Abstract

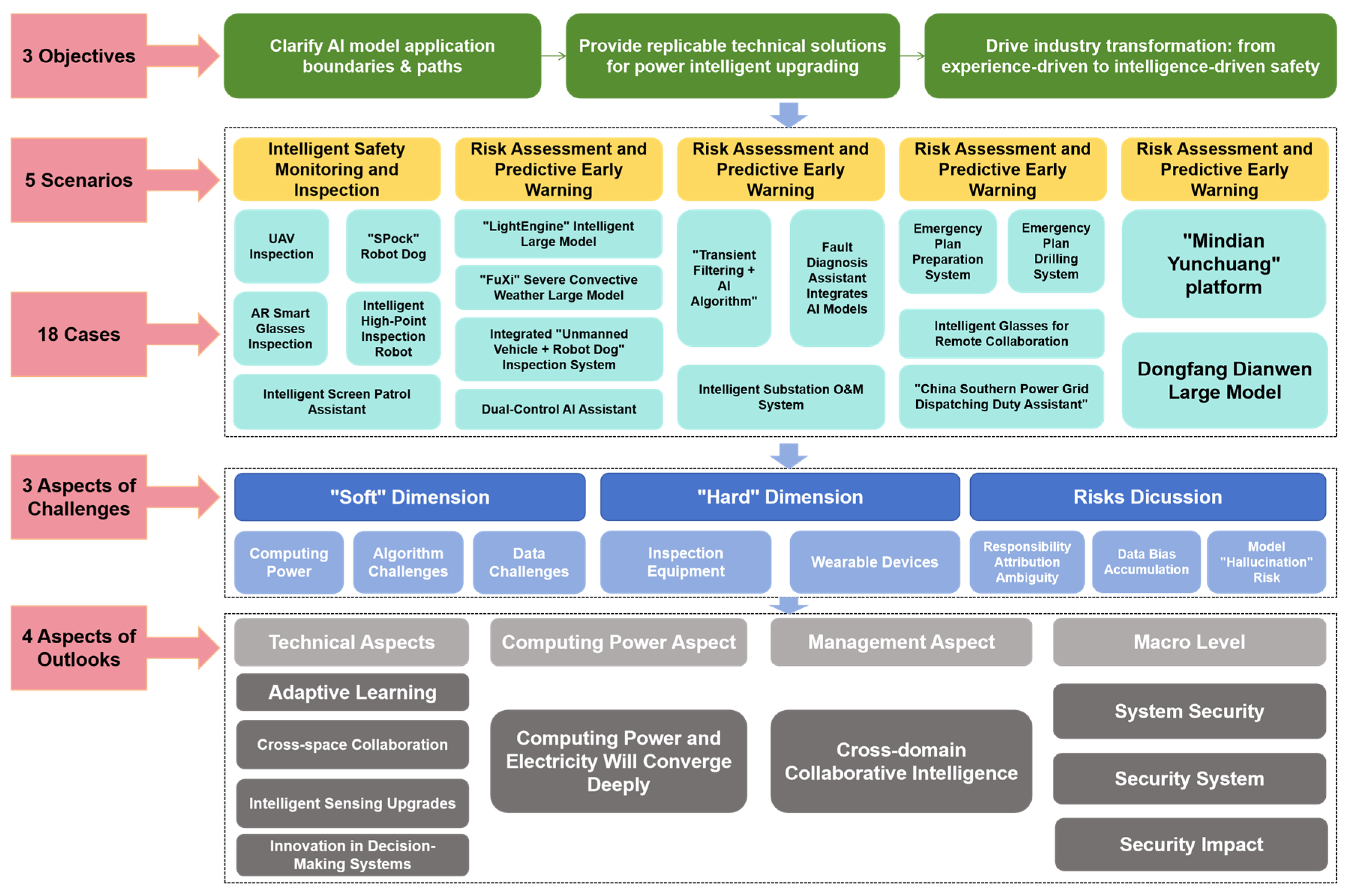

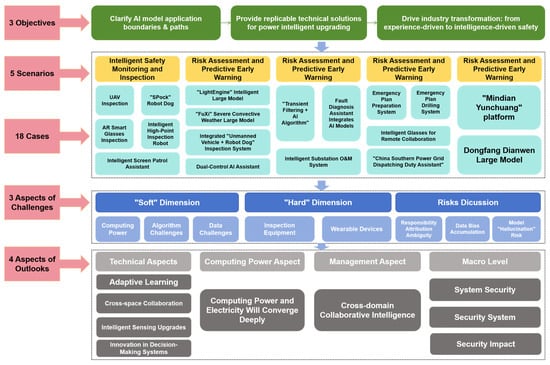

Under the framework of the “dual-carbon” goals of China (“carbon peak” by 2030 and “carbon neutrality” by 2060), the escalating complexity of emerging power systems presents significant challenges to safety governance. Traditional management models are now confronting bottlenecks, notably in knowledge inheritance breakdown and lagging risk prevention and control. This paper explores the application of large AI models in safety and emergency management in the power industry. Through core capabilities—such as natural language processing (NLP), knowledge reasoning, multimodal interaction, and auxiliary decision making—it achieves full-process optimization from data fusion to intelligent decision making. The study, anchored by 18 cases across five core scenarios, identifies three-dimensional challenges (including “soft”—dimension computing power, algorithm, and data bottlenecks; “hard”—dimension inspection equipment and wearable device constraints; and “risk”—dimension responsibility ambiguity, data bias accumulation, and model “hallucination” risks). It further outlines future directions for large-AI-model application innovation in power industry safety and management from a four-pronged outlook, covering technology, computing power, management, and macro-level perspectives. This work aims to provide theoretical and practical guidance for the industry’s shift from “passive response” to “intelligent proactive prevention”, leveraging quantified scenario-case analysis.

1. Introduction

Electricity has permeated almost all fields [1]. The power system serves as the lifeline of national energy security and the cornerstone of social–economic operations. The integration of intelligent technologies into modern power systems has become an irreversible trend [2]. Driven by the “dual-carbon” goals of China (China explicitly announced its goals of achieving a “carbon peak” by 2030 and realizing “carbon neutrality” by 2060 [3]), the new-type power system is accelerating construction. The high-penetration integration of renewable energy and the increasing complexity of smart grids pose unprecedented challenges to safe and stable operation. In recent years, major power equipment accidents have grown increasingly frequent, incurring not only substantial direct economic losses but also triggering cascading effects that result in inestimable indirect production capacity losses (as exemplified by cases documented in notices from China’s National Energy Administration [4]; for example, a turbine-damaging incident at a thermal power company in June 2024 caused direct economic losses of CNY 7.1697 million, while an equipment fire at a power generation company in June 2018 led to direct losses of CNY 8.1 million).

Safety and emergency management in the power industry is critical for national welfare, people’s livelihoods, and social stability. As a cornerstone of modern society, a stable electricity supply directly affects the economy, public services, and daily life. Incidents or interruptions can cause heavy economic losses and social disruption. The industry’s inherently high risks (such as high voltage, high temperatures, complex grids, and field operations) bring significant potential of personal injury, equipment damage, and cascading failures. Thus, rigorous safety management (including risk control, hazard identification, and safety culture) is vital to reduce incidents. Meanwhile, a systematic emergency management framework (encompassing contingency plans, resource allocation, and training) is needed to enable rapid response, effective fault isolation, and timely power restoration during emergencies to minimize losses, protect personnel, ensure grid reliability, and maintain social order.

However, traditional safety and emergency management in the power industry faces severe bottlenecks, as follows:

- Knowledge inheritance gap: difficulty in structuring experts’ tacit experience, with new employees requiring a training cycle of up to 3–5 years and achieving a hidden danger identification accuracy less than 40% of that of experts (based on summaries from multiple enterprises within the industry);

- Lagging risk prevention and control: low coverage of manual inspections (e.g., in traditional distribution rooms, the daily inspection coverage is <60% [5]) and large blind spots in supervision of irregularities (limited by the physiological limits of human vision, coupled with environmental obstructions around lines, the visual range of safety personnel is ≤50 m [6]);

- Inefficient emergency response: traditional emergency response mechanisms heavily rely on manual decision making and intervention, often hampered by delays, inefficiency, and lack of real-time situational awareness [7];

- Unexploited data value: the surge of multi-source heterogeneous data from SCADA, video surveillance, environmental sensors, etc., makes it difficult for traditional systems to integrate and analyze data for effective proactive early warning.

AI breakthroughs like ChatGPT-4 and multimodal models (e.g., Vision Transformer and Segment Anything Model) offer new solutions to safety and emergency management challenges in the power industry. Existing studies have conducted multi-dimensional explorations on the application of artificial intelligence in safety and emergency management within the power industry. For instance, Bajwa (2025) systematically reviewed the application of AI-driven emergency response systems in the safety of smart power infrastructure, covering technical pathways across multiple scenarios such as disaster prediction and real-time event detection [7]. Gao and Zeng (2019) proposed an intelligent electrical safety management system based on BP neural networks, aiming to improve early warning accuracy through multi-dimensional parameter evaluation [1]. Doherty and Esmaeili (2020) explored the practice of using technologies like machine learning and computer vision in electrical risk assessment and compliance analysis [8]. Chen et al. (2024) integrated a CNN and RNN to construct a power grid operation and maintenance, as well as fault prediction, system, enabling real-time monitoring and early warnings of equipment status [9]. Wang et al. (2024) designed an intelligent monitoring model for power systems based on artificial neural networks, significantly enhancing fault prediction accuracy and system adaptability [2]. Zhang (2024) developed an intelligent monitoring and early warning system for power safety based on a CNN, which demonstrated high accuracy in anomaly detection and risk early warning [10]. These studies have laid a theoretical and methodological foundation for the technical application of AI in the field of power safety, but they mostly focus on technical frameworks or optimization of single algorithms.

This paper focuses on specific application scenarios of large AI models in power safety and emergency management, presenting practical implementation pathways and performance data of technical deployment through rich examples. It can provide reusable practical references for peers when deploying AI technologies in actual operations, filling the gap in scenario-based and instantiated presentations in existing studies. The core objective is to clarify the application boundaries and implementation paths of large AI models in power safety and emergency management through the complete logic of “function decomposition-adaptation analysis-scenario verification”. It aims to provide replicable technical solutions for the intelligent upgrading of power enterprises and promote the transformation of the industry from “experience-driven management” to “intelligence-driven safety”.

