Experimental Investigation on the Influence of Proppant Crushing on the Propped Fracture Conductivity

Abstract

1. Introduction

2. Materials and Methods

2.1. Measurement of the Physical Properties of Proppants

2.1.1. Measurement of the Average Diameter

2.1.2. Measurement of the Bulk Density

2.1.3. Measurement of the Crushing Rate

2.1.4. Measurement of the Roundness and Sphericity

2.2. Conductivity Test of the Propped Fracture

- (1)

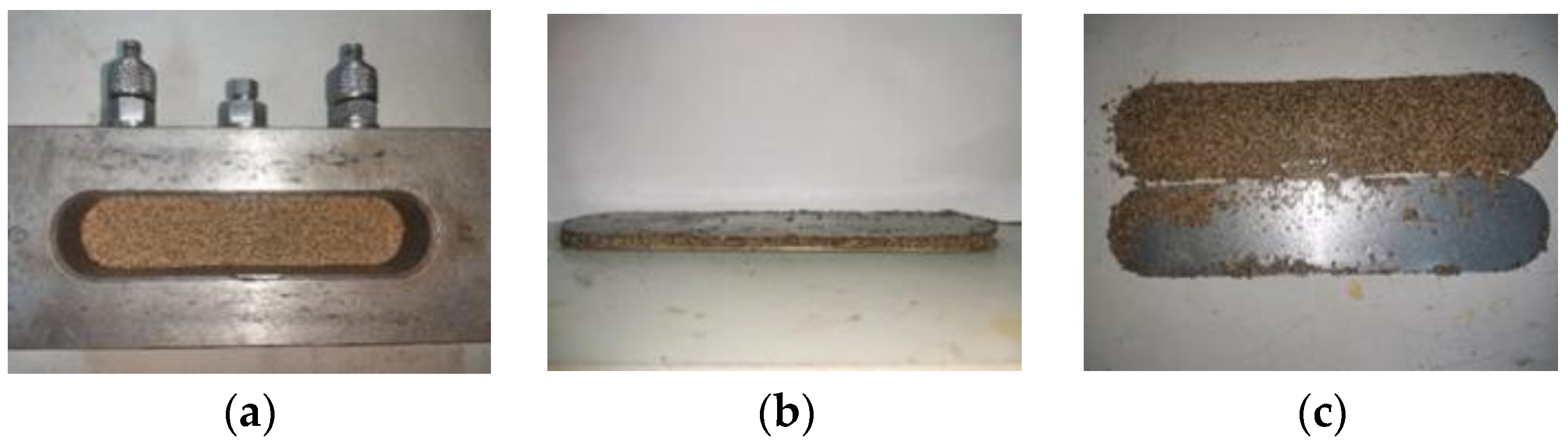

- A metal plate was placed at the base of the testing chamber. The proppant was uniformly poured into the chamber and leveled, after which a second plate was carefully placed over the proppant layer (Figure 1).

- (2)

- The assembled chamber was then positioned between the platens of a hydraulic press. The pressure was gradually increased using an oil pump to a value just below the target closure stress, preventing overshoot that could affect the test results. The oil pump was then deactivated, and a compensation pump was engaged to precisely adjust the pressure to the predetermined value. Once the desired closure stress was reached, the system maintained a stable load throughout the experiment.

- (3)

- The inlet valve and advection pump were activated while the outlet valve remained closed to fill the chamber with distilled water. Once the differential pressure sensor indicated a value of 1, the outlet valve was opened. This saturation process was repeated three times to ensure full saturation of the proppant pack.

- (4)

- After ensuring the system reached steady-state conditions, flow testing was conducted for a continuous period of 30 min. The average flow rate over this period was recorded as the inflow capacity corresponding to the specific pressure condition.

- (5)

- Upon completion of the flow test, all proppant material was removed from the chamber and dried in an oven at 105 °C for 24 h to ensure complete removal of moisture.

- (6)

- The dried proppant was then subjected to a standard sieve analysis. After sufficient vibration, the mass of crushed proppant retained in the collection pan was measured, and the proppant crushing rate was calculated accordingly. These steps were repeated to evaluate conductivity under varying parameters.

