Deciphering the Time-Dependent Deformation and Failure Mechanism of the Large Underground Powerhouse in Baihetan Hydropower Station

Abstract

1. Introduction

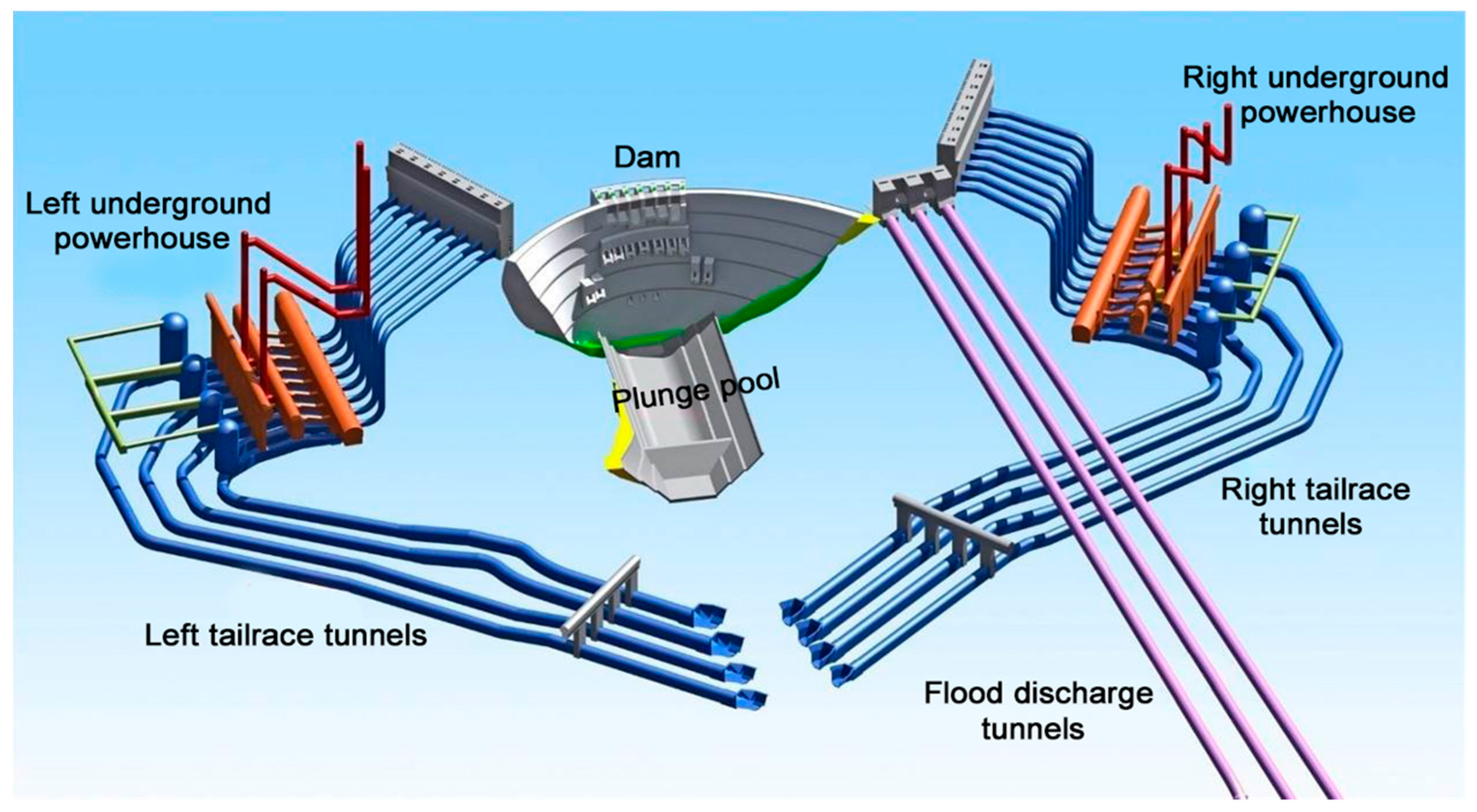

2. Project Background

2.1. Overview

2.2. Geological Conditions

2.2.1. Left-Bank Underground Powerhouse

2.2.2. Right-Bank Underground Powerhouse

2.3. In Situ Stress

3. Constitutive Model Framework and Rock Parameter Determination

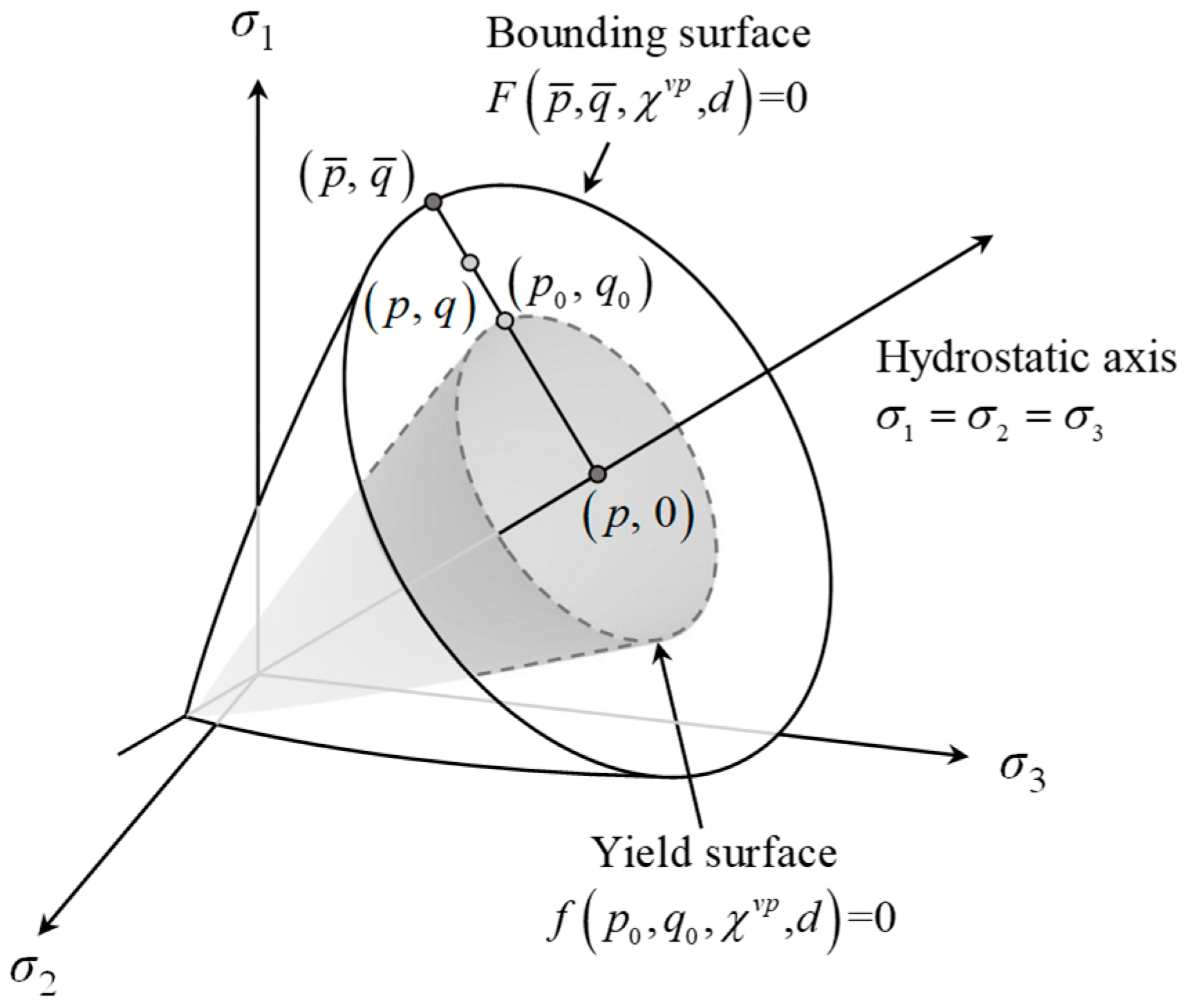

3.1. Brief Introduction of BS-VPD Model

3.2. Construction of the Numerical Model

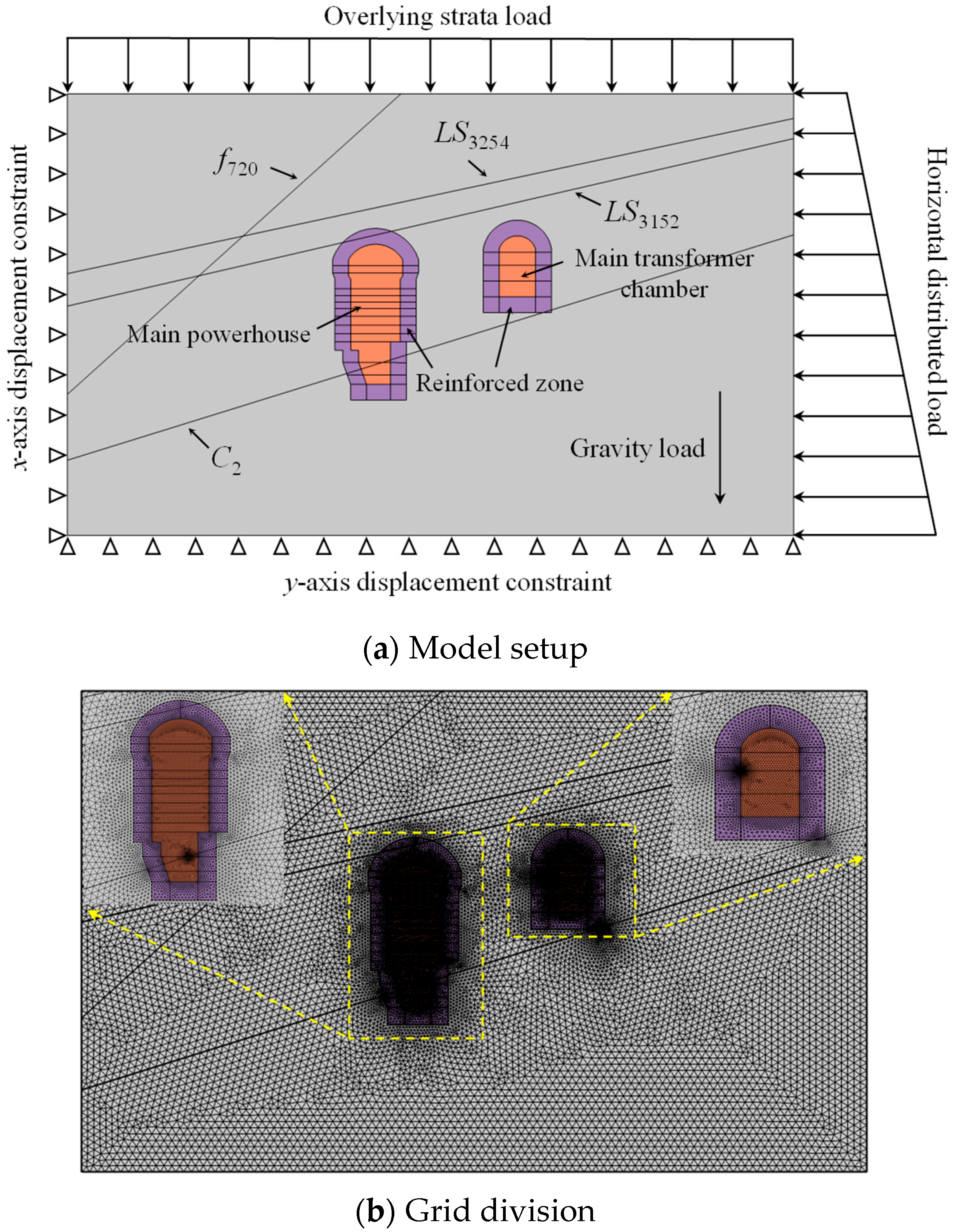

3.2.1. The 0–12.7 m Cross-Section of the Left Bank

- The longitudinal dimension of the underground powerhouse along its axis significantly exceeds its cross-sectional dimensions perpendicular to the axis, while the principal stress directions intersect with the cavern axis at substantial angles, thereby enabling the excavation simulation to be simplified as a plane strain configuration.

