A Review of the Application of Fuzzy Logic in Bioenergy Technology

Abstract

1. Introduction

2. Research Gap

- To provide an extension and integration of other models with fuzzy logic to address the problems of selecting and decision making of bioenergy systems;

- The study contributes to the related body of knowledge by determining the weight of the criteria and ranking bioenergy processes through reviewing different case studies in the literature;

- It proposes and recommends a suitable fuzzy logic modelling technique to reduce the uncertainty present in bioenergy processes with reference to the literature.

- Is it possible to reduce uncertainty in the decision-making process of bioenergy systems?

- Can fuzzy logic improve the efficiency of bioenergy processes and decision making under uncertainties?

- What are the ranking criteria for bioenergy processes via fuzzy logic?

3. Methodologies

4. Bioenergy Technologies

4.1. Thermochemical Processes

4.2. Pyrolysis

4.3. Gasification

5. Biochemical Processes

Anaerobic Digestion Technology

6. Other Processes

Transesterification

7. General Overview of the Fuzzy Logic Model (FLM)

- IF {low signal} AND {low error} THEN {tool wear is small}

- IF {medium signal} AND {low error} THEN {tool wear is medium}

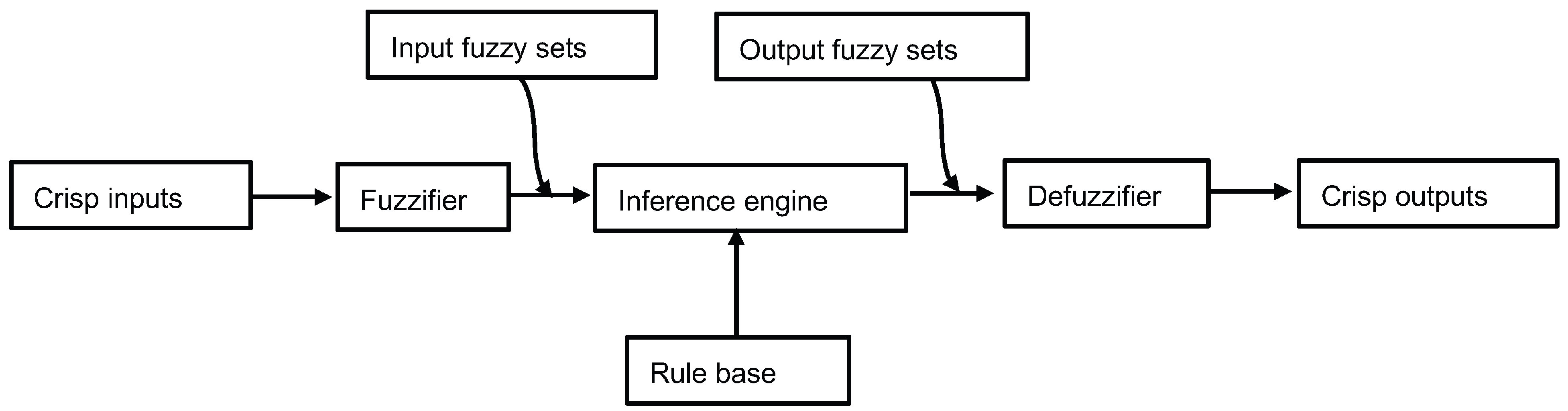

- Fuzzification: This is the conversion of crisp data into fuzzy set data or, in other words, membership functions.

- Fuzzy inference process: This deals with the combination of membership functions in the presence of fuzzy control rules to arrive at a fuzzy output.

- Defuzzification: It is the reverse process of fuzzification, as mentioned earlier, which is the conversion of fuzzy output into crisp output.

- Advantages of fuzzy logic

- The algorithm for FL makes use of little or estimated data. Hence, sensors or little memory are easily employed and required;

- They have a shorter growth time than the conventional methods;

- It provides an effective solution to complex issues and problems because of the resemblance of human reasoning and decision-making exhibited;

- Uncertainty in engineering can be easily handled through the application of fuzzy logic;

- FL is said to be robust with no precise input required;

- With FL, there is compensation over pure numerical methods as a result of the frequent system information that is accessible.

- Disadvantages of fuzzy logic

- Multiple calculations and iterations are required for fuzzification, inference, and defuzzification. This affects the performance of the system as a result of slowing down the process;

- With a complex system or when dealing with a large dataset, FL is computationally expensive;

- As a result of the mathematical explanation, in terms of areas of stability of control systems, proving the individuality of fuzzy systems is not easy;

- FL may be rational when calculating time and memory. Hence, the absolute mathematical realisation can be rigorous;

- The application of membership functions in fuzzy logic is subjective and relies on human expertise and intuition.

