Osmotic Pretreatment and Solar Drying of Eggplant in Tunisian Rural Areas: Assessing the Impact of Process Efficiency and Product Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Sample Pretreatment

2.2. Solar Drying and Drying Kinetics

2.3. Rehydration Capacity

2.4. Physicochemical Properties

2.5. Textural Properties

2.6. Thermal Properties

2.7. Statistical Analysis

3. Results and Discussion

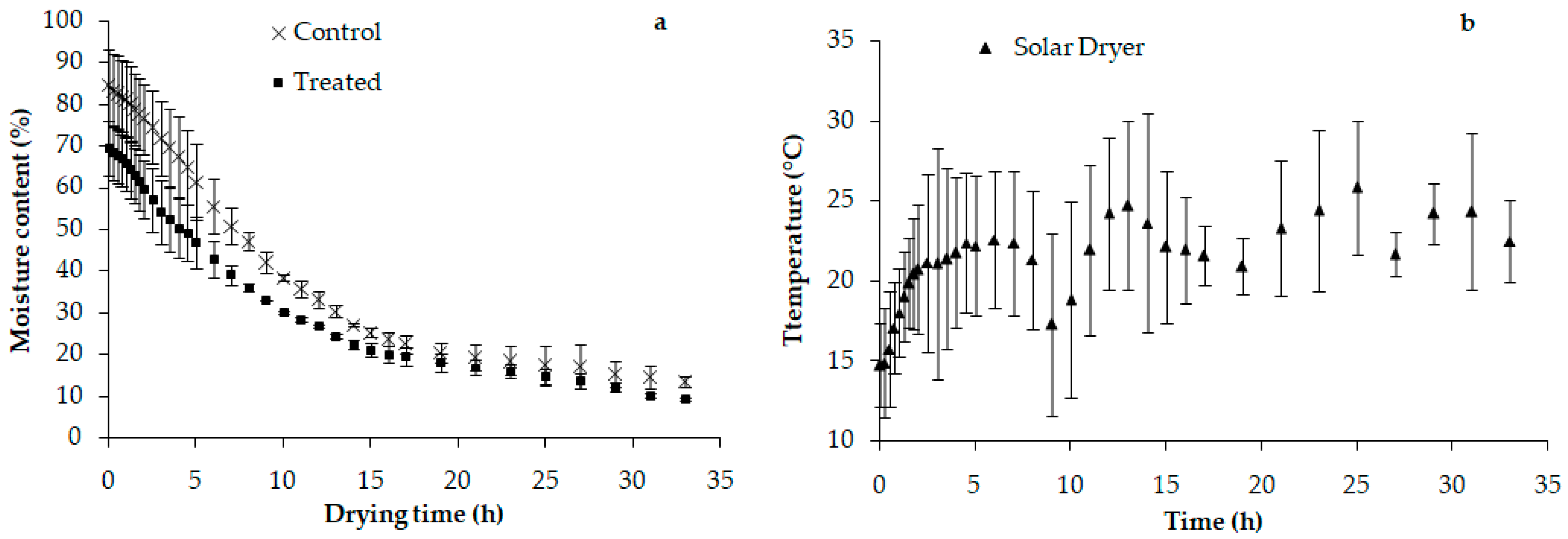

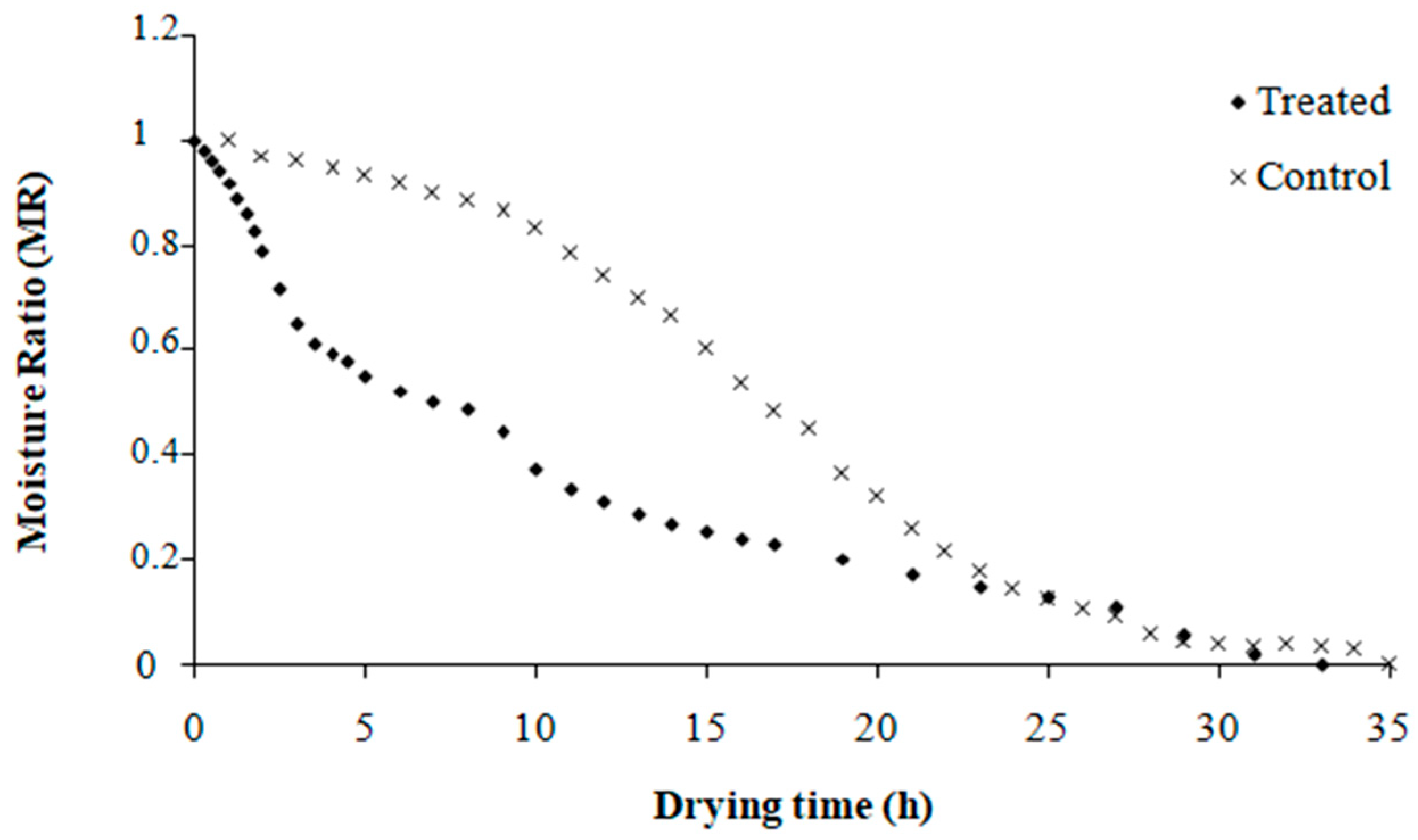

3.1. Drying Kinetics

3.2. Rehydration Capacity

3.3. Physicochemical Properties

3.4. Textural and Thermal Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lane, M.M.; Gamage, E.; Du, S.; Ashtree, D.N.; McGuinness, A.J.; Gauci, S.; Marx, W. Ultra-processed food exposure and adverse health outcomes: Umbrella review of epidemiological meta-analyses. BMJ 2024, 384, e077310. [Google Scholar] [CrossRef]

- World Health Organization. Diet, Nutrition, and the Prevention of Chronic Diseases: Report of a Joint WHO/FAO Expert Consultation; World Health Organization: Geneva, Switzerland, 2003; p. 916. [Google Scholar]

- Harris, J.; de Steenhuijsen Piters, B.; McMullin, S.; Bajwa, B.; de Jager, I.; Brouwer, I.D. Fruits and vegetables for healthy diets: Priorities for food system research and action. In Science and Innovations for Food Systems Transformation; von Braun, J., Afsana, K., Fresco, L.O., Hassan, M.H.A., Eds.; Springer: Cham, Switzerland, 2023; pp. 87–103. [Google Scholar] [CrossRef]

