Addressing Challenges in Large-Scale Bioprocess Simulations: A Circular Economy Approach Using SuperPro Designer

Abstract

1. Introduction

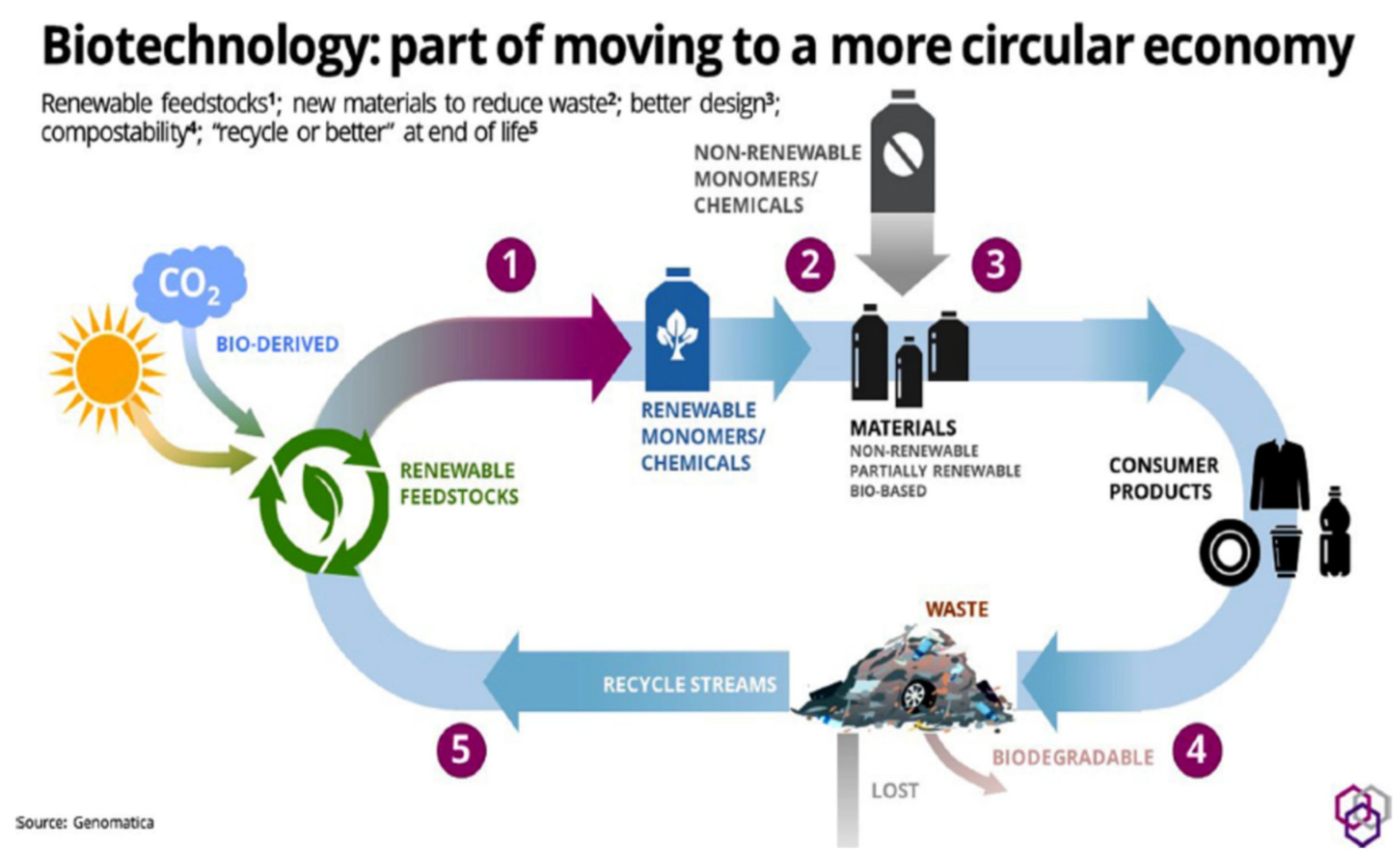

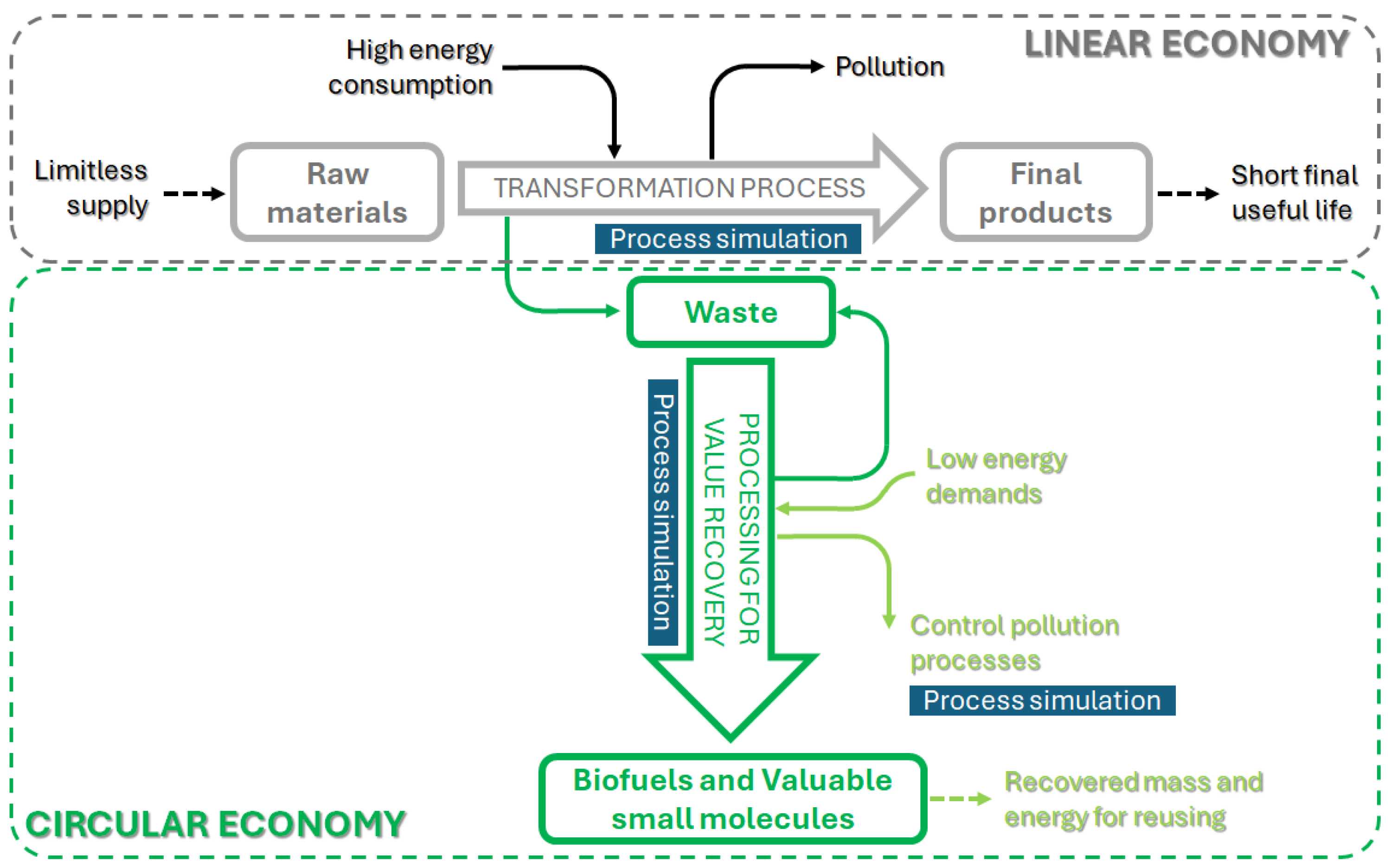

2. Importance of Circular Economy on Industrial Development and Biotechnology

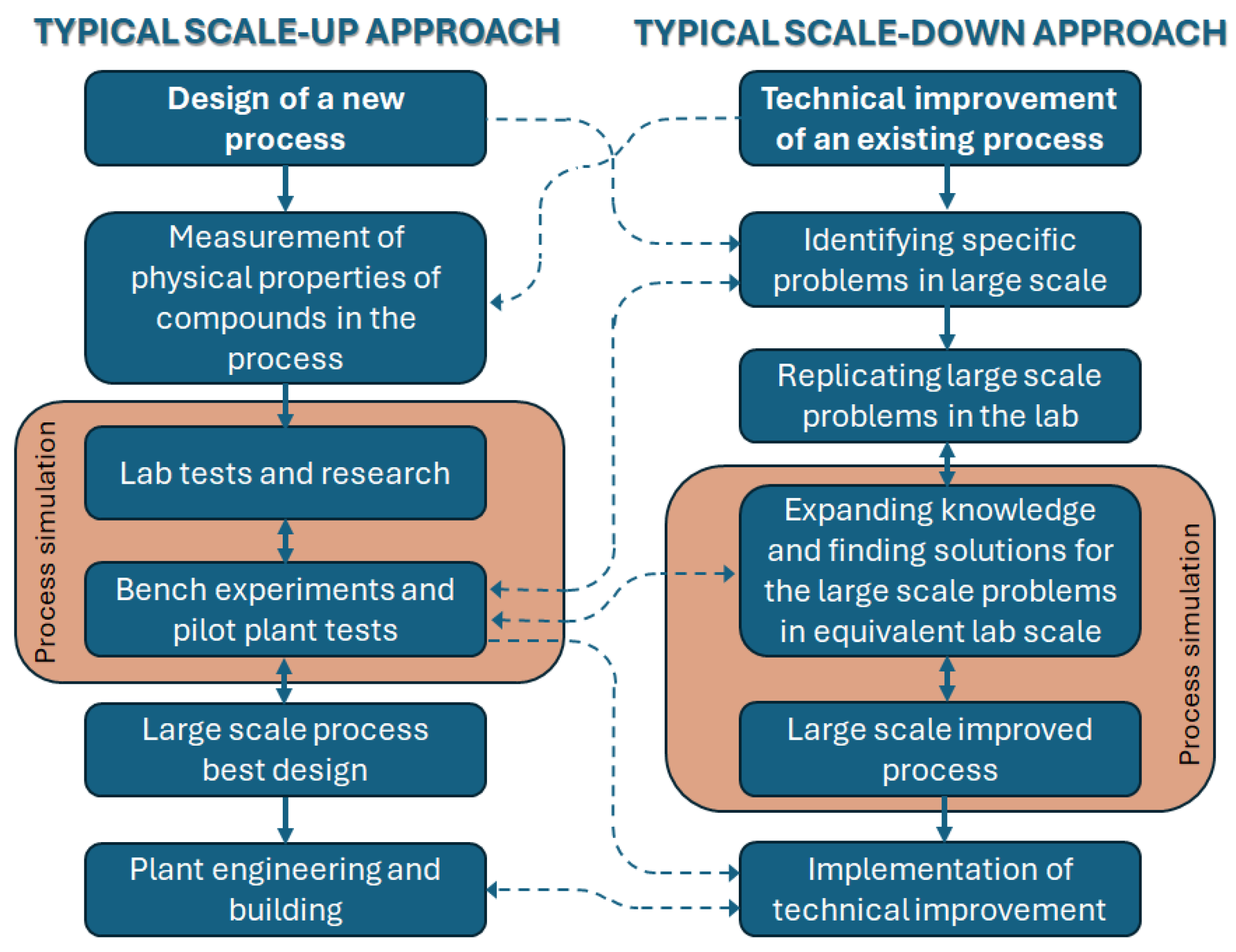

3. Design Methodology and Process Simulation: Process Design and Process Scale Up

- Reaction and information structures (batch or continuous);

- Input–output structures in the process flowsheet (mass and energy balances);

- Recycling structure in the flowsheet;

- Focus on the separation system (downstream);

- Design of the energy network (heat-exchange interconnections);

- Cost diagrams and alternative process scenarios.

3.1. Identifying Techno-Economic Challenges in Large Bioprocess Design

- (i)

- Biocatalyst physiological stability [36,37]. Biological catalysts such as enzymes and microbial, vegetal, or animal cells are strongly dependent on culture conditions that must be adjusted to keep cellular physiological activity in the optimal production of a bioactive molecule. These culture conditions are operational, meaning they are rather controlled by strategies directed to pre-established optimal objectives. Normally, microbial strains or vegetal and animal cellular lines are genetically stable through some generations under proper preservation methods, but eventually, unknown genetic control circuits could alter the expected physiological behavior of the cells, thus producing a reduction in productivity. These aspects should lead to frequent stability assessments in the lab and to checking up on the cellular lines’ kinetic behavior and titer measurements, to confirm productivity data for bioprocess simulation.

- (ii)

- Preserving the biocatalyst production yields between scales [38]. Stoichiometric yields and volumetric productivities from cellular lines and microbial strains are usually maximized in laboratory-scale ideal mixing bioreactors, but in large-scale industrial bioreactors, where mixing heterogeneities often appear, yields and productivities are often lower [39]. This is still an open problem in bioreaction engineering, so the projected amount of the product in industrial bioprocesses must consider the yield loss due to changing scale, as to reach annual production goals. Thus, an actual challenging task is to develop an accurate way to estimate the yield decrease in large bioreactors through what is called the scale-down approach. Scaled-up processes need to be simulated considering the proper adjustments in stoichiometric reactions to deliver good data for the decision-making process.

- (iii)

- Concentration heterogeneities in large bioreactors [40]. Achieving perfect homogeneity in a large bioreactor would be an impossible task with the actual mixing technology, meaning that cells will alternate between rich substrate and oxygen zones, and poorly mixed zones with scarce nutrient availability in the bioreactor. The yield loss stated before is a result of this oscillating culture conditions in large heterogeneously mixed bioreactors.