8. Fuzzy Logic Techniques in Renewable Energy Technologies

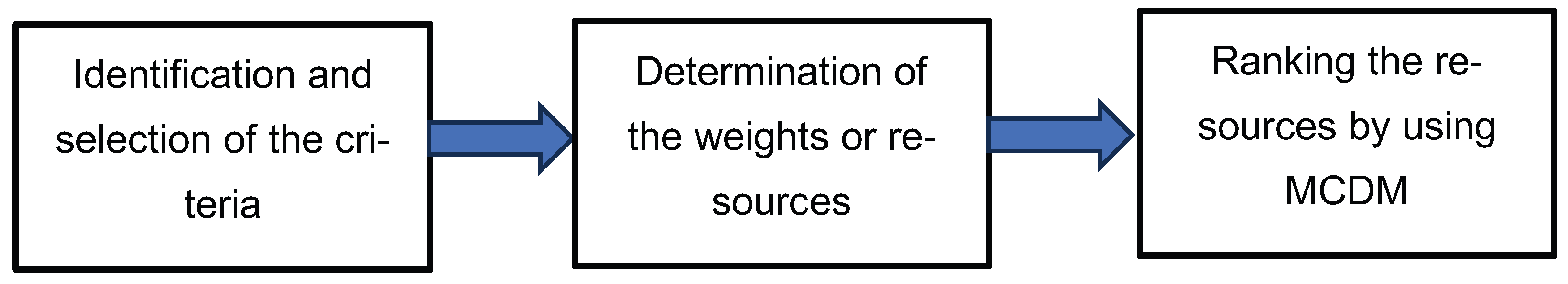

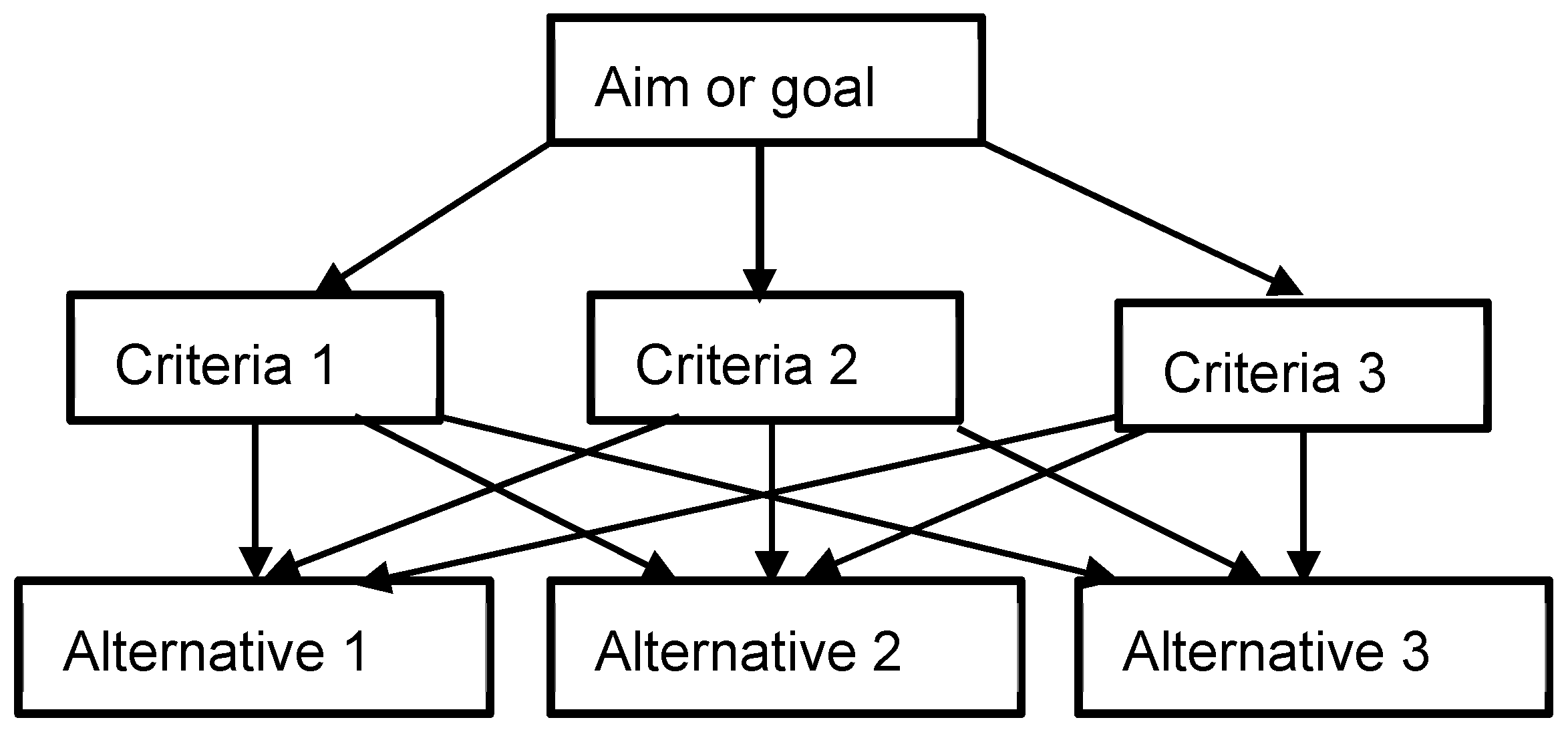

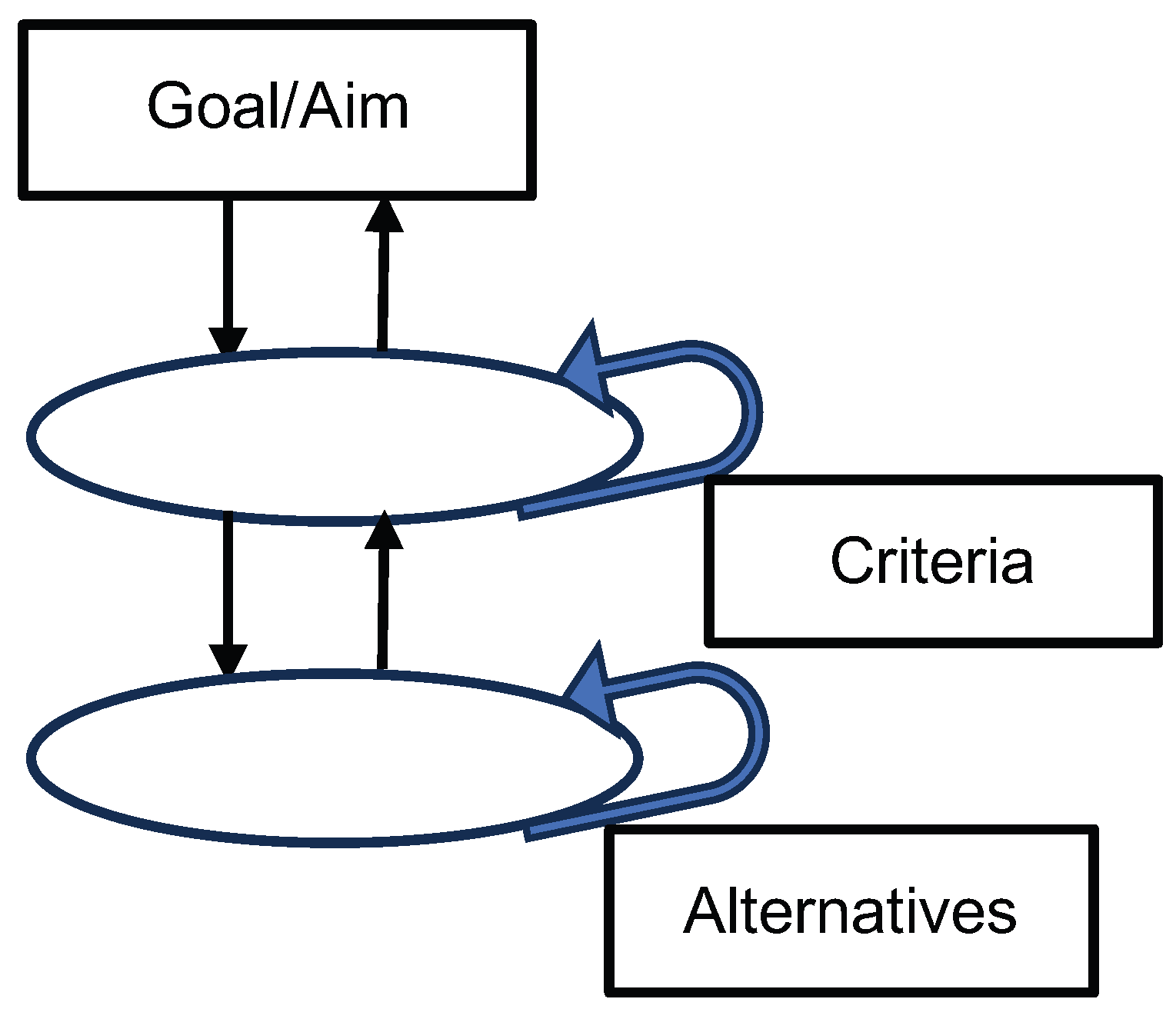

8.1. Multi-Criteria Decision Making (MCDM)

8.2. Vlekriterijumsko KOmpromisno Rangiranje (VIKOR) Method

8.3. Technical for Order of Preference by Similarity to Ideal Solution (TOPSIS)

8.4. Fuzzy Decision-Making Trial and Evaluation Laboratory (DEMATEL)

8.5. Fuzzy Analytic Hierarchy Process (AHP)

8.6. Fuzzy Analytic Network Process (ANP)

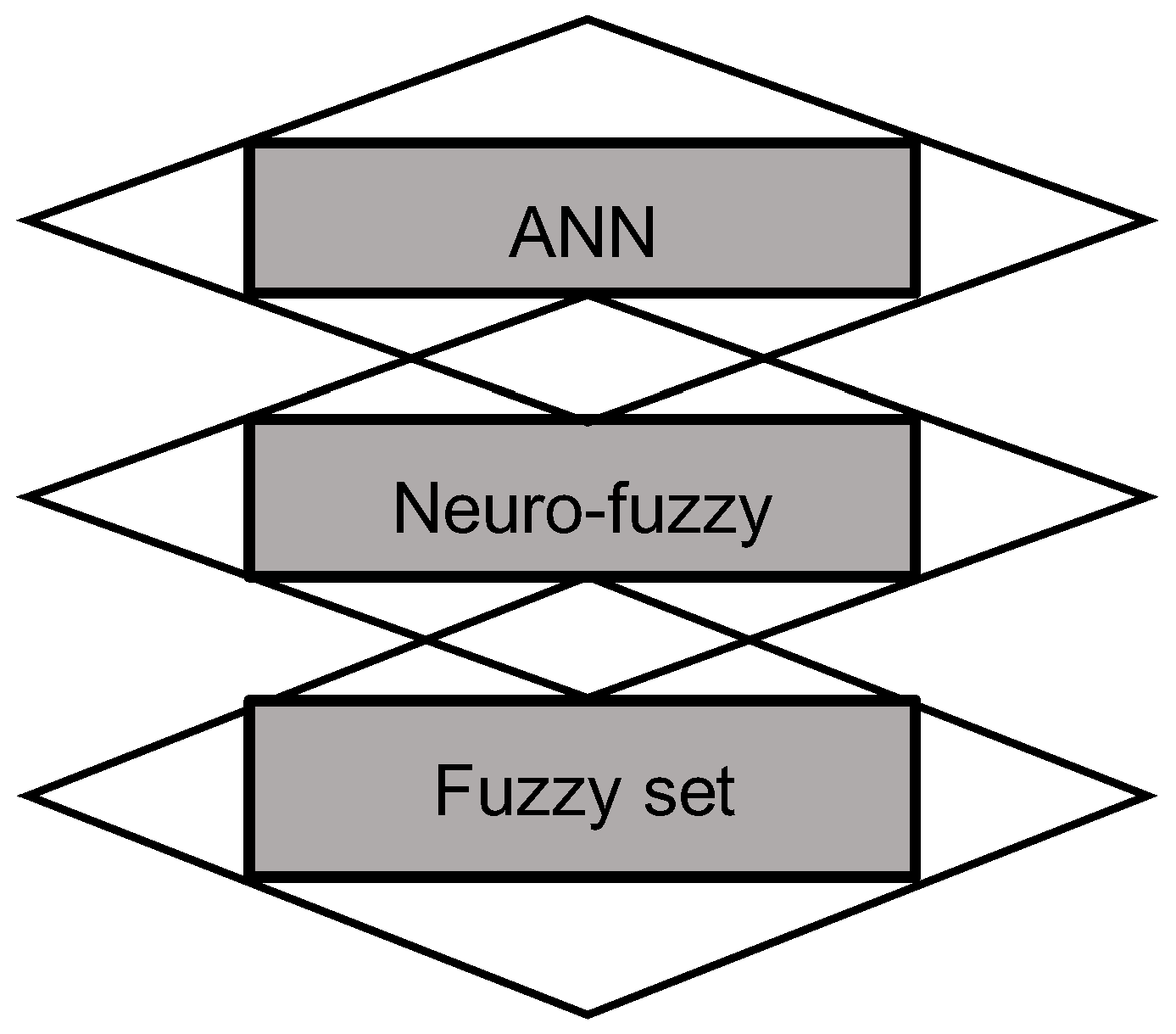

8.7. Neuro-Fuzzy System (NFS)

8.8. Fuzzy C-Means (FCM)

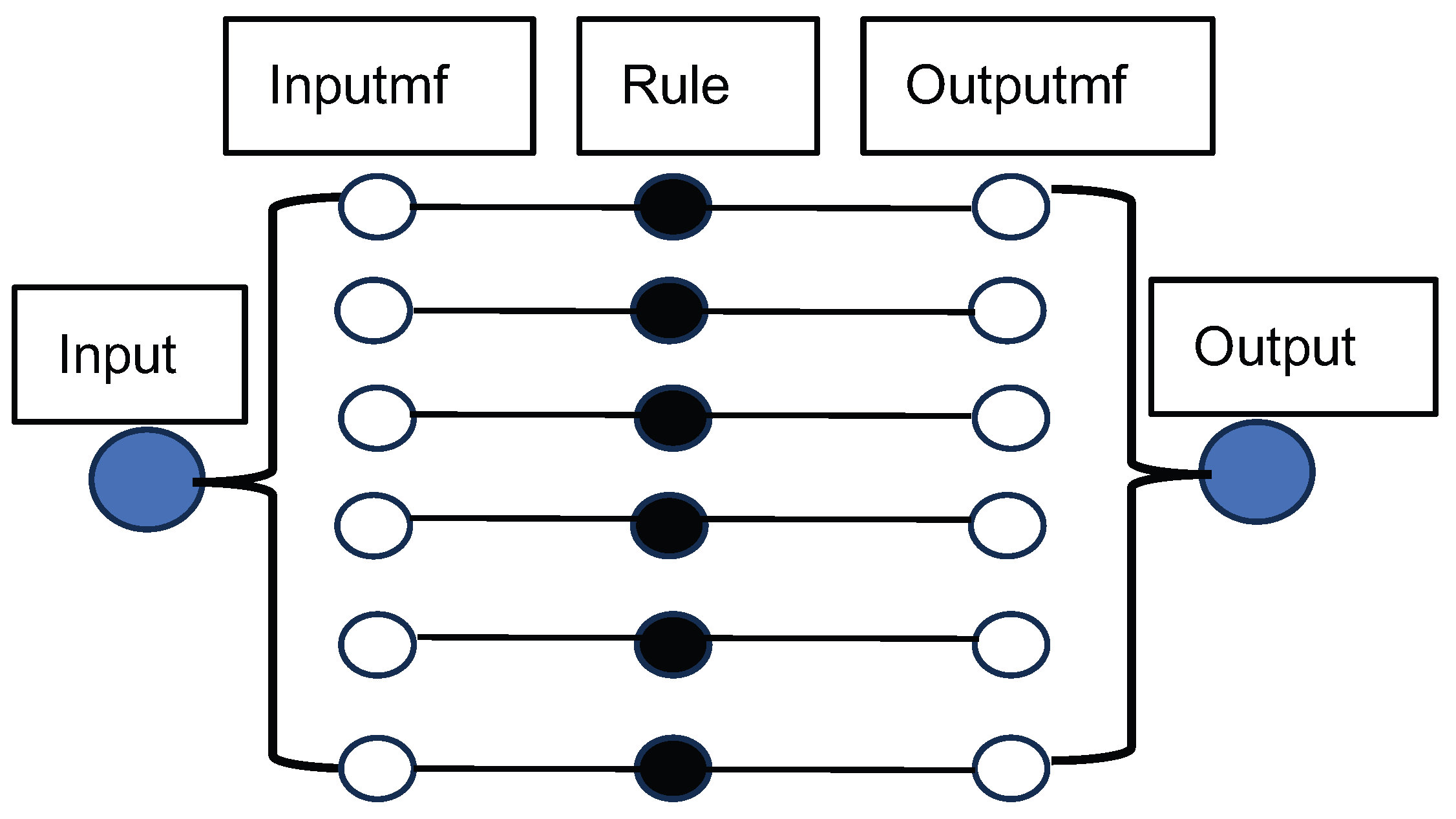

8.9. Adaptive Neuro-Fuzzy Inference System (ANFIS)

9. Studies on the Application of Fuzzy Logic in Bioenergy Technologies

10. Practical Challenges of Fuzzy Logic in Relation to Bioenergy Systems

11. Conclusions, Limitations, and Future Direction

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHP | Analytical Hierarchy Process |

| ANN | Artificial Neural Network |

| ANP | Analytical Network Process |

| ANFIS | Adaptive Neurofuzzy Fuzzy Inference System |

| BOCR | Benefit Opportunity Cost and Risk |

| CCHP | Combined Cooling Heating Power |

| COG | Centre of Gravity |

| CHP | Combined Heat and Power |

| CFD | Computational Fluid Dynamics |

| DAEM | Distributed Activation Energy Model |

| FEM | Finite-Element Method |

| FLM | Fuzzy Logic Model |

