The Effects of Soy Flour and Resistant Starch on the Quality of Low Glycemic Index Cookie Bars

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Analytical Methods

2.3. Cookie Bar Preparation

2.4. Properties of Cookie Bars

2.5. Statistical Analysis

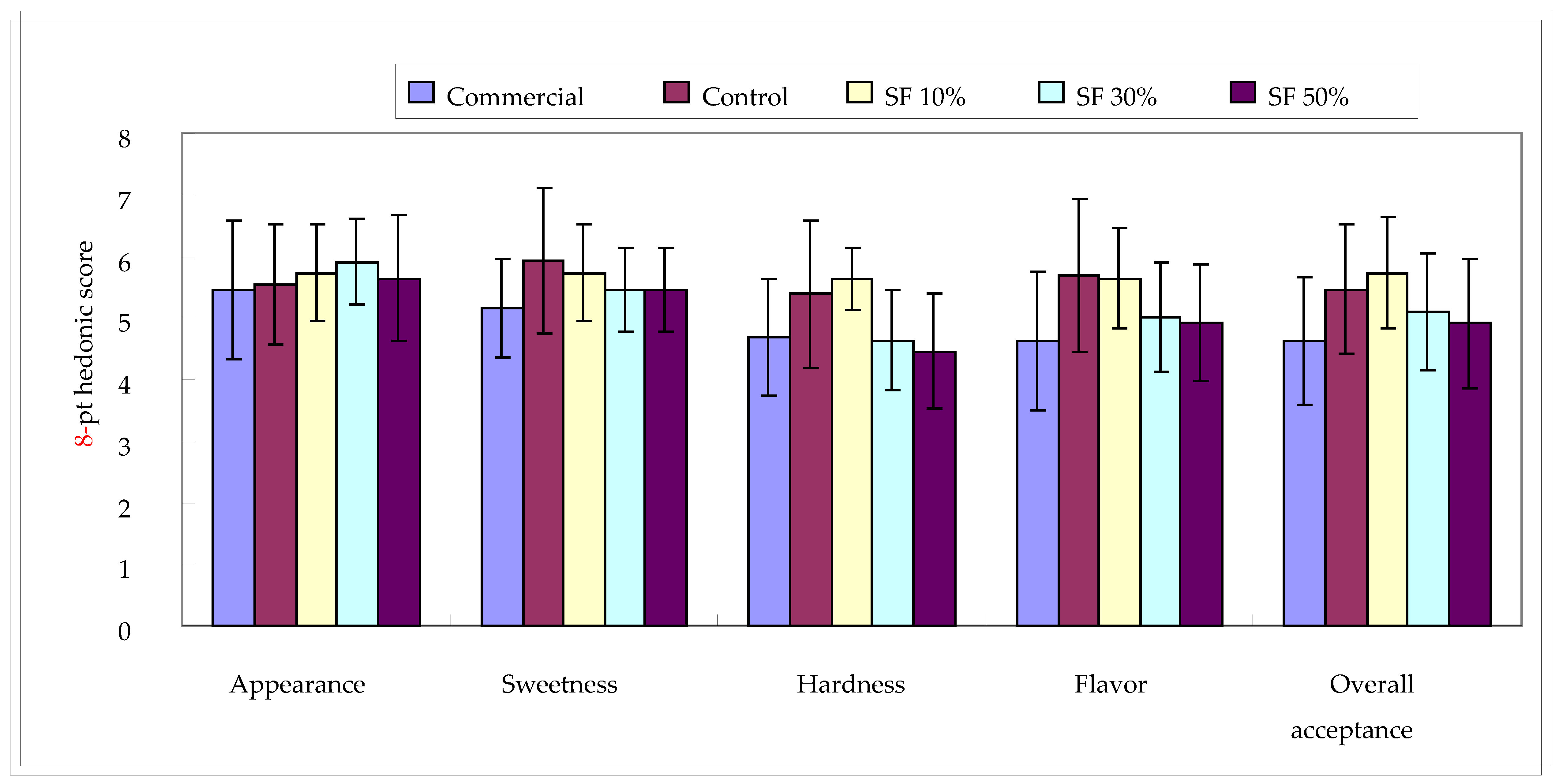

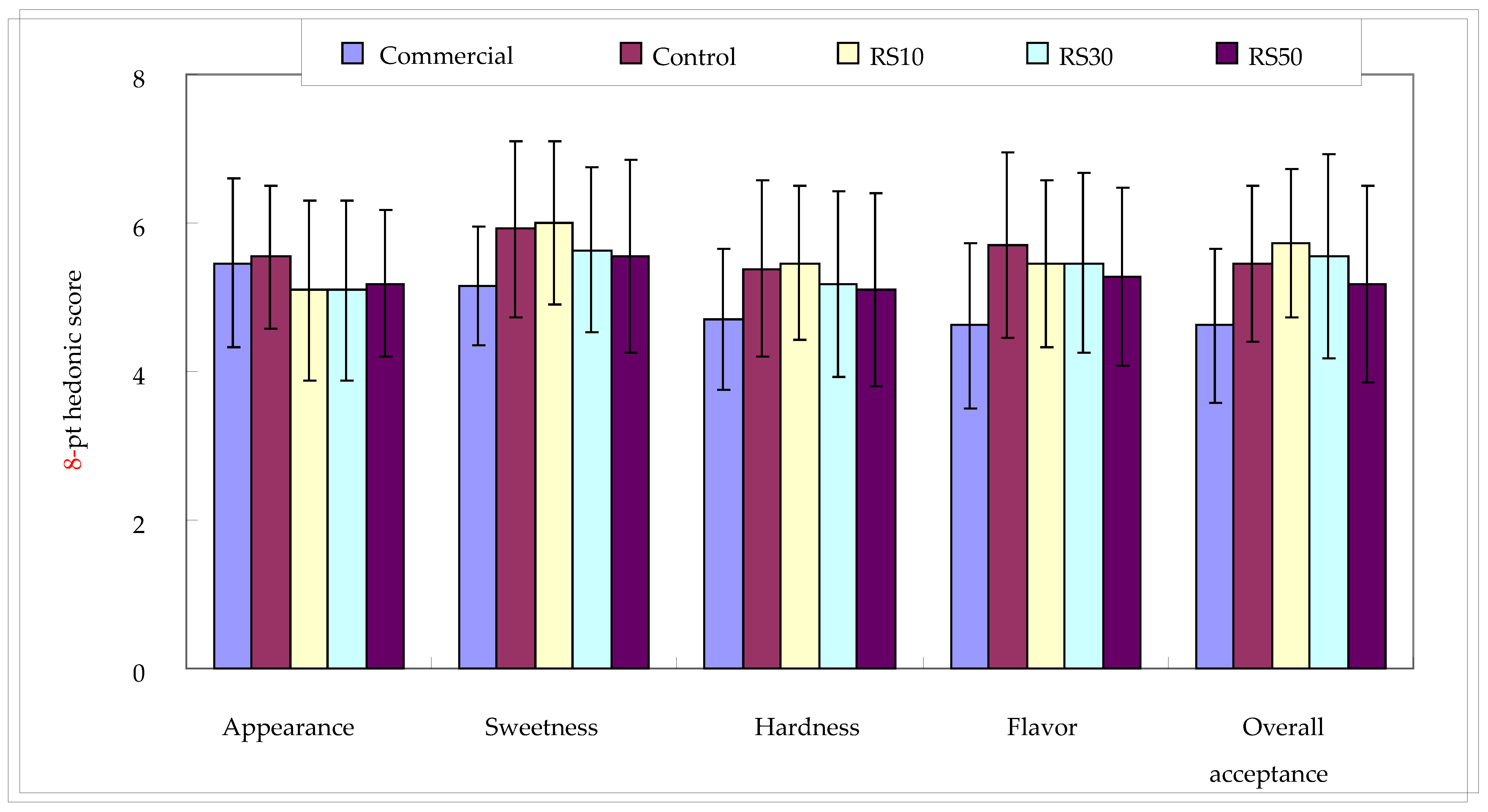

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vlachos, D.; Malisova, S.; Lindberg, F.A.; Karaniki, G. Glycemic index (GI) or glycemic load (GL) and dietary interventions for optimizing postprandial hyperglycemia in patients with T2 diabetes: A review. Nutrients 2020, 12, 1561. [Google Scholar] [CrossRef]

- Meng, H.; Matthan, N.R.; Ausman, L.M.; Lichtenstein, A.H. Effect of prior meal macronutrient composition on postprandial glycemic responses and glycemic index and glycemic load value determinations. Am. J. Clin. Nutr. 2017, 106, 1246–1251. [Google Scholar] [CrossRef]

- Holesh, J.E.; Aslam, S.; Martin, A. Physiology, Carbohydrates. In StatPearls; StatPearls Publishing: Treasure Island, FL, USA, 2023. [Google Scholar]

