An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

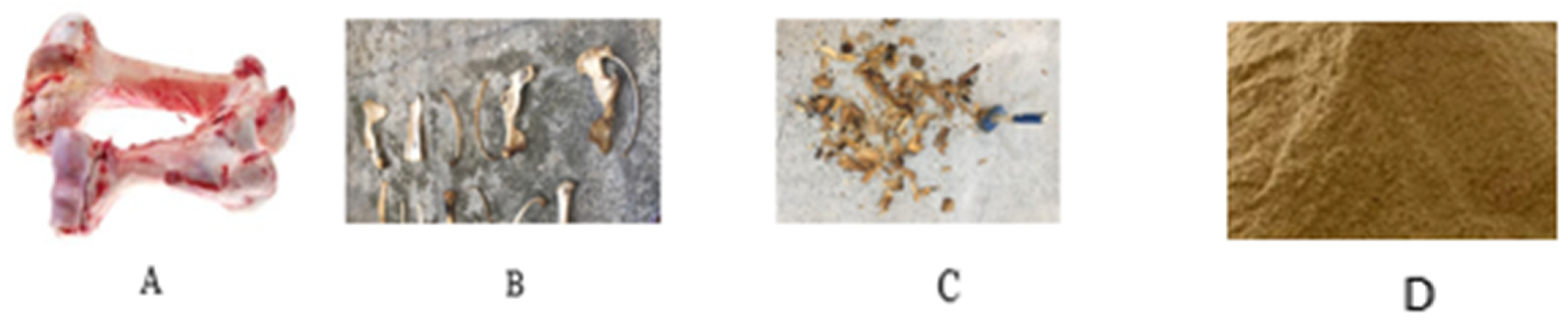

2.2. Processing of Cow Bones

2.3. Preparation of Drilling Fluid

2.4. Drilling Fluid/Mud Tests

2.4.1. Determination of Mud Density

2.4.2. Determination of Mud pH

2.4.3. Determination of Water-Based Mud (WBM) Rheology

2.4.4. Determination of Filtrate Volume and Mud Cake Thickness

2.4.5. Thermal Aging of Mud Samples

3. Results and Discussion

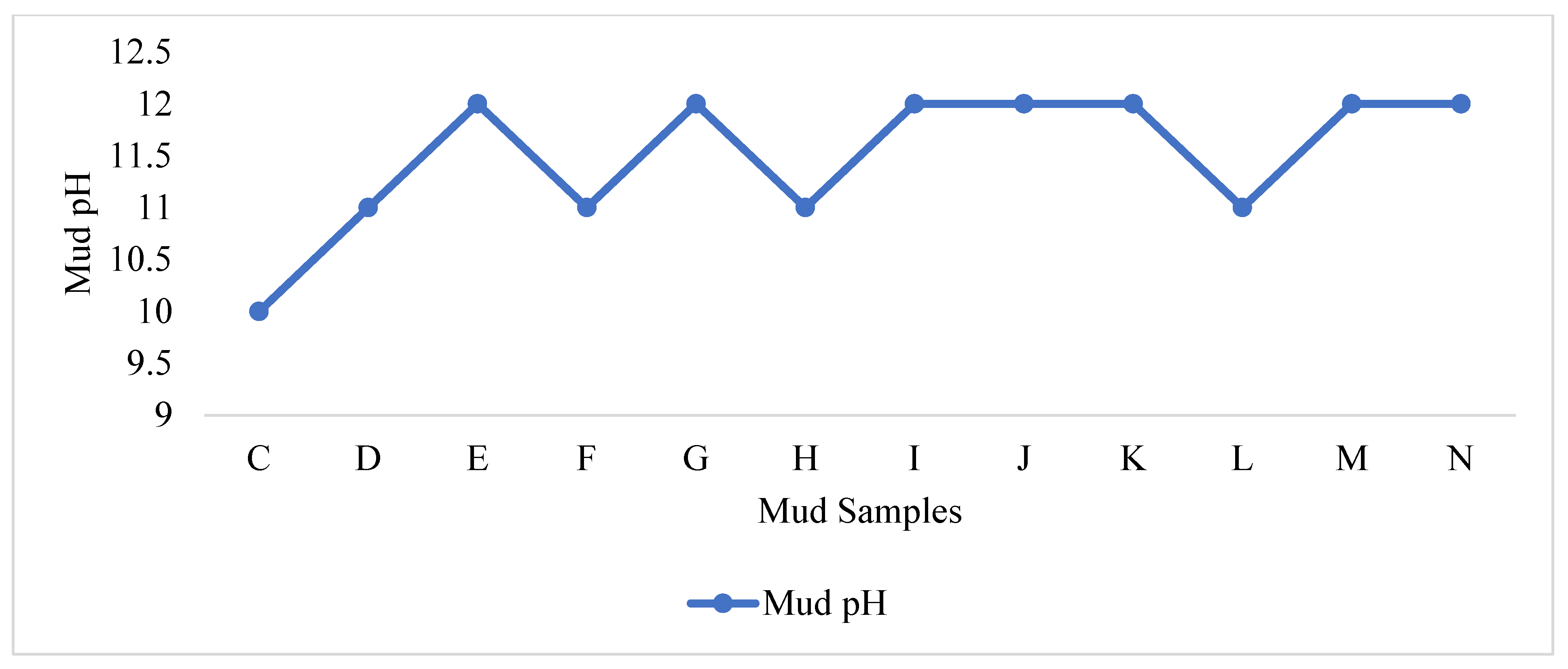

3.1. Impact of CBP and CaCO3 Additives on pH of Mud Samples

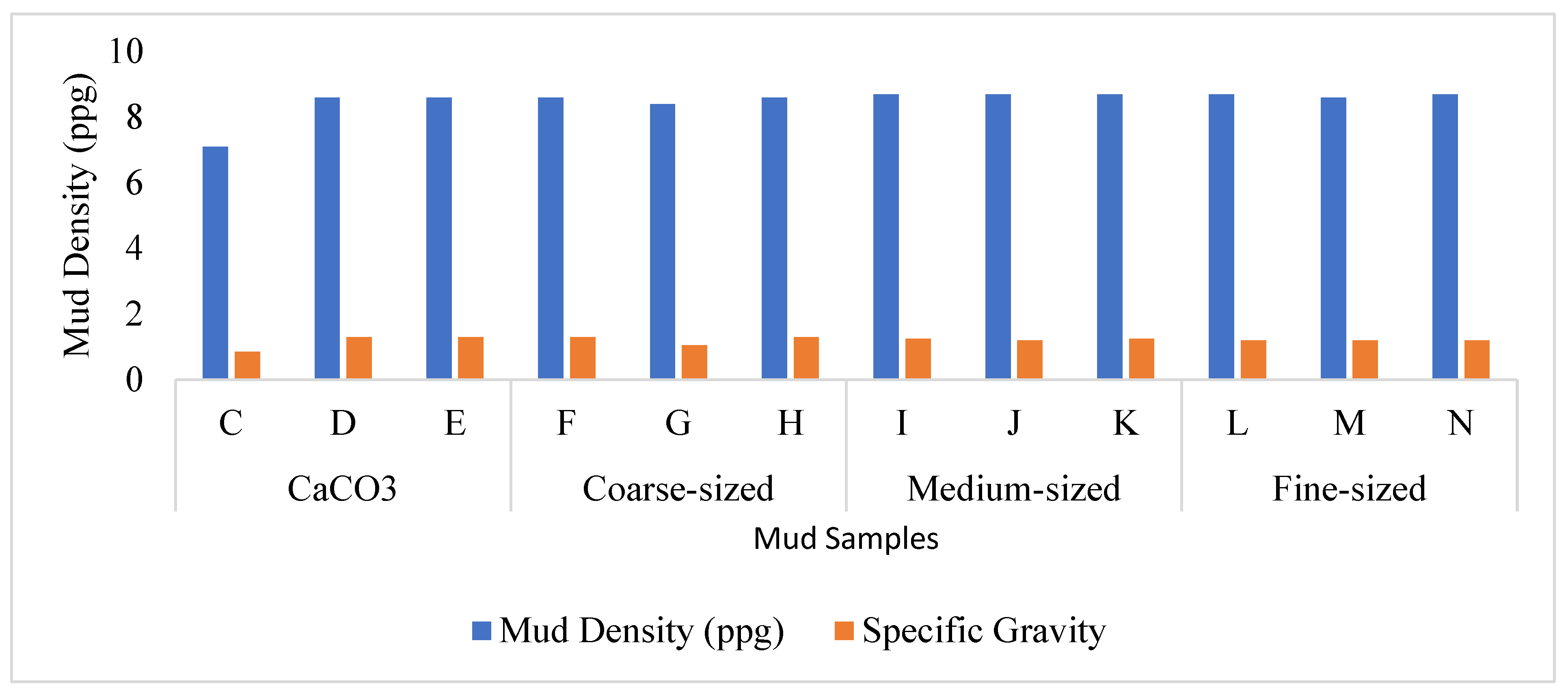

3.2. Impact of CBP and CaCO3 Additives on Density and Specific Gravity of Mud Samples

3.3. Impact of CBP and CaCO3 Additives on Rheological Properties of Mud Samples

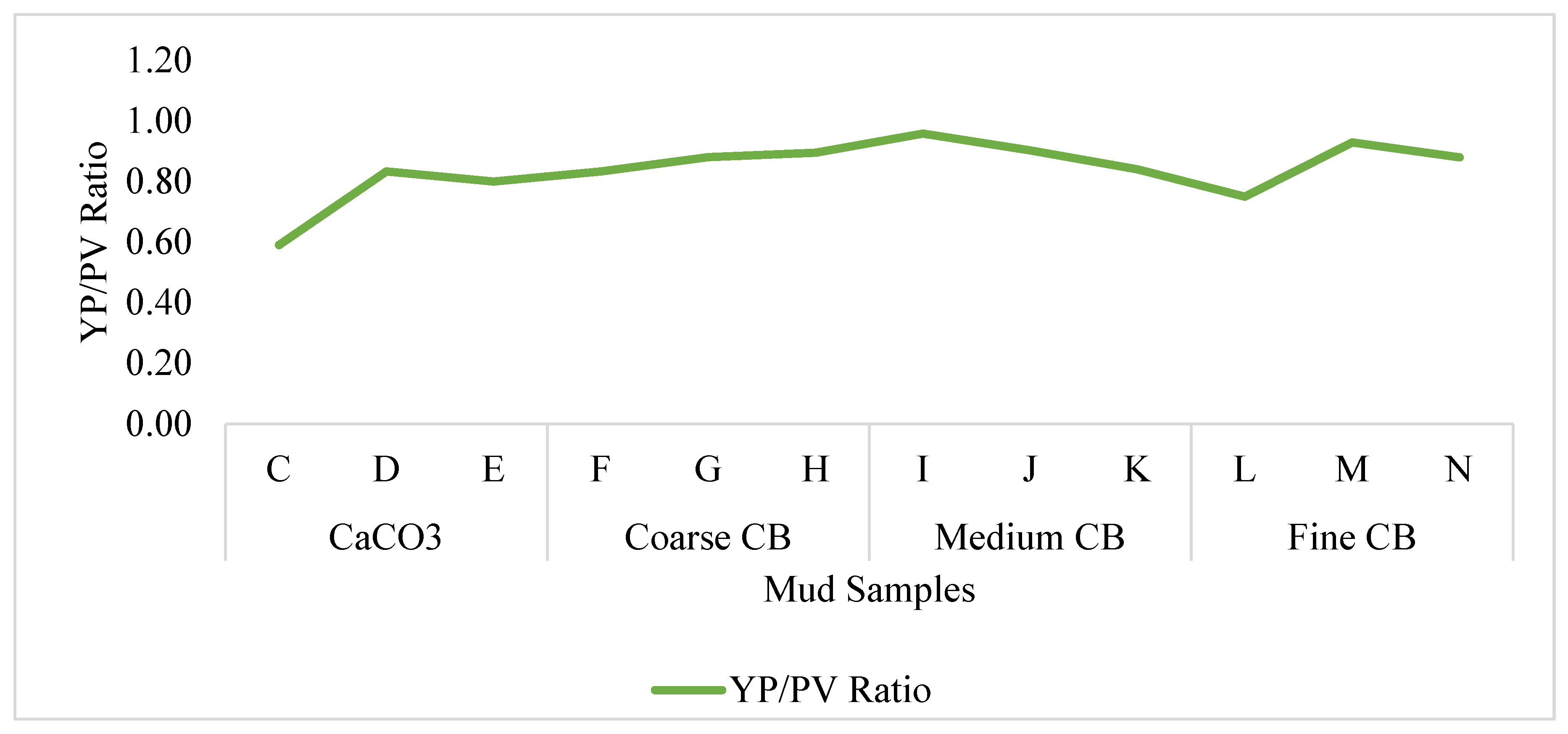

3.3.1. YP/PV Ratio of Mud Samples

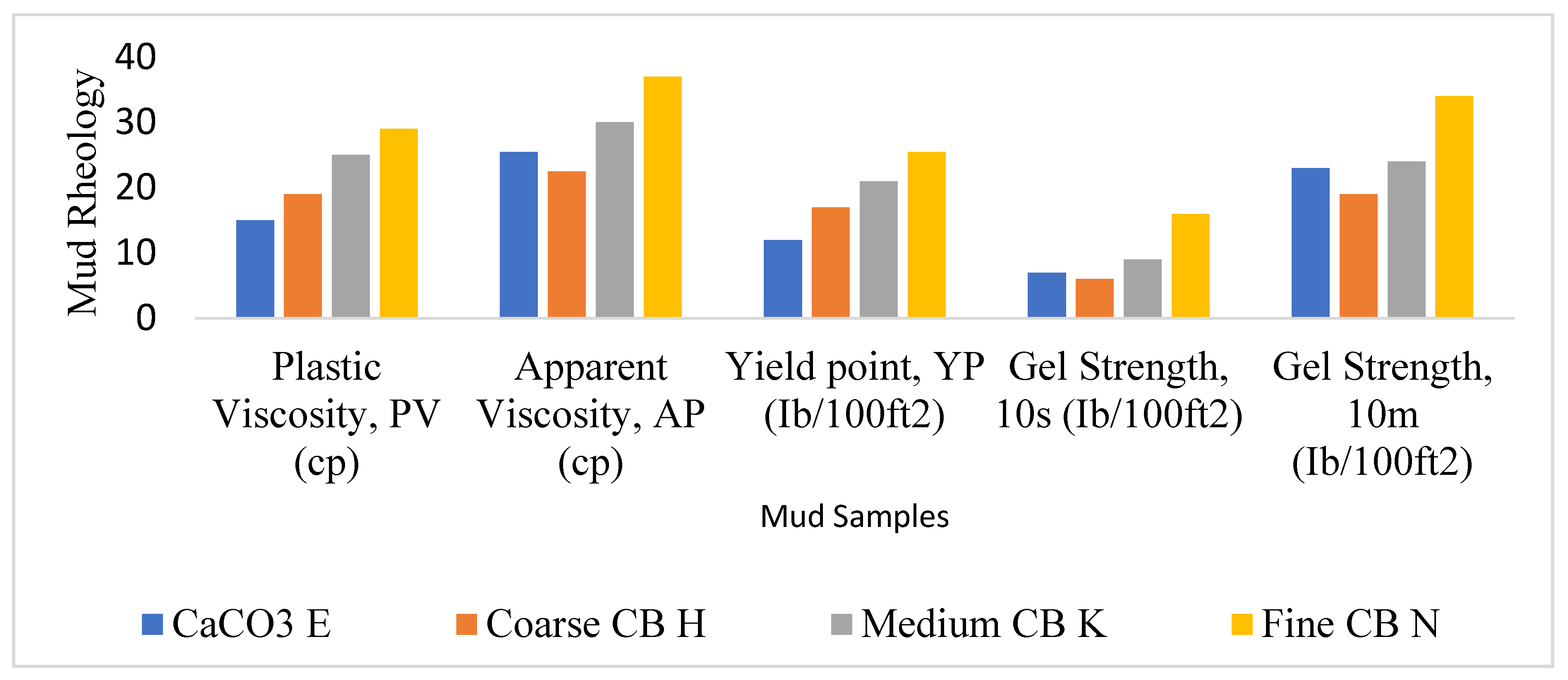

3.3.2. Effect of Different Particle Sizes of Additives on Mud Rheology

