Analysis of the Impact of the Drying Process and the Effects of Corn Race on the Physicochemical Characteristics, Fingerprint, and Cognitive-Sensory Characteristics of Mexican Consumers of Artisanal Tostadas

Abstract

1. Introduction

2. Materials and Methods

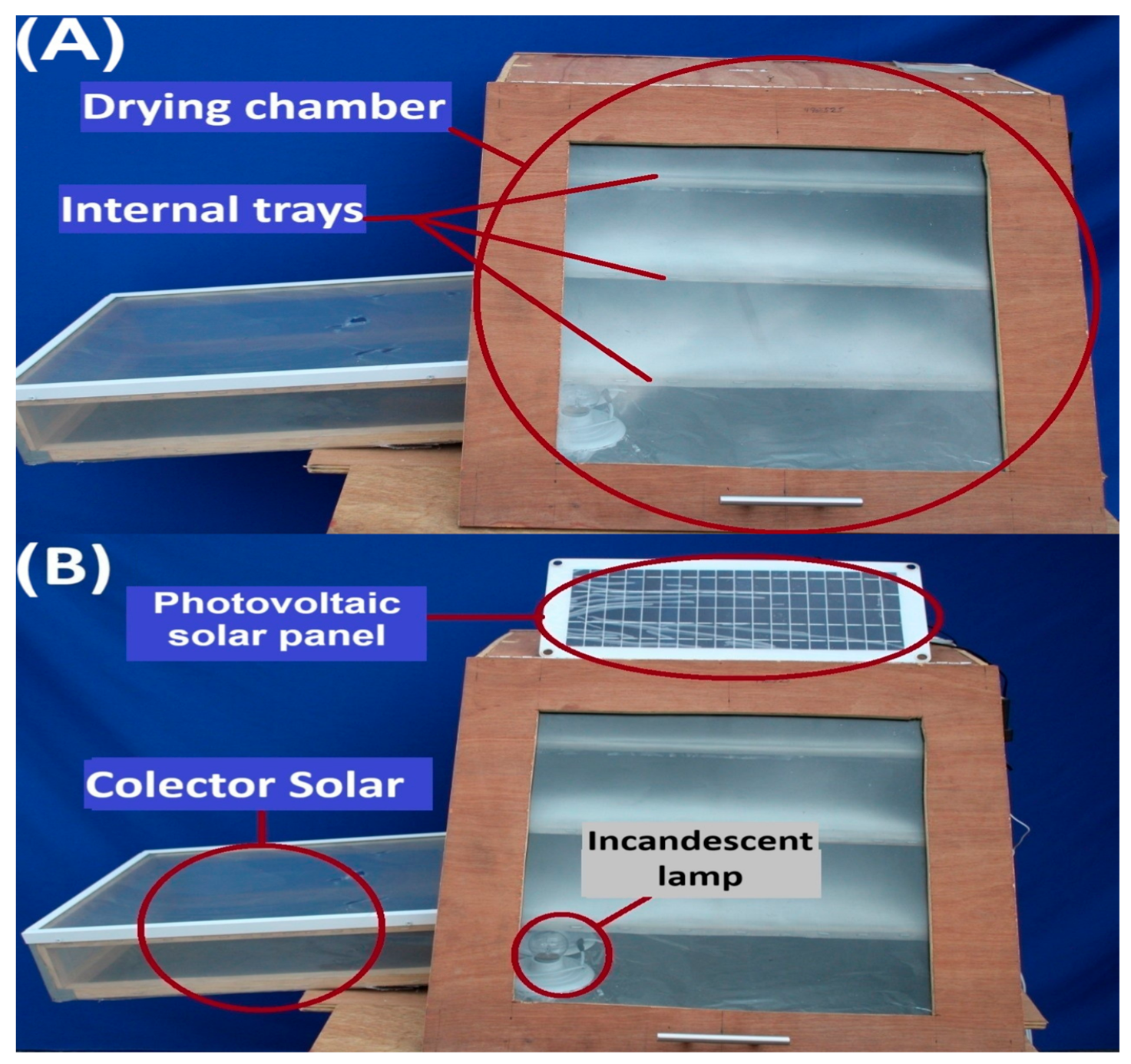

2.1. Solar and Hybrid Dehydration Equipment

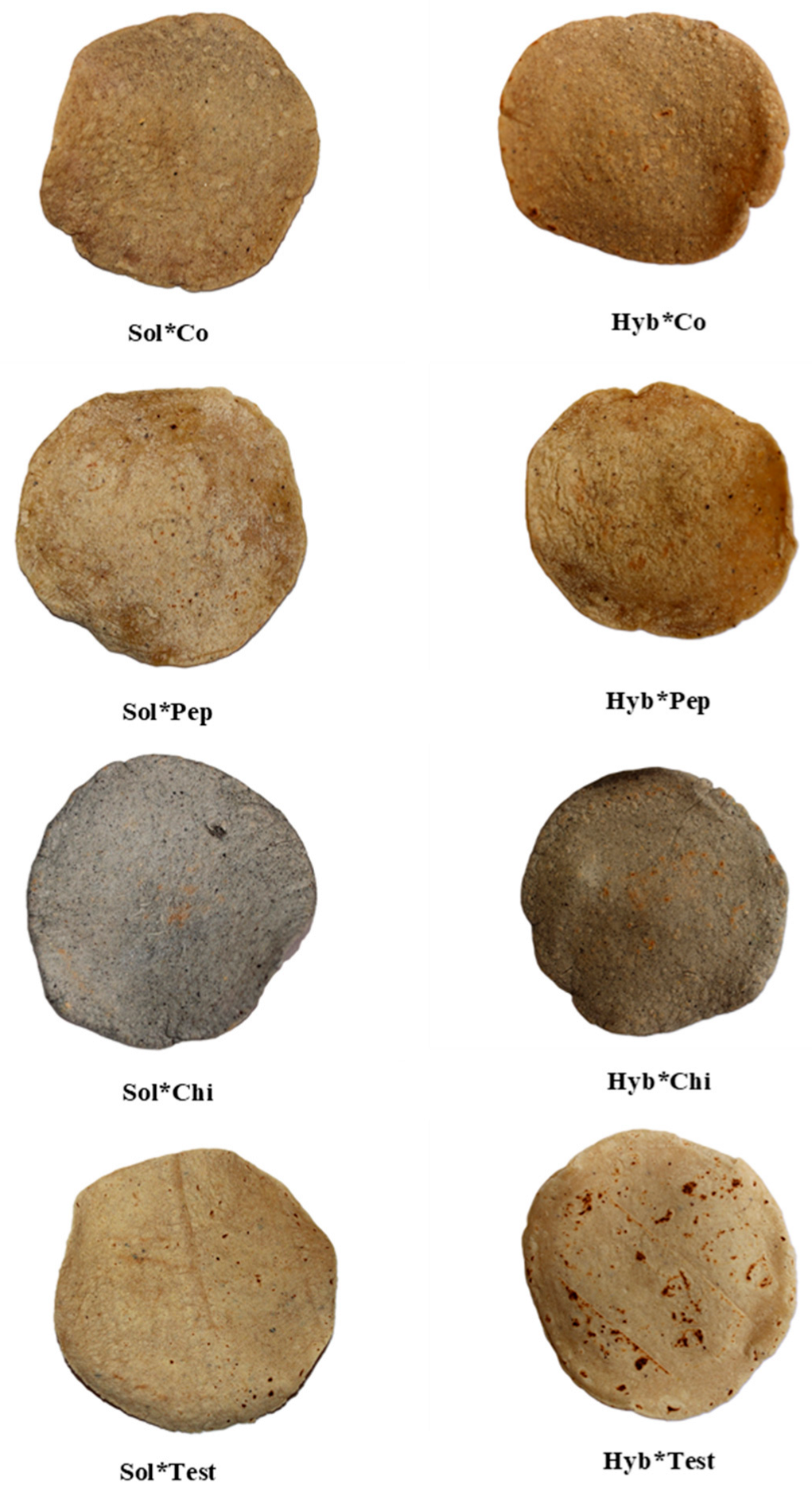

2.2. Manufacturing of Tostadas

2.3. Proximate Chemical Determination and Water Activity of Artisanal Tostadas

2.4. Instrumental Determination of Color and Texture in Artisanal Tostadas

2.5. Fingerprint by FTIR: Analysis for Functional Groups Identification

2.6. Sensory Profile of Artisanal Tostadas and Liking

2.7. Cognitive Profile Based on Online Survey

2.8. Statistical Analysis

2.8.1. Chemical and Instrumental Determination

2.8.2. Identification of Significant Sensory Attributes, Emotions and Memories

2.8.3. Level of Liking Based on Significant Attributes, Emotions, and Memories

3. Results and Discussion

3.1. Chemical and Instrumental Determination

3.2. Fingerprint by FTIR: Analysis for Functional Groups Identification

3.3. Identification of Significant Sensory Attributes, Emotions and Memories

3.4. Identification of Significant Emotions and Memories

3.5. Liking Level Based on Physicochemical and Sensory-Cognitive Aspects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ranum, P.; Peña-Rosas, J.P.; Garcia-Casal, M.N. Global maize production, utilization, and consumption. Ann. N. Y. Acad. Sci. 2014, 1312, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Fernández, S.R.; Morales, C.L.A.; Gálvez, M.A. Importancia de los maíces nativos de México en la dieta nacional. Una revisión indispensable. Rev. Fitotec. Mex. 2013, 36, 275–283. [Google Scholar] [CrossRef]

