A New Methodology for Film Preparation: Comparison Between Doctor Blading and Airbrushing Methods on Scaffold Materials

Abstract

1. Introduction

2. Materials and Methods

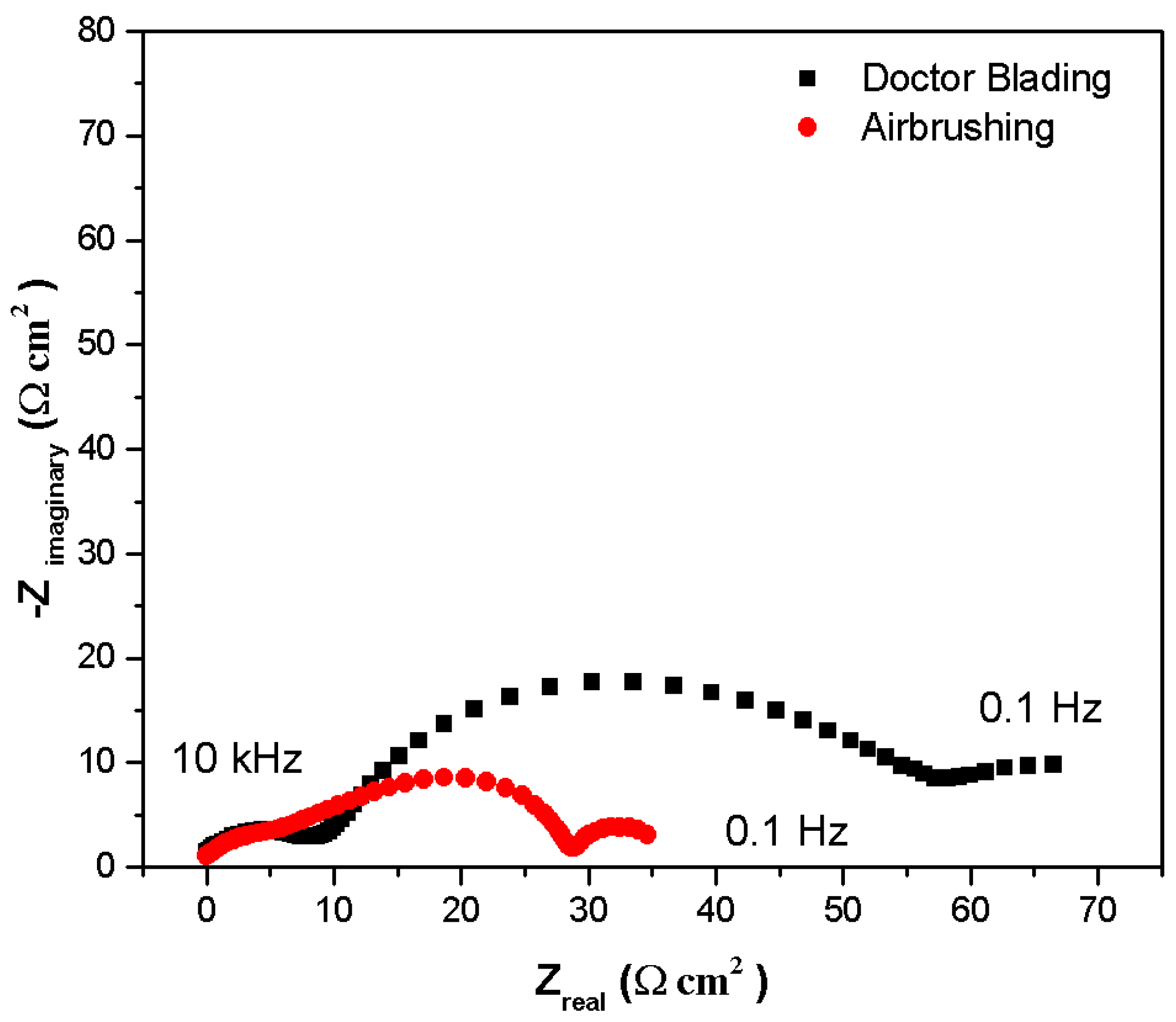

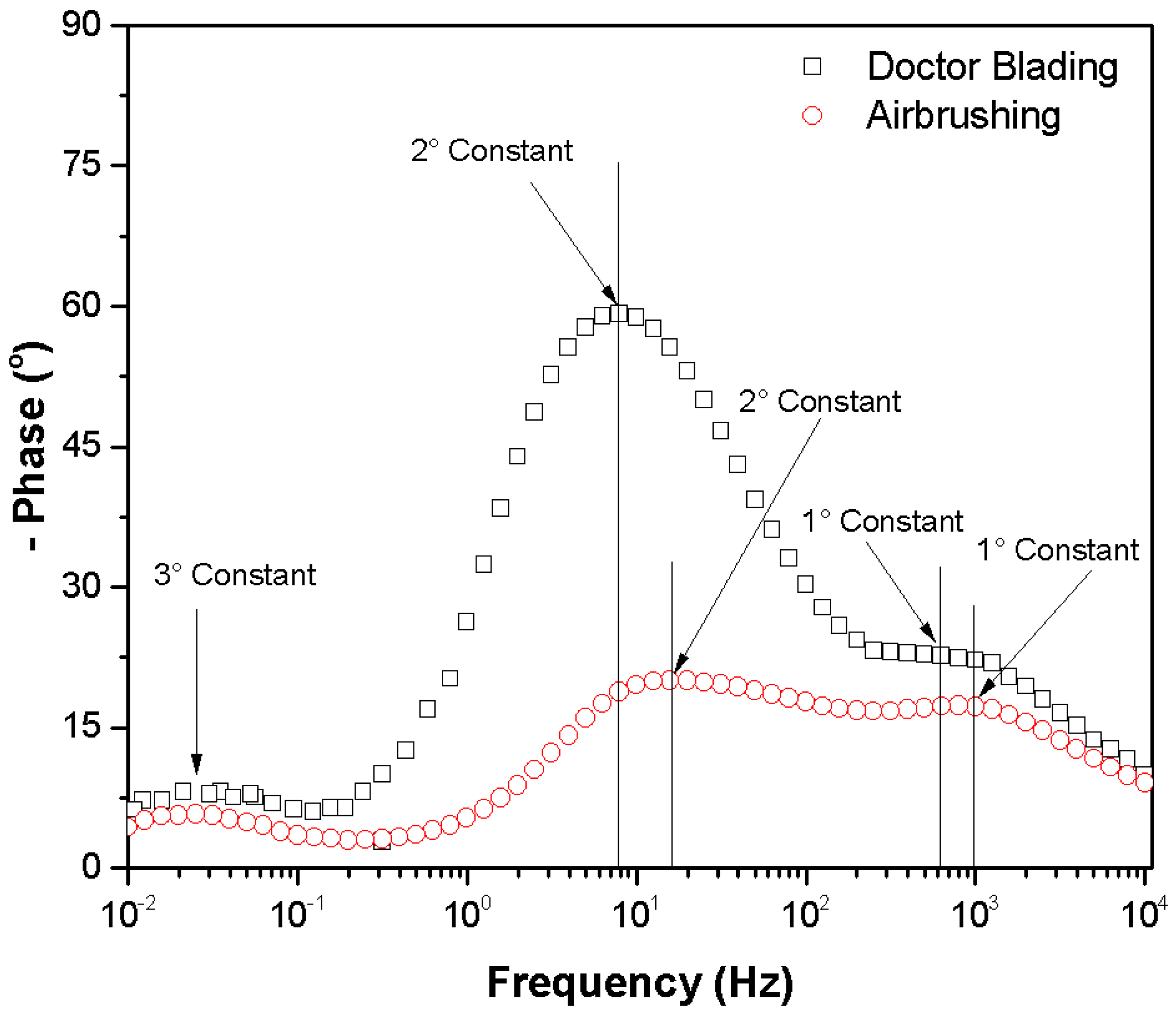

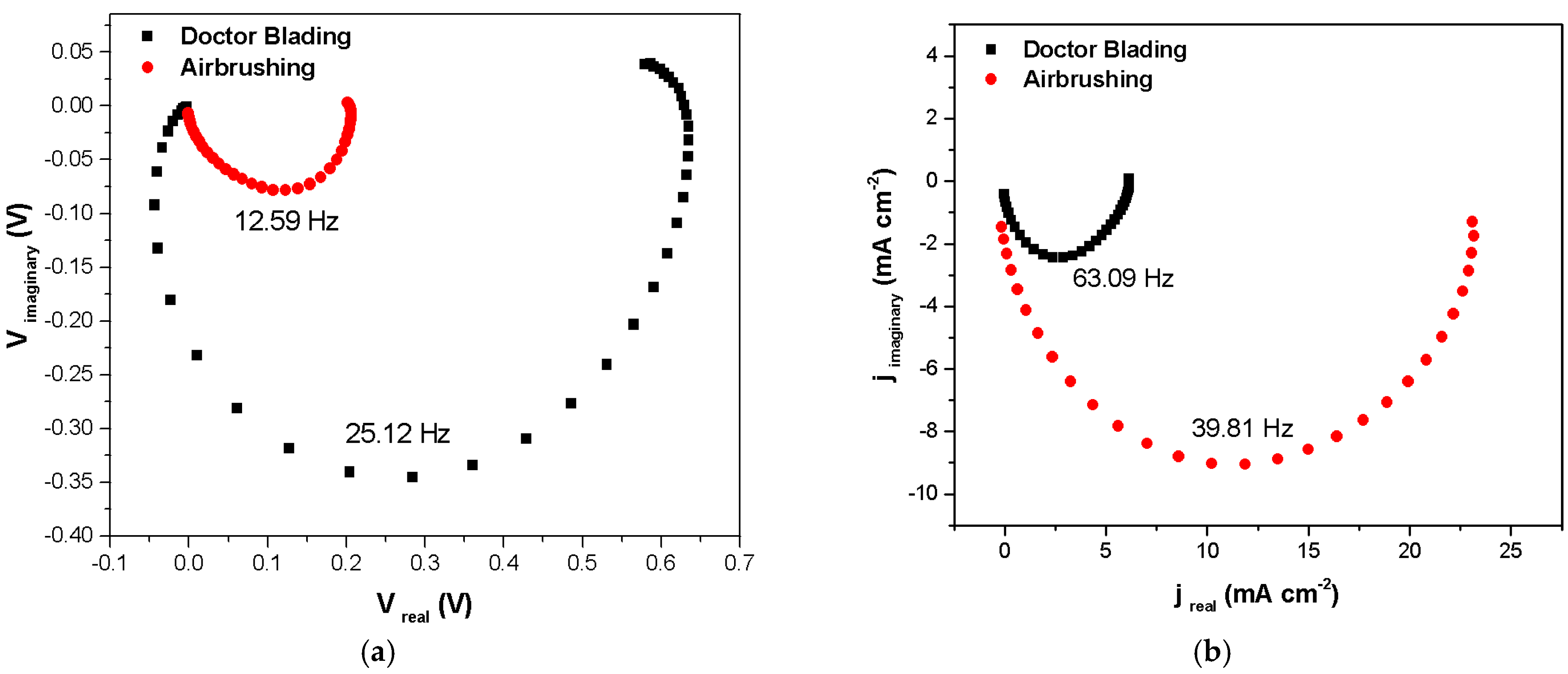

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | Airbrushing |

| DSSC | Dye-Sensitized Solar Cells |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| EIS | Electrochemical Impedance Spectroscopy |

| FTO | Fluorine-Doped Tin Oxide |

| IMPS | Intensity-Modulated Photocurrent Spectroscopy |

| IMVS | Intensity-Modulated Photovoltage Spectroscopy |

| IPCC | Intergovernmental Panel on Climate Change |

| OCP | Open-Circuit Potential |

| SEM | Scanning Electron Microscopy |

| BC | Conduction Band Edge |

| PCE | Photoconversion Energy Efficiency |

References

- Tractz, T.; Regina, S.; Antunes, M.; Rog, P. Nb/TiO2 oxides: A study of synthesis and electron transport mechanism as an ETL in a solar device. J. Photochem. Photobiol. A Chem. 2023, 444, 114899. [Google Scholar] [CrossRef]