- Vandevijvere, S.; Knai, C. Increasing fruit and vegetable intake: Where are we at and how do we reach recommendations? Public Health Nutr. 2015, 18, 2701–2704. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Kamiloglu, S.; Toydemir, G.; Boyacioglu, D.; Beekwilder, J.; Hall, R.D.; Capanoglu, E. A review on the effect of drying on antioxidant potential of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2016, 56, 110–129. [Google Scholar] [CrossRef]

- Qu, H.; Masud, M.H.; Islam, M.; Khan, I.H.; Ananno, A.A.; Karim, A. Sustainable food drying technologies based on renewable energy sources. Crit. Rev. Food Sci. Nutr. 2021, 62, 6872–6886. [Google Scholar] [CrossRef] [PubMed]

- Maskan, M. Microwave/air and microwave finish drying of banana. J. Food Eng. 2000, 48, 71–78. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, J.; Mujumdar, A.S.; Wang, S. Trends in microwave related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Petikirige, J.; Karim, A.; Milla, G. Effect of drying techniques on quality and sensory properties of tropical fruits. Int. J. Food Sci. Technol. 2022, 57, 6963–6979. [Google Scholar] [CrossRef]

- Siriwattananon, L. Effect of drying methods on dietary fiber content in dried fruit and vegetable from non-toxic agricultural field. Int. J. GEOMATE 2016, 11, 2896–2900. [Google Scholar] [CrossRef]

- Guiné, R. The drying of foods and its effect on the physical-chemical, sensorial and nutritional properties. Int. J. Food Eng. 2018, 2, 93–100. [Google Scholar] [CrossRef]

- Devan, P.K.; Bibin, C.; Shabrin, I.A.; Gokulnath, R.; Karthick, D. Solar drying of fruits–A comprehensive review. Mater. Today Proc. 2020, 33, 253–260. [Google Scholar] [CrossRef]

- Perea-Flores, M.J.; Garibay-Febles, V.; Chanona-Perez, J.J.; Calderon-Dominguez, G.; Mendez-Mendez, J.V.; Palacios-González, E.; Gutierrez-Lopez, G.F. Mathematical modelling of castor oil seeds (Ricinus communis) drying kinetics in fluidized bed at high temperatures. Ind. Crops Prod. 2012, 38, 64–71. [Google Scholar] [CrossRef]

- Kholmanskiy, A.S.; Tilov, A.Z.; Sorokina, E.Y. Drying kinetics of plant products: Dependence on chemical composition. J. Food Eng. 2013, 117, 378–382. [Google Scholar] [CrossRef]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Mewa, E.A.; Okoth, M.W.; Kunyanga, C.N.; Rugiri, M.N. Experimental evaluation of beef drying kinetics in a solar tunnel dryer. Renew. Energy 2019, 139, 235–241. [Google Scholar] [CrossRef]

- Arnell, N.W.; Lowe, J.A.; Challinor, A.J.; Osborn, T.J. Global and regional impacts of climate change at different levels of global temperature increase. Clim. Change 2019, 155, 377–391. [Google Scholar] [CrossRef]

- Indiarto, R.; Asyifaa, A.H.; Adiningsih, F.C.A.; Aulia, G.A.; Achmad, S.R. Conventional and advanced food-drying technology: A current review. Int. J. Sci. Technol. Res. 2021, 10, 99–107. [Google Scholar]

- Nandi, P. Dehydrated Fruits & Vegetables Market Research Report Information by Type (Dehydrated Fruits & Dehydrated Vegetables), by Application (Supermarket/Hypermarket, Specialty Retailers, Convenience Stores, E-Commerce, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World)-Forecast Till 2030. 2021. Available online: https://www.marketresearchfuture.com (accessed on 17 December 2024).