- Parker, A.; Kim, Y. The effect of low glycemic index and glycemic load diets on hepatic fat mass, insulin resistance, and blood lipid panels individual with nonalcoholic fatty liver disease. Meta. Syndr. Relat. Disord. 2019, 17, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Volek, J.S.; Fernandez, M.L.; Feinman, P.D.; Phinney, S.D. Dietary carbohydrate restriction induces a unique metabolic state positively affecting atherogenic dyslipidemia, fatty acid partitioning, and metabolic syndrome. Prog. Lipid Res. 2008, 47, 307–318. [Google Scholar] [CrossRef]

- Fawaid As’ad, M.R.; Sari, G.M.; Othman, Z.; Herawati, L. The combination of intermittent caloric restriction and moderate-intensity interval training in decreasing blood glucose and CRP levels with a high glycemic index diet. Kuwait J. Sci. 2022, 49, 1–11. [Google Scholar] [CrossRef]

- Zhou, Z.; Ye, F.; Lei, L.; Zhou, S.; Zhao, G. Fabricating low glycaemic index foods: Enlightened by the impacts of soluble dietary fibre on starch digestibility. Trends Food Sci. Technol. 2022, 122, 110–122. [Google Scholar] [CrossRef]

- Pineli, L.d.O.; Botelho, R.B.A.; Zandonadi, R.P.; Solorzano, J.L.; de Oliveira, G.T.; Reis, C.E.G.; Teixeira, D.d.S. Low glycemic index and increased protein content in a novel quinoa milk. LWT-Food Sci. Technol. 2015, 63, 1261–1267. [Google Scholar] [CrossRef]

- Basset-Sagarminaga, J.; Roumans, K.H.M.; Havekes, B.; Mensink, R.P.; Peters, H.P.F.; Zock, P.L.; de Mutsert, R.; Boren, J.; Lindeboon, L.; Schrauwen, P.; et al. Replacing foods with a high-glycemic index and high in saturated fat by alternatives with a low glycemic index and low saturated fat reduces hepatic fat, even in isocaloric and macronutrient matched conditions. Nutrients 2023, 15, 735. [Google Scholar] [CrossRef]

- Rodriguez, R.; Jimenez, A.; Fernandez-Bolanos, J.; Guillen, R.; Heredia, A. Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci. Technol. 2006, 17, 3–15. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Sun, M.; Li, D.; Hua, M.; Miao, X.; Su, Y.; Chi, Y.; Wang, J.; Niu, H. Optimization of mixed fermentation conditions of dietary fiber from soybean residue and the effect on structure, properties and potential biological activity of dietary fiber from soybean residue. Molecules 2023, 28, 1322. [Google Scholar] [CrossRef]