- O’Regan, B.; Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Grätzel, M. Photoelectrochemical cells. Nature 2001, 414, 338–344. [Google Scholar] [CrossRef]

- Guimarães, R.R.; Parussulo, A.L.A.; Toma, H.E.; Araki, K. Enlightening the synergic effect of anatase/rutile mixtures in solar cells. Electrochim. Acta 2016, 188, 523–528. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H. Dye-Sensitized Solar Cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Ito, S.; Chen, P.; Comte, P.; Nazeeruddin, M.K.; Liska, P.; Gra, M. Fabrication of Screen-Printing Pastes From TiO2 Powders for Dye-Sensitised Solar Cells. Prog. Photovolt. Res. Appl. 2007, 15, 603–612. [Google Scholar] [CrossRef]

- Tractz, T.; Paula, A.; Matheus, C.; Fernanda, L.; Larsson, G.; Rodrigues, P. The use of 2-Mercaptobenzothiazole as a new co-adsorbent in dye-sensitized solar cells. Opt. Mater. 2022, 131, 112658. [Google Scholar] [CrossRef]

- Kumar, M.H.; Yantara, N.; Dharani, S.; Graetzel, M.; Mhaisalkar, S.; Mathews, N. Flexible, low-temperature, solution processed ZnO-based perovskite solar cells using doctor-blading. Energy Environ. Sci. 2013, 6, 3439–3445. [Google Scholar] [CrossRef]

- Tractz, G.T.; Viomar, A.; Dias, B.V.; De Lima, C.A.; Banczek, E.P.; Da Cunha, M.T.; Antunes, S.R.M.; Rodrigues, P.R.P. Recombination study of dye sensitized solar cells with natural extracts. J. Braz. Chem. Soc. 2019, 30, 371–378. [Google Scholar] [CrossRef]

- Nguyen-phan, T.; Hung, V.; Viet, T.; Hong, S.; Jung, E. Fabrication of TiO2 nanostructured fi lms by spray deposition with high photocatalytic activity of methylene blue. Mater. Lett. 2010, 64, 1387–1390. [Google Scholar] [CrossRef]

- Cassano, C.L.; Georgiev, T.Z.; Fan, Z.H. Using airbrushes to pattern reagents for microarrays and paper-fluidic devices. Nat. Publ. Gr. 2017, 3, 17055. [Google Scholar] [CrossRef]

- Ohm, W.; Pandit, P.; Ko, V.; Rojas, R.; Yu, S.; Brett, C.J.; So, D.L.; Roth, S.V. Morphological properties of airbrush spray-deposited enzymatic cellulose thin films. J. Coat. Technol. Res. 2018, 15, 759–769. [Google Scholar] [CrossRef]

- Tarwal, N.L.; Patil, V.L.; Rani, J.R.; Gurav, K.V.; Shaikh, J.S.; Khandekar, M.S.; Harale, N.S.; Patil, P.S.; Jang, J.H. Plasmonic DSSC performance of spray deposited Ag-ZnO and Au-ZnO films. Chin. J. Phys. 2021, 73, 581–588. [Google Scholar] [CrossRef]

- Parussulo, A.L.A.; Bonacin, J.A.; Toma, S.H.; Araki, K.; Toma, H.E. Unravelling the chemical morphology of a mesoporous titanium dioxide interface by confocal Raman microscopy: New clues for improving the efficiency of dye solar cells and photocatalysts. Langmuir 2009, 25, 11269–11271. [Google Scholar] [CrossRef]

- Tractz, G.T.; da Luz, F.S.; Antunes, S.R.M.; Banczek, E.D.P.; da Cunha, M.T.; Rodrigues, P.R.P. Nb2O5 synthesis and characterization by Pechini method to the application as electron transport material in a solar device. Sol. Energy 2021, 216, 1–6. [Google Scholar] [CrossRef]

- Zhang, L.; Cole, J.M. Anchoring groups for dye-sensitized solar cells. ACS Appl. Mater. Interfaces 2015, 7, 3427–3455. [Google Scholar] [CrossRef]