- Sagar, V.R.; Kumar, P.S. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Gürbüz, N.; Uluişik, S.; Frary, A.; Frary, A.; Doğanlar, S. Health benefits and bioactive compounds of eggplant. Food Chem. 2018, 268, 602–610. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, J.; Wang, W.; Hu, T.; Hu, H.; Bao, C. A high-quality chromosome-level genome assembly reveals genetics for important traits in eggplant. Hortic. Res. 2020, 7, 153. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 23 December 2024).

- Sharma, M.; Kaushik, P. Biochemical composition of eggplant fruits: A review. Appl. Sci. 2021, 11, 7078. [Google Scholar] [CrossRef]

- Ferrão, A.C.; Guiné, R.P.F.; Correia, T.; Rodrigues, R. Analysis of Drying Kinetics of Eggplant through Thin Layer Models and Evaluation of Texture and Colour Properties. Chem. Res. J. 2019, 4, 24–32. [Google Scholar]

- Santacatalina, J.V.; Ozuna, C.; Cárcel, J.A.; García-Pérez, J.V.; Mulet, A. Quality assessment of dried eggplant using different drying methods: Hot air drying, vacuum freeze drying, and atmospheric freeze drying. In Proceedings of the 11th International Congress on Engineering and Food, Athens, Greece, 22–26 May 2011. [Google Scholar]

- Salehi, F.; Goharpour, K.; Razavi Kamran, H. Effects of different pretreatment techniques on the color indexes, drying characteristics and rehydration ratio of eggplant slices. Results Eng. 2024, 21, 101690. [Google Scholar] [CrossRef]

- López, J.; Ah-Hen, K.S.; Vega-Gálvez, A.; Morales, A.; García-Segovia, P.; Uribe, E. Effects of drying methods on quality attributes of murta (Ugni molinae Turcz) berries: Bioactivity, nutritional aspects, texture profile, microstructure and functional properties. J. Food Process Eng. 2016, 40, e12511. [Google Scholar] [CrossRef]

- Tsopbou, N.P.; Mawire, A.; Diratsagae, K.; Vanierschot, M. Performance of a portable indirect solar dryer for drying various fruits: Drying characteristics and quality assessment. Renew. Energy 2025, 220, 123625. [Google Scholar] [CrossRef]

- Kidane, H.; Farkas, I.; Buzás, J. Performance evaluation of solar drying chambers and drying kinetics of apple slices. Energy Rep. 2025, 13, 4528–4540. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists, Inc.: Arlington, VA, USA, 1990. [Google Scholar]

- Özkan-Karabacak, A.; Acoğlu, B.; YolciÖmeroğlu, P.; Çopur, Ö.U. Microwave pre-treatment for vacuum drying of orange slices: Drying characteristics, rehydration capacity and quality properties. J. Food Process Eng. 2020, 43, e13511. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of the American Association of Cereal Chemists International, 11th ed.; Methods: 08-01.01 (Ash), 30-10.01 Crude fat, 46-30.01 (Protein); American Association of Cereal Chemists: St Paul, MN, USA, 2012. [Google Scholar]

- AOAC Stakeholder Program on Infant Formula and Adult Nutritionals (SPIFAN). Vitamin C Evaluation Method in Regional Matrices, Final version 3; AOAC INTERNATIONAL: Rockville, MD, USA, 2021. [Google Scholar]

- Can, H.; Ozyigit, I.I.; Can, M.; Hocaoglu-Ozyigit, A.; Yalcin, I.E. Multidimensional scaling of the mineral nutrient status and health risk assessment of commonly consumed fruity vegetables marketed in Kyrgyzstan. Biol. Trace Elem. Res. 2021, 200, 4295–4309. [Google Scholar] [CrossRef]

- Grujić, R.; Savanović, D. Thermal Analysis of Food Products Using Differential Scanning Calorimetry (DSC). Contemp. Mater. 2020, 10, 175–181. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic models for drying techniques—Food materials. Adv. Chem. Eng. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef]

- Xanthopoulos, G.; Yanniotis, S.; Talaiporou, E. Influence of Salting on Drying Kinetics and Water Diffusivity of Tomato Halves. Int. J. Food Prop. 2012, 15, 847–863. [Google Scholar] [CrossRef]

