Abstract

The escalating challenges of greenhouse gas emissions, coupled with the severe depletion of oil reserves and the surging global energy demand, have emerged as critical concerns requiring urgent attention. Against this backdrop, biodiesel has been recognized as a viable alternative fuel for compression ignition (CI) engines. The primary objective of this research is to review the application of biodiesel in CI engines, with a focus on enhancing fuel properties and improving atomization performance. This article examines the spray and atomization characteristics of biodiesel fuels and conducts a comparative analysis with diesel fuel. The results show that biodiesel has a longer spray tip penetration, smaller spray cone angle, larger Sauter mean diameter (SMD) and faster droplet velocity due to its higher viscosity and surface tension. Blending with other fuels, such as ethanol, butanol, dimethyl ether (DME) and di-n-butyl ether, results in reduced viscosity and surface tension in these mixed fuels, representing a simple and effective approach for improving biodiesel atomization performance. A comprehensive analysis of spray and droplet impingement is also conducted. The findings reveal that biodiesel exhibits a higher probability of fuel–wall impingement, suggesting that future research should focus on two key directions: first, developing combined strategies to enhance impact-induced secondary atomization while minimizing fuel deposition; and second, investigating single-droplet impingement, specifically that of microscale biodiesel droplets and blended fuel droplets under real engine operating conditions. This paper also presents several advanced techniques, including air-assisted atomization, dual-fuel impingement, nano-biodiesel, and water-emulsified biodiesel, aimed at mitigating the atomization limitations of biodiesel, thereby facilitating the broader adoption of biodiesel in compression ignition engines.

1. Introduction

The escalating global energy crisis, driven by the rapid depletion of finite fossil fuel reserves and fluctuating oil markets, has underscored the urgent need for sustainable energy alternatives [1,2,3]. Concurrently, growing environmental concerns, particularly climate change driven by greenhouse gas emissions and deteriorating air quality caused by particulate matter and NOx pollutants from conventional diesel combustion, have significantly threatened public health and agricultural productivity [4,5,6,7,8]. These pressing challenges have accelerated global research efforts toward sustainable renewable fuel alternatives. Wind, solar, zero-carbon fuels (ammonia [9], hydrogen [10]), carbon-neutral fuels (biomass and biofuel [11,12,13], methanol [14,15]), and low-carbon fuels (natural gas [16]) have attracted significant research attention due to their potential to address energy and environmental challenges.

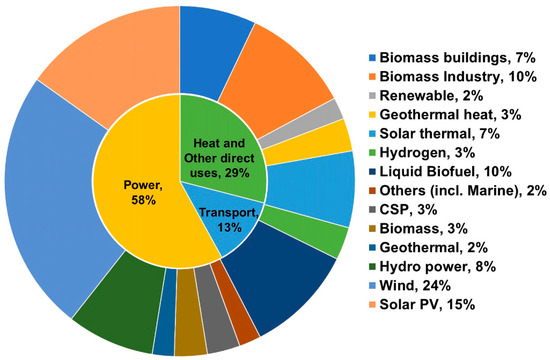

Biodiesel, derived from renewable feedstocks such as vegetable oils, waste cooking oil, and algae, offers a carbon-neutral solution by reducing lifecycle CO2 emissions by 50~80% compared to traditional diesel. Figure 1 illustrates that following solar and wind, biofuels are anticipated to contribute 10% of global renewable energy by 2050 [17]. Compression ignition (CI) engines are major energy consumers and significant emitters of pollutants. Among the diverse strategies for reducing fossil energy consumption in diesel engines, biodiesel stands out as an effective means. CI engines running on biodiesel exhibit improved overall lubricity without the need for engine modifications. Extensive research has been carried out to examine the performance of diesel engines fueled with biodiesel and its blends [18,19,20]. Compared with diesel fuel, biodiesel has a lower aromatic hydrocarbon content, contains no sulfur, and its ignition delay remains essentially unchanged. Adding a small amount of biodiesel to diesel engines can effectively reduce exhaust pollutants, while the original engine’s power performance remains almost unchanged [21]. Allami et al. [22] investigated the diesel engine performance by using biodiesel and biodiesel-blended fuels. They reported that when the blending ratio of biodiesel ranges from 11% to 20%, it can significantly improve engine performance and reduce emissions of HC, CO, and NOx. Uyumaz et al. [23] investigated the combustion performance and exhaust emission characteristics of poppy oil in a CI engine, and found that compared with diesel fuel, poppy oil biodiesel not only exhibits considerable engine performance but also reduces exhaust pollutant emissions.

Figure 1.

A forecast map showing the use of renewable energy in 2050 [17].

However, from the perspective of liquid physical properties, fuel injection and atomization are significantly influenced by viscosity, density, and surface tension [24,25,26,27]. For biodiesel, these properties are higher than those of diesel fuel, resulting in lower gas entrainment mass during the injection process, poor mixing with ambient gas, and inferior atomization [28,29]. Poor fuel atomization leads to degraded combustion and emission performance, making it highly necessary to conduct research on the in-cylinder fuel injection and atomization processes of biodiesel in CI engines [30,31,32]. The macroscopic characteristics of a fuel jet include the jet breakup length and spray morphology evolution [33,34,35], while the atomization quality is typically characterized by key parameters such as the droplet size distribution and velocity profile [36,37,38,39]. Mohan et al. [40] investigated the relationship between the physical properties and spray characteristics of biodiesel and diesel fuel. The results showed that due to the higher density and kinematic viscosity of biodiesel, the density of the liquid core in its spray is greater than that of diesel fuel. Additionally, the volume occupied by the liquid phase of biodiesel is reduced, and the ratio of the liquid core area to the spray projected area of biodiesel is also smaller than that of diesel fuel. Lee et al. [30] examined the atomization and combustion behaviors of biodiesel and biodiesel-blended fuels. They noted that the atomization performance of biodiesel blends is inferior to that of diesel fuel, attributed to their higher viscosity and surface tension.

Impingement between the liquid fuel spray and solid wall is commonly observed in direct-injection CI engines. When a spray impinges on a wall, secondary breakup occurs, significantly influencing the spray morphology, liquid-phase particle size, spatial concentration distribution, and subsequent combustion processes [41,42]. Tripathi et al. [43] found that the probability of wall impingement is higher with palm acid oil (PAO) biodiesel than base diesel due to higher spray penetration of biodiesel. The process of spray impingement is the macroscopic manifestation of numerous droplets colliding with the wall surface [44,45]. Therefore, it is necessary to conduct in-depth studies on the deformation and phase change mechanisms of biodiesel droplets impinging on solid walls under the actual operating conditions of high-pressure in-cylinder direct injection CI engines, summarize the behavioral laws and thermodynamic mechanisms of droplet wall impingement, and statistically analyze the distribution characteristics of secondary droplets. This is of great significance for improving the secondary atomization performance [46,47].

The main purpose of this paper is to provide a comprehensive review of the application of biodiesel in CI engines, mainly focusing on exploring the technical pathways to improve the atomization performance of biodiesel. First, this paper introduces different types of biodiesel fuel and their feedstock, comparing their physical properties with those of diesel and explaining the reasons for the poor atomization performance of biodiesel in Section 2. Second, the spray and atomization characteristics of biodiesel fuels are examined in Section 3. Then, the spray and droplet impingement of biodiesel fuels are analyzed, and the future research directions are identified in Section 4. Finally, some advanced techniques for improving biodiesel atomization are presented in Section 5. The aim is to provide preliminary information to support the work of industrial practitioners, researchers, and engineers working on or interested in biodiesel.

2. Biodiesel Production and Fuel Properties

2.1. Biodiesel Production Technologies

Biodiesel production primarily relies on renewable biomass resources, including oil-bearing plants, algae, fats, CO2, and advanced solar energy-derived materials [3,13,48]. These feedstocks can be categorized into four groups based on their origin. The first generation uses edible crop oils (such as soybean oil, palm oil and rapeseed oil) as raw materials to produce fatty acid methyl esters (FAME) through transesterification [49,50,51]. Bioethanol and butanol are also first-generation biofuels, derived from fermentable carbohydrates and sugars in food-based feedstocks such as rice, wheat, barley, potatoes, corn, sugarcane, and vegetable oil. Though the technology is mature, it faces the issue of “competing with food crops for land”. The second generation shifts to non-edible crops including non-food crops, wheat straw, corn, wood waste, energy crops, non-edible vegetable oil and waste oils. It improves the transesterification process, and develops hydro-processing (HVO), thereby enhancing sustainability [52]. The third generation utilizes microalgae and microbial oils, achieving high yields without occupying arable land, but the cost remains high [53]. The fourth generation explores cutting-edge technologies such as artificial photosynthesis and electro-synthesis, directly producing fuels from CO2. Fourth-generation biofuels hold promising prospects for improved production efficiency, thanks to the abundance, cost-effectiveness, and accessibility of their raw materials [54]. The characteristics of different generations of biodiesel are summarized in Table 1. The future development directions will focus on feedstock diversification, low-carbon processes, and policy support [55].

Table 1.

Different generations of biodiesel and their characteristics.

Table 1.

Different generations of biodiesel and their characteristics.

| Generation | Feedstock | Production Method | Advantages | Challenges |

|---|---|---|---|---|

| 1st [56,57] | Soybean, Rapeseed, Palm oil | Alkali transesterification (FAME) | Mature technology | Food competition, Deforestation |

| 2nd [58] | Waste cooking oil, Animal fat | Acid/enzymatic transesterification, HVO | Waste utilization, Drop-in fuel | Collection logistics, HVO cost |

| 3rd [59] | Microalgae, Yeast oils | Extraction and Transesterification/hydrogenation | High yield, CO2 absorption | High production costs |

| 4th [60] | CO2, Water, Sunlight | Artificial photosynthesis/electrosynthesis | Carbon-negative potential | Lab-scale, Low efficiency |

2.2. Fuel Properties

Analyzing the atomization characteristics of biodiesel fuels, the spray and atomization mechanisms are substantially different from those of conventional diesel fuel due to its intrinsic physical properties such as liquid density, viscosity, and surface tension. In general, the mass flow rate through the injector nozzle varies with the square root of the fuel density, influencing spray penetration and the interaction with ambient gas, thereby altering secondary atomization dynamics [61,62]. Higher viscosity resists liquid breakup due to reduced jet instability and suppressed surface wave growth, leading to larger primary droplets and slower ligament disintegration. This elevated viscosity also causes greater energy dissipation, converting more kinetic energy into heat rather than the surface energy needed for effective droplet fragmentation, which may reduce atomization efficiency [63,64]. Higher surface tension increases the energy barrier for liquid sheet breakup during injection, resulting in larger initial droplet formation due to stronger molecular cohesion forces [65,66]. This effect modifies the spray morphology by reducing the spray cone angle and limiting air entrainment, ultimately decreasing fuel–air mixing efficiency [67,68]. The elevated surface tension also stabilizes droplets against secondary breakup, extending their lifetime in the combustion chamber.