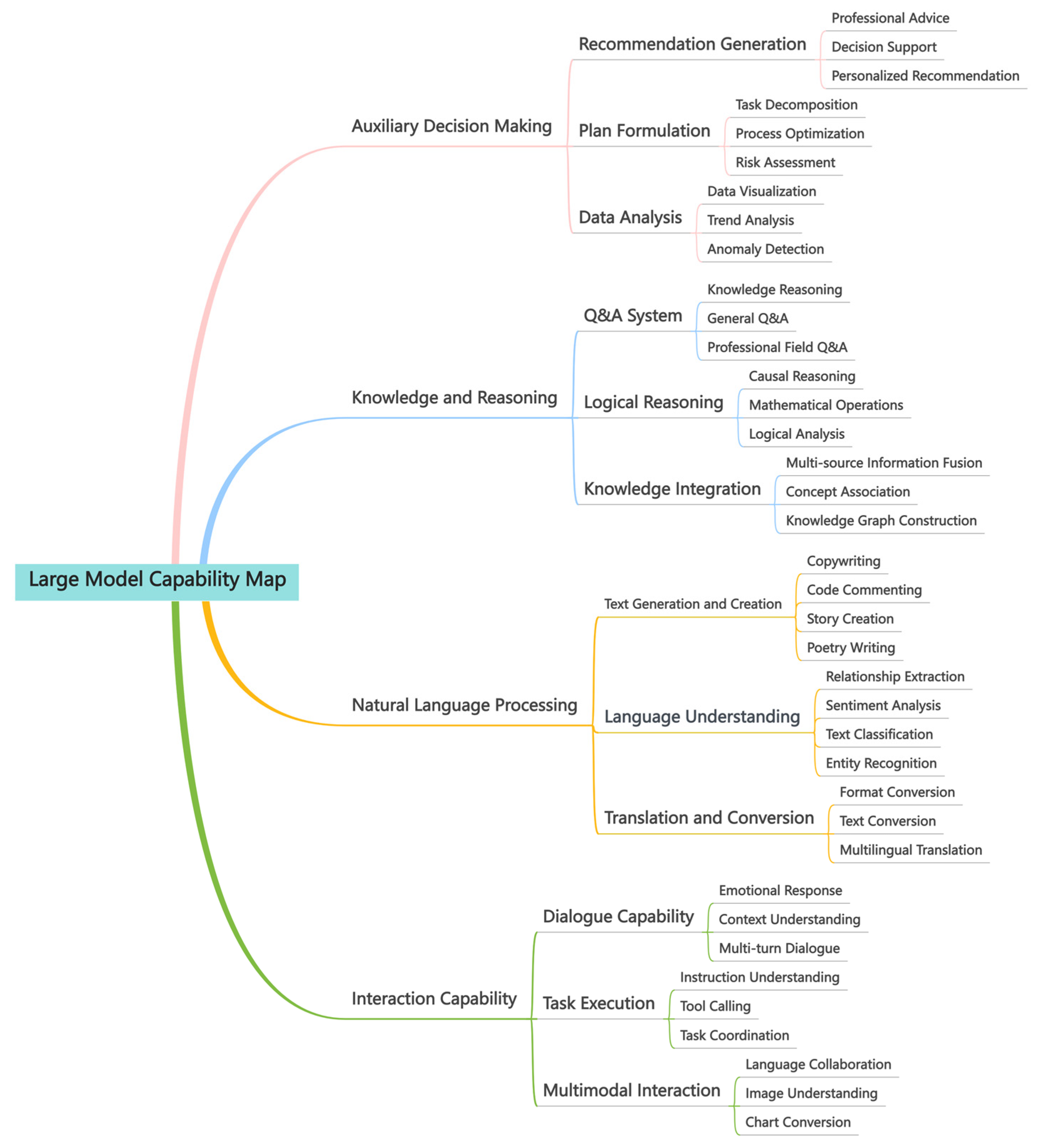

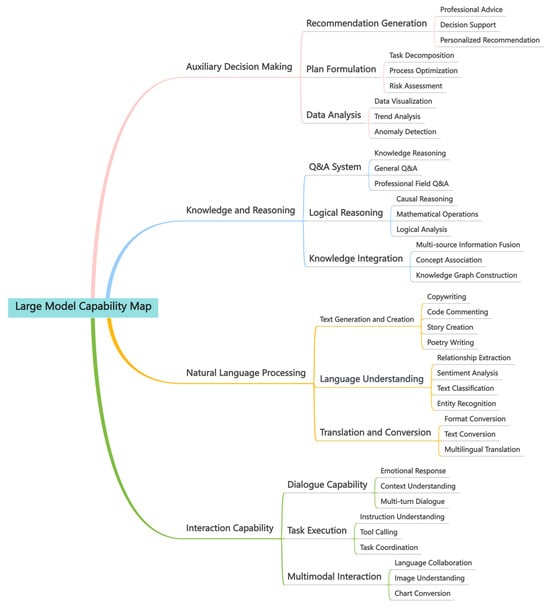

2. The Core Capabilities of Large AI Models and Their Points of Fit

Artificial intelligence (AI) technology is a scientific and technological discipline based on computer science, mathematics, physics, and other subjects. It simulates human intelligence through the study of methods such as data collection, processing, and analysis [2]. Large AI models refer to general-purpose artificial intelligence systems trained on massive datasets and characterized by ultra-large parameter scales (typically ranging from billions to trillions). Their core paradigm employs a pre-training and fine-tuning methodology, as follows: initial self-supervised learning on extensive unlabeled, domain-agnostic data (e.g., text, image, and multimodal) to acquire foundational knowledge, followed by task-specific adaptation via fine-tuning or prompt engineering. Built on complex architectures like Transformers, these models exhibit emergent capabilities absent in traditional AI systems—such as zero-shot reasoning, cross-domain generalization, and complex task execution. As shown in Figure 1, the capabilities of large AI models can be deconstructed into the following four dimensions: natural language processing (NLP), knowledge and reasoning, interactive capability, and auxiliary decision making.

Figure 1.

Large AI model capability map.

2.1. NLP: From Textual Chaos to Structured Knowledge

The technical core is designed for the automatic analysis and representation of human language, enabling the rapid execution of complex tasks, such as word sense disambiguation, textual entailment, and semantic role labeling [8].

Potential application scenarios include the following:

- Intelligent parsing of fault reports: Precisely extract equipment entities, operational events, and causal relationships from massive operation and maintenance logs, replacing traditional manual summarization modes to improve the efficiency and accuracy of information extraction. This logic is consistent with the SIGFRID method proposed by Cimino and Deufemia (2025)—which parses event correlations in Internet of Things (IoT) trigger-action rules through large language models (LLMs), constructs scenario interaction graphs to capture causal relationships, and provides a technical reference for the structured extraction of unstructured logs [11].

- Intelligent regulation management: Convert National Standard and plan texts into retrievable knowledge bases to support semantic queries. This is similar to the practice in the medical field by Guo et al. (2024)—integrating medical norms and cases through knowledge graphs to realize the transformation from text to structured knowledge, which provides ideas for cross-scenario reuse of standard texts [12].

- Automatic report generation: Structured output of video violation descriptions and hidden danger rectification reports. This application can draw on the prompt guidance strategy by Li et al. (2024)—driving LLMs to generate structured chest X-ray reports through anatomical region prompts [13]; meanwhile, the AutoRepo framework by Pu et al. (2024) has demonstrated the feasibility of multimodal LLMs combining scenario data to generate construction inspection reports, confirming the adaptability of structured report generation in industrial scenarios [14].

2.2. Knowledge and Reasoning: From Experience Dependence to Causal Deduction

The technical core integrates case-based reasoning [15], knowledge graphs, and mathematical modeling to enable complex system deduction.

Matching scenarios include the following:

- Fault-chain prediction: fusing meteorological and equipment data to deduce cascading fault paths;

- Root-cause tracing of hidden dangers: locating grounding faults based on waveform analysis logic;

- Violation behavior judgment: reasoning about action compliance by associating actions with safety specification databases.

2.3. Interaction Capability: From Unimodal to Multimodal Collaboration

The technical core integrates cross-modal understanding, real-time feedback, and human–machine collaboration to optimize the perception–action loop, enabling seamless integration of sensory inputs and operational responses.

Synergy points include the following:

- Three-dimensional inspection: unmanned aerial vehicle (UAV)-based visual recognition of insulator damage, quadruped inspection robot (robot dog)-based acoustic feature diagnosis of abnormal sounds, and high-position robots for dynamic tracking of safety violations.

- Emergency collaboration: augmented reality (AR) glasses sharing first-person perspectives, experts providing remote annotation guidance, and real-time tunnel personnel positioning with SOS vibration alarms.

2.4. Auxiliary Decision Making: From Passive Response to Proactive Prevention

The technical core integrates solution generation, resource scheduling, and simulation-driven deduction to achieve closed-loop disposal.

Alignment points include the following:

- Dynamic risk visualization: generating risk heat maps by fusing SCADA operational data and meteorological parameters.

- Intelligent plan deduction: three-dimensional simulation of disaster scenarios for optimal disposal solution deduction.

- Resource scheduling optimization: optimizing emergency repair paths through simulation and cross-domain collaboration.

2.5. Full-Scene Applications of Large AI Models of Safety and Emergency Management in the Power Industry

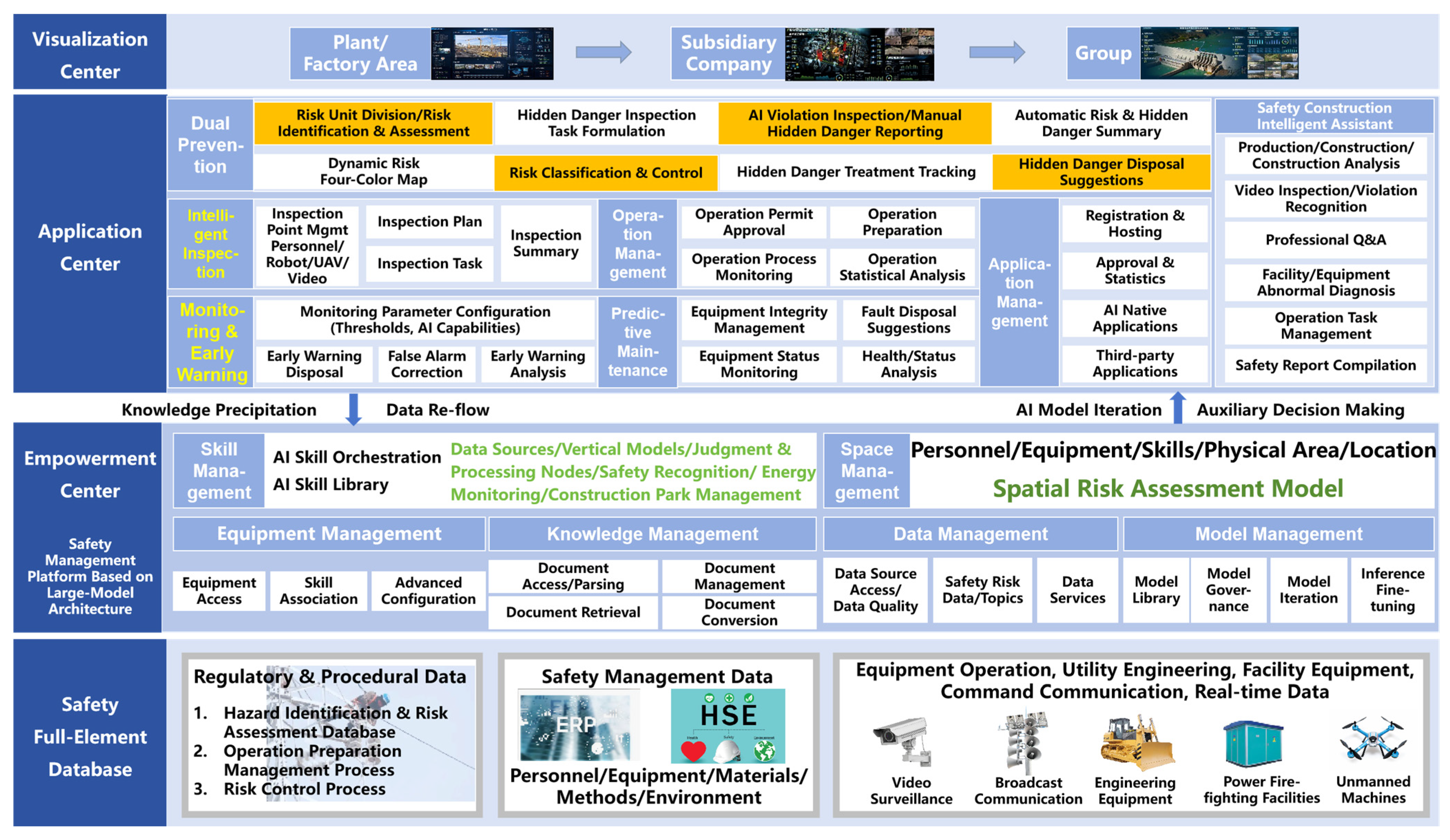

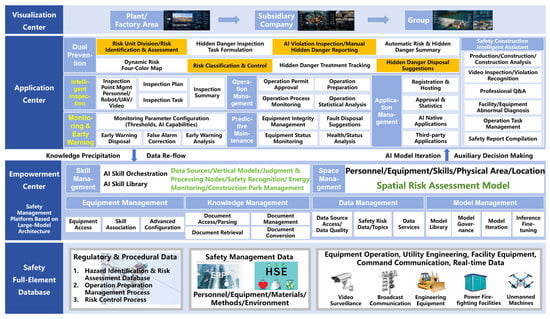

In the field of power safety and emergency management, large AI models have built a full-scene system of “visualization-application-empowerment-data closed-loop” as shown in Figure 2. With the Visualization Center as the perception entrance, the system enables multi-level visual monitoring across stations, subsidiaries, and groups through multimodal interaction technology, converting video images and sensor data into AI-parsable visual information. The Application Center focuses on core businesses functions, including dual prevention mechanisms, intelligent inspection, and monitoring/early warning. It dynamically divides risk units through knowledge reasoning and generates hidden danger investigation tasks using NLP, covering the entire process from risk identification to disposal. The Empowerment Center leverages the large-model safety management architecture to integrate skills, equipment, knowledge, data, and model management. This precipitates frontline operational experience into intelligent decision-making models and promotes cross-system knowledge collaboration with experience reuse. The Safety Full-Factor Database integrates multi-source data (e.g., system regulations, equipment operations, and environmental parameters), providing structured data support for core AI functions such as NLP and knowledge reasoning while constructing the underlying “data fuel library” for system operations.

Figure 2.

Full-scene application of large AI models in safety and emergency management.

The full-scene system delivers the following three core values through module collaboration:

- Experience Crystallization: The Empowerment Center addresses the industry pain point of “knowledge scattered in documents and experience trapped with individuals”. It converts operational specifications and fault disposal processes into reusable intelligent models and knowledge bases, enabling new employees to rapidly master key skills through semantic retrieval and case reasoning;

- Cross-System Efficiency Enhancement: The Application and the Visualization Centers integrate multi-system data (e.g., equipment monitoring, video surveillance, emergency communication, UAV inspection images, and broadcast instructions). The AI reasoning models output risk disposal schemes within seconds, replacing the traditional inefficient mode of “manual cross-system information piecing and scheme compilation” and achieving seamless “perception–decision–disposal” linkage;

- Intelligent Data Analysis & AI-Assisted Decision Making: Leveraging the Safety Full-Factor Database, it synthesizes meteorological, equipment, and regulation data, deduces cascading fault paths through knowledge reasoning, and locates the root causes of hidden dangers (e.g., logical tracing of grounding faults) via multimodal interaction. This drives the shift in power safety management from “experience-driven” to “data and model dual-driven” approaches.

The realization of these values stems from deep coupling of core AI capabilities—NLP, knowledge reasoning, and multimodal interaction—across the full-scene system. This enables power safety and emergency management to evolve from “single-point intelligence” to “systematic intelligent prevention and control”, providing a replicable paradigm for industry-wide intelligent upgrading.

3. Typical Application Scenarios and Cases

The typical application scenarios and cases in this study are all derived from actually implemented projects in the field of AI safety and emergency management in the power industry in recent years. They are selected from dozens of candidate cases through goal-oriented systematic screening—including cases that cover five core scenarios, involve diverse AI technologies, have complete data, and are industry-representative, while excluding unimplemented cases, those with missing data, weakly relevant cases, or cases with untraceable data—to ensure representativeness and reliability.

3.1. Intelligent Safety Monitoring and Inspection

In intelligent safety monitoring and inspection, large AI models enable the entire process of “data collection-intelligent analysis-decision execution” through multimodal fusion and deep reasoning. During data collection, they integrate multi-source data (e.g., visual monitoring, sensor perception, and UAV aerial photography), addressing traditional inspection pain points of information fragmentation and format inconsistency. In intelligent analysis, leveraging computer vision models and knowledge reasoning algorithms, they precisely identify personnel behaviors, environmental conditions, and equipment defects while conducting risk assessments. For decision execution, they coordinate intelligent devices to generate dynamic inspection tasks, achieving full-process automation of “anomaly auto-detection-intelligent task dispatching-closed-loop result feedback”.

