Sustainable and Advanced Strategies for Bioremediation of Highly Contaminated Wastewater

Abstract

1. Introduction

2. Highly Contaminated Wastewater

2.1. Leachate

2.2. Distillery Wastewater

2.3. Pharmaceutical Wastewater

2.4. Brewery Wastewater

2.5. Paper Industry Wastewater

2.6. Municipal Wastewater

2.7. Field-Level Applications of Bioremediation

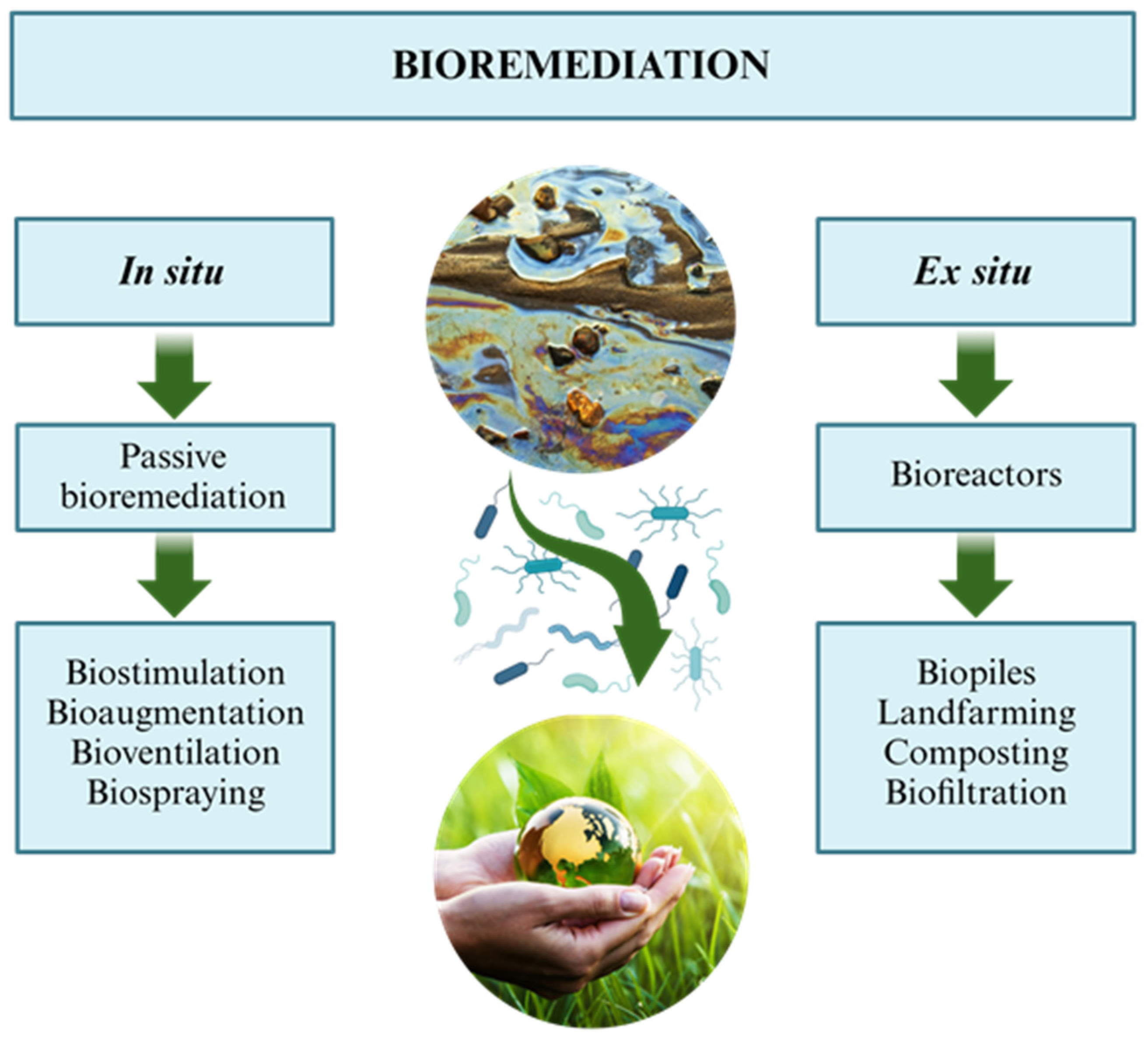

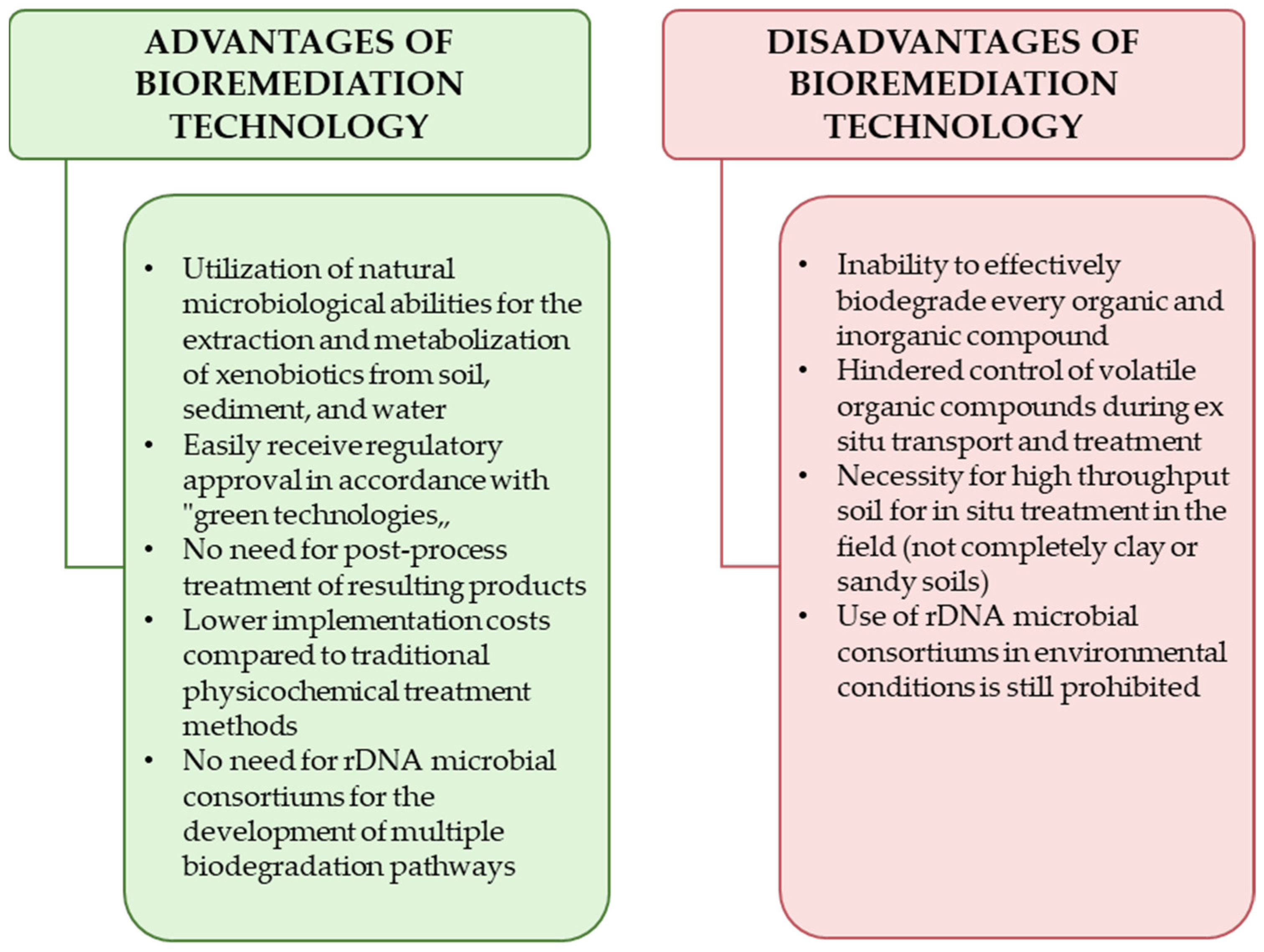

3. Fundamental Principles of Bioremediation Technology

Bioaugmentation and Biostimulation

4. Naturally Occurring Potential for Biodegradation

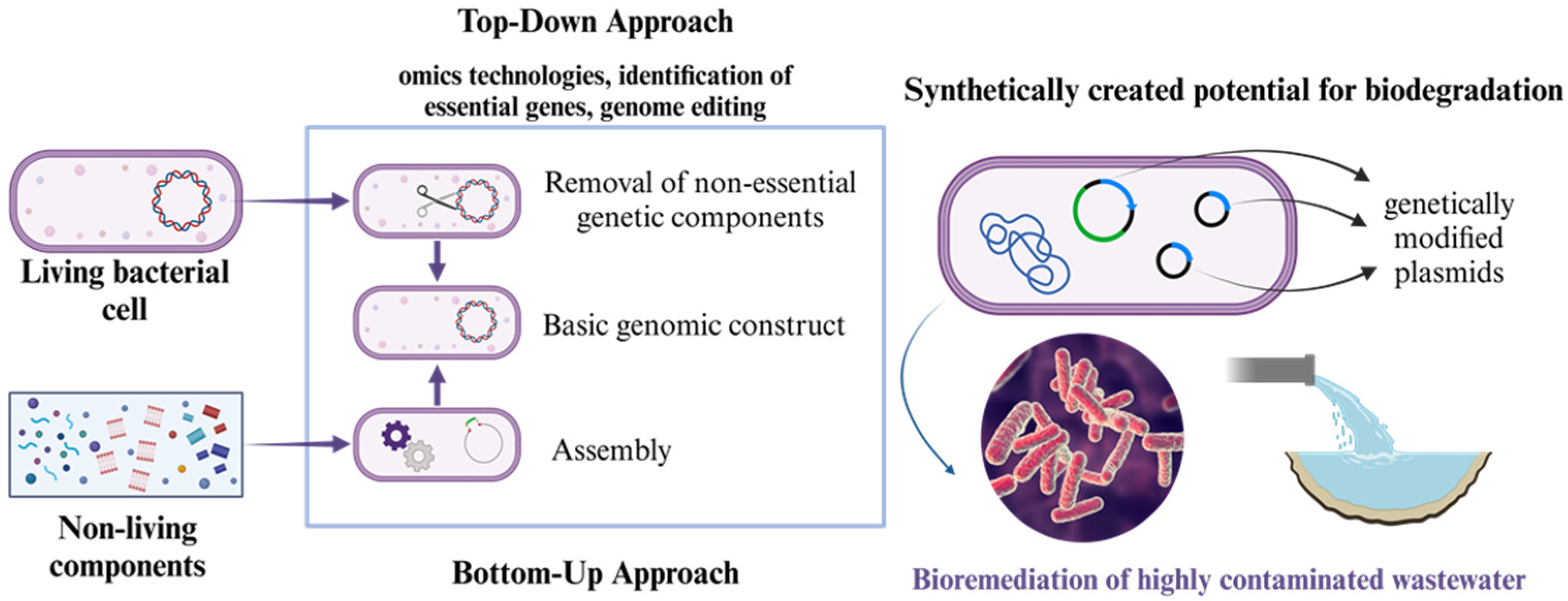

5. Synthetically Engineered Potential for Biodegradation

6. Future Perspectives

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bala, S.; Garg, D.; Thirumalesh, B.V.; Sharma, M.; Sridhar, K.; Inbaraj, B.S.; Tripathi, M. Recent Strategies for Bioremediation of Emerging Pollutants: A Review for a Green and Sustainable Environment. Toxics 2022, 10, 484. [Google Scholar] [CrossRef] [PubMed]

- Raper, E.; Stephenson, T.; Anderson, D.R.; Fisher, R.; Soares, A. Industrial Wastewater Treatment through Bioaugmentation. Process Saf. Environ. Prot. 2018, 118, 178–187. [Google Scholar] [CrossRef]

- Zrnčević, S. Farmaceutici i Metode Obrade Otpadne Vode Iz Farmaceutske Industrije. Hrvat. Vode 2016, 24, 119–136. [Google Scholar]

- Omokhagbor Adams, G.; Tawari Fufeyin, P.; Eruke Okoro, S.; Ehinomen, I. Bioremediation, Biostimulation and Bioaugmention: A Review. Int. J. Environ. Bioremediation Biodegrad. 2020, 3, 28–39. [Google Scholar] [CrossRef]

- Semrany, S.; Favier, L.; Djelal, H.; Taha, S.; Amrane, A. Bioaugmentation: Possible Solution in the Treatment of Bio-Refractory Organic Compounds (Bio-ROCs). Biochem. Eng. J. 2012, 69, 75–86. [Google Scholar] [CrossRef]

- Azubuike, C.C.; Chikere, C.B.; Okpokwasili, G.C. Bioremediation Techniques–Classification Based on Site of Application: Principles, Advantages, Limitations and Prospects. World J. Microbiol. Biotechnol. 2016, 32, 180. [Google Scholar] [CrossRef]