- The influence of transformer cavern excavation on the surrounding rock deformation of the main powerhouse was exclusively considered. This selective simplification is justified by the substantial dimensions of the transformer cavern (spanning 21 m with a height of 39.5 m) and its proximate spatial relationship with the main powerhouse (the net distance between the two chambers is 60.65 m), whereby the secondary stress redistribution resulting from transformer cavern excavation was found to exert significant mechanical effects on the powerhouse periphery. In contrast, the remaining peripheral caverns, which exhibit dimensions substantially smaller than those of the main powerhouse, are characterized by limited stress perturbation ranges that fail to modify the global deformation patterns of the main powerhouse, and their cumulative influence was therefore considered negligible in the computational framework.

- The equivalent simulation of rockbolt support was implemented through the enhancement of mechanical parameters in reinforcement zones. Although the explicit modeling of structural elements allows for accurate representation of stress characteristics in both rock masses and support systems, this approach inevitably incurs substantial computational overhead and prolongs numerical processing time. In fact, the reinforcing mechanism of rockbolts is fundamentally equivalent to the improvement of strength parameters in surrounding rock masses [28,29]. Therefore, the composite system of rock and bolt reinforcements in this study was homogenized as a continuum medium with uniformly enhanced strength properties, where the equivalent mechanical parameters of reinforced rock masses were determined through the following constitutive formulations:

- iv.

- The left-bank surrounding rock mass was uniformly categorized as Class III1, as field investigations at the Baihetan underground powerhouse reveal that over 90% of the geological formation consists of this rock type, thereby justifying the adoption of a simplified Class III1 classification for the entire left-bank rock mass in the numerical model.

- v.

- The macroscopic structural discontinuities were explicitly modeled with elastic thin layer elements, including the interlayer shear zone C2, intrastratal shear zones LS3152 and LS3254, and fault f720 that exerts substantial influence on the powerhouse section at 0–12.7 m, as shown in Figure 4a.