Table 2 lists the physical properties of different types of biodiesel fuel, in comparison with diesel fuel. In practice, the significance of the fuel density for atomization is diminished because most liquid fuels experience only minor differences in fuel density. From this viewpoint, the influence of biodiesel density on spray droplet size during the atomization process is quite small.

Table 2.

Physical properties of different types of biodiesel fuel.

Table 2.

Physical properties of different types of biodiesel fuel.

| Feedstock | Density kg/m3 | Kinematic Viscosity at 40 °C mm2/s | Surface Tension mN/m | Lower Heating Value MJ/kg | Cetane Number | Reference |

|---|---|---|---|---|---|---|

| Diesel | 820~850 | 2~3.5 | 25~30 | 42.7~43.5 | 40~55 | |

| Waste cooking oil | 878 | 4.4 | 32 | 38.85 | 51.34 | [69] |

| Soybean biodiesel | 887 | 4.0 | 34.4 | 37.53 | 51 | [70] |

| Palm oil | 874.4 | 5.53 | 26.2 | 40.03 | 64.2 | [71] |

| Fatty acid methyl ester | 858.4 | 4.71 | 31.2 | - | - | [72] |

| Oxidized jatropha biodiesel | 873.7 | 4.37 | 29.7 | 20.49 | - | [73] |

| Hydrogenated catalytic biodiesel | 785.9 | 6.08 | 27.2 | 44 | - | [74] |

| Cottonseed biodiesel | 864 | 4.14 | 32.4 | 36.8 | 52 | [75] |

3. Spray and Atomization Characteristics of Biodiesel

3.1. Macroscopic Spray Characteristics

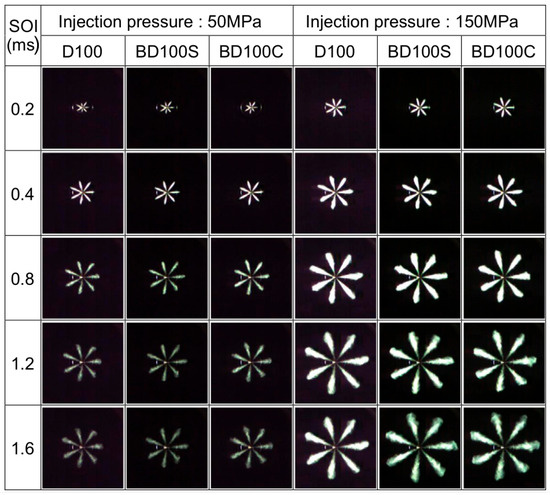

Macroscopic spray characteristics, including spray morphology, spray tip penetration and spray core angle, are key factors for engine combustion chamber design, fuel injector selection, and control system development. They are influenced by biodiesel’s physical properties, which differ from those of conventional diesel. Figure 2 presents a comparison of the spray evolution characteristics between diesel fuel and biodiesel fuels derived from soybean oil (BD100S) and canola oil (BD100C) [76]. In this figure, SOI means ‘start of injection’. As shown in the spray images of the three fuels, under the same injection conditions, the differences in the shape and magnitude of the spray evolution between the biodiesels and diesel fuel are quite small. However, quantitative analysis shows that higher momentum from biodiesel injection contributes to deeper penetration, which can improve air–fuel mixing but may cause wall impingement in small combustion chambers. Biodiesel has a narrower spray cone angle which may reduce air entrainment, affecting combustion efficiency and emissions. Similar results have also been found in Refs. [71,77].

Figure 2.

Comparison of spray evolution between diesel and biodiesel fuels [76].

3.2. Droplet Size and Velocity

In combustion engines, optimal fuel spray atomization plays a pivotal role in achieving homogeneous fuel distribution. This uniform mixing effectively prevents the formation of localized fuel-rich or fuel-lean zones, thereby substantially reducing incomplete combustion phenomena and effectively suppressing soot formation. The comprehensive assessment of atomization quality including the primary breakup of the fuel jet [78,79,80], Sauter mean diameter (SMD), and droplet size and velocity distribution [81,82,83] has been performed by combing experimental measurements (Phase Doppler Particle Analyzer [84], Particle Image Analysis [85], Particle Image Velocimetry [86], X-ray Fluorescence Tracking [87]) with computational simulations [88] under various operating conditions.

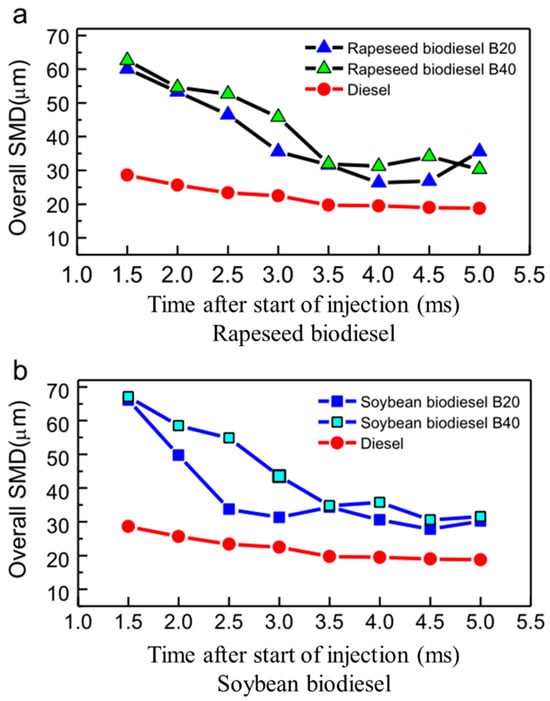

The SMD values of biodiesel blends derived from both soybean oil and rapeseed oil consistently exceed those of conventional diesel fuel, as demonstrated in Figure 3 [30]. Consequently, the diesel droplets decelerate more rapidly due to the drag force exerted by the ambient gas. This phenomenon primarily stems from the fundamental relationship between droplet breakup characteristics and the Weber number [89], where biodiesel’s inherently higher surface tension results in lower Weber numbers that directly contribute to a larger SMD [90]. Concurrently, the elevated kinematic viscosity of biodiesel blends increases frictional forces at the nozzle interface, leading to reduced injection velocities that further exacerbate poor atomization performance. These combined effects collectively manifest in the observed size distribution patterns, with biodiesel blends consistently exhibiting poorer atomization characteristics compared to baseline diesel across all tested injection conditions.

Figure 3.

Comparison of droplet SMD between diesel and biodiesel blended fuels (0.3 mm nozzle diameter, 60 MPa injection pressure): (a) rapeseed biodiesel, (b) soybean biodiesel [30].

3.3. Factors Influencing Spray Evolution and Atomization

The atomization characteristics of biodiesel fuels are governed by a complex interplay of multiple physicochemical and operational factors that collectively determine the resulting spray morphology and droplet size distribution. At the fundamental level, the higher viscosity and surface tension of biodiesel profoundly influence the primary breakup and atomization process. Therefore, blending with other fuels to reduce the viscosity and surface tension of mixed fuels represents an effective technical approach for improving biodiesel atomization performance, as listed in Table 3.

Table 3.

Previous studies that researched how ether fuels affect biodiesel (↑ Increases; ↓ Decreases).

Table 3.

Previous studies that researched how ether fuels affect biodiesel (↑ Increases; ↓ Decreases).

| Base Fuel | Additive Type | Performance | Reference |

|---|---|---|---|

| Soybean biodiesel | Di-n-butyl ether (DBE): DBE15 (15% DBE + 75% biodiesel, by vol.) DBE30 | Spray tip penetration: ↓ Spray core angle: ↑ SMD: 9.1% ↓, 13.1% ↓ | [91] |

| Waste cooking oil | Acetone-butanol-ethanol (ABE): ABE10 (10% ABE + 90% biodiesel, by vol.) ABE20 ABE30 | Spray tip penetration: ↓ Spray core angle: ↑ | [92] |

| Hydrogenated catalytic biodiesel | Ethanol: E15 (15% ethanol + 85% biodiesel, by vol.) E30 | Spray tip penetration: ↓ Spray core angle: ↑ | [74] |

| Soybean biodiesel | Ethanol: BDE20 (20% ethanol + 80% biodiesel, by vol.) | SMD: 9%~17% ↓ | [93] |

| Soybean biodiesel | Dimethyl ether (DME): B75 (25% DME + 75% biodiesel, by wt.) B50 B25 | Spray tip penetration: ↓ Spray core angle: ↑ | [94] |

| 20% Castor biodiesel + 80% diesel, by vol. | Butanol and 1-Butox BDT5 (20% biodiesel + 75% Diesel + 5% butanol, by vol.) BDB5 (20% biodiesel + 75% diesel + 5% 1-Butox, by vol.) | Spray tip penetration: 2%~3% ↓ Spray core angle: 2.8% ↑, 5.3% ↑ | [95] |

The atomization process is further regulated by a range of operational parameters. Higher injection pressure and appropriate injection duration provide more energy to effectively overcome fuel surface tension, promoting the breakup of fuel droplets and enhancing atomization. Conversely, insufficient energy leads to coarse droplets and inadequate atomization [96,97,98]. Ambient pressure alters the atomization process by influencing interactions between the spray and the surrounding gas (e.g., air resistance, mixing rate). Higher ambient pressure strengthens the shearing force of gas on droplets, facilitating their breakup, while low-pressure environments may cause excessive spray diffusion and reduced atomization stability [99,100]. Nozzle type [101,102] or geometry parameters [103,104,105], including orifice diameter, length-to-diameter ratio, and internal surface finish, introduce additional variability by controlling the development of cavitation and turbulence [106] within the injector, which subsequently affects the emerging spray structure. A smaller orifice diameter increases fuel exit velocity and turbulence, making droplets more susceptible to breakup. The length-to-diameter ratio affects fuel flow within the nozzle: an optimal ratio reduces flow losses, enhances turbulence, and promotes cavitation. Furthermore, fuel temperature [107] emerges as a critical control parameter as it directly modulates viscosity and surface tension, with preheating demonstrating particular efficacy for biodiesel fuels in achieving more favorable atomization characteristics. The complex interactions between these factors ultimately determine the temporal evolution of the spray, governing subsequent evaporation and mixing processes. We also note that these factors play a vital role in the development of spray and atomization models [108,109,110,111], which serves as a bridge connecting basic theories and engineering applications. The models require more reliable experimental results for validation to serve the application of biodiesel fuels.