- (iv)

- Oxygen transfer for aerobic processes [41]. Low solubility of oxygen leads to an eventual culture growth limitation by dissolved oxygen exhaustion in the culture medium for aerobic processes, even with continuous air supply for interphase oxygen transfer in the bioreactor. In laboratory scale bioreactors, oxygen transfer rate and then oxygen availability can be improved by increasing the bioreactor stirring speed or the airflow input, which are unfeasible strategies in large bioreactors. Consequently, the culture switches from carbon-limited to oxygen-limited, meaning the growth kinetics would present a linear behavior for growth and bioactive molecule production with respect to culture time, so no exponential production can be expected. These linear-like kinetics should then be considered in scale-up or scale-down procedures and process simulations.

- (v)

- Recovery factors and efficiencies in large-scale downstream equipment. Mass and energy balances in unitary processes throughout the downstream processing could be affected [42] by equipment efficiencies associated with hydrodynamics in specific geometric equipment designs or mass or heat transfer limitations. So, some unitary processes such as distillation, liquid and solid extraction, spray drying, or chromatographic processes need to be scaled up in pilot plant facilities to generate data for more accurate simulations, leading to better large-scale unitary process performance.

- (vi)

- Excessive water and energy consumption. Water and energy consumption are important but often neglected factors in process scale-up. In designing or operating an industrial-scale process, there must always be a strategy for reducing water and energy consumption. Occasionally, if large amounts of water or energy are needed and those are increasing with the process scale, scale-up projects could result in unfeasibility. Water recycling, more efficient use of water, or water recovery by treatment plants should be combined in a strategy for a scalable lower-environmental-impact alternative. Process simulations are, of course, useful in this regard.

- (vii)

- Large environmental impact or irreversible ecological damage [43]. Potential or actual pollution in water, air, and soil in ecosystems should be kept at minimum levels. This can be evaluated from simulated waste and emission estimations in the bioprocess. Under no circumstances should a production process be considered feasible if high pollution degrees or irreversible damage to the environment exist. Environmental protection technologies must be incorporated to scale-up estimations.

- (viii)