- Shikoh, A.S.; Ahmad, Z.; Touati, F.; Shakoor, R.A.; Al-Muhtaseb, S.A. Optimization of ITO glass/TiO2 based DSSC photo-anodes through electrophoretic deposition and sintering techniques. Ceram. Int. 2017, 43, 10540–10545. [Google Scholar] [CrossRef]

- Kumari, J.M.K.W.; Sanjeevadharshini, N.; Dissanayake, M.A.K.L.; Senadeera, G.K.R.; Thotawattahe, C.A. The effect of TiO2 photoanode film thickness on photovoltaic properties of dye-sensitized solar cells. Ceylon J. Sci. 2016, 45, 1. [Google Scholar] [CrossRef]

- Ismail, R.A.; Al-Diabat, M. Structural, optical and electrical properties of nanostructured TiO2 thin films prepared by spin coaing technique for optoelectronic applications. Ceram. Int. 2020, 46, 2391–2399. [Google Scholar] [CrossRef]

- Tractz, G.T.; Maia, G.A.R.; Dias, B.V.; Banczek, E.D.P.; Molinares, M.A.; da Cunha, M.T.; Rodrigues, P.R.P. Influence of deposition methodology and heating treatment on dye sensitized solar cell with natural extract. Orbital Electron. J. Chem. 2018, 10, 3. [Google Scholar] [CrossRef]

- Nissfolk, J.; Fredin, K.; Hagfeldt, A.; Boschloo, G. Recombination and transport processes in dye-sensitized solar cells investigated under working conditions. J. Phys. Chem. B 2006, 110, 17715–17718. [Google Scholar] [CrossRef]

- Correa-Baena, J.P.; Tress, W.; Domanski, K.; Anaraki, E.H.; Turren-Cruz, S.H.; Roose, B.; Boix, P.P.; Grätzel, M.; Saliba, M.; Abate, A.; et al. Identifying and suppressing interfacial recombination to achieve high open-circuit voltage in perovskite solar cells. Energy Environ. Sci. 2017, 10, 1207–1212. [Google Scholar] [CrossRef]

- Meen, T.H.; Jhuo, Y.T.; Chao, S.M.; Lin, N.Y.; Ji, L.W.; Tsai, J.K.; Wu, T.C.; Chen, W.R.; Water, W.; Huang, C.J. Effect of TiO2 nanotubes with TiCl4 treatment on the photoelectrode of dye-sensitized solar cells. Nanoscale Res. Lett. 2012, 7, 1–5. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Sivakumar, G.; Bertoni, A.H.; Kim, H.S.; Marchezi, P.E.; Bernardo, D.R.; Hagfeldt, A.; Grätzel, M.; Zakeeruddin, S.M.; Nogueira, A.F. Design, synthesis and characterization of 1,8-naphthalimide based fullerene derivative as electron transport material for inverted perovskite solar cells. Synth. Met. 2019, 249, 25–30. [Google Scholar] [CrossRef]

- Chen, C.; Song, Z.; Xiao, C.; Zhao, D.; Shrestha, N.; Li, C.; Yang, G.; Yao, F.; Zheng, X.; Ellingson, R.J.; et al. Achieving a high open-circuit voltage in inverted wide-bandgap perovskite solar cells with a graded perovskite homojunction. Nano Energy 2019, 61, 141–147. [Google Scholar] [CrossRef]

- Ding, B.; Huang, S.Y.; Chu, Q.Q.; Li, Y.; Li, C.X.; Li, C.J.; Yang, G.J. Low-temperature SnO2-modified TiO2 yields record efficiency for normal planar perovskite solar modules. J. Mater. Chem. A 2018, 6, 10233–10242. [Google Scholar] [CrossRef]

- Ke, W.; Fang, G.; Wang, J.; Qin, P.; Tao, H.; Lei, H.; Liu, Q.; Dai, X.; Zhao, X. Perovskite solar cell with an efficient TiO2 compact film. ACS Appl. Mater. Interfaces 2014, 6, 15959–15965. [Google Scholar] [CrossRef]