- Bello-Perez, L.A.; Flores-Silva, P.C.; Agama-Acevedo, E.; Figueroa-Cardenas, J.D.; Lopez-Valenzuela, J.A.; Campanella, O.H. Effect of the nixtamalization with calcium carbonate on the indigestible carbohydrate content and starch digestibility of corn tortilla. J. Cereal Sci. 2014, 60, 421–425. [Google Scholar] [CrossRef]

- Colín-Chávez, C.; Virgen-Ortiz, J.J.; Serrano-Rubio, L.E.; Martínez-Téllez, M.A.; Astier, M. Comparison of nutrional properties and bioactive compounds between industrial and artisan fresh tortillas from maize landraces. Curr. Res. Food Sci. 2020, 3, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Arnés, E.; Astier, M. Handmade comal tortillas in Michoacán: Traditional practices along the rural-urban gradient. Int. J. Environ. Res. Public Health 2019, 16, 3211. [Google Scholar] [CrossRef]

- Luga, M.; Akerberg, V.D.A.; Martínez, T.M.G.; Mironeasa, S. Consumer preferences and sensory profile related to the physico-chemical properties and texture of different maize tortillas types. Foods 2019, 8, 533. [Google Scholar] [CrossRef]

- Arnés, E.; Severino-Pérez, P.; Astier, M. Sensory profile and acceptance of maize tortillas by rural and urban consumers in Mexico. J. Sci. Food Agric. 2022, 102, 2300–2308. [Google Scholar] [CrossRef]

- Acosta-Estrada, B.A.; Serna-Saldívar, S.O.; Chuck-Hernández, C. Quality assessment of maize tortillas produced from landraces and high yield hybrids and varieties. Front. Nutr. 2023, 10, 1105619. [Google Scholar] [CrossRef]

- Cabal-Prieto, A.; Herrera-Corredor, J.A.; Vega-Carreño, M.I.; Chay-Canul, A.J.; Chareo-Benítez, B.; Juarez-Barrientos, J.M.; Hernández-Salinas, G.; Guerrero-Ortiz, C.A.; Armida-Lozano, J.; Ramírez-Rivera, E.J. Analysis of sensory and cognitive performance of generational consumers using artisan tortillas. J. Sens. Stud. 2024, 39, e12920. [Google Scholar] [CrossRef]