- Kaur, G.; Kaur, G.; Krol, M.; Kaur Brar, S. Unraveling the Mystery of Subsurface Microorganisms in Bioremediation. Curr. Res. Biotechnol. 2022, 4, 302–308. [Google Scholar] [CrossRef]

- Shah, A.; Shah, M. Characterisation and Bioremediation of Wastewater: A Review Exploring Bioremediation as a Sustainable Technique for Pharmaceutical Wastewater. Groundw. Sustain. Dev. 2020, 11, 100383. [Google Scholar] [CrossRef]

- Sharma, N.; Singh, A.; Batra, N. Modern and Emerging Methods of Wastewater Treatment. In Ecological Wisdom Inspired Restoration Engineering; Achal, V., Mukherjee, A., Eds.; EcoWISE Springer: Singapore, 2019; pp. 223–247. ISBN 9789811301483. [Google Scholar]

- Abatenh, E.; Gizaw, B.; Tsegaye, Z.; Wassie, M. The Role of Microorganisms in Bioremediation—A Review. Open J. Environ. Biol. 2017, 2, 038–046. [Google Scholar] [CrossRef]

- Masindi, V.; Osman, M.S.; Tekere, M. Mechanisms and Approaches for the Removal of Heavy Metals from Acid Mine Drainage and Other Industrial Effluents. In Water Pollution and Remediation: Heavy Metals; Inamuddin, Ahamed, M.I., Lichtfouse, E., Eds.; Environmental Chemistry for a Sustainable World; Springer International Publishing: Cham, Switzerland, 2021; Volume 53, pp. 513–537. ISBN 978-3-030-52420-3. [Google Scholar]

- Malla, M.A.; Dubey, A.; Yadav, S.; Kumar, A.; Hashem, A.; Abd Allah, E.F. Understanding and Designing the Strategies for the Microbe-Mediated Remediation of Environmental Contaminants Using Omics Approaches. Front. Microbiol. 2018, 9, 1132. [Google Scholar] [CrossRef]

- Aidarzhanovich, N.A.; Bekturovna, Y.Z.; Beisenbayuly, N.; Alaldunkyzy, S.N.; Nurzhaniyat, A.; Tureevna, L.Z. Integrating Mathematical Analysis and Biotechnological Approaches for Enhanced Environmental Management. Casp. J. Environ. Sci. 2023, 21, 1185–1201. [Google Scholar] [CrossRef]

