Design and Development of a New 10 kV Overhead Line Fixing Device in Power System

Abstract

1. Introduction

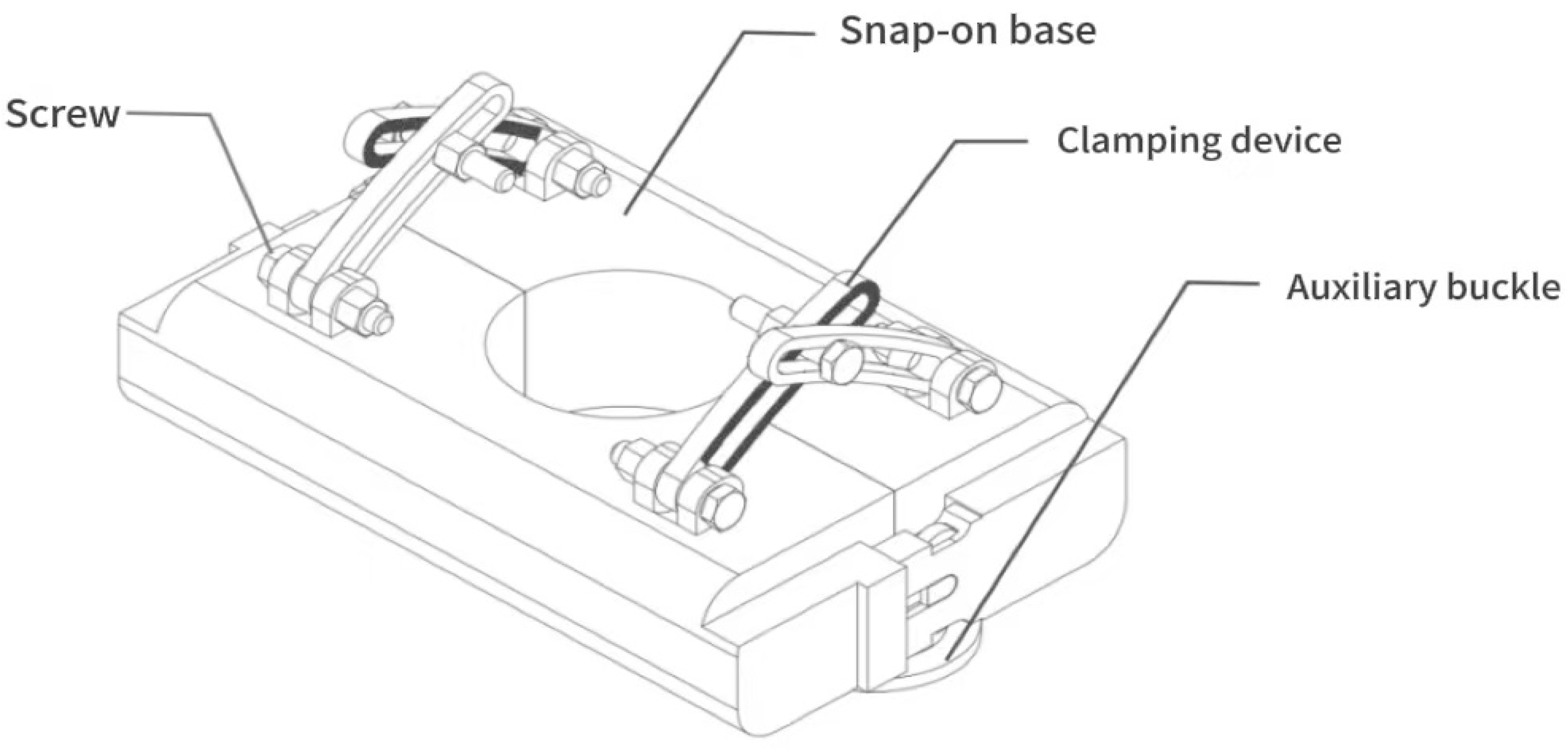

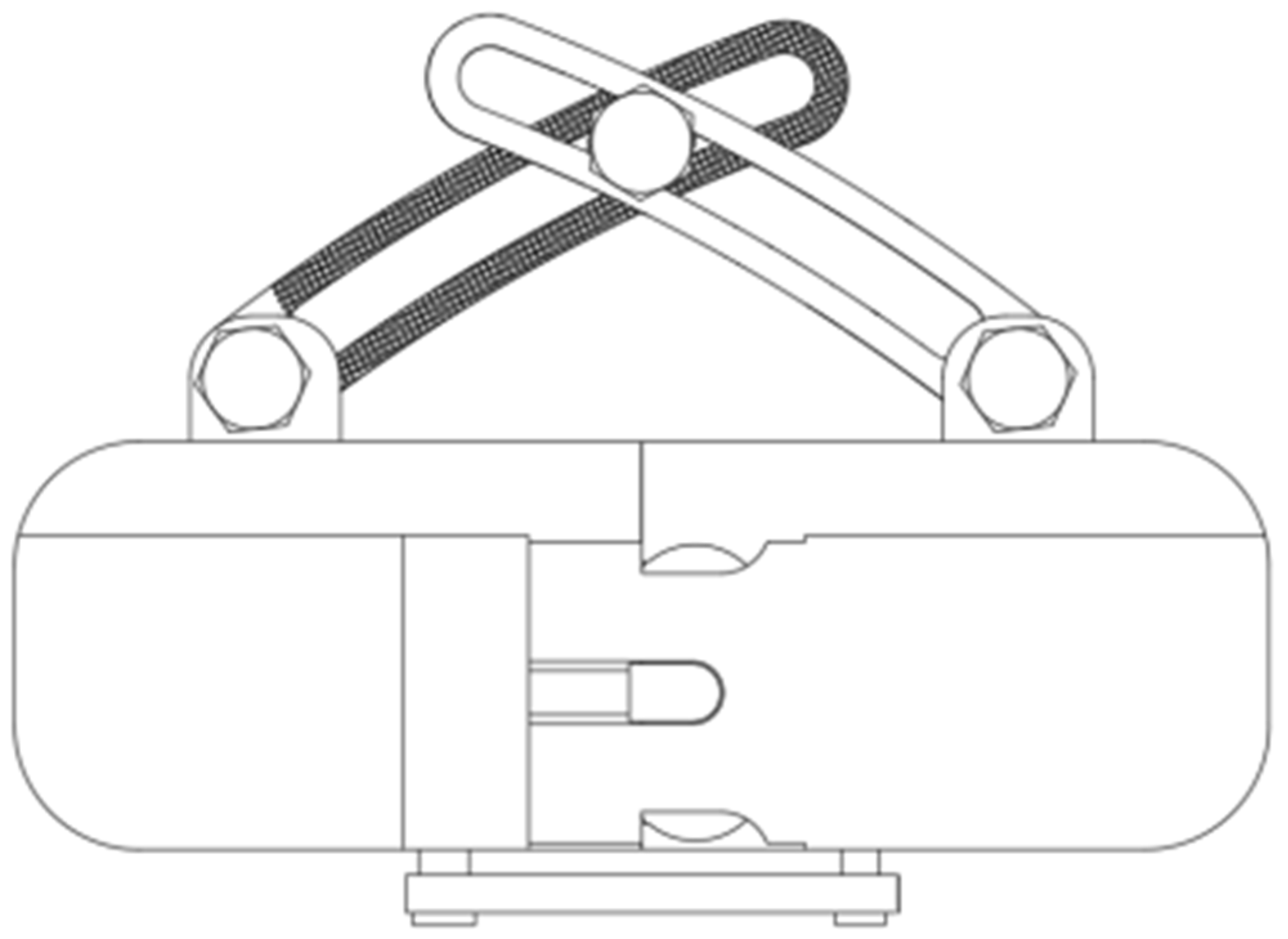

2. Structural Composition and Operating Principle of the Fixing Device