- Osidacz, R.C.; Ambrosio-Ugri, M.C.B. Physicochemical quality of eggplant dehydrated with varied pretreatments. Acta Sci. 2013, 35, 175–179. [Google Scholar] [CrossRef]

- Chobot, M.; Kozłowska, M.; Ignaczak, A.; Kowalska, H. Development of drying and roasting processes for the production of plant-based pro-healthy snacks in the light of nutritional trends and sustainable techniques. Trends Food Sci. Technol. 2024, 149, 104553. [Google Scholar] [CrossRef]

- Lin, Y.; Gao, Y.; Li, A.; Wang, L.; Ai, Z.; Xiao, H.; Li, J.; Li, X. Improvement of Pacific white shrimp (Litopenaeus vannamei) drying characteristics and quality attributes by a combination of salting pretreatment and microwave. Foods 2022, 11, 2066. [Google Scholar] [CrossRef] [PubMed]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef]

- Adiletta, G.; Russo, P.; Crescitelli, A.; Di Matteo, M. Combined pretreatment for enhancing quality of dried and rehydrated eggplant. Food Bioprocess Technol. 2016, 9, 1912–1923. [Google Scholar] [CrossRef]

- Niño-Medina, G.; Muy-Rangel, D.; Gardea-Béjar, A.; González-Aguilar, G.; Heredia, B.; Báez-Sañudo, M.; Siller-Cepeda, J.; Vélez de la Rocha, R. Nutritional and nutraceutical components of commercial eggplant types grown in Sinaloa, Mexico. Not. Bot. Horti Agrobot. 2014, 42, 538–544. [Google Scholar] [CrossRef]

- Fellows, P.J. Food Processing Technology: Principles and Practice; CRC Press: Boca Raton, FL, USA, 2009; Volume 2, pp. 83–93. [Google Scholar]

- Rahmani, Y.; Khama, R. Effect of salting time and drying method on physicochemical characteristics of dried meat from the longissimus muscle of Algerian dromedary camels. J. Food Compos. Anal. 2024, 135, 106572. [Google Scholar] [CrossRef]

- Ünlüsayin, M.; Erdilal, R.; Gümüș, B.; Gülyavuz, H. The effects of different salting methods on extract loss from rainbow trout. Pak. Vet. J. 2010, 131–134. [Google Scholar]

- Arakawa, T.; Timasheff, S.N. The interactions of proteins with salts, amino acids, and sugars at high concentration. In Advances in Comparative and Environmental Physiology: Volume and Osmolality Control in Animal Cells; Springer: Berlin/Heidelberg, Germany, 1991; pp. 226–245. [Google Scholar]

- Catorze, C.; Tavares, A.P.; Cardão, P.; Castro, A.; Silva, M.E.; Ferreira, D.W.; Lopes, S.; Brás, I. Study of a solar energy drying system—Energy savings and effect in dried food quality. Energy Rep. 2022, 8, 392–398. [Google Scholar] [CrossRef]

- Hwang, C.C.; Lin, C.M.; Kung, H.F.; Huang, Y.L.; Hwang, D.F.; Su, Y.C.; Tsai, Y.H. Effect of salt concentrations and drying methods on the quality and formation of histamine in dried milkfish (Chanos chanos). Food Chem. 2012, 135, 839–844. [Google Scholar] [CrossRef]

- Rodriguez-Jimenez, J.R.; Amaya-Guerra, C.A.; Baez-Gonzalez, J.G.; Aguilera-Gonzalez, C.; Urias-Orona, V.; Nino-Medina, G. Physicochemical, Functional, and Nutraceutical Properties of Eggplant Flours Obtained by Different Drying Methods. Molecules 2018, 23, 3210. [Google Scholar] [CrossRef] [PubMed]

- Nudar, J.; Roy, M.; Ahmed, S. Combined osmotic pretreatment and hot air drying: Evaluation of drying kinetics and quality parameters of adajamir (Citrus assamensis). Heliyon 2023, 9, e19545. [Google Scholar] [CrossRef] [PubMed]

