Study on the Risk of Reservoir Wellbore Collapse Throughout the Full Life Cycle of the Qianmiqiao Bridge Carbonate Rock Gas Storage Reservoir

Abstract

1. Introduction

2. Quantitative Evaluation Method for Borehole Instability

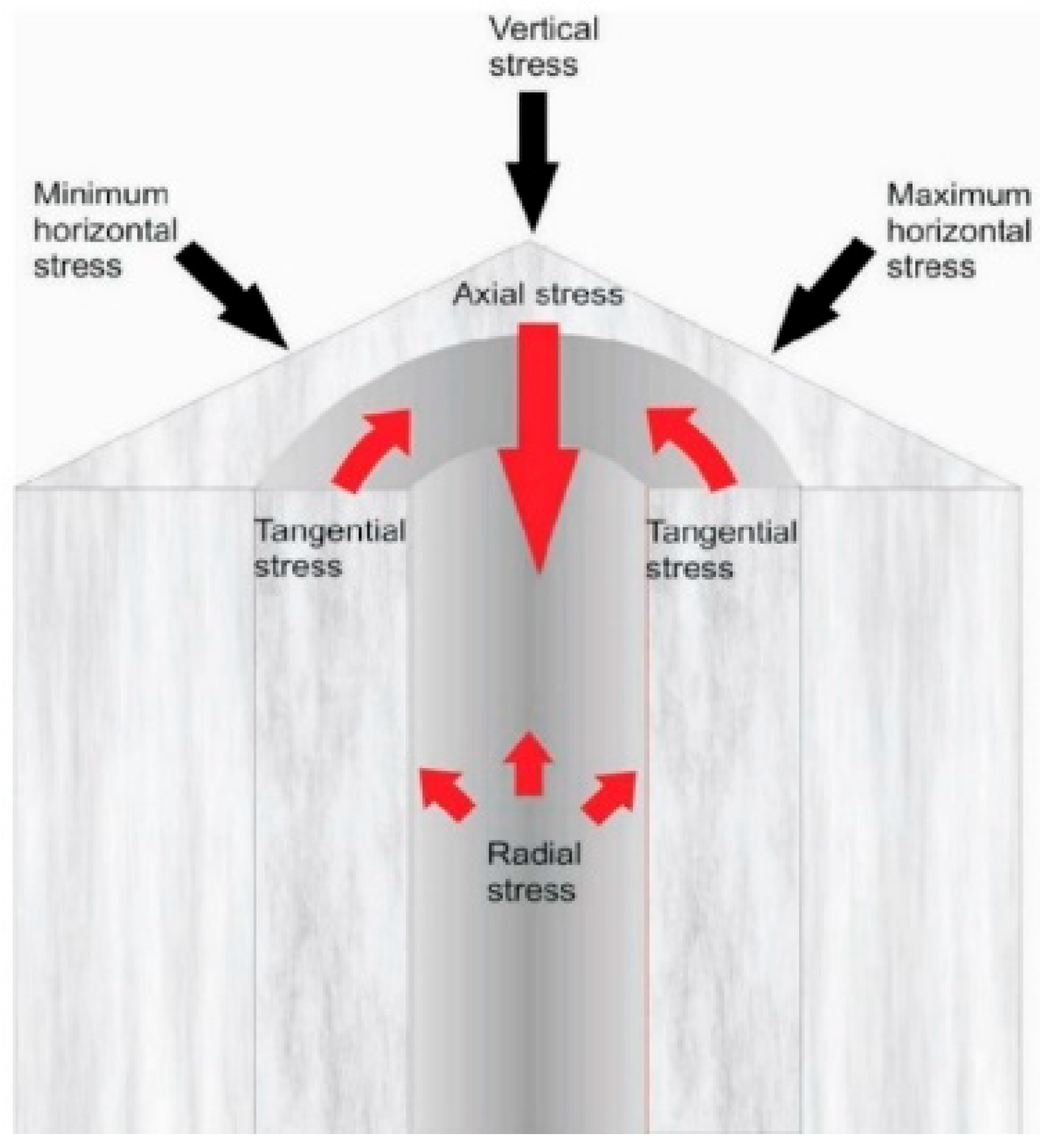

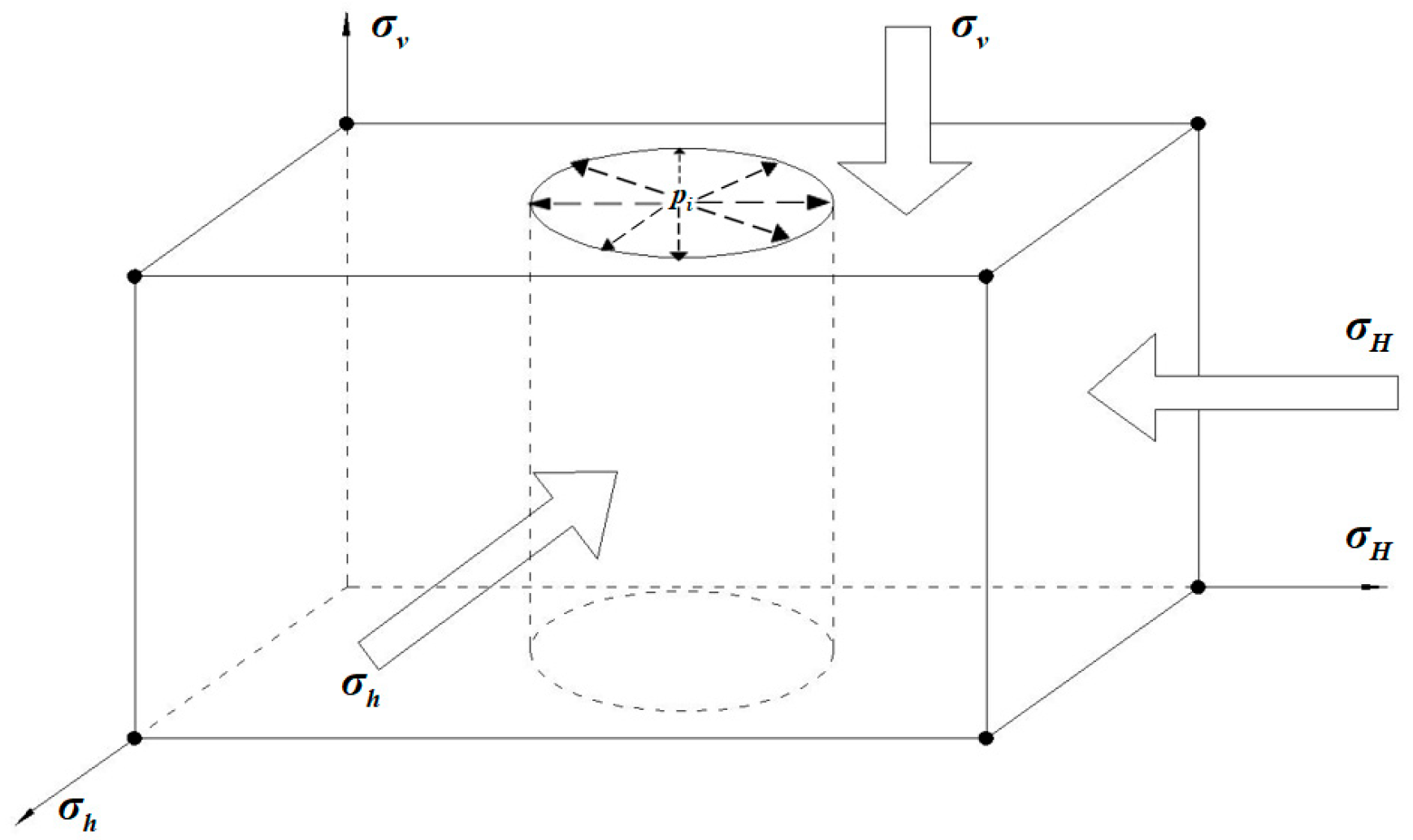

2.1. Wellbore Stress Calculation Method

- (1)

- The stress state around the wellbore under the sole action of wellbore column pressure :

- (2)

- The stress state around the wellbore under the sole action of maximum horizontal in situ :

- (3)

- The stress state around the wellbore under the sole action of minimum horizontal in situ stress .

- (4)

- The stress state around the wellbore under the sole action of overburden pressure .