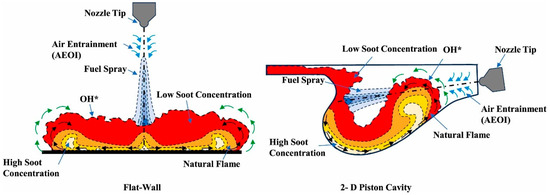

4. Spray and Droplet Impingement

It is a common phenomenon in CI engines that spray impinges the combustion chamber walls at high velocity. After the fuel spray hits the wall, it spreads on the wall surface to form an oil film, and at the same time, the shape of the spray body changes. The process of spray impinging on the wall is a macroscopic manifestation of a large number of droplets colliding with the wall, and droplet–wall impingement is the basic element in the complex process of spray impingement. The behaviors of these droplets upon impact, such as deposition and breakup, are critical to the engine’s combustion performance and emission characteristics. Secondary atomization induced by the impact can enhance the fuel–air mixing process, which in turn, helps reduce nitrogen oxide emissions and improve combustion efficiency [112,113]. However, the droplet deposition and thicker fuel film formation [114,115] upon wall impingement may induce knocking. This behavior can also lead to incomplete combustion and increased particulate emissions, particularly at lower surface temperatures [116]. Zhai et al. [117] have created schematic diagrams of spray flame development and pollutant formation for flat wall impingement and 2-D piston impingement, as shown in Figure 4.

Figure 4.

Spray flame development and pollutant formation for flat wall impingement and 2-D piston impingement (OH* means Hydroxyl radical) [117].

The probability of wall impingement is higher with biodiesel than with base diesel because of the former’s longer spray penetration. Additionally, biodiesel spray impingement is more prone to fuel deposition and film formation than diesel due to its higher viscosity and surface tension, which will lead to combustion inefficiencies and emissions [43,118]. Studies also show that the combined strategy of mild retarded injection timing, compression ratio and EGR could reduce both NOx emissions and the probability of wall impingement [43].

Due to the complexity of spray droplets impacting on the wall, single-droplet impacting is usually employed in literature studies. The dynamic behavior and the heat and mass transfer between droplets and the wall during impingement are influenced by multiple factors, including the droplet physical properties and motion state, wall surface characteristics, and environmental conditions [47,119]. These parameters exhibit linear or nonlinear coupling relationships. To achieve high-fidelity simulations of spray–wall interactions under various engine operating conditions, spray impingement models must incorporate scientifically accurate descriptions of fundamental droplet phase change, aerodynamics, and transport processes [120].

In recent years, research on the dynamic characteristics of single-droplet wall impingement in the context of internal combustion engines has mainly focused on experimental studies on the influence mechanisms of droplet properties [121], liquid film thickness [122], wall morphology and roughness [123], and wall temperature [120]. Additionally, studies have been conducted on a series of sub-models within the droplet–wall impingement dynamic model, such as spreading models based on the law of similarity and energy conservation [124], and the critical conditions for droplet splashing and transition [125]. These efforts aim to meet the requirements of different fuel types and combustion chamber walls in internal combustion engines. However, most of the existing single-droplet wall impingement experiments in the literature were conducted under atmospheric conditions and using millimeter-scale droplets. In the actual working process of CI engines, the impingements occur in high-temperature and high-pressure environments, and the size of droplets is mostly distributed at the micrometer scale. The ambient gas and droplet size exert significant influences on the mass and heat transfer processes during impingement, which in turn, lead to changes in dynamic characteristics [126,127].

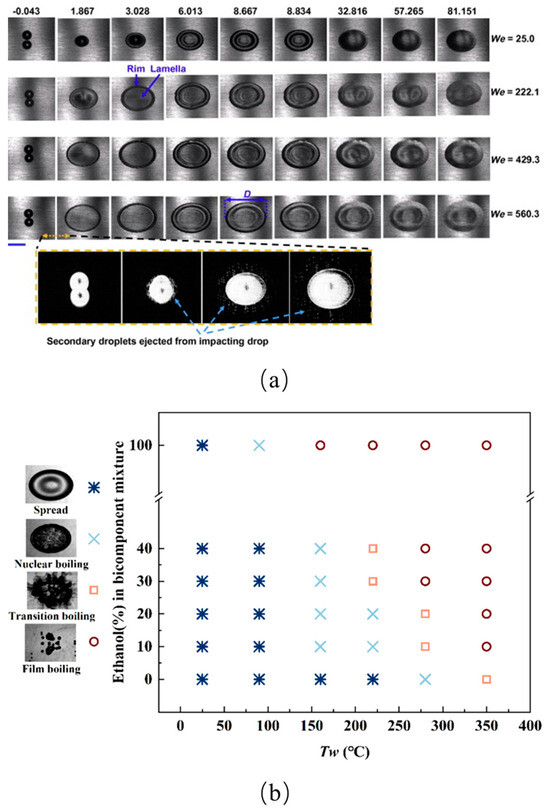

Sen et al. [128] examined the impact dynamics of a biofuel droplet at room temperature within the Weber numbers range of 20~570. Dong et al. [129] experimentally explored the impact dynamics of binary droplets composed of biodiesel and ethanol (ethanol concentrations spanning 10~40%) on a heated stainless-steel surface (temperatures ranging from 25 to 350 °C), under Weber numbers between 40 and 230. Figure 5 presents the typical dynamic behaviors, and the results indicate that higher viscosity reduces droplet spreading velocity and increases the critical Weber number required for splashing, often leading to thicker liquid films upon wall impact. Additionally, biodiesel’s elevated surface tension enhances droplet stability, hindering secondary atomization induced by the impingement. Future research should focus on the impingement of microscale biodiesel and blending fuel droplets on a heated wall under real engine operating conditions.

Figure 5.

The dynamic behaviors of biodiesel droplet impingement: (a) camelina biofuel [128]; (b) methyl oleate droplets with different ethanol concentrations [129].

5. Advanced Techniques for Improving Biodiesel Atomization

5.1. Air-Assisted Atomization

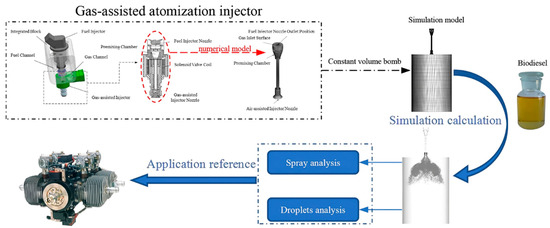

Air-assisted atomization is a promising technology to enhance the spray characteristics. In this system, high-velocity air interacts with the liquid fuel stream, generating intense shear forces that destabilize the fuel jet and promote rapid breakup into finer, more uniform droplets [130,131,132]. This mechanism is especially advantageous for biodiesel, which typically suffers from higher viscosity and surface tension compared to conventional diesel. Studies [133,134] using Phase Doppler Anemometry (PDA) and CFD simulation showed that air-assisted atomization effectively reduces the SMD of biodiesel sprays. The influences of ambient pressure, fuel injection duration, and ambient temperature on spray characteristics of biodiesel with air-assisted atomization injection are also investigated by numerical simulation [135]. The air-assisted atomization injector assembly, simulation model, results and application are shown in Figure 6. Ma et al. [136] further investigated the droplet velocity and size characteristics of biodiesel in an air-assisted pressure swirl atomizer under different oil pressures and air volumes. These findings offer critical insights into the fundamental atomization behavior of biodiesel, establishing a scientific basis for optimizing spray parameters in CI engines, although challenges like nozzle wear and system complexity persist.

Figure 6.

The air-assisted atomization injector and its application [135].

5.2. Dual-Fuel Impingement

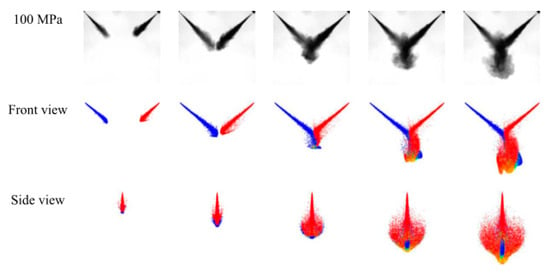

Dual-fuel impingement systems typically involve injecting two fuels (biodiesel and a liquid fuel like ethanol or biodiesel and a gaseous fuel like natural gas) through separate nozzles or a single multi-orifice nozzle. The collision of fuel jets or fuel–gas streams creates shear forces that disrupt the fuel into smaller droplets [137,138]. The atomization mechanism of spray impingement consists of two stages: the fragmentation process where the spray interacts with the ambient gas prior to impingement, and the impingement process between the two sprays. Due to the short distance before impingement, the impingement process in the second stage plays a dominant role in spray atomization. Spray impingement leads to frequent droplet collisions, and the outcomes of these collisions such as fragmentation and coalescence, are influenced by environmental conditions, injection parameters, and fuel properties. Zhang et al. [139] experimentally and numerically investigated the macroscopic and microscopic characteristics of n-butanol/biodiesel spray collision, and the impinging spray behaviors are shown in Figure 7. They observed that butanol–biodiesel dual sprays with optimized injection delay times (0.5~2 ms) produced SMD values 15~20% smaller than single biodiesel sprays. This is attributed to the intense mixing and secondary breakup induced by jet collision. As follows, they explored the cross-impingement characteristics at small (10%), middle (30%), and large (50%) biodiesel–butanol blended proportions [140]. They found that the cross-impingement is likely to decrease the spray–wall impingement owing to a change in the diffusion direction, and the biodiesel blended with a higher proportion of n-butanol presents faster vapor-phase diffusion, which promotes fuel–gas mixing. Dual-fuel impingement represents a breakthrough approach for improving biodiesel atomization, where controlled spray collisions effectively overcome viscosity limitations. This technique necessitates systematic investigations into impinging spray dynamics to fully characterize the atomization mechanisms and optimize operational parameters for biodiesel applications.

