Mechanism Analysis and Evaluation of Formation Physical Property Damage in CO2 Flooding in Tight Sandstone Reservoirs of Ordos Basin, China

Abstract

1. Introduction

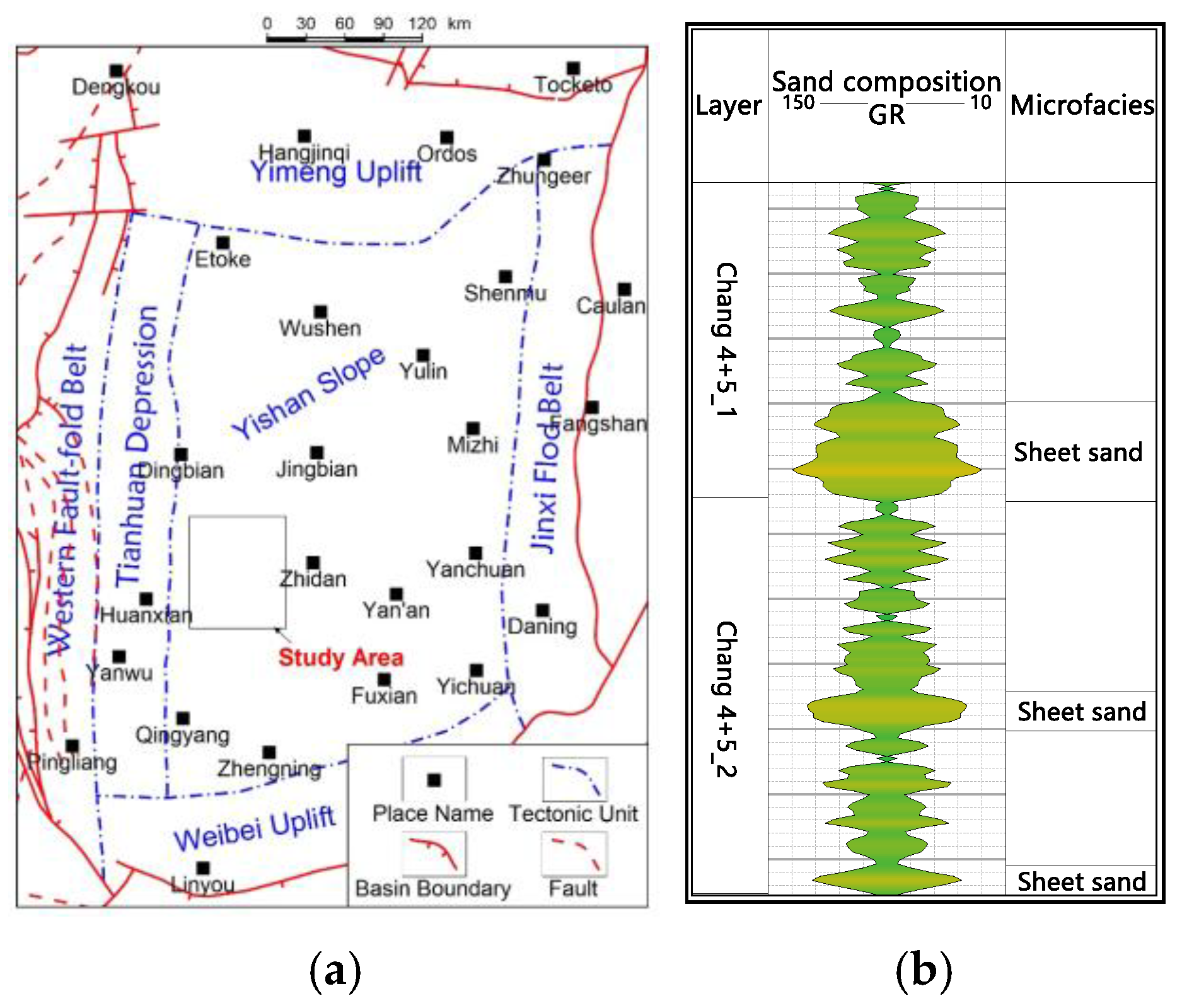

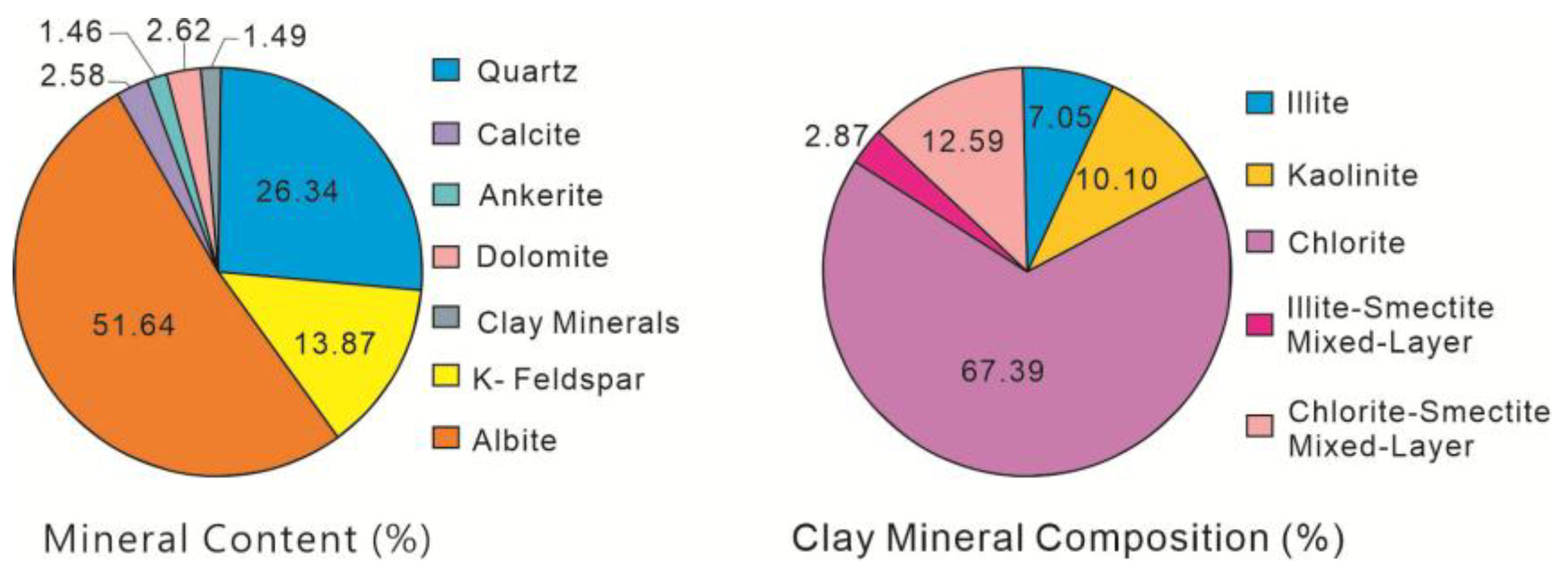

2. Geological Background

3. Materials and Methods

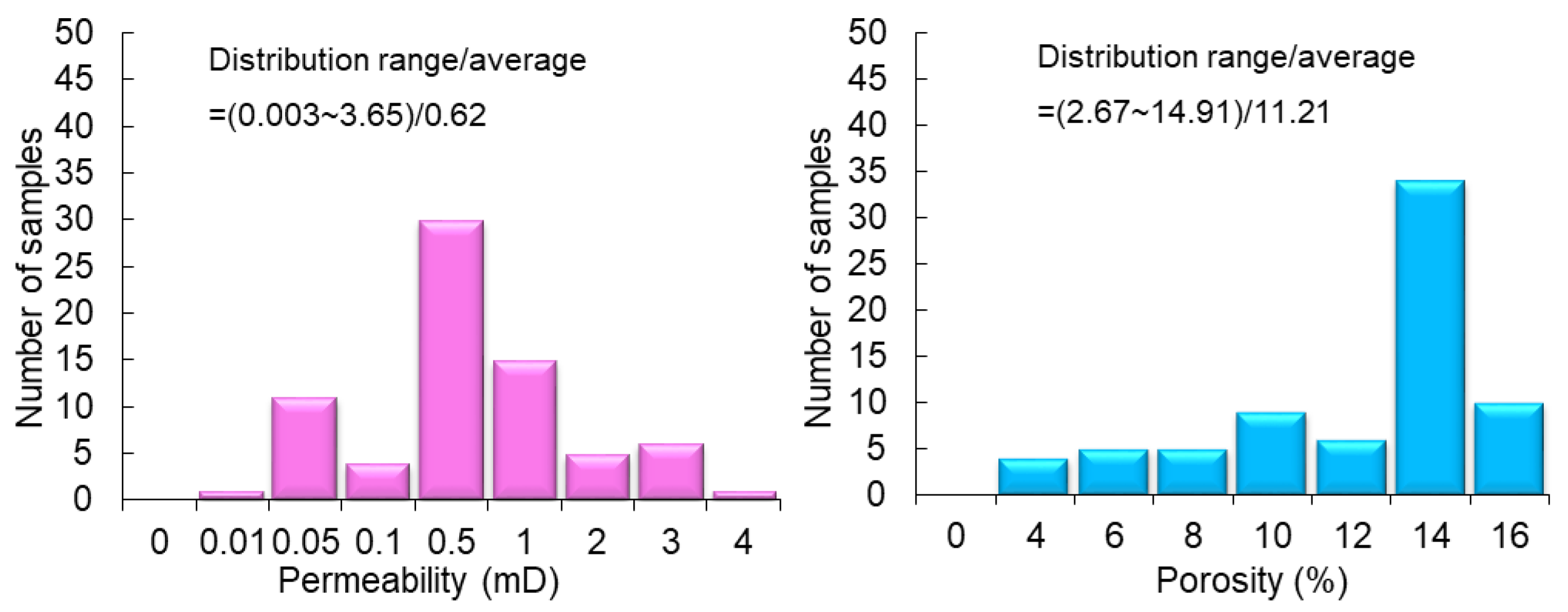

3.1. Materials

3.2. Apparatus and Methods