- Pérez-Ruiz, R.V.; Aguilar-Toalá, J.E.; Cruz-Monterrosa, R.G.; Rayas-Amor, A.A.; Hernández-Rodríguez, M.; Camacho-Villasana, Y.; Herrera-Pérez, J. Mexican native maize: Origin, races and impact on Food gastronomy. Int. J. Gastron. Food Sci. 2024, 37, 100978. [Google Scholar] [CrossRef]

- Palacios-Pola, G.; Perales, H.; Estrada-Lugo, E.I.J.; Figueroa-Cárdenas, J.D. Nixtamal techniques for different maize races prepared as tortillas by women of Chiapas, Mexico. J. Ethn. Foods 2022, 9, 2. [Google Scholar] [CrossRef]

- Quintero-Gutiérrez, A.G.; González-Rosendo, G.; Solano-Navarro, A.; Reyes Navarrete-Reyes, G.E.; Villanueva-Sánchez, J.; Brarvo-Rivera, G. Caracterización de una tortilla tostada elaborada con maiz (Zea mays) y alga (Ulva clathrata) como propspecto funcional. Rev. Española De Nutr. Comunitaria 2014, 20, 22–28. [Google Scholar]

- Ramírez-Ruíz, J.; Reyes-Velasco, L.; Sánchez-Cruz, G.; Castillo-Real, L.M.; Bernardino-Hernández, H.U. La elaboración de tostadas por mujeres de la costa de Oaxaca: El sustento económico que pone en riesgo su salud. Estud. Soc. Rev. De Aliment. Contemp. Y Desarro. Reg. 2021, 30, 1–26. [Google Scholar] [CrossRef]

- Mohammed, S.; Edna, M.; Siraj, K. The effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of fruits: A case of mangoes and pineapples. Heliyon 2020, 6, e04163. [Google Scholar] [CrossRef]

- Akter, J.; Hassan, J.; Rahman, M.M.; Biswas, M.S.; Khan, H.I.; Rajib, M.R.; Ahmed, M.R.; Khan, M.N.; Hasan, M.F.A. Colour, nutritional composition and antioxidant properties of dehydrated carrot (Daucus carota var. sativus) using solar drying techniques and pretreatments. Helihyon 2024, 10, e24165. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K. Low-cost drying methods for developing countries. Trends Food Sci. Technol. 2003, 14, 519–528. [Google Scholar] [CrossRef]

- Kumar, M.; Sansaniwal, S.K.; Khatak, P. Progress in solar dryers for drying various commodities. Renew. Sustain. Energy Rev. 2016, 55, 346–360. [Google Scholar] [CrossRef]

- Kerkhoff, A.J.; Senn, J.; Condori, M.A.; Mantulak, M.J. Caracterización de tres deshidratadores solares-híbridos en misiones, determinación de rendimientos. In Proceedings of the Salão Do Conhecimento 2012 Ijuí, Santa Rosa, Panambi e Três Passos, Rio Grande do Sul, Brazil, 23–26 October 2012; Unijuí, Vice-Reitoria de Pós-Graduação. pp. 1–6. [Google Scholar]

- García, V.; Iriarte, A.A.; Justinovich, S.; Angel, L.; Heredia, T. Secadero solar forzado para productos agrícolas. Av. En Energías Renov. Y Medio Ambiente-AVERMA 2015, 19, 02.21–02.28. [Google Scholar]

- Camacho-Martínez, H.A.; Antonio-Gordillo, D.M.; Robles-Ocampo, J.B.; Sevilla-Camacho, P.J. Deshidratador solar híbrido para el secado de plátano. Rev. De Sist. Exp. 2019, 6, 26–33. [Google Scholar] [CrossRef]

- Botello-Álvarez, J.E.; Martínez-Nolasco, J.J.; Bravo-Sánchez, M.C.; Gonzalez-Figueroa, J.C. 2020. Desarrollo de secadores solares Hybridos con control inteligente para la optimizacion del uso de energia (development of hybrid solar dryers with intelligent control to optimize energy use). Pist. Educ. 2020, 137, 120–133. [Google Scholar]

- Lagunes-Díaz, E.; González-Ávila, M.E.; Ortega-Rubio, A. Transición de leña a gas licuado a presión (GLP) en el sur de México, oportunidad para la mitigación del cambio climático en la región menos desarrollada del país. Acta Univ. 2015, 25, 30–42. [Google Scholar] [CrossRef]

- Martínez-Flores, H.E.; Gaytán-Martínez, M.; Figueroa-Cárdenas, J.D.; Martínez-Bustos, F.; Reyes-Vega, M.L.; Rodríguez-Vidal, A. Effect of some preservatives on shelf-life of corn tortillas obtained from extruded masa. Agrociencia 2004, 38, 285–292. [Google Scholar]

- ISO 8586-1; Sensory Analysis—General Guidance for the Selection, Training, and Monitoring of Assessors, Part 1—Selected Assessors. International Organization for Standardization: Geneva, Switzerland, 1993.

- ISO 11035; Analyse Sensorielle—Recherche et sélection de descripteurs pour l’élaboration d’un profil sensoriel par approche multidimensionnelle. International Organization for Standardization: Saint-Denis, France, 1994.