Figure 7.

The behavior of n-butanol/biodiesel dual-fuel impinging sprays [139].

5.3. Nano-Biodiesel

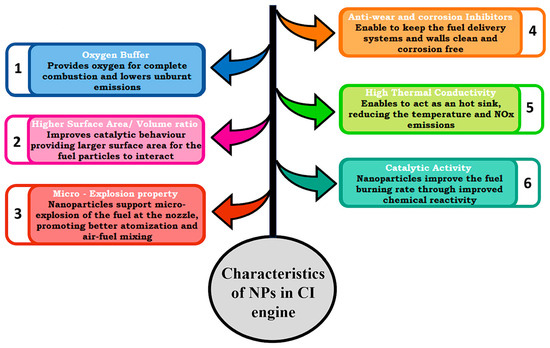

Nanofluids represent an advanced class of solid–liquid composite materials, comprising nanoscale particles (NPs, typically 1~100 nm in diameter) uniformly dispersed in a base liquid [141]. Figure 8 presents several advantages that are linked with the addition of NPs as fuel additives [142]. When this principle is applied to biodiesel blends, the resulting fuel mixture is called nano-biodiesel. Studies [143,144,145] showed that the integration of metal-based additives including Mn, Ni, Mg, and Co and specific oxygenated additives into biodiesel blends leads to reductions in viscosity, density, and flash point. Conversely, such incorporation enhances the oxygen content of the blends. NPs also enhance atomization quality by introducing disturbances that promote the breakup process, thereby widening the spray cone angle, increasing the penetration length, and improving fuel–air mixing [146,147]. The SMD found for D80B20A100 (80% by vol. of diesel, 20% by vol. of biodiesel and 100 ppm of alumina) was 14.3 μm, which is almost comparable with neat diesel (13.1 μm) and much better than D80B20 (17.5 μm) [148]. However, it is crucial to emphasize that most NPs do not fully combust with the fuel and may raise additional environmental concerns when released.

Figure 8.

Positive impacts of nanoparticles as fuel additives.

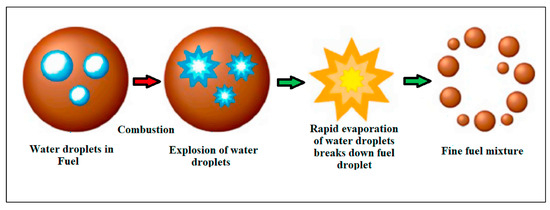

5.4. Water-Emulsified Biodiesel

Water-emulsion fuels are emulsions of water and flammable liquids, typically oil [149,150,151]. Water-emulsified biodiesel is an emulsified fuel system in which water is uniformly dispersed in biodiesel in the form of tiny droplets, and emulsifiers are usually required to maintain its stability. From the perspective of performance, the introduction of water can improve fuel atomization through the “micro-explosion effect”, as shown in Figure 9 [152]. During combustion, the pressure generated by the vaporization of water can promote further breakup of biodiesel droplets, thereby improving combustion efficiency. The spray and atomization performance of biodiesel derived from castor oil and its emulsion with 15% water under an environment temperature of 673K was investigated by Lin et al. [153]. They found that the SMD of the emulsion decreased significantly, coupled with the expanded spread of the spray plume, indicating a greater volume of smaller droplets dispersed in the chamber air. At the same time, the heat absorption property of water evaporation helped reduce the combustion temperature and decrease the emission of pollutants such as nitrogen oxides (NOx) [154]. Currently, findings on emulsions have generally been derived from short-term steady-state and transient tests, long-term durability tests are imperative to examine the corrosive effects of prolonged use of water–biodiesel emulsions on engine components, particularly the fuel injection system.

Figure 9.

Mechanism of a micro-explosion caused by water in fuel [152].

5.5. Comparative Discussion of Each Atomization Enhancement Method

The various biodiesel atomization enhancement methods present distinct trade-offs. Air-assisted atomization offers good droplet breakup and emission reduction at moderate cost, while fuel blending provides the simplest and most scalable solution despite limited effectiveness. Nano-biodiesel demonstrates superior atomization performance but raises concerns about nanoparticle pollution and high production costs. Water-emulsified biodiesel reduces NOx emissions but faces corrosion and stability challenges. Dual-fuel systems deliver strong performance yet require complex infrastructure. The advantages and disadvantages of each method based on parameters such as cost, scalability, environmental impact, and effectiveness are summarized in Table 4.

Table 4.

Comparative analysis of the biodiesel atomization enhancement methods.

Among these methods, nano-biodiesel and water-emulsified biodiesel stand out for their high effectiveness in improving atomization, yet they may raise long-term environmental and health concerns that warrant careful consideration. Nano-biodiesel, which incorporates nanoparticles like TiO2 or Al2O3 to reduce viscosity and enhance dispersion, significantly improves atomization by shrinking droplet sizes. However, the release of nanoparticles during combustion and exhaust emission is a critical issue. These tiny particles, often measuring less than 100 nanometers, can easily penetrate biological barriers, such as cell membranes and even the blood–brain barrier, posing potential risks to human respiratory and cardiovascular systems. Environmentally, they may accumulate in soil and water bodies, disrupting ecosystems by affecting microbial activity and plant growth. Their long-term persistence and bioaccumulation tendencies further amplify these concerns, as the full extent of their ecological impact remains incompletely understood.

Water-emulsified biodiesel, while cost-effective and environmentally beneficial in terms of reducing NOx emissions, faces challenges related to corrosiveness. The presence of water, even in emulsified form, can accelerate the corrosion of metal components in fuel storage tanks, pipelines, and engine systems over time. This corrosion not only reduces the lifespan of equipment but also raises the risk of fuel leakage, which can contaminate soil and groundwater. Furthermore, the emulsifiers employed to stabilize water–biodiesel emulsions may themselves pose environmental concerns. These additives could potentially alter the fuel’s biodegradability or generate harmful combustion byproducts, though comprehensive studies are required to fully evaluate these secondary effects.

We should also note that translating biodiesel atomization enhancements from laboratory to commercial engines presents significant challenges that require careful adaptation. Commercial applications demand solutions that maintain performance across variable operating conditions while meeting strict emissions regulations and cost targets—factors often not fully addressed in laboratory settings [155]. The most promising approaches typically undergo extensive prototype testing and iterative refinement to bridge the gap between ideal lab conditions and harsh engine environments, with fuel blending and air-assisted injection currently showing the most immediate commercial potential due to their balance of effectiveness and practicality.

6. Conclusions and Future Outlook

This review article concludes that biodiesel stands as a promising alternative to diesel fuel, well-suited to meet the operational requirements of CI engines. To assess the application characteristics of biodiesel, a comparative analysis was conducted, encompassing fundamental fuel properties, spray atomization behaviors, spray and droplet impingement and advanced techniques for improving biodiesel atomization. The conclusions derived from the current literature review are presented below, along with areas warranting further research and development regarding biodiesel atomization.

Despite the wide variety and diverse sources of biodiesel fuels, their viscosity and surface tension are generally higher than those of conventional diesel fuel, which can lead to poor atomization performance. The significance of the fuel density for atomization is diminished because most biodiesel fuels experience only minor differences in fuel density.

Biodiesel showed a longer spray tip penetration, smaller spray cone angle, larger SMD and faster droplet velocity compared with diesel fuel. Blending other fuels such as ethanol, butanol, dimethyl ether and di-n-butyl ether, to reduce the viscosity and surface tension of mixed fuels, represents a simple and effective approach for improving biodiesel atomization performance. More studies should be performed in this field in the future.

The probability of fuel–wall impingement is higher with biodiesel than with base diesel because of the former’s longer spray penetration. Additionally, biodiesel spray impingement is more prone to fuel deposition and film formation due to its higher viscosity and surface tension, which lead to combustion inefficiencies and emissions. Further studies should focus on combined strategies such as mild retarded injection timing, compression ratio, and combustion chamber design to enhance impact-induced secondary atomization, as well as reduce fuel deposition.

Droplet–wall impingement is a fundamental element in the complex process of spray–wall impingement. Spray impingement models must incorporate scientifically accurate descriptions of fundamental droplet phase change, aerodynamics, and transport processes. A comprehensive analysis of single-droplet impingement must be conducted, particularly using microscale biodiesel and blending fuel droplets under real engine operating conditions.

Advanced techniques such as air-assisted atomization, dual-fuel impingement, nano-biodiesel and water-emulsified biodiesel, collectively contribute to mitigating the atomization limitations of biodiesel, paving the way for its more efficient application in compression ignition engines. Further research is needed to refine these methods and explore synergistic effects between different approaches.

Author Contributions

Conceptualization, Z.F.; software, J.Z. and J.G.; investigation, Z.F., J.Z. and J.G.; data curation, Z.F., J.Z. and J.G.; writing—review and editing, Z.F., X.L. and K.N.; visualization, Z.F.; supervision, Z.H.; funding acquisition, Z.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the China Postdoctoral Science Foundation (No. 2024M751177). We also acknowledged financial support from the Natural Science Foundation of Jiangsu Province (BK 20240859), and the Jiangsu University Foundation (Grant No. 22JDG040).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shao, S.; Sun, T.; Li, X.; Wang, Y.; Ma, L.; Liu, Z.; Wu, S. Preparation of heavy bio-oil-based porous carbon by pyrolysis gas activation and its performance in the aldol condensation for aviation fuel as catalyst carrier. Ind. Crops Prod. 2024, 218, 118963. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, N.; Xie, H.; Li, J.; Li, G.; Xue, L.; Fu, H.; Feng, Y.; Poinern, G.E.J.; Chen, D. Livestock manure-derived hydrochar is more inclined to mitigate soil Global Warming Potential than raw materials based on soil stoichiometry analysis. Biol. Fertil. Soils 2023, 59, 459–472. [Google Scholar] [CrossRef]

- Ahmad, A.; Naqvi, S.A.; Jaskani, M.J.; Waseem, M.; Ali, E.; Khan, I.A.; Manzoor, M.F.; Siddeeg, A.; Aadil, R.M. Efficient utilization of date palm waste for the bioethanol production through Saccharomyces cerevisiae strain. Food Sci. Nutr. 2021, 9, 2066–2074. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Manning, D.A.C.; Werner, D. The limited potential of soil and vegetation in urban greenspace for nature-based offsetting of institutional carbon emissions. Soil Use Manag. 2023, 40, e13081. [Google Scholar] [CrossRef]