The core value delivers breakthroughs in manual inspection efficiency bottlenecks and subjective limitations. Collaborative “AI + intelligent equipment” enables early risk detection and disposal, significantly enhancing monitoring coverage and inspection accuracy.

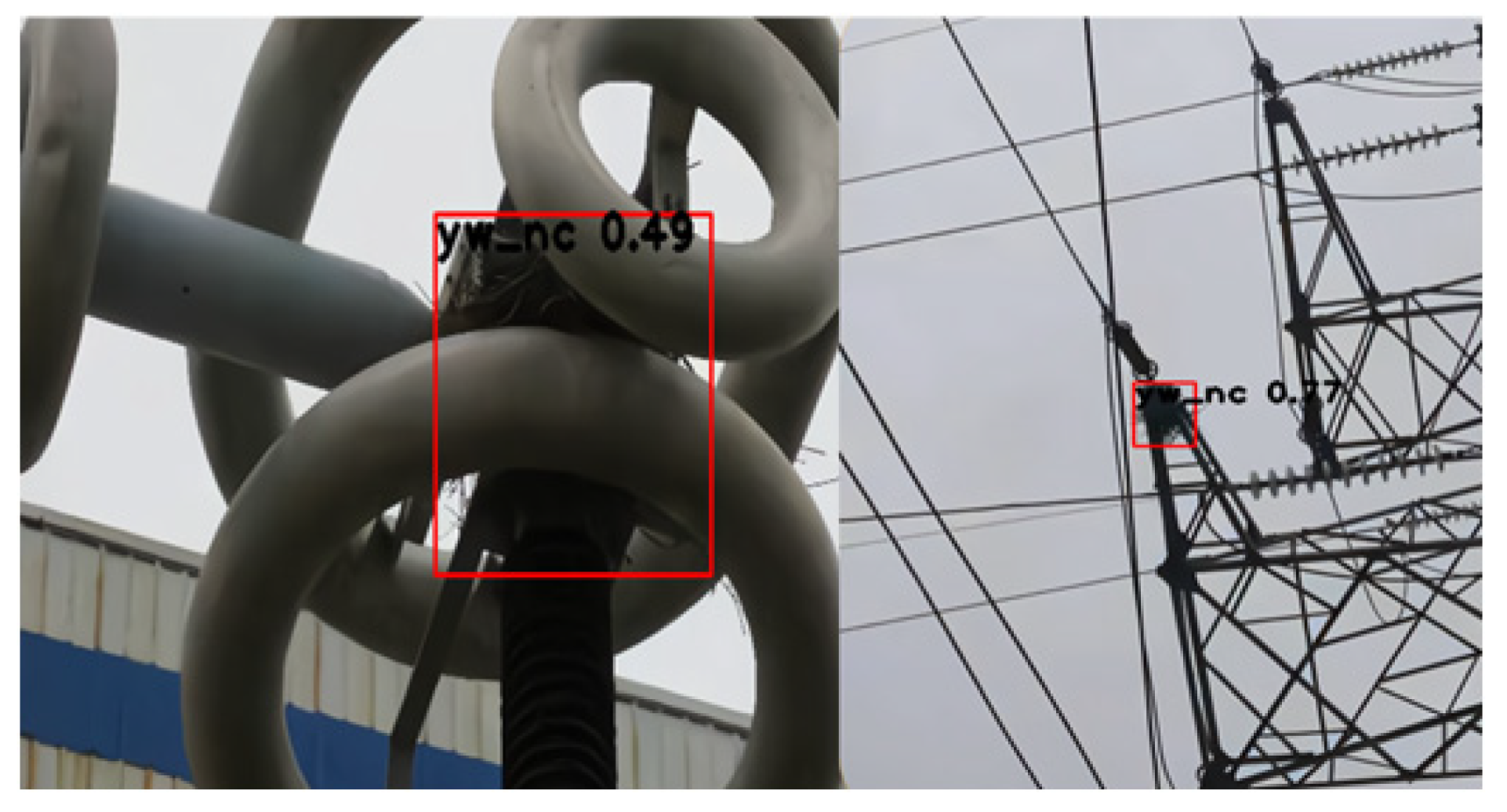

3.1.1. Basic Safety Supervision Algorithms

In power production scenarios, safety accidents may be caused by personnel’s irregular operations, environmental hazards, or equipment failures. The basic safety supervision algorithm system focuses on the three core dimensions—personnel, environment, and equipment—and establishes an all-scenario monitoring network through computer vision and state-sensing technologies. Leveraging pose recognition and semantic understanding capabilities of computer vision models, it accurately identifies non-compliant behaviors such as failure to wear safety gear and unauthorized entry into restricted areas, resolving traditional monitoring limitations of “manual dependency and high missed detection rates”. By correlating sensor data (e.g., temperature, humidity, and gas concentration) with video analytics, multimodal models infer potential impacts of extreme weather or environmental anomalies on equipment. Specific algorithm functions are shown in Table 1.

Table 1.

Basic safety supervision algorithm functions.

Moreover, image segmentation and feature extraction algorithms detect equipment surface defects and operational abnormalities, enabling a shift from “passive maintenance” to “proactive early warning” and fortifying safety defenses.

3.1.2. Mobile End Applications

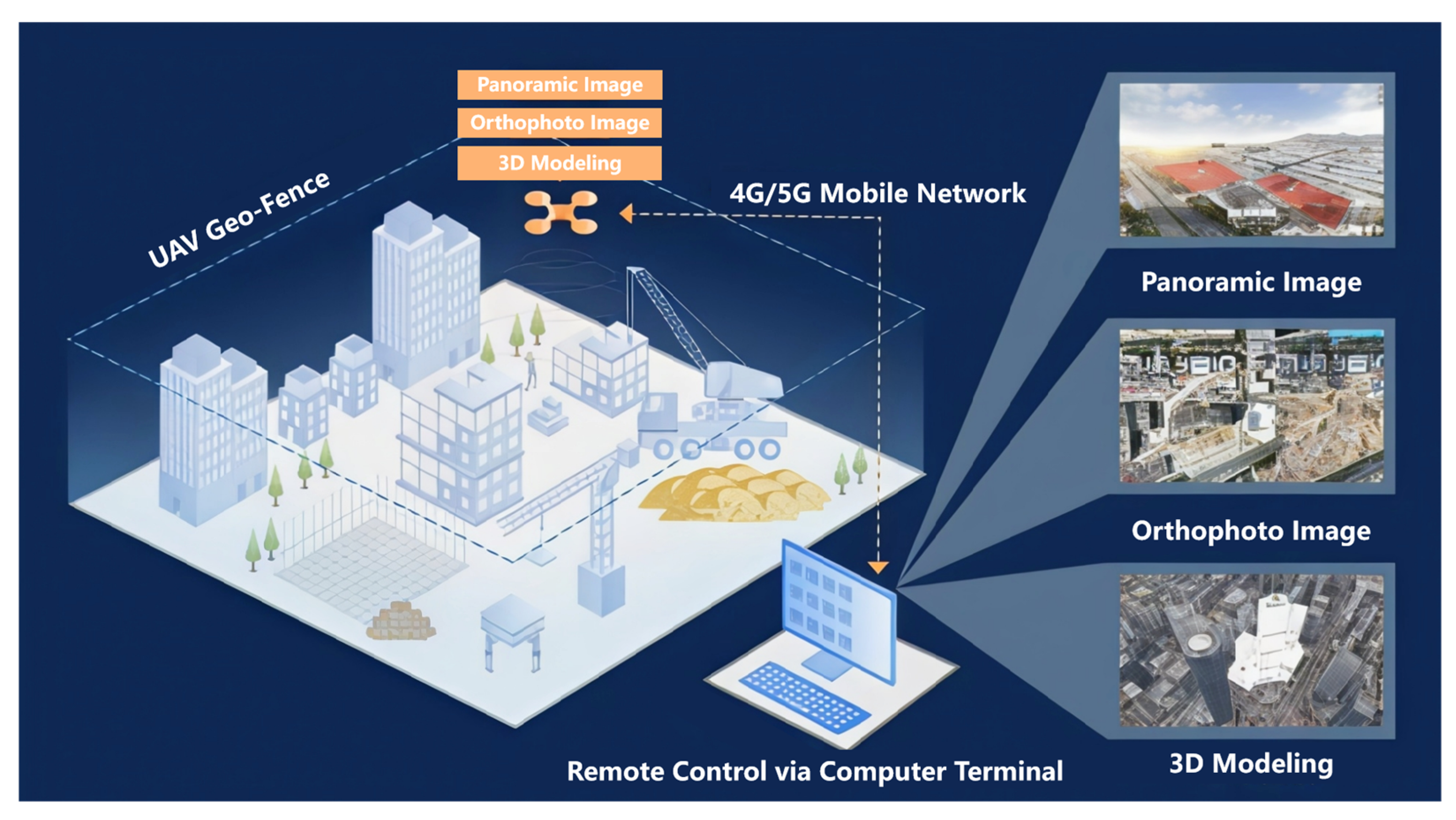

As inspection equipment for different scenarios, UAVs, robot dogs, and AR glasses serve as critical mobile platforms for implementing basic safety supervision algorithms. They achieve full-scenario coverage through “enhanced hardware capabilities + algorithmic empowerment”.

The UAVs developed by the authors’ team have been deployed in practical applications, enabling real-time data transmission via 4G/5G networks and ensuring inspection path compliance using geofencing algorithms (Figure 3). Focusing on five core scenarios—project progress management, safety supervision, green construction, preliminary planning, and O&M detection—they directly integrate AI analytics into engineering management workflows. This advances inspections from “data collection” to “decision support”, substantially improving the per-project inspection efficiency compared to traditional manual approaches.

Figure 3.

Schematic diagram of UAV inspection technology.

When integrated with a large AI model, a robot dog can perform real-time tracking to ensure comprehensive inspections. It detects subtle abnormalities barely noticeable to the human eye, such as tunnel wall cracks or moisture ingress identified via thermal imaging. During tunnel emergencies, it acts as a first responder for situational assessment and real-time updates. For example, in a 40 km underground power cable tunnel, the “SPock” robot dog handles inspections [16]. This application saves the group more than 480 h of manual inspection time annually, enhancing power tunnel safety.

AR smart glasses leverage embedded AI recognition to rapidly detect equipment parameters (e.g., angular alignment, surface wear, belt damage). Their built-in cameras record first-person perspective videos for post-inspection wear analysis. After accessing enterprise knowledge bases, employees query equipment history via voice commands and initiate remote expert assistance when needed. At one utility, technicians use AR glasses for equipment inspections [17], which has significantly improved inspection accuracy, optimized maintenance cycles through real-time analytics, and ensured grid reliability.

