Abstract

To address the challenges of low density, loose structure, high utilization costs, and inadequate molding effects of corn straw char under ambient temperature and pressure conditions, this study investigated the utilization of waste soybean powder (WSP) as a binder to produce biochar pellets via ultrasonic-assisted processing. A single-factor experiment was initially conducted to assess the effects of key variables. Subsequently, a Central Composite Rotatable Design (CCRD) was employed to evaluate the individual and interactive effects of these variables, in which pellet density and durability served as response indicators. Regression models for both responses were developed and validated using analysis of variance (ANOVA). The results indicated that, at a 0.05 significance level, the mixing ratio of corn straw char to WSP and molding pressure had highly significant effects on pellet density, while pelleting time had a significant effect and ultrasonic power had no significant influence. All four factors significantly affected pellet durability, and their interactions were further analyzed. The optimal conditions were a mixing ratio of 45%, pelleting time of 33 s, an ultrasonic power of 150 W, and a molding pressure of 5 MPa, yielding pellets with a density of 1140.41 kg/m3 and a durability of 98.54%. These results demonstrate that WSP is an effective binder for the ultrasonic-assisted fabrication of biochar pellets.

1. Introduction

In 2023, CO2 emissions associated with energy consumption globally reached approximately 37.4 billion tons [1]. As a developing nation, China’s energy demand is anticipated to continue its upward trajectory in the future, predominantly relying on coal as its primary energy source. To tackle these challenges and achieve carbon peak and carbon neutrality goals, an urgent transition in energy systems is imperative [2]. Biomass energy serves as a renewable low-carbon resource that is both readily available and relatively cost-effective [3]. The efficient utilization of biomass energy plays a notable role in promoting China’s energy transition. Biochar represents a high-quality renewable resource characterized by low nitrogen and sulfur content along with minimal CO2 emissions [4,5,6]. However, it is characterized by low density, a loose structure, and high ash content. In contrast, biochar pellets possess higher density and reduced operational costs compared with char powder [7]. Consequently, the development of pelletization technologies will enhance the effective utilization of biochar pellets.

Currently, biochar pellet production faces challenges, such as high binder costs, substantial energy consumption during molding, severe mold wear associated with traditional methods, and suboptimal performance under ambient temperature and pressure conditions. Several scholars have investigated various aspects of biochar pellet production to address the abovementioned challenges. The factors influencing the quality of pellets primarily encompass physicochemical properties (such as particle size and moisture content) as well as process parameters (including pressure, temperature, and the use of additives, etc.). However, ultrasonic vibration-assisted pelleting was found to be capable of producing pellets at room temperature without the application of high pressure or additional adhesives [8]. It exhibited a lower pelleting force, a shorter pelleting time, and reduced swelling when compared to the absence of ultrasonic vibration [9]. Li et al. [10] investigated the effects of particle size, moisture content, molding pressure, pelleting time, ultrasonic power, and the interactions among these variables on the density and durability of pellets produced from corn stover using ultrasonic vibration-assisted pelleting, and determined the optimal processing conditions. A subsequent study revealed that in ultrasonic vibration-assisted pelleting, the mixing ratio of rice straw to corn stover significantly influenced pellet density and durability, which was attributed to differences in their compositional characteristics [11]. Furthermore, Li et al. [12] found that combining urea pretreatment with ultrasonic vibration-assisted pelleting could enhance both the solid density and durability of pellets. This improvement was attributed to the disruption of chemical linkages between lignin and hemicellulose caused by urea pretreatment, which resulted in a rougher and more fragmented cellulose fiber surface. Ultrasonic vibration-assisted pelleting is a potential pretreatment method for modifying biochar properties [13]. Qin et al. [14] utilized camellia oleifera shell biochar combined with lignin (purity exceeding 90%) to produce high-quality quality biochar pellets. Cheng et al. [7] mixed cotton stem biochar powder with biomass tar to obtain optimal biochar pellets at a pressure of 8 kN and temperature of 20 °C with an addition rate of 6%. Chen et al. [15] employed fermented soybean slurry as a binder for biochar pellets which significantly enhanced their density and mechanical durability. Haykiri-Acma et al. [16] incorporated molasses as a binder to remarkedly improve the mechanical durability of biochar pellets.

In the process of carbonization followed by shaping, the raw materials themselves become difficult to shape effectively, as components such as cellulose, hemicellulose, and lignin are decomposed during the carbonization stage. Even with the assistance of ultrasonic vibration, the shaping quality remains unsatisfactory. Therefore, to enhance the quality of the shaped fuel, the addition of a binder is a necessary and effective measure. Using adhesives, such as tar, molasses, and similar substances can significantly increase emissions and pollution during fuel combustion.

Fermented soybean slurry is safe for animal feeding. However, waste soybean powder (WSP) frequently contains mycotoxins, such as aflatoxin, fumonisin, and zearalenone, making it inappropriate for feed use [17]. Nevertheless, WSP comprises valuable components, such as pectin, lipids, and proteins that exhibit strong water absorption properties and high viscosity [18], positioning it as a promising binder for biomass pellets. The integration of ultrasonic vibration and WSP in the preparation of biochar pellets not only enhances pellet quality but also reduces energy consumption and equipment wear, thereby broadening the application field of WSP.