- Ren, G.; Cui, M.; Yu, H.; Fan, X.; Zhu, Z.; Zhang, H.; Dai, Z.; Sun, J.; Yang, B.; Du, D. Global Environmental Change Shifts Ecological Stoichiometry Coupling Between Plant and Soil in Early-Stage Invasions. J. Soil Sci. Plant Nutr. 2024, 24, 2402–2412. [Google Scholar] [CrossRef]

- Yan, H.; Joe Acquah, S.; Zhang, J.; Wang, G.; Zhang, C.; Opoku Darko, R. Overview of modelling techniques for greenhouse microclimate environment and evapotranspiration. Int. J. Agric. Biol. Eng. 2021, 14, 1–8. [Google Scholar] [CrossRef]

- Nazir, M.J.; Li, G.; Nazir, M.M.; Zulfiqar, F.; Siddique, K.H.M.; Iqbal, B.; Du, D. Harnessing soil carbon sequestration to address climate change challenges in agriculture. Soil Tillage Res. 2024, 237, 105959. [Google Scholar] [CrossRef]

- Chauhdary, J.N.; Li, H.; Ragab, R.; Rakibuzzaman, M.; Khan, A.I.; Zhao, J.; Akbar, N. Climate Change Impacts on Future Wheat (Triticum aestivum) Yield, Growth Periods and Irrigation Requirements: A SALTMED Model Simulations Analysis. Agronomy 2024, 14, 1484. [Google Scholar] [CrossRef]

- Tang, Q.; Zhu, X.; Uddeen, K.; Turner, J.; Yao, M. Optical study on ammonia-diesel dual fuel combustion at low engine loads. J. Energy Inst. 2025, 122, 102189. [Google Scholar] [CrossRef]

- Chu, W.; Li, H.; Liu, Y.; Zhou, B.; Luo, H.; Kim, W. Three-dimensional simulation analysis of in-cylinder combustion in space in-orbit hydrogen-oxygen internal combustion engine. Appl. Therm. Eng. 2025, 263, 125391. [Google Scholar] [CrossRef]

- Ren, M.; Kong, F.; Zhou, C.; Fakayode, O.A.; Liang, J.; Li, H.; Zhou, M.; Fan, X. Green, one-pot biomass hierarchical utilization strategy for lignin-containing cellulose nanofibrils and fractionated lignin preparation. Ind. Crops Prod. 2023, 203, 117193. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Y.; Fang, Z.; Shi, G.; Lou, L.; Ren, K.; Cai, Q. Italian ryegrass-rice rotation system for biomass production and cadmium removal from contaminated paddy fields. J. Soils Sediments 2020, 20, 874–882. [Google Scholar] [CrossRef]

- Hassan, G.; Shabbir, M.A.; Ahmad, F.; Pasha, I.; Aslam, N.; Ahmad, T.; Rehman, A.; Manzoor, M.F.; Inam-Ur-Raheem, M.; Aadil, R.M. Cereal processing waste, an environmental impact and value addition perspectives: A comprehensive treatise. Food Chem. 2021, 363, 130352. [Google Scholar] [CrossRef]

- Chen, X.; Kitts, D.D.; Ji, D.; Ding, J. Free radical scavenging activities of phytochemical mixtures and aqueous methanolic extracts recovered from processed coffee leaves. Int. J. Food Sci. Technol. 2019, 54, 2872–2879. [Google Scholar] [CrossRef]

- Pan, S.; Zabed, H.M.; Wei, Y.; Qi, X. Technoeconomic and environmental perspectives of biofuel production from sugarcane bagasse: Current status, challenges and future outlook. Ind. Crops Prod. 2022, 188, 115684. [Google Scholar] [CrossRef]

- Ao, X.; Gan, H.; Xin, M.; Cong, Y.; Lu, D.; Guo, A.; Wang, H. Numerical investigation on the effects of pilot fuel and natural gas injection pressures on methane slip in a large marine dual-fuel engine. Energy 2024, 312, 133675. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Lu, X.C.; Ma, J.J.; Ji, L.B.; Huang, Z. Simultaneous reduction of NOx emission and smoke opacity of biodiesel-fueled engines by port injection of ethanol. Fuel 2008, 87, 1289–1296. [Google Scholar] [CrossRef]

- Suh, H.K.; Roh, H.G.; Lee, C.S. Spray and combustion characteristics of biodiesel/diesel blended fuel in a direct injection common-rail diesel engine. J. Eng. Gas Turb. Power 2008, 130, 032807. [Google Scholar] [CrossRef]

- Yoon, S.H.; Suh, H.K.; Lee, C.S. Effect of Spray and EGR Rate on the Combustion and Emission Characteristics of Biodiesel Fuel in a Compression Ignition Engine. Energ Fuel 2009, 23, 1486–1493. [Google Scholar] [CrossRef]

- Riyadi, T.W.B.; Spraggon, M.; Herawan, S.G.; Idris, M.; Paristiawan, P.A.; Putra, N.R.; Faizullizam, R.M.; Silambarasan, R.; Veza, I. Biodiesel for HCCI engine: Prospects and challenges of sustainability biodiesel for energy transition. Results Eng. 2023, 17, 100916. [Google Scholar] [CrossRef]

- Allami, H.A.; Tabasizadeh, M.; Rohani, A.; Nayebzadeh, H.; Farzad, A.; Hoseinpour, M. Modeling and optimization of performance and emission parameters of a diesel engine: A comparative evaluation between date seed oil biodiesel produced via three different heating systems. Energ Convers. Manag. 2023, 283, 116909. [Google Scholar] [CrossRef]

- Uyumaz, A.; Aydogan, B.; Yilmaz, E.; Solmaz, H.; Aksoy, F.; Mutlu, I.; Ipci, D.; Calam, A. Experimental investigation on the combustion, performance and exhaust emission characteristics of poppy oil biodiesel-diesel dual fuel combustion in a CI engine. Fuel 2020, 280, 118588. [Google Scholar] [CrossRef]

- Jiang, Y.; Issaka, Z.; Li, H.; Tang, P.; Chen, C. Range formula based on angle of dispersion and nozzle configuration from an impact sprinkler. Int. J. Agric. Biol. Eng. 2019, 12, 97–105. [Google Scholar] [CrossRef]

- Lin, H.; Li, H.; Jiang, Y. Axis-switching behavior of liquid jets issued from non-circular nozzles under low-intermediate pressure. Appl. Eng. Agric. 2021, 37, 367–378. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Chen, C.; Xiang, Q. Calculation and verification of formula for the range of sprinklers based on jet breakup length. Int. J. Agric. Biol. Eng. 2018, 11, 49–57. [Google Scholar] [CrossRef]

- Pan, X.; Jiang, Y.; Li, H.; Hui, X.; Xing, S.; Chauhdary, J.N. Numerical simulation and experimental study of jet breakup using a water dispersal needle in irrigation sprinklers. Biosyst. Eng. 2024, 239, 49–67. [Google Scholar] [CrossRef]

- Tate, R.E.; Watts, K.C.; Allen, C.A.W.; Wilkie, K.I. The densities of three biodiesel fuels at temperatures up to 300 °C. Fuel 2006, 85, 1004–1009. [Google Scholar] [CrossRef]

- Tate, R.E.; Watts, K.C.; Allen, C.A.W.; Wilkie, K.I. The viscosities of three biodiesel fuels at temperatures up to 300 °C. Fuel 2006, 85, 1010–1015. [Google Scholar] [CrossRef]

- Lee, C.S.; Park, S.W.; Kwon, S.I. An experimental study on the atomization and combustion characteristics of biodiesel-blended fuels. Energ Fuel 2005, 19, 2201–2208. [Google Scholar] [CrossRef]

- Mehra, K.S.; Pal, J.; Goel, V. A comprehensive review on the atomization and spray characteristics of renewable biofuels. Sustain Energy Technol. 2023, 56, 103106. [Google Scholar] [CrossRef]

- Zhong, W.J.; Tamilselvan, P.; Wang, Q.; He, Z.X.; Feng, H.; Yu, X. Experimental study of spray characteristics of diesel/hydrogenated catalytic biodiesel blended fuels under inert and reacting conditions. Energy 2018, 153, 349–358. [Google Scholar] [CrossRef]

- Pan, X.; Jiang, Y.; Li, H. Effects of the depth of the needle-shaped water dispersion device inserted into the jet on the jet breakup of sprinklers. Irrig. Drain. 2023, 72, 887–909. [Google Scholar] [CrossRef]

- Appah, S.; Jia, W.; Ou, M.; Wang, P.; Gong, C. Investigation of optimum applied voltage, liquid flow pressure, and spraying height for pesticide application by induction charging. Appl. Eng. Agric. 2019, 35, 795–804. [Google Scholar] [CrossRef]

- Appah, S.; Wang, P.; Ou, M.; Gong, C.; Jia, W. Review of electrostatic system parameters, charged droplets characteristics and substrate impact behavior from pesticides spraying. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Xiang, Q.; Chen, C. Comparison of PIV Experiment and Numerical Simulation on the Velocity Distribution of Intermediate Pressure Jets with Different Nozzle Parameters. Irrig. Drain. 2017, 66, 510–519. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Guo, X. Analysis of Droplet Characteristics and Kinetic Energy Distribution for Fixed Spray Plate Sprinkler at Low Working Pressure. Trans. ASABE 2021, 64, 447–460. [Google Scholar] [CrossRef]

- Hong, H.; Jiang, Y.; Tang, P.; Chao, C.; Fordjour, A. Comparative Evaluation on Performance Characteristics of an Impact Sprinkler with Nozzle-Dispersion Devicesand Rotary Plate Sprinkler. Appl. Eng. Agric. 2020, 36, 321–329. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, S.; Darko, R.O. Characteristics of water and droplet size distribution from fluidic sprinklers. Irrig. Drain. 2016, 65, 522–529. [Google Scholar] [CrossRef]

- Li, F.Y.; Fu, W.; Yi, B.L.; Song, L.B.; Liu, T.; Wang, X.H.; Wang, C.X.; Lei, Y.Y.; Lin, Q.Z. Comparison of macroscopic spray characteristics between biodiesel-pentanol blends and diesel. Exp. Therm. Fluid Sci. 2018, 98, 523–533. [Google Scholar] [CrossRef]