- Guimaraes, R.R.; Parussulo, A.L.A.; Araki, K. Impact of nanoparticles preparation method on the synergic effect in anatase/rutile mixtures. Electrochim. Acta 2016, 222, 1378–1386. [Google Scholar] [CrossRef]

- Guimaraes, R.R.; Parussulo, A.L.A.; Matias, T.A.; Toma, H.E.; Araki, K. Electrostatic blocking barrier as an effective strategy to inhibit electron recombination in DSSCs. Electrochim. Acta 2017, 255, 92–98. [Google Scholar] [CrossRef]

- Fabregat-Santiago, F.; Bisquert, J.; Garcia-Belmonte, G.; Boschloo, G.; Hagfeldt, A. Influence of electrolyte in transport and recombination in dye-sensitized solar cells studied by impedance spectroscopy. Sol. Energy Mater. Sol. Cells 2005, 87, 117–131. [Google Scholar] [CrossRef]

- Dhas, V.; Muduli, S.; Agarkar, S.; Rana, A.; Hannoyer, B.; Banerjee, R.; Ogale, S. Enhanced DSSC performance with high surface area thin anatase TiO2 nanoleaves. Sol. Energy 2011, 85, 1213–1219. [Google Scholar] [CrossRef]

- Tsai, C.-H.; Hsiao, Y.-C.; Chuang, P.-Y. Investigation of Electrochemically Deposited and Chemically Reduced Platinum Nanostructured Thin Films as Counter Electrodes in Dye-Sensitized Solar Cells. Coatings 2018, 8, 56. [Google Scholar] [CrossRef]

- Bisquert, J.; Fabregat-Santiago, F. Impedance Spectroscopy: A General Introduction and Application to Dye-Sensitized Solar Cells, Dye-Sensitized Solar Cells; EPFL Press: Lausanne, Switzerland, 2010; p. 98. [Google Scholar]

- Barnes, P.R.F.; Miettunen, K.; Li, X.; Anderson, A.Y.; Bessho, T.; Gratzel, M.; O’Regan, B.C. Interpretation of optoelectronic transient and charge extraction measurements in dye-sensitized solar cells. Adv. Mater. 2013, 25, 1881–1922. [Google Scholar] [CrossRef] [PubMed]

| Deposition Method | V (V) | J (mA cm−2) | FF | PCE (%) |

|---|---|---|---|---|

| Doctor blading | 0.696 ± 0.027 | 3.42 ± 1.04 | 0.430 ± 0.110 | 1.023 ± 0.254 |

| Airbrushing | 0.641 ± 0.090 | 6.09 ± 1.19 | 0.509 ± 0.116 | 1.987 ± 0.640 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonseca, H.E.S.; Tractz, G.T.; Peron, A.P.; Kordiak, W.; Corrêa, M.V.F.; da Cunha, M.T.; Banczek, E.d.P. A New Methodology for Film Preparation: Comparison Between Doctor Blading and Airbrushing Methods on Scaffold Materials. Processes 2025, 13, 2537. https://doi.org/10.3390/pr13082537

Fonseca HES, Tractz GT, Peron AP, Kordiak W, Corrêa MVF, da Cunha MT, Banczek EdP. A New Methodology for Film Preparation: Comparison Between Doctor Blading and Airbrushing Methods on Scaffold Materials. Processes. 2025; 13(8):2537. https://doi.org/10.3390/pr13082537

Chicago/Turabian StyleFonseca, Hagata Emmanuely Slusarski, Gideã Taques Tractz, Ana Paula Peron, Wesley Kordiak, Maria Vitória França Corrêa, Maico Taras da Cunha, and Everson do Prado Banczek. 2025. "A New Methodology for Film Preparation: Comparison Between Doctor Blading and Airbrushing Methods on Scaffold Materials" Processes 13, no. 8: 2537. https://doi.org/10.3390/pr13082537

APA StyleFonseca, H. E. S., Tractz, G. T., Peron, A. P., Kordiak, W., Corrêa, M. V. F., da Cunha, M. T., & Banczek, E. d. P. (2025). A New Methodology for Film Preparation: Comparison Between Doctor Blading and Airbrushing Methods on Scaffold Materials. Processes, 13(8), 2537. https://doi.org/10.3390/pr13082537