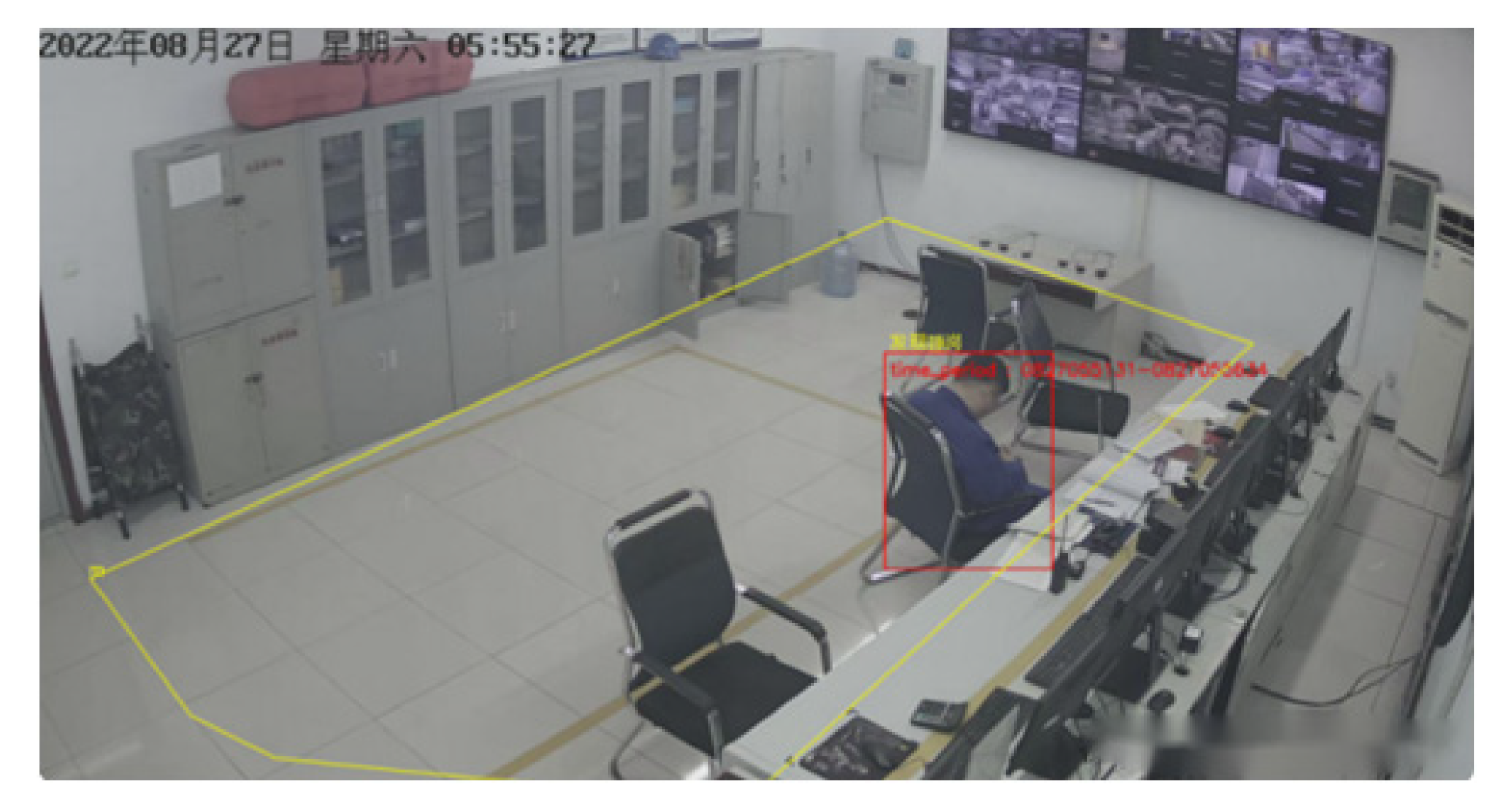

3.1.3. Fixed End Applications

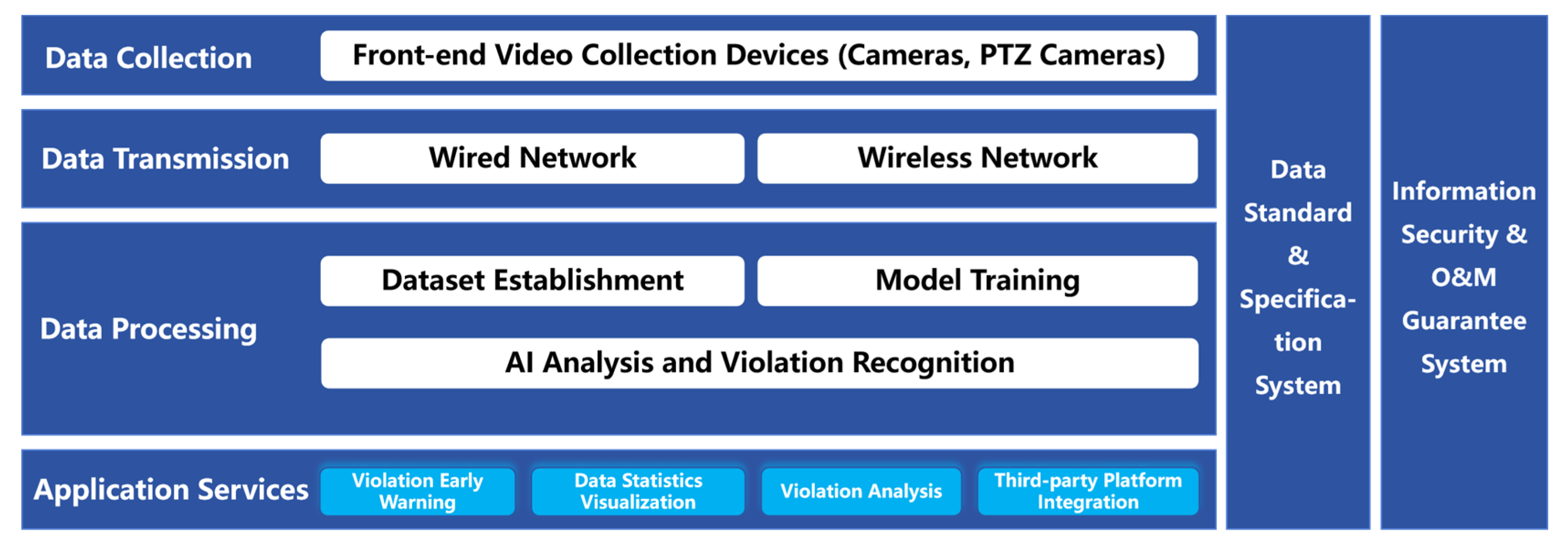

High-altitude inspection robots, developed by the authors’ team and already applied in practical applications, leverage 44× optical zoom and 200 m coverage capabilities while integrating computer vision algorithms for millisecond-level tracking of personnel movements and equipment anomalies. Equipped with core safety supervision algorithms, they enable real-time monitoring of personnel, devices, and environmental compliance throughout operations, ensuring protocol adherence and safety. Cloud-based AI platforms conduct real-time data analysis, automatically generating structured reports with risk levels and defect locations, significantly reducing manual processing time.

The video surveillance assistant’s architecture (Figure 4), developed by the authors’ team and currently in the pilot operation phase, employs visual automation to replace manual video inspection. Its per-frame analytics enable precise key information extraction, significantly increasing inspection accuracy. The embedded behavior recognition module supports surveillance video parsing, image recognition, scene semantics understanding, and regional feature description. An API-driven messaging system pushes AI-identified violations and scenario analyses to relevant safety units, establishing process-driven closed-loop management. Spanning intelligent analysis to actionable outputs, this system builds an efficient safety supervision framework.

Figure 4.

System architecture diagram of an intelligent screen patrol assistant.

3.2. Risk Assessment and Predictive Early Warning

Large AI models enable power systems to respond to diverse risks through end-to-end support, as follows: multi-source data fusion → intelligent modeling → dynamic early warning. During data fusion, they eliminate traditional reliance on singular data sources by integrating meteorological, operational, topological, and historical fault data, mitigating information-isolated assessments. For intelligent modeling, deep learning and knowledge reasoning build scenario-adapted risk models—quantifying extreme weather impacts (e.g., convective hazard impact models) and deducing cascading risks from topology changes (e.g., intelligent brain system). At dynamic warning, results convert to scenario-based outputs—regional risk heatmaps (e.g., township-level storm alerts) or precision field notifications (e.g., real-time defect identification)—linked to auxiliary tools for rapid response.

The core value lies in scenario adaptability: for extreme weather, equipment failures, and grid risks, it delivers custom assessment-warning protocols, advancing risk control from “one-size-fits-all” to “scenario-precision” and “passive reaction” to “proactive prediction”, establishing multidimensional proactive safeguards for grid stability.

3.2.1. “FuXi” Severe-Convective-Weather Large Model

Large AI models enhance early warning systems, improve disaster response, and optimize resource allocation [18]. A power utility deployed the FuXi model to fortify grid resilience against extreme weather [19,20]. Operational since 8 May 2025, it generates hourly forecasts and provides 3 h ultra-short-term predictions at 10 min intervals plus 24 h outlooks. The model was deployed on 8 May 2025, and can achieve forecast updates once every hour. Before severe convective weather, it can provide ultra-short-term forecasts at 10 min intervals for the next 3 h and hourly forecasts for the next 24 h. Its operational efficiency is over a thousand times higher than that of the European Medium-Range Weather Forecasts Center, and it can complete a complete forecast for the next 24 h within 1 min. Since May 14, a meteorological center has applied this model to monitor and warn against rainstorm and lightning risks for power equipment in key areas, with the scope accurate down to the township level. It has issued warnings for 9 substations and 19 transmission lines, with a prediction time deviation of only 1 h. The model is trained based on over 700 million bytes of data, combines equipment disaster-bearing characteristics to achieve graded warnings, and optimizes the prediction accuracy of key indicators, providing a precise basis for disaster prevention and mitigation deployment.

3.2.2. Dual-Control AI Assistant—On-Site Risk Photo Recognition

The Dual-Control AI Assistant, developed by the author’s team and currently in the pilot operation phase, has built a risk prevention system featuring “multi-level architecture + intelligent identification”, providing efficient on-site risk management support. Architecturally, the foundation layer integrates personnel, management, equipment, and environmental data with multi-source information (images/videos, sensor data, historical records, and enterprise/industry databases), establishing a robust database for upper-layer applications. The model layer deploys NLP, computer vision, and multimodal models, leveraging their advanced analytical capabilities for precise risk identification. The capability layer enhances risk assessment through behavior analysis models, domain-specific models, and autonomous agents.

In practice, it enables “instant risk identification via photo capture”. Operators simply photograph risk points, and AI image recognition instantly delivers results. Model-capability layer collaboration automatically matches risk descriptions, hazard databases, and control measures while generating inspection checklists. The application layer’s integrated risk database makes inspections process-driven and checklist-based, enabling rapid risk-mitigation alignment. This streamlines on-site risk management, improves safety efficiency, and embeds risk identification/disposal into every operational workflow.

3.2.3. “LightEngine” Intelligent Large Model

Launched by a utility on 6 May 2025, LightEngine focuses on power system risk control to ensure grid stability [21]. It pioneers a “large-model-driven + small-model-collaborative” architecture: specialized models process grid data (topology and equipment parameters), while the core AI model leverages deep learning to detect and analyze latent grid risks.

Operationally, LightEngine excels in risk assessment. During Jiangyi Substation’s #1 transformer maintenance, dispatchers queried the following: “Analyze grid risks post-maintenance”. Within 5 s, it deduced post-maintenance topology, assessed power-flow/voltage impacts, generated risk reports predicting outage scope, and identified affected critical users, delivering scientific basis for maintenance optimization. And under the pressure of Hangzhou Power Grid’s maximum electricity load exceeding 20 million kilowatts, LightEngine can process all real-time data of the Hangzhou Power Grid in one go, accurately covering over 1800 bus nodes, more than 1400 lines of 35 kV and above, and the real-time status of 20,000 dispatch-managed devices. In April this year, it handled 206 maintenance plans and identified over 60 grid risks. Previously, manual analysis of each risk took an average of 10 min; now, with the “LightEngine” intelligent system generating results in seconds and manual verification taking only 2 min, efficiency has improved by over 80%.

3.2.4. Robot Dog Early Warning System

Hangzhou’s tech parks have deployed an integrated “unmanned vehicle + robot dogs” inspection system. The unmanned vehicle transports the robot to target distribution substations through urban areas. After exiting the vehicle, the robot dog traverses passages, climbs stairs, and enters substations to perform inspections [22].

Its technical advantage lies in deeply integrating computer vision algorithms and AI models, enabling precise identification of equipment indicator status, analysis of infrared thermal imaging and acoustic vibration data, accurate judgment of equipment operation status and hazards, and automatic generation of analysis reports. Via 5G connectivity, it links to grid cloud databases to automatically generate inspection plans, provide real-time risk early warnings, and push disposal plans within seconds, establishing end-to-end “detection–response–disposal” automation.

3.3. Intelligent Fault Diagnosis and Auxiliary Decision Making

This system leverages AI models and multi-technology convergence to establish an end-to-end O&M cycle: data collection → analysis → decision making. Spanning hardware computing power, multimodal data acquisition, and intelligent algorithms to scenario-adapted implementations (fault diagnosis and solution formulation), it transforms heuristic human judgment into data-driven intelligence, establishing intelligent safeguards for grid/station stability.

3.3.1. Waveform-Based Intelligent Fault Identification

This “transient filtering + AI algorithm” technology [23] uses high-precision transient recorders on transmission lines to capture abnormal currents/voltages, forming waveform diagrams. The master station’s AI algorithms then rapidly pinpoint fault locations.

Functioning as a grid diagnostic tool, it enables accurate fault localization, significantly reducing manual inspection ranges while providing key data to staff via simplified graphics/text—eliminating experience-dependent line patrols. In the first half of 2024, it has recorded more than 600,000 waveform files and analyzed nearly 2800 faults of various types. The correct rate of short-circuit fault analysis is 100%, and the correct rate of grounding fault analysis is over 90%.

