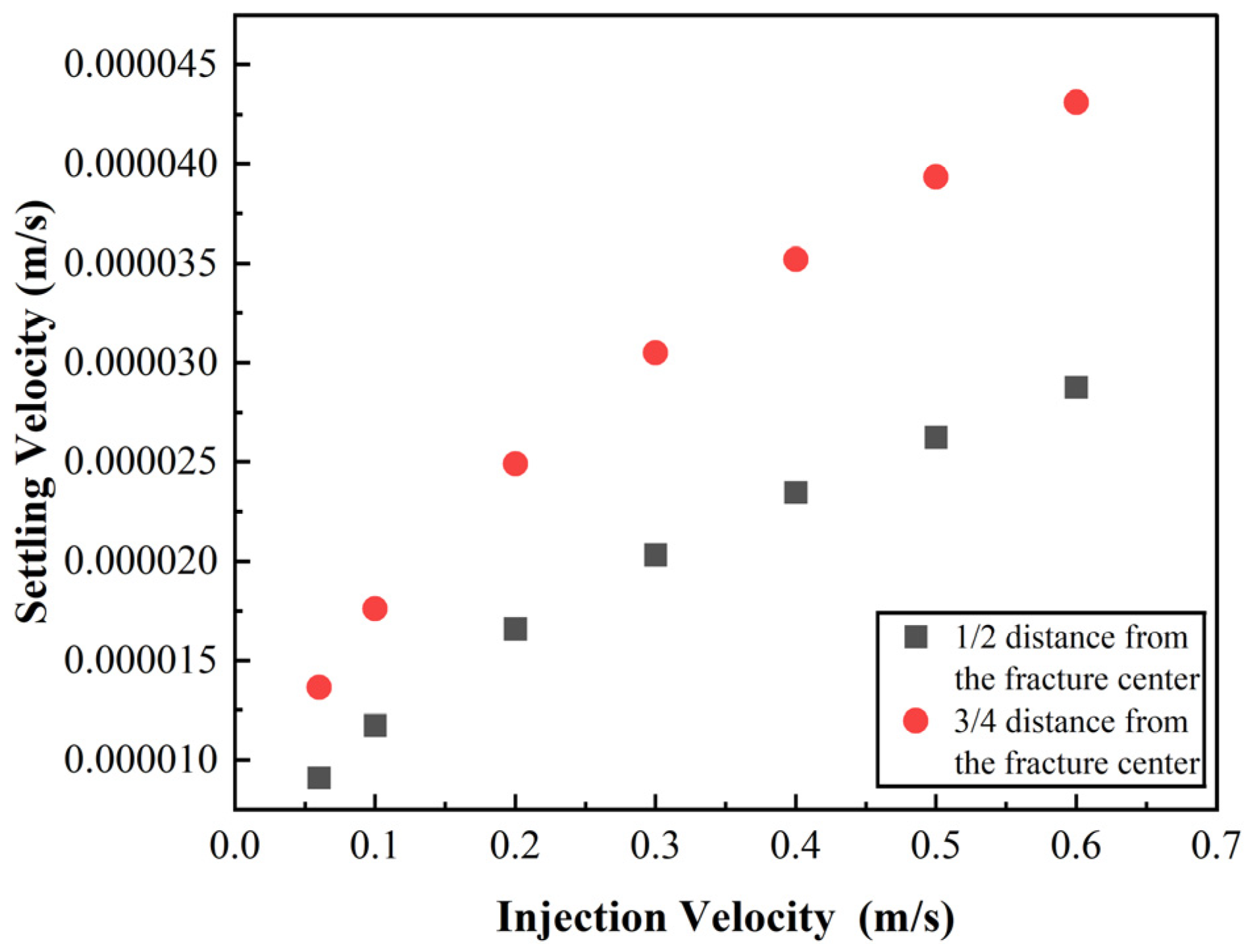

- Non-Newtonian fluids: In power-law shear-thinning fluids, the settling behavior exhibits spatial heterogeneity due to localized variations in shear rate and viscosity. Beyond the viscosity and particle size, the injection position within the fracture critically influences the settling velocity. Near fracture walls, elevated shear rates reduce fluid viscosity, resulting in a rapid settling. In contrast, low-shear regions near the fracture center maintain a high fluid viscosity, which hinders the proppant settling;