- Rizzo, G.; Baroni, L. Soy, soy foods and their role in vegetarian diets. Nutrients 2018, 10, 43. [Google Scholar] [CrossRef] [PubMed]

- Food and Drug Administration. 21 CFR part 101. Food labeling: Health claims: Soy protein and coronary heart disease. Fed. Reg. 2017, 82, 50324. [Google Scholar]

- Van Ee, J.H. Soy constituents: Modes of action in low-density lipoprotein management. Nutr. Rev. 2009, 67, 222–234. [Google Scholar] [CrossRef]

- Wiederstein, M.; Baumgartner, S.; Lauter, K. Soybean (Glycine max) allergens—A Review on an Outstanding Plant Food with Allergenic Potentia. ACS Food Sci. Technol. 2023, 3, 363–378. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, L.; Chen, L.; Yin, B.; Song, Y. Is phytoestrogen intake associated with decreased risk of prostate cancer? A systematic review of epidemiological studies based on 17,546 cases. Andrology 2016, 4, 745–756. [Google Scholar] [CrossRef]

- Jia, H.; Ren, F.; Liu, H. Development of low glycemic index food products with wheat resistant starch: A review. Carbohydr. Polym. 2025, 361, 123637. [Google Scholar] [CrossRef]

- Maningat, C.C.; Seib, P.A.; Bassi, S.D. Resistant starch is typically quantified as part of the total dietary fibre (TDF) by the Prosky Method. Cereal Foods World 2013, 58, 252–263. [Google Scholar] [CrossRef]

- Dobranowski, P.A.; Stintzi, A. Resistant starch, microbiome, and precision modulation. Gut Microbes 2021, 13, 1926842. [Google Scholar] [CrossRef]

- Sajilata, M.G.; Singhal, R.S.; Kulkarni, P.R. Resistant starch—A review. Compr. Rev. Food Sci. Food Saf. 2006, 5, 1–17. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists (AACC). Approved Methods of the AACC, 8th ed.; Method 44-01, Method 08-01, Method 46-12, Method 30-25; The Association: St. Paul, MN, USA, 1990. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis; Method 978.20; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Rodriguez-Ambriz, S.L.; Islas-Hernandez, J.J.; Agama-Acevedo, E.; Tovar, J.; Bello-Perez, L.A. Characterization of fiber-rich powder prepared by liquefaction of unripe banana flour. Food Chem. 2008, 107, 1515–1521. [Google Scholar] [CrossRef]

- Dhingra, S.; Jood, S. Organoleptic and nutritional evaluation of wheat breads supplemented with soybean and barley flour. Food Chem. 2001, 77, 479–488. [Google Scholar] [CrossRef]

- Singh, U.; Khedekar, M.S.; Jambunathan, R. Studies on desi and kabuli chickpea cultivars. The level of amylase inhibitors, level of oligosaccharides and in vitro starch digestibility. J. Food Sci. Technol. 1982, 47, 510. [Google Scholar]

- Adeyeye, S.A.O. Quality Evaluation and Acceptability of Cookies Produced From Rice (Oryza glaberrima) and Soybeans (Glycine max) Flour Blends. J. Culin. Sci. Technol. 2020, 18, 54–66. [Google Scholar] [CrossRef]

- Muir, J.G.; Lu, Z.X.; Young, G.P.; Cameron-Smith, D.; Collier, G.R.; O’Dea, K. Resistant starch in the diet increases breath hydrogen and serum acetate in human subjects. Am. J. Clin. Nutr. 1995, 61, 792–799. [Google Scholar] [CrossRef]

- Singh, M.; Mohamed, A. Influence of gluten-soy protein blends on the quality of reduced carbohydrates cookies. LWT-Food Sci. Technol. 2007, 40, 353–360. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Tang, X. Effects of whey and soy protein addition on bread rheological property of wheat flour. J. Texture Stud. 2018, 49, 38–46. [Google Scholar] [CrossRef]