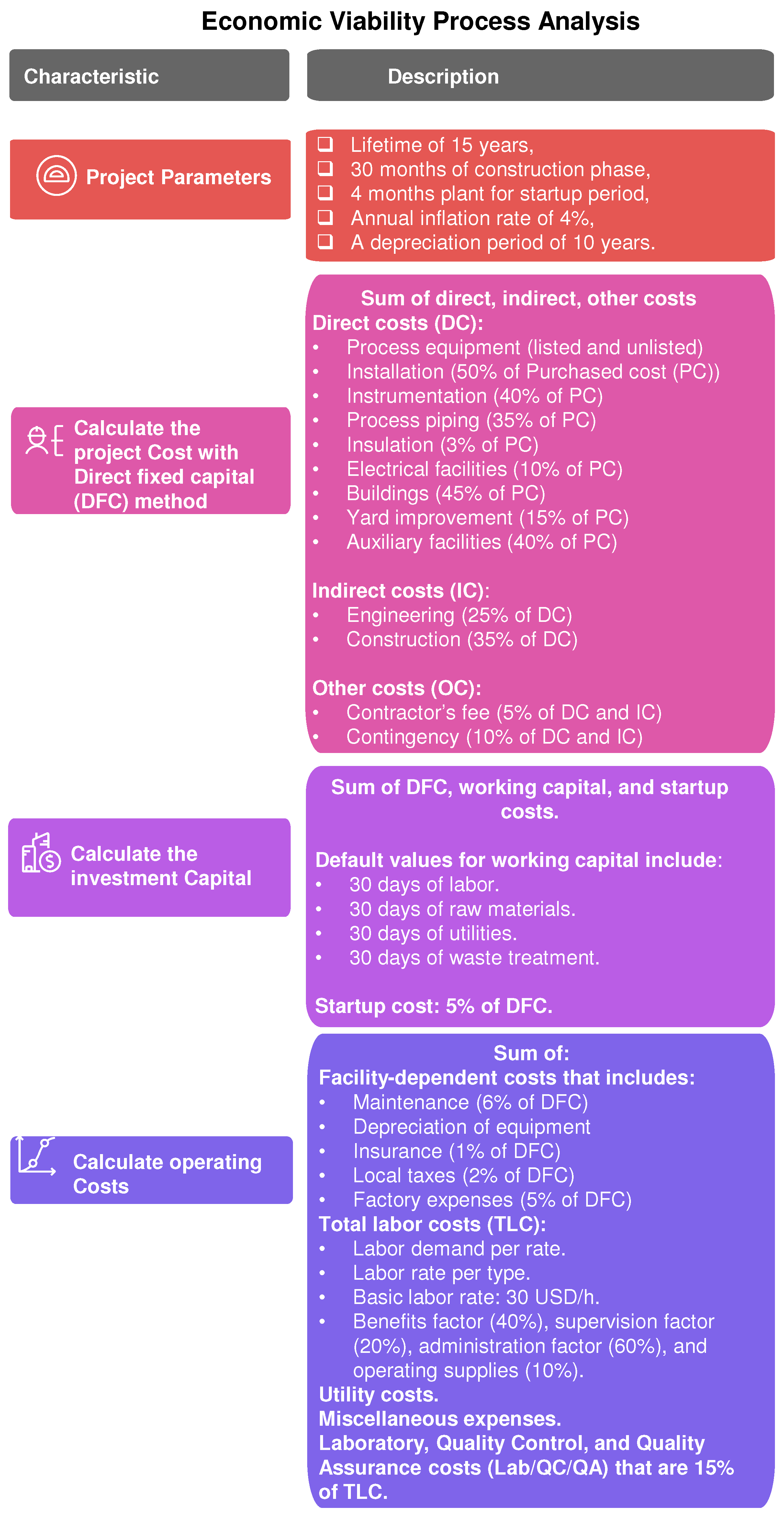

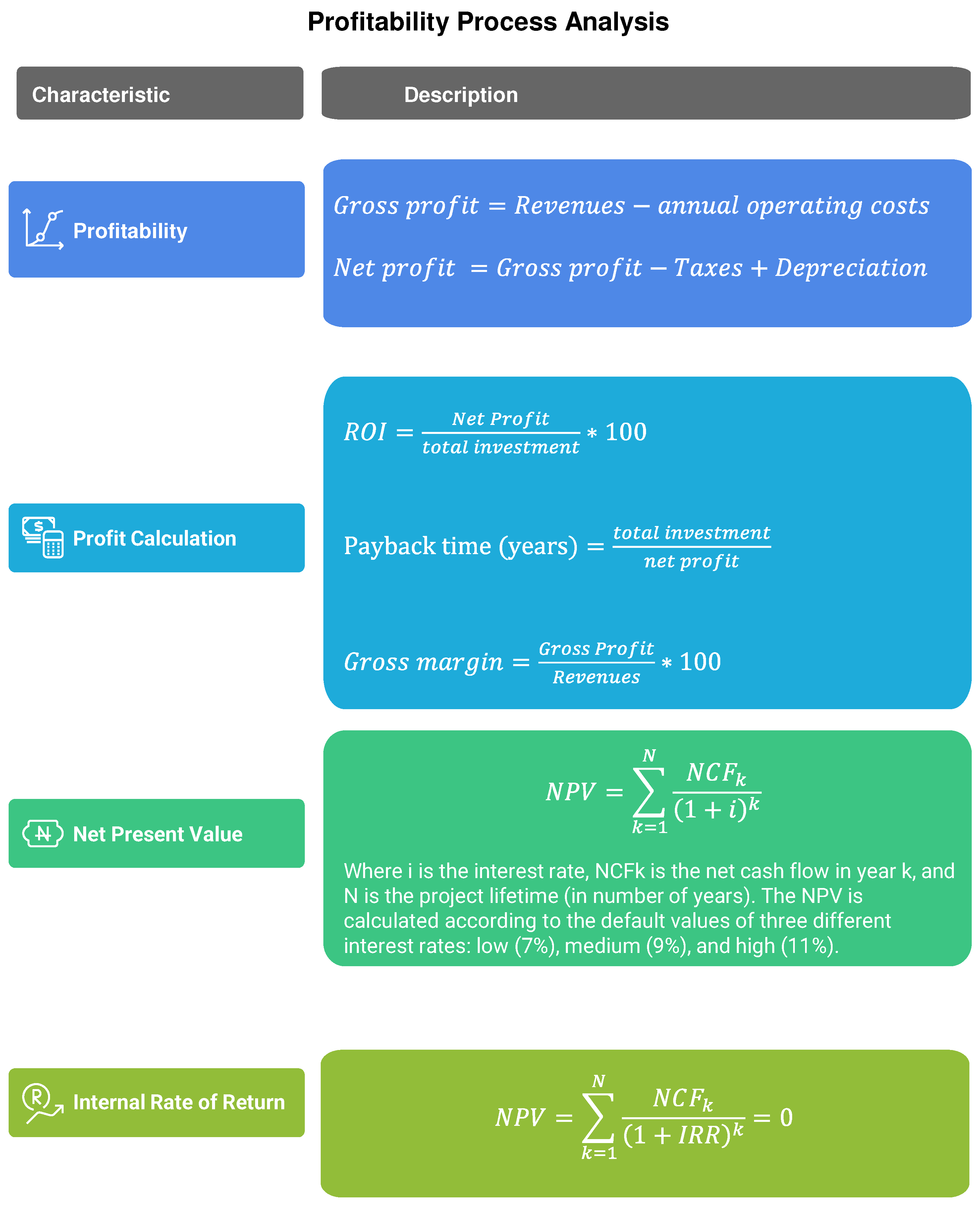

- Accurate cost estimates both for investment and process operation [44]. Process simulation delivers costs and financial indicators that report economic feasibility for scaled-up processes. Precise and accurate figures are important for scaling up decision-making process. Thus, estimating costs and financial indicators needs exact economic data that might be challenging to obtain.

- (ix)

- Raw material availability. Industrial production requires sufficiency of raw materials in accordance with production scheduling on a yearly basis. This is an indirect scaling factor that is not related to other technical difficulties during process scale up, but that still represents an important challenge that should be considered in scale up calculations.

3.2. Lab-Scale to Large-Scale Transition of Bioprocesses Through Assisted Simulation with Bench or Pilot Tests

4. Opportunity Areas with SuperPro Designer for Implementing Technical and Economic Assessments of Bioprocesses

4.1. Using SuperPro Designer for Providing Valuable Data for Decision-Making

4.2. Challenges of Using SuperPro Designer for Large-Scale Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suparmaniam, U.; Lam, M.K.; Uemura, Y.; Lim, J.W.; Lee, K.T.; Shuit, S.H. Insights into the Microalgae Cultivation Technology and Harvesting Process for Biofuel Production: A Review. Renew. Sustain. Energy Rev. 2019, 115, 109361. [Google Scholar] [CrossRef]

- Kostas, E.T.; Adams, J.M.M.; Ruiz, H.A.; Durán-Jiménez, G.; Lye, G.J. Macroalgal Biorefinery Concepts for the Circular Bioeconomy: A Review on Biotechnological Developments and Future Perspectives. Renew. Sustain. Energy Rev. 2021, 151, 111553. [Google Scholar] [CrossRef]

- Okeke, E.S.; Ejeromedoghene, O.; Okoye, C.O.; Ezeorba, T.P.C.; Nyaruaba, R.; Ikechukwu, C.K.; Oladipo, A.; Orege, J.I. Microalgae Biorefinery: An Integrated Route for the Sustainable Production of High-Value-Added Products. Energy Convers. Manag. X 2022, 16, 100323. [Google Scholar] [CrossRef]

- Tham, P.E.; Lim, H.R.; Khoo, K.S.; Chew, K.W.; Yap, Y.J.; Munawaroh, H.S.H.; Ma, Z.; Rajendran, S.; Gnanasekaran, L.; Show, P.L. Insights of Microalgae-Based Aquaculture Feed: A Review on Circular Bioeconomy and Perspectives. Algal Res. 2023, 74, 103186. [Google Scholar] [CrossRef]

- Tsolakis, N.; Goldsmith, A.T.; Aivazidou, E.; Kumar, M. Microalgae-Based Circular Supply Chain Configurations Using Industry 4.0 Technologies for Pharmaceuticals. J. Clean. Prod. 2023, 395, 136397. [Google Scholar] [CrossRef]

- Ramandani, A.A.; Sun, Y.M.; Lan, J.C.W.; Lim, J.W.; Chang, J.S.; Srinuanpan, S.; Khoo, K.S. Upcycling Food Waste as a Low-Cost Cultivation Medium for Chlorella Sp. Microalgae. J. Sci. Food Agric. 2025, 105, 4715–4727. [Google Scholar] [CrossRef] [PubMed]

- Kovalcik, A.; Obruca, S.; Marova, I. Valorization of Spent Coffee Grounds: A Review. Food Bioprod. Process. 2018, 110, 104–119. [Google Scholar] [CrossRef]

- Gregg, J.S.; Jürgens, J.; Happel, M.K.; Strøm-Andersen, N.; Tanner, A.N.; Bolwig, S.; Klitkou, A. Valorization of Bio-Residuals in the Food and Forestry Sectors in Support of a Circular Bioeconomy: A Review. J. Clean. Prod. 2020, 267, 122093. [Google Scholar] [CrossRef]

- Sharma, V.; Sharma, D.; Tsai, M.L.; Ortizo, R.G.G.; Yadav, A.; Nargotra, P.; Chen, C.W.; Sun, P.P.; Dong, C. Di Insights into the Recent Advances of Agro-Industrial Waste Valorization for Sustainable Biogas Production. Bioresour. Technol. 2023, 390, 129829. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Gaffey, J.; Sharma, M.; Dewhurst, R.J.; Moreau, B.; Newbold, J.; Clark, W.; Thakur, V.K.; Gupta, V.K. Valorization of Dairy Waste and By-Products through Microbial Bioprocesses. Bioresour. Technol. 2022, 346, 126444. [Google Scholar] [CrossRef]