3.2.2. The 0–040 m Cross-Section of the Right Bank

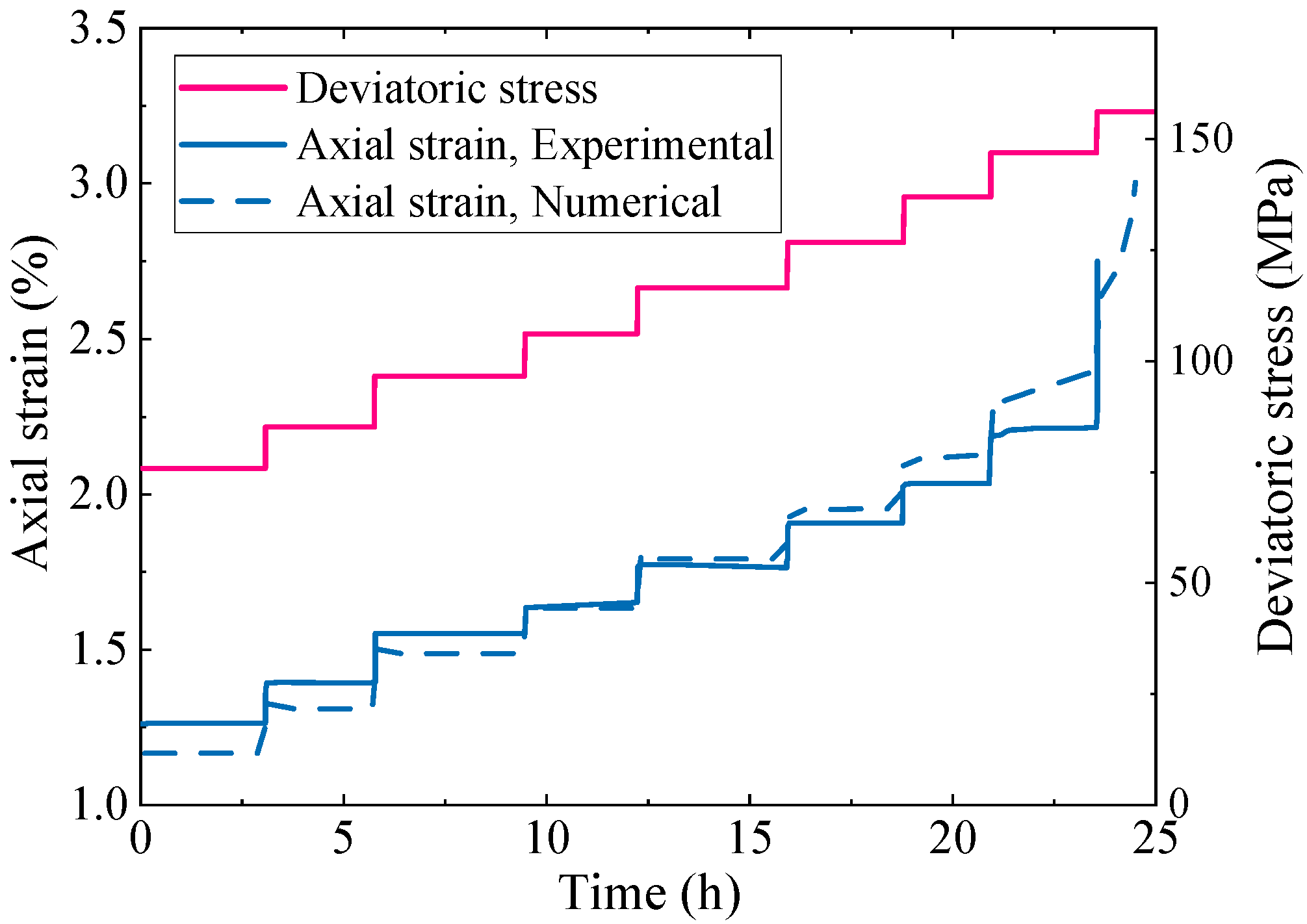

3.3. Rock Parameter Calibration

3.3.1. Model Parameter Calibration of Basalt Based on Laboratory Mechanical Tests

3.3.2. Parameter Determination of Rock Masses and Structural Planes Based on the Displacement Inversion Method

4. Time-Dependent Rock Deformation During the Excavation of Left-Bank Caverns

4.1. In Situ Stress Distribution

4.2. Displacement Evolution of the Underground Powerhouse

4.3. Mechanism of the Time-Dependent Rock Deformation

5. Time-Dependent Rock Deformation During the Excavation of Right-Bank Caverns

5.1. In Situ Stress Distribution

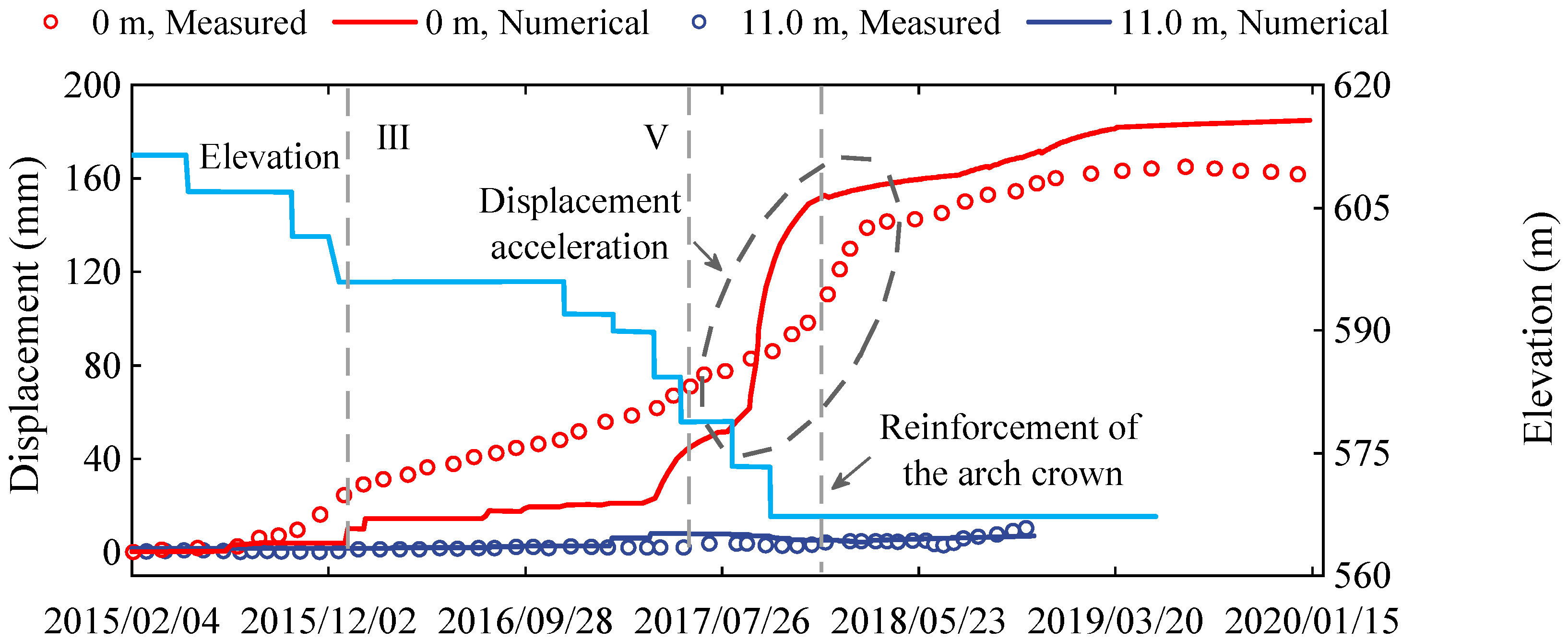

5.2. Displacement Evolution of the Underground Powerhouse

5.3. Mechanism of the Time-Dependent Rock Deformation

6. Conclusions

- (1)

- Due to the higher magnitude of in situ stress in the right-bank underground powerhouse area compared to the left bank, the secondary stress adjustments induced by excavation were more pronounced on the right bank, resulting in the maximum stress trajectories at the right-bank powerhouse under higher stress conditions exceeding those at the left-bank powerhouse by 6 MPa due to large-scale excavation unloading. This significantly amplified the time-dependent deformation of the surrounding rock.

- (2)

- In localized regions of the right-bank underground powerhouse, the stress state of the surrounding rock crossed the yield surface and reached the bounding surface during excavation, leading to accelerated damage development and ultimately accelerated creep failure, indicating that large-scale excavation unloading under high stress conditions significantly exacerbated the time-dependent deformation of the surrounding rock.

- (3)