- Česnik, M.; Findrik Blažević, Z.; Vuković Domanovac, M. Povećanje Učinkovitosti Bioremedijacije Na Razini Gena. Kem. U Ind. 2019, 68, 23–30. [Google Scholar] [CrossRef]

- Demirbas, A.; Bamufleh, H.S.; Edris, G.; Alalayah, W.M. Treatment of Contaminated Wastewater. Pet. Sci. Technol. 2017, 35, 883–889. [Google Scholar] [CrossRef]

- He, X.; Xi, B.; Wei, Z.; Guo, X.; Li, M.; An, D.; Liu, H. Spectroscopic Characterization of Water Extractable Organic Matter during Composting of Municipal Solid Waste. Chemosphere 2011, 82, 541–548. [Google Scholar] [CrossRef]

- Saeed, M.U.; Hussain, N.; Sumrin, A.; Shahbaz, A.; Noor, S.; Bilal, M.; Aleya, L.; Iqbal, H.M.N. Microbial Bioremediation Strategies with Wastewater Treatment Potentialities—A Review. Sci. Total Environ. 2022, 818, 151754. [Google Scholar] [CrossRef]

- Brown, K.; Ghoshdastidar, A.J.; Hanmore, J.; Frazee, J.; Tong, A.Z. Membrane Bioreactor Technology: A Novel Approach to the Treatment of Compost Leachate. Waste Manag. 2013, 33, 2188–2194. [Google Scholar] [CrossRef]

- Salam, M.; Nilza, N. Hazardous Components of Landfill Leachates and Its Bioremediation. In Soil Contamination—Threats and Sustainable Solutions; Larramendy, M.L., Soloneski, S., Eds.; IntechOpen: London, UK, 2021; ISBN 978-1-83880-753-5. [Google Scholar]

- Garcete, L.A.A.; Martinez, J.E.R.; Barrera, D.B.V.; Bonugli-Santos, R.C.; Passarini, M.R.Z. Biotechnological Potential of Microorganisms from Landfill Leachate: Isolation, Antibiotic Resistance and Leachate Discoloration. An. Acad. Bras. Ciênc. 2022, 94, e20210642. [Google Scholar] [CrossRef]

- Tan, B.; He, L.; Dai, Z.; Sun, R.; Jiang, S.; Lu, Z.; Liang, Y.; Ren, L.; Sun, S.; Zhang, Y.; et al. Review on Recent Progress of Bioremediation Strategies in Landfill Leachate—A Green Approach. J. Water Process Eng. 2022, 50, 103229. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Li, P.; Zhang, H.; Xie, L. Bio-Refractory Dissolved Organic Matter and Colorants in Cassava Distillery Wastewater: Characterization, Coagulation Treatment and Mechanisms. Chemosphere 2017, 178, 259–267. [Google Scholar] [CrossRef]

- Ghosh, M.; Ganguli, A.; Tripathi, A.K. Treatment of Anaerobically Digested Distillery Spentwash in a Two-Stage Bioreactor Using Pseudomonas Putida and Aeromonas Sp. Process Biochem. 2002, 37, 857–862. [Google Scholar] [CrossRef]

- Tripathi, S.; Sharma, P.; Chandra, R. Degradation of Organometallic Pollutants of Distillery Wastewater by Autochthonous Bacterial Community in Biostimulation and Bioaugmentation Process. Bioresour. Technol. 2021, 338, 125518. [Google Scholar] [CrossRef]

- Rana, R.S.; Singh, P.; Kandari, V.; Singh, R.; Dobhal, R.; Gupta, S. A Review on Characterization and Bioremediation of Pharmaceutical Industries’ Wastewater: An Indian Perspective. Appl. Water Sci. 2017, 7, 1–12. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Chang, J.-S.; Vigneswaran, S.; Kandasamy, J. Pharmaceutical Wastewater Treatment by Membrane Bioreactor Process—A Case Study in Southern Taiwan. Desalination 2008, 234, 393–401. [Google Scholar] [CrossRef]

- Papadopoulos, K.P.; Economou, C.N.; Dailianis, S.; Charalampous, N.; Stefanidou, N.; Moustaka-Gouni, M.; Tekerlekopoulou, A.G.; Vayenas, D.V. Brewery Wastewater Treatment Using Cyanobacterial-Bacterial Settleable Aggregates. Algal Res. 2020, 49, 101957. [Google Scholar] [CrossRef]

- Hultberg, M.; Bodin, H. Fungi-Based Treatment of Real Brewery Waste Streams and Its Effects on Water Quality. Bioprocess Biosyst. Eng. 2019, 42, 1317–1324. [Google Scholar] [CrossRef]

- Srivastava, A.; Singh, P.; Srivastava, S.; Singh, S. Reclamation and Characterization of Value-Added Products from Pulp and Paper Mill Effluent Using Microbial Fuel Cell. Mater. Today Proc. 2023. S221478532300980X. [Google Scholar] [CrossRef]

- Ayed, L.; Chakroun, I.; Zmantar, T.; Jabeur, C. The Use of Sugarcane Bagasse and Yeast Extract as Agro-Industrial Coproducts for Bioremediation Strategies of Paper Mill Wastewater Using Pseudomonas Putida. Water Air. Soil Pollut. 2023, 234, 470. [Google Scholar] [CrossRef]

- Gugel, I.; Summa, D.; Costa, S.; Manfredini, S.; Vertuani, S.; Marchetti, F.; Tamburini, E. Mycoremediation of Synthetic Azo Dyes by White-Rot Fungi Grown on Diary Waste: A Step toward Sustainable and Circular Bioeconomy. Fermentation 2024, 10, 80. [Google Scholar] [CrossRef]

- Gerba, C.P.; Pepper, I.L. Municipal Wastewater Treatment. In Environmental and Pollution Science; Elsevier: Amsterdam, The Netherlands, 2019; pp. 393–418. ISBN 978-0-12-814719-1. [Google Scholar]

- Isik, O.; Batyrow, M.; Abdelrahman, A.M.; Orman, I.; Ozgun, H.; Ersahin, M.E.; Pasaoglu, M.E.; Demir, I.; Koyuncu, I. Dynamic Membrane Bioreactor Performance for Treatment of Municipal Wastewaters at Different Sludge Concentrations. Environ. Technol. Innov. 2021, 22, 101452. [Google Scholar] [CrossRef]

- Wan, C.-Y.; De Wever, H.; Diels, L.; Thoeye, C.; Liang, J.-B.; Huang, L.-N. Biodiversity and Population Dynamics of Microorganisms in a Full-Scale Membrane Bioreactor for Municipal Wastewater Treatment. Water Res. 2011, 45, 1129–1138. [Google Scholar] [CrossRef]

- Oreščanin, V. Procjedne Vode Odlagališta Otpada–Kemijski Sastav, Toksični Učinci i Metode Pročišćavanja. Hrvat. Vode 2014, 87, 379–390. [Google Scholar]

- Hossain, K.; Ismail, N. Bioremediation and Detoxification of Pulp and Paper Mill Effluent: A Review. Res. J. Environ. Toxicol. 2015, 9, 113–134. [Google Scholar] [CrossRef]

- Starzec, K.; Stańkowska, E.; Supel, P.; Mazur, R.; Surma, P.; Kaszycki, P. Microbiological treatment of post-industrial water: Example of efficient bioremediation of the heavily polluted Kalina pond, Poland. J. Water Land Dev. 2024, 60, 236–245. [Google Scholar] [CrossRef]

- Kupiec, J.M.; Bednarek, A.; Szklarek, S.; Mankiewicz-Boczek, J.; Serwecińska, L.; Dąbrowska, J. Evaluation of the Effectiveness of the SED-BIO System in Reducing the Inflow of Selected Physical, Chemical and Biological Pollutants to a Lake. Water 2022, 14, 239. [Google Scholar] [CrossRef]