- Ares, G.; Bruzzone, F.; Vidal, L.; Cadena, R.S.; Giménez, A.; Pineau, B.; Hunter, D.C.; Paisley, A.G.; Jaeger, S.A. Evaluation of a rating-based variant of Check-All-That-Apply questions: Rate-All-That-Apply (RATA). Food Qual. Prefer. 2014, 36, 87–95. [Google Scholar] [CrossRef]

- Jaeger, S.R.; Cardello, A.V. Direct and indirect hedonic scaling methods: A comparison of the labeled affective magnitude (LAM) scale and best-worst scaling. Food Qual. Prefer. 2009, 20, 249–258. [Google Scholar] [CrossRef]

- Ramírez-Rivera, E.J.; Díaz-Rivera, P.; Ramón-Canul, L.G.; Juárez-Barrientos, J.M.; Rodríguez-Miranda, J.; Herman-Lara, E.; Prinyawiwatkul, W.; Herrera-Corredor, J.A. Comparison of performance and quantitative descriptive analysis sensory profiling and its relationship to consumer liking between the artisanal cheese producers panel and the descriptive trained panel. J. Dairy Sci. 2018, 101, 5851–5864. [Google Scholar] [CrossRef]

- MacFie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L.V. Designs to Balance the Effect of Order of Presentation and First-Order Carry-Over Effects in Hall Tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Taylor & Francis Group: Milton Park, UK, 1988; pp. 50–92. [Google Scholar] [CrossRef]

- Nestrud, M.A.; Meiselman, H.L.; King, S.C.; Lesher, L.L.; Cardello, A.V. Development of EsSense25, a shorter version of the EsSense Profile®. Food Qual. Prefer. 2016, 48, 107–117. [Google Scholar] [CrossRef]

- Cabal-Prieto, A.; Teodoro-Bernabé, G.; Coria-Rincón, C.; Sánchez-Arellano, L.; Ramón-Canul, L.G.; Rodríguez-Miranda, J.; Prinyawiwatkul, W.; Juárez-Barrientos, J.M.; Herrera-Corredor, J.A.; Ramírez-Rivera, E. de J. Development of a memories vocabulary (MemVOC) for food products using coffee as a model. Food Sci. Technol. 2022, 2061, 1–12. [Google Scholar] [CrossRef]

- Baima, J.S.; Ribotta, P.D. Image analysis as a monitoring tool in the dehydration of banana slices. Braz. J. Food Technol. 2019, 22, e2018231. [Google Scholar] [CrossRef]

- Oliveira e Silva, R.; do Carmo Rouxinol, M.I.F.; da Silva Coutinho Patarata, L.A. The use of photography to perform an online consumer test on the freshness of chicken breast and the extension of shelf life. J. Sens. Stud. 2020, 35, e12565. [Google Scholar] [CrossRef]

- Gilbert, A.N.; DiVerdi, J.A. Use of rating scales versus check-all-that-apply ballots in quantifying strain-specific Cannabis aroma. J. Sens. Stud. 2019, 34, e12499. [Google Scholar] [CrossRef]

- Gonzalez-Viejo, C.; Zhang, H.; Khamly, A.; Xing, Y.; Guentes, S. Coffee label assessment using sensory and biometric analysis of self-isolating panelists through videoconference. Beverages 2021, 7, 5. [Google Scholar] [CrossRef]

- Peralta-Cruz, C.; Rodríguez-Buenfil, I.M.; Cabal-Prieto, A.; Cuervo-Osorio, V.D.; Oney-Montalvo, J.E.; Herrera-Corredor, J.A.; Ramírez-Sucre, M.O.; Ramírez-Rivera, E.d.J. Modeling consumer satisfaction to identify drivers for liking: An online survey based on images of Habanero pepper (Capsicum chinense Jacq.). J. Sens. Stud. 2021, 36, e12696. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019. Available online: https://www.r-project.org (accessed on 15 January 2025).

- Vidal, L.; Ares, G.; Hedderley, D.I.; Meyners, M.; Jaeger, S.R. Comparison of Rate-All-That-Apply (RATA) and Check-All-That-Apply (CATA) Questions across Seven Consumer Studies. Food Qual. Prefer. 2018, 67, 49–58. [Google Scholar] [CrossRef]

- Addinsoft. Addinsoft, XLSTAT V2020. Data Analysis and Statistics Software for MS Excel; Addinsoft: New York, NY, USA, 2024. [Google Scholar]

- Le, S.; Husson, F. SensoMineR: A package for sensory data analysis. J. Sens. Stud. 2008, 23, 14–25. [Google Scholar] [CrossRef]

- González-Amaro, R.M.; Figueroa-Cárdenas, J.d.D.; Perales, H.; Velés-Medina, J.J. Physicochemical and Nutritional Properties of Different Maize Races on Toasted Tortillas. Cereal Chem. 2017, 94, 451–457. [Google Scholar] [CrossRef]

- González-Amaro, R.; Figueroa, J.; Perales, H. Maize races on functional and nutritional quality of tejate: A maize-cacao beverage. LWT-Food Sci. Technol. 2015, 63, 1008–1015. [Google Scholar] [CrossRef]

- Delgado, M.R.; Luna-Bárcenas, G.; Arámbula-Villa, G.; Azuara, E.; López-Peréa, P.; Salazar, R. Efecto de la actividad del agua en tortilla y su relación sobre el contenido de acrilamida después de la fritura. J. Ing. Alimentos. 2014, 143, 1–7. [Google Scholar] [CrossRef][Green Version]

- Morales-Pérez, J.; Vélez-Ruiz, J.F. Estudio del Efecto Combinado del Secado y Freido en las Propiedades de Tortillas Tostadas. Inf. Tecnológica 2011, 22, 55–68. [Google Scholar] [CrossRef]

- Rosales Uc, E.M.; Tamayo-Loeza, E.D.; Lopez-Kuk, J.E.; Covian-Oy, J.I.; Estrella-May, J.M. Prototype design of a Hatch type solar dehydrator with monitoring system. Adv. Eng. Innov. 2025, 10, 46–49. [Google Scholar]

- Orphanides, A.; Goulas, V.; Gekas, V. Drying Technologies: Vehicle to High-Quality Herbs. Food Eng Rev. 2016, 8, 164–180. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A.; Sharaf-Eldeen, Y.I. Review on Indian Solar Drying Status. Curr. Sustain. Renew. Energy Rep. 2016, 3, 113–120. [Google Scholar] [CrossRef]