3.3.3. Impact of Cow Bone Particle Sizes on Filtration Properties

3.4. Impact of Cow Bone Powder on Thermal Properties (Aging)

4. Conclusions

- CBP samples showed higher and consistent alkalinity values, improving mud performance and extending drilling bit longevity.

- The CBP mud’s high density and specific gravity made it an efficient bridging material by balancing pressured fluids in the formation.

- Decreasing the particle size (coarse to fine particles) and increasing the concentration from 5 to 15 g positively impacted mud rheology.

- Among all the conditions analyzed, CBP performed excellently when compared with CaCO3 with fine-particle CBP at a 15 g concentration, producing the best properties such as the apparent viscosity (37 cp), plastic viscosity (29 cp), and yield point (25.5 lb/100 ft2), and gel strength of 16 lb/100 ft2 (10 s) and 28 lb/100 ft2 (10 min).

- The filtration control ability of CaCO3 was observed to be better than that of the coarse and medium CBP particle sizes. However, fine-particle-size CBP demonstrated a 6.1% and 34.6% fluid-loss reduction at 10 g and 15 g concentrations when compared to respective amounts of CaCO3.

- The thermal behavior of the Mud Samples demonstrated that using them before aging positively impacted rheology. At the same time, after aging, they exhibited a negative effect where samples grew more viscous and exceeded the API standard range for mud properties.

- Therefore, cow bone powder possesses the potential to be an eco-friendly, economically feasible fluid-loss control additive. Its utilization would not only help transform waste into wealth; further, it would also reduce environmental pollution and enable a cleaner and healthier eco-system since they are mainly discarded by burning.

5. Recommendations

- Characterizing the functional groups in cow bones using Fourier Transform Infrared Spectroscopy (FTIR).

- Conducting biodegradability experiments on Mud Samples.

- Investigating the sealing performance of FL additives blends with various particle size distributions.

- 4.

- Field-testing of cow bone Mud Samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Alkhamis, M.M.; Dunn-Norman, S. Utilizing a new eco-friendly drilling mud additive generated from wastes to minimize the use of the conventional chemical additives. J. Pet. Explor. Prod. Technol. 2020, 10, 3467–3481. [Google Scholar] [CrossRef]

- Olaniyan, D.D.; Sarah, A.A. The rheological and filtration properties of black seed (Nigella sativa L.) ester as a base fluid in drilling fluid. J. Eng. Appl. Sci. 2024, 71, 17. [Google Scholar] [CrossRef]

- Iqbal, R.; Pirzada, F.; Zubair, M.; Mehmood, A. An experimental study on the performance of starch extracted from wheat flour as a filtration control agent in the drilling fluid. Int. J. Adv. Appl. Sci. 2020, 9, 255. [Google Scholar]