- Bragg, J.R.; Prince, R.C.; Harner, E.J.; Atlas, R.M. Bioremediation effectiveness following the exxon valdez spill. Int. Oil Spill Conf. Proc. 1993, 1993, 435–447. [Google Scholar] [CrossRef]

- Bharadwaj, A. Bioremediation of Xenobiotics: An Eco-Friendly Cleanup Approach. In Green Chemistry in Environmental Sustainability and Chemical Education; Parmar, V.S., Malhotra, P., Mathur, D., Eds.; Springer: Singapore, 2018; pp. 1–13. ISBN 978-981-10-8389-1. [Google Scholar]

- Kuppan, N.; Padman, M.; Mahadeva, M.; Srinivasan, S.; Devarajan, R. A Comprehensive Review of Sustainable Bioremediation Techniques: Eco Friendly Solutions for Waste and Pollution Management. Waste Manag. Bull. 2024, 2, 154–171. [Google Scholar] [CrossRef]

- Júlio, A.D.L.; Fernandes, R.D.C.R.; Costa, M.D.; Neves, J.C.L.; Rodrigues, E.M.; Tótola, M.R. A New Biostimulation Approach Based on the Concept of Remaining P for Soil Bioremediation. J. Environ. Manage. 2018, 207, 417–422. [Google Scholar] [CrossRef]

- Vuković Domanovac, M.; Šabić Runjavec, M.; Janton, N.; Kučić Grgić, D. Bioremedijacija farmaceutske otpadne vode. Kem. U Ind. 2019, 68, 437–445. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, L.; Xiang, F.; Zhao, L.; Qiao, Z. Activated Sludge Microbial Community and Treatment Performance of Wastewater Treatment Plants in Industrial and Municipal Zones. Int. J. Environ. Res. Public Health 2020, 17, 436. [Google Scholar] [CrossRef]

- Liu, X.; Nie, Y.; Wu, X.-L. Predicting Microbial Community Compositions in Wastewater Treatment Plants Using Artificial Neural Networks. Microbiome 2023, 11, 93. [Google Scholar] [CrossRef] [PubMed]

- Ibáñez, J.; Pérez-de-Mora, A.; Santiago-Herrera, M.; Belloncle, B.; De Wilde, H.; Martel-Martín, S.; Blanco-Alcántara, D.; Barros, R. Environmental and Socio-Economic Evaluation of a Groundwater Bioremediation Technology Using Social Cost-Benefit Analysis: Application to an in-Situ Metal(Loid) Precipitation Case Study. Sci. Total Environ. 2024, 954, 176720. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Hou, D.; Zhang, J.; O’Connor, D.; Li, G.; Gu, Q.; Li, S.; Liu, P. Environmental and Socio-Economic Sustainability Appraisal of Contaminated Land Remediation Strategies: A Case Study at a Mega-Site in China. Sci. Total Environ. 2018, 610–611, 391–401. [Google Scholar] [CrossRef] [PubMed]

- Komen, J. The Emerging International Regulatory Framework for Biotechnology. GM Crops Food 2012, 3, 78–84. [Google Scholar] [CrossRef]

- Majone, M.; Verdini, R.; Aulenta, F.; Rossetti, S.; Tandoi, V.; Kalogerakis, N.; Agathos, S.; Puig, S.; Zanaroli, G.; Fava, F. In Situ Groundwater and Sediment Bioremediation: Barriers and Perspectives at European Contaminated Sites. New Biotechnol. 2015, 32, 133–146. [Google Scholar] [CrossRef]

- Khanam, Z.; Sultana, F.M.; Mushtaq, F. Environmental Pollution Control Measures and Strategies: An Overview of Recent Developments. In Geospatial Analytics for Environmental Pollution Modeling; Mushtaq, F., Farooq, M., Mukherjee, A.B., Ghosh Nee Lala, M., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 385–414. ISBN 978-3-031-45299-4. [Google Scholar]

- Cervelli, E.; Pindozzi, S.; Capolupo, A.; Okello, C.; Rigillo, M.; Boccia, L. Ecosystem Services and Bioremediation of Polluted Areas. Ecol. Eng. 2016, 87, 139–149. [Google Scholar] [CrossRef]

- Mendoza-Burguete, Y.; De La Luz Pérez-Rea, M.; Ledesma-García, J.; Campos-Guillén, J.; Ramos-López, M.A.; Guzmán, C.; Rodríguez-Morales, J.A. Global Situation of Bioremediation of Leachate-Contaminated Soils by Treatment with Microorganisms: A Systematic Review. Microorganisms 2023, 11, 857. [Google Scholar] [CrossRef]

- Kuppusamy, S.; Venkateswarlu, K.; Megharaj, M.; Vasudevan, N.; Lee, Y.B. Chapter 11. Biostimulation and Bioaugmentation: Modern Strategies for the Successful Bioremediation of Contaminated Environments. In The Handbook of Environmental Remediation; Hussain, C.M., Ed.; Royal Society of Chemistry: Cambridge, UK, 2020; pp. 299–330. ISBN 978-1-78801-380-2. [Google Scholar]

- Wang, J.; Zhang, L.; He, Y.; Ji, R. Biodegradation of Phenolic Pollutants and Bioaugmentation Strategies: A Review of Current Knowledge and Future Perspectives. J. Hazard. Mater. 2024, 469, 133906. [Google Scholar] [CrossRef]

- Herrero, M.; Stuckey, D.C. Bioaugmentation and Its Application in Wastewater Treatment: A Review. Chemosphere 2015, 140, 119–128. [Google Scholar] [CrossRef]

- Chettri, D.; Verma, A.K.; Verma, A.K. Bioaugmentation: An Approach to Biological Treatment of Pollutants. Biodegradation 2024, 35, 117–135. [Google Scholar] [CrossRef]

- Tyagi, M.; Da Fonseca, M.M.R.; De Carvalho, C.C.C.R. Bioaugmentation and Biostimulation Strategies to Improve the Effectiveness of Bioremediation Processes. Biodegradation 2011, 22, 231–241. [Google Scholar] [CrossRef]

- Dzionek, A.; Wojcieszyńska, D.; Guzik, U. Natural Carriers in Bioremediation: A Review. Electron. J. Biotechnol. 2016, 23, 28–36. [Google Scholar] [CrossRef]

- Garbisu, C.; Garaiyurrebaso, O.; Epelde, L.; Grohmann, E.; Alkorta, I. Plasmid-Mediated Bioaugmentation for the Bioremediation of Contaminated Soils. Front. Microbiol. 2017, 8, 1966. [Google Scholar] [CrossRef] [PubMed]

- Tribedi, P.; Goswami, M.; Chakraborty, P.; Mukherjee, K.; Mitra, G.; Bhattacharyya, P.; Dey, S. Bioaugmentation and Biostimulation: A Potential Strategy for Environmental Remediation. J. Microbiol. Exp. 2018, 6, 223–231. [Google Scholar] [CrossRef]

- Wu, M.; Dick, W.A.; Li, W.; Wang, X.; Yang, Q.; Wang, T.; Xu, L.; Zhang, M.; Chen, L. Bioaugmentation and Biostimulation of Hydrocarbon Degradation and the Microbial Community in a Petroleum-Contaminated Soil. Int. Biodeterior. Biodegrad. 2016, 107, 158–164. [Google Scholar] [CrossRef]

- Andreolli, M.; Lampis, S.; Brignoli, P.; Vallini, G. Bioaugmentation and Biostimulation as Strategies for the Bioremediation of a Burned Woodland Soil Contaminated by Toxic Hydrocarbons: A Comparative Study. J. Environ. Manage. 2015, 153, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Q.-B.; Shen, Y.; Huang, Y.-M.; Hu, N. A Comparative Study of Aeration, Biostimulation and Bioaugmentation in Contaminated Urban River Purification. Environ. Technol. Innov. 2018, 11, 276–285. [Google Scholar] [CrossRef]