| FLO | Fuzzy Logic Operation |

| FL | Fuzzy Logic |

| FMCDM | Fuzzy Multi-Criteria Decision Maker |

| GA | Genetic Algorithm |

| HRES | Hybrid Renewable Energy System |

| ISM | Interpretive Structure Modelling |

| SISO | Single-Input Single-Output |

| RSM | Response Surface Methodology |

| TGA | Thermogravimetric Analysis |

| SCWG | Supercritical Water Gasification |

| TG | Triglycerides |

| TMAH | Tetramethylammonium hydroxide |

| MOM | Mean of Maximum |

| MCDM | Multi-Criteria Decision Making |

| PID | Proportional Integral Derivative |

| NDJ | Number of Direct Jobs |

| MILP | Multi-Objective Linear Programming |

References

- Rizzi, F.; van Eck, N.J.; Frey, M. The production of scientific knowledge on renewable energies: Worldwide trends, dynamics and challenges and implications for management. Renew. Energy 2014, 62, 657–671. [Google Scholar] [CrossRef]

- Timilsina, G.R.; Shah, K.U. Economics of renewable energy: A comparison of electricity production costs across technologies. In Oxford Research Encyclopedia of Environmental Science; Oxford University Press: Oxford, UK, 2022. [Google Scholar]

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Atuguba, R.A.; Tuokuu, F.X. Ghana’s renewable energy agenda: Legislative drafting in search of policy paralysis. Energy Res. Soc. Sci. 2020, 64, 101453. [Google Scholar] [CrossRef]

- EIA. 2024. Available online: https://www.eia.gov/energyexplained/biomass/ (accessed on 7 June 2025).