- Agwu, O.E.; Akpabio, J.U. Using agro-waste materials as possible filter loss control agents in drilling muds: A review. J. Pet. Sci. Eng. 2018, 163, 185–198. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Al-Alwani, M.A.; Al-Bazzaz, W.H.; Alshammari, A.F.; Albazzaz, H.W.; Mutar, R.A. Experimental investigation of bio-enhancer drilling fluid additive: Can palm tree leaves be utilized as a supportive eco-friendly additive in water-based drilling fluid system? J. Pet. Explor. Prod. Technol. 2019, 10, 595–603. [Google Scholar] [CrossRef]

- Okon, A.N.; Akpabio, J.U.; Tugwell, K.W. Evaluating the locally sourced materials as fluid loss control additives in water-based drilling fluid. Heliyon 2020, 6, e04091. [Google Scholar] [CrossRef] [PubMed]

- Apaleke, A.S.; Al-Majed, A.; Hossain, M.E. Drilling Fluid: State of The Art and Future Trend. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 20–22 February 2012; SPE: Dallas, TX, USA, 2012; p. SPE-149555-MS. [Google Scholar] [CrossRef]

- Alsaba, M.; Nygaard, R.; Contreras, O. Review of Lost Circulation Materials and Treatments with an Updated Classification. In Proceedings of the 2014 AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 15–16 April 2014. [Google Scholar]

- Dike, H.N.; Kolade, G.O.; Adewumi, C.N.; Adewumi, O.C.D.N.; Olaniyan, D.D. Evaluating the effect of unmodified and modified starch (EDTA-DSD) as fluid-loss control additives in locally-sourced bentonite water-based drilling mud. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2024; SPE: Dallas, TX, USA, 2024; p. D021S002R007. [Google Scholar] [CrossRef]

- Ezeakacha, C.P.; Salehi, S.; Hayatdavoudi, A. Experimental Study of Drilling Fluid’s Filtration and Mud Cake Evolution in Sandstone Formations. J. Energy Resour. Technol. 2017, 139, 022912. [Google Scholar] [CrossRef]

- Kumar, A. Fluid Loss as a Function of Position around the Wellbore. In Proceedings of the 2010 American Association of Drilling Engineers Fluids Conference and Exhibition, Houston, TX, USA, 6–7 April 2010. [Google Scholar]

- Dehghani, F.; Kalantariasl, A.; Saboori, R.; Sabbaghi, S.; Peyvandi, K. Performance of carbonate calcium nanoparticles as filtration loss control agent of water-based drilling fluid. SN Appl. Sci. 2019, 1, 1466. [Google Scholar] [CrossRef]

- Patidar, A.K.; Sharma, A.; Joshi, D. Formulation of cellulose using groundnut husk as an environment-friendly fluid loss retarder additive and rheological modifier comparable to PAC for WBM. J. Pet. Explor. Prod. Technol. 2020, 10, 3449–3466. [Google Scholar] [CrossRef]

- Kelvin, V.K.; Dune, K.K. The Effect of Cassava Starch and Coconut Fibre on Rheological Properties and Fluid Loss Control of Water-Based Drilling Fluid. Int. J. Adv. Eng. Manag. 2022, 4, 742–749. [Google Scholar]

- Fadairo, A.S.; Oni, O. The suitability of eggshell for improving the performance of water-based drilling mud in a high-temperature well. Geothermics 2024, 119, 102920. [Google Scholar] [CrossRef]

- Onuh, C.; Adewale, D.; Paul, A.; Oluwatosin, R. The Chemical Modification of Calophyllum Inophyllum Plant Oil for Potential Base Oil in Drilling Mud Operation. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Virtual, 11 August 2020; SPE: Dallas, TX, USA, 2020; p. D013S002R019. [Google Scholar] [CrossRef]

- Goel, P.N.; Anand, A.; Anand, S.R.; Jha, K.; Richhariya, G. Development of cost-effective drilling fluid from banana peel pectin and fly ash for loss circulation control. Mater. Today Proc. 2022, 62, 4177–4181. [Google Scholar] [CrossRef]

- Michael, O.I. Experimental Study on the Suitability of Local Egg Shell and Snail Shell as Additives for Drilling Mud pH Control. Int. J. Oil Gas Coal Eng. 2023, 17, 37–46. [Google Scholar] [CrossRef]

- Agwu, O.E.; Akpabio, J.U.; Archibong, G.W. Rice husk and sawdust as filter loss control agents for water-based muds. Heliyon 2019, 5, e02059. [Google Scholar] [CrossRef]

- Ajayan, N.; Shahanamol, K.P.; Arun, A.U.; Soman, S. Quantitative Variation in Calcium Carbonate Content in Shell of Different Chicken and Duck Varieties. Adv. Zool. Bot. 2020, 8, 1–5. [Google Scholar] [CrossRef]