- (5)

- By performing superposition processing on the stress states around the wellbore under the sole actions of casing column pressure, horizontal in situ stress, and overburden pressure, we derive the expression for the stress state of the rock around the wellbore in vertical wellbore cylindrical coordinates, which is as follows:

2.2. Wellbore Instability Discriminant Criteria

2.3. Wellbore Collapse Mechanisms

2.4. Coefficient of Wellbore Collapse

3. Borehole Collapse Risks During the Entire Life Cycle of Qianmiqiao Gas Storage

3.1. Research on the Characteristics of Stress Changes Around the Wellbore in Qianmiqiao Gas Storage

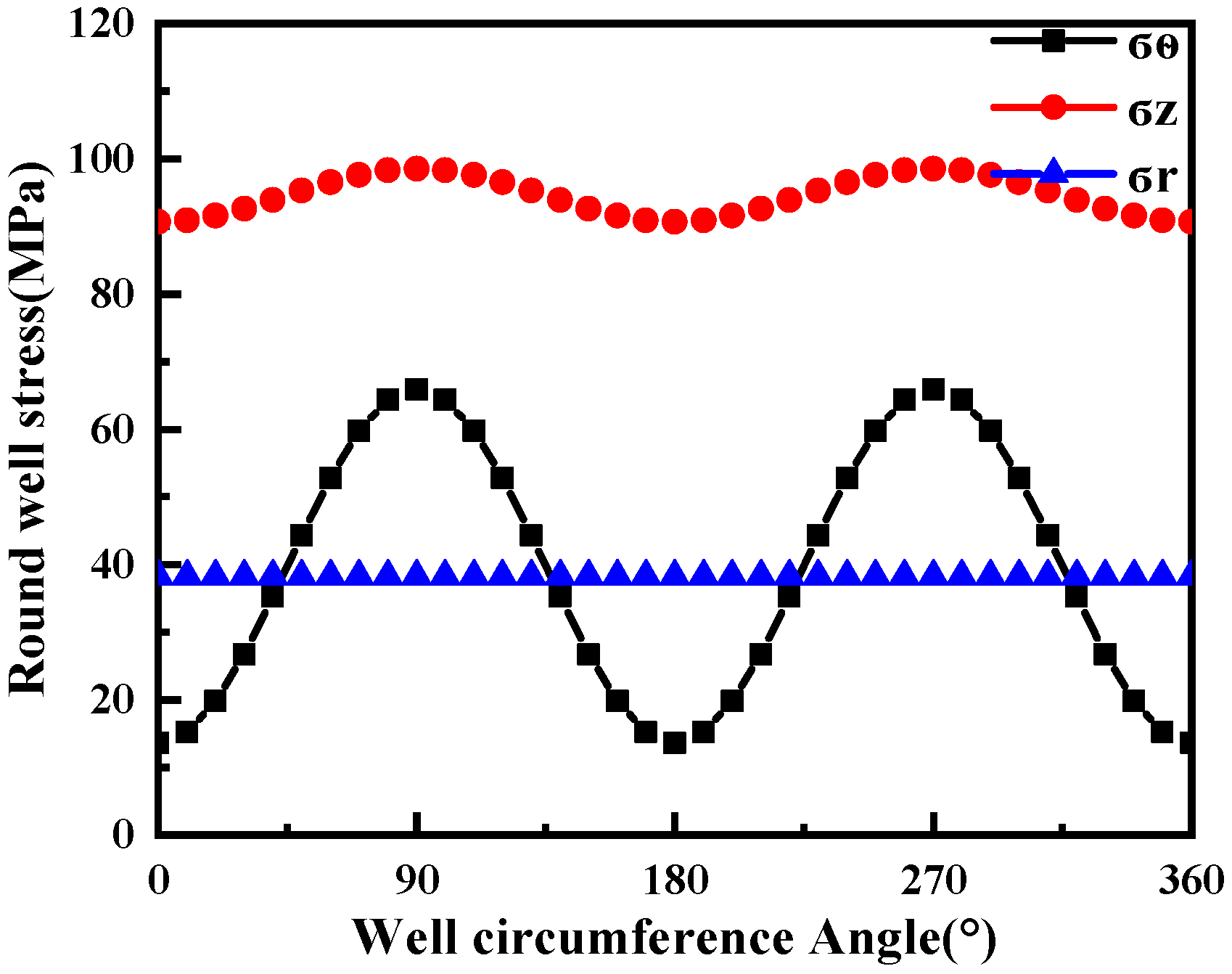

3.1.1. Characteristics of Stress Changes Around the Wellbore During the Drilling Stage

3.1.2. Characteristics of Stress Changes Around the Wellbore During the Acid-Treatment Process

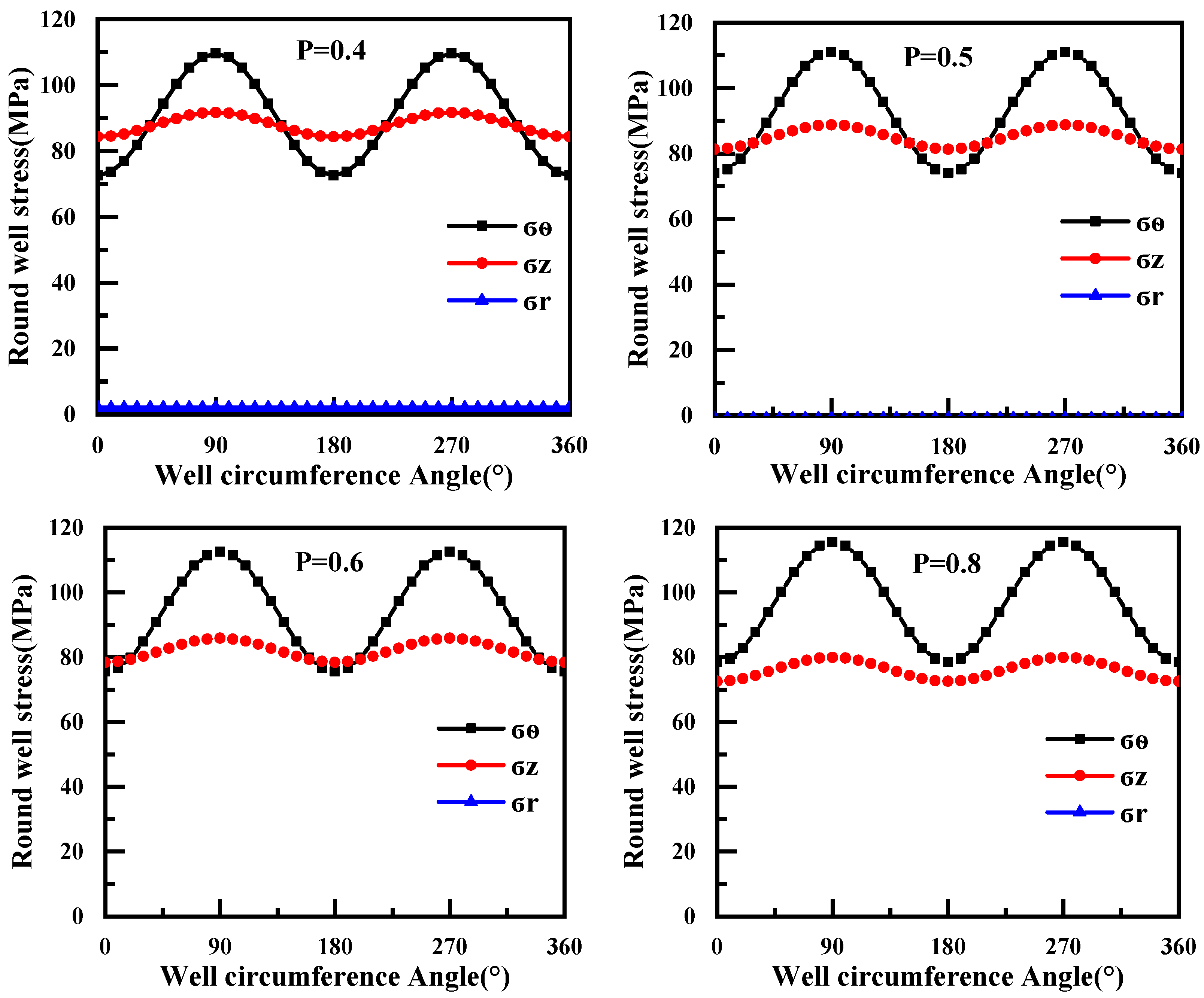

3.1.3. Characteristics of Stress Changes Around the Wellbore During the Injection-Production Process

3.2. Research on the Borehole Collapse Mode of Qianmiqiao Gas Storage