Consequently, this study employed WSP as a binder to compress corn straw char into pellets utilizing an ultrasonic vibration method to address challenges related to low density, loose structure, and excessive dust generation while minimizing energy consumption and enhancing efficient utilization. Single-factor experiments were conducted to investigate the effects of WSP content, pelleting time, ultrasonic power, and molding pressure on the density and durability of biochar pellets. Subsequently, a central composite rotatable design (CCRD) was utilized to identify optimal processing parameters while analyzing interactions among these factors, thereby, providing valuable insights for future research.

2. Materials and Methods

2.1. Materials and Experimental Setup

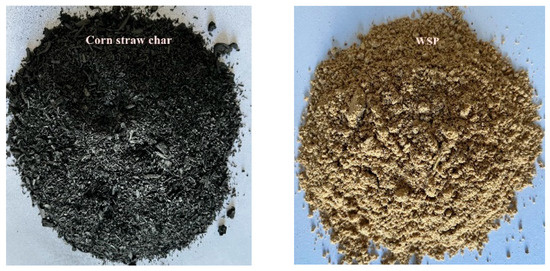

Corn straw was acquired from the experimental field of Heilongjiang Bayi Agricultural University. Following harvesting, the corn straw was collected, cut into small sections using a guillotine (Daqing, China), and air-dried. Ground corn stalks with a particle size of 30 mm were placed in a tubular carbonization furnace (Model Sk2-2-10, Shanghai, China) for pyrolytic carbonization at temperatures ranging from 500 to 550 °C, resulting in the production of corn straw char. The char was thereafter screened to isolate particles within the range of 0–0.5 mm using standard sieves and subsequently stored in sealed bags for the future use. The WSP consisted of moldy soybeans that were crushed to less than 0.5 mm, as listed in Figure 1. Industrial and elemental analyses were conducted on these three raw materials; the results are presented in Table 1.

Figure 1.

Materials for pellets.

Table 1.

The results of industrial analysis and elemental analysis of materials.

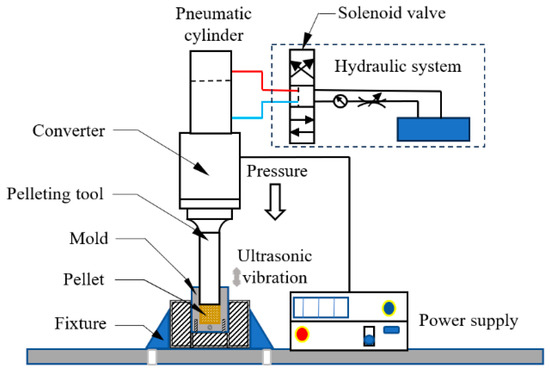

The molding device comprised an ultrasonic generator (Hangzhou Funsonic Co., Ltd., Hangzhou, China), transducer (Hangzhou Funsonic Co., Ltd., Hangzhou, China), amplitude transformer (Hangzhou Funsonic Co., Ltd., Hangzhou, China), and a hydraulic system (Wangfeng Co., Ltd., Shanghai, China). The operational principle of the test apparatus is illustrated in Figure 2. The ultrasonic generator operated at a frequency of 20 kHz with a rated power of 500 W, being adjustable from 20% to 100%. The hydraulic power system maintained pressure control within the range of 0–10 MPa, while the ultrasonic oscillator had a diameter of 16 mm and a length of 265 mm. The molding mold consisted of a detachable aluminum cuboid with a central hole measuring 16.5 mm in diameter.

Figure 2.

Ultrasonic-assisted molding device [11].

The mixing ratio refers to the mass ratio between corn straw char and WSP, and the moisture content of the mixed raw materials was adjusted to 14% using distilled water in preparation for biochar pellet production. A 1 g sample of the mixture was weighed and placed into the mold, after which a titanium tool was utilized to compress the particles into biochar pellets under predefined experimental conditions.

2.2. Experimental Design

2.2.1. Single-Factor Experiment Design

To determine the optimal ranges and effects of the mixing ratio, ultrasonic power, pelleting time, and molding pressure on corn straw char pellets, a single-factor experiment was initially conducted. The specific factors and their corresponding levels are presented in Table 2; these values were based on the findings of prior research and preliminary experimental results.

Table 2.

Factors and levels in single-factor experiment.

2.2.2. RSM Experiment Design

To investigate the relative contributions of the tested variables and their interaction influences on biochar pellet density and durability, as well as to determine the optimal conditions, CCRD based on Design-Expert 13 (Stat-Ease Inc., Minneapolis, MN, USA) was implemented based on the results from the single-factor experiment. The experimental variables and their corresponding levels utilized in this study are listed in Table 3. The holding time was set at 30s, and the moisture content of the mixed raw materials was maintained at 14%.

Table 3.

The variables and levels in CCRD.

2.3. Test Method

Given that the biochar pellets are regular cylinders, their mass and volume can be utilized to calculate their density [19]. Three biochar pellets were randomly selected, and the average value from these three replicates was taken as the pellet density for this condition.

Biochar pellet durability is a critical evaluation criterion during loading, transportation, storage, and utilization processes. According to the international ISO 17225 standard [20], non-wood pellet fuel must have a durability greater than 96.0%, while the domestic standard sets the minimum at 95.0% [19]. In this study, the durability of biochar pellets was evaluated in accordance with the national coal drop strength standard (GB/T 15459-2006 [21]) [22]. Three biochar pellets were randomly selected; after weighing and recording their initial data, they were dropped freely from a height of 2 m onto a steel plate devoid of any other substances on its surface, followed by re-weighing and data recording. Each test was conducted in triplicate. The durability of the biochar pellets was calculated according to Formula (1):

where Du is the biochar pellet durability (%), m1 represents the initial weight (g), and m2 is the weight of the remaining pellets (g).