- Jafari, F.; Movagharnejad, K.; Sadeghi, E. Infrared drying effects on the quality of eggplant slices and process optimization using response surface methodology. Food Chem. 2020, 311, 127423. [Google Scholar] [CrossRef]

- Oomah, B.D.; Der, T.J.; Godfrey, D.V. Thermal characteristics of flaxseed (Linum usitatissimum L.) proteins. Food Chem. 2006, 98, 733–741. [Google Scholar] [CrossRef]

| Eggplant Samples | ||||

|---|---|---|---|---|

| Parameters | Fresh | Dried | Salted Dried | p-Value |

| Moisture (%) | 92.40 ± 0.52 a | 13.58 ± 0.27 b | 9.39 ± 0.09 c | <0.001 |

| aw | 0.984 ± 0.007 a | 0.554 ± 0.007 c | 0.539 ± 0.002 b | <0.001 |

| Protein (% DM) | 0.94 ± 0.01 c | 9.08 ± 1.95 a | 5.11 ± 0.12 b | <0.001 |

| Crude fat (% DM) | 1.35 ± 0.56 a | 0.20 ± 0.01 b | 0.33 ± 0.20 b | 0.003 |

| Ash (% DM) | 0.64 ± 0.02 c | 5.62 ± 0.17 b | 7.93 ± 0.89 a | <0.001 |

| Carbohydrates (% DM) | 4.80 ± 0.85 c | 79.56 ± 0.01 a | 69.22 ± 3.12 b | <0.001 |

| Vitamin C (% DM) | 1.11 ± 0.07 a | 0.84 ± 0.01 c | 0.97 ± 0.00 b | <0.001 |

| Potassium (mg/kg) | 1951.30 ± 333 c | 30,890.43 ± 2115 a | 17,104.47 ± 818 b | <0.001 |

| Parameters | Eggplant Samples | |||

|---|---|---|---|---|

| Fresh | Dried | Salted Dried | p-Value | |

| Texture | ||||

| Hardness (N) | 4.51 ± 2.33 b | 6.19 ± 2.60 ab | 11.15 ± 4.60 a | 0.036 |

| Adhesive force (N) × 10−3 | −2.92 ± 0.002 | −4.75 ± 0.001 | −4.69 ± 0.002 | 0.228 |

| Elastic force (N/mm2) | 0.042 ± 0.006 | 0.039 ± 0.012 | 0.054 ± 0.017 | 0.214 |

| Thermal properties (°C) | ||||

| Ti | 102.05 | 100.78 | ||

| Tp | 107.44 | 107.38 | ||

| Tf | 107.85 | 107.77 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jribi, S.; Essaidi, I.; Ben Rejeb, I.; Ghanem, R.; Hamza, M.E.; Khamassi, F. Osmotic Pretreatment and Solar Drying of Eggplant in Tunisian Rural Areas: Assessing the Impact of Process Efficiency and Product Quality. Processes 2025, 13, 2442. https://doi.org/10.3390/pr13082442

Jribi S, Essaidi I, Ben Rejeb I, Ghanem R, Hamza ME, Khamassi F. Osmotic Pretreatment and Solar Drying of Eggplant in Tunisian Rural Areas: Assessing the Impact of Process Efficiency and Product Quality. Processes. 2025; 13(8):2442. https://doi.org/10.3390/pr13082442

Chicago/Turabian StyleJribi, Sarra, Ismahen Essaidi, Ines Ben Rejeb, Raouia Ghanem, Mahmoud Elies Hamza, and Faten Khamassi. 2025. "Osmotic Pretreatment and Solar Drying of Eggplant in Tunisian Rural Areas: Assessing the Impact of Process Efficiency and Product Quality" Processes 13, no. 8: 2442. https://doi.org/10.3390/pr13082442

APA StyleJribi, S., Essaidi, I., Ben Rejeb, I., Ghanem, R., Hamza, M. E., & Khamassi, F. (2025). Osmotic Pretreatment and Solar Drying of Eggplant in Tunisian Rural Areas: Assessing the Impact of Process Efficiency and Product Quality. Processes, 13(8), 2442. https://doi.org/10.3390/pr13082442