- Mishra, B.; Mohanta, Y.K.; Reddy, C.N.; Reddy, S.D.M.; Mandal, S.K.; Yadavalli, R.; Sarma, H. Valorization of Agro-Industrial Biowaste to Biomaterials: An Innovative Circular Bioeconomy Approach. Circ. Econ. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Dukare, A.; Yadav, R.; Kautkar, S.; Kuppusamy, P.; Sharma, K.; Shaikh, A.; Pawar, A.; Gadade, A.; Vigneshwaran, N.; Saxena, S.; et al. Waste to Wealth: Microbial-Based Sustainable Valorization of Cotton Biomass, Processing Waste and by-Products for Bioenergy and Other Value-Added Products to Promote Circular Economy. Waste Manag. Bull. 2024, 2, 262–280. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Ukaigwe, S.; Manga, M.; Iorhemen, O.T. Valorization of Waste Aerobic Granular Sludge: Exploring the Recovery of Tyrosine, Phenylalanine, and Other High-Value Products. Clean. Chem. Eng. 2025, 11, 100144. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Schunz, S. The ‘European Green Deal’–a Paradigm Shift? Transformations in the European Union’s Sustainability Meta-Discourse. Political Res. Exch. 2022, 4, 2085121. [Google Scholar] [CrossRef]

- The 17 GOALS|Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 9 July 2025).

- ISO—Circular Economy. Available online: https://www.iso.org/sectors/environment/circular-economy (accessed on 9 July 2025).

- Ferrante, M.; Vitti, M.; Sassanelli, C. The Evolution of Circular Economy Performance Assessment: A Systematic Literature Review. Renew. Sustain. Energy Rev. 2025, 217, 115757. [Google Scholar] [CrossRef]

- Piechota, G.; Unpaprom, Y.; Dong, C.-D.; Kumar, G. Recent Advances in Biowaste Management towards Sustainable Environment. Bioresour. Technol. 2023, 368, 128326. [Google Scholar] [CrossRef]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Davila Delgado, J.M.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for Deconstruction Using a Circular Economy Approach: Barriers and Strategies for Improvement. Prod. Plan. Control 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Paul, P.T.; Joy, J.M.; Akshay, P.; Rosemol, J.M.; Amruth, P.; Chatterjee, N.S.; Mathew, S. Assessment of Total Phenolic Content and In Vitro Antioxidant Activity in Brown Seaweeds Turbinaria Conoides and Padina Tetrastromatica from the Mandapam Coast. Fish. Technol. 2024, 61, 264–272. [Google Scholar] [CrossRef]

- European Bioplastics e.V. Available online: https://www.european-bioplastics.org/ (accessed on 9 July 2025).

- Offei, F.; Mensah, M.; Kemausuor, F.; Thygesen, A. A Biorefinery Approach to Bioethanol and Bioelectricity Co-Production from Tropical Seaweeds. J. Appl. Phycol. 2019, 31, 3899–3913. [Google Scholar] [CrossRef]

- Bristol, D.M.N.; Ubando, A.T.; Wang, C.T. Sustainable Design of Microbial Fuel Cells in Consideration of Circular Bioeconomy: A State-of-the-Art Review. J. Water Process Eng. 2025, 75, 108011. [Google Scholar] [CrossRef]

- Tan, Y.M.; Szulczyk, K.R. Enhancing the Commercial Viability of Commercial Algal Bioethanol Production: The Role of Technological Advancements. Bioresour. Technol. Rep. 2024, 27, 101937. [Google Scholar] [CrossRef]

- Garkoti, P.; Thengane, S.K. Techno-Economic and Life Cycle Assessment of Circular Economy-Based Biogas Plants for Managing Organic Waste. J. Clean. Prod. 2025, 504, 145412. [Google Scholar] [CrossRef]

- Schilling, C.; Weiss, S. A Roadmap for Industry to Harness Biotechnology for a More Circular Economy. New Biotechnol. 2021, 60, 9–11. [Google Scholar] [CrossRef]

- Perkins, J.D. Conceptual Design of Chemical Processes J. M. Douglas, McGraw-Hill, New York, 1988. pp. Xviii + 601, Price £ 32.50. ISBN 0-07-017762-7. J. Chem. Technol. Biotechnol. 1989, 46, 249. [Google Scholar] [CrossRef]

- Nishida, N.; Stephanopoulos, G.; Westerberg, A.W. A Review of Process Synthesis. AlChE J. 1981, 27, 321–351. [Google Scholar] [CrossRef]

- Petrides, D.P. Bioprocess Design and Economics. In Bioseparations Science and Engineering; Oxford University Press: Oxford, UK, 2015; Volume 1, pp. 441–510. ISBN 9780195391817. [Google Scholar]

- Petrides, D.; Carmichael, D.; Siletti, C.; Koulouris, A. Bioprocess Simulation and Economics. In Essentials in Fermentation Technology; Springer Nature: Cham, Switzerland, 2019; pp. 273–305. [Google Scholar]

- Douglas, J.M. Conceptual Design of Chemical Processes; McGraw-Hill: Singapore, 1988. [Google Scholar]

- Petrides, D.; Carmichael, D.; Siletti, C. Batch Process Simulation. In Batch Processing Modeling and Design; CRC Press Taylor and Francis Group: Abingdon, UK, 2014; Volume 1, pp. 199–230. ISBN 9781138076747. [Google Scholar]

- Petrides, D.; Koulouris, A.; Silleti, C. Throughput Analysis and Debottlenecking of Biomanufacturing Facilities. BioPharm 2002, 15, 1–7. [Google Scholar]

- Achilleos, E.C.; Calandranis, J.C.; Petrides, D.P. Quatifying the Impact of Uncertain Parameters in the Batch Manufacturing of Active Pharmaceutical Ingredients. Pharm. Eng. 2006, 26, 1–6. [Google Scholar]

- Illanes, A. Stability of Biocatalysts. Electron. J. Biotechnol. 1999, 2, 7–15. [Google Scholar] [CrossRef]

- Kadisch, M.; Willrodt, C.; Hillen, M.; Bühler, B.; Schmid, A. Maximizing the Stability of Metabolic Engineering-Derived Whole-Cell Biocatalysts. Biotechnol. J. 2017, 12, 1600170. [Google Scholar] [CrossRef]

- Tufvesson, P.; Fu, W.; Jensen, J.S.; Woodley, J.M. Process Considerations for the Scale-up and Implementation of Biocatalysis. Food Bioprod. Process. 2010, 88, 3–11. [Google Scholar] [CrossRef]