- Nik Ab Lah, N.K.I.; Ngah, K.; Sauki, A. Study on the viability of eggshell as a lost circulation material in synthetic based drilling fluid. J. Phys. Conf. Ser. 2019, 1349, 012135. [Google Scholar] [CrossRef]

- Ajiri, O.; Salihu, A.; Obe, A.; Ibrahim, K.; Gimba, A. Use of Sawdust and Coconut Fiber As Fluid Loss Control Additive For Water-Based Mud. Nile J. Eng. Appl. Sci. 2024, 2, 1. [Google Scholar] [CrossRef]

- Sid, A.N.E.H.; Tahraoui, H.; Kebir, M.; Bezzekhami, M.A.; Kouini, B.; Hassein-Bey, A.H.; Selma, T.; Amrane, A.; Imessaoudene, A.; Mouni, L. Comparative Investigation of the Effect of EggshellPowder and Calcium Carbonate as Additivesin Eco-Friendly Polymer Drilling Fluids. Sustainability 2023, 15, 3375. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.; Alkinani, H.H.; Dunn-Norman, S.; Alkhamis, M.M.; Al-Alwani, M.A.; Mutar, R.A.; Salem, E. Proposing a new biodegradable thinner and fluid loss control agent for water-based drilling fluid applications. Int. J. Environ. Sci. Technol. 2020, 17, 3621–3632. [Google Scholar] [CrossRef]

- Kurnia, Y.; Agustin, F. Studies on Physical Characteristics, Mineral Composition and Nutritive Value of Bone Meal and Bone Char Produced from Inedible Cow Bones. Pak. J. Nutr. 2017, 16, 426–434. [Google Scholar] [CrossRef]

- Ojuri, O.O.; Osagie, P.O.; Oluyemi-Ayibiowu, B.D.; Fadugba, O.G.; Tanimola, M.O.; Chauhan, V.B.; Jayejeje, O.O. Eco-friendly stabilization of highway lateritic soil with cow bone powder admixed lime and plastic granules reinforcement. Clean. Waste Syst. 2022, 2, 100012. [Google Scholar] [CrossRef]

- Asadu, A.G.; Obayi, C.S.; Nnamchi, P.S.; Offor, P.O. Deposition Time Effect of Dissolved Cow-Bone Powder on Corrosion of Martensitic Stainless Steel in Sea Water. J. Mater. Environ. Sci. 2022, 13, 262–270. [Google Scholar]

- Iqbal, R.; Zubair, M.; Pirzada, F.; Abro, F.N.; Ali, M.; Valasai, A. An Experimental Study on the Performance of Calcium Carbonate Extracted from Eggshells as Weighting Agent in Drilling Fluid. Eng. Technol. Appl. Sci. Res. 2019, 9, 3859–3862. [Google Scholar] [CrossRef]

- Whitfill, D. Lost Circulation Material Selection, Particle Size Distribution, and Fracture Modeling with Fracture Simulation Software. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Jakarta, Indonesia, 25–28 August 2008; SPE: Dallas, TX, USA, 2008; p. SPE-115039-MS. [Google Scholar] [CrossRef]

- Suri, A.; Sharma, M.M. Strategies for Sizing Particles in Drilling and Completion Fluids. SPE J. 2004, 9, 13–23. [Google Scholar] [CrossRef]

- Oladele, I.O.; Adewole, T.A. Influence of Cow Bone Particle Size Distribution on the Mechanical Properties of Cow Bone-Reinforced Polyester Composites. Biotechnol. Res. Int. 2013, 2013, 725396. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Samsuri, A. The use of nano-sized Tapioca starch as a natural water-soluble polymer for filtration control in water-based drilling muds. J. Nat. Gas Sci. Eng. 2016, 34, 832–840. [Google Scholar] [CrossRef]

- Oluwaseyi, A.O.; Omohimoria, C.C.; Falade, A.A. Effects of Cissus populnea on the Rheological Properties of Local Clay. FUOYE J. Eng. Technol. 2021, 6, 83–87. [Google Scholar] [CrossRef]

- Nwabueze, Q.A.; Ighalo, J.O. Utilisation of Sweet Potato (Ipomoe batatas) and Rice Husk (Oryza sativa) Starch Blend as a Secondary Viscosifier and Fluid Loss Control Agent in Water-based Drilling Mud. Pet. Coal 2020, 62, 1230–1241. [Google Scholar]

- Apostolidou, C.; Sarris, E.; Georgakopoulos, A. Dynamic thermal aging of water-based drilling fluids with different types of low-rank coals as environmentally friendly shear thinning additives. J. Pet. Sci. Eng. 2022, 208, 109758. [Google Scholar] [CrossRef]