- Newly proposed model: A practical framework is established by integrating the spatial distribution of the shear rate calculated with the power-law rheological model. The local viscosity is derived from the shear-dependent rheology, and Stokes’ law is then adapted to predict the settling velocity of proppant in the non-Newtonian fluid. The results indicate that the model achieved high accuracy in the fracture center region, with an average relative error of 8.2%. Despite localized deviations in the near-wall region, the analytical model proposed in this study can still reliably predict settling velocities, providing theoretical support for the rapid and accurate estimation of particle settling behavior and key engineering parameters in practical fracturing scenarios.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Z.; Cui, C.; Jia, P.; Wang, Z.; Sui, Y. Advances and challenges in the development of hydraulic fracturing of tight reservoirs: A critical review. Energy Geosci. 2021, 3, 427–435. [Google Scholar] [CrossRef]

- Sun, L.; Zou, C.; Jia, A.; Wei, Y.; Zhu, R.; Wu, S.; Guo, Z. Development characteristics and orientation of tight oil and gas in China. Pet. Explor. Dev. 2019, 46, 1073–1087. [Google Scholar] [CrossRef]

- Zhai, G.M. Speculations on the exploration and development of unconventional hydrocarbon resources. Nat. Gas Ind. 2008, 28, 1–3. [Google Scholar]

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131, 318–323. [Google Scholar] [CrossRef]

- Fredd, C.N.; McConnell, S.B.; Boney, C.L.; England, K.W. Experimental study of fracture conductivity for water-fracturing and conventional fracturing applications. SPE J. 2001, 6, 288–298. [Google Scholar] [CrossRef]

- Li, Q.; Xing, H.; Liu, J.; Liu, X. A review on hydraulic fracturing of unconventional reservoir. Petroleum 2015, 1, 8–15. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, X.; Zhang, X.; Li, P. Proppant Transportation in Cross Fractures: Some Findings and Suggestions for Field Engineering. Energies 2020, 13, 4912. [Google Scholar] [CrossRef]

- Hou, Z.; Yuan, Y.; Chen, Y.; Feng, J.; Liu, Y.; Zhang, X. Experimental Study on Proppant Migration in Fractures Following Hydraulic Fracturing. Water 2024, 16, 1941. [Google Scholar] [CrossRef]

- Yu, H.; Xu, W.L.; Li, B.; Huang, H.; Micheal, M.; Wang, Q.; Huang, M.; Meng, S.; Liu, H.; Wu, H. Hydraulic fracturing and enhanced recovery in shale reservoirs: Theoretical analysis to engineering applications. Energy Fuels 2023, 37, 9956–9997. [Google Scholar] [CrossRef]

- Kong, C.; Yang, L.; Guo, X.; Tian, F.; Li, Y. Proppant Migration Law Considering Complex Fractures. Processes 2023, 11, 14. [Google Scholar] [CrossRef]

- Huang, H.; Zheng, Y.; Zhang, W. Characteristics of proppant transport and placement within rough hydraulic fractures. Pet. Explor. Dev. 2024, 51, 453–463. [Google Scholar] [CrossRef]

- Yang, S.; Cheng, W.; Hu, Q.; Lei, G. Sensitivity analysis of proppant transportation and settling in a hydraulic fracture. Phys. Fluids 2025, 37, 013360. [Google Scholar] [CrossRef]

- Zeng, J.; Li, H.; Zhang, D. Numerical simulation of proppant transport in hydraulic fracture with the upscaling CFD-DEM method. J. Nat. Gas Sci. Eng. 2016, 33, 264–277. [Google Scholar] [CrossRef]

