Impact of Reservoir Properties on Micro-Fracturing Stimulation Efficiency and Operational Design Optimization

Abstract

1. Introduction

2. Governing Equations

2.1. Physical Model

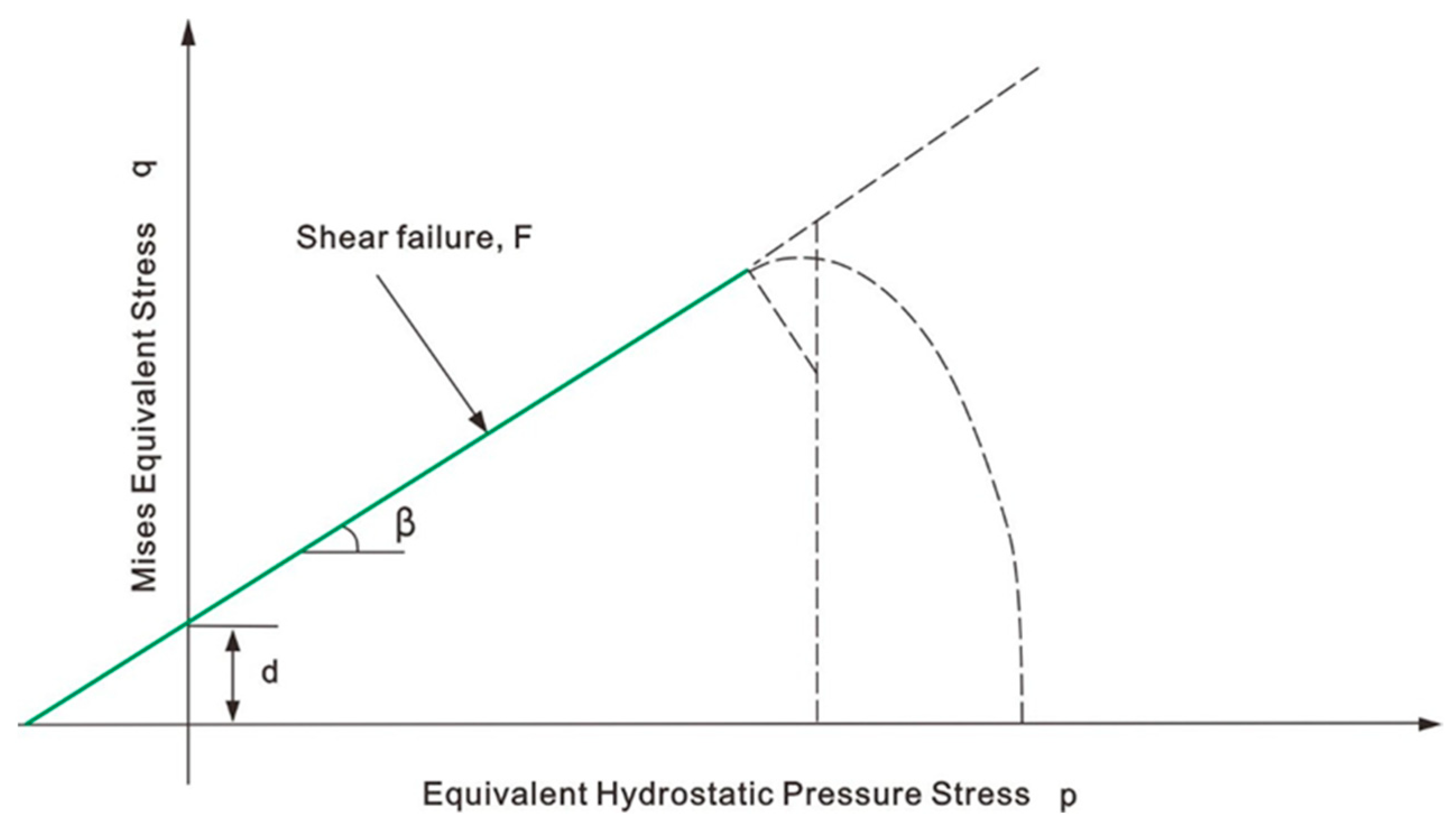

2.2. Mechanical Model

2.3. Permeability Model

3. Impacts of Reservoir Properties on Micro-Fracturing Stimulation Effectiveness

3.1. Effects of Asphaltene Content and Clay Content