- Nivetha, N.; Srivarshine, B.; Sowmya, B.; Rajendiran, M.; Saravanan, P.; Rajeshkannan, R.; Rajasimman, M.; Pham, T.H.T.; Shanmugam, V.; Dragoi, E.-N. A Comprehensive Review on Bio-Stimulation and Bio-Enhancement towards Remediation of Heavy Metals Degeneration. Chemosphere 2023, 312, 137099. [Google Scholar] [CrossRef]

- Romantschuk, M.; Lahti-Leikas, K.; Kontro, M.; Galitskaya, P.; Talvenmäki, H.; Simpanen, S.; Allen, J.A.; Sinkkonen, A. Bioremediation of Contaminated Soil and Groundwater by in Situ Biostimulation. Front. Microbiol. 2023, 14, 1258148. [Google Scholar] [CrossRef]

- Hassan, A.; Hamid, F.S.; Pariatamby, A.; Suhaimi, N.S.M.; Razali, N.M.B.M.; Ling, K.N.H.; Mohan, P. Bioaugmentation-Assisted Bioremediation and Biodegradation Mechanisms for PCB in Contaminated Environments: A Review on Sustainable Clean-up Technologies. J. Environ. Chem. Eng. 2023, 11, 110055. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, Y.; Yang, K.; Wang, Y.; Zhang, C.; Ji, M. Application Oriented Bioaugmentation Processes: Mechanism, Performance Improvement and Scale-Up. Bioresour. Technol. 2022, 344, 126192. [Google Scholar] [CrossRef]

- Xie, M.; Zhang, X.; Jing, Y.; Du, X.; Zhang, Z.; Tan, C. Review on Research and Application of Enhanced In-Situ Bioremediation Agents for Organic Pollution Remediation in Groundwater. Water 2024, 16, 456. [Google Scholar] [CrossRef]

- Fragkou, E.; Antoniou, E.; Daliakopoulos, I.; Manios, T.; Theodorakopoulou, M.; Kalogerakis, N. In Situ Aerobic Bioremediation of Sediments Polluted with Petroleum Hydrocarbons: A Critical Review. J. Mar. Sci. Eng. 2021, 9, 1003. [Google Scholar] [CrossRef]

- Hussain, A.; Rehman, F.; Rafeeq, H.; Waqas, M.; Asghar, A.; Afsheen, N.; Rahdar, A.; Bilal, M.; Iqbal, H.M.N. In-Situ, Ex-Situ, and Nano-Remediation Strategies to Treat Polluted Soil, Water, and Air—A Review. Chemosphere 2022, 289, 133252. [Google Scholar] [CrossRef] [PubMed]

- Naseem, M.; Syab, S.; Akhtar, S.; Ikram, M.; Batool, M.; Saeed, Z.; Iqbal, S.; Sattar, H. Ex-Situ and In-Situ Bioremediation Strategies and Their Limitations for Solid Waste Management: A Mini-Review. J. Qual. Assur. Agric. Sci. 2023, 3, 28–31. [Google Scholar] [CrossRef]

- Micle, V.; Sur, I.M. Experimental Investigation of a Pilot-Scale Concerning Ex-Situ Bioremediation of Petroleum Hydrocarbons Contaminated Soils. Sustainability 2021, 13, 8165. [Google Scholar] [CrossRef]

- Zhang, M.; Shao, W.; Chen, Z.; Liu, C.; Li, W.; Tian, T.; Wang, J.; Chen, Z.; Qiao, W.; Gu, C. Advanced Oxidation Processes of Persulfate Coupled with Sequencing Batch Reactor Activated Sludge Process (AOPs-SBR): Biodegradability and Toxicity Analysis of Degradation Intermediates. Sep. Purif. Technol. 2025, 354, 128921. [Google Scholar] [CrossRef]

- Attarian, P.; Mokhtarani, N. Comparison of Co-Metabolic and Direct Metabolic Biodegradation of MTBE: Monitoring Main Intermediates and SBR Stable Operation. Environ. Technol. Innov. 2021, 22, 101475. [Google Scholar] [CrossRef]

- Aghapour, A.A.; Alizadeh, N.; Khorsandi, H. Biological Degradation and Mineralization of Tetracycline Antibiotic Using SBR Equipped with a Vertical Axially Rotating Biological Bed (SBR-VARB). Biodegradation 2023, 34, 325–340. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Liu, L.; Lee, K.; Miao, J. Review of Biological Processes in a Membrane Bioreactor (MBR): Effects of Wastewater Characteristics and Operational Parameters on Biodegradation Efficiency When Treating Industrial Oily Wastewater. J. Mar. Sci. Eng. 2022, 10, 1229. [Google Scholar] [CrossRef]

- Gharibian, S.; Hazrati, H. Towards Practical Integration of MBR with Electrochemical AOP: Improved Biodegradability of Real Pharmaceutical Wastewater and Fouling Mitigation. Water Res. 2022, 218, 118478. [Google Scholar] [CrossRef]

- Qrenawi, L.; Rabah, F. Membrane Bioreactor (MBR) as a Reliable Technology for Wastewater Treatment: Review. J. Membr. Sci. Res. 2022, 9. [Google Scholar] [CrossRef]

- Garbisu, C.; Alkorta, I. Basic Concepts on Heavy Metal Soil Bioremediation. Eur. J. Miner. Process. Environ. Prot. 2003, 3, 58–66. [Google Scholar]

- Gonçalves, C.R.; Delabona, P. da S. Strategies for Bioremediation of Pesticides: Challenges and Perspectives of the Brazilian Scenario for Global Application—A Review. Environ. Adv. 2022, 8, 100220. [Google Scholar] [CrossRef]

- Gajendiran, A.; Krishnamoorthy, S.; Abraham, J. Microbial Degradation of Low-Density Polyethylene (LDPE) by Aspergillus Clavatus Strain JASK1 Isolated from Landfill Soil. 3 Biotech 2016, 6, 52. [Google Scholar] [CrossRef] [PubMed]

- Wani, A.K.; Akhtar, N.; Naqash, N.; Chopra, C.; Singh, R.; Kumar, V.; Kumar, S.; Mulla, S.I.; Américo-Pinheiro, J.H.P. Bioprospecting Culturable and Unculturable Microbial Consortia through Metagenomics for Bioremediation. Clean. Chem. Eng. 2022, 2, 100017. [Google Scholar] [CrossRef]

- Agrawal, K.; Verma, P. Degradation and Detoxification of Waste via Bioremediation: A Step toward Sustainable Environment. In Emerging Technologies in Environmental Bioremediation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–83. ISBN 978-0-12-819860-5. [Google Scholar]

- Chernysh, Y.; Chubur, V.; Ablieieva, I.; Skvortsova, P.; Yakhnenko, O.; Skydanenko, M.; Plyatsuk, L.; Roubík, H. Soil Contamination by Heavy Metals and Radionuclides and Related Bioremediation Techniques: A Review. Soil Syst. 2024, 8, 36. [Google Scholar] [CrossRef]

- Misra, B.B.; Langefeld, C.; Olivier, M.; Cox, L.A. Integrated Omics: Tools, Advances and Future Approaches. J. Mol. Endocrinol. 2019, 62, R21–R45. [Google Scholar] [CrossRef]

- Brito, I.L. Examining Horizontal Gene Transfer in Microbial Communities. Nat. Rev. Microbiol. 2021, 19, 442–453. [Google Scholar] [CrossRef]

- Bisht, S.; Pandey, P.; Bhargava, B.; Sharma, S.; Kumar, V.; Sharma, K.D. Bioremediation of Polyaromatic Hydrocarbons (PAHs) Using Rhizosphere Technology. Braz. J. Microbiol. 2015, 46, 7–21. [Google Scholar] [CrossRef]