- Stuart, B.H. Spectral Analysis. In Infrared Spectroscopy: Fundamentals and Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2004; pp. 45–70. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Ragadhita, R.; Fiandini, M. Interpretation of Fourier Transform Infrared Spectra (FTIR): A Practical Approach in the Polymer/Plastic Thermal Decomposition. Indones. J. Sci. Technol. 2023, 8, 113–126. [Google Scholar] [CrossRef]

- Bouźyk, A.; Jóźwiak, L.; Rak, J.; Blazejowska, J. Infrared and Raman spectroscopy of 9-acridinones. Vib. Spectrosc. 2001, 27, 139–152. [Google Scholar] [CrossRef]

- Barth, A. Infrared spectroscopy of proteins. Biochim. Biophys. Acta-Bioenerg. 2007, 1767, 1073–1101. [Google Scholar] [CrossRef]

- Robinson, H.; Molendijk, J.; Shah, A.K.; Rahman, T.; Anderson, G.J.; Hill, M.M. Rapid Assessment of Lipidomics Sample Purity and Quantity Using Fourier-Transform Infrared Spectroscopy. Biomolecules 2022, 12, 1265. [Google Scholar] [CrossRef]

- Long, D.A. Infrared and Raman Characteristic Group Frequencies, Tables and Charts George Socrates, 3rd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2004; p. 905. [Google Scholar] [CrossRef]

- Fabian, H.; Schultz, C.P. Fourier Transform Infrared Spectroscopy in Peptide and Protein Analysis. In Encyclopedia of Analytical Chemistry, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 82–130. [Google Scholar] [CrossRef]

- Amin, M.R.; Chowdhury, M.A.; Kowser, M.A. Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon 2019, 5, e02009. [Google Scholar] [CrossRef]

- Saiful; Helwati, H.; Saleha, S.; Iqbalsyah, T.M. Development of bioplastic from wheat Janeng starch for food packaging. IOP Conf. Ser. Mater. Sci. Eng. 2019, 523, 012015. [Google Scholar] [CrossRef]

- Černá, M.; Barros, A.S.; Nunes, A.; Roccha, S.A.; Delgadillo, I.; Čopiková, J.; Coimbra, M.A. Use of FT-IR spectroscopy as a tool for the analysis of polysaccharide food additives. Carbohydr. Polym. 2003, 51, 383–389. [Google Scholar] [CrossRef]

- Leopold, L.F.; Leopold, N.; Diehl, H.A.; Socaciu, C. Quantification of carbohydrates in fruit juices using FTIR spectroscopy and multivariate analysis. J. Spectrosc. 2011, 26, 93–104. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 110–150. [Google Scholar] [CrossRef]

- Allan, M.C.; Chamberlain, M.C.; Mauer, L.J. Effects of sugars and sugar alcohols on the gelatinization temperatures of wheat, potato, and corn starches. Foods 2020, 9, 757. [Google Scholar] [CrossRef]

- Pourfarzad, A.; Yousefi, A.; Ako, K. Steady/dynamic rheological characterization and FTIR study on wheat starch-sage seed gum blends. Food Hydrocoll. 2021, 111, 106380. [Google Scholar] [CrossRef]

- Chakraborty, I.; Pooja, N.; Mal, S.S.; Paul, U.C.; Rahman, M.H.; Mazumder, N. An insight into the gelatinization properties influencing the modified starches used in food industry: A review. Food Bioprocess Technol. 2022, 15, 1195–1223. [Google Scholar] [CrossRef]

- Krishnan, V.; Awana, M.; Singh, A.; Goswami, S.; Vinutha, T.; Kumar, R.R.; Singh, S.P.; Sathyavathi, T.; Sachdev, A.; Praveen, S. Starch molecular configuration and starch-sugar homeostasis: Key determinants of sweet sensory perception and starch hydrolysis in pearl millet (Pennisetum glaucum). Int. J. Biol. Macromol. 2021, 183, 1087–1095. [Google Scholar] [CrossRef]

- Rojas-Molina, I.; Gutiérrez, E.; Rojas, A.; Cortés-Álvarez, M.; Campos-Solis, L.; Hernández-Urbiola, M.; Arjona, J.; Cornejo, A.; Rodríguez-Garcia, M.E. Effect of Temperature and Steeping Time on Calcium and Phosphorus Content in Nixtamalized Corn Flours Obtained by Traditional Nixtamalization Process. Cereal Chem. 2009, 86, 516–521. [Google Scholar] [CrossRef]

- González, R.; Reguera, E.; Mendoza, L.; Figueroa, J.M.; Sánchez-Sinencio, F. Physicochemical Changes in the Hull of Corn Grains during Their Alkaline Cooking. J. Agric. Food Chem. 2004, 52, 3831–3837. [Google Scholar] [CrossRef] [PubMed]

- Santiago-Ramos, D.; Figueroa-Cárdenas, J.D.; Véles-Medina, J.J.; Reynoso-Camacho, R.R.; Ramos-Gómez, M.; Gaytán-Martínez, M.; Morales-Sánchez, E. Effects of annealing and concentration of calcium salts on thermal and rheological properties of maize starch during an ecological nixtamalization process. Cereal Chem. 2015, 92, 475–480. [Google Scholar] [CrossRef]

- Hassan, S.M.; Forsido, S.F.; Tola, Y.B.; Bikila, A.M.; Ahmed, Z. Effect of nixtamalization on the nutritional, anti-nutritional, functional, physicochemical and mineral properties of maize (Zea mays) tortillas. J. Food Chem. Nanotechnol. 2023, 9, 132–140. [Google Scholar] [CrossRef]

- Bustillos-Rodríguez, J.C.; Tirado-Gallegos, J.M.; Ordñez-García, M.; Zamudio-Flores, P.B.; Ornelas-Paz, J.J.; Acosta-Muñiz, C.H.; Gallegos-Morales, G.; Páramo-Calderón, D.E.; Ríos-Velasco, C. Physicochemical, thermal and rheological properties of three native corn starches. Food Sci. Technol. 2019, 39, 149–157. [Google Scholar] [CrossRef]