- Naqvi, S.R.; Jamshaid, S.; Naqvi, M.; Farooq, W.; Niazi, M.B.; Aman, Z.; Zubair, M.; Ali, M.; Shahbaz, M.; Inayat, A.; et al. Potential of biomass for bioenergy in Pakistan based on present case and future perspectives. Renew. Sustain. Energy Rev. 2018, 81, 1247–1258. [Google Scholar] [CrossRef]

- Forsberg, C.W.; Dale, B.E.; Jones, D.S.; Hossain, T.; Morais, A.R.; Wendt, L.M. Replacing liquid fossil fuels and hydrocarbon chemical feedstocks with liquid biofuels from large-scale nuclear biorefineries. Appl. Energy 2021, 298, 117225. [Google Scholar] [CrossRef]

- Welfle, A. Balancing growing global bioenergy resource demands-Brazil’s biomass potential and the availability of resource for trade. Biomass Bioenergy 2017, 105, 83–95. [Google Scholar] [CrossRef]

- Welfle, A.; Thornley, P.; Röder, M. A review of the role of bioenergy modelling in renewable energy research & policy development. Biomass Bioenergy 2020, 136, 105542. [Google Scholar]

- Sadhukhan, J.; Ng, K.S.; Hernandez, E.M. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Ossei-Bremang, R.N.; Kemausuor, F. A decision support system for the selection of sustainable biomass resources for bioenergy production. Environ. Syst. Decisions. 2021, 41, 437–454. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Anand, A.S. Applications of fuzzy logic in renewable energy systems—A review. Renew. Sustain. Energy Rev. 2015, 48, 585–607. [Google Scholar]

- Lerkkasemsan, N. Fuzzy logic-based predictive model for biomass pyrolysis. Appl. Energy 2017, 185, 1019–1030. [Google Scholar] [CrossRef]

- Althubaiti, M.; Bernard, M.; Musilek, P. Fuzzy logic controller for hybrid renewable energy system with multiple types of storage. In Proceedings of the 2017 IEEE 30th Canadian Conference on Electrical and Computer Engineering (CCECE), Windsor, ON, Canada, 30 April–3 May 2017; pp. 1–6. [Google Scholar]

- Stepanenko, V.A.; Zamulko, A.I.; Veremiichuk, Y.A. Fuzzy logic in the decision-making tasks of connecting renewable energy sources into the electricity supply system. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012043. [Google Scholar] [CrossRef]

- Rezk, H.; Inayat, A.; Abdelkareem, M.A.; Olabi, A.G.; Nassef, A.M. Optimal operating parameter determination based on fuzzy logic modeling and marine predator’s algorithm approaches to improve the methane production via biomass gasification. Energy 2022, 239, 122072. [Google Scholar] [CrossRef]

- Mahmoudi, S.M.; Maleki, A.; Ochbelagh, D.R. A novel method based on fuzzy logic to evaluate the storage and backup systems in determining the optimal size of a hybrid renewable energy system. J. Energy Storage 2022, 49, 104015. [Google Scholar] [CrossRef]

- Ghadi, M.Y.; Sakka, F.; Al Nakeeb, A.; Al Shloul, T. Critical Analysis of the Application of Fuzzy Logic in Renewable Energy Systems. TEM J. 2021, 10, 1610–1615. [Google Scholar] [CrossRef]

- Wang, L. Sustainable Bioenergy Production; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Liu, T.; Miao, P.; Shi, Y.; Tang, K.H.; Yap, P.S. Recent advances, current issues and future prospects of bioenergy production: A review. Sci. Total Environ. 2022, 810, 152181. [Google Scholar] [CrossRef]

- Lanjekar, P.R.; Panwar, N.L.; Agrawal, C. A comprehensive review on hydrogen production through thermochemical conversion of biomass for energy security. Bioresour. Technol. Rep. 2022, 21, 101293. [Google Scholar] [CrossRef]

- Aravind, S.; Kumar, P.S.; Kumar, N.S.; Siddarth, N. Conversion of green algal biomass into bioenergy by pyrolysis. A review. Environ. Chem. Lett. 2020, 18, 829–849. [Google Scholar] [CrossRef]

- Kaczor, Z.; Buliński, Z.; Werle, S. Modelling approaches to waste biomass pyrolysis: A review. Renew. Energy 2020, 159, 427–443. [Google Scholar] [CrossRef]

- Xia, C.; Cai, L.; Zhang, H.; Zuo, L.; Shi, S.Q.; Lam, S.S. A review on the modeling and validation of biomass pyrolysis with a focus on product yield and composition. Biofuel Res. J. 2021, 8, 1296–1315. [Google Scholar] [CrossRef]

- Hameed, S.; Sharma, A.; Pareek, V.; Wu, H.; Yu, Y. A review on biomass pyrolysis models: Kinetic, network and mechanistic models. Biomass Bioenergy 2019, 123, 104–122. [Google Scholar] [CrossRef]

- Elhenawy, Y.; Fouad, K.; Mansi, A.; Bassyouni, M.; Gadalla, M.; Ashour, F.; Majozi, T. Experimental analysis and numerical simulation of biomass pyrolysis. J. Therm. Anal. Calorim. 2024, 149, 10369–10383. [Google Scholar] [CrossRef]

- Branca, C.; Galgano, A. Kinetic Modelling of Biomass Pyrolysis Processes. Processes 2024, 12, 706. [Google Scholar] [CrossRef]

- Marcantonio, V.; Di Paola, L.; De Falco, M.; Capocelli, M. Modeling of biomass gasification: From thermodynamics to process simulations. Energies 2023, 16, 7042. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.J. Thermochemical conversion of biomass: Potential future prospects. Renew. Sustain. Energy Rev. 2023, 187, 113754. [Google Scholar] [CrossRef]

- Singh, D.K.; Tirkey, J.V. Process modelling and thermodynamic performance optimization of biomass air gasification fuelled with waste poultry litter pellet by integrating Aspen plus with RSM. Biomass Bioenergy 2022, 158, 106370. [Google Scholar] [CrossRef]

- Suparmin, P.; Purwanti, N.; Nelwan, L.O.; Mardjan, S.S. Biomass Gasification Modelling Development: A Review. IOP Conf. Ser. Earth Environ. Sci. 2024, 1386, 012018. [Google Scholar] [CrossRef]

- Mutlu, Ö.Ç.; Zeng, T. Challenges and opportunities of modeling biomass gasification in Aspen Plus: A review. Chem. Eng. Technol. 2020, 43, 1674–1689. [Google Scholar] [CrossRef]

- Pilar González-Vázquez, M.; Rubiera, F.; Pevida, C.; Pio, D.T.; Tarelho, L.A. Thermodynamic analysis of biomass gasification using aspen plus: Comparison of stoichiometric and non-stoichiometric models. Energies 2021, 14, 189. [Google Scholar] [CrossRef]

- Kushwah, A.; Reina, T.R.; Short, M. Modelling approaches for biomass gasifiers: A comprehensive overview. Sci. Total Environ. 2022, 834, 155243. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sar, T.; Gowd, S.C.; Rajendran, K.; Kumar, V.; Sarsaiya, S.; Li, Y.; Sindhu, R.; Binod, P.; Zhang, Z.; et al. A comprehensive review on thermochemical, and biochemical conversion methods of lignocellulosic biomass into valuable end product. Fuel 2023, 342, 127790. [Google Scholar] [CrossRef]

- Poornima, S.; Manikandan, S.; Prakash, R.; Deena, S.R.; Subbaiya, R.; Karmegam, N.; Kim, W.; Govarthanan, M. Biofuel and biochemical production through biomass transformation using advanced thermochemical and biochemical processes—A review. Fuel 2024, 372, 132204. [Google Scholar] [CrossRef]

- Show, P.L.; Vo, D.V.; Ponnusamy, S.K.; Rajendran Alta, S.; Kumar, G. Advanced thermochemical and biochemical processes for biomass transformation to biofuels and biochemicals. Biomass Convers. Bioref. 2024. [Google Scholar] [CrossRef]

- Sevillano, C.A.; Pesantes, A.A.; Peña Carpio, E.; Martínez, E.J.; Gómez, X. Anaerobic digestion for producing renewable energy—The evolution of this technology in a new uncertain scenario. Entropy 2021, 23, 145. [Google Scholar] [CrossRef]

- Aworanti, O.A.; Agbede, O.O.; Agarry, S.E.; Ajani, A.O.; Ogunkunle, O.; Laseinde, O.T.; Rahman, S.A.; Fattah, I.M. Decoding anaerobic digestion: A holistic analysis of biomass waste technology, process kinetics, and operational variables. Energies 2023, 16, 3378. [Google Scholar] [CrossRef]

- Hasan, M.M.; Mofijur, M.; Uddin, M.N.; Kabir, Z.; Badruddin, I.A.; Khan, T.Y. Insights into anaerobic digestion of microalgal biomass for enhanced energy recovery. Front. Energy Res. 2024, 12, 1355686. [Google Scholar] [CrossRef]

- Awogbemi, O.; Desai, D.A. Application of computational technologies for transesterification of waste cooking oil into biodiesel. Biomass Bioenergy 2025, 194, 107620. [Google Scholar] [CrossRef]

- Win, S.S.; Trabold, T.A. Sustainable waste-to-energy technologies: Transesterification. In Sustainable Food Waste-To-Energy Systems; Academic Press: Cambridge, MA, USA, 2018; pp. 89–109. [Google Scholar]