- Zhang, G.; Si, Z.; Zhai, C.; Luo, H.; Ogata, Y.; Nishida, K. Characteristics of wall-jet vortex development during fuel spray impinging on flat-wall under cross-flow conditions. Fuel 2022, 317, 123507. [Google Scholar] [CrossRef]

- Xuan, T.M.; Wang, Y.T.; Liu, L.; Yang, C.L.; He, Z.X.; Wang, Q.; Yao, M.F. Experimental study on flame structure and soot formation of jet/wall impinging combustion under diesel-like conditions. Therm. Sci. Eng. Prog. 2023, 43, 102016. [Google Scholar] [CrossRef]

- Tripathi, S.; Subramanian, K.A. Control of fuel spray wall impingement on piston bowl in palm acid oil biodiesel fueled direct injection automotive engine using retarded injection timing, EGR and increased compression ratio. Appl. Therm. Eng. 2018, 142, 241–254. [Google Scholar] [CrossRef]

- Bian, Q.F.; Xie, Y.W.; Zhang, W.Q.; Fan, X.J.; Li, W. Investigation on droplet spreading and energy conversion process on solid surface with low impinging velocity. Int. J. Heat Fluid Flow 2024, 110, 109607. [Google Scholar] [CrossRef]

- Guggilla, G.; Sielaff, A.; Stephan, P. Boiling regimes of a single droplet impinging on a superheated surface: Effect of the surrounding medium. Int. J. Heat Mass Transf. 2024, 220, 124982. [Google Scholar] [CrossRef]

- Khan, D.; Hansen, S.; Bjernemose, J.H.; Bebe, J.E.; Lund, I. Experimentation and numerical modeling of SCR spray droplets pre and post impingement on a mixer plate. Fuel 2023, 336, 126788. [Google Scholar] [CrossRef]

- Wang, X.; Xu, B.; Guo, S.; Zhao, Y.; Chen, Z.Q. Droplet impacting dynamics: Recent progress and future aspects. Adv. Colloid Interface 2023, 317, 102919. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Jing, Z.F.; Zhang, T.; Chen, Q.Y.; Qiu, F.X.; Peng, Y.X.; Tang, S. Fabrication of functional biomass carbon aerogels derived from sisal fibers for application in selenium extraction. Food Bioprod. Process. 2018, 111, 93–103. [Google Scholar] [CrossRef]

- Riaz, T.; Iqbal, M.W.; Mahmood, S.; Yasmin, I.; Leghari, A.A.; Rehman, A.; Mushtaq, A.; Ali, K.; Azam, M.; Bilal, M. Cottonseed oil: A review of extraction techniques, physicochemical, functional, and nutritional properties. Crit. Rev. Food Sci. Nutr. 2023, 63, 1219–1237. [Google Scholar] [CrossRef] [PubMed]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Shao, S.; Ma, L.; Li, X.; Zhang, H.; Xiao, R. Preparation of activated carbon with heavy fraction of bio-oil from rape straw pyrolysis as carbon source and its performance in the aldol condensation for aviation fuel as carrier. Ind. Crops Prod. 2023, 192, 115912. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K.; Hazrat, M.A. Second Generation Biodiesel: Potential Alternative to Edible Oil-Derived Biodiesel. Enrgy Procedia 2014, 61, 1969–1972. [Google Scholar] [CrossRef]

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energ Convers. Manag. 2021, 228, 113647. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Shu, C.M.; Sarangi, P.K.; Shadangi, K.P.; Rakshit, S.; Kennedy, J.F.; Gupta, V.K.; Sharma, M. Catalytic hydrodeoxygenation of bio-oil and model compounds—Choice of catalysts, and mechanisms. Renew. Sustain. Energy Rev. 2023, 187, 113700. [Google Scholar] [CrossRef]

- Ahmed, M.; Abdullah, A.; Patle, D.S.; Shahadat, M.; Ahmad, Z.; Athar, M.; Aslam, M.; Vo, D.V.N. Feedstocks, catalysts, process variables and techniques for biodiesel production by one-pot extraction-transesterification: A review. Environ. Chem. Lett. 2022, 20, 335–378. [Google Scholar] [CrossRef]

- Smeets, E.; Tabeau, A.; van Berkum, S.; Moorad, J.; van Meijl, H.; Woltjer, G. The impact of the rebound effect of the use of first generation biofuels in the EU on greenhouse gas emissions: A critical review. Renew. Sustain. Energy Rev. 2014, 38, 393–403. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Kim, S.H.; Yoon, J.J.; Yang, Y.H. Current status and strategies for second generation biofuel production using microbial systems. Energ Convers. Manag. 2017, 148, 1142–1156. [Google Scholar] [CrossRef]

- Alaswad, A.; Dassisti, M.; Prescott, T.; Olabi, A.G. Technologies and developments of third generation biofuel production. Renew. Sustain. Energy Rev. 2015, 51, 1446–1460. [Google Scholar] [CrossRef]

- Godbole, V.; Pal, M.K.; Gautam, P. A critical perspective on the scope of interdisciplinary approaches used in fourth-generation biofuel production. Algal Res. 2021, 58, 102436. [Google Scholar] [CrossRef]

- Tang, C.L.; Feng, Z.H.; Zhan, C.; Ma, W.A.; Huang, Z.H. Experimental study on the effect of injector nozzle factor on the spray characteristics in a constant volume chamber: Near nozzle spray initiation, the acroscopic and the droplet statistics. Fuel 2017, 202, 583–594. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J.; Li, H.; Hua, L.; Yong, Y. Droplet distribution characteristics of impact sprinklers with circular and noncircular nozzles: Effect of nozzle aspect ratios and equivalent diameters. Biosyst. Eng. 2021, 212, 200–214. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, C.; Li, H.; Xiang, Q. Influences of nozzle parameters and low-pressure on jet breakup and droplet characteristics. Int. J. Agric. Biol. Eng. 2016, 9, 22–32. [Google Scholar]

- Feng, Z.H.; Tong, S.Q.; Tang, C.L.; Zhan, C.; Nishida, K.; Huang, Z.H. Decoupling the Effect Of Surface Tension And Viscosity on Spray Characteristics under Different Ambient Pressures: Near-Nozzle Behavior And Macroscopic Characteristics. At. Sprays 2019, 29, 629–654. [Google Scholar] [CrossRef]

- Yang, W.; Zhong, W.; Jia, W.; Ou, M.; Dong, X.; Zhang, T.; Ding, S.; Yu, P. The effect of oil-in-water emulsion pesticide on the evolution of liquid sheet rim disintegration and the spraying distribution. Crop Prot. 2024, 177, 106547. [Google Scholar] [CrossRef]

- Gong, C.; Kang, C.; Jia, W.; Yang, W.; Wang, Y. The effect of spray structure of oil-based emulsion spray on the droplet characteristics. Biosyst. Eng. 2020, 198, 78–90. [Google Scholar] [CrossRef]

- Li, H.; Issaka, Z.; Jiang, Y.; Tang, P.; Chen, C. Influence Of a Fixed Water Dispersion Device on Jet Dispersion And Range From an Impact Sprinkler. Irrig. Drain. 2019, 68, 669–678. [Google Scholar] [CrossRef]

- Liao, J.; Luo, X.; Wang, P.; Zhou, Z.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the Influence of Different Parameters on Droplet Characteristics and Droplet Size Classification Categories for Air Induction Nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef]

- Hwang, J.; Bae, C.; Gupta, T. Application of waste cooking oil (WCO) biodiesel in a compression ignition engine. Fuel 2016, 176, 20–31. [Google Scholar] [CrossRef]

- Liu, H.F.; Huo, M.; Liu, Y.; Wang, X.; Wang, H.; Yao, M.F.; Lee, C.F.F. Time-resolved spray, flame, soot quantitative measurement fueling-butanol and soybean biodiesel in a constant volume chamber under various ambient emperatures. Fuel 2014, 133, 317–325. [Google Scholar] [CrossRef]

- Wang, X.G.; Huang, Z.H.; Kuti, O.A.; Zhang, W.; Nishida, K. Experimental and analytical study on biodiesel and diesel spray characteristics under ultra-high injection pressure. Int. J. Heat Fluid Flow 2010, 31, 659–666. [Google Scholar] [CrossRef]

- Fu, W.; Li, F.Y.; Meng, K.S.; Liu, Y.J.; Shi, W.D.; Lin, Q.Z. Experiment and analysis of spray characteristics of biodiesel blending with di-butyl ether in a direct injection combustion chamber. Energy 2019, 185, 77–89. [Google Scholar] [CrossRef]

- Ma, X.; Li, F.; Wang, S.; Zhang, H. Evolution of biodiesel flow spray inside and near field in pressure swirl nozzles: Flow rate, atomization angle, and droplet size. Energy 2024, 291, 130337. [Google Scholar] [CrossRef]

- Chen, J.F.; Liu, Q.; Huang, Y.L.; Pachiannan, T.; Zhou, S.F.; Wang, Q.; Zhong, W.J. An optical study on spray and combustion characteristics of ethanol/ hydrogenated catalytic biodiesel blends in a constant volume combustion chamber. Therm. Sci. Eng. Prog. 2024, 49, 102448. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Al-Lwayzy, S. Butanol-acetone mixture blended with cottonseed biodiesel: Spray characteristics evolution, combustion characteristics, engine performance and emission. Proc. Combust. Inst. 2019, 37, 4729–4739. [Google Scholar] [CrossRef]

- Lee, D.; Jho, Y.; Lee, C.S. Effects of Soybean and Canola Oil-Based Biodiesel Blends on Spray, Combustion, and Emission Characteristics in a Diesel Engine. J. Energy Eng. 2014, 140, A4014012. [Google Scholar] [CrossRef]

- Battistoni, M.; Grimaldi, C.N. Numerical analysis of injector flow and spray characteristics from diesel injectors using fossil and biodiesel fuels. Appl Energy 2012, 97, 656–666. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Hua, L.; Zhang, D.; Issaka, Z. Experimental Study on Jet Breakup Morphologies and Jet Characteristic Parameters of Non-circular Nozzles under Low-intermediate Pressures. Appl. Eng. Agric. 2019, 35, 617–632. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Chen, C.; Hua, L.; Zhang, D. Hydraulic Performance and Jet Breakup Characteristics of the Impact Sprinkler with Circular and Non-circular Nozzles. Appl. Eng. Agric. 2019, 35, 911–924. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Hua, L.; Zhang, D. Three-dimensional flow breakup characteristics of a circular jet with different nozzle geometries. Biosyst. Eng. 2020, 193, 216–231. [Google Scholar] [CrossRef]