- Targeted supplementary reinforcement measures applied to regions strongly disturbed by excavation unloading can constrain the stress state of the surrounding rock within the elastic domain. The damage development rate at the hole opening was reduced from 0.295 to 0.0015, thereby effectively preventing abrupt deformation resulting from the continuous accumulation of damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |||

| BS-VPD | Bounding surface viscoplastic damage | f | Yield surface of brittle rocks |

| GBE | Grain-based model | gvp | Viscoplastic potential function |

| NMM | Numerical manifold method | Avp | Flow parameter |

| Symbols | b0 | Similarity ratio between the yield surface and the bounding surface | |

| p | Hydrostatic stress | Stress | |

| q | Deviatoric stress | E | Equivalent elastic modulus |

| Projection of p on the boundary surface | φ | Internal friction angle | |

| Projection of q on the boundary surface | c | Cohesion of the reinforced rock mass | |

| F | Bounding surface | Py | Overburden pressure |

| b | Similarity ratio between the bounding surface and the implicit loading surface where the current stress point is located | Px | Horizontally distributed pressure |

| p0,q0 | Intersection point of the mapping trajectory of p and q on the boundary surface and the rock yield surface | hr | Buried depth |

| Viscoplastic internal variable | Eb | Elastic modulus of rockbolt | |

| d | Damage variable | rb | Rockbolt radius |

| sl | Axial pitch of the rockbolt | ||

| sr | Circumferential pitch of the rockbolt | ||

| α | Anchor density factor | ||

| ηb | Friction coefficient between the rock and the rockbolt | ||

References

- Liu, G.F.; Liu, Z.Q.; Xu, D.P.; Jiang, Q. Prediction method of rock spalling risk in large underground cavern excavation based on Bayesian network: A case study from the Baihetan hydropower station, China. Tunn. Undergr. Space Technol. 2025, 158, 106381. [Google Scholar] [CrossRef]