3. Results and Discussion

3.1. Single-Factor Experiment

3.1.1. Effects of Mixing Ratio on Biochar Pellet Density and Durability

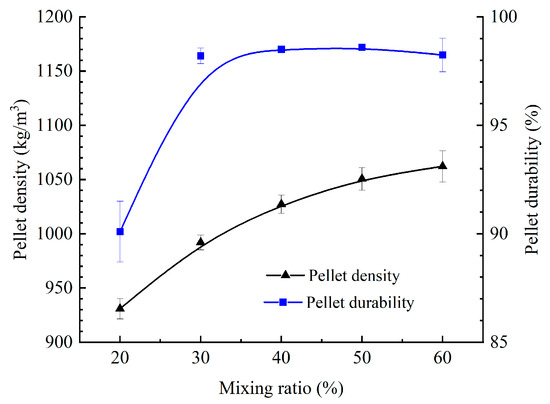

Figure 3 illustrates the effects of mixing ratio on biochar pellet density and durability. The results were acquired with an ultrasonic power of 200 W, a pelleting time of 30 s, and a molding pressure of 4 MPa. As the mixing ratio increased, the biochar pellet density also rose correspondingly. The highest value recorded was 1062.19 kg/m3 at a mixing ratio of 60%, which is 14.1% higher than that observed at a mixing ratio of 20%. Pellet durability increased rapidly within the mixing ratio range of 20–40%, reaching a peak of 95.60% at 50%. Beyond this point, durability exhibited a slight decline, while nonetheless remaining consistently above 98%. This minor fluctuation was likely cause by the strong water absorption capacity of WSP. As the WSP content increased, uniform mixing between the carbon and WSP after water absorption decreased. Consequently, carbon particles located near the edges became more susceptible to detachment due to uneven force distribution and varying impact angles during contact with the steel plate.

Figure 3.

The biochar pellet density and durability with mixing ratio.

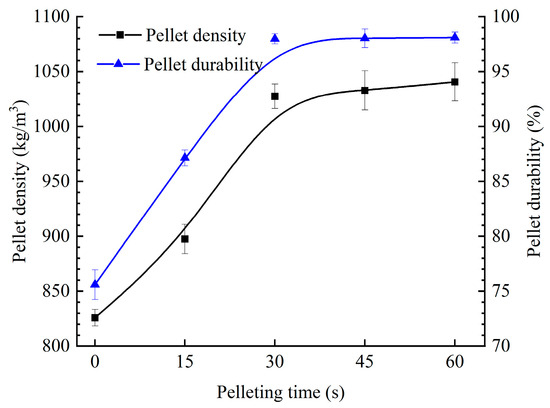

3.1.2. Effects of Pelleting Time on Biochar Pellet Density and Durability

Figure 4 shows the effects of pelleting time on biochar pellet density and durability. The results were obtained with a mixing ratio of 40%, an ultrasonic power of 200 W, and a molding pressure of 4 MPa. As pelleting time increased, both density and durability initially rose before stabilizing. At 30s, the biochar pellet density and durability improved by 25.05% and 29.77%, respectively, compared with the values at 0s. The highest recorded biochar pellet density was 1040.57 kg/m3, while durability reached 98.09%. This phenomenon can be primarily attributed to insufficient ultrasonic effects during shorter pelleting time. As pelleting time increased, the amount of transferred heat also rose [23], promoting closer bonding of particles under the applied pressure.

Figure 4.

The biochar pellet density and durability with pelleting time.

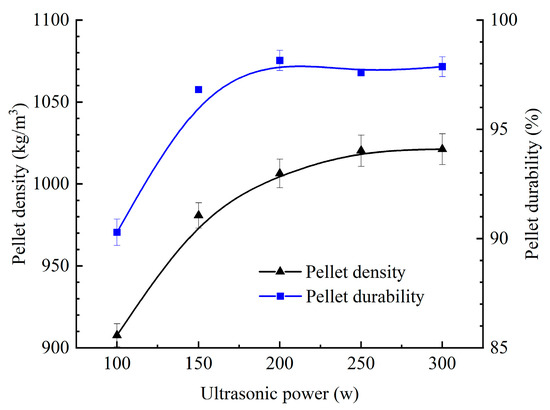

3.1.3. Effects of Ultrasonic Power on Biochar Pellet Density and Durability

Figure 5 illustrates the effect of ultrasonic power on pellet density and durability. The results were obtained with a mixing ratio of 40%, pelleting time of 30 s, and molding pressure of 4 MPa. As displayed in Figure 5, the biochar pellet density increased most rapidly within the range of 100 to 200 W. The rate of increase in pellet density slowed noticeably between 200 and 250 W, and minimal changes were found beyond 250 W. Overall, the density increased from 907.70 kg/m3 at 100 W to 1021.20 kg/m3 at 300 W, corresponding to a relative increase of 12.50%. Pellet durability exhibited a similar pattern, rising with density up to 200 W and reaching a maximum of 98.15%. After exceeding this threshold, durability showed a slight decline, while nonetheless remaining consistently above 97.5%. Comparable trends were reported by Zhang et al. [24] and Fan et al. [25]. The increase in ultrasonic power led to additional heat generation, which elevated the temperature sufficiently to soften the starch and protein in WSP, thereby enhancing inter-particle bonding and contributing to higher pellet density.

Figure 5.

The biochar pellet density and durability with ultrasonic power.