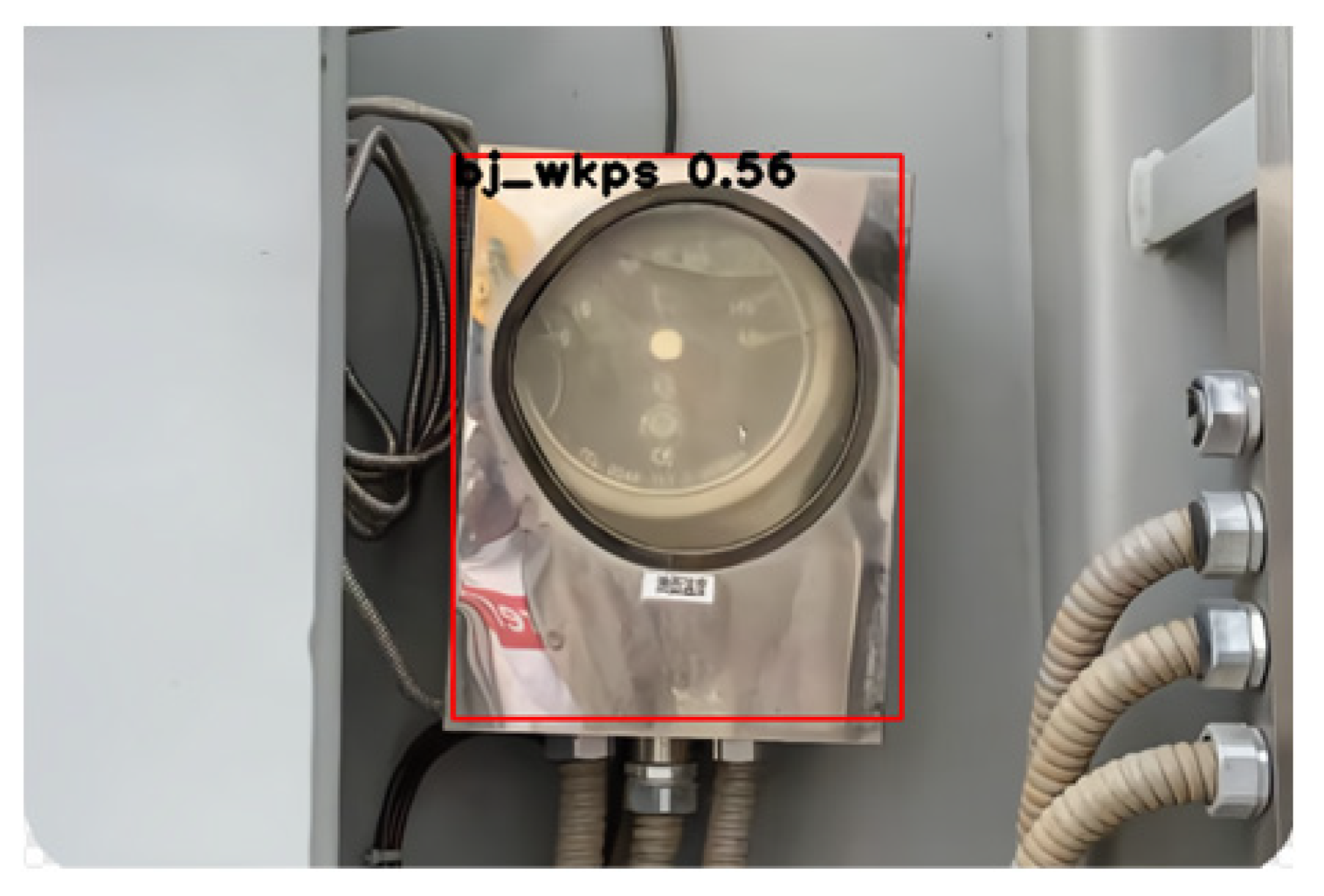

3.3.2. Dashboard-Based Fault Identification

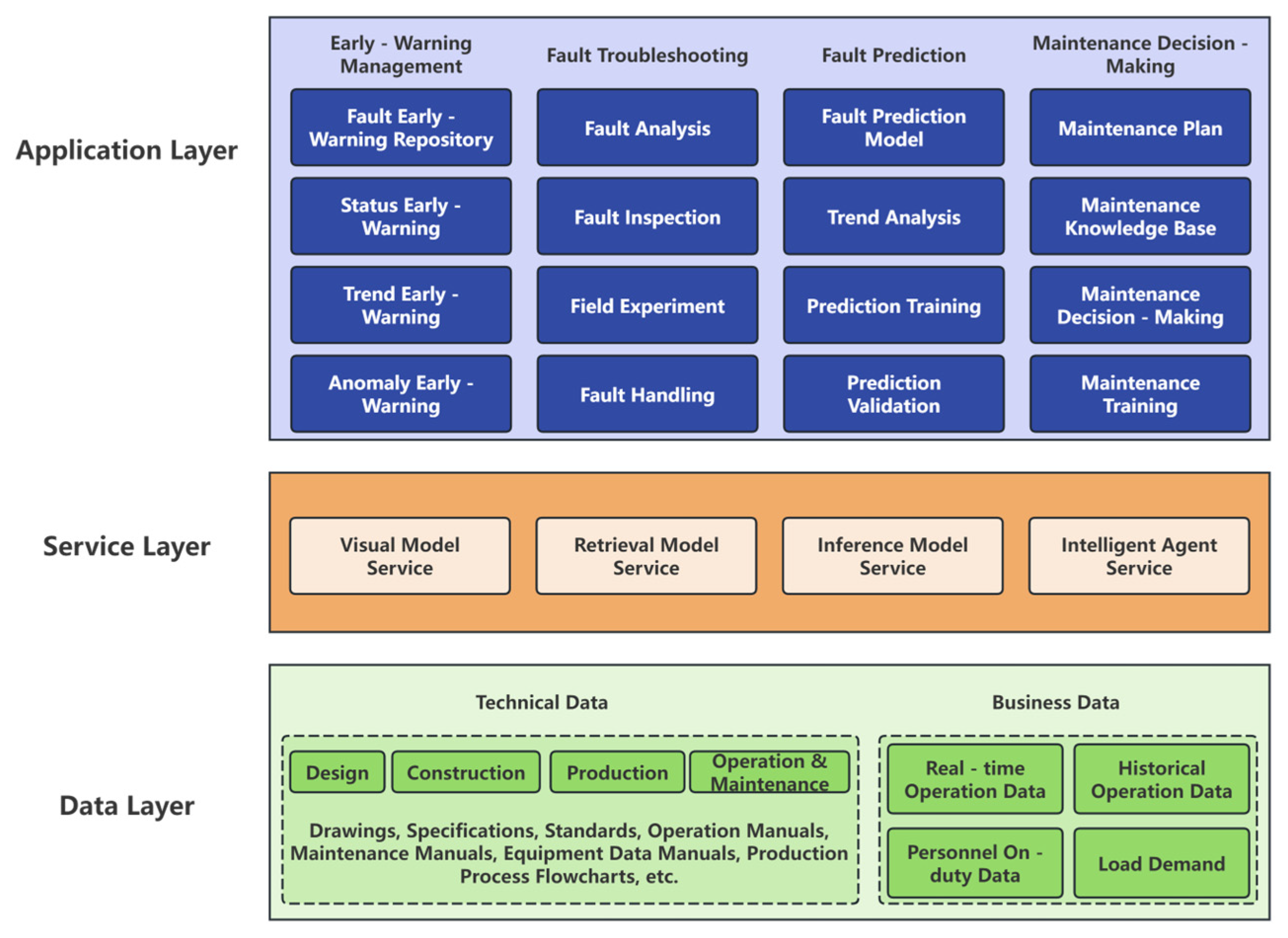

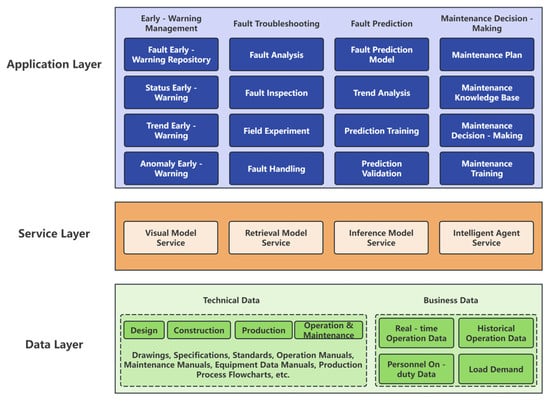

Early detection of critical equipment failures is essential for operational safety and performance [24]. The Fault Diagnosis Assistant, developed by the authors’ team and currently in the pilot operation phase, integrates large AI models, whose system architecture diagram is shown in Figure 5, in a three-tier architecture: (1) the data layer consolidates multi-source technical/operational data, (2) the service layer executes intelligent analysis via vision, retrieval, reasoning, and agent models, and (3) the application layer manages end-to-end fault processes (identification, prediction, and maintenance guidance), reducing unscheduled outages and ensuring station stability.

Figure 5.

System architecture diagram of a fault troubleshooting assistant.

Technicians photograph instrument fault codes via mobile interface. The service layer then activates visual recognition, performs retrieval matching, and conducts reasoning analysis, locating faults within seconds. Coupled with predictive maintenance, it advances from “reactive fixing” to “proactive prevention + AI-driven decisions”, enabling intelligent power station O&M.

3.3.3. Intelligent Substation O&M System

AI diagnostic models drive efficient substation O&M. At a 500 kV substation, an integrated AI system builds intelligent diagnosis-to-decision loops, transforming O&M models.

Following the “data-transmission-analysis-application” pipeline, it embeds AI for the following: (1) data acquisition by sensors, cameras, and robots collect equipment/environmental parameters for model training; (2) real-time data transmission by 5G/fiber optics; (3) machine/deep learning models [25] functioning as diagnostic engines—detecting explicit defects (e.g., oil leaks) via computer vision and predicting failures through data mining; and (4) IoT integration fueling model development [26].

For diagnosis, the models enable multi-device collaboration (e.g., “big-eyed cute” robots, 5G UAVs, and cameras work in linkage and parse data in real time, generating reports and identifying abnormalities). A 3D inspection network formed by “HD PTZ + track robots + outdoor inspection robots”, combined with “Beidou positioning + 3D modeling”, integrates multi-dimensional data to issue real-time warnings for equipment abnormalities and personnel violations, intercepting hidden dangers early.

For decision support, the models generate O&M reports/equipment analyses and optimize maintenance scheduling/resource allocation. Defect detection rates tripled and inspection efficiency quadrupled compared to manual methods. It has transformed substation operation and maintenance from “manual experience-based decision-making” to “AI-driven intelligent decision-making”, setting a benchmark for power grid operation and maintenance intellectualization.

3.4. Emergency Command and Collaborative Communication

In the field of emergency command and collaborative communication, large AI models have reshaped traditional emergency response models through full-link empowerment of “information fusion—intelligent decision-making—collaborative execution”. Relying on multimodal perception technology, they integrate multi-source data, such as voice, video, and text, break down information silos, and realize real-time information interaction between the command layer and the execution layer. For example, they can automatically extract key information from cross-departmental meetings to generate decision maps, and synchronize on-site situations to the command center, ensuring that all participants obtain accurate situation awareness. At the same time, based on trillion-parameter models that correlate historical cases with real-time data, emergency disposal plans can be generated within seconds.

Large AI models further promote collaborative execution toward intelligence, by means of a real-time collaborative reasoning engine. They integrate cross-departmental data streams, generate dynamic strategies, and improve the efficiency of cross-departmental linkage. Combined with converged communication technology, they dynamically monitor the status of rescue resources, achieve precise scheduling, and ensure the efficient implementation of instructions. This full-process intelligence from information interaction to decision execution has promoted emergency management from scattered response to integrated collaboration, building a solid emergency defense line for the safe and stable operation of the power grid.

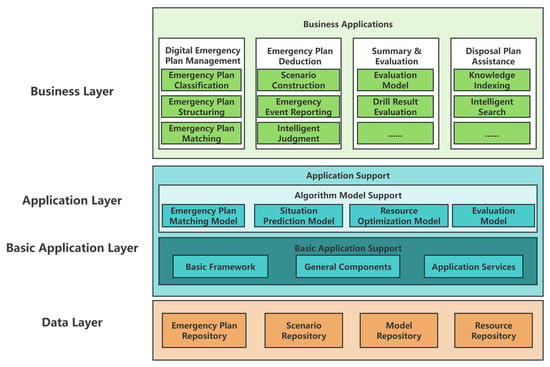

3.4.1. Emergency Plan Preparation System

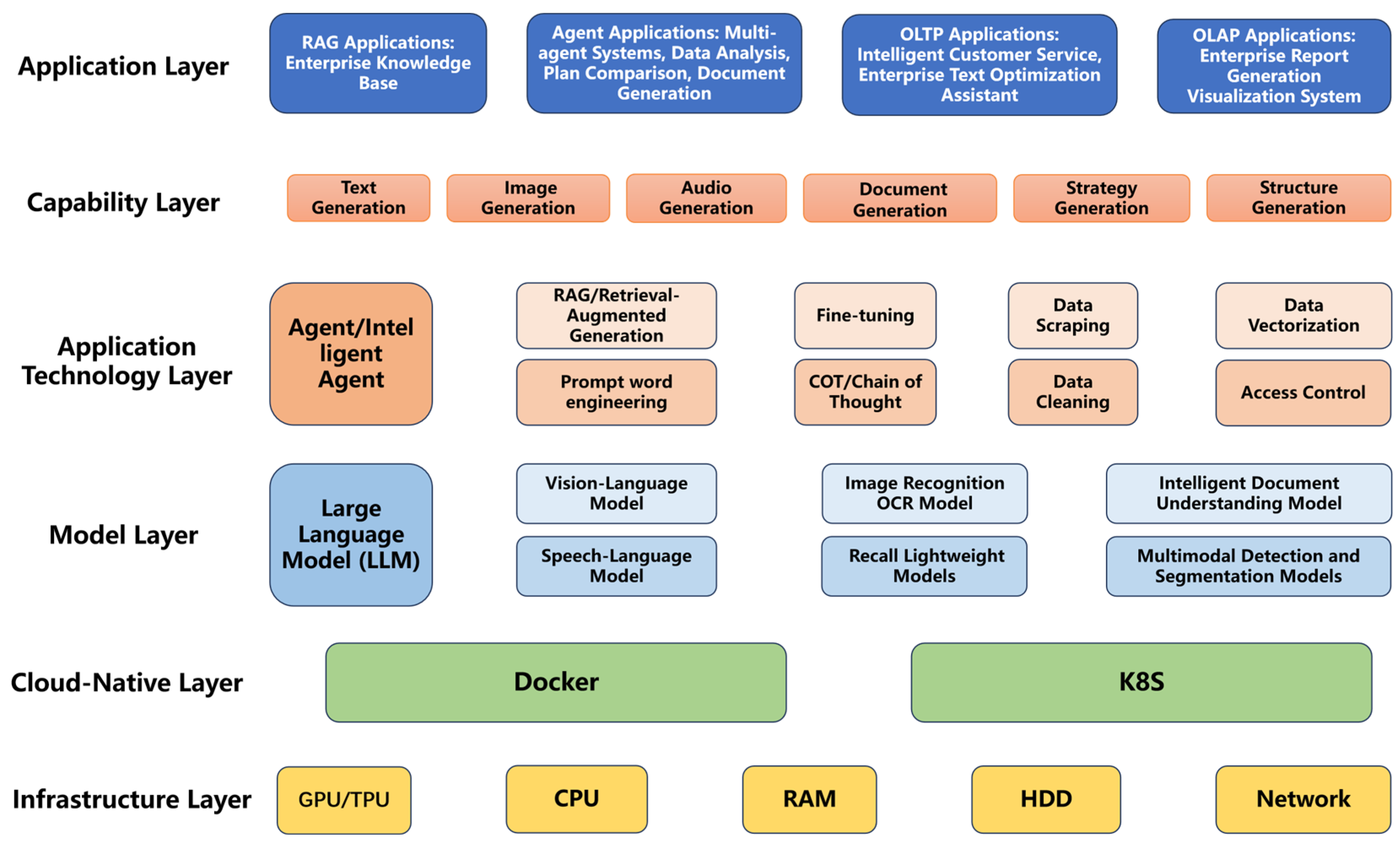

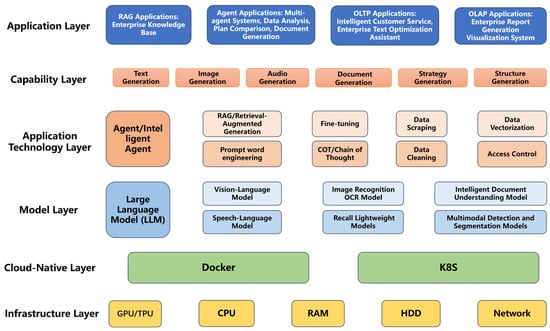

In the power generation industry, efficiently and accurately formulating emergency plans is crucial for responding to emergencies and ensuring production safety. An emergency plan formulation system, developed by the author’s team and currently in the pilot operation phase, deeply integrates large AI model technology, building a comprehensive intelligent system from infrastructure to application layers and innovating emergency plan formulation.