- Li, C. Recent progress in understanding starch gelatinization—An important property determining food quality. Carbohydr. Polym. 2022, 293, 119735. [Google Scholar] [CrossRef]

- Santiago-Cruz, I.A.; Ramírez-Rivera, E.J.; López-Espíndola, M.; Hidalgo-Contreras, J.V.; Prinyawiwatkul, W.; Herrera-Corredor, J.A. Use of online questionnaires to identify emotions elicited by different types of corn tortilla in consumers of different gender and age. J. Sens. Stud. 2021, 36, e12638. [Google Scholar] [CrossRef]

- De Santis, D. Food Flavor Chemistry and Sensory Evaluation. Foods 2024, 13, 634. [Google Scholar] [CrossRef]

- Saleh, M.; Lee, Y. Instrumental Analysis or Human Evaluation to Measure the Appearance, Smell, Flavor, and Physical Properties of Food. Foods 2023, 12, 3453. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; King, J.M.; Prinyawiwatkul, W. A review of measurement and relationships between food, eating behavior and emotion. Trends Food Sci. Technol. 2014, 36, 15–28. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Hernandez, F.; Melgarejo, P.; Lech, K.; Carbonell-Barrachina, A. Chemical composition, antioxidant capacity, and sensory quality of pomegranate (Punica granatum L.) arils and rind as affected by drying method. Food Bioprocess Technol. 2013, 6, 1644–1654. [Google Scholar] [CrossRef]

- Elias, N.; Berbert, P.; Molina, M.; Viana, A.; Dionello, R.; Queiroz, V. Nutritional and sensory evaluation of osmo-convective dried Fuyu persimmons. Food Sci. Technol. 2008, 28, 322–328. [Google Scholar] [CrossRef]

| Race | Municipality | Locality | Altitude | Soil Type | Climate Type | Annual Precipitation |

|---|---|---|---|---|---|---|

| Chiquito | Rafael Delgado | Las Sirenas | 1163 | Chromic Luvisol | (A)C(m) | 1500–2000 |

| Pepitilla | Texhuacán | El Mirador | 2067 | Chromic Luvisol | C(m) (f) | 1200–1500 |

| Cónico | Xoxocotla | Xoxocotla | 2115 | Chromic Luvisol | C(m) (f) | 1200–500 |

| Determination | Race | Method | Race*Method |

|---|---|---|---|

| Moisture | <0.0001 | <0.0001 | <0.0001 |

| Lipid | <0.0001 | 0.009 | 0.211 |

| Ash | 0.301 | <0.0001 | 0.119 |

| Protein | 0.329 | 0.301 | 0.020 |

| Carbohydrates | <0.0001 | <0.0001 | <0.0001 |

| aw | <0.0001 | <0.0001 | <0.0001 |

| L | <0.0001 | 0.218 | <0.0001 |

| a* | <0.0001 | 0.965 | 0.308 |

| b* | <0.0001 | 0.027 | 0.032 |

| Chroma | <0.0001 | 0.059 | 0.147 |

| Hue Angle | <0.0001 | 0.961 | 0.181 |

| Fracturability | 0.288 | <0.0001 | 0.040 |

| Texture | 0.078 | 0.361 | 0.501 |

| Factor: Race | ||||||

| Moisture | Lipid | Ash | Protein | Carbohydrate | aw | |

| Cónico | 7.42 ± 0.143 b | 1.73 ± 0.103 a | 1.49 ± 0.153 a | 3.93 ± 0.073 a | 85.40 ± 0.347 c | 0.67 ± 0.002 c |

| Chiquito | 8.00 ± 0.143 a | 1.22 ± 0.103 b | 1.43 ± 0.153 a | 4.23 ± 0.073 a | 85.11 ± 0.347 c | 0.64 ± 0.002 a |

| Pepitilla | 6.52 ± 0.143 c | 0.86 ± 0.103 c | 1.09 ± 0.153 a | 3.79 ± 0.073 a | 87.71 ± 0.347 b | 0.66 ± 0.002 b |

| Commercial (Control) | 5.73 ± 0.143 d | 0.63 ± 0.103 c | 1.31 ± 0.153 a | 3.50 ± 0.073 a | 88.81 ± 0.347 a | 0.69 ± 0.002 d |

| Factor: Dehydration Method | ||||||

| Moisture | Lipid | Ash | Protein | Carbohydrate | aw | |

| Hybrid | 7.72 ± 0.101 a | 1.26 ± 0.073 a | 1.675 ± 0.108 a | 4.01 ± 0.193 a | 85.31 ± 0.245 b | 0.65 ± 0.002 a |

| Solar | 6.10 ± 0.101 b | 0.96 ± 0.073 b | 1.00 ± 0.108 b | 3.72 ± 0.193 a | 88.20 ± 0.245 a | 0.69 ± 0.002 b |

| Interaction: Race-Dehydration Method | ||||||

| Moisture | Lipid | Ash | Protein | Carbohydrate | aw | |

| Hyb*Co | 8.56 ± 0.202 b | 2.02 ± 0.146 a | 1.93 ± 0.216 a | 4.66 ± 0.386 a | 82.81 ± 0.49 c | 0.70 ± 0.004 ef |

| Hyb*Chi | 10.32 ± 0.202 a | 1.19 ± 0.146 a | 1.43 ± 0.216 a | 4.66 ± 0.386 a | 82.37 ± 0.49 c | 0.60 ± 0.004 a |

| Hyb*Pep | 5.85 ± 0.202 de | 0.99 ± 0.146 a | 1.49 ± 0.216 a | 3.20 ± 0.386 c | 88.44 ± 0.49 b | 0.61 ± 0.004 b |