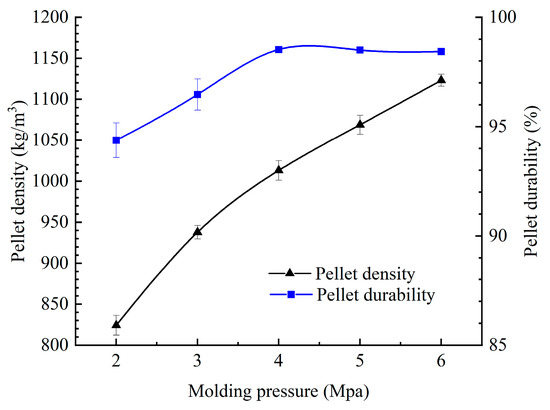

3.1.4. Effects of Molding Pressure on Biochar Pellet Density and Durability

The effects of molding pressure on biochar pellet density and durability are depicted in Figure 6. The results were attained with a mixing ratio of 40%, an ultrasonic power of 200 W, and pelleting time of 30 s. Pellet density increased with rising molding pressure, reaching a maximum of 1123.10 kg/m3 at 6 MPa, yielding 36.27% higher than the density at 2 MPa. As molding pressure increased, the internal pellet temperature also rose [26], enhancing biochar pellet durability from 94.37% to 98.52% up to 4 MPa. Beyond this pressure, a slight decline in durability was found, although values remained above 98%

Figure 6.

The biochar pellet density and durability with molding pressure.

3.2. CCRD Experiment

3.2.1. Response Surface Model of Density and Durability of Pellets

The experimental results are presented in Table 4. It was revealed that the data were fitted to second-order polynomial models using analysis of variance (ANOVA), as documented in Table 5.

Table 4.

Pellet density and durability based on CCRD.

Table 5.

ANOVA for Quadratic model of biochar pellet density and durability.

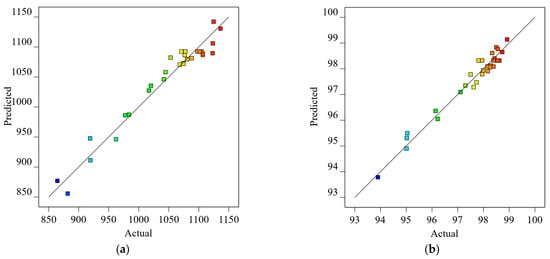

The results of the ANOVA for biochar pellet density, also shown in Table 5, indicated that the model was highly significant (p < 0.0001). Furthermore, the lack of significance in the residual error test suggested a good fit between the model and the observed data. The coefficients of determination, including R2, adjusted R2 (Adj-R2), and predicted R2 (Pred-R2), were 0.9563, 0.9154, and 0.7755, respectively. The coefficient of variation (CV) and adequate precision (AP) were 2.08% and 18.5802, respectively. These data demonstrate that the model fitted the experimental data well [27]. Figure 7a illustrates a comparison between actual values and predicted values for density, further validating that the quadratic regression model was both accurate and reliable.

Figure 7.

Comparison between the actual values and the predicted values. (a) Biochar pellet density; (b) Biochar pellet durability.

Based on the p-values presented in Table 5, the mixing ratio, pelleting time, molding pressure, as well as the interactions among the mixing ratio and ultrasonic power, mixing ratio and molding pressure, pelleting time and molding pressure, and ultrasonic power and molding pressure, all had significant impacted biochar pellet density. After excluding insignificant factors with p-values ≤ 0.05, a regression equation relating biochar pellet density to these factors was devised (Equation (2)):

The model for biochar pellet durability was highly significant (p < 0.0001), and the test for residual error was not significant, indicating a good model fit. The coefficients of determination R2, Adj-R2, and Pred-R2 were 0.9637, 0.9299, and 0.8448, respectively. The CV and AP were 0.3568% and 21.7500, respectively. Figure 7b illustrates a comparison between actual values and predicted values for durability, validating that the quadratic regression model was both accurate and reliable.

According to the p-values in Table 5, it can be concluded that all factors and their interactions related to molding pressure significantly impacted biochar pellet durability. After excluding insignificant items, a regression equation for biochar pellet durability was formulated (Equation (3)):