3. Results

3.1. Physical Properties of the Proppants

3.2. Conductivity of the Propped Fracture

3.2.1. Influence of Closure Stress on the Propped Fracture Conductivity

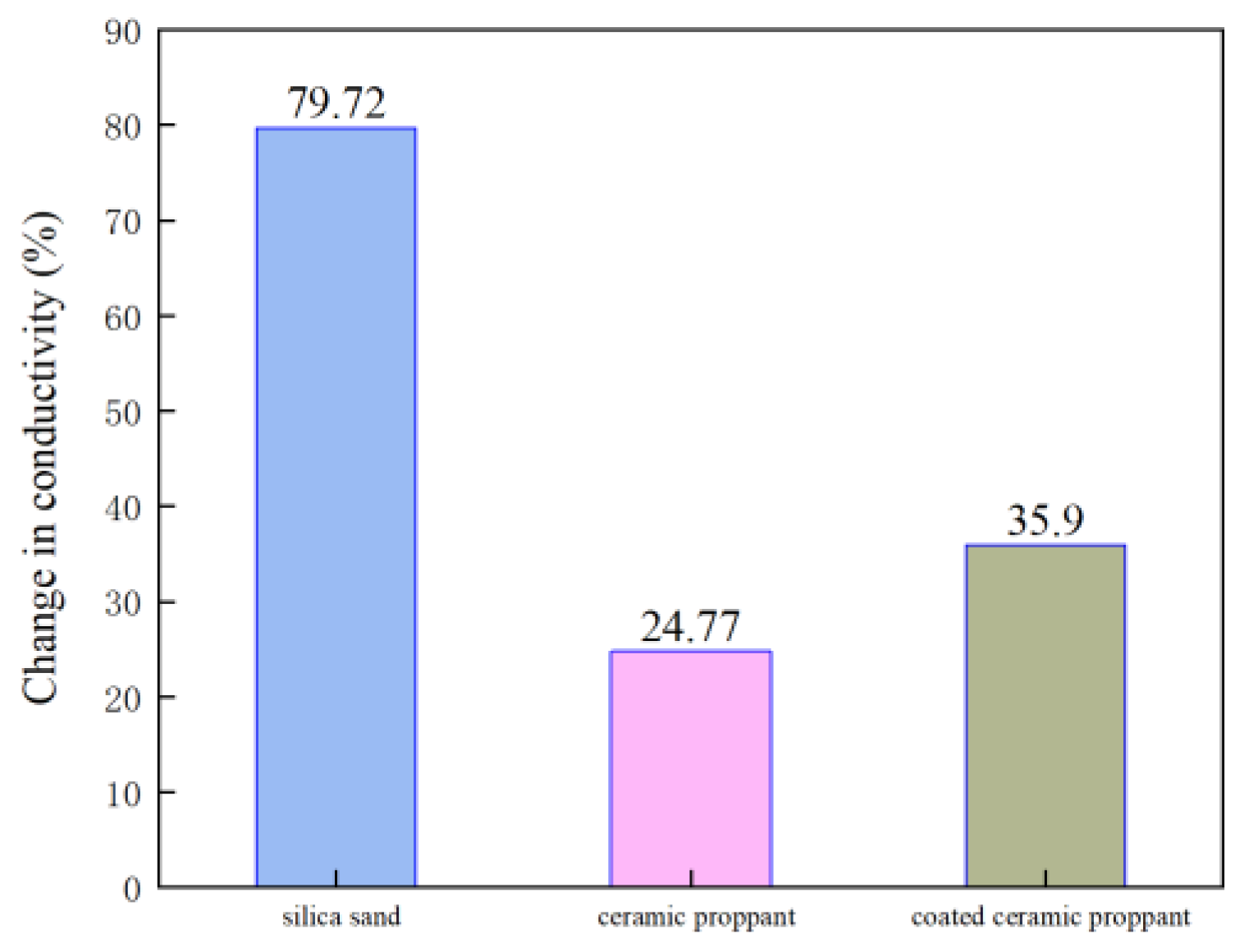

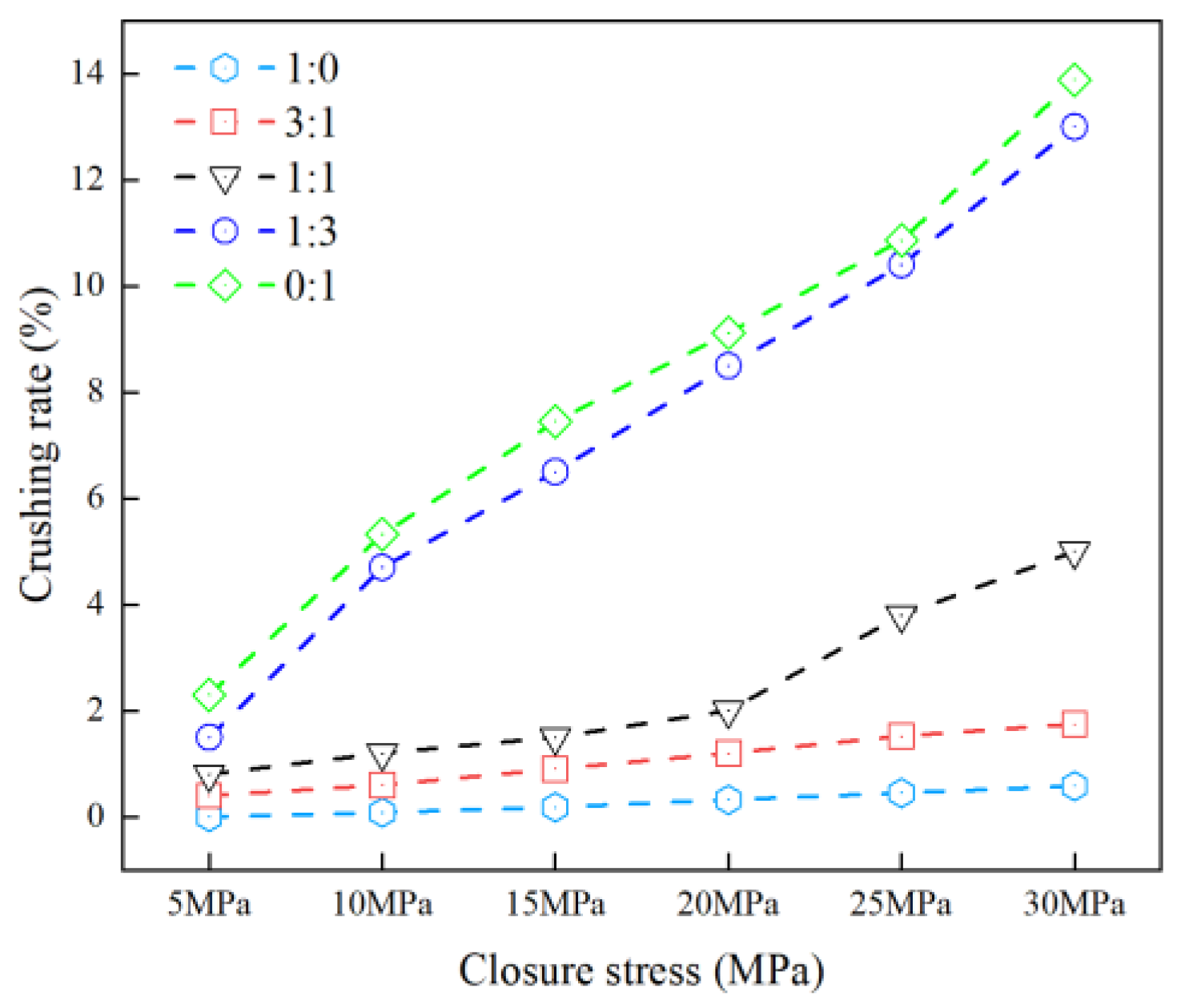

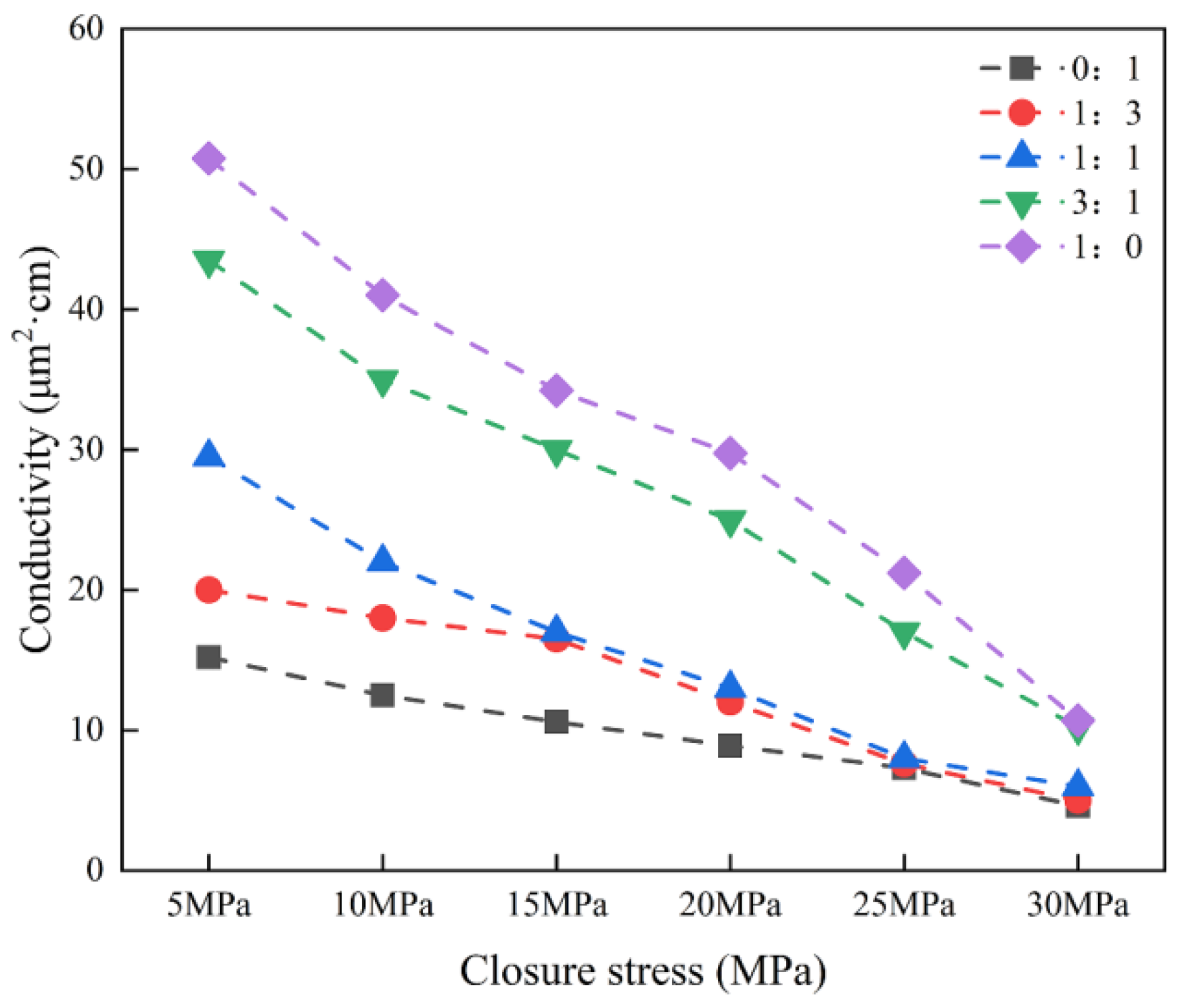

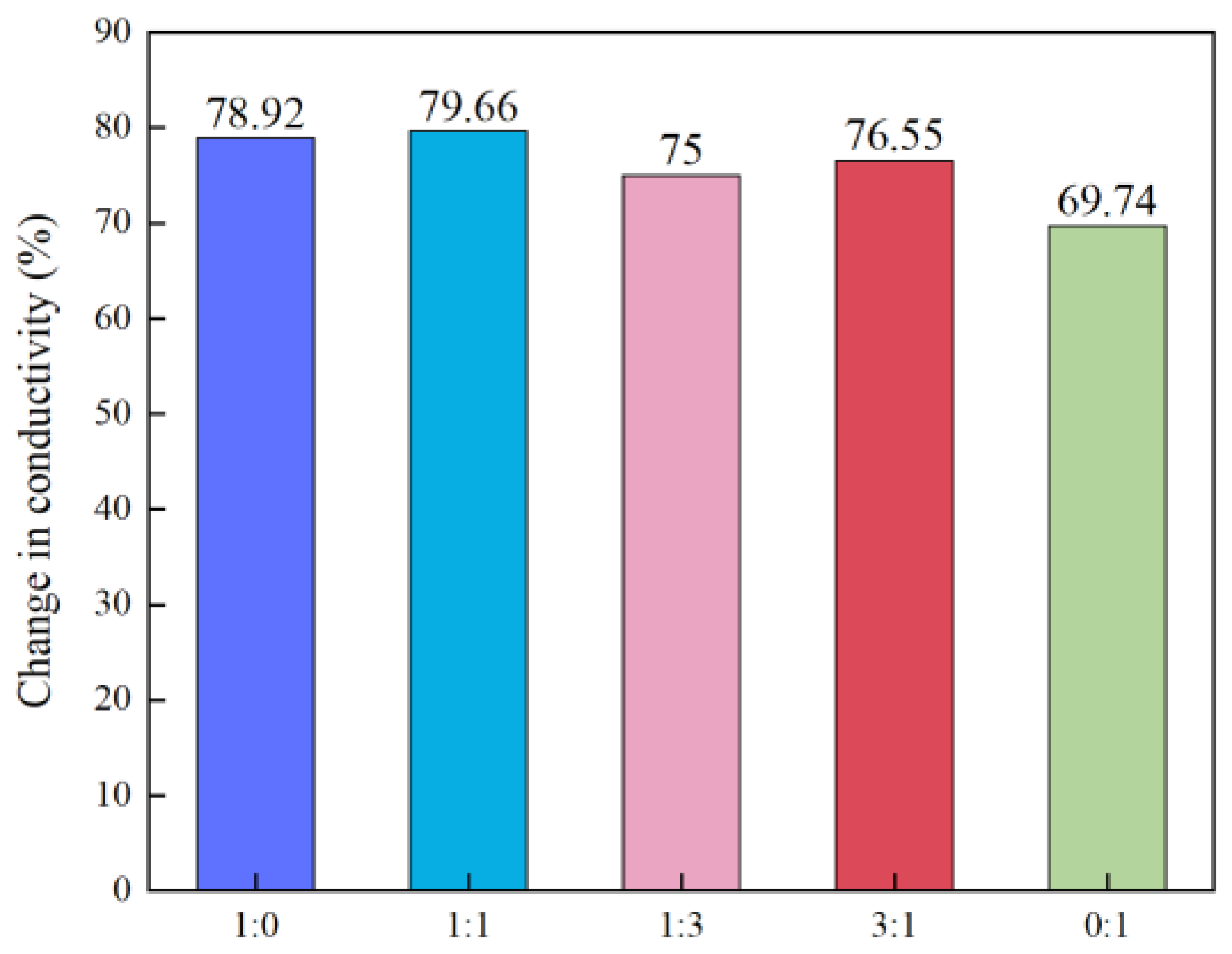

3.2.2. Influence of Different Proppant Combination on the Propped Fracture Conductivity