3.2.1. Borehole Collapse Mode During the Drilling Stage

3.2.2. Borehole Collapse Mode During the Acidization Stage

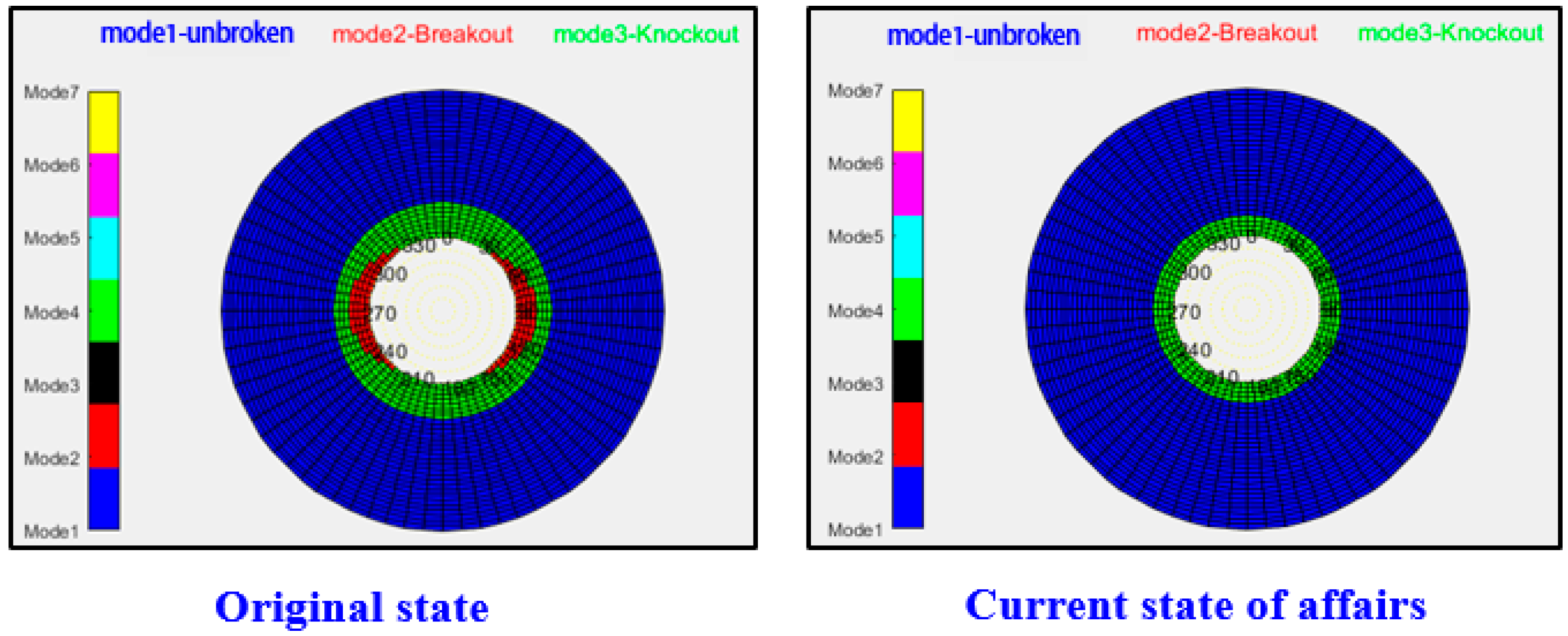

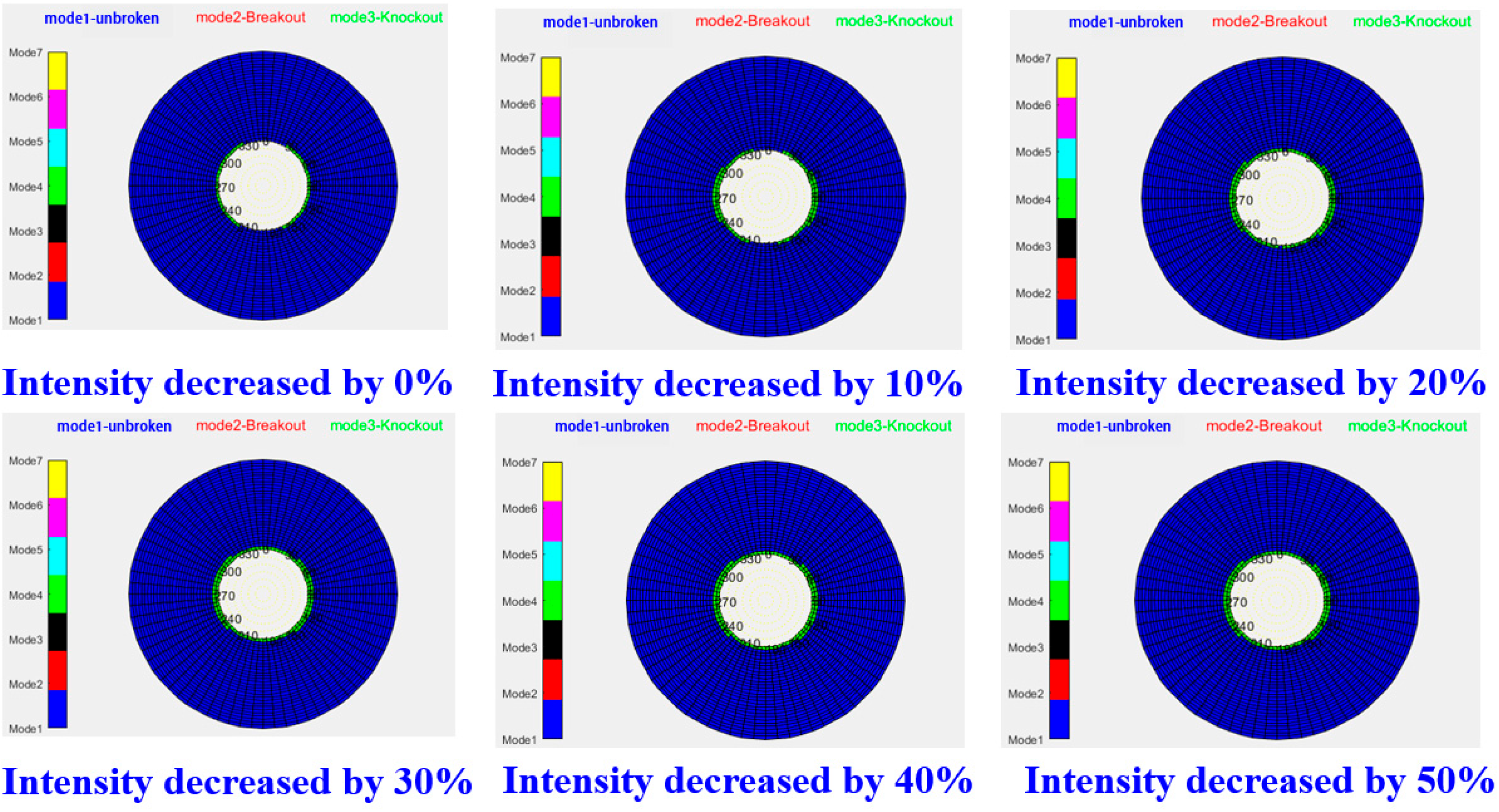

3.2.3. Borehole Collapse Mode During the Injection-Production Stage

4. Discussion

5. Conclusions

- (1)

- The stress field of the wellbore in carbonate rock gas storage shows significant dynamic evolution characteristics throughout its full life cycle, highlighting the inadequacy of traditional static evaluation methods. Specifically, stress states at 4277 m depth showed complex shifts, with deep well sections exhibiting greater susceptibility to stress changes.

- (2)

- During the drilling and initial gas injection stages, the wellbore predominantly exhibits shear-failure-induced collapse, with higher instability risk and severity observed in deeper well sections (e.g., 4277 m). Acidizing, while maintaining the same primary collapse mode (shallow breakout shear failure), effectively reduced overall collapse risk by decreasing the maximum–minimum stress difference and weakening rock strength.