- Wang, W.; Wang, L.; Shao, Z. Polycyclic Aromatic Hydrocarbon (PAH) Degradation Pathways of the Obligate Marine PAH Degrader Cycloclasticus Sp. Strain P1. Appl. Environ. Microbiol. 2018, 84, e01261-18. [Google Scholar] [CrossRef]

- Poi, G.; Aburto-Medina, A.; Mok, P.C.; Ball, A.S.; Shahsavari, E. Bioremediation of Phenol-Contaminated Industrial Wastewater Using a Bacterial Consortium—From Laboratory to Field. Water Air Soil Pollut. 2017, 228, 89. [Google Scholar] [CrossRef]

- Gu, Q.; Wu, Q.; Zhang, J.; Guo, W.; Ding, Y.; Wang, J.; Wu, H.; Sun, M.; Hou, L.; Wei, X.; et al. Isolation and Transcriptome Analysis of Phenol-Degrading Bacterium From Carbon–Sand Filters in a Full-Scale Drinking Water Treatment Plant. Front. Microbiol. 2018, 9, 2162. [Google Scholar] [CrossRef]

- Sebastian, P.M.; Bhaskara Rao, K.V. Approaches in Bioremediation of Dioxins and Dioxin-Like Compounds—A Review on Current and Future Prospects. Nat. Environ. Pollut. Technol. 2022, 21, 1381–1387. [Google Scholar] [CrossRef]

- Colquhoun, D.R.; Hartmann, E.M.; Halden, R.U. Proteomic Profiling of the Dioxin-Degrading Bacterium Sphingomonas wittichii RW1. BioMed Res. Int. 2012, 2012, 408690. [Google Scholar] [CrossRef]

- Bento, F.M.; Camargo, F.A.D.O.; Okeke, B.; Frankenberger-Júnior, W.T. Bioremediation of Soil Contaminated by Diesel Oil. Braz. J. Microbiol. 2003, 34, 65–68. [Google Scholar] [CrossRef]

- Khade, S.M.; Srivastava, S.K. Genetically Modified Microbes for Bioremediation of Oil Spills in Marine Environment. In Bioremediation: Current Research and Applications; Rathoure, A.K., Ed.; I K International Publishing House: New Delhi, India, 2017; pp. 231–251. ISBN 978-93-85909-60-3. [Google Scholar]

- Verma, S.; Kuila, A. Bioremediation of Heavy Metals by Microbial Process. Environ. Technol. Innov. 2019, 14, 100369. [Google Scholar] [CrossRef]

- Shekher Giri, B.; Geed, S.; Vikrant, K.; Lee, S.S.; Kim, K.-H.; Kumar Kailasa, S.; Vithanage, M.; Chaturvedi, P.; Nath Rai, B.; Sharan Singh, R. Progress in Bioremediation of Pesticide Residues in the Environment. Environ. Eng. Res. 2020, 26, 200446. [Google Scholar] [CrossRef]

- Bajaj, A.; Mayilraj, S.; Mudiam, M.K.R.; Patel, D.K.; Manickam, N. Isolation and Functional Analysis of a Glycolipid Producing Rhodococcus Sp. Strain IITR03 with Potential for Degradation of 1,1,1-Trichloro-2,2-Bis(4-Chlorophenyl)Ethane (DDT). Bioresour. Technol. 2014, 167, 398–406. [Google Scholar] [CrossRef]

- Mahmoudi Jalali, F.; Chahkandi, B.; Gheibi, M.; Eftekhari, M.; Behzadian, K.; Campos, L.C. Developing a Smart and Clean Technology for Bioremediation of Antibiotic Contamination in Arable Lands. Sustain. Chem. Pharm. 2023, 33, 101127. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Z.; Deng, L.; Niu, D.; Fan, B.; Huhe, T.; Li, Z.; Zhang, J.; Li, C. Biodegradation of Erythromycin by Delftia Lacustris RJJ-61 and Characterization of Its Erythromycin Esterase. J. Basic Microbiol. 2021, 61, 55–62. [Google Scholar] [CrossRef]

- Caruso, G. Plastic Degrading Microorganisms as a Tool for Bioremediation of Plastic Contamination in Aquatic Environments. J. Pollut. Eff. Control 2015, 3, 1–2. [Google Scholar] [CrossRef]

- Ghatge, S.; Yang, Y.; Ahn, J.-H.; Hur, H.-G. Biodegradation of Polyethylene: A Brief Review. Appl. Biol. Chem. 2020, 63, 27. [Google Scholar] [CrossRef]

- Zhao, L.; Dai, T.; Qiao, Z.; Sun, P.; Hao, J.; Yang, Y. Application of Artificial Intelligence to Wastewater Treatment: A Bibliometric Analysis and Systematic Review of Technology, Economy, Management, and Wastewater Reuse. Process Saf. Environ. Prot. 2020, 133, 169–182. [Google Scholar] [CrossRef]

- Singh, K.R.; Nagpure, G.; Singh, J.; Singh, R.P. Introduction. In Nanobiotechnology for Bioremediation; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–21. ISBN 978-0-323-91767-4. [Google Scholar]

- Janssen, D.B.; Stucki, G. Perspectives of Genetically Engineered Microbes for Groundwater Bioremediation. Environ. Sci. Process. Impacts 2020, 22, 487–499. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, S.; Yin, R.; Wang, J.; Wang, Y.; Ren, H. Machine Learning Assisted in Situ Synthesis of Functional Microbiomes towards Sustainable Wastewater Treatment. Commun. Earth Environ. 2025, 6, 509. [Google Scholar] [CrossRef]

| Wastewater Type | COD, mg O2/L | BOD5, mg O2/L | Other Contamination Indicators | Treatment Example | Reference |

|---|---|---|---|---|---|

| Industrial– Distillery | 80,000–100,000 | 40,000–60,000 | pH 3.9–4.5 TN 680–900 mg/L EC 6.3–6.7 ms/cm Dark brown colour | COD reduced following treatment in a two-stage bioreactor: Pseudomonas putida 44% and Aeromonas sp. 66%, within 24 h. | [22,23] |

| Landfill Leachate | 100–79,000 | 3–25,000 | pH 5.8–8.5 TSS 13–5000 mg/L TN 5–13,000 mg/L | COD removal efficiency through SBR treatment ranges from 62 to 75%, data significantly vary depending on landfill age and climatic conditions. | [35] |

| Industrial– Pharmaceutical | 250–60,000 | 1–21,000 | pH 6.6–9.4 TSS 60–360 mg/L EC 518–2840 ms/cm | MBR technology for pharmaceutical industry wastewater removed over 95% of COD and 99% of BOD. | [26] |

| Industrial– Breweries | 80,000–90,000 | 8000–65,000 | pH 5.1 TN 730–778 mg/L TP 367–385 mg/L | Highly loaded brewery wastewaters treated with P. ostreatus, COD removal rate was 77%. | [28] |

| Industrial– Pulp and Paper | 6300–6500 | 860–950 | pH 5.5 TSS 1309 mg/L Intense colouration, dissolved lignin, high concentration of chlorinated compounds | Highly loaded wastewaters from the paper industry treated with Bacillus subtilis and Micrococcus luteus, COD removal percentage 97%, BOD 87% over 9 days. | [36] |

| Municipal | 500–1200 | 200–600 | pH 7.5 TSS 258–282 mg/L TN 50–55 mg/L TP 7.4–7.5 mg/L Turbidity 221–244 NTU | Treatment in an aerobic MBR removed 89% of COD value. | [33] |

| Environmental Components | Soil, Water, Sediment |

|---|---|

| Inoculum Concentration | Optimal amount of added autochthonous/exogenous microbiological cultures for a successful biodegradation process |

| Oxygen Concentration | Depends on the specific needs of individual microorganisms; obligate aerobes, obligate anaerobes, facultative anaerobes, aerotolerant anaerobes, microaerophiles |