- Aleem Zaker, M.D.; Genitha, T.R.; Syed, I.H. Effects of defatted soy flour incorporation on physical, sensorial and nutritional properties of biscuits. J. Food Process Technol. 2012, 3, 100149. [Google Scholar] [CrossRef]

- HadiNezhad, M.; Butler, F. Effect of flour type and dough rheological properties on cookie spread measured dynamically during baking. J. Cereal Sci. 2009, 49, 38–46. [Google Scholar] [CrossRef]

- Hoseney, R.C.; Rogers, D.E. Mechanism of sugar functionality in cookies. In The Science of Cookie and Cracker Production; Faridi, H., Ed.; Chapman and Hall: New York, NY, USA, 1994; pp. 203–205. [Google Scholar]

- Lee, S.; Inglett, G.E. Rheological and physical evaluation of jet-cooked oat bran in low calorie cookies. Int. J. Food Sci. Technol. 2006, 41, 553–559. [Google Scholar] [CrossRef]

- Zoulias, E.I.; Piknis, S.; Oreopoulou, V. Effect of sugar replacement by polyols and acesulfame-K on properties of low-fat cookies. J. Sci. Food Agric. 2000, 80, 2049–2056. [Google Scholar] [CrossRef]

- McWattewrs, K.H.; Ouedraogo, J.B.; Resurreccion, V.A.; Hung, Y.C.; Phillips, R.D. Physical and sensory characteristics of sugar cookies containing a mixture of fonio (Digitaria exilis) and cowpea (Vigina unguiculata) flours. Int. J. Food Sci. Technol. 2003, 38, 403–410. [Google Scholar] [CrossRef]

- Nogueira, A.C.; Steel, C.J. Protein enrichment of biscuits: A review. Food Rev. Int. 2018, 34, 796–809. [Google Scholar] [CrossRef]

- Tang, X.; Liu, J. A comparative study of partial replacement of wheat flour with whey and soy protein on rheological properties of dough and cookie quality. J. Food Qual. 2017, 2618020. [Google Scholar] [CrossRef]

- Holm, J.; Hagander, B.; Bjorck, I.; Eliasson, A.C.; Lundquist, I. The effect of various thermal processes on the glycemic response to whole grain wheat products in humans and rats. J. Nutr. 1989, 119, 1631–1638. [Google Scholar] [CrossRef]

- Jenkins, D.J.A.; Thorne, M.J.; Wolever, T.M.S.; Jenkins, A.L.; Rao, A.V.; Thompson, L.U. The effect of starch-protein interaction in wheat on the glycemic response and rate of in vitro digestion. Am. J. Clin. Nutr. 1987, 45, 946–951. [Google Scholar] [CrossRef] [PubMed]

- Dona, A.C.; Pages, G.; Gilbert, R.G.; Kuchel, P.W. Digestion of starch: In vivo and in vitro kinetic models used to characterise oligosaccharide or glucose release. Carbohydr. Polym. 2010, 80, 599–617. [Google Scholar] [CrossRef]

- Uysal, H.; Bilgicli, N.; Elgun, A.; Ibanoglu, S.; Herken, E.N.; Demir, M.K. Effect of dietary fiber and xylanase enzyme addition on the selected properties of wire-cut cookies. J. Food Eng. 2007, 78, 1074–1078. [Google Scholar] [CrossRef]