| Hyb*Test | 6.17 ± 0.202 d | 0.84 ± 0.146 a | 1.83 ± 0.216 a | 3.50 ± 0.386 bc | 87.63 ± 0.49 b | 0.68 ± 0.004 d |

| Sol*Co | 6.28 ± 0.202 d | 1.45 ± 0.146 a | 1.06 ± 0.216 a | 3.20 ± 0.386 c | 87.99 ± 0.49 b | 0.65 ± 0.004 c |

| Sol*Chi | 5.67 ± 0.202 de | 1.24 ± 0.146 a | 1.43 ± 0.216 a | 3.79 ± 0.386 abc | 87.84 ± 0.49 b | 0.69 ± 0.004 e |

| Sol*Pep | 7.2 ± 0.202 c | 0.72 ± 0.146 a | 0.70 ± 0.216 a | 4.37 ± 0.386 ab | 86.99 ± 0.49 b | 0.70 ± 0.004 f g |

| Sol*Test | 5.28 ± 0.202 e | 0.42 ± 0.146 a | 0.79 ± 0.216 a | 3.50 ± 0.386 bc | 89.99 ± 0.49 a | 0.71 ± 0.004 g |

| Factor: Race | |||||||

| L | a* | b* | Chroma | Hue Angle | Fracture (N) | Texture | |

| Cónico | 40.11 ± 1.47 b | 4.81 ± 0.40 b | 21.44 ± 0.71 b | 21.95 ± 0.73 b | 78.60 ± 1.01 a | 1.94 ± 0.17 a | 1.31 ± 0.13 a |

| Chiquito | 35.21 ± 1.47 a | 1.78 ± 0.40 a | 8.01 ± 0.71 a | 8.22 ± 0.73 a | 78.01 ± 1.01 a | 1.79 ± 0.17 a | 1.39 ± 0.13 a |

| Pepitilla | 39.15 ± 1.47 ab | 2.15 ± 0.40 a | 21.45 ± 0.71 b | 22.06 ± 0.73 b | 85.08 ± 1.01 b | 1.97 ± 0.17 a | 1.45 ± 0.13 a |

| Commercial (Control) | 71.48 ± 1.47 c | 1.92 ± 0.40 a | 20.21 ± 0.71 b | 20.32 ± 0.73 b | 84.58 ± 1.01 b | 2.28 ± 0.17 a | 0.98 ± 0.13 a |

| Factor: Dehydration Method | |||||||

| L | a* | b* | Chroma | Hue Angle | Fracture (N) | Texture | |

| Hybrid | 45.54 ± 1.04 a | 2.67 ± 0.28 a | 18.64 ± 0.50 b | 18.89 ± 0.52 a | 81.54 ± 0.71 a | 2.42 ± 0.12 b | 1.34 ± 0.9 a |

| Solar | 47.43 ± 1.04 a | 2.65 ± 0.28 a | 16.91 ± 0.50 a | 17.38 ± 0.52 a | 81.59 ± 0.71 a | 1.57 ± 0.12 a | 1.22 ± 0.9 a |

| Interaction: Race-Dehydration Method | |||||||

| L | a* | b* | Chroma | Hue Angle | Fracture (N) | Texture | |

| Hyb*Co | 44.72 ± 2.09 d | 4.68 ± 0.57 a | 22.55 ± 1.00 d | 23.04 ± 1.04 a | 78.37 ± 1.43 a | 2.58 ± 0.22 c d | 1.55 ± 0.19 a |

| Hyb*Chi | 27.550 ± 2.08 a | 2.39 ± 0.57 a | 9.61 ± 1.00 b | 9.93 ± 1.04 a | 76.28 ± 1.43 a | 1.90 ± 0.24 a b c | 1.43 ± 0.19 a |

| Hyb*Pep | 37.06 ± 2.09 bc | 2.21 ± 0.57 a | 21.18 ± 1.00 cd | 21.30 ± 1.04 a | 85.36 ± 1.43 a | 2.19 ± 0.24 b c | 1.47 ± 0.19 a |

| Hyb*Test | 72.83 ± 2.09 e | 1.41 ± 0.57 a | 21.24 ± 1.00 cd | 21.28 ± 1.04 a | 86.17 ± 1.43 a | 2.99 ± 0.24 d | 0.93 ± 0.19 a |

| Sol*Co | 35.50 ± 2.09 b | 4.94 ± 0.57 a | 20.33 ± 1.00 cd | 20.85 ± 1.04 a | 78.84 ± 1.43 a | 1.29 ± 0.24 a | 1.08 ± 0.19 a |

| Sol*Chi | 42.87 ± c d | 1.17 ± 0.57 a | 6.40 ± 1.00 a | 6.51 ± 1.04 a | 79.74 ± 1.43 a | 1.68 ± 0.24 ab | 1.35 ± 0.19 a |

| Sol*Pep | 41.23 b c d | 2.08 ± 0.57 a | 21.72 ± 1.00 cd | 22.82 ± 1.04 a | 84.81 ± 1.43 a | 1.74 ± 0.24 ab | 1.43 ± 0.19 a |

| Sol*Test | 70.14 ± 0.57 e | 2.43 ± 0.57 a | 19.19 ± 1.00 c | 19.35 ± 1.04 a | 82.99 ± 1.43 a | 1.56 ± 0.24 ab | 1.02 ± 0.19 a |

| Bond/Stretching | Wavenumber Range (cm−1) | Associated Principal Component | Reference |

|---|---|---|---|

| O–H, N–H | 3000–3700 | Water, polysaccharides, proteins | [49] |

| C–H | 2800–3000 | Lipids, polysaccharides (carbohydrates) | [50,51] |

| C=O, N–H | 1500–1750 | Amide (proteins), lipids | [52,53] |

| C–O, C–N, | 1200–1500 | Carbohydrates, proteins | [54,55] |

| C–O–C, C–O, C–C, C–H | 900–1200 | Polysaccharides (carbohydrates) | [56,57,58,59] |