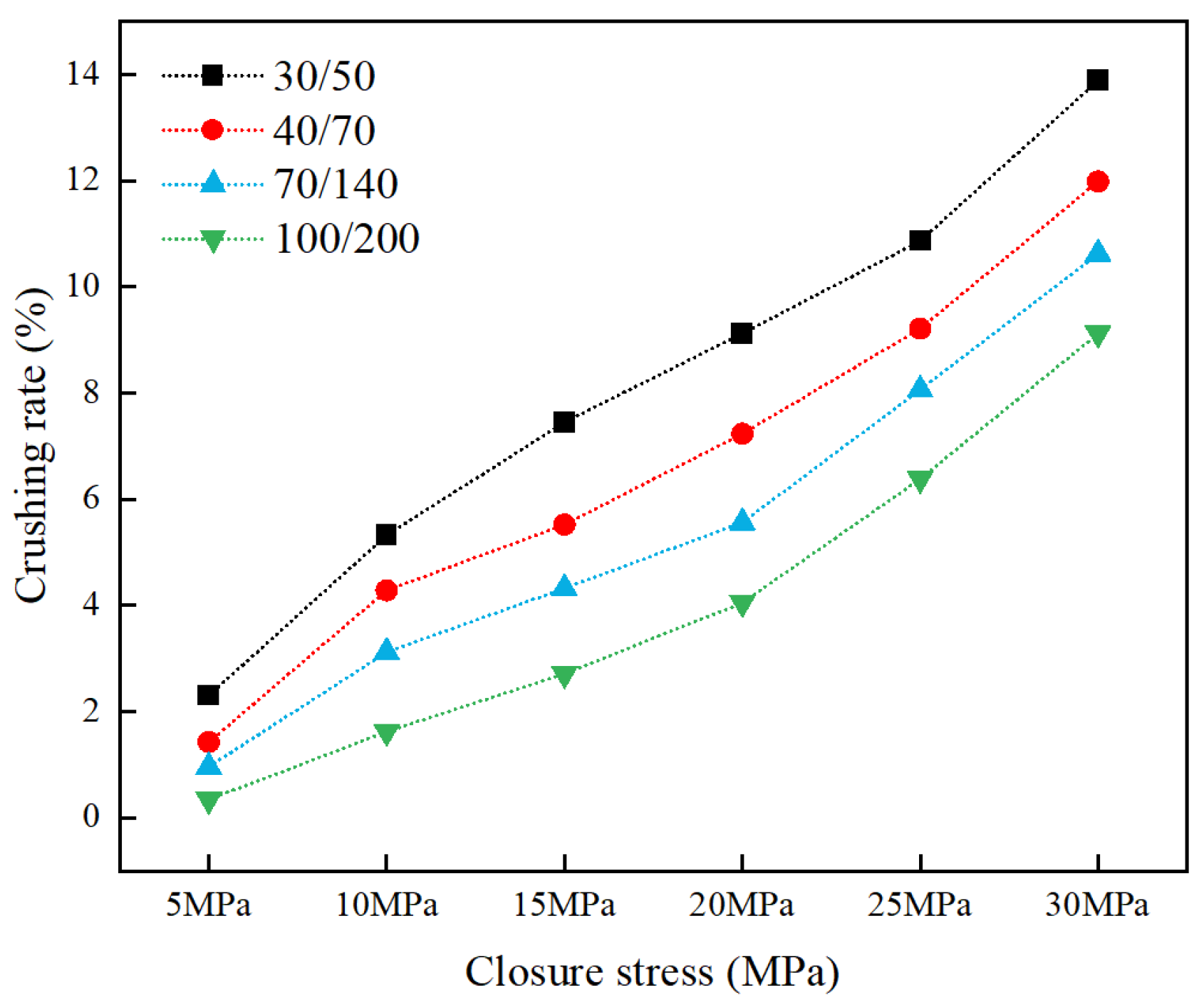

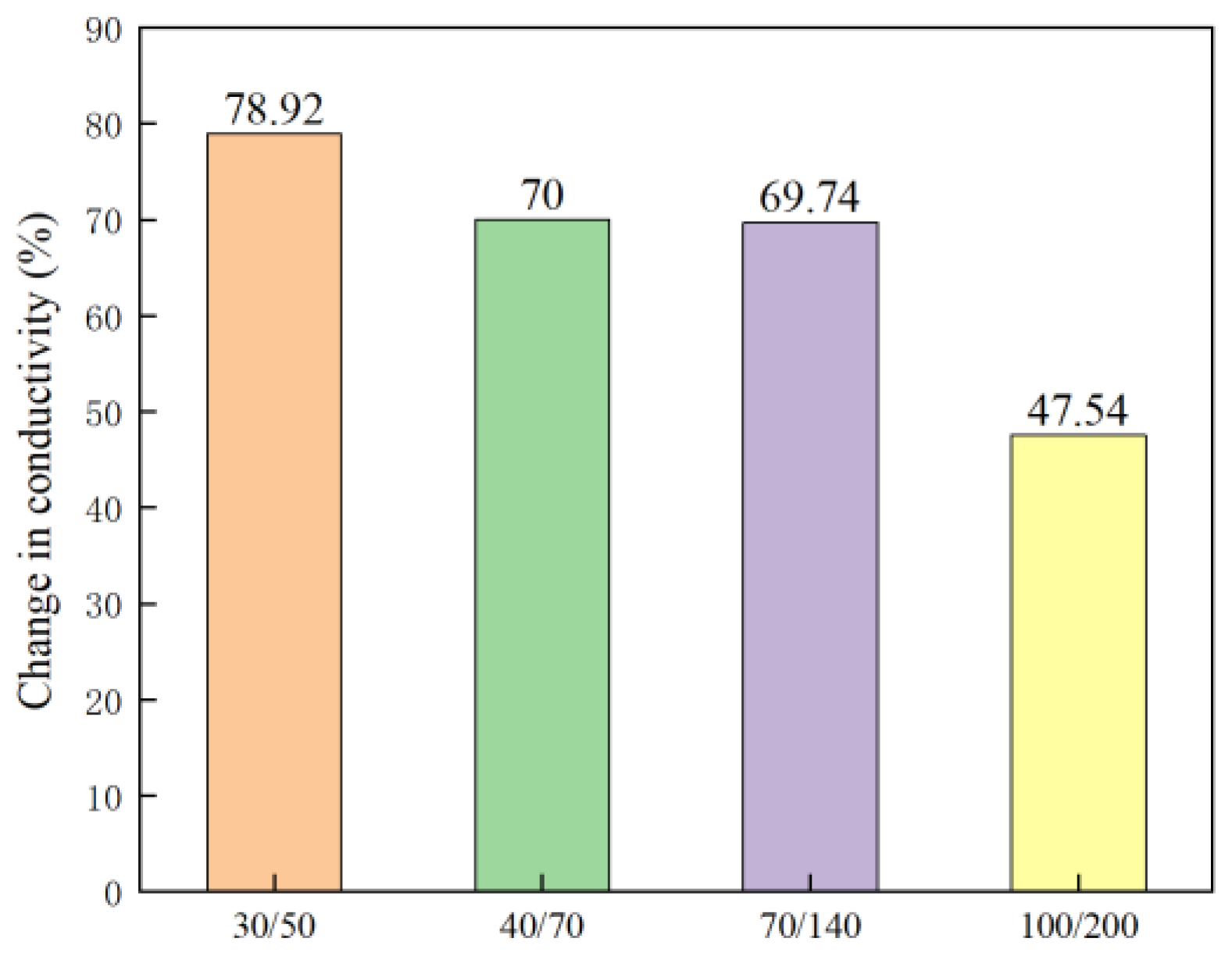

3.2.3. Influence of Proppant Size on the Propped Fracture Conductivity

3.2.4. Influence of Proppant Combination Varying Mesh Size on the Propped Fracture Conductivity

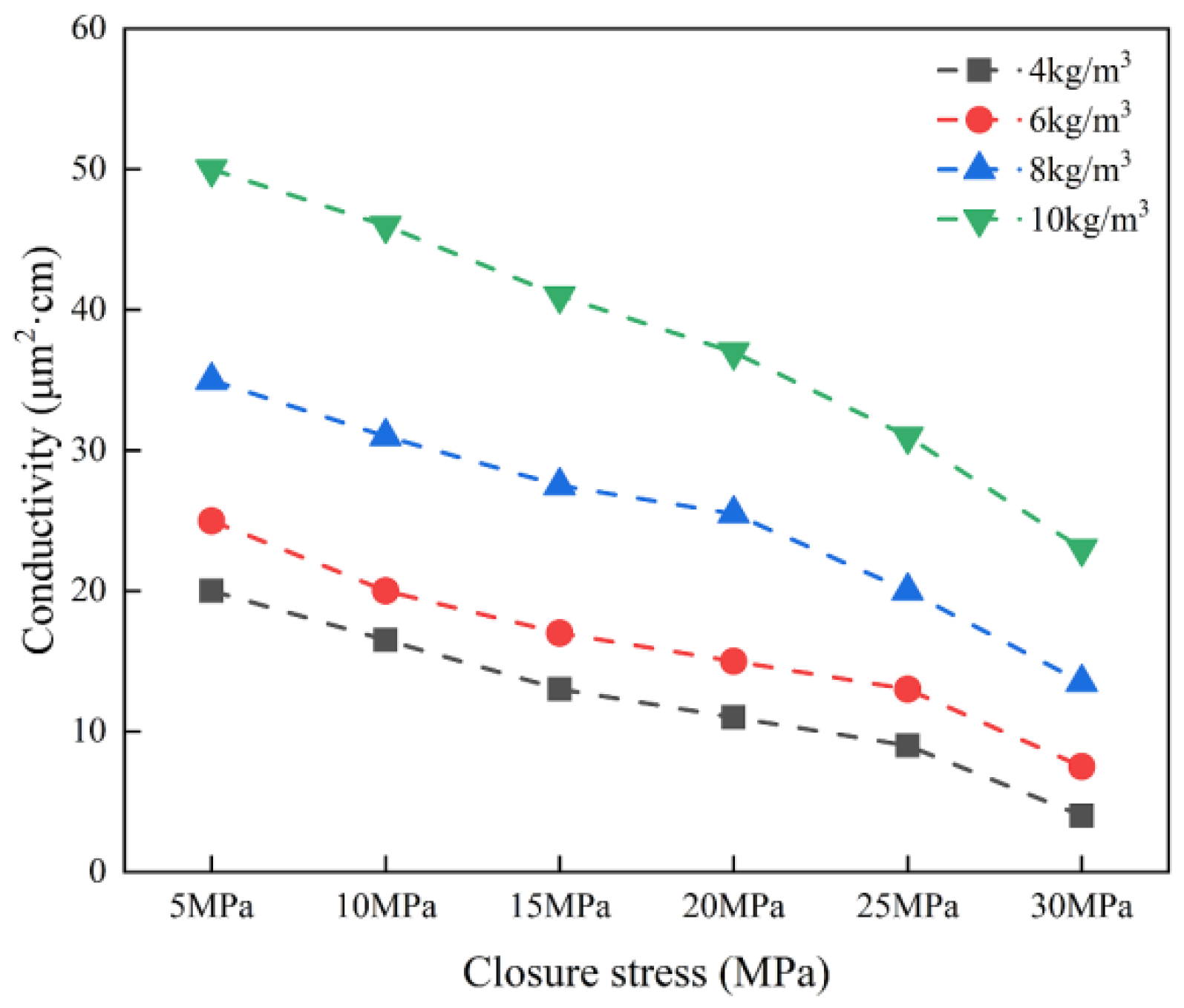

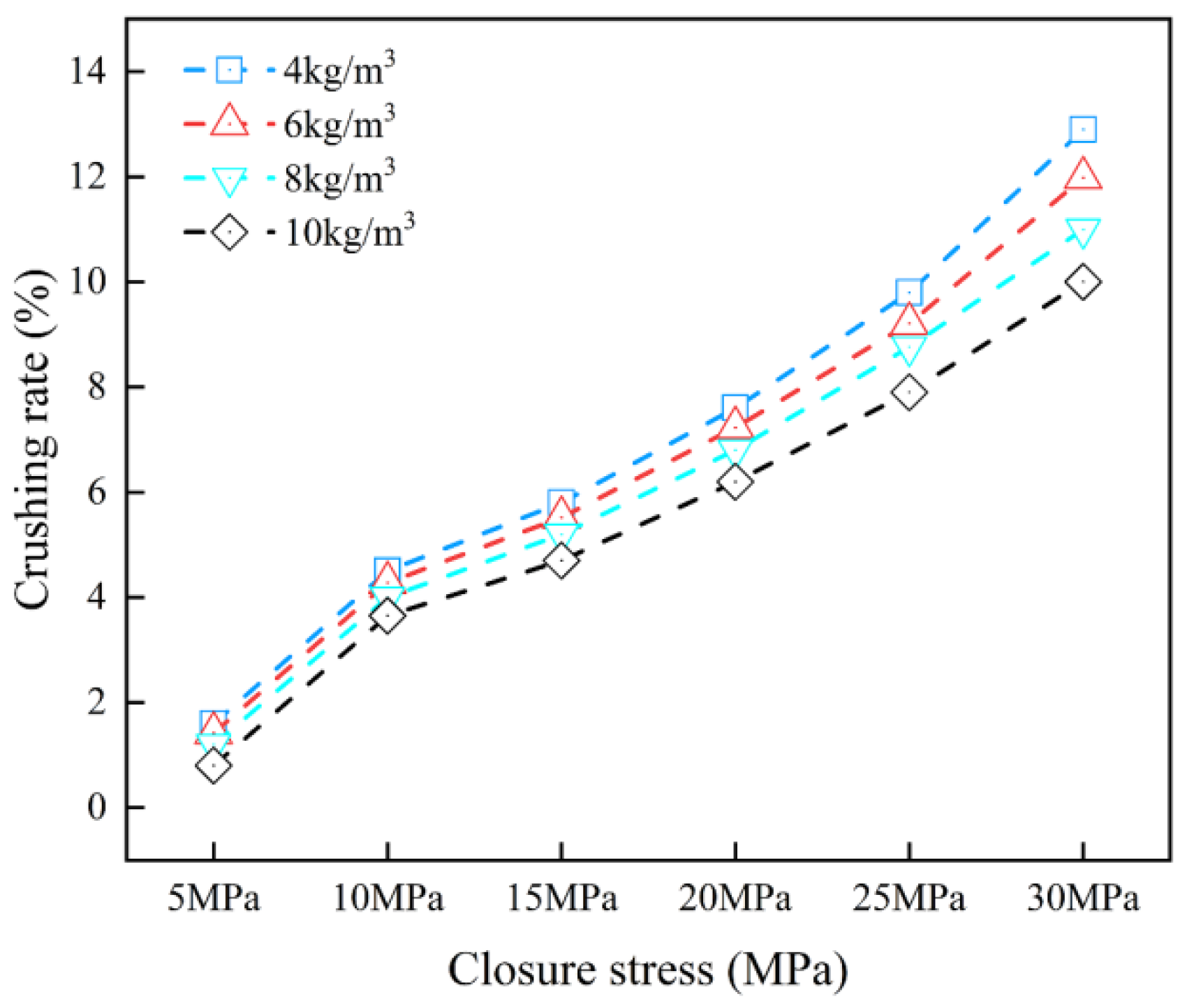

3.2.5. Influence of Proppant Pack Concentration on the Propped Fracture