| Composition (%) | Resistant Starch | Soy Flour | Soft Wheat Flour |

|---|---|---|---|

| Moisture | 11.67 ± 0.04 | 7.82 ± 0.05 | 10.81 ± 0.03 |

| Crude protein b | 0.41 ± 0.16 | 33.80 ± 0.31 | 8.60 ± 0.53 |

| Ash | 1.06 ± 0.01 | 5.13 ± 0.03 | 0.41 ± 0.01 |

| Crude fat | 0.00 ± 0.00 | 22.35 ± 0.04 | 0.95 ± 0.05 |

| Carbohydrate + fiber | 86.72 | 26.46 | 78.99 |

| Crude fiber c | 70 ± 0.04 | 4.44 ± 0.01 | 0.24 ± 0.04 |

| Calories (Kcal/100 g) | 76.9 | 442.19 | 358.9 |

| Water-holding capacity (mL/g) d | 0.76 ± 0.05 A | 2.20 ± 0.22 B | 0.71 ± 0.03 A |

| Soft Wheat Flour Replacement (%) | Moisture (%) | Geometry of Cookie Bar | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (cm) | Width (cm) | Thickness (cm) | ||||||||||

| Control cookie bar | 7.62 | ± | 0.11 a | 5.75 | ± | 0.02 c | 4.18 | ± | 0.04 d | 1.42 | ± | 0.03 b |

| Soy flour | ||||||||||||

| 10 | 8.28 | ± | 0.16 b | 5.68 | ± | 0.09 b | 3.88 | ± | 0.09 c | 1.62 | ± | 0.03 d |

| 30 | 8.81 | ± | 0.05 c | 5.43 | ± | 0.02 a | 3.80 | ± | 0.02 b | 1.65 | ± | 0.04 d |

| 50 | 8.32 | ± | 0.09 b | 5.41 | ± | 0.04 a | 3.70 | ± | 0.04 a | 1.73 | ± | 0.03 e |

| Resistant starch | ||||||||||||

| 10 | 7.50 | ± | 0.08 a | 5.80 | ± | 0.05 c | 4.29 | ± | 0.02 e | 1.51 | ± | 0.04 c |

| 30 | 7.42 | ± | 0.15 a | 6.08 | ± | 0.03 d | 4.37 | ± | 0.02 f | 1.51 | ± | 0.04 c |

| 50 | 7.63 | ± | 0.11 a | 6.10 | ± | 0.05 d | 4.77 | ± | 0.10 g | 1.38 | ± | 0.03 a |

| Soft Wheat Flour Replacement (%) | Breaking Point (mm) | Maximum Breaking Force (g) | Work of Breaking (g × mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Control cookie bar | 3.15 | ± | 0.64 a | 1072.6 | ± | 73.1 b | 3355.5 | ± | 575.1 a |

| Soy flour | |||||||||

| 10 | 3.93 | ± | 0.66 a | 1239.3 | ± | 101.3 c | 4924.9 | ± | 1202.6 b |

| 30 | 4.80 | ± | 0.97 b | 1802.1 | ± | 113.6 d | 8670.9 | ± | 1949.6 c |

| 50 | 5.38 | ± | 0.38 b | 2002.7 | ± | 185.9 d | 10,738.3 | ± | 843.1 d |

| Resistant starch | |||||||||

| 10 | 3.54 | ± | 0.24 a | 1065.2 | ± | 101.1 b | 3757.6 | ± | 273.9 ab |

| 30 | 3.61 | ± | 0.35 a | 838.7 | ± | 150.9 a | 3062.4 | ± | 786.7 a |

| 50 | 3.01 | ± | 0.48 a | 872.1 | ± | 154.1 a | 2670.9 | ± | 813.2 a |

| Commercial 1 (Cocoa flavor) | 1.93 | ± | 0.86 a | 652.4 | ± | 170.5 a | 1346.0 | ± | 936.7 a |

| Commercial 2 (Soy Joy) | 4.67 | ± | 0.40 b | 1636.5 | ± | 279.3 b | 7621.9 | ± | 1360.5 c |

| Commercial 3 (Soy protein) | 2.41 | ± | 0.49 a | 3584.9 | ± | 563.8 e | 8861.9 | ± | 3225.4 c |