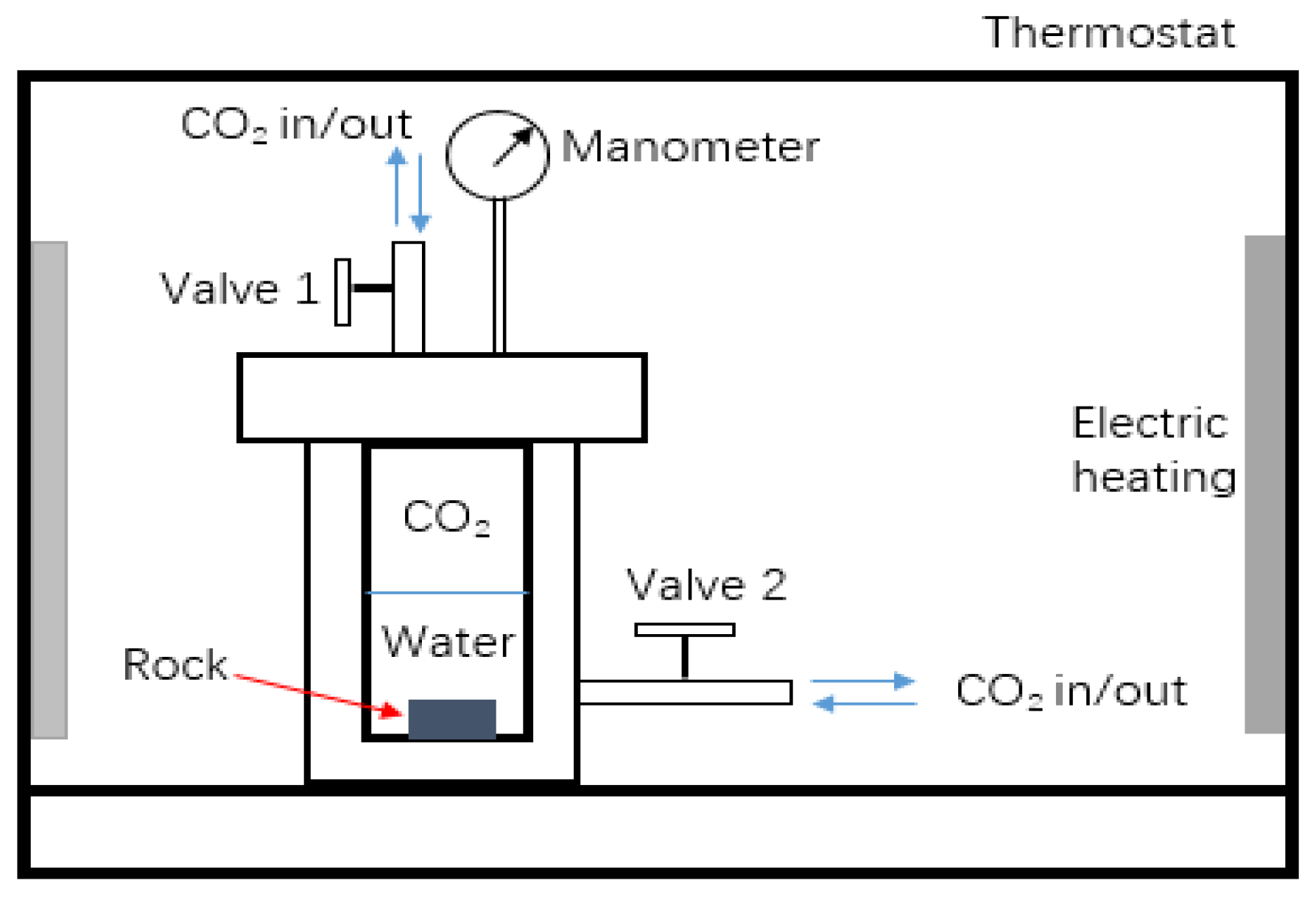

3.2.1. Static Reaction Experiments

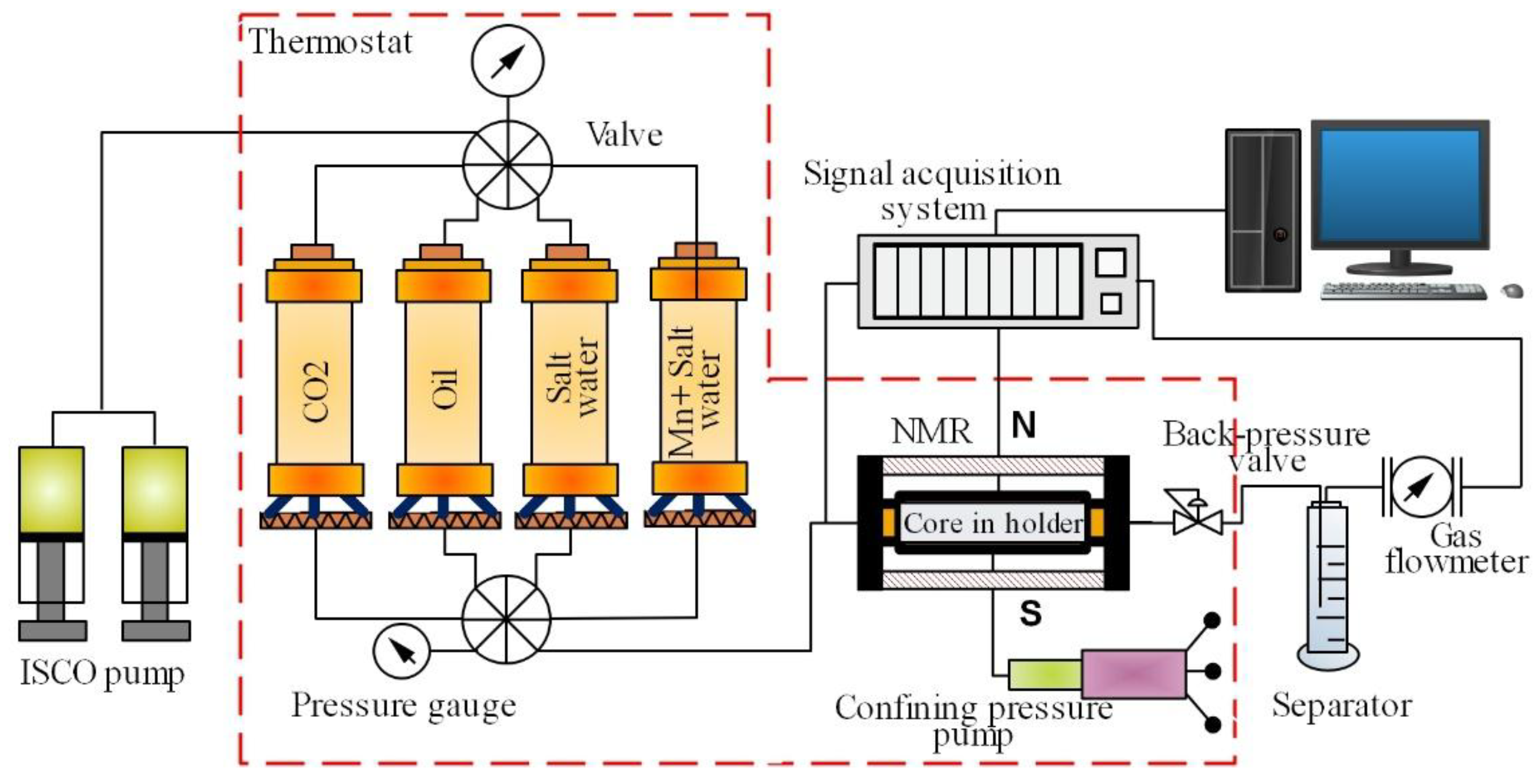

3.2.2. Displacement Experiments

3.3. Metrics

4. Results and Discussion

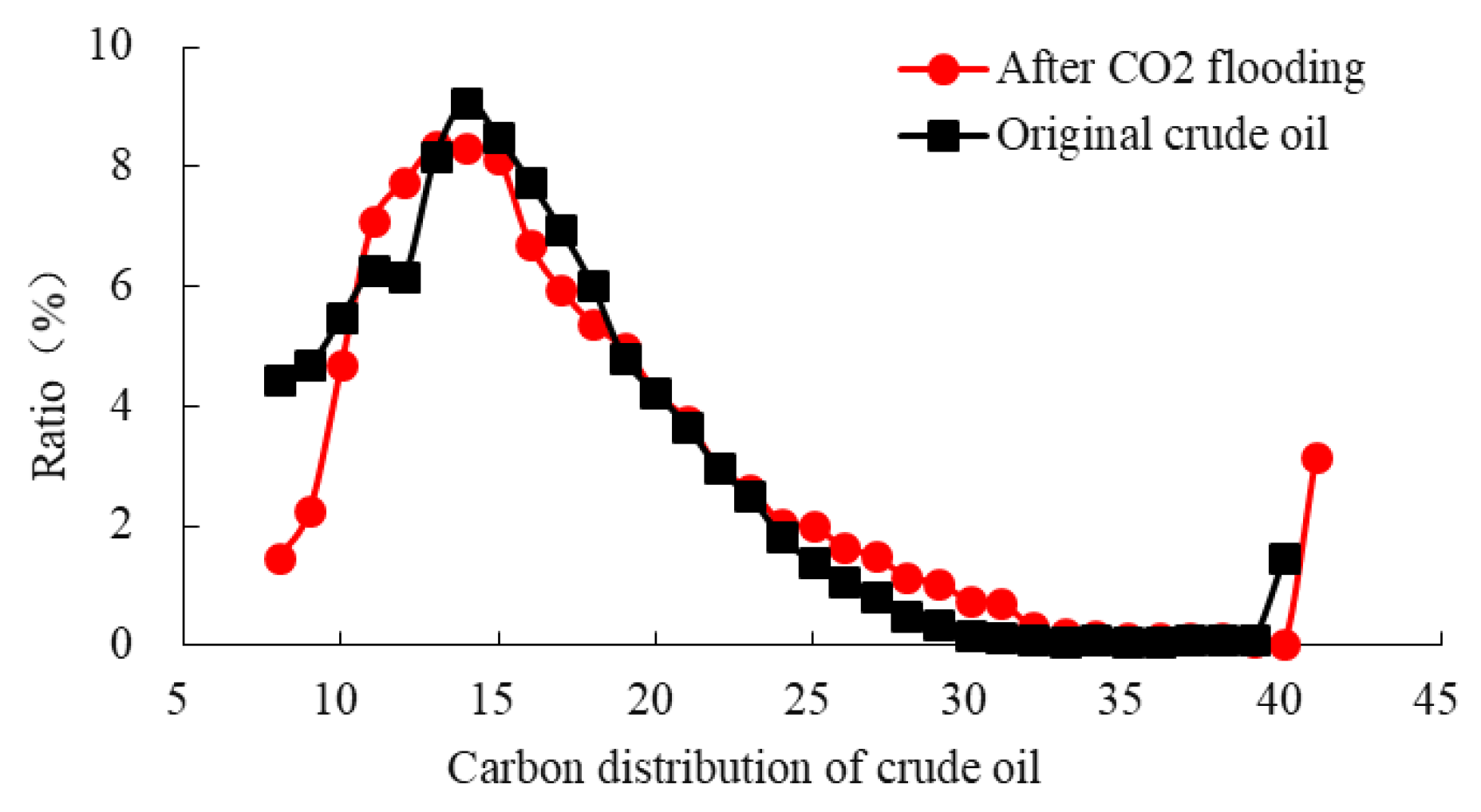

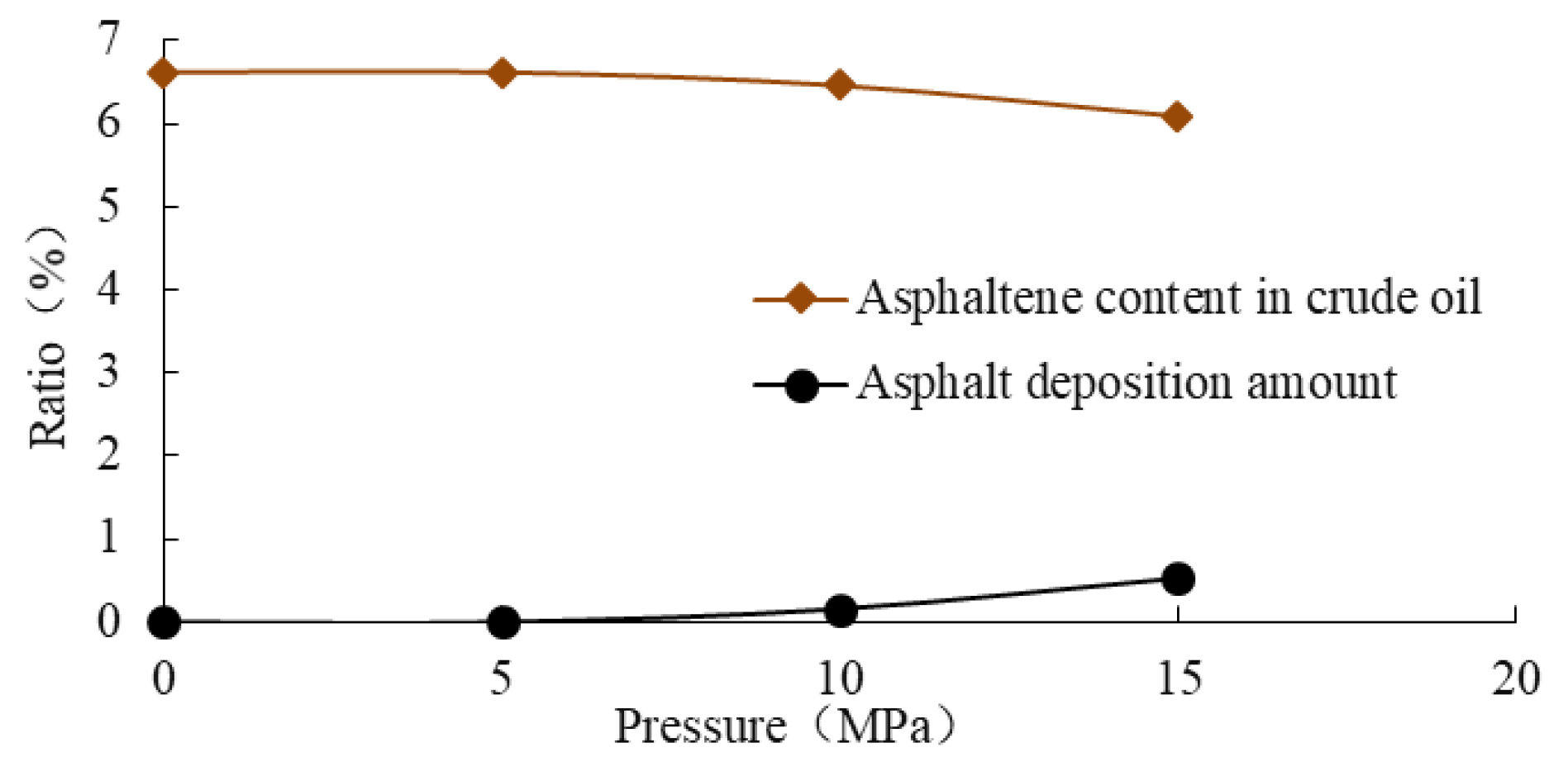

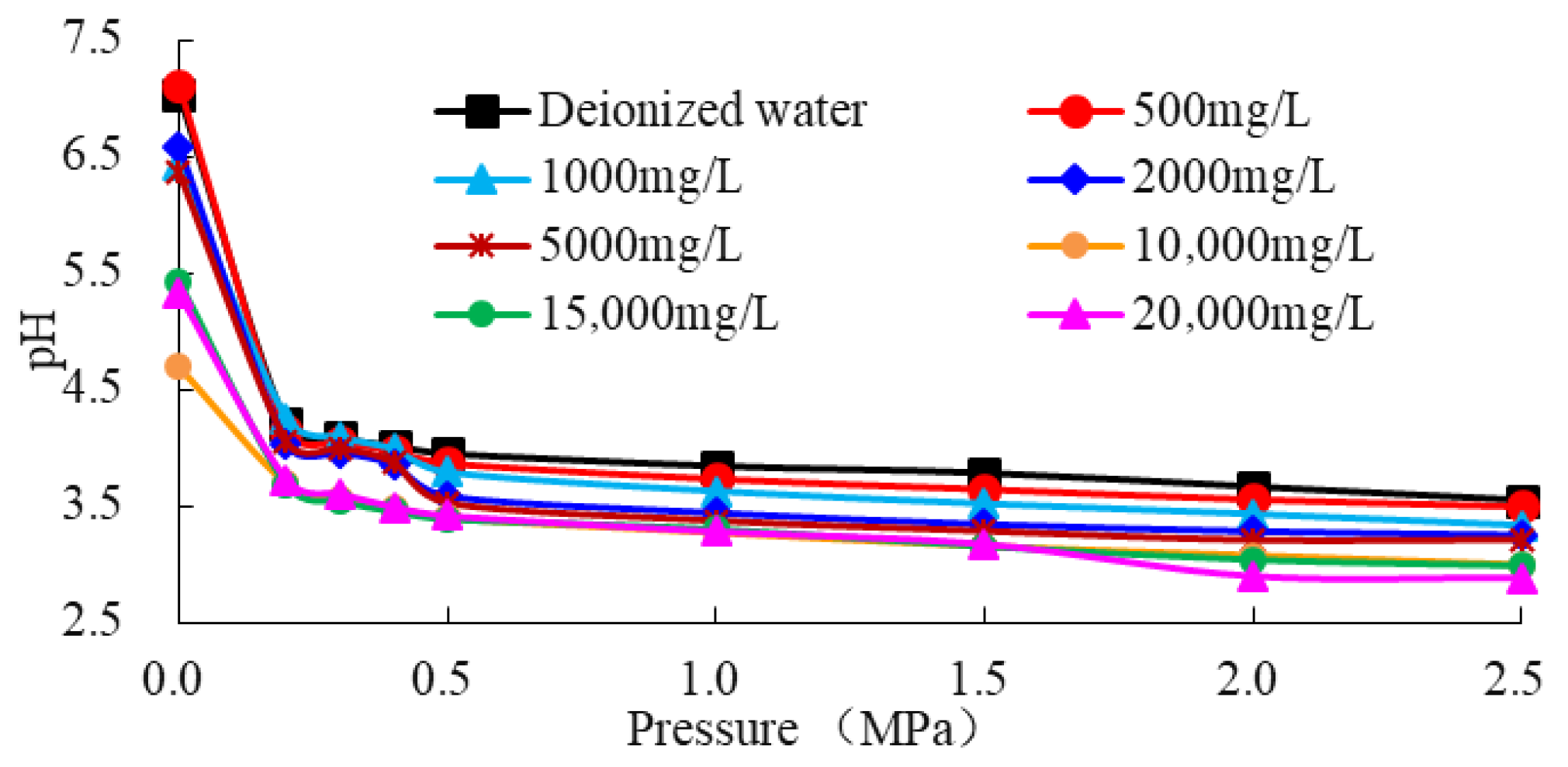

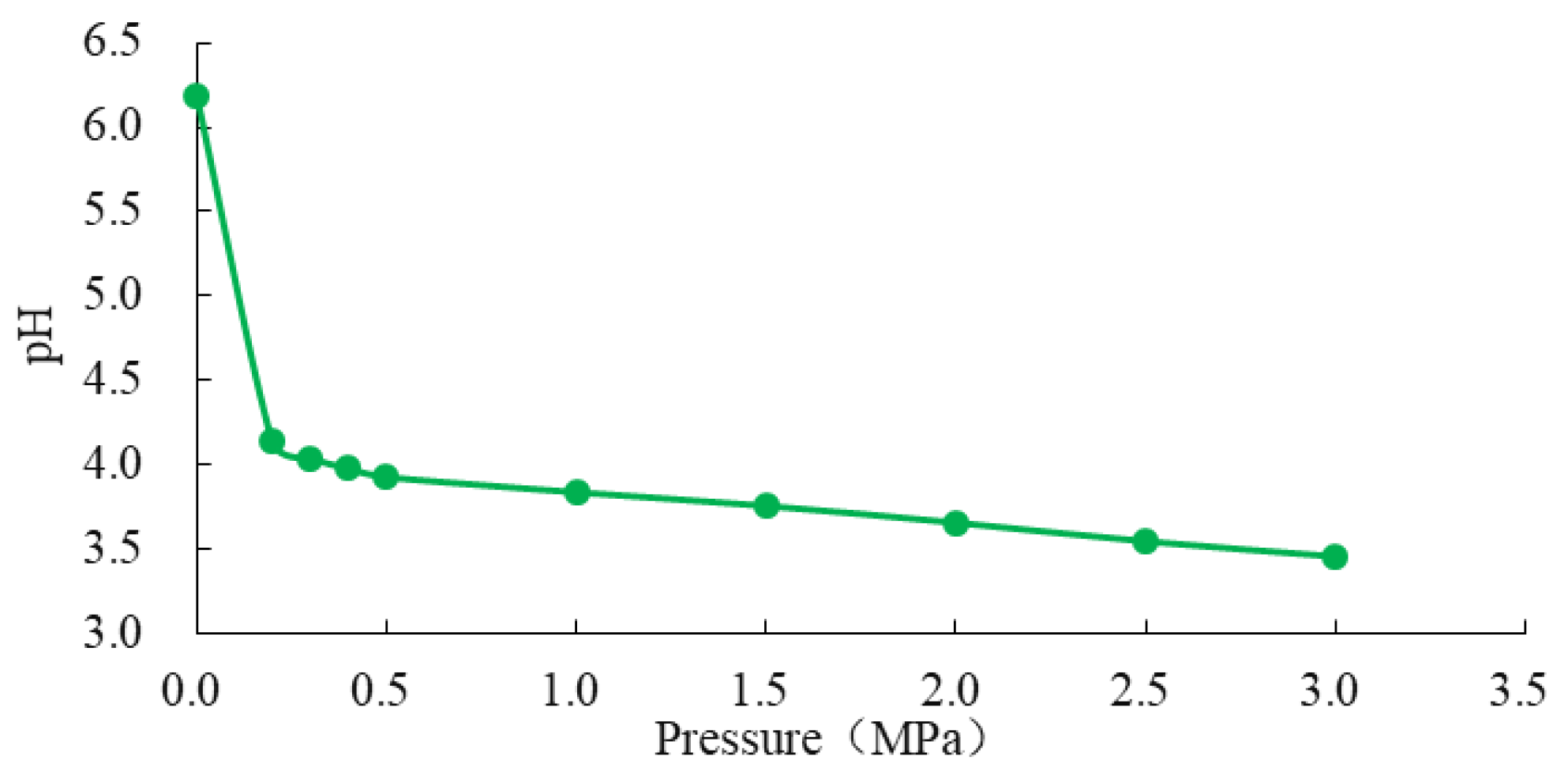

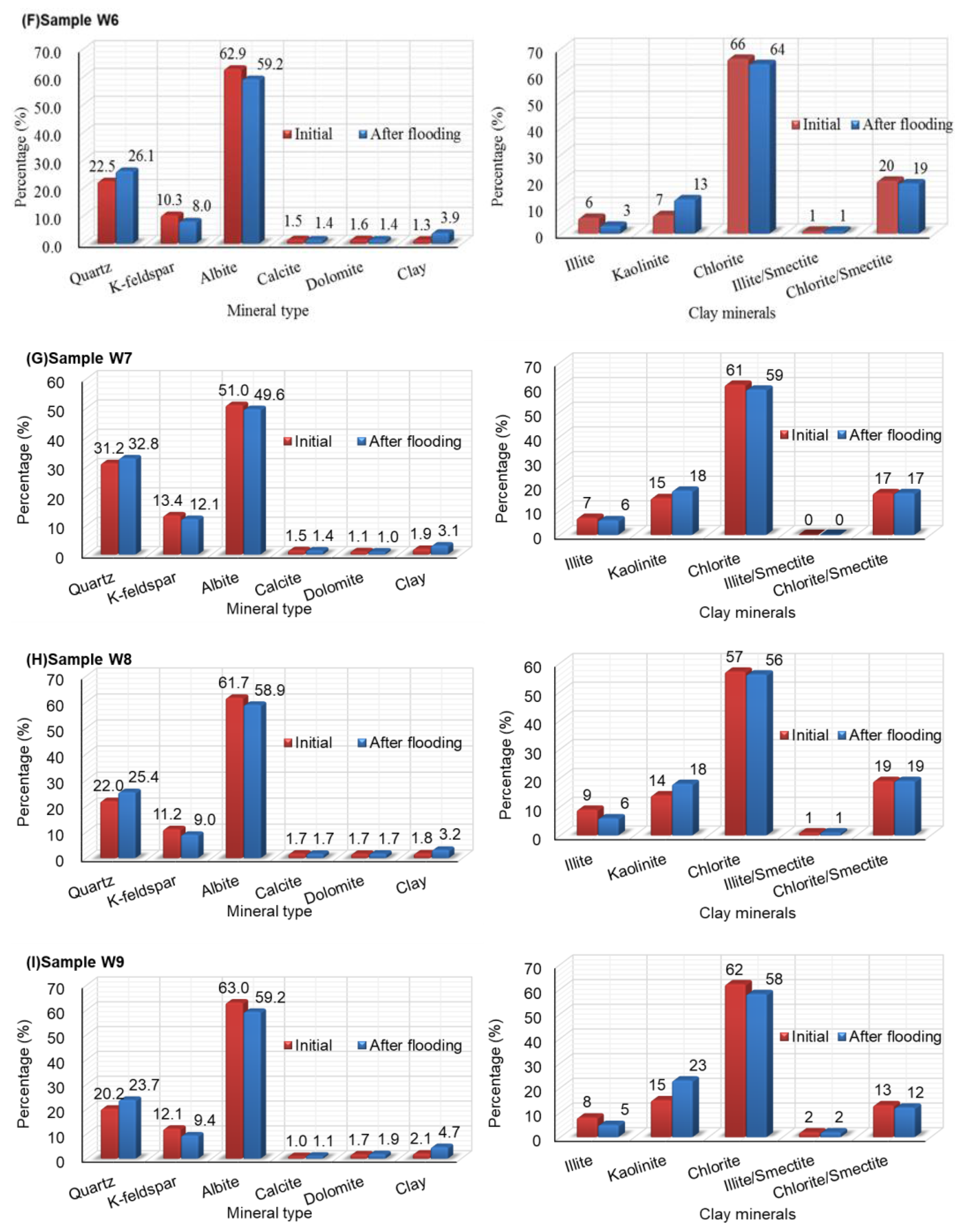