- Wayo DD, K.; Irawan, S.; Bin Mohamad Noor, M.Z.; Badrouchi, F.; Khan, J.A.; Duru, U.I. A CFD validation effect of YP/PV from laboratory-formulated SBMDIF for productive transport load to the surface. Symmetry 2022, 14, 2300. [Google Scholar] [CrossRef]

- ASME Shale Shaker ASME Shale Shaker Committee. Drilling Fluids Processing Handbook; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Ikumapayi, O.M.; Akinlabi, E.T.; Adedeji, P.A.; Akinlabi, S.A. Preparation, Characterization, Image Segmentation and Particle Size Analysis of Cow Bone Powder for Composite Applications. In Trends in Manufacturing and Engineering Management; Vijayan, S., Subramanian, N., Sankaranarayanasamy, K., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 273–283. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Ghazali, S.; Beg, M.D.H.; Jeyaratnam, N. Characterization and Elemental Quantification of Natural hydroxyapatite produced from Cow bone. Chem. Eng. Technol. 2019, 42, 1805–1815. [Google Scholar] [CrossRef]

- Fapohunda, C.A.; Akinsanya, A.Y.; Aderoju, S.O.; Shittu, K.A. Suitability of Crushed Cow Bone as Partial Replacement of Fine Aggregates for Concrete Production. West Indian J. Eng. 2016, 39, 25–31. [Google Scholar]

- Hossain, M.S.; Uddin, M.N.; Sarkar, S.; Ahmed, S. Crystallographic dependency of waste cow bone, hydroxyapatite, and β-tricalcium phosphate for biomedical application. J. Saudi Chem. Soc. 2022, 26, 101559. [Google Scholar] [CrossRef]

- Madu, C.; Faraji, F.; Abdalqadir, M.; Gomari, S.R.; Chong, P.L. Feasibility study of biodegradable coffee ground waste and watermelon rind as water-based drilling fluid additives. Gas Sci. Eng. 2024, 125, 205322. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Al-Alwani, M.A.; Alshammari, A.F.; Alkhamis, M.M.; Mutar, R.A.; Al-Bazzaz, W.H. Experimental investigation of environmentally friendly drilling fluid additives (mandarin peels powder) to substitute the conventional chemicals used in water-based drilling fluid. J. Pet. Explor. Prod. Technol. 2019, 10, 407–417. [Google Scholar] [CrossRef]

- Ali, J.A.; Abdalqadir, M.; Najat, D.; Hussein, R.; Jaf, P.T.; Simo, S.M.; Abdullah, A.D. Application of ultra-fine particles of potato as eco-friendly green additives for drilling a borehole: A filtration, rheological and morphological evaluation. Chem. Eng. Res. Des. 2024, 206, 89–107. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Alkhamis, M.M.; Feliz, J.D. Full-set measurements dataset for a water-based drilling fluid utilizing biodegradable environmentally friendly drilling fluid additives generated from waste. Data Brief 2020, 28, 104945. [Google Scholar] [CrossRef]

- Okrajni, S.S.; Azar, J.J. The Effects of Mud Rheology on Annular Hole Cleaning in Directional Wells. SPE Drill. Eng. 1986, 1, 297–308. [Google Scholar] [CrossRef]

- Siddiqui, M.A.; Al-Ansari, A.A.; Al-Afaleg, N.I.; Al-Anazi, H.A.; Hembling, D.E.; Bataweel, M.A. Drill-in Fluids for Multi-Lateral MRC Wells in Carbonate Reservoir-PSD Optimization and Best Practices Lead to High Productivity: A Case Study. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Adelaide, Australia, 11–13 September 2006; SPE: Dallas, TX, USA, 2006; p. SPE-101169-MS. [Google Scholar] [CrossRef]

- Watson, R.B.; Viste, P.; Lauritzen, J.R. The Influence of Fluid Loss Additives in High-Temperature Reservoirs. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15–17 February 2012; SPE: Dallas, TX, USA, 2012; p. SPE-151662-MS. [Google Scholar] [CrossRef]

- Punyanitya, S.; Koonawoot, R.; Ruksanti, A.; Thiensem, S.; Raksujarit, A. Structure and Mechanical Properties of Retrograded Rice Starch and Cow Bone Powder Composite Sponge. Mater. Sci. Forum 2018, 923, 84–88. [Google Scholar] [CrossRef]

| Category | Standard Range of LCM (µm) | Average Particle Size of CBP and CaCO3 Powder |

|---|---|---|

| Fine | 15–25 | 20 |

| Medium | 36–63 | 48 |

| Coarse | >63 | 85 |

| Mud Components | Function | Mud Samples | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calcium Carbonate Powder | Coarse-Particle-Size Powder | Medium-Particle-Size Powder | Fine-Particle-Size Powder | ||||||||||