As shown in Figure 6, its system architecture includes the following: a hardware-equipped infrastructure layer (GPU/TPU and CPU) for computing support; a cloud-native layer (Docker (https://www.docker.com/, accessed on 15 July 2025) and K8S (https://kubernetes.io/, accessed on 16 July 2025)) ensuring flexibility and scalability; a model layer (LLMs and vision-language models) as the technical foundation; an application technology layer (Agent and RAG) to tap model potential; a capability layer with multimodal generation (text, images, and audio); and an application layer focusing on business scenarios, with emergency plan formulation as a key link.

Figure 6.

System architecture diagram of emergency plan preparation system.

In practice, the system offers significant advantages. The NLP and knowledge integration capabilities of the large AI model automatically retrieve and integrate massive regulatory standards, historical cases, and risk data to quickly generate compliant plan frameworks and content—shortening lengthy formulation cycles and reducing human-induced content deviations. Its dynamic learning and reasoning adjust plan details based on real-time risk data, upgrading plans from “static documents” to “dynamic responses”. Additionally, multimodal generation (text, charts, etc.) combined with intelligent detection verifies plans for compliance, logic, and operability, thereby improving quality. The model also systematically accumulates scattered emergency knowledge to promote reuse and inheritance, continuously enhancing intelligent plan formulation and helping power companies to respond calmly to potential risks and emergencies.

As shown in Table 2, the emergency plan preparation system and other cases mentioned earlier have all achieved significant improvements in efficiency compared with traditional models.

Table 2.

Application effectiveness of large AI models in partial cases.

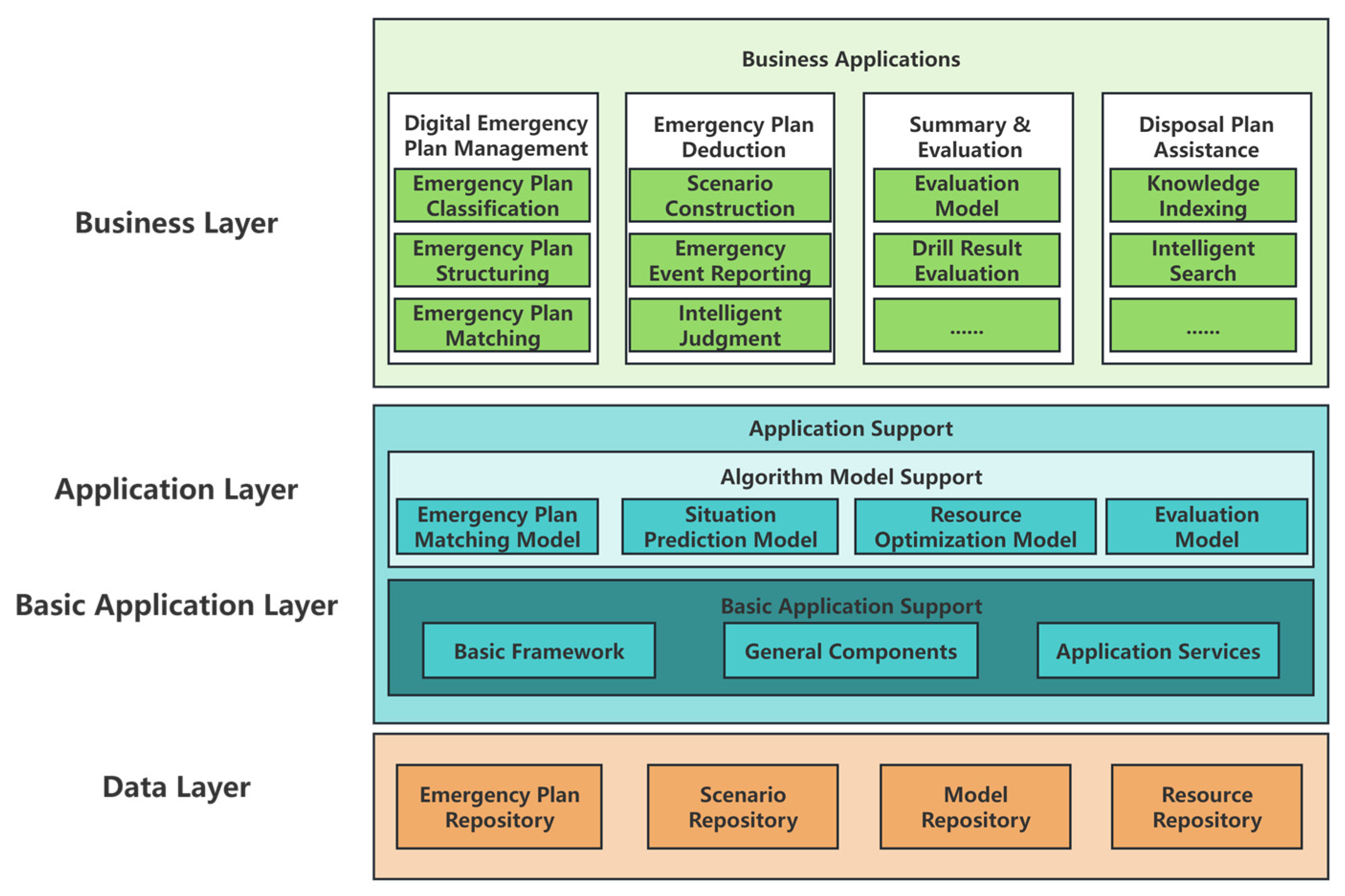

3.4.2. Emergency Plan Drilling System

The emergency plan drilling system illustrated in Figure 7, which is developed by the author’s team and currently in the trial operation phase, constructs a “scenario-response” management model in emergency command and collaborative communication scenarios, forming a closed-loop management of task assignment, execution, tracking, and evaluation. The system supports structured input and storage of drill plans, allows associating plans and selecting drill types when releasing schedules, and issues commands through a unified platform to ensure information synchronization between the command layer and execution layer.

Figure 7.

System architecture diagram of emergency plan drilling system.

This system enhances the real-time performance of collaborative communication, enabling full-process status tracking of drills. In practical exercises, commanders issue commands and provide real-time scoring, with data synchronized to the intelligent platform for cross-level information sharing. The 3D drilling scenario supports multi-user online interaction, simulating real environments to optimize command communication processes.

3.4.3. Intelligent Glasses for Remote Collaboration

The virtual expert system platform integrated into a company’s AI intelligent glasses [27] deeply integrates large AI model technology, building an intelligent collaboration closed loop of “on-site—expert—background”. During daily maintenance, the large model pushes accurate technical materials to inspectors in real time through knowledge retrieval and integration. In case of emergencies, the large model drives machine vision to automatically identify equipment abnormalities (such as instrument values and component status) and quickly matches historical cases. After assisting front-line personnel in initiating video connections, it provides experts with decision support including “problem background + reference solutions”, making remote guidance more targeted.

In practical applications, the large AI model significantly improves collaboration efficiency: when experts give guidance through voice and marking functions, the large model verifies the information matching degree in real time, reducing communication deviations. In the scenario of power grid supervision in mountainous areas, the large model conducts intelligent analysis on the visual content collected by the glasses, predicts risks in advance and synchronizes them in real time to the central control screen, shortening the time for troubleshooting complex faults from several hours to within half an hour. The defect detection rate in the supervision link has been significantly improved, which not only reduces labor costs but also strengthens the safety management and control capabilities of power grids in remote areas.

3.4.4. Intelligent Scheduling

Developed based on Baidu Wenxin large model capabilities, the “China Southern Power Grid Dispatching Duty Assistant” represents an important achievement in AI innovation for the power industry. When facing power system emergencies, dispatching duty officers can generate high-quality disposal plans within seconds by issuing simple commands, timely meeting the 15 min power market adjustment requirements. In the past, dispatching duty officers faced inefficiency and heavy workloads in troubleshooting and resolving power system faults, which has been significantly improved by the emergence of this assistant. During emergency command, it can quickly provide reasonable dispatching strategies, ensure stable and safe power supply, enhance collaborative coordination among departments during emergency response, and improve the emergency response speed of the entire power system [28].

3.5. Knowledge Management and Personnel Training

In knowledge management and personnel training, large AI models and digital technologies are fundamentally overcoming traditional limitations. For knowledge management, it goes beyond simple file storage and classification: using NLP and knowledge graphs, it deeply deconstructs and connects fragmented knowledge from paper manuals, electronic documents, and historical cases to form a dynamically updated intelligent knowledge base. Employees can get accurate information instantly via natural language queries instead of searching through massive materials. The system also automatically captures new practical experiences and updates the knowledge base in real time, enabling continuous accumulation and activation of knowledge assets.

In personnel training, its innovative value is more prominent. Traditional training struggles to realistically simulate high-risk or high-cost scenarios (e.g., live-line operations and complex equipment disassembly), leaving employees to learn indirectly from books or videos. By contrast, large AI models, combined with the Metaverse and AR, build highly simulated virtual training scenarios for immersive practice. Its intelligent Q&A function breaks time and space constraints: employees can query professional knowledge during work intervals and get immediate guidance for on-site operations, effectively achieving “learning by doing”. This transforms knowledge from “passive reception” to “active application” and training from “one-time teaching” to “regular empowerment”, addressing potential risks and cost issues in practical training while providing efficient, sustainable support for talent development and knowledge inheritance in the power industry.

3.5.1. Personnel Immersive Training

The “Mindian Yunchuang” platform constructs scenarios of “metaverse + substation operation and maintenance operations”, applying new terminals and digital twin technologies to overlay operation tickets, 3D equipment models, historical defect databases, and other information onto the operation site as holographic images [29]. During switching operations and equipment inspection, on-site workers achieve intelligent guidance through AR holographic image marking and smart-assistant prompts. It also establishes a “metaverse + training” scenario, integrating metaverse virtual space, digital twin technology, and AI smart assistants with the entire training process to enable immersive training in the metaverse.

The platform’s application has significantly improved operational efficiency, reduced operational risks, and mitigated practical teaching problems such as conducting high-risk live operations and replicating complex tasks in training.

3.5.2. Intelligent Knowledge Q&A

The Dual-Control AI Assistant, developed by the authors’ team, builds a centralized dynamic knowledge repository integrating risk identification databases, laws, and other multi-dimensional safety knowledge. Employees retrieve accurate information via a mini-program, while the system digitally stores practical risk identification experience to continuously enrich enterprise knowledge assets. For training, it supports micro-learning: employees query professional knowledge during work breaks via the mini-program and combine on-site risk images to get real-time risk descriptions and handling measures, effectively enabling “learning by doing”. The automatically generated risk identification reports deliver targeted guidance for employees and references for training, enhancing professional literacy and risk handling capabilities while promoting coordinated improvement of safe production and personnel skills.

The Dongfang Dianwen Large Model, built by locally deploying the latest DeepSeek model and integrating document processing interfaces [30], covers a spectrum of needs from basic knowledge queries to complex document Q&A without leaking data. Supported by NLP, it serves as an enterprise one-stop knowledge platform: employees retrieve power expertise (e.g., grid operation principles) in daily language (e.g., “What steps should dispatchers pre-check to ensure dispatching safety?”). In training scenarios, it offers real-time learning assistance with answers, extended links, and case analyses. Its intelligent assessment system generates personalized questions based on learner progress to assess understanding and boost professional abilities.

3.6. Cases Summary

This chapter focuses on the power sector, with five key scenarios as the thread, and vividly illustrates the full-link empowerment logic of large AI models through 18 typical cases listed in Table 3. Such intelligent practices are not unique to China—currently, the global power industry is collectively facing the need for intelligent transformation and upgrading of safety management, and similar explorations have been implemented in many countries: Pacific Gas and Electric Company (PG&E) in Oakland, CA, USA has optimized the operation and maintenance of remote lines through UAV inspections combined with AI image recognition [31]; the UK’s energy network has utilized an AI-driven distributed fault-diagnosis platform to reduce line fault detection time to the minute level, significantly lowering the risk of power outages [32]. Their core logic of “data-driven intelligent decision-making” is highly consistent with the cases in this paper.

Table 3.

Overview of large AI model application cases.

4. Challenges and Future Prospects

4.1. Existing Challenges

From a macro perspective, the challenges faced by the current power industry in the application of large AI models can be divided into two major dimensions, “soft” and “hard”, which jointly constrain the depth and efficiency of intelligent transformation. Beyond this, considerations of risk-related issues are also indispensable.

4.1.1. “Soft” Dimension: Bottlenecks in Computing Power, Algorithms, and Data Collaboration

- Computing Power: Large AI models demand extremely high computing power for training and inference. Real-time applications like power monitoring and emergency decision making further require high-performance hardware for low-latency responses, leading to persistently high costs. Additionally, existing computing resources are dispersed and lack large-scale collaborative scheduling. This often results in insufficient capacity for complex tasks like renewable energy grid integration and multimodal data processing, failing to meet high-density, high-stability demands.