Conductivity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, X.; Wang, X.; Zhang, Y.; Huang, X.; Zeng, F. Experimental study of strong imbibition in microcapillaries representing pore/throat characteristics of tight rocks. Fuel 2023, 342, 127775. [Google Scholar] [CrossRef]

- Gu, X.; Yan, D.; Zhang, Z.; Liu, Z.; Jing, C.; Meng, X.; Liu, Y. Study on the Wettability Alteration of Tight Sandstone by Low-Frequency Vibration and Nanofluid. ACS Omega 2024, 9, 5705–5714. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, Y.; Malekpour, M.; Kikhavani, T.; Bayati, B. The study of the spontaneous oil imbibition in the presence of new polymer-coated nanocomposites compatible with reservoir conditions. Pet. Sci. Technol. 2024, 42, 974–992. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Liu, K.; Su, L.; Bai, B.; Zhang, X.; Yuan, X.; Wang, J. Tight gas sandstone reservoirs in China: Characteristics and recognition criteria. J. Pet. Sci. Eng. 2012, 88, 82–91. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Reinicke, A.; Rybacki, E.; Stanchits, S.; Huenges, E.; Dresen, G. Hydraulic fracturing stimulation techniques and formation damage mechanisms—Implications from laboratory testing of tight sandstone–proppant systems. Geochemistry 2010, 70, 107–117. [Google Scholar] [CrossRef]