- Olmos, E.; Mehmood, N.; Haj Husein, L.; Goergen, J.L.; Fick, M.; Delaunay, S. Effects of Bioreactor Hydrodynamics on the Physiology of Streptomyces. Bioprocess. Biosyst. Eng. 2013, 36, 259–272. [Google Scholar] [CrossRef]

- Nadal-Rey, G.; McClure, D.D.; Kavanagh, J.M.; Cornelissen, S.; Fletcher, D.F.; Gernaey, K.V. Understanding Gradients in Industrial Bioreactors. Biotechnol. Adv. 2021, 46, 107660. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor Scale-up and Oxygen Transfer Rate in Microbial Processes: An Overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef] [PubMed]

- Gerstweiler, L.; Bi, J.; Middelberg, A.P.J. Continuous Downstream Bioprocessing for Intensified Manufacture of Biopharmaceuticals and Antibodies. Chem. Eng. Sci. 2021, 231, 116272. [Google Scholar] [CrossRef]

- Koller, G.; Fischer, U.; Hungerbühler, K. Assessing Safety, Health, and Environmental Impact Early during Process Development. Ind. Eng. Chem. Res. 2000, 39, 960–972. [Google Scholar] [CrossRef]

- Dandan, T.H.; Sweis, G.; Sukkari, L.S.; Sweis, R.J. Factors Affecting the Accuracy of Cost Estimate during Various Design Stages. J. Eng. Des. Technol. 2020, 18, 787–819. [Google Scholar] [CrossRef]

- Rao, P.M.; Saxena, S. Bioprocess Scale-Up and Scale-Down: Bulk Production. In Biotechnology Concepts and Applications; Black Prints: New Delhi, India, 2022; pp. 67–74. [Google Scholar]

- Shi, C.; Chen, X.J.; Jiao, B.; Liu, P.; Jing, S.Y.; Zhong, X.Z.; Chen, R.; Gong, W.; Lin, D.Q. Model-Assisted Process Design for Better Evaluation and Scaling up of Continuous Downstream Bioprocessing. J. Chromatogr. A 2022, 1683, 463532. [Google Scholar] [CrossRef]

- Papavasileiou, V.; Koulouris, A.; Siletti, C.; Petrides, D. Optimize Manufacturing of Pharmaceutical Products with Process Simulation and Production Scheduling Tools. Chem. Eng. Res. Des. 2007, 85, 1086–1097. [Google Scholar] [CrossRef]

- Roussos, A.; Misailidis, N.; Koulouris, A.; Zimbardi, F.; Petrides, D. A Feasibility Study of Cellulosic Isobutanol Production-Process Simulation and Economic Analysis. Processes 2019, 7, 667. [Google Scholar] [CrossRef]

- Canizales, L.; Rojas, F.; Pizarro, C.A.; Caicedo-Ortega, N.H.; Villegas-Torres, M.F. SuperPro Designer®, User-Oriented Software Used for Analyzing the Techno-Economic Feasibility of Electrical Energy Generation from Sugarcane Vinasse in Colombia. Processes 2020, 8, 1180. [Google Scholar] [CrossRef]

- Van Rijn, R.; Nieves, I.U.; Shanmugam, K.T.; Ingram, L.O.; Vermerris, W. Techno-Economic Evaluation of Cellulosic Ethanol Production Based on Pilot Biorefinery Data: A Case Study of Sweet Sorghum Bagasse Processed via L plus SScF. Bioenergy Res. 2018, 11, 414–425. [Google Scholar] [CrossRef]

- Harrison, R.G.; Todd, P.W.; Rudge, S.R.; Petrides, D.P. Bioseparations Science and Engineering; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Rouf, S.A.; Douglas, P.L.; Moo-Young, M.; Scharer, J.M. Computer Simulation for Large Scale Bioprocess Design. Biochem. Eng. J. 2001, 8, 229–234. [Google Scholar] [CrossRef]

- Michailos, S.; Parker, D.; Webb, C. A Multicriteria Comparison of Utilizing Sugar Cane Bagasse for Methanol to Gasoline and Butanol Production. Biomass Bioenergy 2016, 95, 436–448. [Google Scholar] [CrossRef]

- Lin, L.; Shah, A.; Keener, H.; Li, Y.B. Techno-Economic Analyses of Solid-State Anaerobic Digestion and Composting of Yard Trimmings. Waste Manag. 2019, 85, 405–416. [Google Scholar] [CrossRef]

- Adeyi, O.; Adeyi, A.J.; Oke, E.O.; Okolo, B.I.; Olalere, A.O.; Otolorin, J.A.; Taiwo, A.E.; Arellano-Garcia, H. Techno-Economic and Uncertainty Analyses of Heat- and Ultrasound-Assisted Extraction Technologies for the Production of Crude Anthocyanins Powder from Hibiscus Sabdariffa Calyx. Cogent Eng. 2021, 8, 1–22. [Google Scholar] [CrossRef]

- Gómez-Cisneros, A.; Ordaz, A.; Santos-Zea, L.; Escalante-Aburto, A.; Ponce-Alquicira, E.; Calderón-Oliver, M. Orange Sweet Potato Flour Production: Comparative Effects on Ultrasound, Drying, Storage, and Techno-Economic Assessment. Appl. Food Res. 2025, 5, 100751. [Google Scholar] [CrossRef]

- Pang, Y.X.; Yan, Y.; Foo, D.C.Y.; Sharmin, N.; Zhao, H.; Lester, E.; Wu, T.; Pang, C.H. The Influence of Lignocellulose on Biomass Pyrolysis Product Distribution and Economics via Steady State Process Simulation. J. Anal. Appl. Pyrolysis 2021, 158, 104968. [Google Scholar] [CrossRef]

- Mabrouki, J.; Abbassi, M.A.; Guedri, K.; Omri, A.; Jeguirim, M. Simulation of Biofuel Production via Fast Pyrolysis of Palm Oil Residues. Fuel 2015, 159, 819–827. [Google Scholar] [CrossRef]

- Villegas-Méndez, M.A.; Montañez, J.; Contreras-Esquivel, J.C.; Salmerón, I.; Koutinas, A.; Morales-Oyervides, L. Coproduction of Microbial Oil and Carotenoids within the Circular Bioeconomy Concept: A Sequential Solid-State and Submerged Fermentation Approach. Fermentation 2022, 8, 258. [Google Scholar] [CrossRef]

- Czinkóczky, R.; Németh, Á. Techno-Economic Assessment of Bacillus Fermentation to Produce Surfactin and Lichenysin. Biochem. Eng. J. 2020, 163, 107719. [Google Scholar] [CrossRef]

- Bakari, R.; Kivevele, T.; Huang, X.; Jande, Y.A.C. Simulation and Optimisation of the Pyrolysis of Rice Husk: Preliminary Assessment for Gasification Applications. J. Anal. Appl. Pyrolysis 2020, 150, 104891. [Google Scholar] [CrossRef]