- Algorithm Challenges: There are two core issues. First, model interpretability is insufficient. The “black-box” nature hinders decision logic tracing, reducing trust among dispatch and O&M personnel, who still require manual verification in critical scenarios. Second, specialized vertical large models lag in development. General models lack deep integration with power domain expertise (e.g., relay protection and stability control), leading to suboptimal accuracy and adaptability in scenarios like equipment fault diagnosis and grid simulation.

- Data Challenges: Power data face application limitations despite diverse sources. Strict restrictions on cross-departmental/regional sharing due to security and privacy concerns hinder efficient multi-source data integration, limiting comprehensive training samples for large models. Additionally, uneven data quality—such as labeling errors, noise, and format inconsistencies—directly impacts model training effectiveness and reduces the reliability of functions like fault prediction and status evaluation [33].

4.1.2. “Hard” Dimension: Practical Difficulties in Hardware Equipment and Scenario Adaptation

- Inspection Equipment: AI-integrated inspection tools like robot dogs and UAVs face limitations. Robot dogs lack sufficient endurance in terrains like substations and mountains, hindering long-cycle inspections. UAVs are constrained by battery life and weather, and their data transmission is vulnerable to interruption under strong electromagnetic interference. Both suffer from slow fault identification and feedback, failing to meet real-time monitoring needs.

- Wearable Devices: Devices such as smart glasses encounter the following challenges: inadequate image stabilization during movement, compromising AI identification accuracy for instruments and fault codes; limited battery life, requiring frequent recharging during extended operations and disrupting workflows; and decreased image recognition accuracy in harsh environments (e.g., strong light and oil stains), impairing remote collaboration and real-time guidance efficiency.

4.1.3. Risks Faced by the Widespread Application of Large AI Models in the Power Sector

In high-risk fields such as power safety and emergency management, the application of large AI models is confronted with significant ethical, legal, and social risks. In terms of responsibility attribution, the “black-box” nature of AI decision making leads to blurred responsibility demarcation after faults occur. It is possible to draw on the “multi-level accountability mechanism” proposed by Kaur et al. (2023) [34], clarify the rights and responsibilities of model developers, power enterprises, and regulators, and realize responsibility traceability through the “operation logs—manual review” system. Data bias issues are equally prominent: regional sample imbalance in operation and maintenance logs may result in decision bias. Referring to the “ethical practice—trust transmission” logic by Fakhri et al. (2025) [35], technical measures need to be adopted to expand scarce samples and constrain the model with industry knowledge so as to avoid the accumulation of biases.

In addition, the “hallucination” issue of large models also poses a significant challenge—their generated erroneous outputs may lead to misjudgments in equipment defect diagnosis and inappropriate handling of emergency instructions, triggering serious risks. To address this, prevention and control measures tailored to industry characteristics are required, as follows: constraining model training through a vertical knowledge base covering equipment mechanisms and regulatory standards (e.g., linking to the Regulations on Preventive Tests for Power Equipment); conducting multimodal cross-validation (comparing text outputs with sensing data and physical simulations); setting dynamic confidence thresholds and manual review nodes (triggering secondary verification by senior personnel when the confidence level in high-risk scenarios is below 95%); thus forming a closed loop of “initial model judgment—multi-source verification—human-machine collaboration”.

4.2. Future Outlook—Technical Aspects

4.2.1. Deep Integration of AI with XR and Digital Twin Technologies

The integration of AI and VR is enabling new trends and applications across various fields, including human–computer interaction, education, agriculture, transportation, 3D image reconstruction, and healthcare [36,37]. Within the power industry, the deep integration of AI with XR (extended reality—encompassing VR, AR, and MR) and digital twin technology (digital twins are an emerging digital technology [38]) is building an “immersive management and control ecosystem” for power safety. For instance, digital twins can simulate extreme grid fault scenarios, while AI-driven XR devices provide operation and maintenance personnel with immersive “virtual-real fusion” emergency-response training and practical guidance. This enables more efficient development of complex fault-handling capabilities.

Looking ahead, the deeper convergence of large power models and XR technologies will propel work safety management toward “adaptive learning” and “cross-space collaboration”.

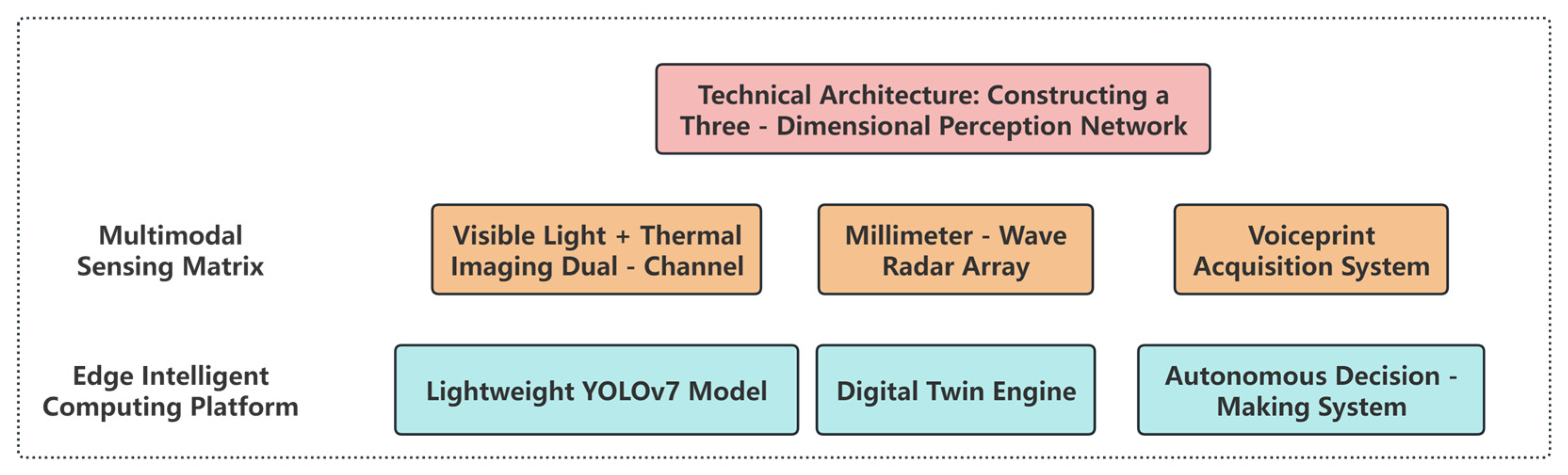

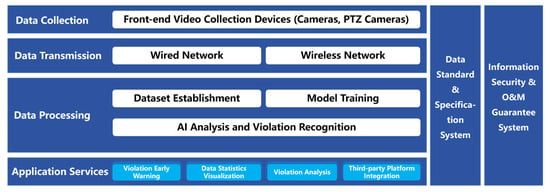

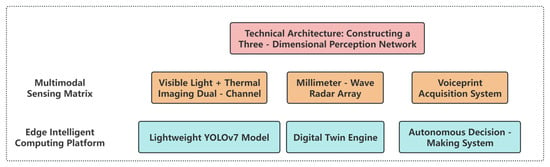

4.2.2. Intelligent Sensing Upgrades—Multimodal Sensing Networks

Multimodal sensing networks integrate multi-source data from vision, acoustic fingerprints, infrared, and other modalities to create a “full-dimensional health monitoring system” for power equipment. For example, low-altitude UAV swarms equipped with multispectral imaging, lidar, and AI edge computing are transforming power equipment inspection across spatial and temporal dimensions [39]. Its system architecture diagram is shown in Figure 8. Pilot data from a provincial power grid shows a 28-fold increase in UAV inspection efficiency compared to manual methods, with the defect recognition accuracy reaching 97.3%. This marks the entry of power operation and maintenance into the “air—ground—space—integrated” intelligent monitoring era.

Figure 8.

System architecture diagram of 3D perception network.

With the integrated application of 5G communication, quantum sensing, and digital twin technologies, next-generation UAV systems will gain autonomous diagnosis and repair capabilities. This “detection—diagnosis—repair” closed-loop system will fundamentally transform power equipment maintenance logic, advancing the energy system toward a self-healing smart grid.

4.2.3. Innovation in Decision-Making Systems—Architectural Innovation of Power-Specific Large Models

A power grid’s “BigWatt-Yudian” intelligent simulation large model [40] pioneered the use of neural networks for solving high-dimensional differential-algebraic equations, breaking through the “curse of dimensionality” bottleneck of traditional simulation tools. This achieved a 1000-fold speed increase with a less than 1.5% error rate. The LLM4OPF framework, proposed by Huang et al. (2023) in their research [41], enables large models to iteratively optimize and output optimal power flow solutions that meet physical constraints through natural language interaction alone, without relying on traditional optimization solvers. In five-machine test cases, its results were highly consistent with those from the Gurobi solver, verifying the feasibility of large models directly participating in core decision making within power systems [41].

Future innovation in power-specific large model architectures will focus on the following two areas: enhanced multi-physics coupling modeling for accurate simulation of complex conditions and improved precision and wider adoption of federated learning architectures to enable joint training among regional grids, integrating causal reasoning to boost prediction accuracy and enhance model generalization ability to effectively address the strong randomness of wind and photovoltaic power generation [42].

4.3. Future Outlook—Computing Power Aspect

Computing power and electricity will converge deeply [43], promoting power balance through source–load interaction, unlocking grid feedback potential via storage-load interaction, enhancing supply reliability with grid-load collaboration, and driving the integration of source—grid—load—storage for deep convergence of computing and electricity. This involves precise supply–demand matching through computing power load scheduling and expanding green power/certificate trading to increase the share of green power applications.

4.4. Future Outlook—Management Aspect

Cross-domain collaborative intelligence is a key management development direction. For example, the “Dian’anxing” model [44] establishes a new emergency management mechanism enabled by transparent government–enterprise data sharing. Future efforts will deepen AI and digital twin integration, extending it to new power scenarios like renewable energy stations and virtual power plants, and create a cross-domain collaborative governance network covering the entire “source–grid–load–storage–usage” chain. This will shift urban safety management from “post-disaster response” to a full-cycle active defense system (“pre-disaster prediction—in-disaster intelligent control—post-disaster optimization”), enhancing social safety resilience and intelligent governance capabilities. Ultimately, it will lay a digital-intelligent foundation for future safety management and open a more efficient, forward-looking security framework.

4.5. Future Outlook—Macro Level

Comprehensive AI security encompasses the following three dimensions: system security, security system, and security impact.

System Security: Focuses on risks and protection for AI algorithms, computing power, and data. Future research will focus on enhancing the algorithmic robustness and interpretability of power AI models, thereby avoiding mis-dispatching issues, mitigating the risk of misoperation caused by the models’ “black-box nature”, and improving the safety and reliability of AI applications in power systems [45]; build dedicated edge-cloud computing architectures to prevent theft; and establish full-life-cycle protection mechanisms for grid data against poisoning or leakage.

Security System: The AI security “ten elements” are safety connotation, safety domain, safety state, safety process, safety factor, safety strategy, safety system, safety capability, safety space–time, and safety participation [46]. Future goals include the following: achieving comprehensive security coverage across power generation to distribution; establishing an emergency mechanism for “normal—transition—abnormal” states; and enhancing multi-party collaboration (government, enterprise, and society) in AI security governance.

Security Impact: Needs to balance AI’s benefits and risks. Future actions will leverage AI’s positive values (e.g., improving emergency efficiency and replacing high-risk operations); and mitigate risks (e.g., misdecision making from algorithm black boxes and technical abuse) through mechanisms like manual review, model interpretability, and attack-defense tests.

5. Conclusions

As the “lifeline” of the national economy, the safe and stable operation of the power industry is crucial to national development and people’s livelihood. From ensuring that cities are lit up, to supporting industrial production and safeguarding people’s basic needs of heating and cooling, power security serves as a core benchmark for the stability of the energy foundation.

This paper focuses on the field of power security and emergency management, analyzing the core capabilities of large AI models and their alignment with this domain. This work systematically categorizes the specific application practices of large AI models in power security and emergency management, introducing 18 specific cases across five application scenarios to demonstrate, from multiple perspectives and in a hierarchical manner, the extensiveness and significance of large AI model applications. These contents comprehensively show how AI technology has permeated the entire process of power security and emergency management.

Subsequently, it dissects challenges across three interrelated dimensions—the Soft dimension (computing power, algorithmic, and data bottlenecks), Hard dimension (limitations in inspection equipment and wearable devices), and Risk dimension (ambiguities in responsibility attribution, data bias accumulation, and model “hallucination” risks)—totaling eight sub-aspects.

For future prospects, it articulates a four-fold framework, as follows: technical advancements (encompassing adaptive learning, cross-space collaboration, intelligent sensing upgrades, and decision-making system innovation), the deep convergence of computing power and electricity, cross-domain collaborative intelligence, and macro-level security imperatives (including system security, security architecture, and safety impact), encompassing nine sub-points in total. The thread of the entire paper can be intuitively shown in Figure 9.

Figure 9.

Summary of application of large AI models in safety and emergency management of the power industry in China.

This paper aims to illustrate, through the presentation of these application cases, how AI technology solves problems in traditional security and emergency management models—such as difficulties in inheriting expert knowledge, challenges in equipment operation and maintenance, low efficiency of manual inspections, slow emergency response, and lagging manual judgment and decision making under extreme weather or complex faults. Furthermore, it extracts that AI technology is driving the upgrading of power security and emergency management from “passive response” to “active intelligent prevention” and looks forward to the continued evolution of AI applications in power industry security and emergency management toward “in-depth technical integration”, “ecological collaborative development”, and “extension of management value”.

Author Contributions

Conceptualization, W.G. and F.Z.; methodology, W.G., F.Z. and J.Z.; validation, J.Z. and F.H.; formal analysis, S.H., F.Z. and J.Z.; investigation, W.G., F.Z. and F.H.; resources, Y.Y. and S.H.; writing—original draft preparation, W.G. and F.H.; writing—review and editing, W.G. and F.H.; supervision, Y.Y., S.H. and F.H.; project administration, W.G. and F.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

We also extend our thanks to the members of our research group. Their lively discussions, hard-working attitudes, and willingness to share knowledge have created a positive and productive research environment.