- (3)

- The dynamic change of formation pressure is the dominant factor in the evolution of the borehole collapse mode during the injection-production stage. Specifically, as formation pressure increased from initial depletion levels, the collapse mode at 4277 m depth transformed from predominantly shallow breakout shear failure to wide breakout shear failure, significantly expanding the affected area and indicating a greater challenge to wellbore integrity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| σr | Radial stress (MPa) |

| σθ | Tangential (circumferential/hoop) stress (MPa) |

| σz | Axial stress (MPa) |

| σH | Maximum horizontal in situ stress (MPa) |

| σh | Minimum horizontal in situ stress (MPa) |

| σv | Vertical (overburden) stress (MPa) |

| pi | Wellbore fluid column pressure (mud column pressure) (MPa) |

| R | Wellbore radius (m) |

| r | Distance from any point in the formation to the wellbore center (m) |

| θ | Angular coordinate around the wellbore (°) |

| ν | Poisson’s ratio |

| σmax | Maximum principal stress (MPa) |

| σmin | Minimum principal stress (MPa) |

| C | Cohesion (MPa) |

| φ | Internal friction angle (°) |

| K | Wellbore stability coefficient |

References

- Tang, H.; Zheng, X.; Wang, X.; Zhao, Z.; Chen, Y.; Zhao, Y.; Zhang, L. Mechanical stability analysis of fracture-cavity carbonate gas storage. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024. [Google Scholar]

- Zhao, C.; Shi, L.; Su, H.; Yan, L.; Luo, Y.; Luo, S.; Qiu, P.; Hu, Y. Study on the Four-Dimensional Variations of In Situ Stress in Stress-Sensitive Ultra-High-Pressure Tight Gas Reservoirs. Processes 2025, 13, 1508. [Google Scholar] [CrossRef]

- Zhang, M.; Li, D.; Fan, X. Study on wellbore collapse pressure and instability area around wellbore in broken formation. Fault-Block Oil Gas Field 2024, 31, 916–921. [Google Scholar]

- Gao, J.; Chen, F.; Zhao, Y.; Meng, M.; Peng, H.; Bian, G.; Huang, L. Quantitative risk analysis and parameter sensitivity evaluation of wellbore instability in poroelastic media considering uncertainty of geomechanical parameters. Comput. Geotech. 2024, 170, 106234. [Google Scholar] [CrossRef]

- Huang, L.; Yu, Y.; Ren, G.; Meng, W.; Zheng, W. Analysis of wellbore instability probability and parameter sensitivity of openhole testing. Oil Drill. Prod. Technol. 2023, 45, 143–150. [Google Scholar]

- Gao, J.; Kong, D.; Peng, Y.; Zhou, Y.; Liu, Y.; Zhu, W. Seepage law of gas-reservoir UGSs during multi-cycle injection and production. Nat. Gas Ind. 2023, 43, 103–111. [Google Scholar]

- Guo, J.; Gou, B.; Lu, D.; Liu, Z.; Xiao, B.; Xu, K.; Ren, J. Advance and prospect of acid fracturing in deep carbonate reservoirs. Drill. Prod. Technol. 2024, 47, 121–129. [Google Scholar]

- Liu, H.B.; Cui, S.; Meng, Y.F.; Han, X. Dynamic analysis of wellbore stress field and wellbore stability in carbonate reservoir production process. Arab. J. Geosci. 2019, 12, 585. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, C.; Ma, T. A risk assessment method of wellbore instability based on the reliability theory. Nat. Gas Ind. 2019, 39, 97–104. [Google Scholar]

- Pašić, B.; Gaurina Međimurec, N.; Matanović, D. Wellbore instability: Causes and consequences. Rud.-Geološko-Naft. Zb. 2007, 19, 87–98. [Google Scholar]

- Rezmer-Cooper, I.; Bratton, T.; Krabbe, H. The use of resistivity-at-the-bit images and annular pressure while drilling in preventing drilling problems. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, New Orleans, LA, USA, 23–25 February 2000. [Google Scholar]

- Li, M.; Wang, Q.; Yao, C.; Chen, F.; Wang, Q.; Zhang, J. Optimization of development strategies and injection-production parameters in a fractured-vuggy carbonate reservoir by considering the effect of karst patterns: Taking c oilfield in the tarim basin as an example. Energies 2025, 18, 319. [Google Scholar] [CrossRef]

- Abdollahipour, A.; Soltanian, H.; Pourmazaheri, Y.; Kazemzadeh, E.; Fatehi-Marji, M. Sensitivity analysis of geomechanical parameters affecting a wellbore stability. J. Cent. South Univ. 2019, 26, 768–778. [Google Scholar] [CrossRef]