4.1. Static Experiments

4.2. Dynamic Displacement Experiments

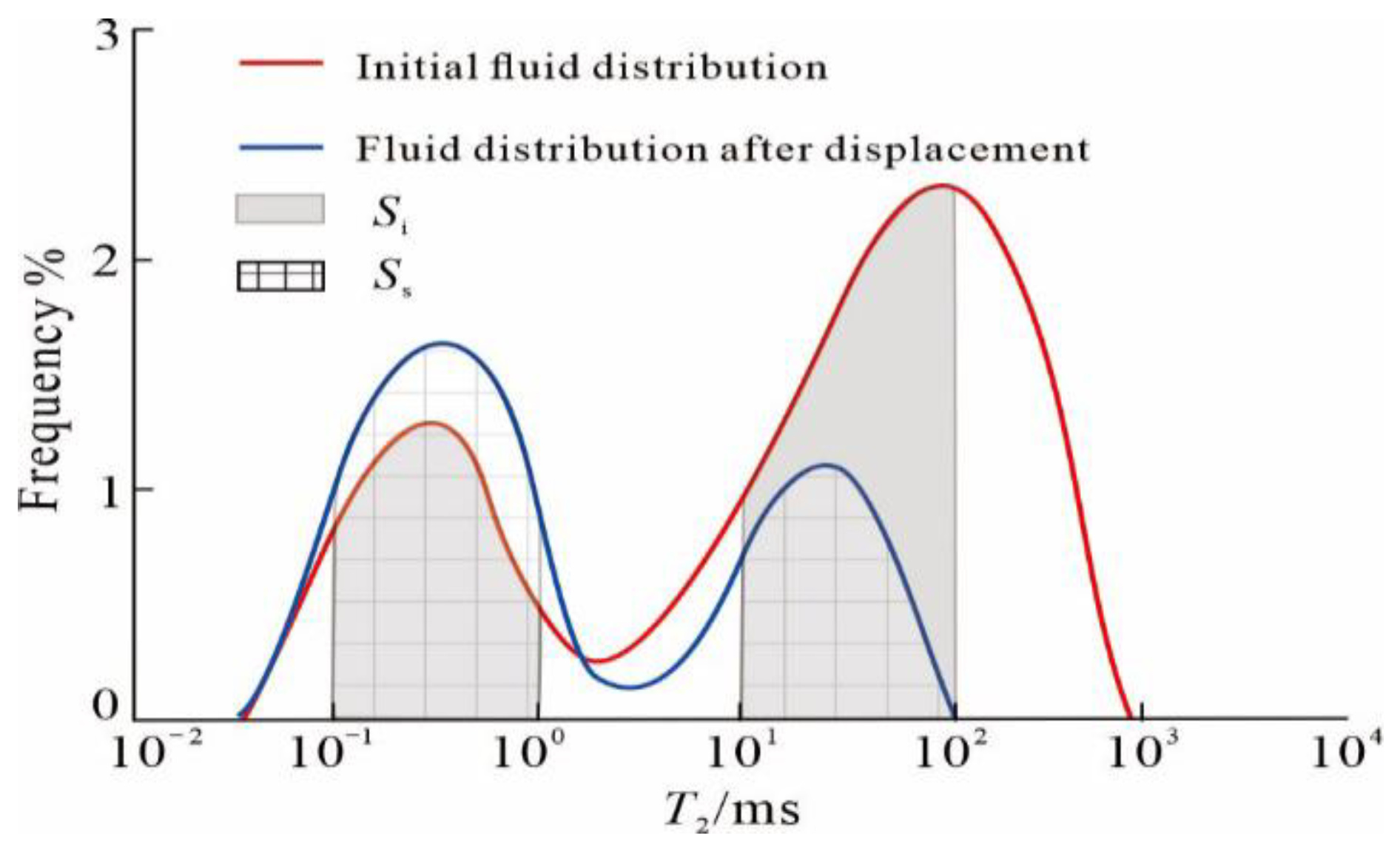

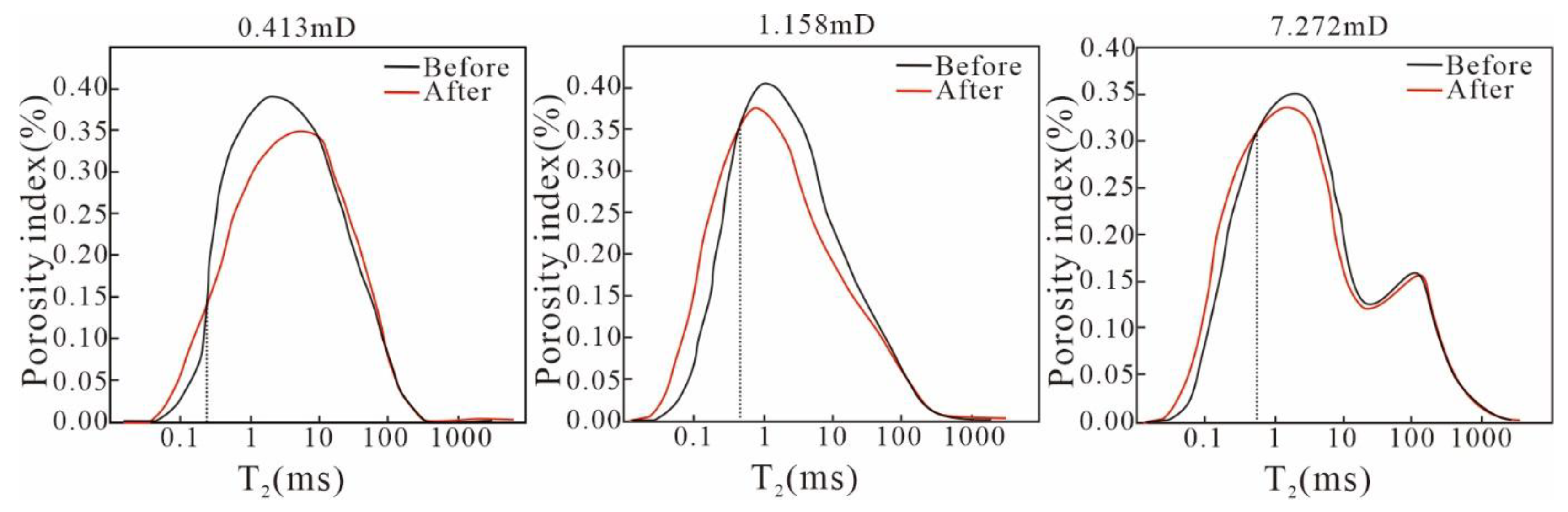

4.2.1. Movable Fluid Saturation

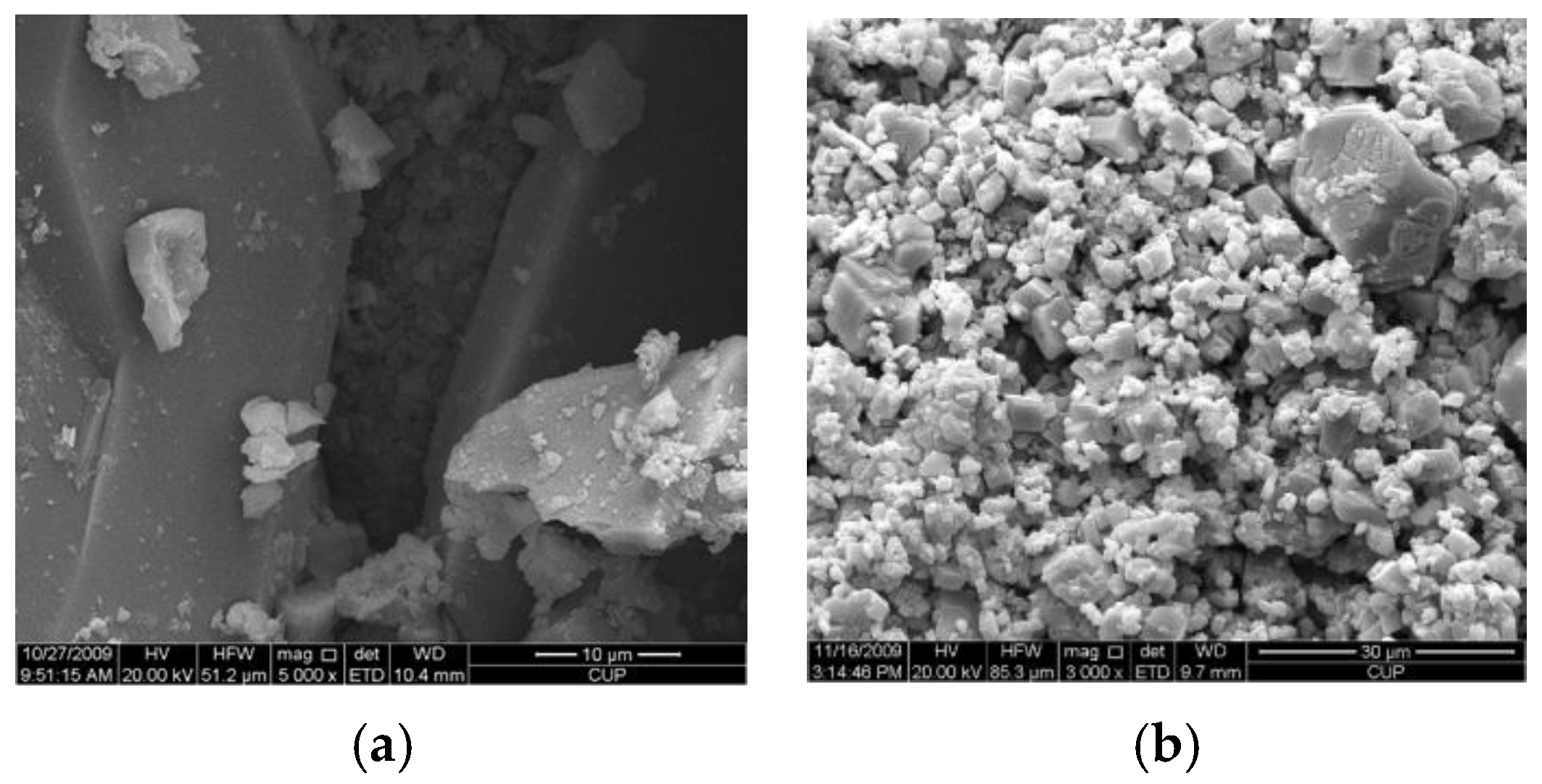

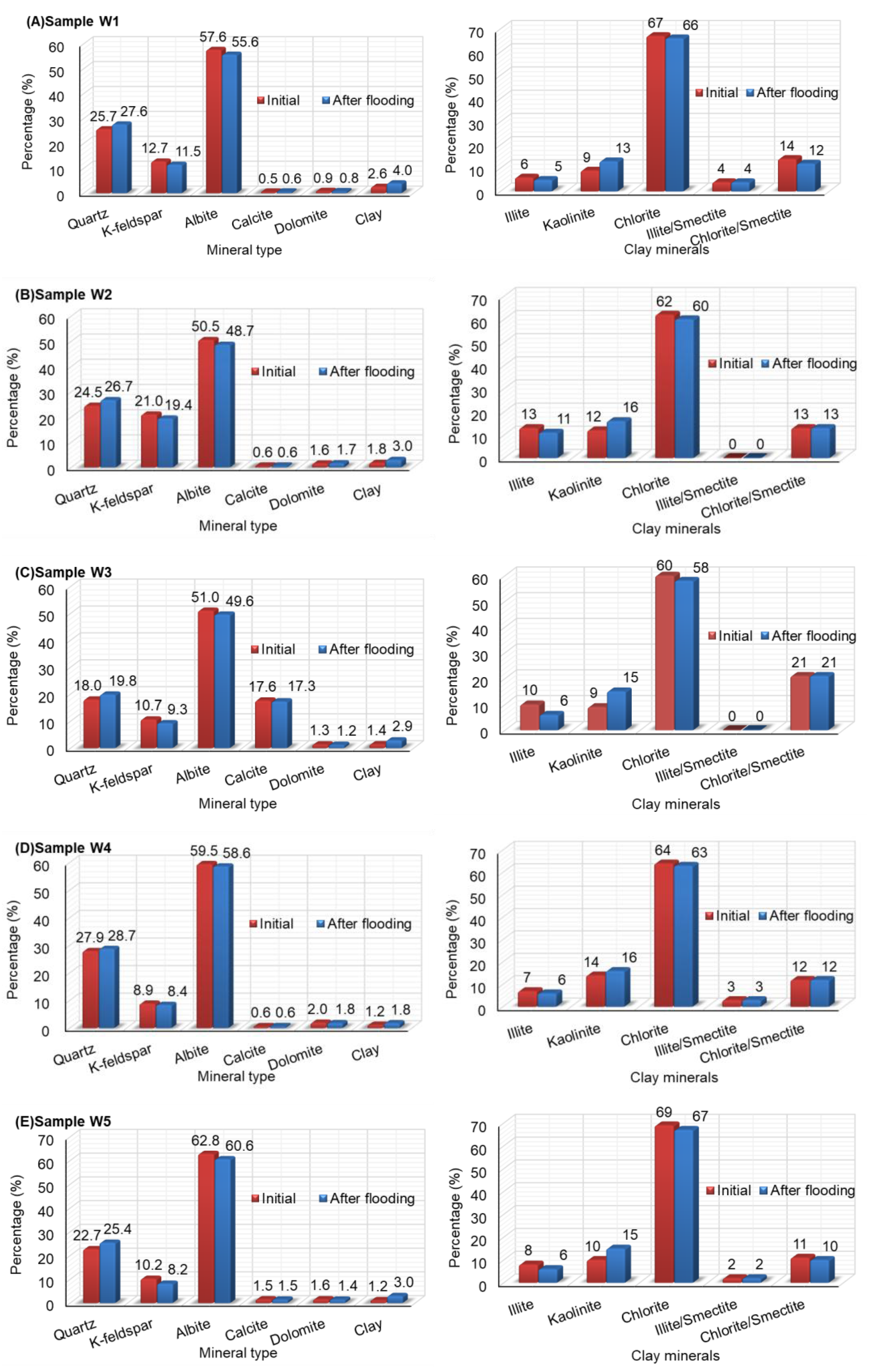

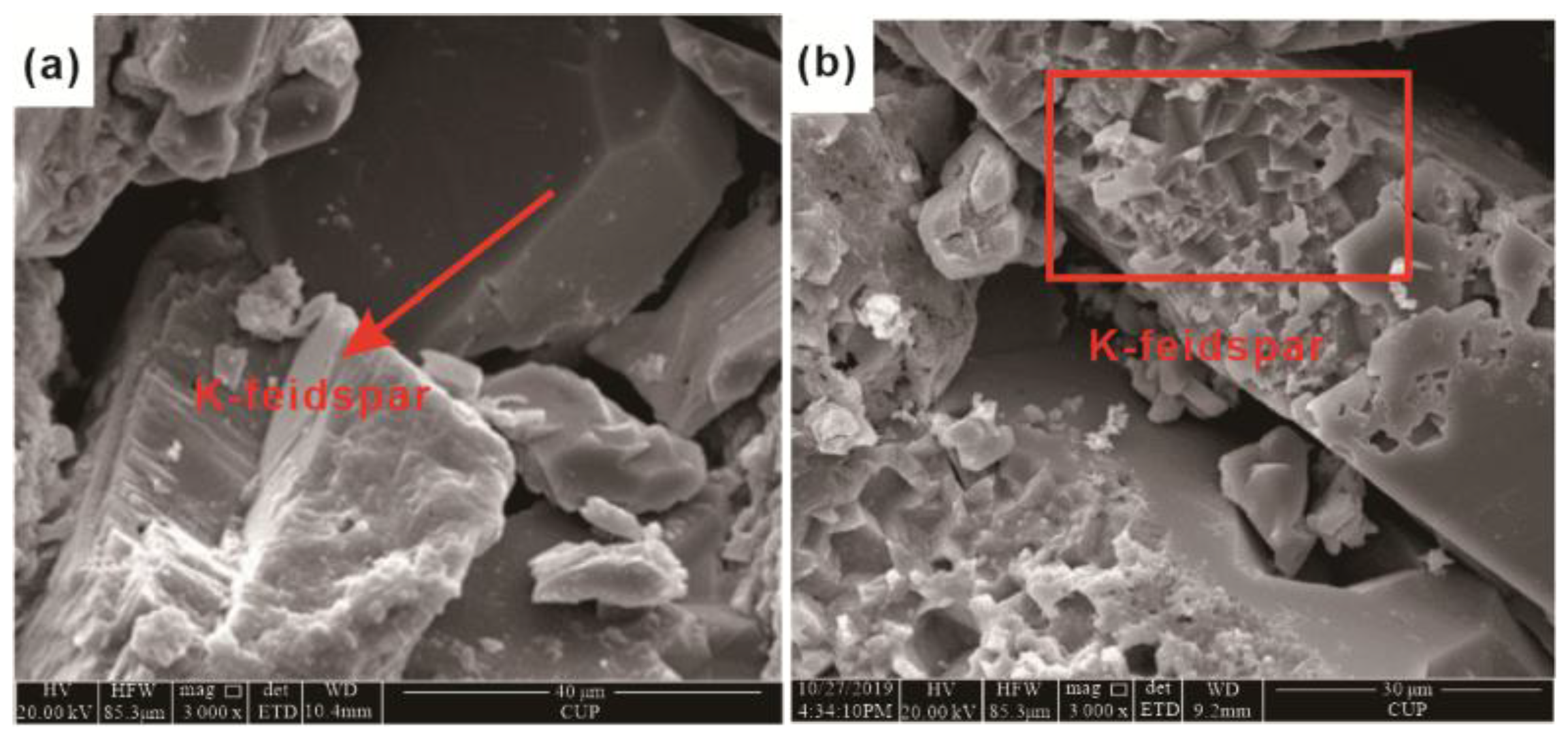

4.2.2. Minerals Changes

5. Conclusions

- (1)

- Under current reservoir temperature and pressure conditions, there will be no significant asphaltene deposition or calcium carbonate precipitation during CO2 flooding in the Chang 4 + 5 tight sandstone reservoir in the Ordos Basin. However, due to the combined effects of dissolution and secondary particle migration, CO2 injection may cause certain damage to the reservoir in the study area, resulting in a porosity reduction of approximately 2% and permeability decline ranging from 2% to 6%. Moreover, in areas near oil wells where pressure drops occur, the risk of calcium carbonate precipitation increases significantly. Therefore, during the production process, it is essential to reasonably control the production pressure difference, with a recommended limit within 4 MPa, in order to minimize potential damage to the reservoir.

- (2)