Conflicts of Interest

Authors Wenxiang Guang, Yin Yuan, Shixin Huang, Fan Zhang, and Jingyi Zhao are employed by the company Hubei Anyuan Safety & Environmental Protection Technology Co., Ltd. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

| AI | Artificial intelligence |

| API | Application programming interface |

| AR | Augmented reality |

| H1 | The first half of the year |

| IoT | Internet of things |

| LLM | Large language model |

| MR | Mixed reality |

| NLP | Natural language processing |

| O&M | Operation and management |

| Q&A | Question and answer |

| RAG | Retrieval augmented generation |

| UAV | Unmanned aerial vehicle |

| VR | Virtual reality |

| XR | Extended reality |

References

- Gao, A.; Zeng, D. A Novel Concept of Artificial Intelligence Utilization in Electrical Safety Intelligent Management System. In Proceedings of the 2019 9th International Conference on Fire Science and Fire Protection Engineering (ICFSFPE), Chengdu, China, 18–20 October 2019; pp. 1–4. [Google Scholar]

- Wang, L.; Weidong, X.; Xiaoxia, L. Intelligent Monitoring and Control of Power Systems Based on Artificial Intelligence Technology. Procedia Comput. Sci. 2024, 247, 963–969. [Google Scholar] [CrossRef]

- Xinhua News Agency, the Central Committee of the Communist Party of China (CPC) and the State Council, Opinions on Fully, Accurately and Comprehensively Implementing the New Development Philosophy to Well Conduct the Work of Carbon Peak and Carbon Neutrality. Available online: https://www.gov.cn/zhengce/2021-10/24/content_5644613.htm (accessed on 31 July 2025). (In Chinese)

- National Energy Administration. Available online: https://www.nea.gov.cn/ (accessed on 2 August 2025). (In Chinese)

- NetEase. Smart Distribution Room Construction Plan. Available online: https://www.163.com/dy/article/JTQNL3OE0556CLTM.html (accessed on 2 August 2025). (In Chinese).

- Ministry of Health of the People’s Republic of China, Science and Education Department. Ophthalmic Examination Methods, 1st ed.; People’s Medical Publishing House: Beijing, China, 1997. (In Chinese) [Google Scholar]

- Bajwa, A. AI-Based emergency response systems: A systematic literature review on smart infrastructure safety. Am. J. Adv. Technol. Eng. Solut. 2025, 1, 174–200. [Google Scholar] [CrossRef]

- Doherty, M.; Esmaeili, B. Application of Artificial Intelligence in Electrical Safety. In Proceedings of the 2020 IEEE IAS Electrical Safety Workshop (ESW), Reno, Nevada, 2–6 March 2020; pp. 1–6. [Google Scholar]

- Chen, Z.; Li, W.; Yin, F.; Deng, X.; Zhou, G.; Pan, W.; Gu, H. Research on Intelligent Power Grid Operation and Maintenance and Fault Prediction System Based on Artificial Intelligence. In Proceedings of the 2024 IEEE 4th International Conference on Electronic Technology, Communication and Information (ICETCI), Changchun, China, 24 May 2024; IEEE: New York, NY, USA, 2024; pp. 1281–1286. [Google Scholar]

- Zhang, F. Intelligent Monitoring and Early Warning System for Electric Power Safety Using Artificial Intelligence Approach. In Proceedings of the 2024 Second International Conference on Data Science and Information System (ICDSIS), Hassan, India, 17 May 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar]

- Cimino, G.; Deufemia, V. SIGFRID: Unsupervised, Platform-Agnostic Interference Detection in IoT Automation Rules. ACM Trans. Internet Things 2025, 6, 1–33. [Google Scholar] [CrossRef]

- Guo, L.; Tahir, A.M.; Zhang, D.; Wang, Z.J.; Ward, R.K. Automatic Medical Report Generation: Methods and Applications. SIP 2024, 13, e24. [Google Scholar] [CrossRef]

- Li, H.; Wang, H.; Sun, X.; He, H.; Feng, J. Prompt-Guided Generation of Structured Chest X-Ray Report Using a Pre-Trained LLM 2024. In Proceedings of the 2024 IEEE International Conference on Multimedia and Expo (ICME), Niagara Falls, ON, Canada, 15–19 July 2024. [Google Scholar]

- Pu, H.; Yang, X.; Li, J.; Guo, R. AutoRepo: A General Framework for Multimodal LLM-Based Automated Construction Reporting. Expert Syst. Appl. 2024, 255, 124601. [Google Scholar] [CrossRef]

- Yu, X.; Xu, C.; Lu, D.; Zhu, Z.; Zhou, Z.; Ye, N.; Mi, C. Design and Application of a Case Analysis System for Handling Power Grid Operational Accidents Based on Case-Based Reasoning. Information 2020, 11, 91. [Google Scholar] [CrossRef]

- In Addition to Becoming a Large Toy, the Robot Dog Realizes the Functions of Inspection, Post-Disaster Rescue and Cultural Tourism Scene—Today’s Headlines. Available online: https://www.toutiao.com/article/7491929615632564790/ (accessed on 30 June 2025). (In Chinese).

- AR Smart Glasses: A Digital Pioneer to Enable UHV Transmission. Available online: https://m.sohu.com/a/753450060_121836361/m.sohu.com/a/753450060_121836361 (accessed on 30 June 2025). (In Chinese).

- Liu, J.; Lee, J.; Zhou, R. Review of Big-Data and AI Application in Typhoon-Related Disaster Risk Early Warning in Typhoon Committee Region. Trop. Cyclone Res. Rev. 2023, 12, 341–353. [Google Scholar] [CrossRef]

- Chen, L.; Zhong, X.; Zhang, F.; Cheng, Y.; Xu, Y.; Qi, Y.; Li, H. FuXi: A Cascade Machine Learning Forecasting System for 15-Day Global Weather Forecast. npj Clim. Atmos. Sci. 2023, 6, 190. [Google Scholar] [CrossRef]

- The ‘Zhejiang-Fuxi’ Meteorological Model Helps the Precise Early Warning of Severe Convective Weather in Zhejiang Power Grid—Today’s Headlines. Available online: https://www.toutiao.com/article/7504982640064348708/ (accessed on 30 June 2025). (In Chinese).

- The “Guangqing” Intelligent Brain Model Has Been Launched, Helping Upgrade the Intelligent Management of Hangzhou Power Grid. Available online: https://baijiahao.baidu.com/s?id=1831461041679702725&wfr=spider&for=pc (accessed on 30 June 2025). (In Chinese).

- The Integrated Inspection System of “Unmanned Vehicle + Machine Dog” Is “on Duty” in Hangzhou. Available online: https://www.hangzhou.gov.cn/art/2025/4/9/art_812269_59111352.html (accessed on 30 June 2025). (In Chinese)

- The Accuracy Rate of Short-Circuit Fault Diagnosis is 100%! This Intelligent AI Assistant Makes Fault Handling in Distribution Networks More Efficient—Today’s Headlines. Available online: https://www.toutiao.com/article/7386220302407172635/ (accessed on 30 June 2025). (In Chinese).

- Sethu, M.; Kotla, B.; Russell, D.; Madadi, M.; Titu, N.A.; Coble, J.B.; Boring, R.L.; Blache, K.; Agarwal, V.; Yadav, V.; et al. Application of Artificial Intelligence in Detection and Mitigation of Human Factor Errors in Nuclear Power Plants: A Review. Nucl. Technol. 2023, 209, 276–294. [Google Scholar] [CrossRef]

- Al-Katheri, A.A.; Al-Ammar, E.A.; Alotaibi, M.A.; Ko, W.; Park, S.; Choi, H.-J. Application of Artificial Intelligence in PV Fault Detection. Sustainability 2022, 14, 13815. [Google Scholar] [CrossRef]

- Hua, H.; Li, Y.; Wang, T.; Dong, N.; Li, W.; Cao, J. Edge Computing with Artificial Intelligence: A Machine Learning Perspective. ACM Comput. Surv. 2023, 55, 1–35. [Google Scholar] [CrossRef]

- Afarlon|Arming Power with AI. Available online: https://m.sohu.com/a/389574679_120107608/m.sohu.com/a/389574679_120107608 (accessed on 30 June 2025). (In Chinese).

- The Power Industry Ushered in the AI Big Model for the First Time! Risk at a Glance, Fault Second Response. Available online: https://static.nfapp.southcn.com/content/202310/07/c8171146.html (accessed on 30 June 2025). (In Chinese).

- “Protospace + UAV” Dual-Engine Drive Power Operation and Inspection Digital Transformation—Today’s Headlines. Available online: https://www.toutiao.com/article/7499039789287670312/?upstream_biz=doubao&source=m_redirect (accessed on 30 June 2025). (In Chinese).

- DeepSeek Edition: Domestic AI Enables Power Industry. Available online: https://mp.weixin.qq.com/s?__biz=MzA3NjYyNzIyOA==&idx=2&mid=2654963457&sn=7b9ecf5fde1ee380658222b99d342abc&poc_token=HKg8YmijCD-ThDseXe5IHbl-dsURNSnLA0MidHjv (accessed on 30 June 2025). (In Chinese).

- In-Depth Analysis of Typical Applications of Visual Large Models in U.S. Power Grids and Power Systems—Today’s Headlines. Available online: https://www.toutiao.com/article/7530291315431539235/ (accessed on 1 August 2025). (In Chinese).

- Overseas Student Talks About AI|Driving Energy Transition with Artificial Intelligence—Today’s Headlines. Available online: https://www.toutiao.com/article/7502296032929104399/ (accessed on 1 August 2025). (In Chinese).

- Yan, P.; Li, F.; Xiang, Z.; Li, M.; Fan, S. Research and Application of Power Data Management Key Technology. In Proceedings of the 2021 IEEE 2nd International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA), Nanchang, China, 17–19 December 2021; Volume 2, pp. 98–102. [Google Scholar]

- Kaur, D.; Uslu, S.; Rittichier, K.J.; Durresi, A. Trustworthy Artificial Intelligence: A Review. ACM Comput. Surv. 2023, 55, 1–38. [Google Scholar] [CrossRef]

- Fakhri, M.M.; Jannah, D.M.; Isma, A.; Dewantara, H.; Nirmala, S.A. From Ethics to Impact: Modeling the Role of AI Perception Dynamics in the Relationship Between Ethics AI Practices, AI-Driven Societal Impact, and AI Behavioral Analysis. J. Appl. Sci. Eng. Technol. Educ. 2025, 7, 56–68. [Google Scholar] [CrossRef]

- Ribeiro De Oliveira, T.; Biancardi Rodrigues, B.; Moura Da Silva, M.; Antonio, N.; Spinassé, R.; Giesen Ludke, G.; Ruy Soares Gaudio, M.; Iglesias Rocha Gomes, G.; Guio Cotini, L.; Da Silva Vargens, D.; et al. Virtual Reality Solutions Employing Artificial Intelligence Methods: A Systematic Literature Review. ACM Comput. Surv. 2023, 55, 1–29. [Google Scholar] [CrossRef]

- AI + XR Integration: The Way to Build a New Ecology of Power Safety Production. Available online: https://m.163.com/dy/article/JUA6FQJ9053800ZY.html (accessed on 30 June 2025). (In Chinese).

- Sarker, I.H.; Janicke, H.; Mohsin, A.; Gill, A.; Maglaras, L. Explainable AI for Cybersecurity Automation, Intelligence and Trustworthiness in Digital Twin: Methods, Taxonomy, Challenges and Prospects. ICT Express 2024, 10, 935–958. [Google Scholar] [CrossRef]

- A New Era of Intelligent Inspection: Low-Altitude UAV Multi-Modal Sensing Technology Enables Efficient Inspection of Substation Equipment. Available online: https://www.sohu.com/a/888798040_122278230 (accessed on 30 June 2025). (In Chinese).

- China Southern Power Grid’s “Big Watt · Yudian” Was Selected as One of the Top Ten Central Enterprises in 2024. Available online: https://www.cpem.cn/list/3/17495.html (accessed on 30 June 2025). (In Chinese).

- Huang, C.; Li, S.; Liu, R.; Wang, H.; Chen, Y. Large Foundation Models for Power Systems 2023. In Proceedings of the IEEE General Meeting Power& Energy Society, Austin, TX, USA, 21–25 July 2024. [Google Scholar]

- Wang, H.; Fu, T.; Du, Y.; Gao, W.; Huang, K.; Liu, Z.; Chandak, P.; Liu, S.; Van Katwyk, P.; Deac, A.; et al. Scientific Discovery in the Age of Artificial Intelligence. Nature 2023, 620, 47–60. [Google Scholar] [CrossRef] [PubMed]

- The Research Report on the Coordinated Development of Computing Power and Electricity (2025) Has Been Officially Released. Available online: https://www.hcp.ac.cn/news/720071589999399346.html (accessed on 30 June 2025). (In Chinese).

- Dian ‘Anxing—A New Emergency Management Mechanism Based on Transparent Sharing of Government and Enterprise Data. Available online: https://sdg-china.net/NewsList/info.aspx?itemid=70585 (accessed on 30 June 2025). (In Chinese).

- Majumder, S.; Dong, L.; Doudi, F.; Cai, Y.; Tian, C.; Kalathil, D.; Ding, K.; Thatte, A.A.; Li, N.; Xie, L. Exploring the Capabilities and Limitations of Large Language Models in the Electric Energy Sector. Joule 2024, 8, 1544–1549. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.J. Integrated Artificial Intelligence Security: The Convergence of Artificial Intelligence and Security. J. Soc. Sci. Hunan Norm. Univ. 2025, 54, 37–49. (In Chinese) [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).