| O–P–O | <900 | Phosphates | [60] |

| Attribute | Sample | Consumer | ||

|---|---|---|---|---|

| F | p-Value | F | p-Value | |

| Crunchy | 23.69 | <0.0001 | 3.08 | <0.0001 |

| Corn-F | 7.86 | <0.0001 | 3.16 | <0.0001 |

| Sweet-BT | 6.70 | <0.0001 | 6.47 | <0.0001 |

| Salty-BT | 4.81 | <0.0001 | 6.56 | <0.0001 |

| Lime-F | 4.89 | <0.0001 | 5.28 | <0.0001 |

| Burnt-F | 5.77 | <0.0001 | 3.21 | <0.0001 |

| Hard | 23.95 | <0.0001 | 2.27 | <0.0001 |

| Porous | 8.40 | <0.0001 | 5.01 | <0.0001 |

| Dough-F | 4.12 | <0.0001 | 5.16 | <0.0001 |

| Sour-BT | 3.40 | 0.001 | 3.13 | <0.0001 |

| Emotion | p-Value | Emotion | p-Value | Memorie | p-Value | Memorie | p-Value |

|---|---|---|---|---|---|---|---|

| Active (+) | 0.414 | Warm (+) | 0.001 | Traditional food (+) | <0.0001 | Cold weather (+) | 0.973 |

| Enthusiastic (+) | 0.275 | Satisfied (+) | <0.0001 | Party (+) | <0.0001 | Hot weather (+) | 0.022 |

| Free (+) | 0.0001 | Calm (+) | <0.0001 | Family (+) | <0.0001 | Mild weather (+) | 0.001 |

| Good (+) | <0.0001 | Adventurous (+) | <0.0001 | Birthplace (+) | 0.105 | Disease (−) | 0.323 |

| Good nature (+) | 0.304 | Interested (+) | 0.0001 | Childhood (+) | <0.0001 | Pain (−) | 0.001 |

| Happy (+) | <0.0001 | Aggressive (−) | 0.005 | Friendship (+) | 0.013 | Hurt (−) | 0.012 |

| Joyful (+) | 0.003 | Disgusted (−) | <0.0001 | Sport (+) | 0.006 | Obesity (−) | 0.973 |

| Loving (+) | 0.716 | Nostalgic (−) | 0.005 | Alive (+) | 0.008 | Stench (−) | 0.398 |

| Mild (+) | 0.009 | Wild (−) | 0.022 | Gift (+) | 0.009 | Addiction (−) | 0.550 |

| Pleasant (+) | 0.854 | Worried (−) | 0.045 | Spring (+) | 0.448 | Poverty (−) | 0.179 |

| Secure (+) | 0.661 | Bored (−) | <0.0001 | Summer (+) | 0.007 | Death (−) | 0.208 |

| Tame (+) | 0.030 | Guilty (−) | 0.003 | Fall (+) | 0.548 | Interpersonal conflict (−) | 0.564 |

| Understanding (+) | 0.701 | Winter (+) | 0.158 | Accident (−) | 0.015 | ||

| Rainy weather (+) | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salas-Valdez, O.; Ramírez-Rivera, E.d.J.; Cabal-Prieto, A.; Rodríguez-Miranda, J.; Juárez-Barrientos, J.M.; Hernández-Salinas, G.; Herrera-Corredor, J.A.; Rodríguez-Girón, J.S.; Marín-Vega, H.; Castillo-Martínez, S.I.; et al. Analysis of the Impact of the Drying Process and the Effects of Corn Race on the Physicochemical Characteristics, Fingerprint, and Cognitive-Sensory Characteristics of Mexican Consumers of Artisanal Tostadas. Processes 2025, 13, 2243. https://doi.org/10.3390/pr13072243

Salas-Valdez O, Ramírez-Rivera EdJ, Cabal-Prieto A, Rodríguez-Miranda J, Juárez-Barrientos JM, Hernández-Salinas G, Herrera-Corredor JA, Rodríguez-Girón JS, Marín-Vega H, Castillo-Martínez SI, et al. Analysis of the Impact of the Drying Process and the Effects of Corn Race on the Physicochemical Characteristics, Fingerprint, and Cognitive-Sensory Characteristics of Mexican Consumers of Artisanal Tostadas. Processes. 2025; 13(7):2243. https://doi.org/10.3390/pr13072243

Chicago/Turabian StyleSalas-Valdez, Oliver, Emmanuel de Jesús Ramírez-Rivera, Adán Cabal-Prieto, Jesús Rodríguez-Miranda, José Manuel Juárez-Barrientos, Gregorio Hernández-Salinas, José Andrés Herrera-Corredor, Jesús Sebastián Rodríguez-Girón, Humberto Marín-Vega, Susana Isabel Castillo-Martínez, and et al. 2025. "Analysis of the Impact of the Drying Process and the Effects of Corn Race on the Physicochemical Characteristics, Fingerprint, and Cognitive-Sensory Characteristics of Mexican Consumers of Artisanal Tostadas" Processes 13, no. 7: 2243. https://doi.org/10.3390/pr13072243

APA StyleSalas-Valdez, O., Ramírez-Rivera, E. d. J., Cabal-Prieto, A., Rodríguez-Miranda, J., Juárez-Barrientos, J. M., Hernández-Salinas, G., Herrera-Corredor, J. A., Rodríguez-Girón, J. S., Marín-Vega, H., Castillo-Martínez, S. I., Valdivia-Sánchez, J., Uribe-Cuauhtzihua, F., & Montané-Jiménez, V. H. (2025). Analysis of the Impact of the Drying Process and the Effects of Corn Race on the Physicochemical Characteristics, Fingerprint, and Cognitive-Sensory Characteristics of Mexican Consumers of Artisanal Tostadas. Processes, 13(7), 2243. https://doi.org/10.3390/pr13072243