- Huang, X.; Wang, M.; Guo, X.; Xu, M.; Long, X. Application of 4D Geomechanical in Fault Sealing Capacity Evaluation of Underground Gas Storage-A Case Study from China. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 27 February–1 March 2024. [Google Scholar]

- Chen, X.; Gao, D.; Yang, J.; Luo, M.; Feng, Y.; Li, X. A comprehensive wellbore stability model considering poroelastic and thermal effects for inclined wellbores in deepwater drilling. J. Energy Resour. Technol. 2018, 140, 092903. [Google Scholar] [CrossRef]

- Ma, T.; Liu, J.; Fu, J.; Qiu, Y.; Fan, X.; Martyushev, D.A. Fully coupled thermo-hydro-mechanical model for wellbore stability analysis in deep gas-bearing unsaturated formations based on thermodynamics. Rock Mech. Rock Eng. 2025, 58, 33–64. [Google Scholar] [CrossRef]

- Suo, Y.; Dong, M.; Fu, X.; He, W.; Pan, Z. Experimental and numerical simulation research on hot dry rock wellbore stability under different cooling methods. Geothermics 2024, 119, 102977. [Google Scholar] [CrossRef]

- Kanfar, M.F.; Chen, Z.; Rahman, S.S. Analyzing wellbore stability in chemically-active anisotropic formations under thermal, hydraulic, mechanical and chemical loadings. J. Nat. Gas Sci. Eng. 2017, 41, 93–111. [Google Scholar] [CrossRef]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Plumb, D.; Krabbe, H.; Rasmus, J.; Li, Q.; Bornemann, T.; Bratton, T. Logging-while-drilling images for geomiechanical, geological and petrophysical interpretations. In Proceedings of the SPWLA Annual Logging Symposium, Oslo, Norway, 30 May–3 June 1999; p. SPWLA-1999-JJJ. [Google Scholar]

| Well Section (m) | Compressive Strength (MPa) | Cohesion (MPa) | Internal Friction Angle (°) | Formation Pressure (MPa) | Poisson’s Ratio | Maximum Horizontal In Situ Stress (MPa) | Minimum Horizontal In Situ Stress (MPa) | Vertical In Situ Stress (MPa) |

|---|---|---|---|---|---|---|---|---|

| 4277 | 77.20 | 2.24 | 18.84 | 1.00 | 0.20 | 77.12 | 67.90 | 100.60 |

| 4277 (Acidized) | 54.04 | 1.57 | 13.19 | 1.00 | 0.20 | 77.12 | 67.90 | 100.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Tian, F.; Qin, F.; Zhang, B.; Guo, S.; Cai, Q.; Chi, Z.; Ma, C. Study on the Risk of Reservoir Wellbore Collapse Throughout the Full Life Cycle of the Qianmiqiao Bridge Carbonate Rock Gas Storage Reservoir. Processes 2025, 13, 2480. https://doi.org/10.3390/pr13082480

Yu Y, Tian F, Qin F, Zhang B, Guo S, Cai Q, Chi Z, Ma C. Study on the Risk of Reservoir Wellbore Collapse Throughout the Full Life Cycle of the Qianmiqiao Bridge Carbonate Rock Gas Storage Reservoir. Processes. 2025; 13(8):2480. https://doi.org/10.3390/pr13082480

Chicago/Turabian StyleYu, Yan, Fuchun Tian, Feixiang Qin, Biao Zhang, Shuzhao Guo, Qingqin Cai, Zhao Chi, and Chengyun Ma. 2025. "Study on the Risk of Reservoir Wellbore Collapse Throughout the Full Life Cycle of the Qianmiqiao Bridge Carbonate Rock Gas Storage Reservoir" Processes 13, no. 8: 2480. https://doi.org/10.3390/pr13082480

APA StyleYu, Y., Tian, F., Qin, F., Zhang, B., Guo, S., Cai, Q., Chi, Z., & Ma, C. (2025). Study on the Risk of Reservoir Wellbore Collapse Throughout the Full Life Cycle of the Qianmiqiao Bridge Carbonate Rock Gas Storage Reservoir. Processes, 13(8), 2480. https://doi.org/10.3390/pr13082480