- Qin, W.; Xue, X.; Cui, L.; Zhou, Q.; Xu, Z.; Chang, F. Optimization and test for spraying parameters of cotton defoliant sprayer. Int. J. Agric. Biol. Eng. 2016, 9, 63–72. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, Y.; Liu, J.; Li, H.; Li, H. Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios. Agriculture 2022, 12, 2133. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Zhu, X.; Yuan, S. Droplet characterisation of a complete fluidic sprinkler with different nozzle dimensions. Biosyst. Eng. 2016, 148, 90–100. [Google Scholar] [CrossRef]

- Jing, D.L.; Zhang, F.; Li, Y.F.; Xu, H.M.; Shuai, S.J. Experimental investigation on the macroscopic and microscopic spray characteristics of dieseline fuel. Fuel 2017, 199, 478–487. [Google Scholar] [CrossRef]

- Feng, Z.H.; Yang, Z.; Jin, Y.; Si, Z.B.; He, Z.X. Experimental study on dribbling characteristics of gasoline/biodiesel blends after the end-of-injection. Int. J. Eng. Res. 2024, 25, 1053–1068. [Google Scholar] [CrossRef]

- Zhu, X.; Fordjour, A.; Agyen Dwomoh, F.; Kwame Lewballah, J.; Anim Ofosu, S.; Liu, J.; Dai, X.; Oteng, J. Experimental study on the effects of pressure loss on uniformity, application rate and velocity on different working conditions using the dynamic fluidic sprinkler. Heliyon 2024, 10, e27140. [Google Scholar] [CrossRef] [PubMed]

- Magnotti, G.M.; Genzale, C.L. Detailed assessment of diesel spray atomization models using visible and X-ray extinction measurements. Int. J. Multiph. Flow 2017, 97, 33–45. [Google Scholar] [CrossRef]

- Kim, H.J.; Suh, H.K.; Park, S.H.; Lee, C.S. An experimental and numerical investigation of atomization characteristics of biodiesel, dimethyl ether, and biodiesel-ethanol blended fuel. Energy Fuel 2008, 22, 2091–2098. [Google Scholar] [CrossRef]

- Lee, C.S.; Reitz, R.D. Effect of liquid properties on the breakup mechanism of high-speed liquid drops. At. Sprays 2001, 11, 1–19. [Google Scholar] [CrossRef]

- Esteban, B.; Riba, J.R.; Baquero, G.; Puig, R.; Rius, A. Characterization of the surface tension of vegetable oils to be used as fuel in diesel engines. Fuel 2012, 102, 231–238. [Google Scholar] [CrossRef]

- Guan, L.; Tang, C.L.; Yang, K.; Mo, J.; Huang, Z.H. Effect of di-n-butyl ether blending with soybean-biodiesel on spray and atomization characteristics in a common-rail fuel injection system. Fuel 2015, 140, 116–125. [Google Scholar] [CrossRef]

- Sun, F.Y.; Chen, H.; Geng, L.M.; Qi, D.H.; Wu, H.; Yan, X.G.; Ji, Z.H.; Zhang, P.; Chen, Z.M.; Zhang, W.B. Study on spray and combustion of acetone-butanol-ethanol (ABE)/biodiesel blends in a constant volume chamber. Energy 2025, 332, 137180. [Google Scholar] [CrossRef]

- Park, S.H.; Suh, H.K.; Lee, C.S. Nozzle flow and atomization characteristics of ethanol blended biodiesel fuel. Renew. Energy 2010, 35, 144–150. [Google Scholar] [CrossRef]

- Bang, S.H.; Lee, C.S. Fuel injection characteristics and spray behavior of DME blended with methyl ester derived from soybean oil. Fuel 2010, 89, 797–800. [Google Scholar] [CrossRef]

- ul Haq, M.; Jafry, A.T.; Ahmad, S.; Cheema, T.A.; Kamran, M.; Ajab, H.; Masjuki, H.H. Macroscopic spray behavior in pressurized chamber alongside thermal performance of quaternary castor biodiesel with butanol and 1-butoxybutane. Energy 2023, 282, 128912. [Google Scholar] [CrossRef]

- Hussain, Z.; Liu, J.; Chauhdary, J.N.; Zhao, Y. Evaluating the effect of operating pressure, nozzle size and mounting height on droplet characteristics of rotating spray plate sprinkler. Irrig. Sci. 2024. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.J.; Suh, H.K.; Lee, C.S. A study on the fuel injection and atomization characteristics of soybean oil methyl ester (SME). Int. J. Heat Fluid Flow 2009, 30, 108–116. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Song, Z. Critical factors influencing soil runoff and erosion in sprinkler irrigation: Water application rate and droplet kinetic energy. Agric. Water Manag. 2023, 283, 108299. [Google Scholar] [CrossRef]

- Tonini, S.; Gavaises, M.; Theodorakakos, A.; Cossali, G.E. Numerical investigation of a multiple injection strategy on the development of high-pressure diesel sprays. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2010, 224, 125–141. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, Y.F.; Dong, P.B.; Zhai, C.; Nishida, K.; Wang, Y.; Leng, X.Y. Diesel Spray Characteristics Of Multi-Hole Injectors under Geometrical Similarity Condition. At. Sprays 2025, 35, 19–45. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Guo, X.; Song, Z. Comparisons of Spray Characteristics between Non-circular and Circular Nozzles with Rotating Sprinklers. Appl. Eng. Agric. 2022, 38, 61–75. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Lakhiar, I.A.; Solangi, K.A.; Qureshi, W.A.; Shaikh, S.A.; Chen, J. Influence of Atomization Nozzles and Spraying Intervals on Growth, Biomass Yield, and Nutrient Uptake of Butter-Head Lettuce under Aeroponics System. Agronomy 2021, 11, 97. [Google Scholar] [CrossRef]

- Chen, R.; Li, H.; Wang, J.; Chen, C. Effects of Plate Structure and Nozzle Diameter on Hydraulic Performance of Fixed Spray Plate Sprinklers at Low Working Pressures. Trans. ASABE 2021, 64, 231–242. [Google Scholar] [CrossRef]

- Hua, L.; Jiang, Y.; Li, H.; Qin, L. Effects of Different Nozzle Orifice Shapes on Water Droplet Characteristics for Sprinkler Irrigation. Horticulturae 2022, 8, 538. [Google Scholar] [CrossRef]

- Kuti, O.A.; Zhu, J.Y.; Nishida, K.; Wang, X.G.; Huang, Z.H. Characterization of spray and combustion processes of biodiesel fuel injected by diesel engine common rail system. Fuel 2013, 104, 838–846. [Google Scholar] [CrossRef]

- Xu, S.H.; Guo, G.M.; Yang, K.; Yuan, J.P.; Guan, W.; Jin, Y.; He, Z.X. Evaluation of a liquid-vapor mass transfer model for string cavitation inside the liquid nozzle with non-condensable gas effects. Phys. Fluids 2025, 37, 053329. [Google Scholar] [CrossRef]

- Joshi, R.M.; Pegg, M.J. Flow properties of biodiesel fuel blends at low temperatures. Fuel 2007, 86, 143–151. [Google Scholar] [CrossRef]

- Liao, J.; John Hewitt, A.; Wang, P.; Luo, X.; Zang, Y.; Zhou, Z.; Lan, Y.; O’Donnell, C. Development of droplet characteristics prediction models for air induction nozzles based on wind tunnel tests. Int. J. Agric. Biol. Eng. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Junping, L.; Xingye, Z.; Shouqi, Y.; Xingfa, L. Droplet Motion Model and Simulation of a Complete Fluidic Sprinkler. Trans. ASABE 2018, 61, 1297–1306. [Google Scholar] [CrossRef]

- Kegl, B.; Lesnik, L. Modeling of macroscopic mineral diesel and biodiesel spray characteristics. Fuel 2018, 222, 810–820. [Google Scholar] [CrossRef]

- Wang, J.; Song, Z.; Chen, R.; Yang, T.; Tian, Z. Experimental Study on Droplet Characteristics of Rotating Sprinklers with Circular Nozzles and Diffuser. Agriculture 2022, 12, 987. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Shlegel, N.E.; Solomatin, Y.; Strizhak, P.A. Combined techniques of secondary atomization of multi-component droplets. Chem. Eng. Sci. 2019, 209, 115199. [Google Scholar] [CrossRef]

- Li, T.X.; Zhu, D.L.; Akafuah, N.K.; Saito, K.; Law, C.K. Synthesis, droplet combustion, and sooting characteristics of biodiesel produced from waste vegetable oils. Proc. Combust. Inst. 2011, 33, 2039–2046. [Google Scholar] [CrossRef]

- Xi, T.; Li, C.; Qiu, W.; Wang, H.; Lv, X.; Han, C.; Ahmad, F. Droplet Deposition Behavior on a Pear Leaf Surface under Wind-Induced Vibration. Appl. Eng. Agric. 2020, 36, 913–926. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Wang, J.; Hao, D.; Wang, R. The Motion of Strawberry Leaves in an Air-Assisted Spray Field and its Influence on Droplet Deposition. Trans. ASABE 2021, 64, 83–93. [Google Scholar] [CrossRef]

- Zhou, W.J.; Xi, H.Y.; Zhou, S.; Zhang, Z.; Shreka, M. Numerical study on knock characteristics and mechanism of a heavy duty natural gas/diesel RCCI engine. Int. J. Hydrogen Energy 2022, 47, 37072–37089. [Google Scholar] [CrossRef]

- Zhai, C.; Li, K.C.; Chen, R.; Luo, H.L. Experimental investigation of fuel spray and combustion with wall impingement under premixed conditions: A comparative analysis of flat wall and 2-D piston cavity. Energy 2025, 315, 134386. [Google Scholar] [CrossRef]

- Lahane, S.; Subramanian, K.A. Impact of nozzle holes configuration on fuel spray, wall impingement and NO emission of a diesel engine for biodiesel-diesel blend (B20). Appl. Therm. Eng. 2014, 64, 307–314. [Google Scholar] [CrossRef]