- Nwosu-obieogu, K.; Ezeugo, J.; Onukwuli, O.D.; Ude, C.N. Modelling and optimizing the transesterification process of shea butter via CD-BaCl-IL catalyst using soft computing algorithms. Results Eng. 2024, 22, 102004. [Google Scholar] [CrossRef]

- Šánek, L.; Jiří, P.; Husár, J.; Kolomazník, K. Mathematical modeling of transesterification process kinetics of triglycerides catalyzed by TMAH. MATEC Web Conf. 2019, 292, 01027. [Google Scholar] [CrossRef]

- Izida, T.; Silva, J.R.; Andrade, L.H.; Simionatto, E.; Simionatto, E.L.; Scharf, D.R.; Lima, S.M. Modeling transesterification reaction kinetics using fluorescence spectroscopy to interpret biodiesel production. Chem. Eng. Sci. 2020, 211, 115292. [Google Scholar] [CrossRef]

- Galvan, D.; Chendynski, L.T.; Mantovani, A.C.; Quadri, M.B.; Killner, M.; Cremasco, H.; Borsato, D. Mathematical modeling of the transesterification reaction by finite elements: Optimization of kinetic parameters using the simplex sequential method. J. Braz. Chem. Soc. 2020, 31, 313–319. [Google Scholar] [CrossRef]

- Carvalho, S.C.; Senra, T.D.; Silva, M.M.; Aguiar, L.G.; Ferreira, A.L. Mathematical modeling of the reactions involved in biodiesel production from waste oils and fats in a batch reactor. Biofuels 2025, 16, 150–154. [Google Scholar] [CrossRef]

- Stanescu, R.C.; Leahu, C.I.; Soica, A. Aspects regarding the modelling and optimization of the transesterification process through temperature control of the chemical reactor. Energies 2023, 16, 2883. [Google Scholar] [CrossRef]

- Jaber, A.A. Design of an Intelligent Embedded System for Condition Monitoring of an Industrial Robot; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Gernaey, K.V.; Huusom, J.K.; Gani, R. 12th International Symposium on Process Systems Engineering and 25th European Symposium on Computer Aided Process Engineering: Parts A, B and C; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Liu, H.; Yan, G.; Duan, Z.; Chen, C. Intelligent modeling strategies for forecasting air quality time series: A review. Appl. Soft Comput. 2021, 102, 106957. [Google Scholar] [CrossRef]

- Zadeh, L.A.; Aliev, R.A. Fuzzy Logic Theory and Applications: Part I and Part II; World Scientific Publishing: Singapore, 2018. [Google Scholar]

- Cuka, B.; Kim, D.W. Fuzzy logic-based tool condition monitoring for end-milling. Robot. Comput. Manuf. 2017, 47, 22–36. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition monitoring using machine learning: A review of theory, applications, and recent advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Bai, R.; Bouwmeester, R. Mohan, Fuzzy Logic Water Quality Index and Importance of Water Quality Parameters; Air, Soil and Water Research: Thousand Oaks, CA, USA, 2016; Volume 2, pp. 51–59. [Google Scholar]

- Bhattacharjee, D.; Kim, W.; Chattopadhyay, A.; Waser, R.; Rana, V. Multi-valued and fuzzy logic realization using TaOx memristive devices. Sci. Rep. 2018, 8, 8. [Google Scholar] [CrossRef]

- Kambalimath, S.; Deka, P.C. A basic review of fuzzy logic applications in hydrology and water resources. Appl. Water Sci. 2020, 10, 191. [Google Scholar] [CrossRef]

- Kilic, M.; Kaya, İ. Investment project evaluation by a decision-making methodology based on type-2 fuzzy sets. Appl. Soft Comput. 2015, 27, 399–410. [Google Scholar] [CrossRef]

- Kaya, I.; Çolak, M.; Terzi, F. A comprehensive review of fuzzy multi-criteria decision-making methodologies for energy policy making. Energy Strat. Rev. 2019, 24, 207–228. [Google Scholar] [CrossRef]

- Mamlook, R.; Akash, B.A.; Nijmeh, S. Fuzzy sets programming to perform evaluation of solar systems in Jordan. Energy Convers. Manag. 2001, 42, 1717–1726. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F.; Shi, G.H.; Zhang, X.T. A fuzzy multi-criteria decision-making model for trigeneration system. Energy Policy 2008, 36, 3823–3832. [Google Scholar] [CrossRef]

- Jing, Y.Y.; Bai, H.; Wang, J.J. A fuzzy multi-criteria decision-making model for CCHP systems driven by different energy sources. Energy Policy 2012, 42, 286–296. [Google Scholar] [CrossRef]

- Wu, Y.; Geng, S.; Xu, H.; Zhang, H. Study of decision framework of wind farm project plan selection under intuitionistic fuzzy set and fuzzy measure environment. Energy Convers. Manag. 2014, 87, 274–284. [Google Scholar] [CrossRef]

- Cutz, L.; Haro, P.; Santana, D.; Johnsson, F. Assessment of biomass energy sources and technologies: The case of Central America. Renew. Sustain. Energy Rev. 2016, 58, 1411–1431. [Google Scholar] [CrossRef]

- Khishtandar, S.; Zandieh, M.; Dorri, B. A multi-criteria decision-making framework for sustainability assessment of bioenergy production technologies with hesitant fuzzy linguistic term sets: The case of Iran. Renew. Sustain. Energy Rev. 2017, 77, 1130–1145. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-criteria decision making (MCDM) methods and concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Silgado, S.S.; Valdiviezo, L.C.; Domingo, S.G.; Roca, X. Multi-criteria decision analysis to assess the environmental and economic performance of using recycled gypsum cement and recycled aggregate to produce concrete: The case of Catalonia (Spain). Resour. Conserv. Recycl. 2018, 133, 120–131. [Google Scholar] [CrossRef]

- Mulliner, E.; Malys, N.; Maliene, V. Comparative analysis of MCDM methods for the assessment of sustainable housing affordability. Omega 2016, 59, 146–156. [Google Scholar] [CrossRef]

- Chen, T.Y. An evolved VIKOR method for multiple-criteria compromise ranking modeling under T-spherical fuzzy uncertainty. Adv. Eng. Inform. 2022, 54, 101802. [Google Scholar] [CrossRef]

- Ebrahimnejad, S.; Mousavi, S.M.; Tavakkoli-Moghaddam, R.; Heydar, M. Evaluating high risks in large-scale projects using an extended VIKOR method under a fuzzy environment. Int. J. Ind. Eng. Comput. 2012, 3, 463–476. [Google Scholar] [CrossRef]

- Wang, B.; Song, J.; Ren, J.; Li, K.; Duan, H.; Wang, X.E. Selecting sustainable energy conversion technologies for agricultural residues: A fuzzy AHP-VIKOR based prioritization from a life cycle perspective. Resour. Conserv. Recycl. 2019, 142, 78–87. [Google Scholar] [CrossRef]

- Rani, P.; Mishra, A.R.; Pardasani, K.R.; Mardani, A.; Liao, H.; Streimikiene, D. A novel VIKOR approach based on entropy and divergence measures of Pythagorean fuzzy sets to evaluate renewable energy technologies in India. J. Clean. Prod. 2019, 238, 117936. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Karabulut, Y. Energy project performance evaluation with sustainability perspective. Energy 2017, 119, 549–560. [Google Scholar] [CrossRef]

- Şengül, Ü.; Eren, M.; Shiraz, S.E.; Gezder, V.; Şengül, A.B. Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew. Energy 2015, 75, 617–625. [Google Scholar] [CrossRef]

- Chaghooshi, A.J.; Fathi, M.R.; Kashef, M. Integration of fuzzy Shannon’s entropy with fuzzy TOPSIS for industrial robotic system selection. J. Ind. Eng. Manag. 2012, 5, 102–114. [Google Scholar]

- Alao, M.A.; Ayodele, T.R.; Ogunjuyigbe, A.S.; Popoola, O.M. Multi-criteria decision-based waste-to-energy technology selection using entropy-weighted TOPSIS technique: The case study of Lagos, Nigeria. Energy 2020, 201, 117675. [Google Scholar] [CrossRef]

- Islam, S.; Ponnambalam, S.G.; Lam, H.L. A sustainable energy planning endeavor for selecting a waste-to-energy option. In 2016. In Proceedings of the 4th International Conference on the Development of Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 7–9 January 2016; pp. 1–7. [Google Scholar]

- Afrane, S.; Ampah, J.D.; Jin, C.; Liu, H.; Aboagye, E.M. Techno-economic feasibility of waste-to-energy technologies for investment in Ghana: A multicriteria assessment based on fuzzy TOPSIS approach. J. Clean. Prod. 2021, 318, 128515. [Google Scholar] [CrossRef]