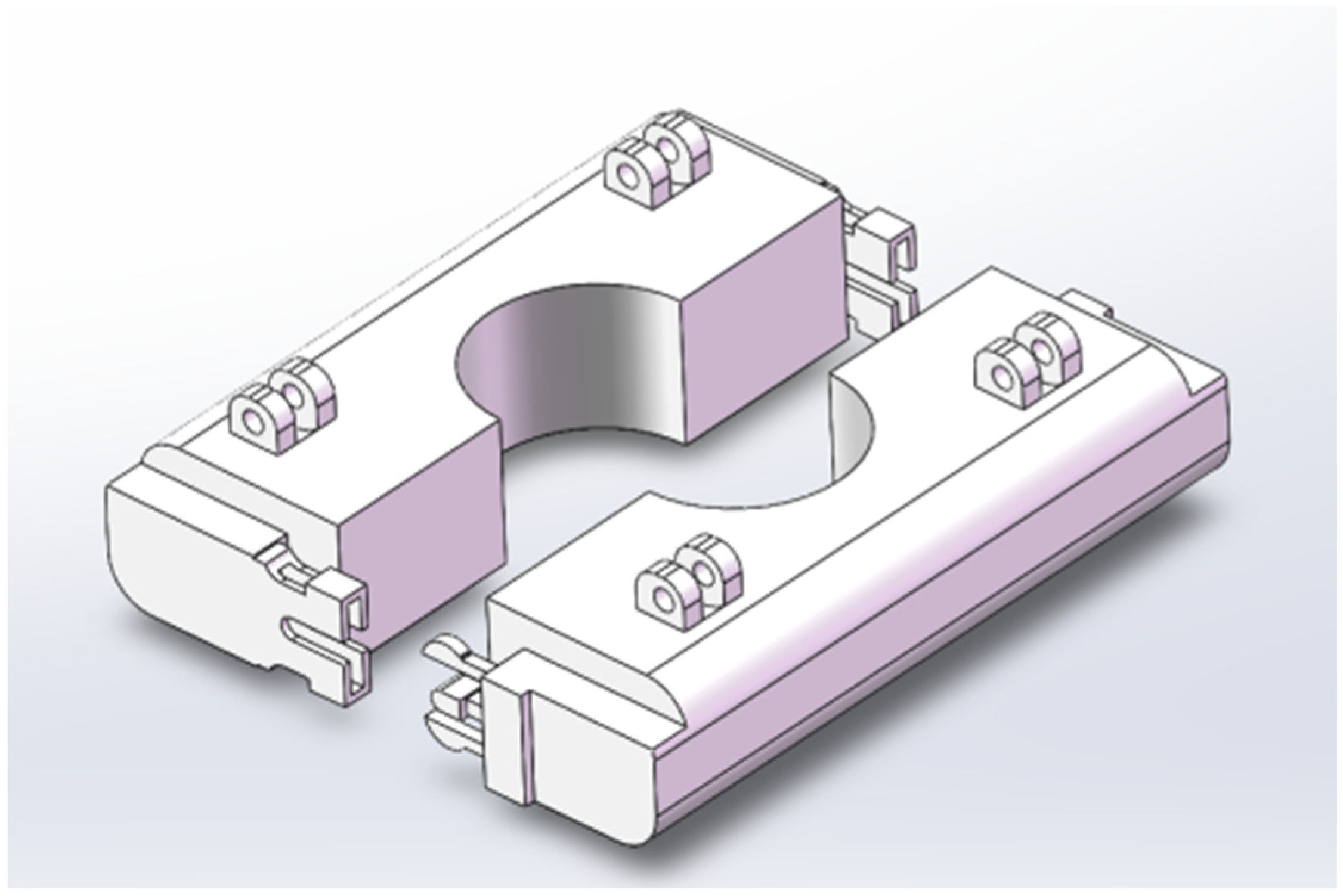

2.1. Base of the Fixed Device

2.1.1. Base Material

2.1.2. Base Form

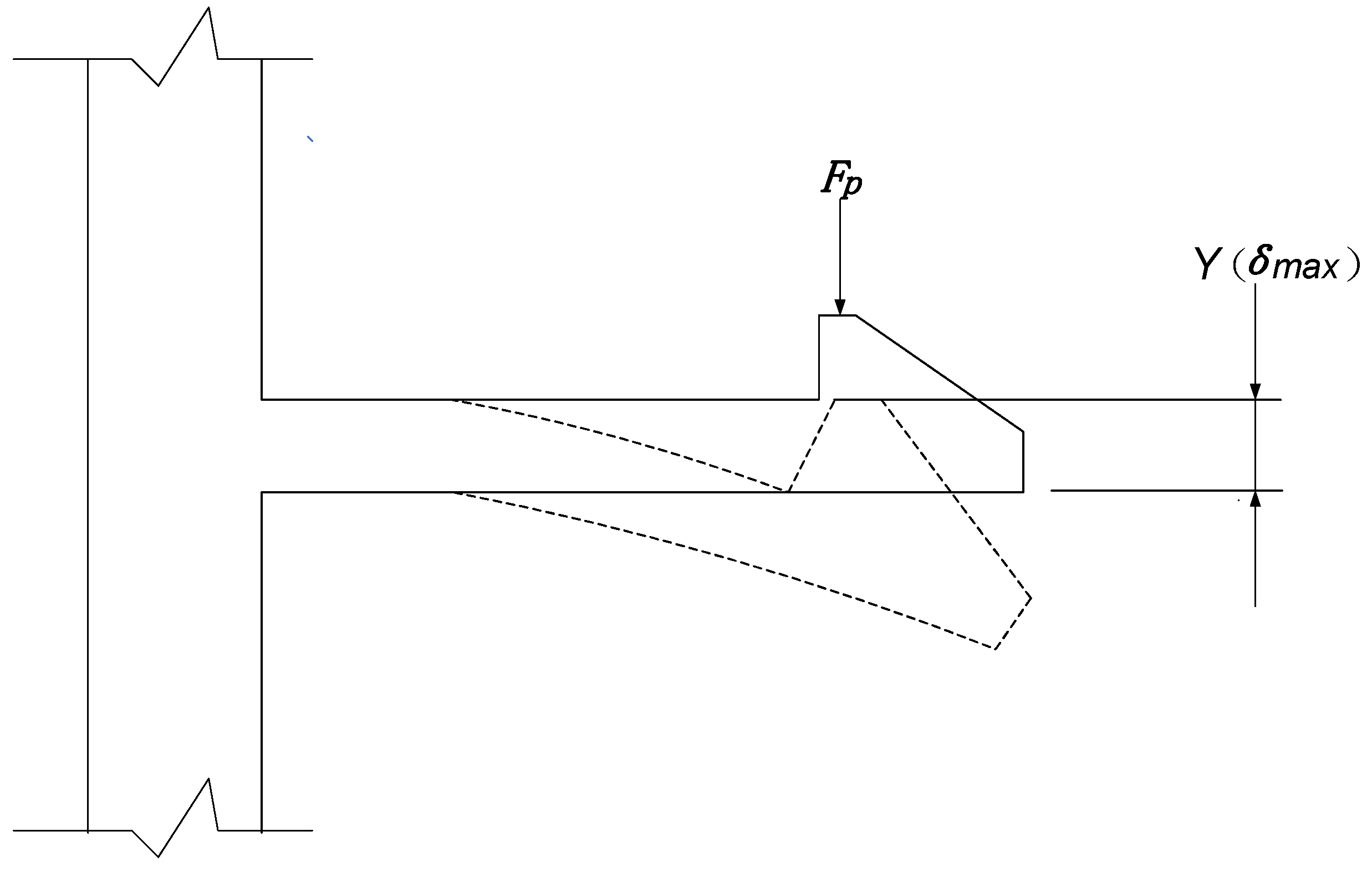

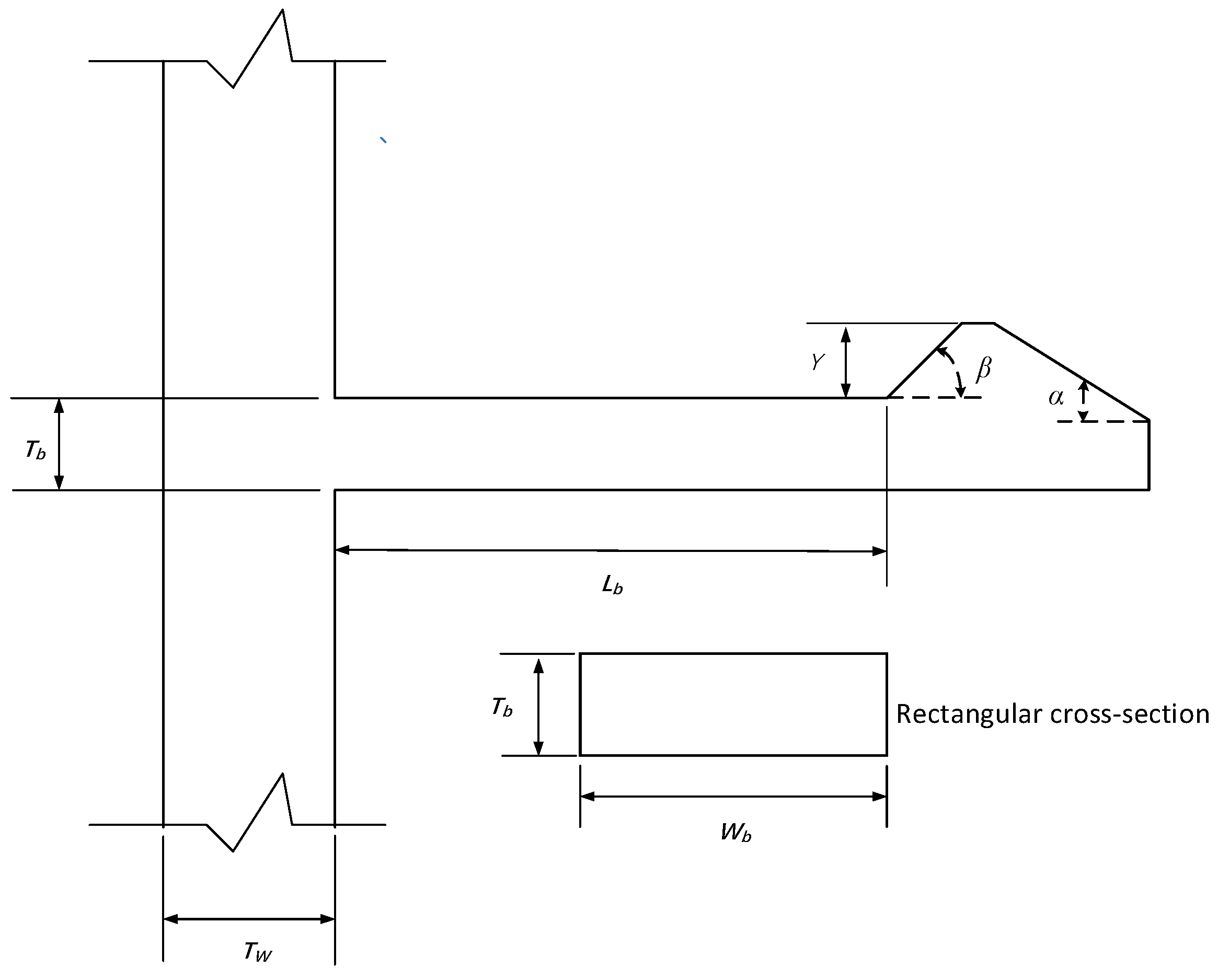

2.1.3. Mechanical Principal Analysis of Base Buckle

2.2. Clamping Device of the Fixture

2.2.1. Gripper Material