- Liu, G.F.; Zhou, C.; Feng, K.; Jiang, Q.; Li, S.; Bao, H.; Li, A. Probabilistic evaluation method for the stability of large underground cavern considering the uncertainty of rock mass mechanical parameters: A case study of Baihetan underground powerhouse project. Eng. Geol. 2024, 340, 107660. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.G.; Li, H.T.; Zhou, J.-W.; Fan, G.; Lu, G.-D. Effects of In-Situ stresses on dynamic rock responses under blast loading. Mech. Mater. 2020, 145, 103374. [Google Scholar] [CrossRef]

- Xiao, P.W.; Yang, X.G.; Li, B.; Zhou, X.; Sun, Y.; Ding, X.; Xu, N. Roof arch collapse of underground cavern in fractured rock mass: In-Situ monitoring and numerical modeling. J. Rock Mech. Geotech. Eng. 2025, 17, 2778–2792. [Google Scholar] [CrossRef]

- Zhang, C.S. The Baihetan Hydropower Station Project in Jinsha River. Engineering 2024, 43, 28–36. [Google Scholar] [CrossRef]

- Xia, Y.J.; Zhang, C.Q.; Zhou, H.; Chen, J.; Gao, Y.; Liu, N.; Chen, P. Structural characteristics of columnar jointed basalt in drainage tunnel of Baihetan hydropower station and its influence on the behavior of P-wave anisotropy. Eng. Geol. 2020, 264, 105304. [Google Scholar] [CrossRef]

- Fan, Q.X.; Feng, X.T.; Weng, W.L.; Fan, Y.; Jiang, Q. Unloading performances and stabilizing practices for columnar jointed basalt: A case study of Baihetan hydropower station. J. Rock Mech. Geotech. Eng. 2017, 9, 1041–1053. [Google Scholar] [CrossRef]

- Fan, Q.X.; Wang, Z.L.; Xu, J.R.; Zhou, M.; Jiang, Q.; Li, G. Study on Deformation and Control Measures of Columnar Jointed Basalt for Baihetan Super High Arch Dam Foundation. Rock Mech. Rock Eng. 2018, 51, 2569–2595. [Google Scholar] [CrossRef]

- Shi, A.C.; Wei, Y.F.; Wu, J.Y.; Ren, D.; Tang, M. Study on the shear deformation of intralayer shear bands at the Baihetan hydropower station dam foundation. Bull. Eng. Geol. Environ. 2020, 79, 3517–3532. [Google Scholar] [CrossRef]

- Zhao, J.S.; Feng, X.T.; Jiang, Q.; Zhou, Y.-Y. Microseismicity monitoring and failure mechanism analysis of rock masses with weak interlayer zone in underground intersecting chambers: A case study from the Baihetan Hydropower Station, China. Eng. Geol. 2018, 245, 44–60. [Google Scholar] [CrossRef]

- Xiao, Y.X.; Feng, X.T.; Chen, B.R.; Feng, G.-L.; Yao, Z.-B.; Hu, L.-X. Excavation-induced microseismicity in the columnar jointed basalt of an underground hydropower station. Int. J. Rock Mech. Min. Sci. 2017, 97, 99–109. [Google Scholar] [CrossRef]

- Feng, X.T.; Hao, X.J.; Jiang, Q.; Li, S.-J.; Hudson, J.A. Rock Cracking Indices for Improved Tunnel Support Design: A Case Study for Columnar Jointed Rock Masses. Rock Mech. Rock Eng. 2016, 49, 2115–2130. [Google Scholar] [CrossRef]

- Hao, X.J.; Feng, X.T.; Yang, C.X.; Jiang, Q.; Li, S.-J. Analysis of EDZ Development of Columnar Jointed Rock Mass in the Baihetan Diversion Tunnel. Rock Mech. Rock Eng. 2016, 49, 1289–1312. [Google Scholar] [CrossRef]

- Jiang, Q.; Feng, X.T.; Hatzor, Y.H.; Hao, X.-J.; Li, S.-J. Mechanical anisotropy of columnar jointed basalts: An example from the Baihetan hydropower station, China. Eng. Geol. 2014, 175, 35–45. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Q.; Huang, Q.F.; Xiang, T.; Liu, J. Advances in stability analysis and optimization design of large underground caverns under high geostress condition. Deep Resour. Eng. 2024, 1, 100113. [Google Scholar] [CrossRef]

- Zhao, J.S.; Chen, B.R.; Jiang, Q.; Xu, D.-P.; He, B.-G.; Duan, S.-Q. In-Situ comprehensive investigation of deformation mechanism of the rock mass with weak interlayer zone in the Baihetan hydropower station. Tunn. Undergr. Space Technol. 2024, 148, 105690. [Google Scholar] [CrossRef]

- Shi, A.C.; Li, C.J.; Hong, W.B.; Lu, G.; Zhou, J.; Li, H. Comparative analysis of deformation and failure mechanisms of underground powerhouses on the left and right banks of Baihetan hydropower station. J. Rock Mech. Geotech. Eng. 2022, 14, 731–745. [Google Scholar] [CrossRef]