- Guo, J.; Lu, Q.; Liu, Z.; Zeng, F.; Guo, T.; Liu, Y.; Liu, L.; Qiu, L. Concept and key technology of “multi-scale high-density” fracturing technology: A case study of tight sandstone gas reservoirs in the western Sichuan Basin. Nat. Gas Ind. B 2023, 10, 283–292. [Google Scholar] [CrossRef]

- Gillard, M.; Medvedev, O.; Peña, A.; Medvedev, A.; Penacorada, F.; d’Huteau, E. A new approach to generating fracture conductivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010; p. SPE–135034–MS. [Google Scholar]

- Elsarawy, A.M.; Nasr-El-Din, H.A. Propped fracture conductivity in shale reservoirs: A review of its importance and roles in fracturing fluid engineering. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018; p. SPE–192451–MS. [Google Scholar]

- Mack, M.G.; Coker, C.E. Proppant selection for shale reservoirs: Optimizing conductivity, proppant transport and cost. In Proceedings of the SPE Unconventional Resources Conference, Calgary, Alberta, Canada, 5-7 November 2013; p. SPE–167221–MS. [Google Scholar]

- Wang, J.; Elsworth, D. Role of proppant distribution on the evolution of hydraulic fracture conductivity. J. Pet. Sci. Eng. 2018, 166, 249–262. [Google Scholar] [CrossRef]

- Fan, M.; Han, Y.; Gu, M.; McClure, J.; Ripepi, N.; Westman, E.; Chen, C. Investigation of the conductivity of a proppant mixture using an experiment/simulation-integrated approach. J. Nat. Gas Sci. Eng. 2020, 78, 103234. [Google Scholar] [CrossRef]

- Ramlan, A.S.; Zin, R.M.; Bakar, N.F.A.; Othman, N.H. Recent progress on proppant laboratory testing method: Characterisation, conductivity, transportation, and erosivity. J. Pet. Sci. Eng. 2021, 205, 108871. [Google Scholar] [CrossRef]

- Hari, S.; Krishna, S.; Gurrala, L.N.; Singh, S.; Ranjan, N.; Vij, R.K.; Shah, S.N. Impact of reservoir, fracturing fluid and proppant characteristics on proppant crushing and embedment in sandstone formations. J. Nat. Gas Sci. Eng. 2021, 95, 104187. [Google Scholar] [CrossRef]

- Tian, F.; Jia, Y.; Yang, L.; Liu, X.; Guo, X.; Martyushev, D.A. Experimental study on factors affecting fracture conductivity. Processes 2024, 12, 1465. [Google Scholar] [CrossRef]

- Liang, F.; Sayed, M.; Al-Muntasheri, G.; Chang, F.F. Overview of existing proppant technologies and challenges. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 8–11 March 2015; p. SPE–172763–MS. [Google Scholar]

- Kamel, A.; Salem, Z.; Chemini, R.; Khodja, M.; Allia, K. Characterization of natural sand proppant used in hydraulic fracturing fluids. Part. Sci. Technol. 2019, 37, 716–724. [Google Scholar] [CrossRef]

- Shafiq, M.U.; Alajmei, S.; Aljawad, M.S.; Wang, L.; Bahri, A. A Comprehensive Review of Proppant Selection in Unconventional Reservoirs. ACS Omega 2025, 10, 13046–13059. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Li, Y. Preparation and characterization of low-density mullite-based ceramic proppant by a dynamic sintering method. Mater. Lett. 2015, 152, 72–75. [Google Scholar] [CrossRef]

- Ma, X.; Tian, Y.; Zhou, Y.; Wang, K.; Chai, Y.; Li, Z. Sintering temperature dependence of low-cost, low-density ceramic proppant with high breakage resistance. Mater. Lett. 2016, 180, 127–129. [Google Scholar] [CrossRef]

- Ding, D.; Fang, Y.; Xiao, G.; Zhu, X.; Fu, P.; Chong, X. Effects of sintering temperature on microstructure and properties of low-grade bauxite-based ceramic proppant. Int. J. Appl. Ceram. Technol. 2021, 18, 1832–1844. [Google Scholar] [CrossRef]

- Xie, X.; Niu, S.; Miao, Y.; Gao, X.; Cheng, L.; Gao, F. Preparation and properties of resin coated ceramic proppants with ultra light weight and high strength from coal-series kaolin. Appl. Clay Sci. 2019, 183, 105364. [Google Scholar] [CrossRef]

- Fan, F.; Li, F.-X.; Tian, S.-C.; Sheng, M.; Khan, W.; Shi, A.-P.; Zhou, Y.; Xu, Q. Hydrophobic epoxy resin coated proppants with ultra-high self-suspension ability and enhanced liquid conductivity. Pet. Sci. 2021, 18, 1753–1759. [Google Scholar] [CrossRef]

- Liu, P.; Huang, Q.; Li, J.; Du, J.; Lu, X.; Liu, J.; Liu, C.; Lan, X. Review and perspectives of coated proppant technology. Energy Fuels 2023, 37, 3355–3370. [Google Scholar] [CrossRef]

- Zheng, W.; Silva, S.C.; Tannant, D.D. Crushing characteristics of four different proppants and implications for fracture conductivity. J. Nat. Gas Sci. Eng. 2018, 53, 125–138. [Google Scholar] [CrossRef]

- Dilireba, T.; Wang, J. Effect of Proppant Damages on Fracture Conductivity and Long-Term Recovery in Shale Gas Reservoirs. Energy Fuels 2024, 38, 11695–11705. [Google Scholar] [CrossRef]

- Yin, B.; Zhang, Y.; Lou, Y.; Liu, S. Damage mechanism of proppant and conductivity reduction post fracturing in unconventional reservoirs. FUEL 2025, 380, 133086. [Google Scholar] [CrossRef]

- Gidley, J.L.; Penny, G.S.; McDaniel, R.R. Effect of proppant failure and fines migration on conductivity of propped fractures. SPE Prod. Facil. 1995, 10, 20–25. [Google Scholar] [CrossRef]