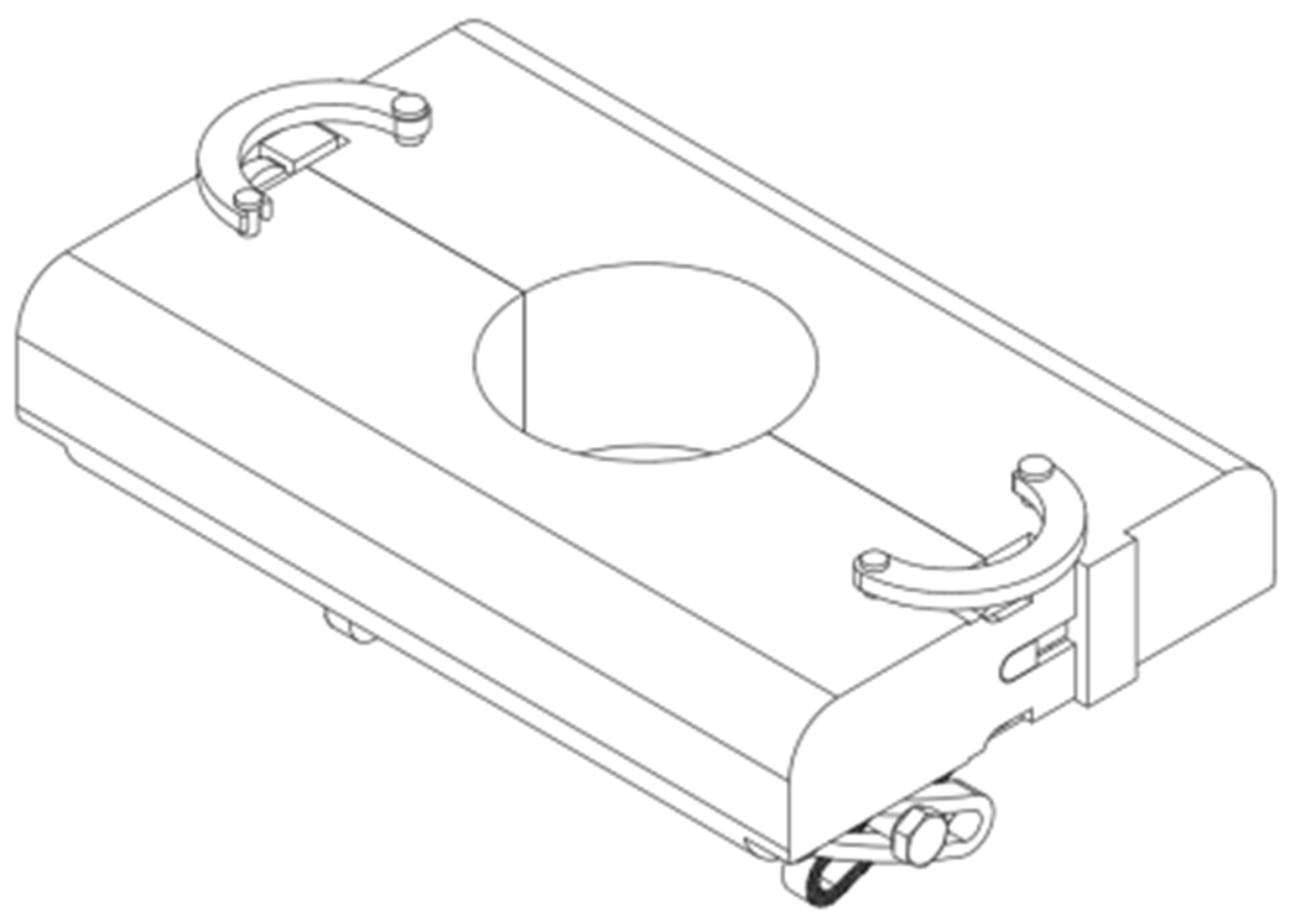

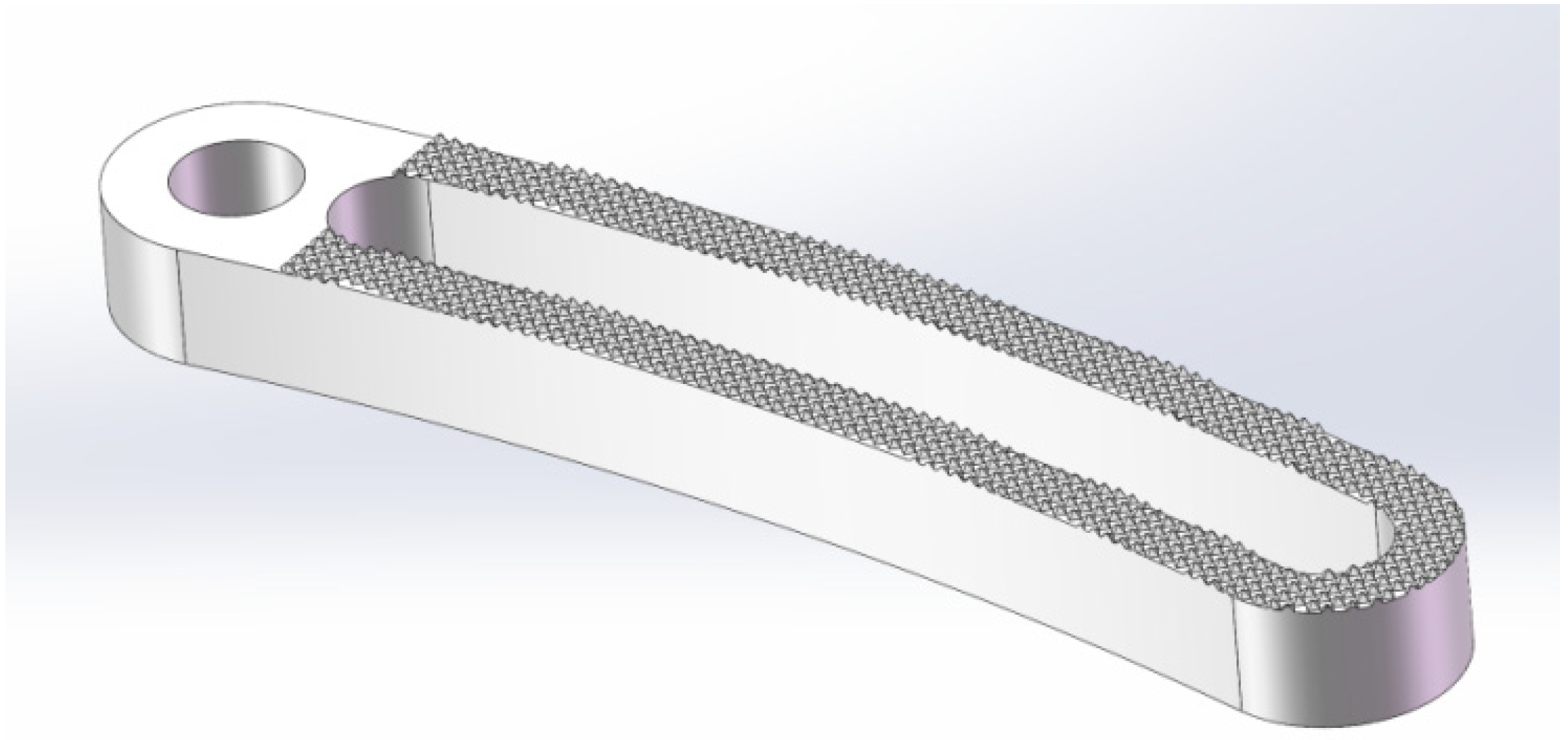

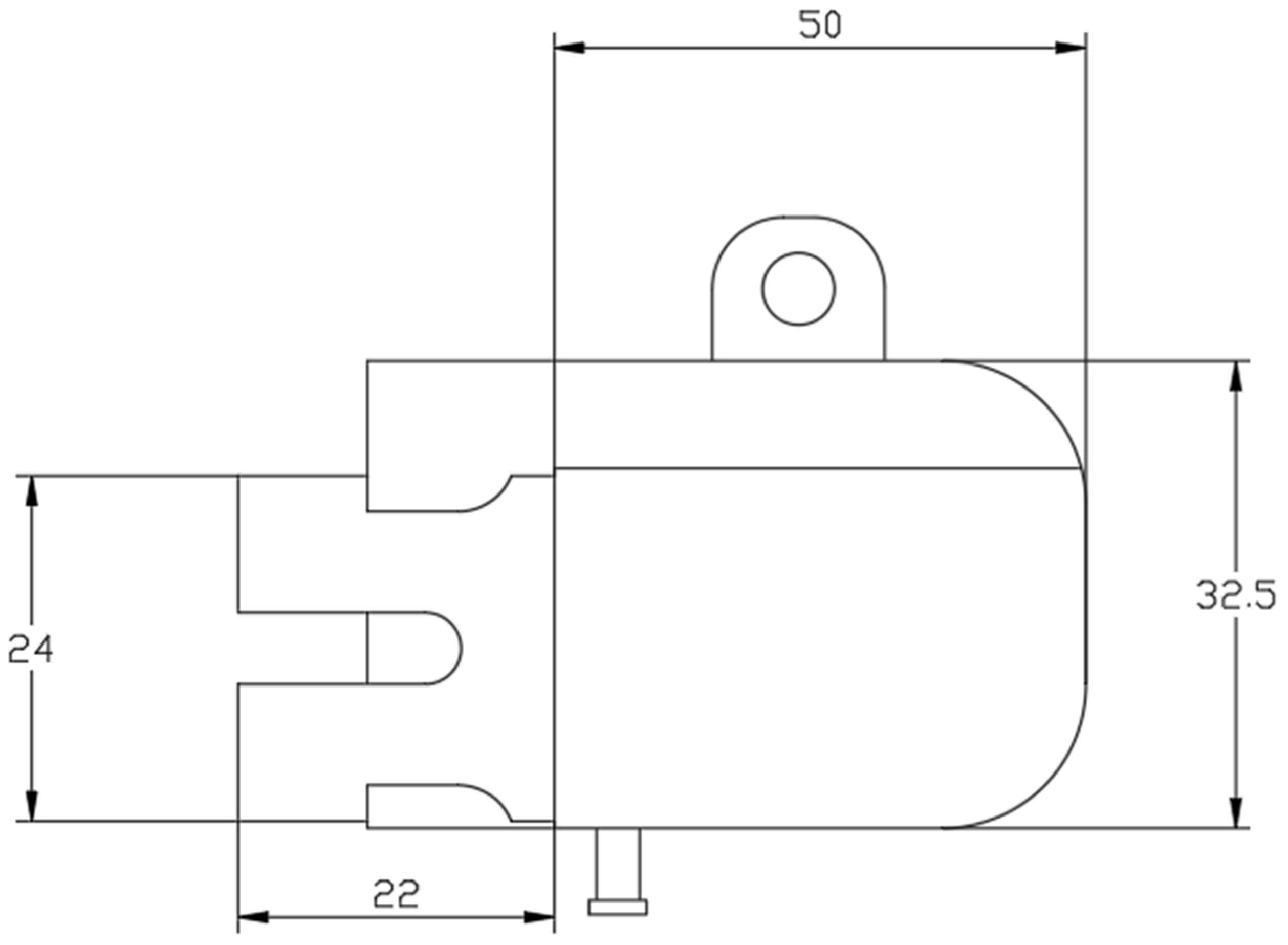

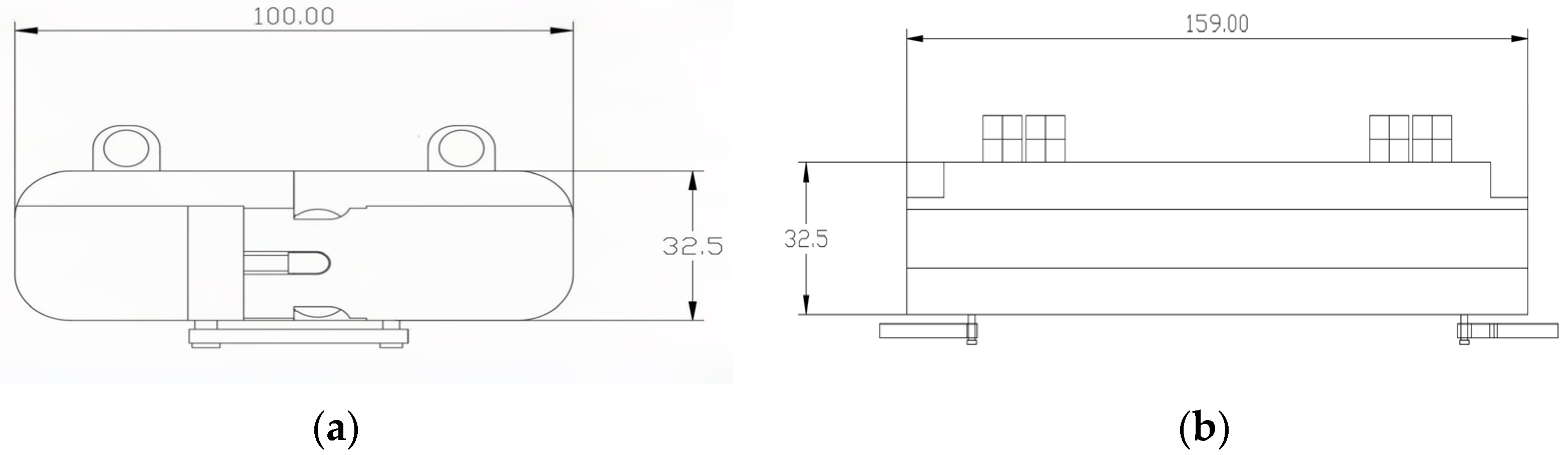

2.2.2. Structural Composition

2.2.3. Mechanical Principal Analysis of Gripper

3. Installation Method of Fixtures