- Afrane, S.; Ampah, J.D.; Agyekum, E.B.; Amoh, P.O.; Yusuf, A.A.; Fattah, I.M.; Agbozo, E.; Elgamli, E.; Shouran, M.; Mao, G.; et al. Integrated AHP-TOPSIS under a fuzzy environment for the selection of waste-to-energy technologies in Ghana: A performance analysis and socio-enviro-economic feasibility study. Int. J. Environ. Res. Public Health 2022, 19, 8428. [Google Scholar] [CrossRef]

- Madi, E.N.; Garibaldi, J.M.C. An exploration of issues and limitations in current methods of TOPSIS and fuzzy TOPSIS. In Proceedings of the 2016 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Vancouver, BC, Canada, 24–29 July 2016; pp. 2098–2105. [Google Scholar]

- Aliyeva, K. Application of type-2 fuzzy TOPSIS method for estimating renewable energy sources. Reliab. Theory Appl. 2025, 20, 857–867. [Google Scholar]

- Narayanamoorthy, S.; Annapoorani, V.; Kang, D.; Baleanu, D.; Jeon, J.; Kureethara, J.V.; Ramya, L. A novel assessment of bio-medical waste disposal methods using integrating weighting approach and hesitant fuzzy MOOSRA. J. Clean. Prod. 2020, 275, 122587. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, J.; Goodsite, M.E.; Xu, G. Waste-to-energy, municipal solid waste treatment, and best available technology: Comprehensive evaluation by an interval-valued fuzzy multi-criteria decision-making method. J. Clean. Prod. 2018, 172, 887–899. [Google Scholar] [CrossRef]

- Jeong, J.S.; Ramírez-Gómez, Á. Optimizing the location of a biomass plant with a fuzzy-Decision-Making Trial and Evaluation Laboratory (F-DEMATEL) and multi-criteria spatial decision assessment for renewable energy management and long-term sustainability. J. Clean. Prod. 2018, 182, 509–520. [Google Scholar] [CrossRef]

- Mondal, A.; Giri, B.K.; Roy, S.K. An integrated sustainable biofuel and bio-energy supply chain: A novel approach based on DEMATEL and fuzzy-random robust flexible programming with Me measure. Appl. Energy 2023, 343, 121225. [Google Scholar] [CrossRef]

- Saaty, T.L. The analytic hierarchy process (AHP). J. Oper. Res. Soc. 1980, 41, 1073–1076. [Google Scholar]

- Løken, E. Use of multicriteria decision analysis methods for energy planning problems. Renew. Sustain. Energy Rev. 2007, 11, 1584–1595. [Google Scholar] [CrossRef]

- Daniel, J.; Vishal, N.V.; Albert, B.; Selvarsan, I. Evaluation of the significant renewable energy resources in India using Analytical Hierarchy Process. In Multiple Criteria Decision Making for Sustainable Energy and Transportation Systems; Springer: Berlin/Heidelberg, Germany, 2009; pp. 13–26. [Google Scholar]

- Erol, Ö.; Kılkış, B. An energy source policy assessment using analytical hierarchy process. Energy Convers. Manag. 2012, 63, 245–252. [Google Scholar] [CrossRef]

- Thanki, S.; Govindan, K.; Thakkar, J. An investigation on lean-green implementation practices in Indian SMEs using analytical hierarchy process (AHP) approach. J. Clean. Prod. 2016, 135, 284–298. [Google Scholar] [CrossRef]

- Lee, S.K.; Mogi, G.; Kim, J.W. Decision support for prioritizing energy technologies against high oil prices: A fuzzy analytic hierarchy process approach. J. Loss Prev. Process. Ind. 2009, 22, 915–920. [Google Scholar] [CrossRef]

- Jaber, J.O.; Jaber, Q.M.; Sawalha, S.A.; Mohsen, M.S. Evaluation of conventional and renewable energy sources for space heating in the household sector. Renew. Sustain. Energy Rev. 2008, 12, 278–289. [Google Scholar] [CrossRef]

- Shen, Y.C.; Lin, G.T.; Li, K.P.; Yuan, B.J. An assessment of exploiting renewable energy sources with concerns of policy and technology. Energy Policy 2010, 38, 4604–4616. [Google Scholar] [CrossRef]

- Kahraman, C.; Kaya, I. A fuzzy multicriteria methodology for selection among energy alternatives. Expert Syst. Appl. 2010, 37, 6270–6281. [Google Scholar] [CrossRef]

- Oğuztimur, S. Why Fuzzy Analytic Hierarchy Process Approach for Transport Problems? European Regional Science Association: Brussels, Belgium, 2011. [Google Scholar]

- Xi, X.; Qin, Q. Product quality evaluation system based on AHP fuzzy comprehensive evaluation. J. Ind. Eng. Manag. 2013, 6, 356–366. [Google Scholar] [CrossRef]

- Khotimah, B.K.; Irhamni, F.; Kustiyahningsih, Y. Integration fuzzy analytic network process (ANP) and SWOT business strategy for the development of small and medium enterprises (SME). AIP Conf. Proc. 2017, 1867, 020055. [Google Scholar][Green Version]

- Joulaei, H.; Moridi, A.; Heidari, M.S.; Vafaeinajad, A. Developing a fuzzy analytic network process (ANP) and fuzzy analytic hierarchy process (AHP) model to evaluate small hydropower plant potential. J. Geomat. Sci. Technol. 2024, 14, 71–87. [Google Scholar] [CrossRef]

- Topaloğlu, F. Analytic network process (ANP) based decision support tool for nuclear power plant location and reactor type selection. Nucl. Eng. Technol. 2025, 57, 103228. [Google Scholar] [CrossRef]

- Kabak, M.E.; Dağdeviren, M.; Burmaoğlu, S. A MCDM model for energy policy evaluation. Uncertain. Model. Knowl. Eng. Decis. Mak. 2012, 131–136. [Google Scholar]

- Kabak, M.; Köse, E.; Kırılmaz, O.; Burmaoğlu, S. A fuzzy multi-criteria decision-making approach to assess building energy performance. Energy Build. 2014, 72, 382–389. [Google Scholar] [CrossRef]

- Oztaysi, B.; Ugurlu, S.; Kahraman, C. Assessment of green energy alternatives using fuzzy ANP. Assess. Simul. Tools Sustain. Energy Systems 2013, 129, 55–77. [Google Scholar]

- Chen, H.H.; Pang, C. Organizational forms for knowledge management in photovoltaic solar energy industry. Knowl. Based Syst. 2010, 23, 924–933. [Google Scholar] [CrossRef]

- Lee, A.H.; Chen, H.H.; Kang, H.Y. A model to analyze strategic products for photovoltaic silicon thin-film solar cell power industry. Renew. Sustain. Energy Rev. 2011, 15, 1271–1283. [Google Scholar] [CrossRef]

- Gu, W.; Saaty, T.L.; Wei, L. Evaluating and optimizing technological innovation efficiency of industrial enterprises based on both data and judgments. Int. J. Inf. Technol. Decis. Mak. 2018, 17, 9–43. [Google Scholar] [CrossRef]

- Alptekin, S.E.; Alptekin, G.I. A fuzzy quality function deployment approach for differentiating cloud products. Int. J. Comput. Intell. Syst. 2018, 11, 1041–1055. [Google Scholar] [CrossRef]

- Yousefi, J.; Hamilton-Wright, A. Characterizing EMG data using machine-learning tools. Comput. Biol. Med. 2014, 51, 1–13. [Google Scholar] [CrossRef]

- Gomez, J.; Dasgupta, D. Evolving fuzzy classifiers for intrusion detection. In Proceedings of the 2002 IEEE Workshop on Information Assurance, West Point, NY, USA, 17 June 2002; Volume 6, pp. 321–323. [Google Scholar]

- Chavan, S.; Shah, K.; Dave, N.; Mukherjee, S.; Abraham, A.; Sanyal, S. Adaptive neuro-fuzzy intrusion detection systems. In Proceedings of the International Conference on Information Technology: Coding and Computing, 2004; Proceedings; ITCC 2004, Las Vegas, NV, USA, 5 April 2004; Volume 1, pp. 70–74. [Google Scholar]

- Mohajerani, M.; Moeini, A.; Kianie, M. NFIDS: A neuro-fuzzy intrusion detection system. In Proceedings of the 10th IEEE International Conference on Electronics, Circuits and Systems, 2003, ICECS 2003; Proceedings of 2003. Sharjah, United Arab Emirates, 14–17 December 2003; Volume 1, pp. 348–351. [Google Scholar]