- Giwa, A.; Yusuf, A.; Ajumobi, O.; Dzidzienyo, P. Pyrolysis of Date Palm Waste to Biochar Using Concentrated Solar Thermal Energy: Economic and Sustainability Implications. Waste Manag. 2019, 93, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M.D.; Guigou, M.; Lareo, C. Energy Consumption Evaluation of Fuel Bioethanol Production from Sweet Potato. Bioresour. Technol. 2013, 136, 377–384. [Google Scholar] [CrossRef] [PubMed]

- Lam, K.F.; Leung, C.C.J.; Lei, H.M.; Lin, C.S.K. Economic Feasibility of a Pilot-Scale Fermentative Succinic Acid Production from Bakery Wastes. Food Bioprod. Process. 2014, 92, 282–290. [Google Scholar] [CrossRef]

- Chen, J.X.; Tyagi, R.D.; Li, J.; Zhang, X.L.; Drogui, P.; Sun, F.Y. Economic Assessment of Biodiesel Production from Wastewater Sludge. Bioresour. Technol. 2018, 253, 41–48. [Google Scholar] [CrossRef]

- Michailos, S. Process Design, Economic Evaluation and Life Cycle Assessment of Jet Fuel Production from Sugar Cane Residue. Environ. Prog. Sustain. Energy 2018, 37, 1227–1235. [Google Scholar] [CrossRef]

- Baral, N.R.; Shah, A. Techno-Economic Analysis of Cellulosic Butanol Production from Corn Stover through Acetone-Butanol-Ethanol Fermentation. Energy Fuels 2016, 30, 5779–5790. [Google Scholar] [CrossRef]

- Yang, M.L.; Rosentrater, K.A. Techno-Economic Analysis of the Production Process of Structural Bio-Adhesive Derived from Glycerol. J. Clean. Prod. 2019, 228, 388–398. [Google Scholar] [CrossRef]

- Sayar, N.A.; Sam, S.D.; Pinar, O.; Serper, D.; Akbulut, B.S.; Kazan, D.; Sayar, A.A. Techno-Economic Analysis of Caffeine and Catechins Production from Black Tea Waste. Food Bioprod. Process. 2019, 118, 1–12. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Jayamuthunagai, J.; Sreejith, R.; Iyyappan, J.; Praveenkumar, R. Techno Economic Analysis of Malic Acid Production Using Crude Glycerol Derived from Waste Cooking Oil. Bioresour. Technol. 2022, 351, 126956. [Google Scholar] [CrossRef]

- Kumar, D.; Murthy, G.S. Impact of Pretreatment and Downstream Processing Technologies on Economics and Energy in Cellulosic Ethanol Production. Biotechnol. Biofuels 2011, 4, 27. [Google Scholar] [CrossRef]

- Hasanly, A.; Talkhoncheh, M.K.; Alavijeh, M.K. Techno-Economic Assessment of Bioethanol Production from Wheat Straw: A Case Study of Iran. Clean. Technol. Environ. Policy 2018, 20, 357–377. [Google Scholar] [CrossRef]

- López-Sánchez, A.; García-López, C.D.; Lara-Topete, G.O.; Castanier-Rivas, J.D.; Barajas-Alvarez, P.; González-López, M.E.; Silva-Gálvez, A.L.; Zhou, H.Y.; Lan, C.Q.; Robles-Rodriguez, C.E.; et al. Consequential Life Cycle Assessment of Pretreatment Strategies for a Microalgae-Based Wastewater Treatment Pilot Unit in a Circular Livestock Industry Bioeconomy. Algal Res.-Biomass Biofuels Bioprod. 2025, 89, 104041. [Google Scholar] [CrossRef]

- Anuradha, A.; Sampath, M.K. Optimization of Alkali, Acid and Organic Solvent Pretreatment on Rice Husk and Its Techno Economic Analysis for Efficient Sugar Production. Prep. Biochem. Biotechnol. 2023, 53, 279–287. [Google Scholar] [CrossRef]

- Castanier-Rivas, J.D.; Larrea-Cedeño, A.S.; Sukumara, S.; de Alba-Verduzco, J.G.; González-López, M.E.; Gradilla-Hernández, M.S. Towards Circularity: Integrating Biochar Production from Maize Stover into the Tequila Industry. Sustain. Chem. Pharm. 2025, 45, 102027. [Google Scholar] [CrossRef]

- Ramírez-Partida, A.E.; García-Cayuela, T.; Amador-Castro, L.F.; Alper, H.S.; Carrillo-Nieves, D. Towards a Biorefinery Processing Sargassum Seaweed: Techno-Economic Assessment of Alginate and Fucoidan Production through SuperPro Designer® Process Simulation. Environ. Technol. Innov. 2024, 34, 103587. [Google Scholar] [CrossRef]

- Rodríguez, R.; Espada, J.J.; Moreno, J.; Vicente, G.; Bautista, L.F.; Morales, V.; Sánchez-Bayo, A.; Dufour, J. Environmental Analysis of Spirulina Cultivation and Biogas Production Using Experimental and Simulation Approach. Renew. Energy 2018, 129, 724–732. [Google Scholar] [CrossRef]

- Viswanathan, M.B.; Cheng, M.H.; Clemente, T.E.; Dweikat, I.; Singh, V. Economic Perspective of Ethanol and Biodiesel Coproduction from Industrial Hemp. J. Clean. Prod. 2021, 299, 126875. [Google Scholar] [CrossRef]

| Reference | Target Biomolecule | Raw Material | Brief Description of the Simulated Process in SuperPro | Size of the Plant | Variables Studied During the Sensitivity Analysis |

|---|---|---|---|---|---|

| [50] | Bioethanol | Sugarcane bagasse and sweet sorghum | Biomass collection Bagasse preparation Pre-treatment Screw press Culture propagation Liquefaction Fermentation Downstream processing | 300,000 MT/year of sugarcane dry matter or sweet sorghum bagasse | Enzyme dosage Conversion efficiency Solids loading Biomass throughput |

| [54] | Compost and biogas | Yard trimmings | Material preparation Material mixing Anaerobic digestion Biogas utilization Digestate utilization | Capacity of 20,000 MT/year | Plant size Total solids (TS) content and organic components of materials Retention time Degradation efficiency Heat recovery Boiler efficiency Tipping fees By-product/compost price Drying temperature Percentage of compost sold in bags |

| [62] | Biochar | Date palm waste | Feedstock preparation Pyrolysis reaction Heat recovery Biochar collection By-product gas and liquid management | 20,000 MT/year | Plant size Feedstock cost Biochar yield Energy input requirements Market price of biochar Operational efficiency |

| [63] | Bioethanol | Sweet potato | Reception and washing Crushing Drying and milling Gelatinization and liquefaction Simultaneous saccharification and fermentation. Ethanol recovery and dehydration Product storage. | 130 t/h sweet potato with an annual production of 90,000 m3 anhydrous ethanol | Dry matter ratio of sweet potato to water: 0.13 to 0.50 kg dry matter/kg total water. Fermentation efficiency: 70% to 92%. Sweet potato sugar content: 69% to 82%. Final humidity of sweet potato flour: 8% to 20%. |