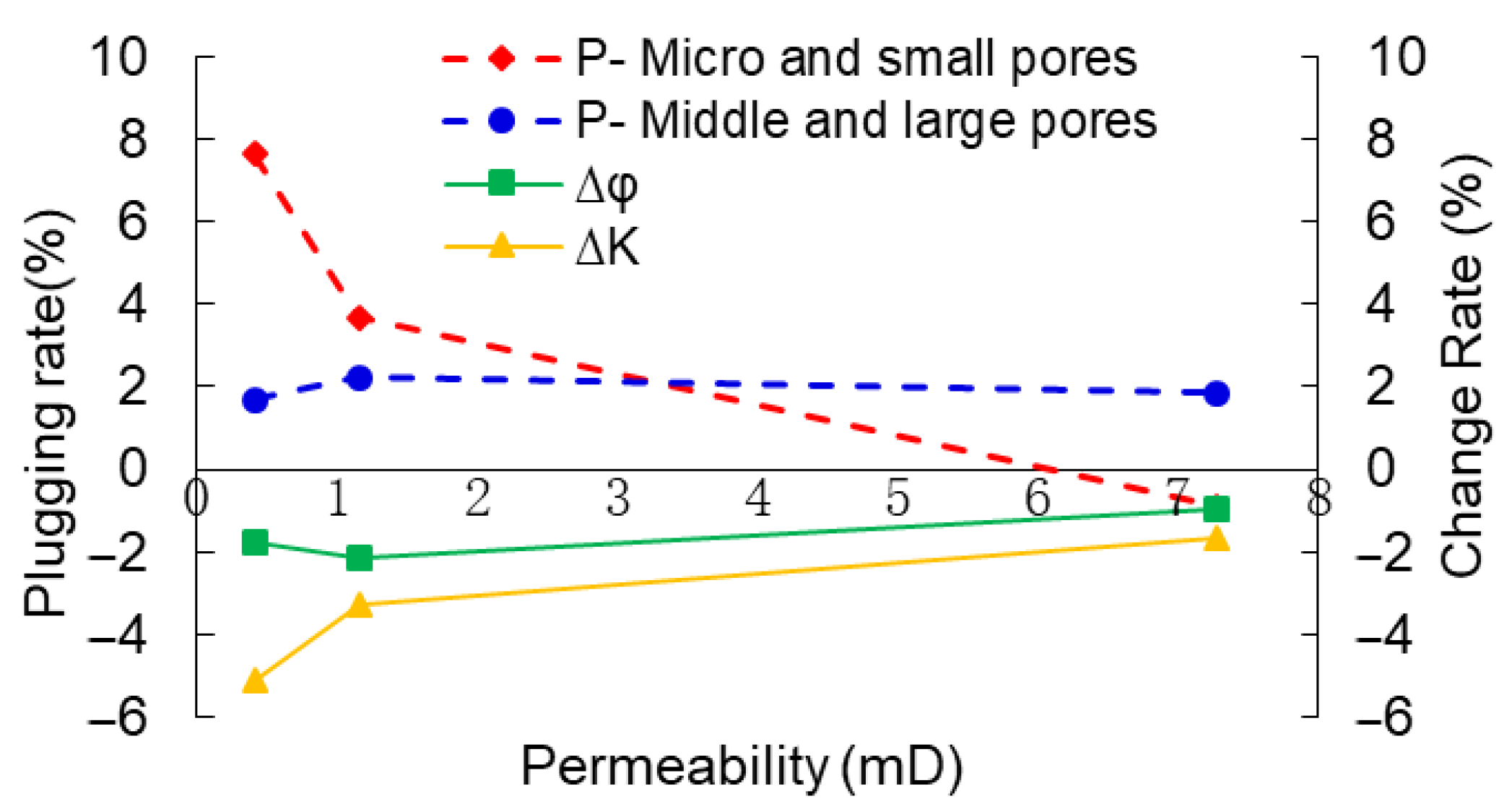

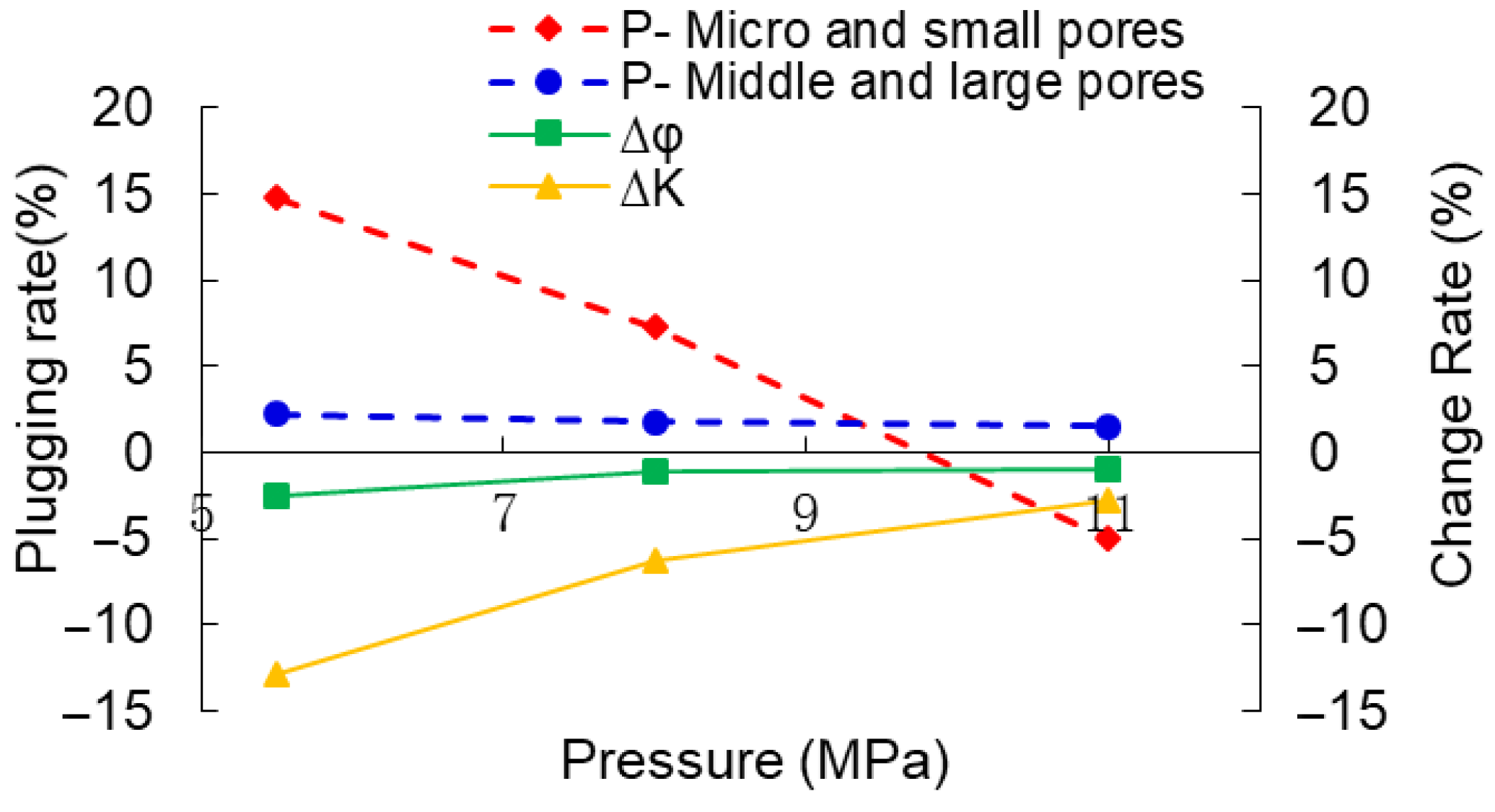

- The dissolution of feldspar and secondary particles migration are the fundamental reasons for the changes in reservoir properties during CO2 flooding in the tight sandstone reservoir in the Ordos Basin, and the degree of reservoir damage varies with different permeabilities and pore throat structures. With increasing permeability, micro pore blockage decreases, and the damage of CO2 flooding to the permeability of the reservoir is weakened. The proportion and the size of micro pores in tight reservoir are significant factors determining the damage degree of CO2 flooding to the reservoir. When permeability is lower than 0.5 × 10−3 μm2, the reservoir is dominated by micro-nano pore throats, and CO2-induced permeability damage becomes significant. During reservoir screening for CO2 flooding, reservoirs with permeability greater than 1 × 10−3 μm2 are recommended, while ultra-low permeability reservoirs with narrow pore throats should be avoided where possible.

- (3)