- Dragomir, O.E.; Dragomir, F.; Păun, M.; Duca, O.; Gurgu, I.V.; Drăgoi, I.C. Application of Neuro-Fuzzy techniques for energy scheduling in smart grids integrating photovoltaic panels. Processes 2023, 11, 1021. [Google Scholar] [CrossRef]

- Ulutas, A.; Altas, I.H.; Onen, A.; Ustun, T.S. Neuro-fuzzy-based model predictive energy management for grid-connected microgrids. Electronics 2020, 9, 900. [Google Scholar] [CrossRef]

- Ndiaye, A.; Ngom, B. Neuro-Fuzzy Energy Management Strategy (NFEMS) in DC Micro-Grids multiple sources (PV/SSE). Int. J. Innov. Sci. Eng. Technol. 2021, 8, 29. [Google Scholar]

- Nie, F.; Zhang, R.; Duan, Y.; Wang, R. Unconstrained Fuzzy C-Means Based on Entropy Regularization: An Equivalent Model. IEEE Trans. Knowl. Data Eng. 2024, 37, 979–990. [Google Scholar] [CrossRef]

- Nayak, J.; Naik, B.; Behera, H. Fuzzy C-means (FCM) clustering algorithm: A decade review from 2000 to 2014. In Computational Intelligence in Data Mining-Volume 2; Springer: New Delhi, India, 2014; pp. 133–149. [Google Scholar]

- Guo, M.F.; Yang, N.C. Features-clustering-based earth fault detection using singular-value decomposition and fuzzy c-means in resonant grounding distribution systems. Int. J. Electr. Power Energy Syst. 2017, 93, 97–108. [Google Scholar] [CrossRef]

- Pimentel, B.A.; de Amorim Silva, R.; Costa, J.C. Fuzzy C-means clustering algorithms with weighted membership and distance. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2022, 30, 567–594. [Google Scholar] [CrossRef]

- de Barros Franco, D.G.; Steiner, M.T. Clustering of solar energy facilities using a hybrid fuzzy c-means algorithm initialized by metaheuristics. J. Clean. Prod. 2018, 191, 445–457. [Google Scholar] [CrossRef]

- Gomez, V.; Casanovas, A. Fuzzy modeling of solar irradiance on inclined surfaces. Sol. Energy 2003, 75, 307–315. [Google Scholar] [CrossRef]

- Benmouiza, K.; Tadj, M.; Cheknane, A. Classification of hourly solar radiation using fuzzy c-means algorithm for optimal stand-alone PV system sizing. Int. J. Electr. Power Energy Syst. 2016, 82, 233–241. [Google Scholar] [CrossRef]

- Jang, J.S. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Kassem, Y.; Çamur, H.; Esenel, E. Adaptive neuro-fuzzy inference system (ANFIS) and response surface methodology (RSM) prediction of biodiesel dynamic viscosity at 313 K. Procedia Comput. Sci. 2017, 120, 521–528. [Google Scholar] [CrossRef]

- Akkaya, E. ANFIS based prediction model for biomass heating value using proximate analysis components. Fuel 2016, 180, 687–693. [Google Scholar] [CrossRef]

- Fajobi, M.O.; Lasode, O.A.; Adeleke, A.A.; Ikubanni, P.P.; Balogun, A.O.; Paramasivam, P. Prediction of Biogas Yield from Codigestion of Lignocellulosic Biomass Using Adaptive Neuro-Fuzzy Inference System (ANFIS) Model. J. Eng. 2023, 2023, 9335814. [Google Scholar] [CrossRef]

- Adedeji, P.A.; Masebinu, S.O.; Akinlabi, S.A.; Madushele, N. Adaptive neuro-fuzzy inference system (ANFIS) modelling in energy system and water resources. In Optimization Using Evolutionary Algorithms and Metaheuristics; CRC Press: Boca Raton, FL, USA, 2019; pp. 117–133. [Google Scholar]

- Elena Dragomir, O.; Dragomir, F.; Stefan, V.; Minca, E. Adaptive neuro-fuzzy inference systems as a strategy for predicting and controlling the energy produced from renewable sources. Energies 2015, 8, 13047–13061. [Google Scholar] [CrossRef]

- Amara, K.; Fekik, A.; Hocine, D.; Bakir, M.L.; Bourennane, E.B.; Malek, T.A.; Malek, A. Improved performance of a PV solar panel with adaptive neuro fuzzy inference system ANFIS based MPPT. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14 October 2018; pp. 1098–1101. [Google Scholar]

- Lestari, W.; Susanto, R.; Hasanah, H.; Nuryani, N.; Purnama, B. Prediction of solar energy radiation using adaptive neuro fuzzy inference system in the tropical region. AIP Conf. Proc. 2019, 2202, 020093. [Google Scholar]

- Salleh, M.N.; Talpur, N.; Hussain, K. Adaptive neuro-fuzzy inference system: Overview, strengths, limitations, and solutions. In Proceedings of the Data Mining and Big Data: Second International Conference, DMBD 2017, Fukuoka, Japan, 1 August 2017; pp. 527–535. [Google Scholar]

- Jurado, F.; Saenz, J.R. Neuro-fuzzy control for autonomous wind–diesel systems using biomass. Renew. Energy 2002, 27, 39–56. [Google Scholar] [CrossRef]

- Soliman, A.; Rizzoni, G.; Kim, Y.W. Diagnosis of an automotive emission control system using fuzzy inference. Control Eng. Pract. 1999, 7, 209–216. [Google Scholar] [CrossRef]

- Jurado, F.; Ortega, M.; Cano, A.; Carpio, J. Neuro-fuzzy controller for gas turbine in biomass-based electric power plant. Electr. Power Syst. Res. 2002, 60, 123–135. [Google Scholar] [CrossRef]

- Ayoub, N.; Martins, R.; Wang, K.; Seki, H.; Naka, Y. Two levels decision system for efficient planning and implementation of bioenergy production. Energy Convers. Manag. 2007, 48, 709–723. [Google Scholar] [CrossRef]

- Bitar, S.D.; da Costa Junior, C.T.; Barreiros, J.A.; Neto, J.C. Expansion of isolated electrical systems in the Amazon: An approach using fuzzy multi-objective mathematical programming. Energy Policy 2009, 37, 3899–3905. [Google Scholar] [CrossRef]

- Romeo, L.M.; Gareta, R. Fouling control in biomass boilers. Biomass Bioenergy 2009, 33, 854–861. [Google Scholar] [CrossRef]

- Frantti, T.; Mähönen, P. Fuzzy logic-based forecasting model. Eng. Appl. Artif. Intell. 2001, 14, 189–201. [Google Scholar] [CrossRef]

- Acosta-Michlik, L.; Lucht, W.; Bondeau, A.; Beringer, T. Integrated assessment of sustainability trade-offs and pathways for global bioenergy production: Framing a novel hybrid approach. Renew. Sustain. Energy Rev. 2011, 15, 2791–2809. [Google Scholar] [CrossRef]

- Cheng, S.F.; Hung, C.I.; Yang, I.C. Exploring biomass energy of microorganisms using data mining methods. Energy Convers. Manag. 2011, 52, 1272–1279. [Google Scholar] [CrossRef]

- Tan, R.R.; Aviso, K.B.; Barilea, I.U.; Culaba, A.B.; Cruz, J.B., Jr. A fuzzy multi-regional input–output optimization model for biomass production and trade under resource and footprint constraints. Appl. Energy 2012, 90, 154–160. [Google Scholar] [CrossRef]

- Tan, R.R.; Culaba, A.B.; Aviso, K.B. A fuzzy linear programming extension of the general matrix-based life cycle model. J. Clean. Prod. 2008, 16, 1358–1367. [Google Scholar] [CrossRef]

- Tan, R.R.; Ballacillo, J.A.; Aviso, K.B.; Culaba, A.B. A fuzzy multiple-objective approach to the optimization of bioenergy system footprints. Chem. Eng. Res. Des. 2009, 87, 1162–1170. [Google Scholar] [CrossRef]

- Wiedmann, T. A review of recent multi-region input–output models used for consumption-based emission and resource accounting. Ecol. Econ. 2009, 69, 211–222. [Google Scholar] [CrossRef]

- Djatkov, D.; Effenberger, M.; Lehner, A.; Martinov, M.; Tesic, M.; Gronauer, A. New method for assessing the performance of agricultural biogas plants. Renew. Energy 2012, 40, 104–112. [Google Scholar] [CrossRef]