3.1. Base Installation

3.2. Clamping Jaw Installation

4. Advantages of Fixed Devices

4.1. Advantages of Snap-On Base

4.2. Advantages of Clamping Device

5. Mechanical Simulation Analysis of Fixed Devices

5.1. Mechanical Simulation

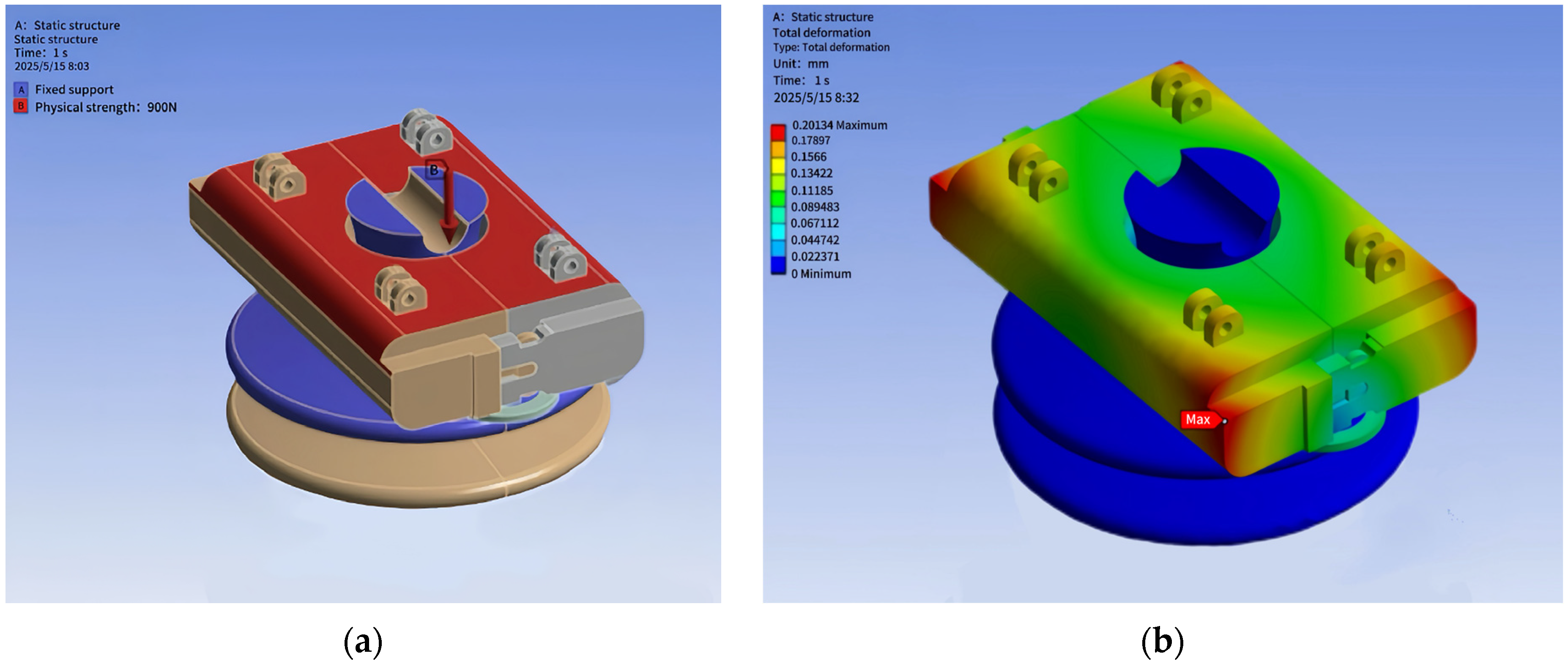