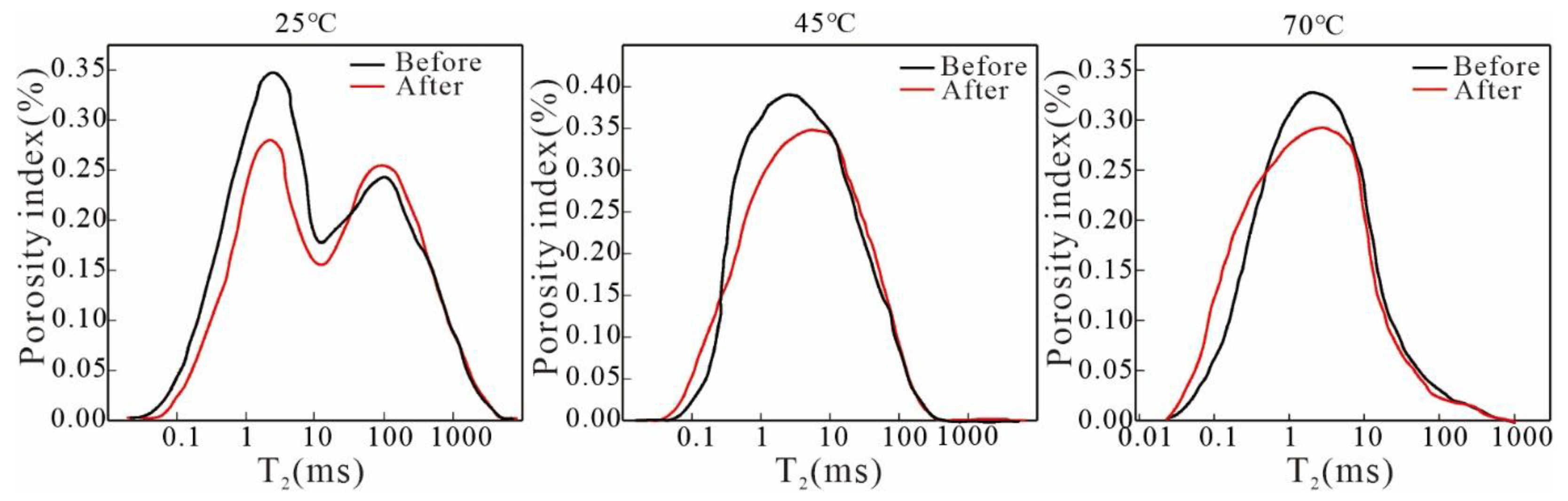

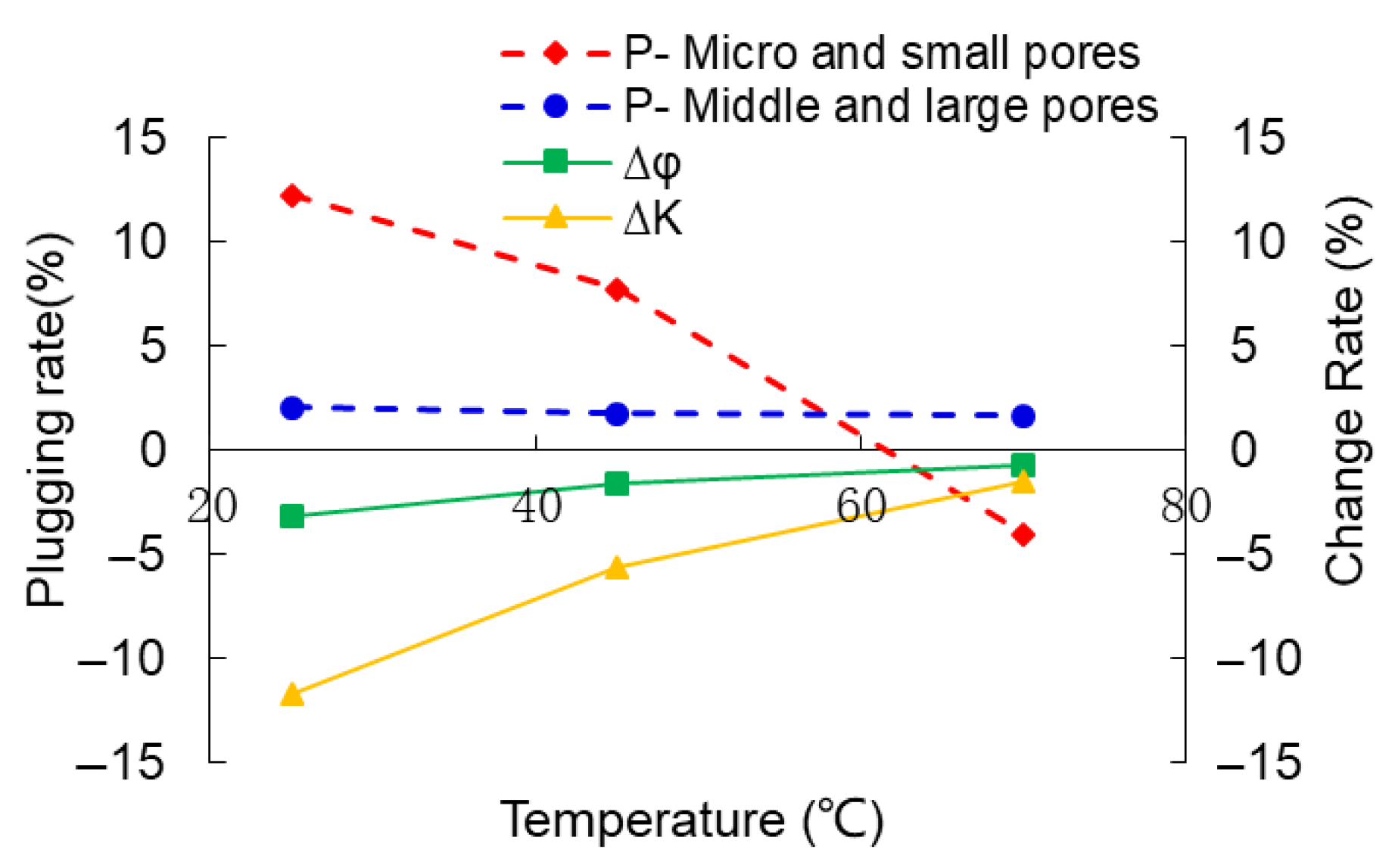

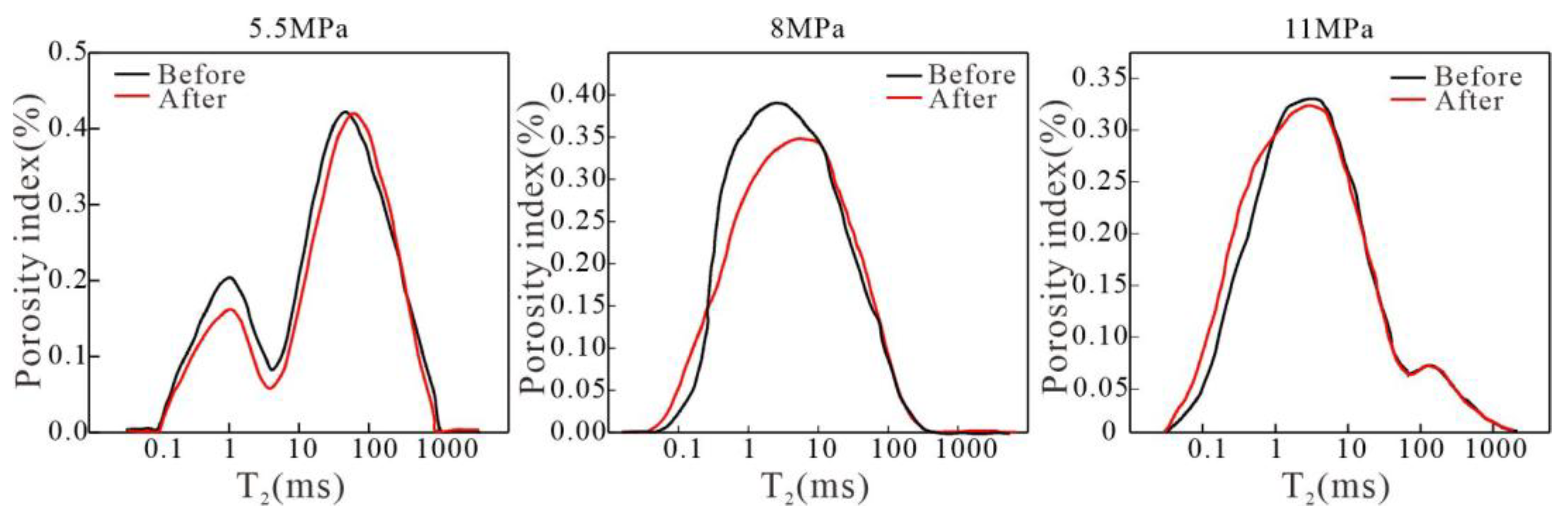

- Temperature and pressure have a significant impact on the extent of reservoir damage caused by CO2 flooding in the study region. As both parameters increase, the damage inflicted on the reservoir by CO2 injection gradually diminishes. Specifically, when the temperature exceeds 70 °C and the pressure surpasses 11 MPa, the impact of CO2 injection on reservoir permeability becomes minimal. Under certain reservoir temperature, increasing CO2 injection pressure can reduce damage to the reservoir. It is therefore advised to avoid implementing CO2 flooding projects in areas characterized by low temperatures and severe reservoir pressure depletion.

- (4)

- Long-term CO2 injection can lead to significant dissolution of reservoir rocks. In reservoirs with potential fluid channeling pathways such as fractures and faults, leakage risk increases significantly during the mid-to-late stage of CO2 injection. It is recommended to enhance leakage monitoring at critical locations, including areas near injection/production wellbores, fault zones, and along preferential CO2 migration pathways. This ensures both the effectiveness and safety of the CO2 flooding and sequestration project.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO2 | Carbon dioxide |

| EOR | Enhanced oil recovery |

| XRD | X-ray diffraction |

| SEM | Scanning electron microscope |

| NMR | Nuclear magnetic resonance |

| ICP | Inductively coupled plasma |

| IG | Ion chromatograph |

References

- Hackley, P.C.; Warwick, P.D. Unconventional energy resources: 2015 review. Nat. Resour. Res. 2015, 24, 443–508. [Google Scholar] [CrossRef]

- Zou, C.; Zhai, G.; Zhang, G.; Wang, H.; Zhang, G.; Li, J.; Wang, Z.; Wen, Z.; Ma, F.; Liang, Y.; et al. Formation, distribution, potential and prediction of global conventional and unconventional hydrocarbon resources. Petroleum Explor. Dev. 2015, 42, 13–25. [Google Scholar] [CrossRef]

- Wang, H.; Ma, F.; Tong, X.; Liu, Z.; Zhang, X.; Wu, Z.; Li, D.; Wang, B.; Xie, Y.; Yang, L. Assessment of global unconventional oil and gas resources. Petroleum Explor. Dev. 2016, 43, 850–862. [Google Scholar] [CrossRef]

- Hein, F.; Ambrose, W.; Hackley, P.; Mead, J.S. Unconventional energy resources: 2017 review. Nat. Resour. Res. 2017, 28, 1661–1751. [Google Scholar] [CrossRef]

- Zhu, R.; Li, G.; Cui, J.; Huang, F.; Lu, X.; Guo, Z.; Cao, Z. Geological accumulation conditions and exploration prospects of tight oil and gas in China. Acta Pet. Sin. 2025, 46, 17–32. [Google Scholar]

- Hu, S.; Zhu, R.; Wu, S.; Bai, B.; Yang, Z.; Cui, J. Exploration and development of continental tight oil in China. Petroleum Explor. Dev. 2018, 45, 790–802. [Google Scholar] [CrossRef]

- Liu, S. Review of the Development Status and Technology of Tight Oil: Advances and Outlook. Energy Fuels 2023, 37, 14645–14665. [Google Scholar] [CrossRef]

- Tao, L.; Li, Z.; Zhang, N.; Sun, H. CO2 Capture and for Improving Heavy Oil Recovery. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 28 March 2009. [Google Scholar]

- Yang, Y.; Liao, G.; Wu, Y.; Ma, X.; Dong, Z.; Li, W.; Wei, J. Displacement efficiency and storage characteristics of CO2 in low permeability reservoirs: An experimental work. Energy Explor. Exploit. 2023, 41, 601–618. [Google Scholar] [CrossRef]

- Qin, J.; Han, H.; Liu, X. Application and enlightenment of carbon dioxide flooding in the United States of America. Pet. Explor. Dev. 2015, 42, 232–240. [Google Scholar] [CrossRef]

- Lv, G.; Li, Q.; Wang, S.; Li, X. Key techniques of reservoir engineering and injection–production process for CO2 flooding in China’s SINOPEC Shengli Oilfield. J. CO2 Util. 2015, 11, 31–40. [Google Scholar] [CrossRef]

- Rahimi, V.; Bidarigh, M.; Bahrami, P. Experimental Study and Performance Investigation of Miscible Water-Alternating-CO2 Flooding for Enhancing Oil Recovery in the Sarvak Formation. Oil Gas Sci. Technol.-Rev. D IFP Energ. Nouv. 2017, 72, 35–47. [Google Scholar] [CrossRef]

- Wang, Y.; Morozov, I. Time-lapse acoustic impedance variations during CO2 injection in Weyburn oilfield, Canada. Geophysics 2020, 85, M1–M13. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, Z.; Zhu, G. Research and Application of CO2 Flooding to Improve Oil Recovery in Low Permeability Oilfield. In Proceedings of the 6th International Conference on Energy and Environmental Protection, Zhuhai, China, 29 June 2017. [Google Scholar]

- Lu, M.; Qian, Q.; Zhong, A.; Zhang, Z.; Zhang, L. Investigation on the flow behavior and mechanisms of water flooding and CO2 immiscible/miscible flooding in shale oil reservoirs. J. CO2 Util. 2024, 80, 102660. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.; Meng, X.; Chen, Y.; Song, W.; Yuan, C. Key parameters and dominant EOR mechanism of CO2 miscible flooding applied in low-permeability oil reservoirs. Geoenergy Sci. Eng. 2023, 225, 211724. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Feng, Y.; Qu, L.; Liu, J.; Li, W.; Dai, M. Damage of reservoir rock induced by CO2 injection. Pet. Sci. 2022, 19, 1674–1681. [Google Scholar] [CrossRef]

- Wang, C.; Cui, M.; Wang, K.; Wei, Y.; Wang, K.; Gao, H. Full-Scale Experimental Study on the Effect of CO2 Flooding on Storage-Seepage Capacity of Tight Sandstone Reservoirs. ACS Omega 2023, 8, 11897–11907. [Google Scholar] [CrossRef]

- Sbai, M.; Azaroual, M. Numerical modeling of formation damage by two-phase particulate transport processes during CO2 injection in deep heterogeneous porous media. Adv. Water Resour. 2011, 34, 62–82. [Google Scholar] [CrossRef]

- Behbahani, T.; Ghotbi, C.; Taghikhani, V.; Shahrabadi, A. Investigation on asphaltene deposition mechanisms during CO2 flooding processes in porous media: A novel experimental study and a modified model based on multilayer theory for asphaltene adsorption. Energy Fuels 2012, 26, 5080–5091. [Google Scholar] [CrossRef]

- Khurshid, I.; Fujii, Y. Geomechanical analysis of formation deformation and permeability enhancement due to low-temperature CO2 injection in subsurface oil reservoirs. J. Pet. Explor. Prod. Technol. 2021, 11, 1915–1923. [Google Scholar] [CrossRef]

- Huang, X.; Tian, Z.; Zuo, X.; Li, X.; Yang, W.; Lu, J. The microscopic pore crude oil production characteristics and influencing factors by DME-assisted CO2 injection in shale oil reservoirs. Fuel 2022, 331, 125843. [Google Scholar] [CrossRef]