- Ren, J.; Fedele, A.; Mason, M.; Manzardo, A.; Scipioni, A. Fuzzy multi-actor multi-criteria decision making for sustainability assessment of biomass-based technologies for hydrogen production. Int. J. Hydrogen Energy 2013, 38, 9111–9120. [Google Scholar] [CrossRef]

- Lewis, S.M.; Fitts, G.; Kelly, M.; Dale, L. A fuzzy logic-based spatial suitability model for drought-tolerant switchgrass in the United States. Comput. Electron. Agric. 2014, 103, 39–47. [Google Scholar] [CrossRef]

- Jiang, H.; Eastman, J.R. Application of fuzzy measures in multi-criteria evaluation in GIS. Int. J. Geogr. Inf. Sci. 2000, 14, 173–184. [Google Scholar] [CrossRef]

- Balaman, Ş.Y.; Selim, H. A fuzzy multi-objective linear programming model for design and management of anaerobic digestion-based bioenergy supply chains. Energy 2014, 74, 928–940. [Google Scholar] [CrossRef]

- Pérez-Fortes, M.; Laínez-Aguirre, J.M.; Arranz-Piera, P.; Velo, E.; Puigjaner, L. Design of regional and sustainable bio-based networks for electricity generation using a multi-objective MILP approach. Energy 2012, 44, 79–95. [Google Scholar] [CrossRef]

- Foo, D.C.; Tan, R.R.; Lam, H.L.; Aziz, M.K.; Klemeš, J.J. Robust models for the synthesis of flexible palm oil-based regional bioenergy supply chain. Energy 2013, 55, 68–73. [Google Scholar] [CrossRef]

- Ekşioğlu, S.D.; Acharya, A.; Leightley, L.E.; Arora, S. Analyzing the design and management of biomass-to-biorefinery supply chain. Comput. Ind. Eng. 2009, 57, 1342–1352. [Google Scholar] [CrossRef]

- Lerkkasemsan, N.; Achenie, L.E. Pyrolysis of biomass—fuzzy modeling. Renew. Energy 2014, 66, 747–758. [Google Scholar] [CrossRef]

- Kanthasamy, R.; Almatrafi, E.; Ali, I.; Sait, H.H.; Zwawi, M.; Abnisa, F.; Peng, L.C.; Ayodele, B.V. Bayesian optimized multilayer perceptron neural network modelling of biochar and syngas production from pyrolysis of biomass-derived wastes. Fuel 2023, 350, 128832. [Google Scholar] [CrossRef]

- Khan, H.; Savvopoulos, S.; Janajreh, I. Artificial neural network-assisted thermogravimetric analysis of thermal degradation in combustion reactions: A study across diverse organic samples. Environ. Res. 2024, 249, 118463. [Google Scholar] [CrossRef] [PubMed]

- Wahmkow, C.; Knape, M.; Konnerth, E. Biogas Intelligence-operate biogas plants using Neural Network and Fuzzy logic. In Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting (IFSA/NAFIPS), Edmonton, AB, Canada, 24 June 2013; pp. 1483–1488. [Google Scholar]

- Aigbe, U.O.; Ukhurebor, K.E.; Osibote, A.O.; Hassaan, M.A.; El Nemr, A. Optimization and prediction of biogas yield from pretreated Ulva Intestinalis Linnaeus applying statistical-based regression approach and machine learning algorithms. Renew. Energy 2024, 235, 121347. [Google Scholar] [CrossRef]

- Oluwaseun, A.T.; Mgbachi, C.A.; Ajenikoko, G. Development of a fuzzy logic technique for biogas generation of electrical energy. Int. J. Adv. Sci. Tech. Res. 2018, 5, 30–39. [Google Scholar]

- Bukhtoyarov, V.; Tynchenko, V.; Bashmur, K.; Kolenchukov, O.; Kukartsev, V.; Malashin, I. Fuzzy Neural Network Applications in Biomass Gasification and Pyrolysis for Biofuel Production: A Review. Energies 2024, 18, 16. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Nadian, M.H.; Davoodnia, V.; Soltanian, S. Prognostication of lignocellulosic biomass pyrolysis behavior using ANFIS model tuned by PSO algorithm. Fuel 2019, 253, 189–198. [Google Scholar] [CrossRef]

| Study Inclusion Criteria | Study Exclusion Criteria |

|---|---|

| Scholarly published contribution in the form of original article, review paper, book chapter from peer-reviewed journals, and energy reports | Published contribution outside original article, review paper, book chapter from peer-reviewed journals and energy reports are excluded. |

| Time span of 1965–2025 | Outside the time span of 1965–2025 |

| Publications written in English language only are included | Publications written aside English language are excluded |

| The type of publication considered is review article | Not any other review as publication type (systematic review, etc.) |

| Fuzzy Logic Techniques/Model | Types of Applications | Main Findings | References |

|---|---|---|---|

| ANFIS | Biomass/Pyrolysis | Suitable for predicting pyrolysis outcome with imprecise data | [152] |

| Multilayer perceptron neural network | Biochar | High R2 of 0.984, provides accurate predictions | [153] |

| ANFIS + K-means clustering | Co-pyrolysis of biomass | High energy yield (19.8 Mg/kg) and reduced emissions by 82.4% | [154] |

| Neural network + FL | Anaerobic digestion | Reduces complexity and improves gas production efficiency | [155] |

| RSM/ANN/ANFIS | Anaerobic digestion | 0.8841 and 0.9402 for MSE and RMSE; R2 = 0.9995 and 0.9998 | [156] |

| Fuzzy logic controller | Anaerobic digestion | Biogas electrical power output increased by 3.65 kWh, 45.6% increase because of the introduction of fuzzy logic controller | [157] |

| FNN | Biomass gasification and pyrolysis | Enhances prediction accuracy and managed efficient process uncertainty | [158] |

| ANFIS | Pyrolysis | Highly predictive ability. 91.82% and 97.29% of pyrolysis reactions of P. Pinnata and J. Curcas | [14] |

| Neuro-fuzzy expert | Biomass boiler | Optimises soot blowing, saving up to 12 GWh/year of biomass boiler. Increases turbine output by 3.5% | [136] |

| Multiobjective linear programming (MILP) | Anaerobic digestion | Proposed model can effectively be used in practice | [148] |

| Advantages of Fuzzy Logic Technique to Bioenergy Systems | Limitations of Fuzzy Logic to Bioenergy Systems |

|---|---|

| It provides and improves adaptability and accuracy in modelling non-linear systems for biomass conversion processes. | The FL may require extensive or large dataset for optimisation and complex model. |

| The FL can optimise and predict the performance of bioenergy system. | The technique is usually limited to specific variables such as temperature, pH, and feedstock properties in relation biomass and anaerobic digestion characterisation. |

| The technique plays a role in advancing decision-making framework under uncertainties, thereby improving process efficiency. | Fuzzy logic lacks transparency in decision model, which results in hindrance to its adoption in the bioenergy industries. |

| Characterisation of bioenergy involves incorporation of imprecise data, vague and linguistic information. With fuzzy logic, these concerns are addressed. | Fuzzy logic models trained on a narrow dataset are impossible to generalise to new conditions. Hence, this results in decreased performance and accuracy of bioenergy data. |

| The technique has the tendency to map input (temperature, biomass composition) to output (syngas composition) variable to reflect inherent uncertainties in the biomass system. | The technique is said to function as a “black box”, limiting interpretability. |

| Ability to learn from bioenergy data and adjust model parameters based on empirical observation. | |

| The FL has the tendency to integrate expert knowledge and data-driven insight in bioenergy processing systems, specifically as regards prediction accuracy and better generalisation, as well as decision making. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zenani, S.; Obileke, K.; Ndiweni, O.; Mukumba, P. A Review of the Application of Fuzzy Logic in Bioenergy Technology. Processes 2025, 13, 2251. https://doi.org/10.3390/pr13072251

Zenani S, Obileke K, Ndiweni O, Mukumba P. A Review of the Application of Fuzzy Logic in Bioenergy Technology. Processes. 2025; 13(7):2251. https://doi.org/10.3390/pr13072251

Chicago/Turabian StyleZenani, Sibabalwe, KeChrist Obileke, Odilo Ndiweni, and Patrick Mukumba. 2025. "A Review of the Application of Fuzzy Logic in Bioenergy Technology" Processes 13, no. 7: 2251. https://doi.org/10.3390/pr13072251

APA StyleZenani, S., Obileke, K., Ndiweni, O., & Mukumba, P. (2025). A Review of the Application of Fuzzy Logic in Bioenergy Technology. Processes, 13(7), 2251. https://doi.org/10.3390/pr13072251