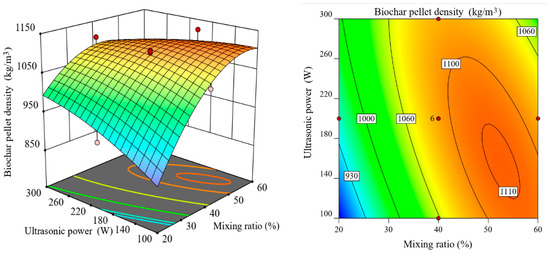

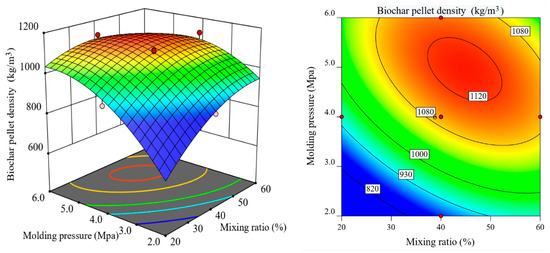

3.2.2. Interaction Effects on Biochar Pellet Density

The interaction effects of mixing ratio and ultrasonic power on biochar pellet density are illustrated in Figure 8, under conditions of a pelleting time of 30 s and a molding pressure of 4 MPa. The response surface revealed that at lower ultrasonic power levels, biochar pellet density increased with the mixing ratio, reaching a maximum of 1057.96 kg/m3 at a mixing ratio of 60%. At higher ultrasonic power levels, the density initially increased from 994.50 to 1090.44 kg/m3 as the mixing ratio rose to 43%, and thereafter decreased to 1035.60 kg/m3 with further increases in the mixing ratio. At lower mixing ratios, biochar pellet density increased with rising ultrasonic power; conversely, it decreased at higher mixing ratios. The biochar density exceeded 1100 kg/m3 when the mixing ratio was between 50% to 60% and the ultrasonic power ranged from 140 to 180 W, while the lowest density was 863.24 kg/m3 at an ultrasonic power level of 100 W and a mixing ratio of 20%. This phenomenon could be attributed to the rich natural substances present in WSP, such as starch, protein, oil, pectin, and water, which exhibited notable fluidity and viscosity. These substances filled into biochar pores evenly through high-frequency vibration, resulting in tighter particle bonding [28]. As the proportion of WSP and ultrasonic power continued to increase, this effect became more remarkable. However, excessive heat generated by high ultrasonic power led to reduced pellet density due to moisture evaporation and organic matter loss.

Figure 8.

Response surface plots of biochar pellet density between mixing ratio and ultrasonic power.

The interaction effect of the mixing ratio and molding pressure on biochar pellet density is illustrated in Figure 9, particularly under conditions of a pelleting time of 30 s and an ultrasonic power setting of 200 W. The response surface analysis revealed that biochar pellet density increased with elevation of both the molding pressure (up to 5.5 MPa) and the mixing ratio. Specifically, when the mixing ratio ranged from 40% to 50% and the molding pressure varied between 4.5 and 5.5 MPa, the density reached its maximum value, exceeding 1100 kg/m3. Conversely, at a mixing ratio of 20% and a molding pressure of only 2 MPa, the biochar pellet density dropped below 700 kg/m3. This phenomenon could be attributed to the increased molding pressure, further promoting fragmentation of raw material particles. Consequently, there were more contact points among particles leading to the enhanced mutual compression. Additionally, moisture penetration and flow among particles became more uniform, resulting in a continuous increase in density [29,30]. However, excessive molding pressure combined with high mixing ratios resulted in greater loss of natural substances, thereby causing a decline in biochar pellet density [31].

Figure 9.

Response surface plots of biochar pellet density between mixing ratio and molding pressure.

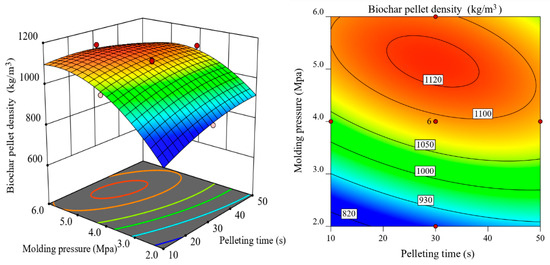

The interaction effect of pelleting time and molding pressure on biochar pellet density is illustrated in Figure 10; these data were obtained under conditions of a mixing ratio of 40% and an ultrasonic power setting of 200 W. According to the response surface analysis, as molding pressure increased, the density initially rose before subsequently decreasing; it gradually increased with extended pelleting time until stabilizing. The maximum biochar density was 1124.67 kg/m3 at pelleting time of 30s and molding pressure of 5 MPa, while the minimum density was 774.19 kg/m3 at 10s and 2 MPa. This molding pressure initially disrupted the material’s structure, thereby facilitating filling, adhesion, and densification among molecular components. A higher molding pressure could further diminish voids within particles, resulting in the enhanced density and compressive strength [32,33,34]. Furthermore, with appropriate pelleting time, the thermal effect generated by the ultrasonic transducer softened the WSP, allowing it to flow uniformly into the raw char, thereby creating stronger bonds between particles that further reduced gaps among mixed materials.

Figure 10.

Response surface plots of biochar pellet density between pelleting time and molding pressure.

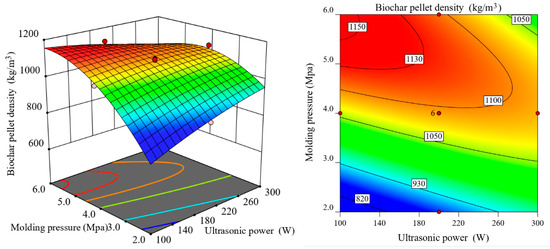

The interaction effect of ultrasonic power and molding pressure on biochar pellet density is illustrated in Figure 11, which was obtained under mixing ratio of 40% and a pelleting time of 30 s. A response surface analysis revealed that pellet density was gradually elevated with increasing ultrasonic power at pressure below 4 MPa; however, when the pressure exceeded 4 MPa, density decreased as power increased. When ultrasonic power was less than 150 W, pellet density rose with increasing molding pressure. Conversely, beyond 150 W, density initially increased before subsequently decreasing with further increments in molding pressure. The maximum density was 1155.84 kg/m3 recorded at pressure of 6 MPa and ultrasonic power of 100 W, while the minimum value was found at 763.76 kg/m3 under conditions of 2 MPa and 100 W. This phenomenon could primarily be attributed to vertical vibrations generated by the tool during ultrasonic conversion that filled gaps between particles. Appropriate combinations of molding pressure and ultrasonic power enhanced the bonding forces among particles, thereby improving pellet density [35]. However, excessive levels of both ultrasonic power and molding pressure led to increased heat transmission; this excess heat accumulated in the pellets, leading to the evaporation of internal moisture into water vapor, thereby disrupting particle bonding forces and diminishing overall biochar pellet quality [36].