- Zhao, F.; Hou, J.; Huang, S. Asphaltene Deposition Induced by Carbon Oxide and its Influence on Displacement Efficiency. Adv. Mater. Res. 2012, 594–597, 2451–2454. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, T.; Song, Y.; Liu, Y.; Dong, B.; Zhu, N. Visualization of asphaltene deposition effects on porosity and permeability during CO2 flooding in porous media. J. Vis. 2016, 19, 603–614. [Google Scholar] [CrossRef]

- Li, R.; Liao, X.; Zou, J.; Gao, C.; Zhao, D.; Zhang, Y.; Zhou, X. Asphaltene Deposition during CO2 Flooding in Ultralow Permeability Reservoirs: A Case Study from Changqing Oil Field. Geofluids 2021, 6626114. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.; Dou, H.; Pang, J.; Huang, Y. Formation damage due to asphaltene precipitation during CO2 flooding processes with NMR technique. Oil Gas Sci. Technol.-Rev. D IFP Energ. Nouv. 2019, 74, 11. [Google Scholar] [CrossRef]

- Wang, C.; Li, T.; Gao, H.; Zhao, J.; Li, H. Effect of asphaltene precipitation on CO2-flooding performance in low-permeability sandstones: A nuclear magnetic resonance study. RSC Adv. 2017, 7, 38367–38376. [Google Scholar] [CrossRef]

- Behbahani, T.; Ghotbi, C.; Taghikhani, V.; Shahrabadi, A. Investigation of asphaltene adsorption in sandstone core sample during CO2 injection: Experimental and modified modeling. Fuel 2014, 133, 63–72. [Google Scholar] [CrossRef]

- Shiraki, R.; Dunn, T. Experimental study on water-rock interactions during CO2 flooding in the Tensleep Formation, Wyoming, USA. Appl. Geochem. 2000, 15, 265–279. [Google Scholar] [CrossRef]

- Tang, Y.; Lv, C.; Wang, R.; Cui, M. Mineral dissolution and mobilization during CO2 injection into the water-flooded layer of the Pucheng Oilfield, China. J. Nat. Gas Sci. Eng. 2016, 33, 1364–1373. [Google Scholar] [CrossRef]

- Han, J.; Han, S.; Sung, W.; Lee, Y. Effects of CO2 miscible flooding on oil recovery and the alteration of rock properties in a carbonate reservoir. J. CO2 Util. 2018, 28, 26–40. [Google Scholar] [CrossRef]

- Narayanan, P.; Khosravi, M.; Weibel, R.; Meirles, L.; Schovsbo, N.; Stenby, E.; Yan, W. Long tube flooding tests for investigating salt precipitation induced by CO2 injection. Carbon Capture Sci. Technol. 2023, 9, 100143. [Google Scholar] [CrossRef]

- Yusof, M.; Neuyam, Y.; Ibrahim, M.; Saaid, I.; Idris, A.; Mohamed, M. Experimental study of CO2 injectivity impairment in sandstone due to salt precipitation and fines migration. J. Pet. Explor. Prod. Technol. 2022, 12, 2191–2202. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, M.; Wang, C.; Xu, S.; Meng, F.; Shen, Y.; Yan, Y. The Damage Caused by Particle Migration to Low-Permeability Reservoirs and Its Effect on the Seepage Capacity after CO2 Flooding. Processes 2023, 11, 3279. [Google Scholar] [CrossRef]

- Khurshid, I.; Afgan, I. Geochemical investigation of CO2 injection in oil and gas reservoirs of Middle East to estimate the formation damage and related oil recovery. Energies 2021, 14, 7676. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, S.; Lorinczi, P.; Glover, P.; Lei, H. Experimental investigation of oil recovery performance and permeability damage in multilayer reservoirs after CO2 and water−alternating-CO2 (CO2−WAG) flooding at miscible pressures. Energy Fuels 2020, 34, 624–636. [Google Scholar] [CrossRef]

- Sadati, E.; Sahraei, E.; Rahnema, M.; Aghdam, S.; Reyhani, M. The effect of CO2-enriched water salinity on enhancing oil recovery and its potential formation damage: An experimental study on shaly sandstone reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 3791–3802. [Google Scholar] [CrossRef]

- Kord, S.; Mohammadzadeh, O.; Miri, R.; Soulgani, B. Further investigation into the mechanisms of asphaltene deposition and permeability impairment in porous media using a modiffed analytical model. Fuel 2014, 117, 259–268. [Google Scholar] [CrossRef]

- Alimohammadi, S.; Zendehboudi, S.; James, L. A comprehensive review of asphaltene deposition in petroleum reservoirs: Theory, challenges, and tips. Fuel 2019, 252, 753–791. [Google Scholar] [CrossRef]

- Cao, M.; Gu, Y. Oil recovery mechanisms and asphaltene precipitation phenomenon in immiscible and miscible CO2 flooding processes. Fuel 2013, 109, 157–166. [Google Scholar] [CrossRef]

- Wang, H.; Alvarado, V.; Bagdonas, D.; McLaughlin, J.; Kaszuba, J.; Grana, D.; Campbell, E.; Ng, K. Effect of CO2-brine-rock reactions on pore architecture and permeability in dolostone: Implications for CO2 storage and EOR. Int. J. Green. Gas Control 2021, 107, 103283. [Google Scholar] [CrossRef]

- Cui, G.; Ning, F.; Dou, B.; Li, T.; Zhou, Q. Particle migration and formation damage during geothermal exploitation from weakly consolidated sandstone reservoirs via water and CO2 recycling. Energy 2022, 240, 122507. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, L.; Yang, Y.; Li, S.; Yang, Y. An experimental study of CO2-brine-rock interaction at in situ pressure–temperature reservoir conditions. Chem. Geol. 2012, 326, 88–101. [Google Scholar] [CrossRef]

- SY/T 7454-2019; Technical Specifications of Compiling the Development Plan of Sandstone Oilfield CO2 Flooding [Standard in Chinese]. National Energy Administration (NEA): Beijing, China, 2019. Available online: https://std.samr.gov.cn/db/search/stdDBDetailed?id=CA1B5CFFE8E14A15E05397BE0A0A1C07 (accessed on 14 July 2025).

- SY/T 6490-2023; Specification for Measurement of Rock NMR Parameter in Laboratory [Standard in Chinese]. National Energy Administration (NEA): Beijing, China, 2023. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=1C3F24E40A0DE543E06397BE0A0AFB62# (accessed on 14 July 2025).

- SY/T 5163-2018; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction [Standard in Chinese]. National Energy Administration (NEA): Beijing, China, 2018. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=8B1827F256BDBB19E05397BE0A0AB44A (accessed on 14 July 2025).

- Andrade, F.; Polo, L.; Janasi, V.; Carvalho, F. Volcanic glass in Cretaceous dacites and rhyolites of the Parana Magmatic Province, southern Brazil: Characterization and quantification by XRD-Rietveld. J. Volcanol. Geotherm. Res. 2017, 355, 219–231. [Google Scholar] [CrossRef]

- SY/T 5162-2021; Analytical Method for Rock Samples by Scanning Electron Microscope [Standard in Chinese]. National Energy Administration (NEA): Beijing, China, 2021. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=DA2A0F8D9A299F00E05397BE0A0A8D2D (accessed on 14 July 2025).

- SY/T 5523-2016; Method for Analysis of Oilfiled Water [Standard in Chinese]. National Energy Administration (NEA): Beijing, China, 2016. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=8B1827F1CCD3BB19E05397BE0A0AB44A (accessed on 14 July 2025).

- Brownstein, K.; Tarr, C. Importance of classical diffusion in NMR studies of water in biological cells. Phys. Rev. 1979, 19, 2446–2453. [Google Scholar] [CrossRef]

- Kweon, H.; Deo, M. The impact of reactive surface area on brine-rock-carbon dioxide reactions in CO2 sequestration. Fuel 2017, 188, 39–49. [Google Scholar] [CrossRef]

- Zhao, H.; Dilmore, R.; Allen, D.; Hedges, S.; Soong, Y.; Lvov, S. Measurement and modeling of CO2 solubility in natural and synthetic formation brines for CO2 sequestration. Environ. Sci. Technol. 2015, 49, 1972–1980. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Guan, Y.; Li, T.; Yin, G. Solubility Variation and Prediction Model of CO2 in Water-Bearing Crude Oil. ACS Omega 2022, 48, 44420–44427. [Google Scholar] [CrossRef]

- Gao, Z.; Feng, J.; Cui, J.; Wang, X.; Zhou, C.; Shi, Y. Physical simulation and quantitative calculation of increased feldspar dissolution pores in deep reservoirs. Petroleum Explor. Dev. 2017, 44, 387–398. [Google Scholar] [CrossRef]

- Du, S.; Zhao, Y.; Jin, J.; Kou, G.; Shi, Y.; Huang, X. Significance of the secondary pores in perthite for oil storage and flow in tight sandstone reservoir. Mar. Pet. Geol. 2019, 110, 178–188. [Google Scholar] [CrossRef]

- Sorai, M.; Ohsumi, T.; Ishikawa, M. Nanoscale surface observation of feldspar dissolved under supercritical CO2-water-mineral system. Energy 2005, 30, 2334–2343. [Google Scholar] [CrossRef]

| Core Number | Length (cm) | Diameter (cm) | Permeability (×10−3 μm2) | Porosity (%) |

|---|---|---|---|---|

| W1 | 6.6 | 2.54 | 0.413 | 9.25 |

| W2 | 6.8 | 2.51 | 1.158 | 10.07 |

| W3 | 6.5 | 2.52 | 7.272 | 12.34 |

| W4 | 6.3 | 2.51 | 0.472 | 9.29 |

| W5 | 6.7 | 2.53 | 0.435 | 9.26 |

| W6 | 6.5 | 2.52 | 0.501 | 9.32 |

| W7 | 6.4 | 2.54 | 0.419 | 9.25 |

| W8 | 6.7 | 2.51 | 0.487 | 9.30 |

| W9 | 6.6 | 2.52 | 0.445 | 9.27 |

| Composition | Na+ | K+ | Ca2+ | Mg2+ | Ba2+ | Sr2+ | Cl− | HCO3− | SO42− | Total Salinity |

|---|---|---|---|---|---|---|---|---|---|---|

| Concentration mg/L | 9040.3 | 1907.2 | 21,380.0 | 108.1 | 130.9 | 1383.3 | 62,125.0 | 214.9 | 114.2 | 96,403.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Q.; Wang, Y.; Wei, D.; Chen, L. Mechanism Analysis and Evaluation of Formation Physical Property Damage in CO2 Flooding in Tight Sandstone Reservoirs of Ordos Basin, China. Processes 2025, 13, 2320. https://doi.org/10.3390/pr13072320

Shang Q, Wang Y, Wei D, Chen L. Mechanism Analysis and Evaluation of Formation Physical Property Damage in CO2 Flooding in Tight Sandstone Reservoirs of Ordos Basin, China. Processes. 2025; 13(7):2320. https://doi.org/10.3390/pr13072320

Chicago/Turabian StyleShang, Qinghua, Yuxia Wang, Dengfeng Wei, and Longlong Chen. 2025. "Mechanism Analysis and Evaluation of Formation Physical Property Damage in CO2 Flooding in Tight Sandstone Reservoirs of Ordos Basin, China" Processes 13, no. 7: 2320. https://doi.org/10.3390/pr13072320

APA StyleShang, Q., Wang, Y., Wei, D., & Chen, L. (2025). Mechanism Analysis and Evaluation of Formation Physical Property Damage in CO2 Flooding in Tight Sandstone Reservoirs of Ordos Basin, China. Processes, 13(7), 2320. https://doi.org/10.3390/pr13072320