- Kumar, D.; Ghassemi, A. Modeling and Analysis of Proppant Transport and Deposition in Hydraulic/Natural Fracture Networks. In Proceedings of the 7th Unconventional Resources Technology Conference, Denver, Colorado, 22–24 July 2019. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, J.; Xu, H.; Zhang, L.; Jiang, H. Numerical simulation of proppant migration and sedimentation behavior in complex fractures based on computational fluid dynamics. Phys. Fluids 2023, 35, 093103. [Google Scholar] [CrossRef]

- Tang, P.; Zeng, J.; Zhang, D.; Li, H. Constructing sub-scale surrogate model for proppant settling in inclined fractures from simulation data with multi-fidelity neural network. J. Pet. Sci. Eng. 2022, 210, 110051. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, Y.; Lu, B.; Jiang, T. Study on the Law and Influencing Factors of Proppant Settling in Fracturing Fluid. In Proceedings of the International Field Exploration and Development Conference 2020, Chengdu, China, 23–25 September 2020; Springer: Singapore, 2020; pp. 2834–2842. [Google Scholar]

- Du, Q.; Yang, H.; He, S.; Deng, P.; Yang, X.; Lin, C.; Sun, Z.; Ren, L.; Yin, H.; He, B.; et al. Numerical Simulation and Application of Coated Proppant Transport in Hydraulic Fracturing Systems. Processes 2025, 13, 1062. [Google Scholar] [CrossRef]

- Stokes, G.G. On the effect of the internal friction of fluids on the motion of pendulums. In Transactions of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1851. [Google Scholar]

- Wrobel, M.; Mishuris, G.; Papanastasiou, P. On the influence of fluid rheology on the hydraulic fracture evolution. arXiv 2020. [Google Scholar] [CrossRef]

- Almubarak, T.; Li, L.; Ng, J.H.; Nasr-El-Din, H.; AlKhaldi, M. New Insights into Hydraulic Fracturing Fluids used for High Temperature Wells. Petroleum 2020, 70, 70–79. [Google Scholar] [CrossRef]

- Abdelaal, A.; Aljawad, M.S.; Alyousef, Z.; Almajid, M.M. A review of foam-based fracturing fluids applications: From lab studies to field implementations. J. Nat. Gas Sci. Eng. 2021, 95, 104236. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A. Shale gas fracturing using foam-based fracturing fluid: A review. Environ. Earth Sci. 2017, 76, 91. [Google Scholar] [CrossRef]

- Arabi, A.S.; Sanders, R.S. Particle terminal settling velocities in non-Newtonian viscoplastic fluids. Can. J. Chem. Eng. 2016, 94, 1092–1101. [Google Scholar] [CrossRef]

- Moreira, B.A.; de Oliveira Arouca, F.; Damasceno, J.J.R. Analysis of suspension sedimentation in fluids with rheological shear-thinning properties and thixotropic effects. Powder Technol. 2017, 308, 290–297. [Google Scholar] [CrossRef]

- Alghalibi, D.; Fornari, W.; Rosti, M.E.; Brandt, L. Sedimentation of finite-size particles in quiescent wall-bounded shear-thinning and Newtonian fluids. Int. J. Multiph. Flow 2020, 129, 103291. [Google Scholar] [CrossRef]

- Murch, W.L.; Shaqfeh, E.S.G. Collective effects in the sedimentation of particles in a viscoelastic fluid. Phys. Rev. Fluids 2020, 5, 073301. [Google Scholar] [CrossRef]

- Patankar, N.A.; Huang, P.Y.; Ko, T.; Joseph, D.D. Lift-off of a single particle in Newtonian and viscoelastic fluids by direct numerical simulation. J. Fluid Mech. 2001, 438, 67–100. [Google Scholar] [CrossRef]

- Chhabra, R.P. Bubbles, Drops, and Particles in Non-Newtonian Fluids; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Matveenko, V.N.; Kirsanov, E.A. Rheology of structured liquids. Flow regimes and rheological equations. Colloid J. 2025, 87, 38–48. [Google Scholar] [CrossRef]