- Wang, M.; Li, H.B.; Han, J.Q.; Xiao, X.-H.; Zhou, J.-W. Large deformation evolution and failure mechanism analysis of the multi-freeface surrounding rock mass in the Baihetan underground powerhouse. Eng. Fail. Anal. 2019, 100, 214–226. [Google Scholar] [CrossRef]

- Dai, F.; Li, B.; Xu, N.W.; Fan, Y.; Zhang, C. Deformation forecasting and stability analysis of large-scale underground powerhouse caverns from microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2016, 86, 269–281. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Q.H.; Huang, R.Q.; Chen, J.; Xue, Y.; Xu, P. Identification of structural domains considering the size effect of rock mass discontinuities: A case study of an underground excavation in Baihetan Dam, China. Tunn. Undergr. Space Technol. 2016, 51, 75–83. [Google Scholar] [CrossRef]

- Xiao, Y.X.; Feng, X.T.; Feng, G.L.; Liu, H.-J.; Jiang, Q.; Qiu, S.-L. Mechanism of evolution of stress–structure controlled collapse of surrounding rock in caverns: A case study from the Baihetan hydropower station in China. Tunn. Undergr. Space Technol. 2016, 51, 56–67. [Google Scholar] [CrossRef]

- Li, X.; Konietzky, H.; Li, X.B. Numerical study on time dependent and time independent fracturing processes for brittle rocks. Eng. Fract. Mech. 2016, 163, 89–107. [Google Scholar] [CrossRef]

- Fu, T.F.; Xu, T.; Heap, M.J.; Meredith, P.G.; Mitchell, T.M. Mesoscopic time-dependent behavior of rocks based on three-dimensional discrete element grain-based model. Comput. Geotech. 2020, 121, 103472. [Google Scholar] [CrossRef]

- Yu, X.Y.; Xu, T.; Heap, M.J.; Baud, P.; Reuschlé, T.; Heng, Z.; Zhu, W.-C.; Wang, X.-W. Time-dependent deformation and failure of granite based on the virtual crack incorporated numerical manifold method. Comput. Geotech. 2021, 133, 104070. [Google Scholar] [CrossRef]

- Lu, G.D.; Zhou, J.W.; Liu, J.F.; Liu, L.; Yang, X.-G.; Tao, J. A bounding surface viscoplastic damage model for time-dependent rock deformation. Mech. Mater. 2023, 180, 104609. [Google Scholar] [CrossRef]

- Espada, M.; Muralha, J.; Lemos, J.V.; Jiang, Q.; Feng, X.-T.; Fan, Q.; Fan, Y. Safety Analysis of the Left Bank Excavation Slopes of Baihetan Arch Dam Foundation Using a Discrete Element Model. Rock Mech. Rock Eng. 2018, 51, 2597–2615. [Google Scholar] [CrossRef]

- Feng, X.T.; Yang, C.X.; Kong, R.; Zhao, J.; Zhou, Y.; Yao, Z.; Hu, L. Excavation-induced deep hard rock fracturing: Methodology and applications. J. Rock Mech. Geotech. Eng. 2022, 14, 1–34. [Google Scholar] [CrossRef]

- Indraratna, B.; Kaiser, P.K. Analytical model for the design of grouted rock bolts. Int. J. Numer. Anal. Methods Geomech. 1990, 14, 227–251. [Google Scholar] [CrossRef]

- Zhu, F.S.; Zheng, Y.T. Support action analysis tensioned and grouted bolts. Chin. J. Rock Mech. Eng. 1996, 15, 333–337. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, C.S.; Zhu, Y.S.; Chu, W.J.; Liu, N. Mechanical behaviors of basalt at Baihetan hydropower station and simulation with Hoek-Brown constitutive model. Chin. J. Rock Mech. Eng. 2019, 38, 1964–1978. (In Chinese) [Google Scholar] [CrossRef]

- Liu, K.W.; Hao, H.; Li, X.B. Numerical analysis of the stability of abandoned cavities in bench blasting. Int. J. Rock Mech. Min. Sci. 2017, 92, 30–39. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.G.; Li, H.T.; Zhou, J.-W.; Qi, S.-C.; Lu, G.-D. Numerical investigation of blast-induced rock fragmentation. Comput. Geotech. 2020, 128, 103846. [Google Scholar] [CrossRef]