5.1.1. Simulation Analysis of Snap-On Base

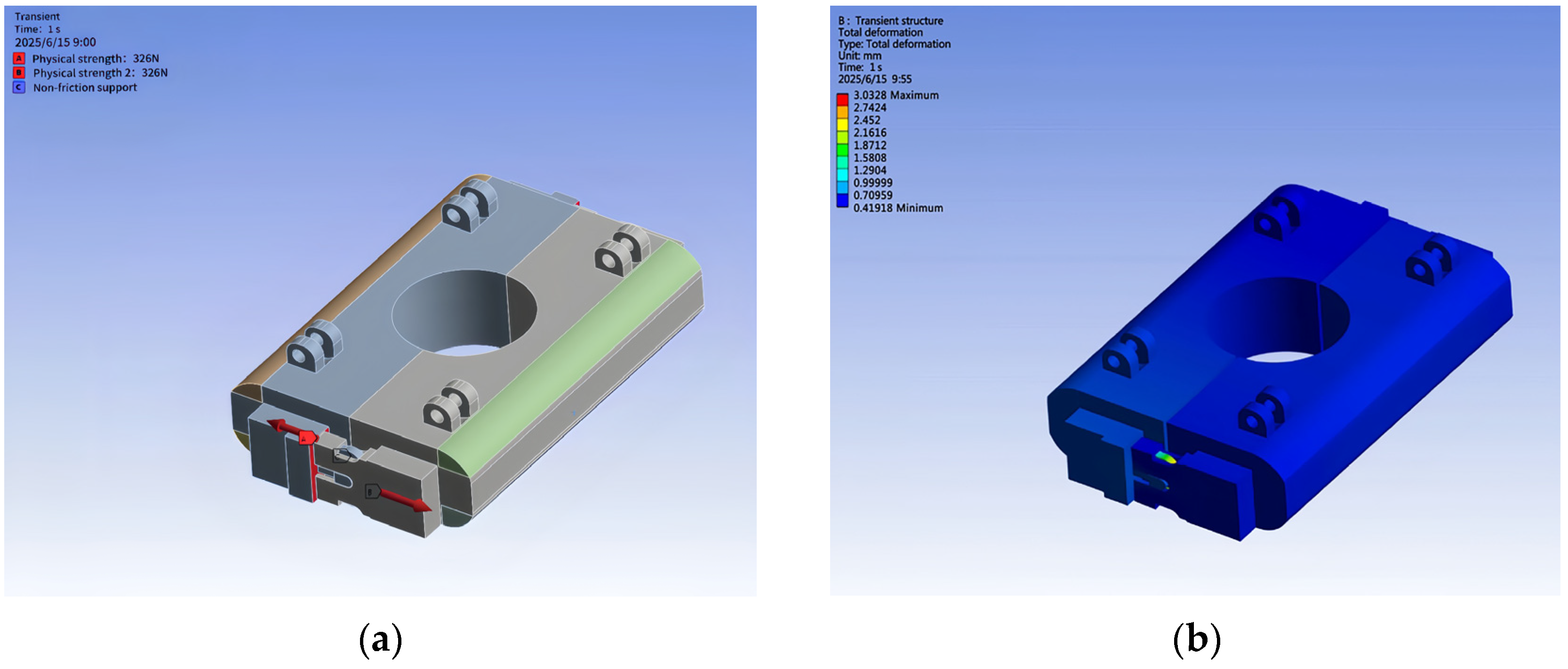

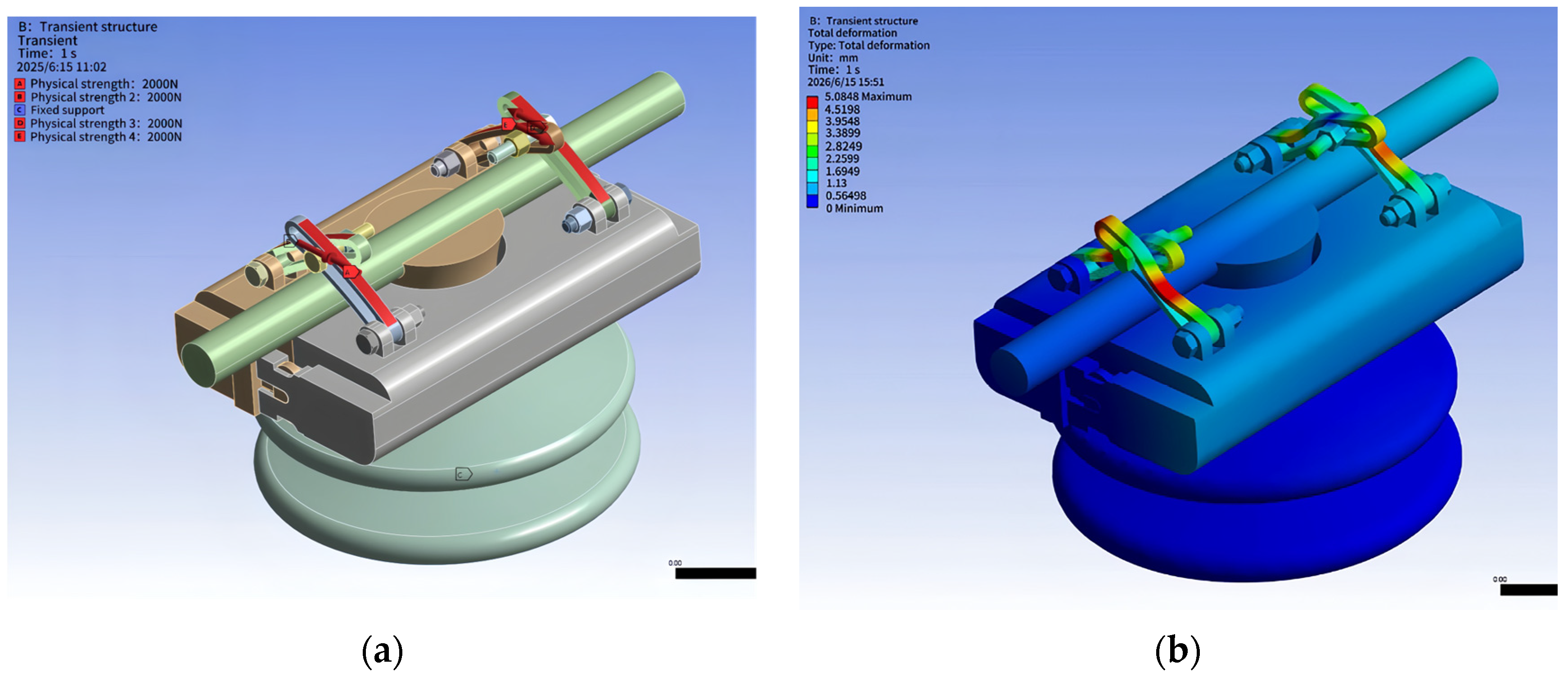

5.1.2. Simulation Analysis of Infinite Adjustment Gripper

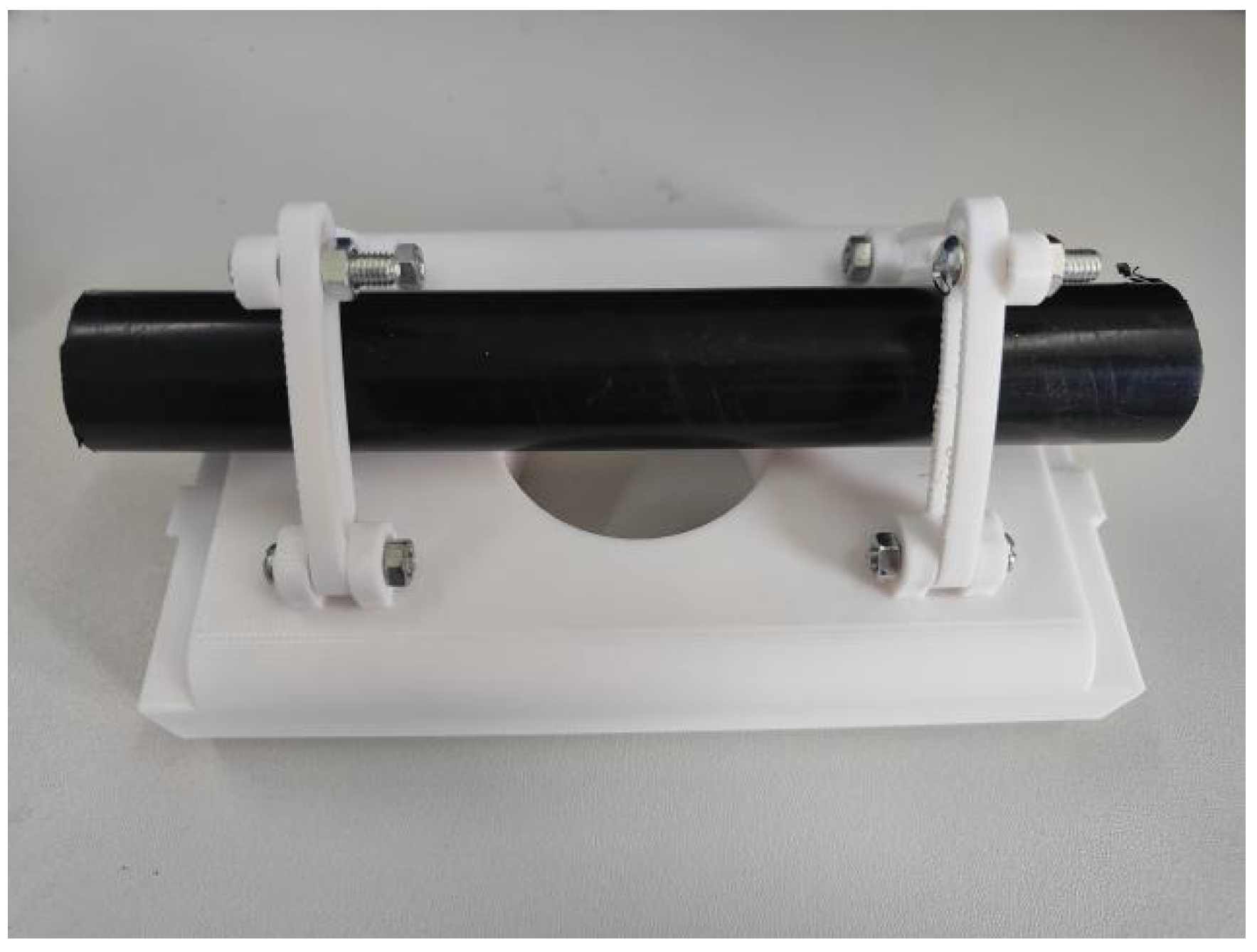

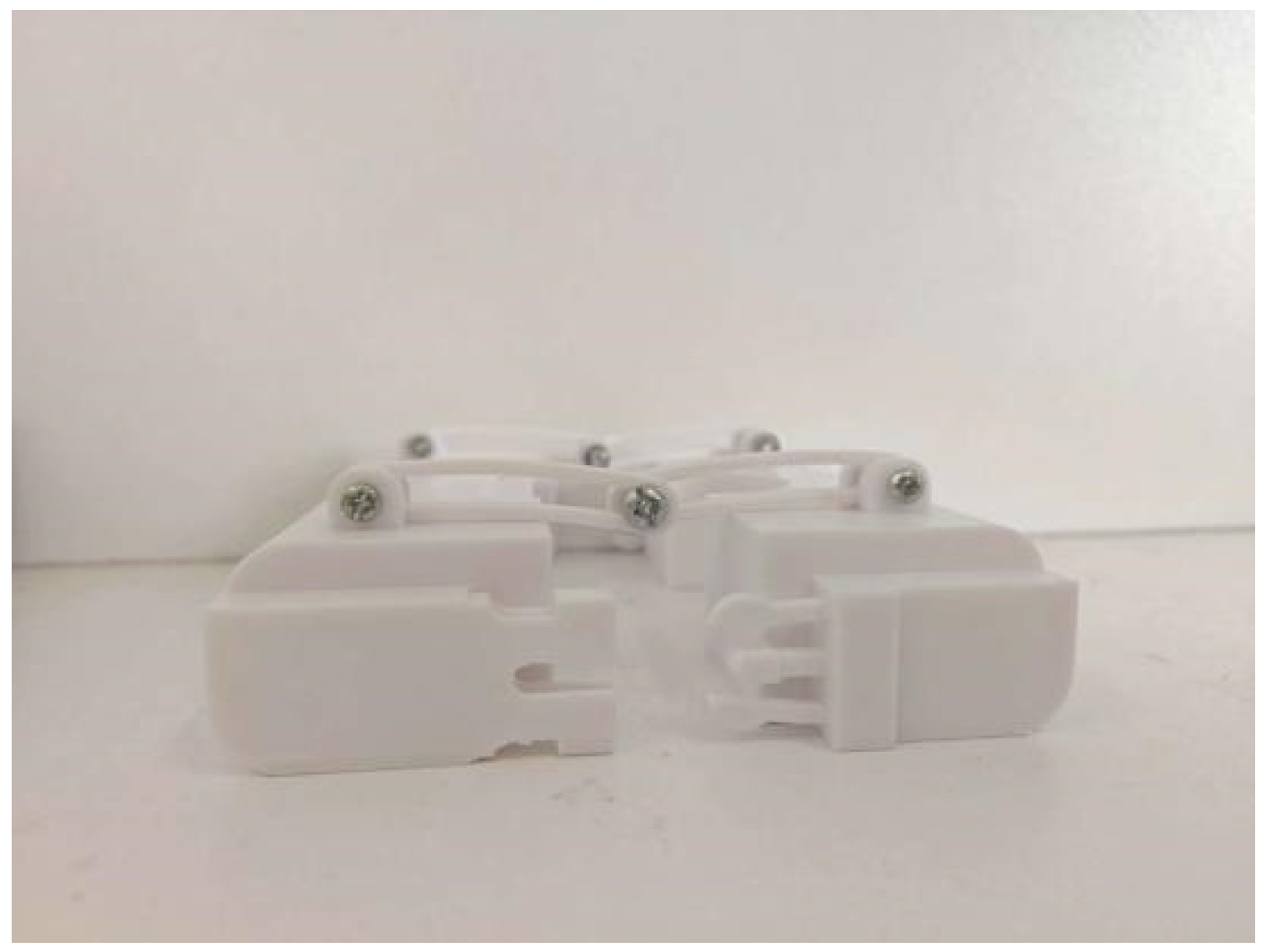

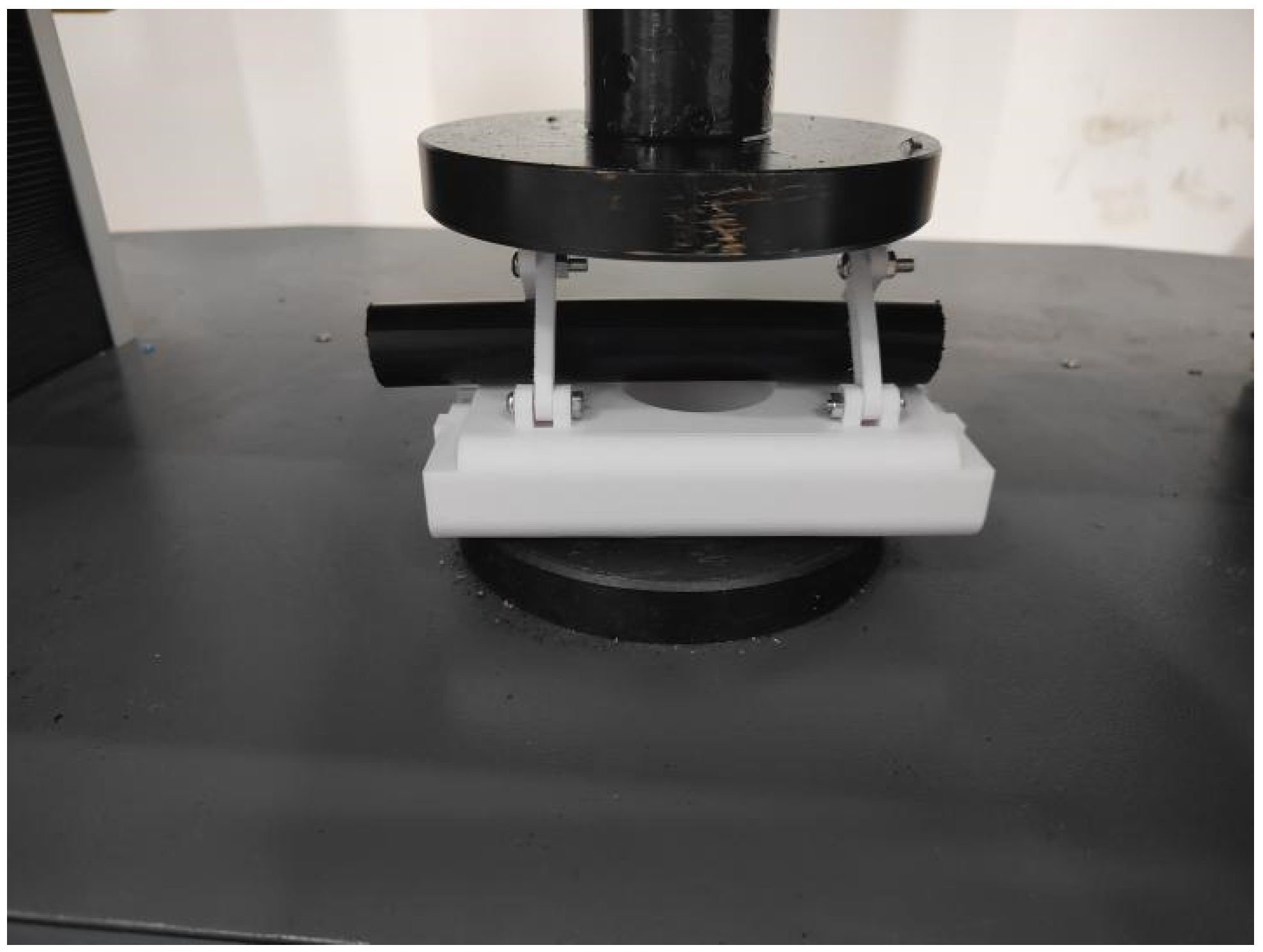