| Soft Wheat Flour Replacement (%) | L | a | b | Whiteness Index | E | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control cookie bar with sucrose | 96.56 | ± | 0.11 c | −16.54 | ± | 0.19 c | 47.06 | ± | 0.34 c | 49.99 | ± | 0.38 e | - | ||

| Control cookie bar without sucrose | 97.54 | ± | 0.32 b | −17.80 | ± | 0.39 e | 43.95 | ± | 0.98 d | 52.52 | ± | 0.77 d | 3.51 | ||

| Soy flour | |||||||||||||||

| 10 | 96.58 | ± | 0.19 c | −16.59 | ± | 0.31 c | 47.04 | ± | 0.46 c | 50.00 | ± | 0.32 e | 0.37 | ||

| 30 | 95.51 | ± | 0.21 d | −14.97 | ± | 0.45 b | 49.20 | ± | 0.32 b | 48.38 | ± | 0.16 f | 2.89 | ||

| 50 | 93.60 | ± | 0.51 e | −11.52 | ± | 1.00 a | 50.89 | ± | 0.32 a | 47.42 | ± | 0.03 g | 7.03 | ||

| Resistant starch | |||||||||||||||

| 10 | 97.89 | ± | 0.14 b | −17.91 | ± | 0.06 e | 42.56 | ± | 0.73 e | 53.77 | ± | 0.65 c | 4.89 | ||

| 30 | 98.47 | ± | 0.07 a | −17.48 | ± | 0.11 de | 38.72 | ± | 0.49 f | 57.49 | ± | 0.40 b | 8.61 | ||

| 50 | 98.77 | ± | 0.05 a | −16.74 | ± | 0.10 cd | 35.84 | ± | 0.43 g | 60.42 | ± | 0.43 a | 11.44 | ||

| Cookie Bar Samples | Starch Digestibility (mg Glucose Released/g Cookie Bar) * | ||

|---|---|---|---|

| Control cookie bar (with sucrose) | 42.37 | ± | 2.40 ab |

| Control cookie bar (sucrose-free) | 38.91 | ± | 1.25 ab |

| Soft wheat flour with soy flour substituted (%) | |||

| 10 | 35.20 | ± | 2.82 ab |

| 30 | 34.33 | ± | 1.37 ab |

| 50 | 32.57 | ± | 0.40 a |

| Soft wheat flour with resistant starch substituted (%) | |||

| 10 | 37.60 | ± | 1.25 ab |

| 30 | 35.82 | ± | 0.85 ab |

| 50 | 39.17 | ± | 0.15 ab |

| Commercial low GI cookie bars | 164.33 | ± | 2.11 c |

| White bread | 267.37 | ± | 10.98 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.-T.V.; Yeh, G.-L.; Tsai, J.-S.; Sung, W.-C. The Effects of Soy Flour and Resistant Starch on the Quality of Low Glycemic Index Cookie Bars. Processes 2025, 13, 2420. https://doi.org/10.3390/pr13082420

Lin H-TV, Yeh G-L, Tsai J-S, Sung W-C. The Effects of Soy Flour and Resistant Starch on the Quality of Low Glycemic Index Cookie Bars. Processes. 2025; 13(8):2420. https://doi.org/10.3390/pr13082420

Chicago/Turabian StyleLin, Hong-Ting Victor, Guei-Ling Yeh, Jenn-Shou Tsai, and Wen-Chieh Sung. 2025. "The Effects of Soy Flour and Resistant Starch on the Quality of Low Glycemic Index Cookie Bars" Processes 13, no. 8: 2420. https://doi.org/10.3390/pr13082420

APA StyleLin, H.-T. V., Yeh, G.-L., Tsai, J.-S., & Sung, W.-C. (2025). The Effects of Soy Flour and Resistant Starch on the Quality of Low Glycemic Index Cookie Bars. Processes, 13(8), 2420. https://doi.org/10.3390/pr13082420