Figure 11.

Response surface plots of biochar pellet density between ultrasonic power and molding pressure.

3.2.3. Interaction Effects on Biochar Pellet Durability

The interaction effects of ultrasonic power and molding pressure on the durability of biochar pellets are illustrated in Figure 12, which was obtained under conditions of pelleting time of 30s and ultrasonic power 200 W. The durability of the biochar pellets increased with rising molding pressure at a mixing ratio of 40% or less. Conversely, the pellet durability initially increased to a maximum value of 98.75%, after which it slightly declined when the mixing ratio exceeded 40%.

Figure 12.

Response surface plots of biochar pellet durability between mixing ratio and molding pressure.

The trend in biochar pellet durability relative to mixing ratio mirrored that associated with molding pressure, featuring a critical threshold around 5 MPa. The minimum pellet durability was 90.67%, particularly at a pressure of 2 MPa and a mixing ratio of 20%. This phenomenon could be attributed to the fact that as molding pressure increased, WSP flowed more effectively under the applied pressure, filling the interstitial spaces between particles, thereby reducing these gaps progressively and enhancing adhesion as well as shaping within corn straw char powder. However, further increases in molding pressure did not enhance durability once the interparticle voids had been adequately minimized and optimal compaction had been achieved. Furthermore, excessive molding pressures may compromise intermolecular forces and damage internal structures by inducing cracks, ultimately diminishing mechanical durability and adversely affecting pellet quality [37].

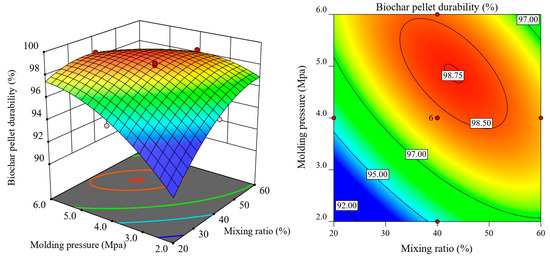

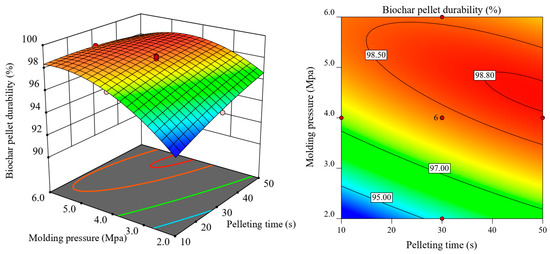

Figure 13 presents response surface plots illustrating the relationship between molding pressure and pelleting time on biochar pellet durability at a mixing ratio of 40% and an ultrasonic power of 200 W. Overall, pellet durability increased with pelleting time, rising from 93.43% to 96.68% at a pressure of 2 MPa. However, it exhibited a slight decrease once molding pressure exceeded 5 MPa, peaking at a maximum value of 98.83%. Initially, pellet durability promptly increased but thereafter stabilized or slightly declined as the pressure continued to rise under consistent pelleting time. Optimal combinations of molding pressure and pelleting time could enhance the compactness of the internal structure of mixed raw materials, thereby improving mechanical durability while also reducing energy consumption during the molding process and lowering unit costs.

Figure 13.

Response surface plots of biochar pellet durability between molding pressure and pelleting time.

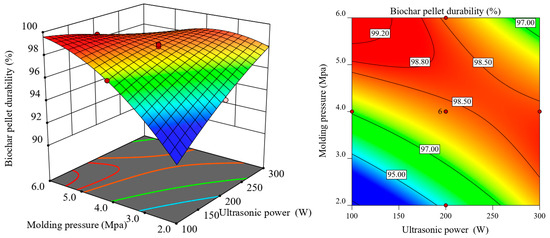

Figure 14 presents response surface plots depicting the combined effects of molding pressure and ultrasonic power on biochar pellet durability, under conditions of a mixing ratio of 40% and pelleting time of 30 s. It was found that pellet durability significantly increased with molding pressure below ultrasonic power of 200 W; however, once the power exceeded this threshold, it reached a peak before subsequently declining, and this decline became more remarkable as the ultrasonic power continued to increase. Durability also rose with increasing power within a pressure of 5 MPa, while it exhibited an initial increase followed by a reduction after surpassing this pressure level. The minimum durability was 91.70%, occurring at 100 W and 2 MPa, while the maximum observed was 99.59% at 100 W and 6 MPa. Under conditions of 300 W and 6 MPa, the measured value was found to be 96.32%. Within certain limits, a higher molding pressure could improve the filling of gaps among raw material particles; concurrently, high-frequency vibrations from the ultrasonic transducer promoted uniform mixing of these materials. This process also transferred additional heat into the mixed raw materials, enhancing molecular bonding forces for tighter cohesion among them [38]. Nevertheless, excessive levels of molding pressure and ultrasonic power are detrimental [31,39]. Excessively high pressures can compromise intermolecular bonding, leading to internal cracking and reduced mechanical durability. Similarly, excessive heat transfer from the ultrasonic transducer may cause gelatinization of WSP and an increase in ash content, further deteriorating mechanical durability while simultaneously escalating energy consumption during molding processes.

Figure 14.

Response surface plots of biochar pellet durability between molding pressure and ultrasonic power.