- Palisch, T.; Duenckel, R.; Chapman, M.; Woolfolk, S.; Vincent, M.C. How to use and misuse proppant crush tests–exposing the top 10 myths. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009; p. SPE–119242–MS. [Google Scholar]

- Chen, S.; Wang, J.; Yang, Y. Numerical simulation of oil-water two-phase conductivity in hydraulic fracturing considering proppant crushing. J. Phys. Conf. Ser. 2023, 2503, 012026. [Google Scholar] [CrossRef]

- Bandara, K.; Ranjith, P.G.; Rathnaweera, T.D. Proppant crushing mechanisms under reservoir conditions: Insights into long-term integrity of unconventional energy production. Nat. Resour. Res. 2019, 28, 1139–1161. [Google Scholar] [CrossRef]

- Han, J.; Wang, J.Y. Fracture conductivity decrease due to proppant deformation and crushing, a parametrical study. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 21–23 October 2014; p. SPE–171019–MS. [Google Scholar]

- Han, J.; Wang, J.Y.; Puri, V. A fully coupled geomechanics and fluid flow model for proppant pack failure and fracture conductivity damage analysis. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014; p. SPE–168617–MS. [Google Scholar]

- Man, S.; Wong, R.C.-K. Compression and crushing behavior of ceramic proppants and sand under high stresses. J. Pet. Sci. Eng. 2017, 158, 268–283. [Google Scholar] [CrossRef]

- Zheng, W.; Tannant, D.D. Influence of proppant fragmentation on fracture conductivity-insights from three-dimensional discrete element modeling. J. Pet. Sci. Eng. 2019, 177, 1010–1023. [Google Scholar] [CrossRef]

- Mittal, A.; Rai, C.S.; Sondergeld, C.H. Proppant-conductivity testing under simulated reservoir conditions: Impact of crushing, embedment, and diagenesis on long-term production in shales. SPE J. 2018, 23, 1304–1315. [Google Scholar] [CrossRef]

- Jianguang, W.; Xiaofeng, Z.; Xiaofei, F.; Yinghe, C.; Fan, B. Experimental investigation of long-term fracture conductivity filled with quartz sand: Mixing proppants and closing pressure. Int. J. Hydrogen Energy 2021, 46, 32394–32402. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, D.; Chen, Y. Numerical Calculation and Application for Crushing Rate and Fracture Conductivity of Combined Proppants. Energies 2024, 17, 3868. [Google Scholar] [CrossRef]

- Vega, F.G.; Carlevaro, C.M.; Baldini, M.; Madrid, M.A.; Pugnaloni, L.A. Simulation of proppant conductivity test: Effect of particle size dispersion. Pet. Sci. Technol. 2025, 43, 1010–1028. [Google Scholar] [CrossRef]

- ASTM, E. Standard specification for woven wire test sieve cloth and test sieves. In ASTM International; American Society for Testing and Materials: Conshohocken, PA, USA, 2017. [Google Scholar]

- Yang, H.; Liu, Y.-L.; Bai, G.-L.; Feng, Z.; Zhang, Y.; Xia, S.-B. Solidification and utilization of water-based drill cuttings to prepare ceramsite proppant with low-density and high performance. Pet. Sci. 2022, 19, 2314–2325. [Google Scholar] [CrossRef]

- Hu, K.; Sun, J.; Wong, J.; Hall, B. Proppants selection based on field case studies of well production performance in the Bakken shale play. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 15–18 April 2014; p. SPE-169566-MS. [Google Scholar]

| Proppant Type | Silica Sand | Ceramic Proppant | Coated Ceramic Proppant | |||

|---|---|---|---|---|---|---|

| Mesh | 30/50 | 40/70 | 70/140 | 100/200 | 30/50 | 30/50 |

| Average diameter, μm | 445 | 351 | 145 | 122 | 461 | 465 |

| Bulk density, g/cm3 | 1.79 | 1.76 | 1.54 | 1.48 | 1.86 | 1.65 |

| Proppant Type | Silica Sand | Ceramic Proppant | Coated Ceramic Proppant | |||

|---|---|---|---|---|---|---|

| Mesh | 30/50 | 40/70 | 70/140 | 100/200 | 30/50 | 30/50 |

| Roundness | 0.8 | 0.7 | 0.6 | 0.5 | 0.9 | 0.9 |

| Sphericity | 0.7 | 0.7 | 0.5 | 0.5 | 0.9 | 0.9 |

| Proppant Type | Silica Sand | Ceramic Proppant | Coated Ceramic Proppant |

|---|---|---|---|

| Price | About $111/t (about $48/t for localized sand sources) | About $187/t | About $215/t |

| Performance characteristics | Low compressive strength, high brittleness, and easy to break when the closing pressure is high | High compressive strength, high hardness, and resistance to breakage when subjected to high closing pressure | High compressive strength and high flow conductivity, strong corrosion resistance |

| Scope of application | Suitable for shallow wells or oil and gas wells with low closure pressure | Suitable for deep low-permeability oil and gas reservoirs | Suitable for oil and gas wells with high closure pressure, requirements for flow conductivity and corrosion resistance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhou, D.; Gu, T.; Yan, Y.; Yang, X.; Xu, S. Experimental Investigation on the Influence of Proppant Crushing on the Propped Fracture Conductivity. Processes 2025, 13, 2166. https://doi.org/10.3390/pr13072166

Wang W, Zhou D, Gu T, Yan Y, Yang X, Xu S. Experimental Investigation on the Influence of Proppant Crushing on the Propped Fracture Conductivity. Processes. 2025; 13(7):2166. https://doi.org/10.3390/pr13072166

Chicago/Turabian StyleWang, Wen, Desheng Zhou, Tuan Gu, Yanhua Yan, Xin Yang, and Shucan Xu. 2025. "Experimental Investigation on the Influence of Proppant Crushing on the Propped Fracture Conductivity" Processes 13, no. 7: 2166. https://doi.org/10.3390/pr13072166

APA StyleWang, W., Zhou, D., Gu, T., Yan, Y., Yang, X., & Xu, S. (2025). Experimental Investigation on the Influence of Proppant Crushing on the Propped Fracture Conductivity. Processes, 13(7), 2166. https://doi.org/10.3390/pr13072166