- Khataniar, S.; Chukwu, G.A.; Xu, H. Evaluation of rheological models and application to flow regime determination. J. Pet. Sci. Eng. 1994, 11, 155–164. [Google Scholar] [CrossRef]

- Shah, S.N. Proppant-settling correlations for non-Newtonian Fluids. SPE Prod. Eng. 1986, 1, 446–448. [Google Scholar] [CrossRef]

- Roodhart, L.P. Proppant settling in non-Newtonian fracturing fluids. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, Colorado, 19–22 May 1985; SPE: Richardson, TX, USA, 1985. SPE-13905-MS. [Google Scholar]

- Ovarlez, G.; Bertrand, F.; Coussot, P.; Chateau, X. Shear-induced sedimentation in yield stress fluids. J. Non-Newton. Fluid Mech. 2012, 177–178, 19–28. [Google Scholar] [CrossRef]

- Amaratunga, M.; Rabenjafimanantsoa, H.A.; Time, R.W. Estimation of shear rate change in vertically oscillating non-Newtonian fluids: Predictions on particle settling. J. Non-Newton. Fluid Mech. 2020, 277, 104236. [Google Scholar] [CrossRef]

- Anyaoku, C.C.; Bhattacharya, S.; Parthasarathy, R. Sheared settling in viscoelastic shear-thinning fluids: Empirical studies and model development. AIChE J. 2024, 70, e18460. [Google Scholar] [CrossRef]

- Bai, Z.; Li, M. Prediction of proppant settling velocity in fiber-containing fracturing fluids. ACS Omega 2023, 8, 31857–31869. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Fan, W. Velocity distribution and scaling properties of wall bounded flow. J. Zhejiang Univ.-Sci. A 2010, 11, 505–510. [Google Scholar] [CrossRef]

- Liu, Y. Settling and Hydrodynamic Retardation of Proppants in Hydraulic Fractures. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2006. [Google Scholar]

- Richardson, J.F.; Zaki, W.N. Sedimentation and fluidisation: Part I. Chem. Eng. Res. Des. 1997, 75, S82–S100. [Google Scholar] [CrossRef]

- Daneshy, A.A. Numerical solution of sand transport in hydraulic fracturing. J. Pet. Technol. 1978, 30, 132–140. [Google Scholar] [CrossRef]

- Happel, J.; Brenner, H. Low Reynolds Number Hydrodynamics: With Special Applications to Particulate Media; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

| Distance from Fracture Center | Average Relative Error (%) |

|---|---|

| 1/2 (near center) | 8.2 |

| 2/3 | 10.6 |

| 3/4 | 23.3 |

| 4/5 (near wall) | 30.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, T.; Deng, Z.; Wu, J.; Xu, F.; Zheng, L.; Yang, M.; Zhou, F. A Power-Law-Based Predictive Model for Proppant Settling Velocity in Non-Newtonian Fluid. Processes 2025, 13, 2631. https://doi.org/10.3390/pr13082631

Liang T, Deng Z, Wu J, Xu F, Zheng L, Yang M, Zhou F. A Power-Law-Based Predictive Model for Proppant Settling Velocity in Non-Newtonian Fluid. Processes. 2025; 13(8):2631. https://doi.org/10.3390/pr13082631

Chicago/Turabian StyleLiang, Tianbo, Zilin Deng, Junlin Wu, Fangzhou Xu, Leyi Zheng, Maoqin Yang, and Fujian Zhou. 2025. "A Power-Law-Based Predictive Model for Proppant Settling Velocity in Non-Newtonian Fluid" Processes 13, no. 8: 2631. https://doi.org/10.3390/pr13082631

APA StyleLiang, T., Deng, Z., Wu, J., Xu, F., Zheng, L., Yang, M., & Zhou, F. (2025). A Power-Law-Based Predictive Model for Proppant Settling Velocity in Non-Newtonian Fluid. Processes, 13(8), 2631. https://doi.org/10.3390/pr13082631