6. 3D Printed Physical Structure of Fixed Device

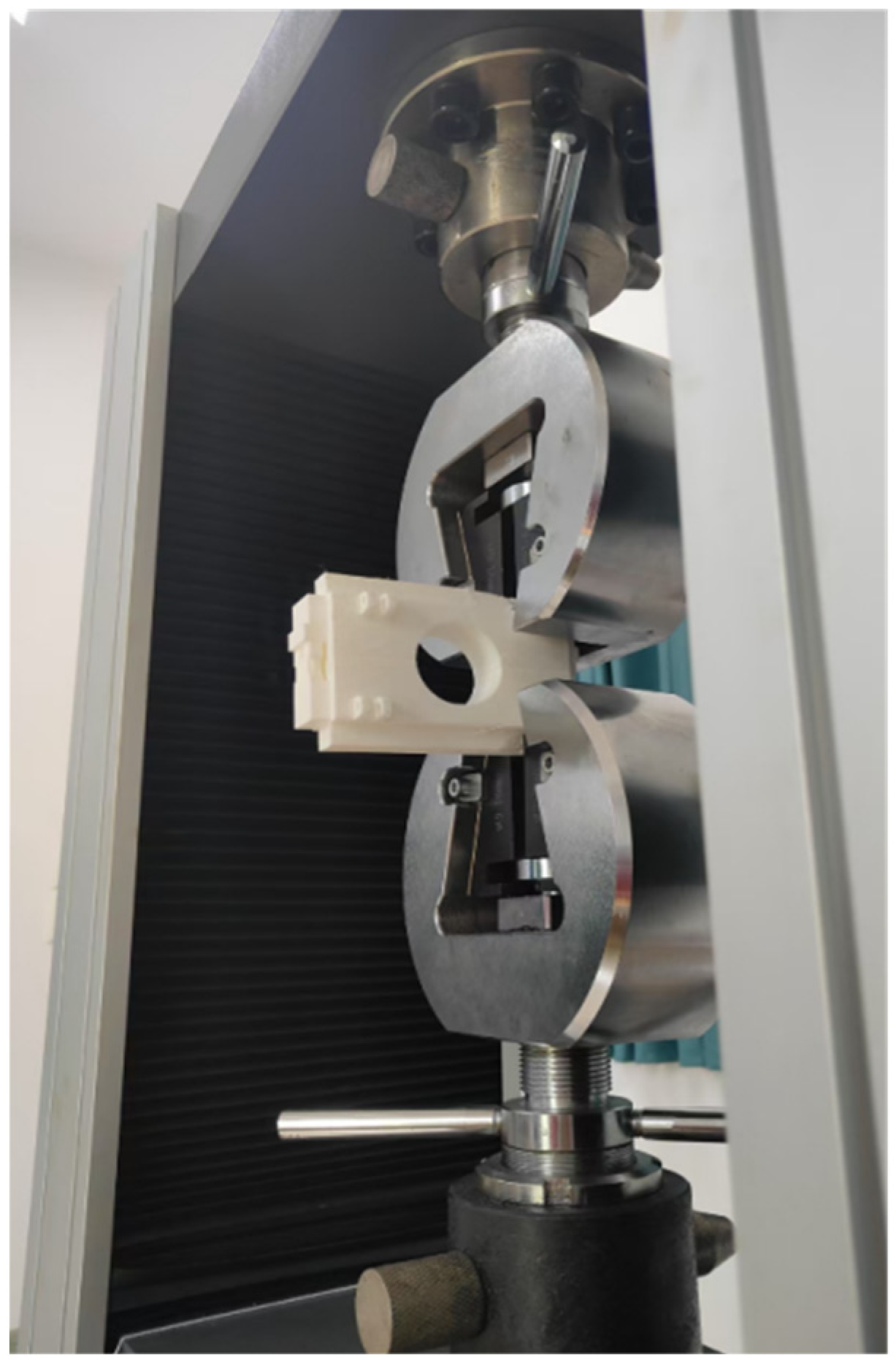

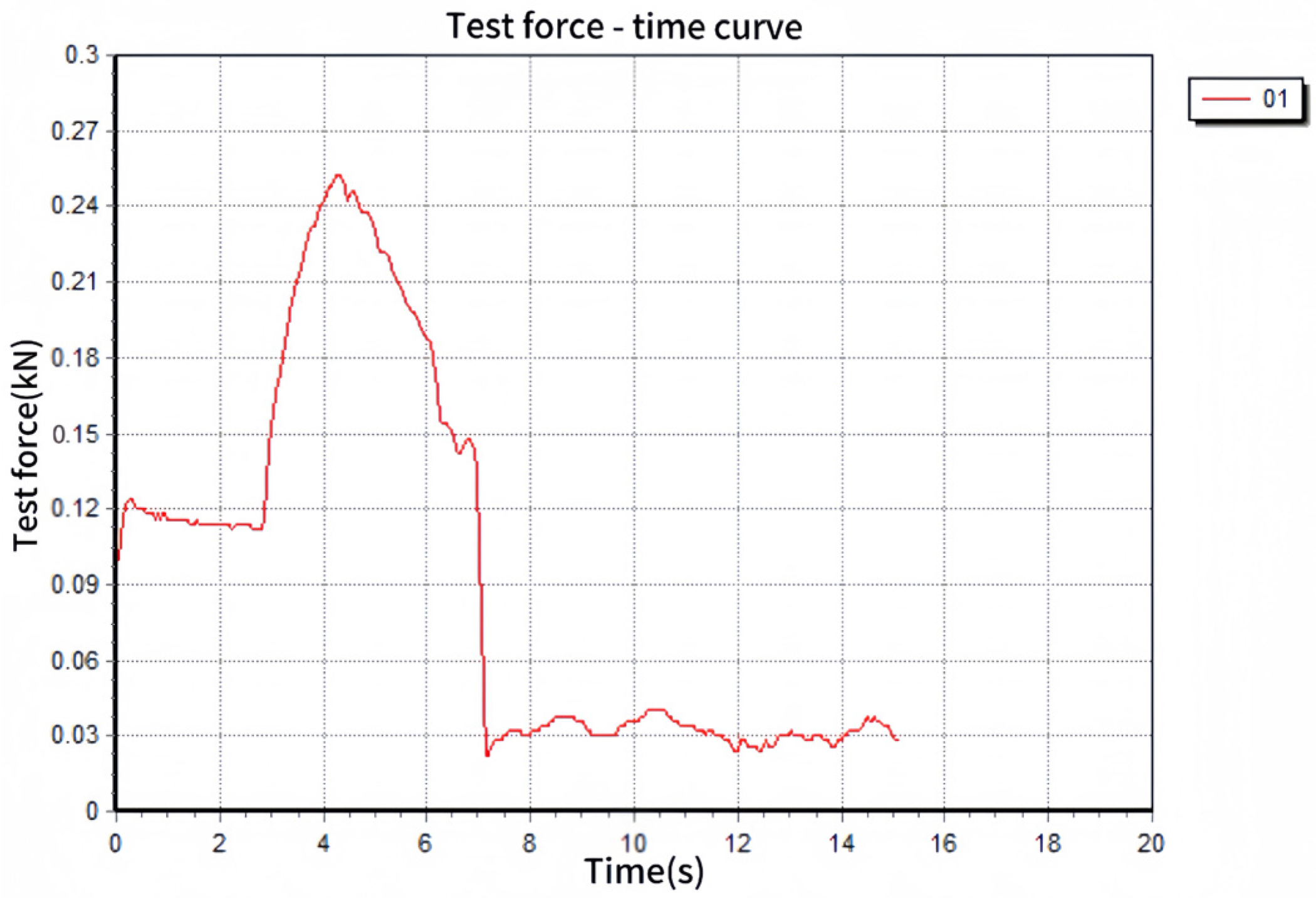

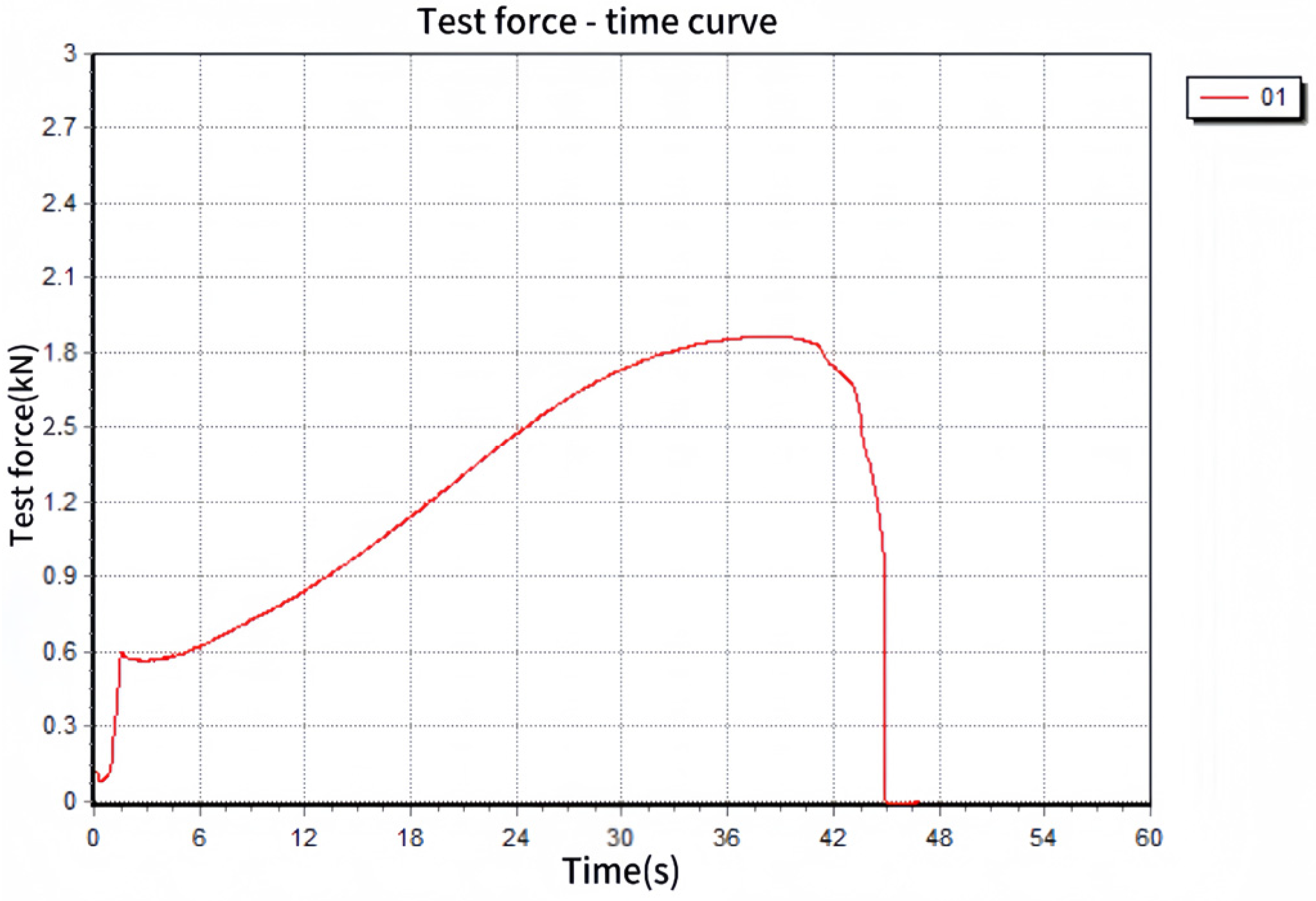

7. Mechanical Performance Testing of Fixed Devices

7.1. Test and Analysis of Snap-On Base

7.2. Test and Analysis of Infinite Adjustment Gripper

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, G.; Qiu, Y.; Zhai, Y. Design of Fixed Devices for Overhead Line Conductors and Insulators in Distribution Networks. Rural. Electr. 2025, 33, 36–37. [Google Scholar] [CrossRef]