| Metal Concentration | Essential metal concentration is necessary, heavy metal concentration is inhibitory |

| Moisture | Depends on the environmental component; the optimal ratio is 60% |

| Salinity | Halotolerant (0–5% NaCl), mildly to extremely halophilic microorganisms (2–30% NaCl) |

| Nutrients (C:N:P) | 100:10:1 |

| Temperature | 20–30 °C; enzyme activity range and highest efficiency of biodegradation |

| pH | 6–8 |

| Type of Method | Removal Efficiency | Applicability | Cost-Effectiveness | System Scalability | Environmental Footprint | Process Implementation Time | References |

|---|---|---|---|---|---|---|---|

| Biostimulation | Enhanced biodegradation increases with increased microbial activity, with an average improvement of 80% to over 90. Some by-products remain as partially degraded compounds. | In situ application for the treatment of contaminated soil layers and surface waters by adding nutrients, oxygen, or electron donors/acceptors. Ex situ application in reactor systems to optimise the biodegradation process. Possible complications include excessive stimulation of the process (overgrowth of biomass and lack of oxygen in the soil pores). | A cost-efficient process. The operating costs include the procurement of nutrients (substrate, nutrients, and oxygen) and transport vehicles to bring them to the intended location, without the need for expensive equipment. | High scalability for the specified process. Easy expansion of scalability from pilot plants to large wastewater treatment plants and contaminated areas. | It is an innovative green treatment method, as it only minimally disturbs the natural balance of ecosystems. No additional energy consumption is required. | The achievable contamination reduction is 50–70% over several months, depending on the initial contaminant load and the chosen treatment approach (in situ field application vs. ex situ reactor systems). | [53,64,65] |

| Bioaugmentation | It significantly accelerates the degradation rate of persistent organic pollutants. Studies show varying effectiveness and the possibility of partial degradation of xenobiotics. Both indigenous and exogenous microbial communities require association with biostimulation techniques. | Broadly applicable for ex situ (biofilters, reactor systems) and in situ applications (field sites, surface water, and groundwater). Process control (C/N/P, pH, and dissolved oxygen) is required to maintain biomass viability and metabolic activity in the field. | Less costly than conventional physico-chemical treatment processes, as only reactors for the cultivation of biomass are required as process equipment. The process costs increase with the energy requirement if larger quantities of biomass have to be produced (aeration, mixing). | Favourable scale-up potential from laboratory to pilot plant and field applications but requires strain adaptation. Ex situ implementation is often limited by competing interactions between introduced strains and the indigenous microbiota. | Favourable ecological effects, as natural microorganisms are used as inoculum, thus eliminating the need for costly and aggressive chemicals. Particular caution is required when genetically modified strains are used, as they could be competitive with indigenous strains in the ecosystem. | When using tested microbial consortia and under controlled conditions, optimal degradation kinetics generally require weeks to months to fully remediate a site while maintaining environmental safety and reducing by-product production. | [56,66,67] |

| In situ bioremediation | A number of variables influence efficacy, including chemical composition, bioavailability of contaminants to microorganisms, environment, and appropriate process control. | Application of a biodegradation technique in situ at the site of contamination without relocation. This includes techniques such as biosparging, bioventing, biostimulation, bioaugmentation, and phytoremediation, which require a minimum of physical intervention. | This approach is less costly than ex situ treatment as it does not require excavation, transport, or processing in specialised facilities. Infrastructure investment costs are limited to minor construction projects, process control equipment, biomass spraying systems and water recirculation devices. The overall implementation of the project takes longer. | High adaptability—the process can be adapted to the size of the contamination site. For smaller areas, there are technical solutions such as injection wells and special drainage systems, while for larger sites, methods for irrigation with nutrients or the application of biomass are used. Maintaining uniform process conditions proves difficult in extensive, heterogeneous areas. | The most environmentally sustainable remediation approach that only minimally disturbs the balance of ecosystems. As no material transport is required, the risk of secondary emissions is eliminated and environmental damage caused by excavation work is avoided. Energy consumption is limited to the operation of pumps and compressors. | The biodegradation process requires a longer duration, as natural degradation processes are slow by nature and often take years. This makes long-term monitoring necessary. For urgent remediation scenarios involving highly toxic contaminants, treatment in an ex situ reactor is a more suitable alternative. | [68,69,70] |

| Ex situ bioremediation | Exceptionally high efficiency under controlled conditions enables complete degradation with more than 99% contaminant removal. Strict process control (pH, temperature, and agitation) combined with biofilters removes virtually all known organic contaminants. | Applicable when physical access to contaminated zones is possible, e.g., industrial wastewater streams. High implementation complexity with excavation, transport, multi-stage treatment, and subsequent by-product/sludge management. Requires constant monitoring by operators, full process automation, and comprehensive maintenance support. Technically more demanding than in situ processes. | Significant initial costs due to excavation, transport, reactor system, plant design, and waste management. Treatment is faster and more efficient, reducing long-term monitoring costs. Economic compensation can be achieved through anaerobic reactor treatment with biogas production. | The scalability is high—it ranges from small reactor systems for limited quantities of wastewater to larger technical units for the treatment of large quantities, which require higher investment costs. Spatial and temporal components become significant challenges for scaling. | Moderate sustainability and environmental footprint compared to passive methods; higher resource requirements for excavation/transport fuel and process energy requirements. Better resource utilisation is achieved through biogas production during anaerobic treatment or recycling of wastewater. Long-term benefits for the ecosystem result from the rapid removal of contaminants. | Rapid contaminant removal. In specially designed reactors with contaminant-specific inoculum, biodegradation takes place within days to weeks. Complete remediation of the site is achieved within months, whereas years are required for passive treatment methods. | [70,71,72] |

| SBR (Sequencing Batch Reactor) | A well designed and operated SBR system achieves 90–98% removal of COD, BOD, and suspended solids. The system has proven itself with an 85% COD reduction in wastewater from the textile industry, 97% reduction in initial BOD5 levels in landfill leachate, and 95% ammonia removal. Batch operation improves microbial resistance to toxic conditions. | Excellent for wastewater treatment through different process cycles: inoculation, aeration, settling, and discharge of wastewater. Suitable for various wastewater streams, including landfill leachate, wastewater from the food/pharmaceutical industry, and wastewater from the agricultural industry. | A cost-effective and efficient process that does not require separate tanks, clarifiers, or sedimentation tanks—all treatment takes place in a single reactor tank, which significantly reduces investment costs. Although the operating costs include the energy required to implement the process, these are offset by the rapid completion of treatment and the high quality of the wastewater, resulting in long-term savings. | Excellent scalability: from household/commercial SBR units to large municipal SBR plants. Small systems use a single reactor, while larger plants require parallel SBR units (modular operation). Effective automatic cycle monitoring by the operators is essential. | Low environmental footprint. Space-efficient design eliminates the need for separate basins. Intermittent operating mode: no continuous oxygen supply required—aeration is phased (pumps are deactivated during settling and draining phases). Extended endogenous respiration reduces the production of active sludge as secondary waste. | A fast cyclical process with daily operating cycles of 5–8 h ensures a constant, visible daily treatment performance. Although the settling time is extended to 60 min, this duration is justified as it eliminates the need for additional clarifiers. | [73,74,75] |