- Gong, C.; Jia, F.; Kang, C. Deposition of Water and Emulsion Hollow Droplets on Hydrophilic and Hydrophobic Surfaces. Agriculture 2024, 14, 960. [Google Scholar] [CrossRef]

- Cai, C.; Mudawar, I. Review of the dynamic Leidenfrost point temperature for droplet impact on a heated solid surface. Int. J. Heat Mass Transf. 2023, 217, 124639. [Google Scholar] [CrossRef]

- Cai, C.; Chen, H.; Liu, H.; Si, C. Effect of iso-propanol additive on the impact dynamics of a Leidenfrost water droplet. Appl. Therm. Eng. 2023, 234, 121326. [Google Scholar] [CrossRef]

- Cai, Y.C.; Qin, Z.P.; Zhu, L.; Zhu, C.C.; Zhao, X.; Xie, Z.Q.; Sun, C.M.; You, H. The splashing of a droplet falling on a low-speed, immiscible rotating liquid film. Int. J. Multiphase Flow 2023, 169, 104587. [Google Scholar] [CrossRef]

- Xia, L.; Yang, Z.; Chen, F.Z.; Liu, T.; Tian, Y.L.; Zhang, D.W. Droplet impacting on pillared hydrophobic surfaces with different solid fractions. J. Colloid Interface Sci. 2024, 658, 61–73. [Google Scholar] [CrossRef]

- Laan, N.; de Bruin, K.G.; Bartolo, D.; Josserand, C.; Bonn, D. Maximum Diameter of Impacting Liquid Droplets. Phys. Rev. Appl. 2014, 2, 044018. [Google Scholar] [CrossRef]

- Breitenbach, J.; Roisman, I.V.; Tropea, C. From drop impact physics to spray cooling models: A critical review. Exp. Fluids 2018, 59, 85. [Google Scholar] [CrossRef]

- Xu, L. Liquid drop splashing on smooth, rough, and textured surfaces. Phys. Rev. E 2007, 75, 056316. [Google Scholar] [CrossRef]

- Jadidbonab, H.; Malgarinos, I.; Karathanassis, I.; Mitroglou, N.; Gavaises, M. We-T classification of diesel fuel droplet impact regimes. Proc. R. Soc. A Math. Phys. Eng. Sci. 2018, 474, 20170759. [Google Scholar] [CrossRef]

- Sen, S.; Vaikuntanathan, V.; Sivakumar, D. Experimental investigation of biofuel drop impact on stainless steel surface. Exp. Therm. Fluid Sci. 2014, 54, 38–46. [Google Scholar] [CrossRef]

- Dong, Q.X.; Liu, C.; Lai, C.L.; Lin, J.Y.; Zhao, J.Y.; Liu, M.H. Experimental study on the dynamics characteristics of biodiesel/ethanol droplets impacting upon the heated wall. Int. Commun. Heat Mass Transf. 2024, 159, 108038. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Kang, C. Visualization of the evolution of bubbles in the spray sheet discharged from the air-induction nozzle. Pest Manag. Sci. 2022, 78, 1850–1860. [Google Scholar] [CrossRef]

- Hu, J.C.; Liu, B.L.; Zhang, C.; Gao, H.L.; Zhao, Z.F.; Zhang, F.J.; Wang, Y. Experimental study on the spray characteristics of an air-assisted fuel injection system using kerosene and gasoline. Fuel 2019, 235, 782–794. [Google Scholar] [CrossRef]

- Xiang, Q.; Qureshi, W.A.; Tunio, M.H.; Solangi, K.A.; Xu, Z.; Lakhiar, I.A. low-pressure drop size distribution characterization of impact sprinkler jet nozzles with and without aeration. Agric. Water Manag. 2021, 243, 106458. [Google Scholar] [CrossRef]

- Tan, E.S.; Anwar, M.; Kumaran, P.; Indra, T.M.; Yoshikawa, K. Air assist atomization characterization of palm biodiesel through experimental investigation and CFD simulation. Biofuels 2017, 8, 571–577. [Google Scholar] [CrossRef]

- Kardos, R.A.; Rácz, E.; Maly, M.; Jedelsky, J.; Józsa, V. Detailed spray analysis of airblast atomization of various fuels in a reacting environment. Int. J. Heat Mass Transf. 2024, 227, 125548. [Google Scholar] [CrossRef]

- Liu, R.; Zhong, L.F.; Li, S.H.; Li, J.; Ji, H.C. Numerical investigation on the spray characteristics of biodiesel with gas-assisted atomization injection. Fuel 2024, 358, 130178. [Google Scholar] [CrossRef]

- Ma, X.; Li, F.S.; Wang, S. Droplet velocity and size characteristics of biodiesel in an air-assisted pressure swirl atomizer during industrial furnace. Fuel 2025, 388, 134446. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, Y.; Li, H.; Wang, L. Enhancing hydraulic efficiency in jet impingement sprinklers: Comparative analysis of aperture ratios compared with non-impingement sprinklers. Biosyst. Eng. 2024, 248, 162–176. [Google Scholar] [CrossRef]

- Wu, D.; Li, J.; Liu, Z.H.; Xiong, Y.; Zheng, C.G.; Medwell, P.R. Eulerian and Lagrangian stagnation plane behavior of moderate Reynolds number round opposed-jets flow. Comput. Fluids 2016, 133, 116–128. [Google Scholar] [CrossRef]

- Zhang, Q.K.; Zhang, P.; Chi, Y.C.; Yang, T.; Zhu, J.Z.; Lu, X.C. Eulerian-Lagrangian simulation and validating experiment of n-butanol/biodiesel dual-fuel impinging sprays. Fuel 2023, 350, 128761. [Google Scholar] [CrossRef]

- Zhang, Q.K.; Wu, H.Q.; Mi, S.J.; Lu, X.C. Experimental Investigation on Cross-Impingement Characteristics Under Various Biodiesel-Butanol Blended Proportions and Ambient Conditions. J. Eng. Gas Turbines Power 2023, 145, 111005. [Google Scholar] [CrossRef]

- Kegl, T.; Kova, A.; Kegl, B.; Kegl, M. Nanomaterials as fuel additives in diesel engines: A review of current state, opportunities, and challenges. Prog. Energy Combust. 2021, 83, 100897. [Google Scholar] [CrossRef]

- Ul Haq, M.; Turab Jafry, A.; Ali, M.; Ajab, H.; Abbas, N.; Sajjad, U.; Hamid, K. Influence of nano additives on Diesel-Biodiesel fuel blends in diesel engine: A spray, performance, and emissions study. Energy Convers. Manag. X 2024, 23, 100574. [Google Scholar] [CrossRef]

- Devarajan, Y.; Nagappan, B.; Subbiah, G. A comprehensive study on emission and performance characteristics of a diesel engine fueled with nanoparticle-blended biodiesel. Environ. Sci. Pollut. Res. 2019, 26, 10662–10672. [Google Scholar] [CrossRef]

- Basha, J.S.; Anand, R.B. The influence of nano additive blended biodiesel fuels on the working characteristics of a diesel engine. J. Braz. Soc. Mech. Sci. Eng. 2013, 35, 257–264. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Tamilarasu, A.; Johny, A.; Mohan, A. Influence on the effect of zinc oxide and titanium dioxide nanoparticles as an additive with methyl ester in a CI engine. Energy Convers. Manag. 2017, 146, 8–19. [Google Scholar] [CrossRef]

- Mei, D.Q.; Fang, Y.; Adu-Mensah, D.; Cai, W.Y.; Yuan, Y.N. Spray characteristics of fuel with cerium oxide nanoparticles. Chem. Eng. Sci. 2023, 266, 118298. [Google Scholar] [CrossRef]

- Ul Haq, M.; Jafry, A.T.; Abbasi, M.S.; Jawad, M.; Ahmad, S.; Cheema, T.A.; Abbas, N. Numerical and Experimental Spray Analysis of Castor and Jatropha Biodiesel under Non-Evaporating Conditions. Energies 2022, 15, 7808. [Google Scholar] [CrossRef]

- Tomar, M.; Kumar, N. Effect of multi-walled carbon nanotubes and alumina nano-additives in a light duty diesel engine fuelled with biodiesel blends. Sustain. Energy Technol. 2020, 42, 100833. [Google Scholar] [CrossRef]

- Wang, L.; Yu, X.; Geng, F.; Cheng, C.; Yang, J.; Deng, Q. Effects of tocopherols on the stability of flaxseed oil-in-water emulsions stabilized by different emulsifiers: Interfacial partitioning and interaction. Food Chem. 2022, 374, 131691. [Google Scholar] [CrossRef]

- Mahdi, A.A.; Mohammed, J.K.; Al-Ansi, W.; Al-Maqtari, Q.A.; Al-Adeeb, A.; Cui, H.; Lin, L. Stabilization of the oil-in-water emulsions of Citrus reticulata essential oil by different combinations of gum arabic/maltodextrin/whey protein. J. Food Process. Preserv. 2022, 46, e16976. [Google Scholar] [CrossRef]

- Gu, H.; Lv, R.; Huang, X.; Chen, Q.; Dong, Y. Rapid quantitative assessment of lipid oxidation in a rapeseed oil-in-water (o/w) emulsion by three-dimensional fluorescence spectroscopy. J. Food Compos. Anal. 2022, 114, 104762. [Google Scholar] [CrossRef]

- Park, S.; Woo, S.; Kim, H.; Lee, K. The characteristic of spray using diesel water emulsified fuel in a diesel engine. Appl. Energy 2016, 176, 209–220. [Google Scholar] [CrossRef]

- Lin, Y.S.; Lin, H.P. Spray characteristics of emulsified castor biodiesel on engine emissions and deposit formation. Renew. Energy 2011, 36, 3507–3516. [Google Scholar] [CrossRef]

- Sudarshan, G.; Preetika, R.; Krishnasamy, A.; Basavaraja, M.G.; Indrapal, S.A. Preparation and utilization of biodiesel-water emulsions in compression ignition engines—A critical review. Fuel 2025, 394, 135124. [Google Scholar] [CrossRef]

- Najafi, G.; Shadidi, B. The influence of single and multi-carbon nanotubes as additives in diesel-biodiesel fuel blends on diesel engine combustion characteristics, performance, and emissions. Biofuels 2023, 15, 177–190. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).