3.2.4. Optimization and Model Verification

Based on the findings from the orthogonal experiments, optimal process parameters were identified using the Optimization function in Design-Expert v13 software. Through a multi-objective optimization approach, the ideal parameter combination was established: a mixing ratio of 45.08%, pelleting time of 32.98 s, an ultrasonic power of 150.06 W, and a molding pressure of 4.96 MPa. The results demonstrated a density of 1140.76 kg/m3 and a pellet durability of 98.93%. To validate these findings, verification experiments were conducted with a mixing ratio of 45%, pelleting time adjusted to 33 s, an ultrasonic power maintained at 150 W, and molding pressure modified to 5 MPa. The average values obtained from these tests indicated density and durability of 1140.41 kg/m3 and 98.54%, respectively, thereby confirming the reliability of the optimization outcomes as shown in Figure 15.

Figure 15.

Biochar pellets.

4. Conclusions

In this experiment, the factors and trends influencing biochar pellet density and durability were determined through a single-factor analysis. Mathematical regression models were established via orthogonal experiments to analyze the impact of each factor on density and durability, and the results were verified through variance analysis. The coefficient of determination (R2) for all models exceeded 0.95, demonstrating the effectiveness of the models. Based on the p-values, the factors influencing density ranked as molding pressure, mixing ratio, and pelleting time, whereas for durability, the order was molding pressure, mixing ratio, ultrasonic power, and pelleting time. Additionally, interactions among these factors were analyzed. The optimal conditions included a mixing ratio of 45%, pelleting time of 33 s, an ultrasonic power of 150 W, and a molding pressure of 5 MPa; under these conditions, biochar pellet density and durability reached 1140.41 kg/m3 and 98.54%, respectively.

Author Contributions

Conceptualization, W.L. and J.S.; methodology, J.S. and S.Y.; validation, L.L. and S.Y.; writing—original draft preparation, W.L.; writing—review and editing, W.L.; supervision, W.L.; project administration, W.L.; funding acquisition, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Daqing guiding science and technology plan project (Grant No. zd-2024-23); and the Technological Project of Heilongjiang Province “the open competition mechanism to select the best candidates” (Grant No. 2022ZXJ05C02).

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

The authors declare that they have no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| WSP | Waste soybean powder |

| CCRD | Central Composite Rotatable Design |

| ANOVA | analysis of variance |

References

- CO2 Emissions in 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 15 March 2024).

- Wei, L.; Li, Z.; Pan, Z.; Yi, Z.; Li, G.; An, L. A design of solar-driven thermochemical reactor integrated with heat recovery for continuous production of renewable fuels. Energy Convers. Manag. 2024, 310, 118484. [Google Scholar] [CrossRef]

- Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy 2020, 199, 117426. [Google Scholar] [CrossRef]

- Yousaf, H.; Amin, A.; Baloch, A.; Akbar, M. Investigating household sector’s non-renewables, biomass energy consumption and carbon emissions for Pakistan. Environ. Sci. Pollut. Res. 2021, 28, 40824–40834. [Google Scholar] [CrossRef]

- Hou, J.; Wang, W.; Zhang, L.; Sun, X. Modern biomass energy technology system and its industrial application trend. Mod. Chem. Ind. 2022, 42, 7–13. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, Q.; He, T.; Yang, H.; Wang, X.; Chen, H. Integrate quality upgrading stduy of biomass through pyrolysis and densification. Acta Energiae Solaris Sin. 2018, 39, 1398–1945. [Google Scholar]

- Sheng, C.; Yao, Z.; Zhao, L.; Meng, H.; Dai, M.; Cong, H. Condensification and co-combustion characteristics of blends of cotton stalk chae and bio-tar. Acta Energiae Solaris Sin. 2022, 43, 458–464. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Q.; Deines, T.W.; Pei, Z.; Wang, D. Ultrasonic Vibration-Assisted Peiieting of Wheat Straw: A Designed Experimentai Investigation on Pellet Quality and Sugar Yield. J. Manufaoturing Sci. Eng. 2012, 134, 1–10. [Google Scholar] [CrossRef]

- Cong, W.; Pei, Z.; Zhang, P.; Qin, N.; Deines, T.W.; Lin, B. Ultrasonic-vibration-assisted pelleting of switchgrass: Effects of ultrasonic vibration. Trans. Tianjin Univ. 2011, 17, 313–319. [Google Scholar] [CrossRef]

- Li, W.; Li, C.; Zhang, B.; Zhou, G.; Liu, D. Optimization of density and durability of pellets using the response surface methodology in ultrasonic vibration-assisted pelleting of corn stover. Sci. Agric. 2023, 80, 1–11. [Google Scholar] [CrossRef]

- Li, W.; Yu, R.; Luo, L.; Shi, H. Process Optimization of Pellet Manufacturing from Mixed Materials in Ultrasonic Vibration-Assisted Pelleting. Energies 2024, 17, 2087. [Google Scholar] [CrossRef]

- Li, W.; Sui, J.; Wang, L.; Song, J. The Effect of Urea Pretreatment Combined with Ultrasonic Vibration-Assisted Pelleting on Pellet Solid Density and Durability. Processes 2023, 11, 2170. [Google Scholar] [CrossRef]

- Meng, F.; Wang, D.; Zhang, M. Effect of ultrasonic vibration-assisted pelleting of biomass on biochar properties. J. Clean. Prod. 2021, 279, 123900. [Google Scholar] [CrossRef]