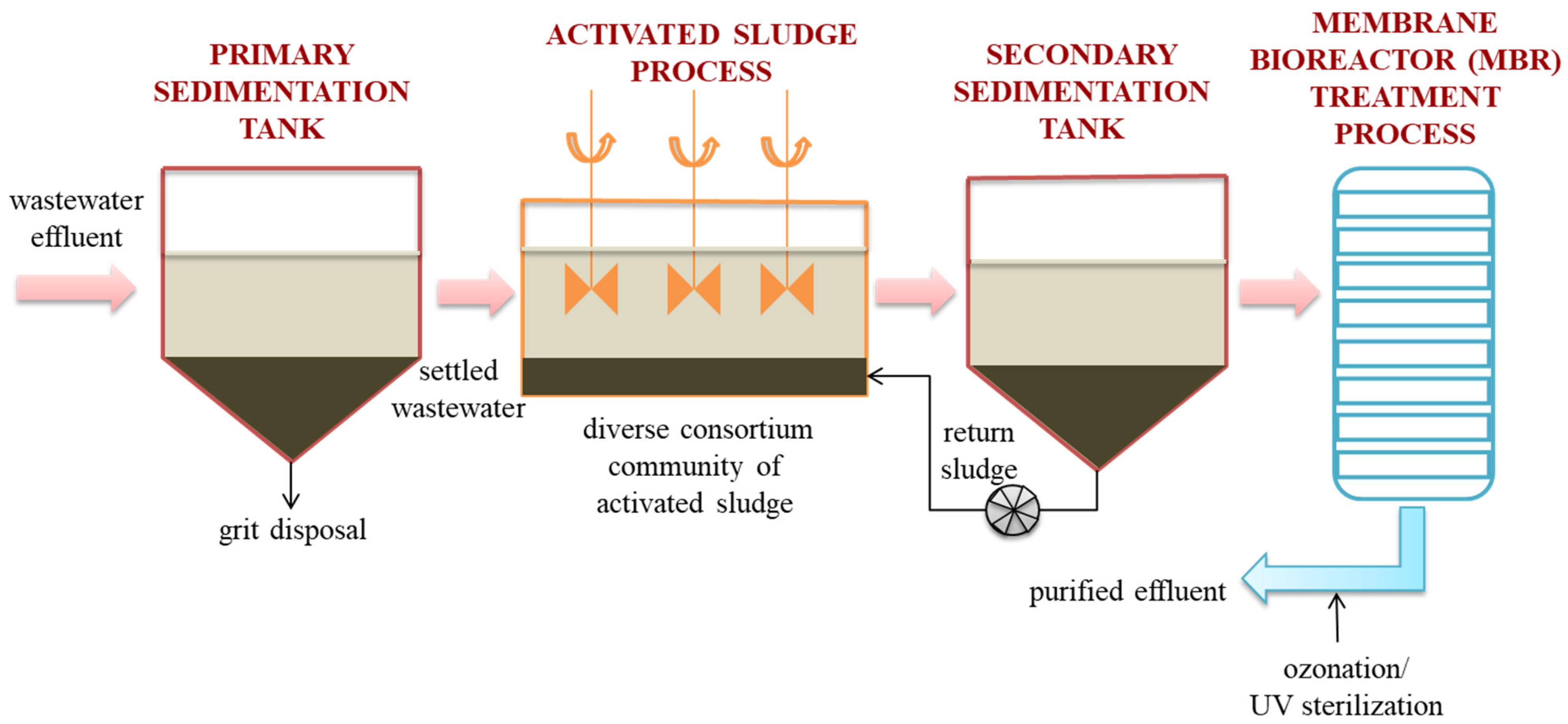

| MBR (Membrane Bioreactor) | A high-efficiency system—100% removal of suspended solids and up to 99% reduction in COD and BOD values. The wastewater often fulfils the legal discharge standards without the need for additional treatment. It is not effective at removing nutrients (N/P) unless designed with anoxic phases or chemical precipitation. It has the best removal efficiency compared to other biological treatment methods. | In practise, it is suitable for treating a wide range of municipal and industrial wastewater that place high demands on wastewater quality. The system can be used as a larger stationary plant or as a smaller mobile unit in containers. It is a complex treatment system that combines activated sludge and membrane processes. Automation is essential. It is the most technologically sophisticated of all biological treatment systems. | High costs in terms of investment and maintenance. In addition to the activated sludge module, additional filtration equipment such as cleaning systems, pumps, and similar components is required. Considerable energy expenditure for operation: sludge aeration and pressure for membrane processes. Additional filtration or disinfection is not required. The costs are justified by the high efficiency of the process. | Scaling is feasible in practice—from small modular field units to large municipal wastewater treatment plants. Most systems consist of several membrane modules. Larger scaling means higher costs, but also higher process efficiency (larger systems are more energy efficient per wastewater flow unit). | The high energy consumption means that more space is required, but this is offset by returning the wastewater to the cycle at a high quality. The production of sewage sludge is reduced by up to 30% compared to conventional biological methods, as the biomass remains in the system for longer. The plant requires less space, which minimises the need for construction. The process remains ecologically sustainable due to its high purification performance. | The targeted degradation of contaminants is achieved by a high inoculum mass, which enables treatment within a few hours. Membranes continuously separate the treated wastewater stream, eliminating the sedimentation time. This results in a fast, highly efficient treatment process with continuous water inflow and outflow. | [76,77,78] |

| Contaminant Type | Chemical Formula | Natural Degradation Potential | Synthetic Degradation Potential | Reference |

|---|---|---|---|---|

| PAH (Polycyclic Aromatic Hydrocarbons) | CnHn | Pseudomonas aeruginosa, Mycobacterium sp., and Rhodococcus sp. | Cycloclasticus sp. P1 | [87,88] |

| Phenol | C6H5OH | Microbial consortium: Acinetobacter sp., Bacillus sp., and Pseudomonas sp. | Rhodococcus sp. CS-1 | [89,90] |

| Dioxins | C12H10-XClX | Bacillus megaterium, Norcardiopsis sp., and Geobacillus sp. | Sphingomonas wittichii RW1 | [91,92] |

| Diesel | C12H23 | Bacillus cereus, Bacillus sphaericus, Bacillus fusiformis, and Acinetobacter junii | Pseudomonas fluorescens HK44, Pseudomonas putida KT2442 | [93,94] |

| Heavy Metals (Cadmium) | Cd | Eichhorina crassipes, Thlaspi caerulescens | Escherichia coli JM109, Pseudomonas putida 06909, Bacillus subtilis BR151 (pTOO24) | [95] |

| Pesticides (DDT) | C14H9Cl5 | Chryseobacterium sp., Trametes versicolor | Rhodococcus sp. IITR0 | [96,97] |

| Pharmaceuticals (Erythromycin) | C37H67NO13 | Penicillium oxalicum RJJ-2, Penicillium restrictum, and Trametes versicolor | Delftia lacustris RJJ-61 | [98,99] |

| Plastic (Polyethylene, PE) | (C2H4)n | Rhodococcus ruber, Penicillium simplicissimum, Streptomyces sp., and Brevibacillus borstelensis | Pseudomonas sp. AKS2 | [100,101] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vuković Domanovac, M.; Volf, M.; Šabić Runjavec, M.; Terzić, I. Sustainable and Advanced Strategies for Bioremediation of Highly Contaminated Wastewater. Processes 2025, 13, 2250. https://doi.org/10.3390/pr13072250

Vuković Domanovac M, Volf M, Šabić Runjavec M, Terzić I. Sustainable and Advanced Strategies for Bioremediation of Highly Contaminated Wastewater. Processes. 2025; 13(7):2250. https://doi.org/10.3390/pr13072250

Chicago/Turabian StyleVuković Domanovac, Marija, Mirela Volf, Monika Šabić Runjavec, and Ivana Terzić. 2025. "Sustainable and Advanced Strategies for Bioremediation of Highly Contaminated Wastewater" Processes 13, no. 7: 2250. https://doi.org/10.3390/pr13072250

APA StyleVuković Domanovac, M., Volf, M., Šabić Runjavec, M., & Terzić, I. (2025). Sustainable and Advanced Strategies for Bioremediation of Highly Contaminated Wastewater. Processes, 13(7), 2250. https://doi.org/10.3390/pr13072250