| C | D | E | F | G | H | I | J | K | L | M | N | ||

| Ionized Water (mL) | Base Fluid | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Bentonite (g) | Viscosity modifier and fluid-loss control agent | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Barite (g) | Weighting material | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| NaOH (g) | pH control agent | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Calcium Carbonate (g) | Filtration loss control agent | 5 | 10 | 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Coarse Cow Bone (g) | Filtration loss control agent | 0 | 0 | 0 | 5 | 10 | 15 | 0 | 0 | 0 | 0 | 0 | 0 |

| Medium-Size Cow Bone (g) | Filtration loss control agent | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 10 | 15 | 0 | 0 | 0 |

| Fine-Size Cow Bone (g) | Filtration loss control agent | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 10 | 15 |

| Mud Properties | (Oilfield Units) |

|---|---|

| Plastic viscosity (PV) | 8–35 (cP) |

| Yield point (YP) | 5–50 (lb/100 ft2) |

| Apparent viscosity (AV) | 15 to 40 cP |

| Gel strength @ 10 s | 3–20 (lb/100 ft2) |

| Gel strength @ 10 min | 8–30 (lb/100 ft2) |

| API fluid loss (in 30 min) | 15.0 mL (max) |

| Filter cake | ≤2 (mm) |

| YP/PV ratio | 0.75–1.5 (lb/100 ft2/cP) |

| Density (mud weight) | 8.65–9.60 (lb/gal) |

| pH | 9.0–12.5 |

| Mud Samples | CaCO3 | Coarse CB | Medium CB | Fine CB | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | D | E | F | G | H | I | J | K | L | M | N | |

| Plastic Viscosity, PV (cp) | 11 | 12 | 15 | 9 | 12.5 | 19 | 12 | 18 | 25 | 16 | 21 | 29 |

| Apparent Viscosity, AV (cp) | 14.25 | 18 | 25.5 | 12.5 | 17.22 | 23 | 17 | 22.5 | 30 | 18.8 | 29 | 37 |

| Yield Point, YP (lb/100 ft2) | 6.5 | 10 | 12 | 7.5 | 11 | 17 | 12 | 16.3 | 21 | 12 | 19.5 | 25.5 |

| Gel Strength, 10 s (lb/100 ft2) | 3 | 4 | 7 | 2 | 3 | 6 | 4 | 6 | 9 | 7 | 11 | 16 |

| Gel Strength, 10 m (lb/100 ft2) | 12 | 19 | 23 | 9 | 13 | 19 | 14 | 17 | 24 | 19 | 23 | 28 |

| Rheological Properties | CaCO3 | Coarse-Sized | Medium-Sized | Fine-Sized | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | D | E | F | G | H | I | J | K | L | M | N | |

| PV before aging (cp) | 11 | 12 | 15 | 12.5 | 19 | 19 | 18 | 20 | 12 | 14 | 14 | 14 |

| PV after aging (cp) | 17 | 22 | 24 | 17 | 23 | 17 | 22 | 23 | 18 | 18 | 19 | 24 |

| AV before aging (cp) | 14.25 | 18 | 20 | 18 | 12.5 | 30.5 | 37 | 25.5 | 29.5 | 16.5 | 18.5 | 22.5 |

| AV after aging (cp) | 38.5 | 45.5 | 69.5 | 56.5 | 41.5 | 39.5 | 41.5 | 47 | 43.5 | 37.5 | 39.5 | 43 |

| YP before aging (lb/100 ft2) | 6.5 | 12 | 10 | 11 | 7 | 23 | 26 | 11 | 35 | 25 | 9 | 17 |

| YP after aging (lb/100 ft2) | 43 | 47 | 91 | 29 | 37 | 45 | 33 | 48 | 51 | 19 | 41 | 58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dike, H.N.; Chibueze, L.N.; Ipinsokan, S.; Adewumi, C.N.; Olabode, O.; Olaniyan, D.D.; Pius, I.E.; Oke, M.A. An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations. Processes 2025, 13, 2205. https://doi.org/10.3390/pr13072205

Dike HN, Chibueze LN, Ipinsokan S, Adewumi CN, Olabode O, Olaniyan DD, Pius IE, Oke MA. An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations. Processes. 2025; 13(7):2205. https://doi.org/10.3390/pr13072205

Chicago/Turabian StyleDike, Humphrey Nwenenda, Light Nneoma Chibueze, Sunday Ipinsokan, Chizoma Nwakego Adewumi, Oluwasanmi Olabode, Damilola Deborah Olaniyan, Idorenyen Edet Pius, and Michael Abidemi Oke. 2025. "An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations" Processes 13, no. 7: 2205. https://doi.org/10.3390/pr13072205

APA StyleDike, H. N., Chibueze, L. N., Ipinsokan, S., Adewumi, C. N., Olabode, O., Olaniyan, D. D., Pius, I. E., & Oke, M. A. (2025). An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations. Processes, 13(7), 2205. https://doi.org/10.3390/pr13072205