| [64] | Succinic acid | Bakery wastes | Grinding of bakery wastes Blending in process water and enzymatic hydrolysis. Fermentation using Actinobacillus succinogenes Solid–liquid separation and adsorption of impurities. Distillation and crystallization Drying | The treatment plant was designed to process 1 t/day of bakery waste | Quantity of bakery waste treated. Utility costs. Succinic acid price. Variables were varied within ±20%. |

| [65] | Biodiesel and glycerol as a by-product | Wastewater sludge | Sludge drying Sludge grinding Lipid extraction Transesterification Biodiesel purification Cultivation of oleaginous microorganisms using sludge Biomass harvesting Biomass drying Lipid extraction from microorganisms 2nd Transesterification Biodiesel and glycerol purification | The treatment plant was designed to process 260 t/day of dry sludge | The plant scale (80 to 440 t/day of sludge) Lipid content in the biomass Lipid productivity The necessity of sterilization in the fermentation process |

| [66] | Biojet fuel, specifically farnesane, | Sugarcane bagasse | Bagasse reception and pretreatment Cellulose hydrolysis Sugars fermentation to farnesene Product recovery Farnesene upgrading to jet fuel Combined heat and power (CHP) unit | The simulated treatment plant was designed to handle a capacity of 100 t/h of dry raw bagasse | Sugars conversion: 12% to 22% Natural gas utilization (for steam reforming hydrogen production): 350 kg/h to 850 kg/h Urea consumption (fertilizer): 80 kg/ha to 160 kg/ha |

| [67] | Primary final product: butanol. By-products: acetone and ethanol (during ABE fermentation) | Corn stover | Pre-treatment of corn stover Enzymatic hydrolysis Fermentation using Clostridium species to produce ABE (acetone, butanol, ethanol) Downstream processing to separate and purify butanol, acetone, and ethanol Waste treatment and by-product management | The treatment plant simulated processes around 1000 MT/day of dry corn stover | Feedstock cost (ranging between 30 to 70 USD per dry metric ton) Enzyme loading rates and costs Fermentation yield and efficiency Capital costs and plant scale-up scenarios Operating costs, including labor, utilities, and maintenance |

| [68] | A modified acrylic bio-adhesive | Glycerol (by-product of biodiesel) | Producing acrylated glycerin (AG) via Fischer esterification of acrylic acid and bio-based glycerol. Production of the chain transfer agent (CTA). RAFT (Reversible Addition-Fragmentation Chain Transfer) polymerization of AG with CTA and azobisisobutyronitrile (AIBN) to produce polyacrylated glycerin. Precipitating the polymerized product to obtain the final liquid bio-adhesive. | Simulated plant scales: 1 t/d, 2 t/d, 5 t/d, 10 t/d, and 40 t/d | Total capital investment: +50% to −30%. Bio-adhesive selling price: ±50%. Comparison of glycerol sources: biodiesel by-product vs. crude oil-derived. Key factors in production cost: materials, labor, capital, and catalyst price. |

| [53] | Using sugar cane bagasse to produce methanol to gasoline (MTG) and butanol | Cane bagasse | Bagasse pre-treatment (crushing and drying) Gasification and syngas cleaning (for MTG process) Methanol synthesis and conversion to gasoline Cellulose hydrolysis and fermentation (for butanol process) Distillation and product recovery (for butanol process) Power generation using combined heat and power units | The simulated treatment plant processes 100 MT/h of bagasse | Technical parameters: enzyme loading and sugar conversion rates for butanol production. Catalysts cost and recycling rates for the MTG process. Parameter variations range: ±10% to ±30% |

| [69] | crystallized caffeine and powdered catechins | Black tea waste | Collection and transport of black tea waste. Leaching with hot water. Clarification and filtration. Differential extraction using dichloromethane (DCM) for caffeine or ethyl acetate (EA) for catechins. Evaporation, crystallization, and drying of caffeine and catechins. | The size of the treatment plant simulated processes 30,000 metric tons (MT) of black tea waste per year. | Leaching yield. Recovery yield of caffeine and catechins. Crystallization yield. Vaporization fraction during evaporation. The ranges for these variables were adjusted for suitable conditions based on feasibility assessments. |

| [70] | Malic acid | Crude glycerol derived from waste cooking oil | Preparation of fermentation media Seed fermentation Production fermentation In situ recovery Purification of malic acid | Production capacity of 510 t/year of malic acid | Direct fixed costs Plant volume Equipment purchase cost Crude glycerol cost Energy consumption. Variable ranges analyzed: ±20% |

| [59] | Microbial oil and carotenoids | Brewer’s spent grain, pasta processing waste and bakery waste | Fermentation Biomass recovery Separation of carotenoids and microbial oil | Working volume of 1500 L in the production bioreactors | Sensitivity analysis variables: microbial oil (MO) price and batch throughput MO price ranges: 1–4 USD/g Batch throughput ranges: 5 g to 5 kg per batch |

| Reference | Product | CAPEX (Million USD) | OPEX (Million USD) | Payback Time (Years) | NPV (Million USD) | ROI (%) | GM (%) |

|---|---|---|---|---|---|---|---|

| [52] | 11 kg/year of Monoclonal antibodies | 48.4 | 92.9 | ND | ND | 115 | 47 |

| [59] | 695.6 kg/year of carotenoids and microbial oil | 2.268 | 0.82 | 2.44 | 4.235 | 40.95 | 59.65 |

| [69] | 1.7 MT/day of crystallized caffeine and powdered catechins | 60.7 | 44.616 | 6.79 | 4.379 | 14.74 | 12.28 |

| [70] | 510 MT/year of malic acid | 7.067 | 1.179 | 7.78 | 2.246 | 12.85 | 45.16 |

| [78] | 3.95 million gallons of biodiesel | 534.07 | 149 | ND | ND | ND | ND |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aranda-Barradas, J.S.; Guerrero-Barajas, C.; Ordaz, A. Addressing Challenges in Large-Scale Bioprocess Simulations: A Circular Economy Approach Using SuperPro Designer. Processes 2025, 13, 2259. https://doi.org/10.3390/pr13072259

Aranda-Barradas JS, Guerrero-Barajas C, Ordaz A. Addressing Challenges in Large-Scale Bioprocess Simulations: A Circular Economy Approach Using SuperPro Designer. Processes. 2025; 13(7):2259. https://doi.org/10.3390/pr13072259

Chicago/Turabian StyleAranda-Barradas, Juan Silvestre, Claudia Guerrero-Barajas, and Alberto Ordaz. 2025. "Addressing Challenges in Large-Scale Bioprocess Simulations: A Circular Economy Approach Using SuperPro Designer" Processes 13, no. 7: 2259. https://doi.org/10.3390/pr13072259

APA StyleAranda-Barradas, J. S., Guerrero-Barajas, C., & Ordaz, A. (2025). Addressing Challenges in Large-Scale Bioprocess Simulations: A Circular Economy Approach Using SuperPro Designer. Processes, 13(7), 2259. https://doi.org/10.3390/pr13072259