- Qin, L.; Zhang, S.; Gao, Z.; JIiang, E. Molding Fuel and Combustion Characteristics of Biochar and Lignin. Trans. Chin. Soc. Agric. Mach. 2017, 48, 276–283. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, W.; Liu, Y.; Song, Y.; Wu, L.; Liu, C.; Wang, T. Effects of Wet Fermented Soybean Dregs on Physical and Mechanical Properties of Pellets of Corn Stover. Animals 2022, 12, 2632. [Google Scholar] [CrossRef]

- Haykiri-Acma, H.; Yaman, S.; Kucukbayrak, S. Production of biobriquettes from carbonized brown seaweed. Fuel Process. Technol. 2013, 106, 33–40. [Google Scholar] [CrossRef]

- Liu, M.; Ren, X.; Zheng, D.; Lin, T.; Zhang, P.; Wang, H. Determination of aflatoxin B1 in corn or corn products by post-column photochemical derivatization. China Feed. 2022, 9, 92–95. [Google Scholar] [CrossRef]

- Liang, Z.; Peng, L. A review of the current status of crop mildew. Grain Sci. Technol. Econ. 2020, 45, 89–90. [Google Scholar] [CrossRef]

- Huo, L.; Zhao, L.; Hao, Y.; Meng, H.; Yao, Z.; Liu, Z.; Liu, T.; Yuan, Y. Quality standard system of densified biomass fuels at home and abroad. Trans. Chin. Soc. Agric. Eng. 2020, 36, 245–254. [Google Scholar] [CrossRef]

- ISO 17225-1:2021; Solid Biofuels—Fuel Specifications and Classes. Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2021.

- GB/T 15459-2006; Determination of Shatter Indices of Coal. Standardization Administration of China (SAC): Beijing, China, 2006.

- Wang, W.; Zhou, G.; Cai, D.; Zheng, Q.; Li, Z.; Liu, L.; Chen, L. Design and experiment of the biomass briquetting machine with honeycomb structure bionic ring-die. Trans. Chin. Soc. Agric. Eng. 2023, 39, 267–274. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, P.; Pei, Z.; Rys, M.; Wang, D.; Zhou, J. Ultrasonic vibration-assisted pelleting of cellulosic biomass for ethanol manufacturing: An investigation on pelleting temperature. Renew. Energy 2016, 86, 895–908. [Google Scholar] [CrossRef]

- Zhang, P.; Pei, Z.J.; Wang, D.; Wu, X.R.; Cong, W.; Zhang, M.; Deines, T. Ultrasonic Vibration-Assisted Pelleting of Cellulosic Biomass for Biofuel Manufacturing. J. Manuf. Sci. Eng. 2011, 133, 011012. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, P.; Pei, Z.J. Ultrasonic vibration-assisted pelleting of wheat straw: A predictive model for pellet density using response surface methodology. Biofuels 2014, 3, 259–267. [Google Scholar] [CrossRef]

- Tang, Y.; Cong, W.; Xu, J.; Zhang, P.; Liu, D. Ultrasonic vibration-assisted pelleting for cellulosic biofuels manufacturing: A study on in-pellet temperatures. Renew. Energy 2015, 76, 296–302. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, P.; Ji, H.; Wu, Y.; Liu, Z.; Lu, Q. The individual and interactive effects of acid and basic oxides on ash fusibility during oxy-biomass combustion with recycled SO2. Fuel 2023, 331, 125888. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Peng, J.; Bi, H.T.; Sokhansanj, S.; Lim, J. A Study of Particle Size Effect on Biomass Torrefaction and Densification. Energy Fuels 2012, 26, 3826–3839. [Google Scholar] [CrossRef]

- Sun, B.; Yu, J.; Tahmasebi, A.; Han, Y. An experimental study on binderless briquetting of Chinese lignite: Effects of briquetting conditions. Fuel Process. Technol. 2014, 124, 243–248. [Google Scholar] [CrossRef]

- Fan, K.Q.; Tang, Y.J.; Fang, Y. Ultrasonic Vibration-Assisted Pelleting of Cellulosic Biomass: A Review. Adv. Mater. Res. 2013, 805–806, 151–155. [Google Scholar] [CrossRef]

- Lei, T.; Xin, X.; Li, Z.; Li, J.; Zhang, L. A review of torrefaction pretreatment for preparation biomass clean briquette fuels. Chem. Ind. For. Prod. 2021, 41, 110–118. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Wen, K.; Zhang, Y.; Yao, Z.; Zhang, J. Study on factors affecting pellet drop resistance during dual ultrasonic vibration-assisted pelletizing of biomass. Electromachining Mould. 2016, 1, 47–50. [Google Scholar]

- Xu, J.; Tang, Y.; Hu, H.; Zhang, Y. Study on the influencing factors to pellet density during dual ultrasonic vibration-assisted pelleting of sawdust. Renew. Energy Resour. 2015, 33, 143–148. [Google Scholar] [CrossRef]

- Rao, Y.; Liu, R.; Yang, F.; Chen, Z.; Yue, H.; Zhang, X.; Cai, Z. Optimization of molding process parameters for biomass particles fuel from tobacco stems and wood chips. Renew. Energy Resour. 2019, 37, 650–655. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Zhang, Q.; Shi, Z.; Zhang, P.; Zhang, M.; Li, Z.; Chen, X.; Zhou, J. Ultrasonic-Assisted Pelleting of Sorghum Stalk: Predictive Models for Pellet Density and Durability Using Multiple Response Surface Methodology. Energies 2018, 11, 1214. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).