- Zhao, L.; Qin, X.; Guo, X.; Luo, S.; Zhao, H. Design and Development of a New High Voltage Line Tightener. Electr. Technol. 2021, 114–115. [Google Scholar] [CrossRef]

- Shi, M.; Wang, P.; Duan, C.; Chen, Y.; Zhang, M.; Xia, B.; Liu, H.; He, Z. Discussion on a standardized fixed device technology for 10 kV overhead power lines. J. Anhui Electr. Eng. Vocat. Tech. Coll. 2024, 29, 30–35. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z8k6SbQNN3s4HTU7n_yrS5eTQyEJVR6RLdhG_oJCzE8HnhZkFxOCo-N1lomByaN1lWL9LssG_9iIC6qBjeKZ9SCDwl9Jb0DmPdeX3QwXC5bGFXSOqwPGuSuWn6xNZiCrlfXwqdBMZwYEv0KJ7yQVihjbS_VJz7NPC0nQQLpSVgmHw==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- Luo, J.; He, J.; Yang, J. Design and Application of a Wire Fixing Device on Insulators. Integr. Circuit Appl. 2022, 39, 244–245. [Google Scholar] [CrossRef]

- Wang, Z.; Li, W.; Li, Y. Research on Fixed Drainage Lines and Jumper Insulation Devices for Live Working of 10kV Distribution Lines. J. Electr. Eng. 2017, 12, 19–23. [Google Scholar] [CrossRef]

- Yu, F.; Kai, W.; Shaolei, W. Design of clamping device for overhead line branch line with live installation. In Proceedings of the 2020 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Tianjin, China, 26–28 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 321–324. [Google Scholar] [CrossRef]

- Gong, X.; Zhang, M. Research on Construction Technology for Cable Laying and Installation of 10kV Overhead Distribution Network. Electr. Technol. Econ. 2025, 81–83. Available online: https://kns.cnki.net/kcms2/article/abstract?v=hQuCc5bkPPNRrfYUX_Dgo41iqc0VttEnp--1coZmXGkUJrnveARXPXlJloTYvHIULqUywzvKSArUoihkbDNnAh801nMIazuxCRalyRMamYifspkRNfAftqTJaccx60Oa6H-XYBOMPrOQP0odK7cVIbynFcKUj0yg-E0Rt9DtH17wuHIBF9sRPw==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- Li, G.; Ni, J. Development of 10kV Live Overlapping Lead Fixing Equipment. Zhejiang Electr. Power 2013, 32, 67–69. [Google Scholar] [CrossRef]

- Sun, C.; Yang, Y. Development of 10kV Live Working Tools. Yunnan Electr. Power Technol. 2013, 41, 61–63. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z94Q67YeMarprudaG-p74_OGtwZ6buCjqOmw5-vX5iTli_q9-T5jB-C8RZPnJdb1mPQ6cpReg_q3mJcf0BSJCP91xacnptbTrnYOYGv7YY4k7pWhXWWxKK6rOzaJBawFal_x-WUmhJa5aCgbX0lhCjBFpf5LTpiw6-qCrlUIvLBDg==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- Wen, H.; Zhang, J. Development of Fixed Device for Replacing Tension Insulators of Overhead Power Lines. Rural. Electrif. 2022, 66–69. [Google Scholar] [CrossRef]

- Zhang, X. Research on Construction Issues and Key Points for High Voltage Overhead Lines. Shandong Ind. Technol. 2018, 153. [Google Scholar] [CrossRef]

- Shen, X. Development of a New Type of Line Tightener. Electr. Era 2019, 69–71. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z8kF83EfuezlN_sm68pu7-Pe5dbWSdN49730BFsrUGH_qLUlWgLNYEyWT74LbmjxKj9nFrXoAfXewtVVEQdVOX1RvTgt84yy2pwQ6qoKXHqgRDTsxl-bDI7T3gqLQjBJgCYXs0_x3Y_8ZCC-QSy20pAh-hV4KyP3Uq07lch3-dDeA==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- Ahsan, M.; Baharom, M.N.R.; Khalil, I.U.; Zanial, Z. Simulation-based analysis of electric field characteristics under high-voltage double-circuit and quadrupole overhead transmission lines. J. Electrost. 2025, 135, 104080. [Google Scholar] [CrossRef]

- Tingting, J.; Li, D.; Hongjuan, X.; Zhong, W. Study on the influence of aging and high impedance faults on line loss of 10kV distribution line. IOP Conf. Ser. Earth Environ. Sci. 2019, 233, 022016. [Google Scholar] [CrossRef]

- He, Y.; Huang, Y.; Cai, J.; Chen, Z. A Numerical Analysis on the Wind-Resistance Strengthening with Guy Wires for Distribution Lines. In Proceedings of the 2017 International Conference on Manufacturing Engineering and Intelligent Materials (ICMEIM 2017), Guangzhou, China, 25–26 February 2017. [Google Scholar] [CrossRef]

- Tian, C. Research on Relay Protection Configuration and Setting of 10kV Distribution Lines Based on High Reliability. Power Equip. Manag. 2025, 154–156. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z_WMgydJD2ydZSZMKf2jRoBFX01ebLrbb89VC9Nik-RxowZUjWSp9nAXQ_w_DUiJ5naClVRPlttekVNg8KSpQUQDQtFqae6Ie9boXv3IG8MaxDRI43LiZyN3IniqD82Edhcs36I5Agm_7xvOBhn3hq0ignZti49H85o_A7-oc64pw==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- GB 50217-2018; Design Standard for Power Engineering Cables. China Planning Press: Beijing, China, 2018. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z_LjccH5l0sH9VpCxWPsO97HaQoTBKISqloTYZ-ebvgo0HccDk60rSkDOv72DmBJuQSmuLJvq5mJSFx8sTFKMRBzJ9QEIFDZOcBplXgNGk5fCczDBeN3kCs-p53dhjvQk59bMN11kmkO3oRqK1stZIj9V8UkdGmtgo=&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- Zhang, A. Fixed Device for Insulators and Conductors in Distribution Lines Shandong Province, State Grid Shandong Electric Power Company Changle County Power Supply Company. 26 April 2021. Available online: https://kns.cnki.net/kcms2/article/abstract?v=lHYhtDVi6z_vrhrB_4RX5hazY5FjlLTJomY-6Pn5G1XnH2sfXxZkx27-cii-D16c5DcikI2Mzdv6D3zNqePFvV-DzQ7ZdAcZidPBWTL4qtIZ2dGWebs6kFfHSZZML75rTka9_FjWvm4a5IXCT57eXpynpLik87DISf1Qxtaq4CWW2bINv0rrdQ==&uniplatform=NZKPT&language=CHS (accessed on 18 July 2025).

- GB50009-2001; Code for Load of Building Structures GB50009-2001. China Academy of Building Research: Beijing, China, 2007. Available online: https://kns.cnki.net/kcms2/article/abstract?v=hQuCc5bkPPNQjLuRqXAWqkN-KXNejkSBu9TrBXYAjR2g7HVctqRcU_RAl8IJrKv2TISerLHVFPXPSf0WgtW9uL2FC5KkomGD4Dl1i9LZITLuL3ydSVltFP5Lpuiq0bgJBU9Vqn0edfhobzKeMYH1LPmgKUQQB5nlHEYk4Ki4BCFhQ1r_KcQ1xY6TM2YQpxX7UdO-49QZ0vM=&uniplatform=NZKPT (accessed on 21 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Tao, S.; Chen, L.; Li, J.; Zhong, X.; Bao, L.; Shu, Y.; Liu, Y. Design and Development of a New 10 kV Overhead Line Fixing Device in Power System. Processes 2025, 13, 2379. https://doi.org/10.3390/pr13082379

Liu B, Tao S, Chen L, Li J, Zhong X, Bao L, Shu Y, Liu Y. Design and Development of a New 10 kV Overhead Line Fixing Device in Power System. Processes. 2025; 13(8):2379. https://doi.org/10.3390/pr13082379

Chicago/Turabian StyleLiu, Bohan, Shuhan Tao, Lingxi Chen, Jiawen Li, Xingtong Zhong, Lanxin Bao, You Shu, and Yi Liu. 2025. "Design and Development of a New 10 kV Overhead Line Fixing Device in Power System" Processes 13, no. 8: 2379. https://doi.org/10.3390/pr13082379

APA StyleLiu, B., Tao, S., Chen, L., Li, J., Zhong, X., Bao, L., Shu, Y., & Liu, Y. (2025). Design and Development of a New 10 kV Overhead Line Fixing Device in Power System. Processes, 13(8), 2379. https://doi.org/10.3390/pr13082379