- Liu, Y.R.; Zhang, R.J.; Hou, S.K.; Zhu, L.; Pang, Z.; Zhuang, W. Investigation of energy evolution process of rock mass during deep tunnel excavation based on elasto-viscoplastic damage model and time-dependent energy indices. Acta Geotech. 2025, 20, 1549–1570. [Google Scholar] [CrossRef]

| Elastic Modulus Eb (GPa) | Rockbolt Radius rb (mm) | Axial Pitch sl (m) | Circumferential Pitch sr (m) | Frictional Coefficient ηb |

|---|---|---|---|---|

| 210 | 16 | 1.2 | 1.2 | 0.32 |

| (GPa) | k | m | |||||

| 45 | 0.25 | 80 | 0.92 | 0.75 | 0.45 | 0.66 | 0.50 |

| β | ς | s | κ (MPa) | ω1 | ω2 | Avp (1/s) | nvp |

| 0.40 | 0.05 | 1.0 | 80 | 1.0 | −0.08 | 5 × 10−4 | 8 |

| Petrographic Classification | E′ (GPa) | k′ | m′ | ||||

|---|---|---|---|---|---|---|---|

| III1 category | 10 | 25 | 0.94 | 0.50 | 0.15 | 0.30 | 0.22 |

| Serial Number | Type | Deformation Modulus (GPa) | Thickness (cm) | Normal Stiffness (GPa/m) | Shear Stiffness (GPa/m) | Shear Strength | |

|---|---|---|---|---|---|---|---|

| f | c (MPa) | ||||||

| C2 | Interlayer shear zone | 0.12 | 20 | 0.20 | 0.24 | 0.25 | 0.04 |

| LS3152 | Intralayer shear zone | 0.30 | 3.5 | 8.57 | 3.42 | 0.50 | 0.10 |

| LS3254 | Intralayer shear zone | 0.25 | 15 | 1.67 | 0.67 | 0.46 | 0.15 |

| F720 | Fault | 0.30 | 25 | 1.20 | 0.48 | 0.50 | 0.10 |

| Petrographic Classification | E′ (GPa) | k′ | m′ | ||||

|---|---|---|---|---|---|---|---|

| III1 category | 10 | 20 | 0.92 | 0.45 | 0.15 | 0.25 | 0.20 |

| Serial Number | Construction Type | Deformation Modulus (GPa) | Thickness (cm) | Normal Stiffness (GPa/m) | Shear Stiffness (GPa/m) | Shear Strength | |

|---|---|---|---|---|---|---|---|

| f | c (MPa) | ||||||

| C3 | Interlayer shear zone | 0.18 | 40 | 0.45 | 0.72 | 0.28 | 0.04 |

| C4 | Interlayer shear zone | 0.13 | 40 | 0.33 | 0.35 | 0.25 | 0.03 |

| C5 | Interlayer shear zone | 0.12 | 30 | 0.40 | 0.48 | 0.25 | 0.03 |

| Drilling Number | Buried Depth (m) | Data Source | Maximum Principal Stress (MPa) | Error (%) | Minimum Principal Stress (MPa) | Error (%) |

|---|---|---|---|---|---|---|

| DK1 | 506 | Measurement | 16.5 | 4.2 | 5.9 | 32.2 |

| Simulation | 15.8 | 7.8 | ||||

| DK2 | 512 | Measurement | 13.1 | 22.1 | 6.7 | 17.9 |

| Simulation | 16.0 | 7.9 | ||||

| σCZK3 | 455 | Measurement | 13.0 | 18.5 | 7.0 | 2.8 |

| Simulation | 15.4 | 7.2 |

| Drilling Number | Buried Depth (m) | Data Source | Maximum Principal Stress (MPa) | Error (%) | Minimum Principal Stress (MPa) | Error (%) |

|---|---|---|---|---|---|---|

| DK4 | 506 | Measurement | 21.1 | 30.8 | 5.2 | 94.2 |

| Simulation | 27.6 | 10.1 | ||||

| DK5 | 512 | Measurement | 21.3 | 29.1 | 11.5 | 13 |

| Simulation | 27.5 | 10.0 | ||||

| DK6 | 455 | Measurement | 22.9 | 17.5 | 6.9 | 37.7 |

| Simulation | 26.9 | 9.5 |

| Petrographic Classification | E′ (GPa) | k′ | m′ | ||||

|---|---|---|---|---|---|---|---|

| III1 category | 10 | 20 | 0.92 | 0.68 | 0.23 | 0.40 | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zu, W.; Tao, J.; Wang, J. Deciphering the Time-Dependent Deformation and Failure Mechanism of the Large Underground Powerhouse in Baihetan Hydropower Station. Processes 2025, 13, 2244. https://doi.org/10.3390/pr13072244

Zu W, Tao J, Wang J. Deciphering the Time-Dependent Deformation and Failure Mechanism of the Large Underground Powerhouse in Baihetan Hydropower Station. Processes. 2025; 13(7):2244. https://doi.org/10.3390/pr13072244

Chicago/Turabian StyleZu, Wenjie, Jian Tao, and Jun Wang. 2025. "Deciphering the Time-Dependent Deformation and Failure Mechanism of the Large Underground Powerhouse in Baihetan Hydropower Station" Processes 13, no. 7: 2244. https://doi.org/10.3390/pr13072244

APA StyleZu, W., Tao, J., & Wang, J. (2025). Deciphering the Time-Dependent Deformation and Failure Mechanism of the Large Underground Powerhouse in Baihetan Hydropower Station. Processes, 13(7), 2244. https://doi.org/10.3390/pr13072244