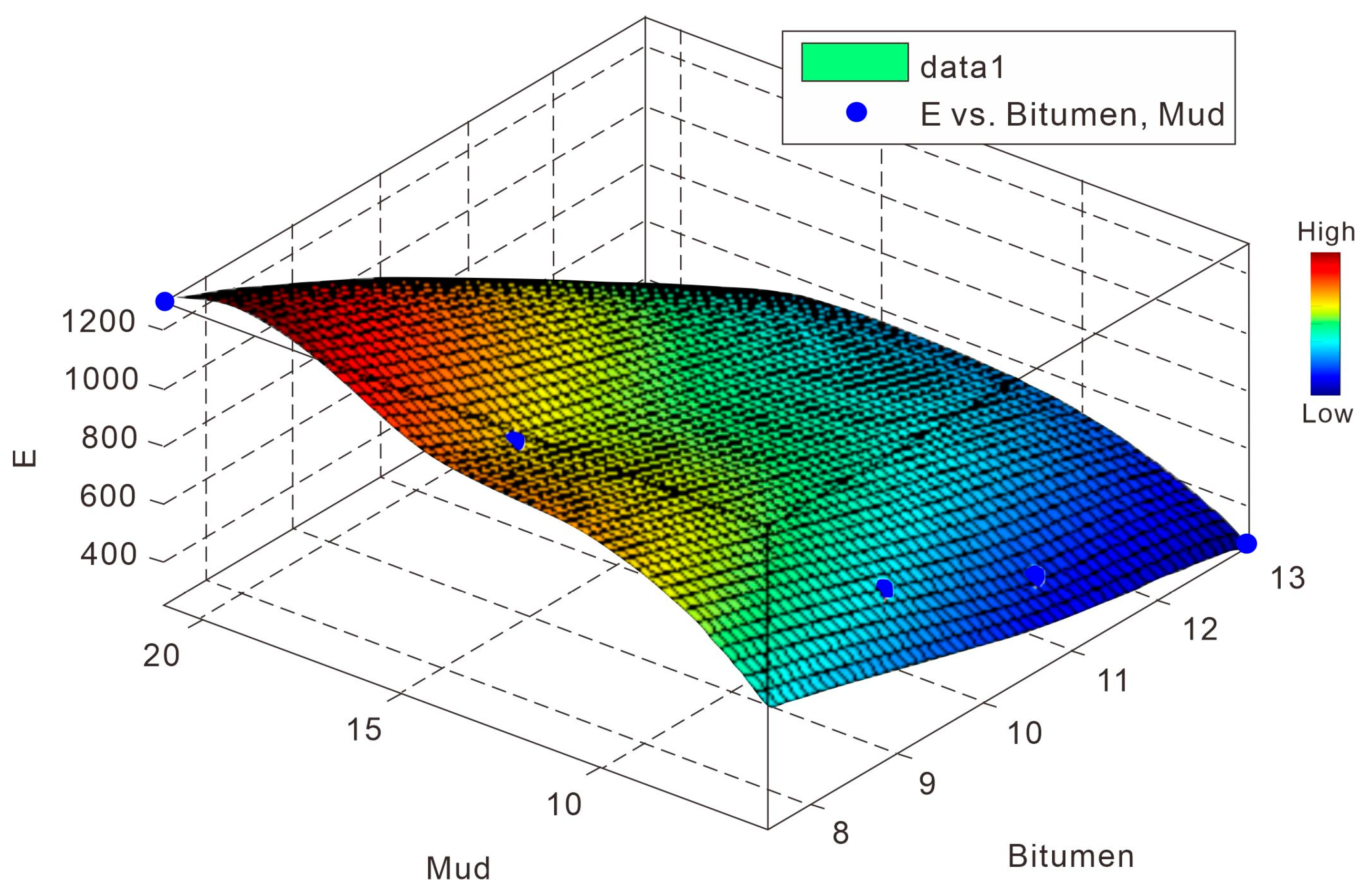

3.1.1. Relationship Between Asphaltene Content, Clay Content, and Young’s Modulus

- (a)

- Three-dimensional surface fitting

- (b)

- Weighted analysis method

- (1)

- Relationship between asphaltene content, clay content, and Poisson’s ratio. The relationship between asphaltene content, clay content, and Poisson’s ratio can be expressed as

- (2)

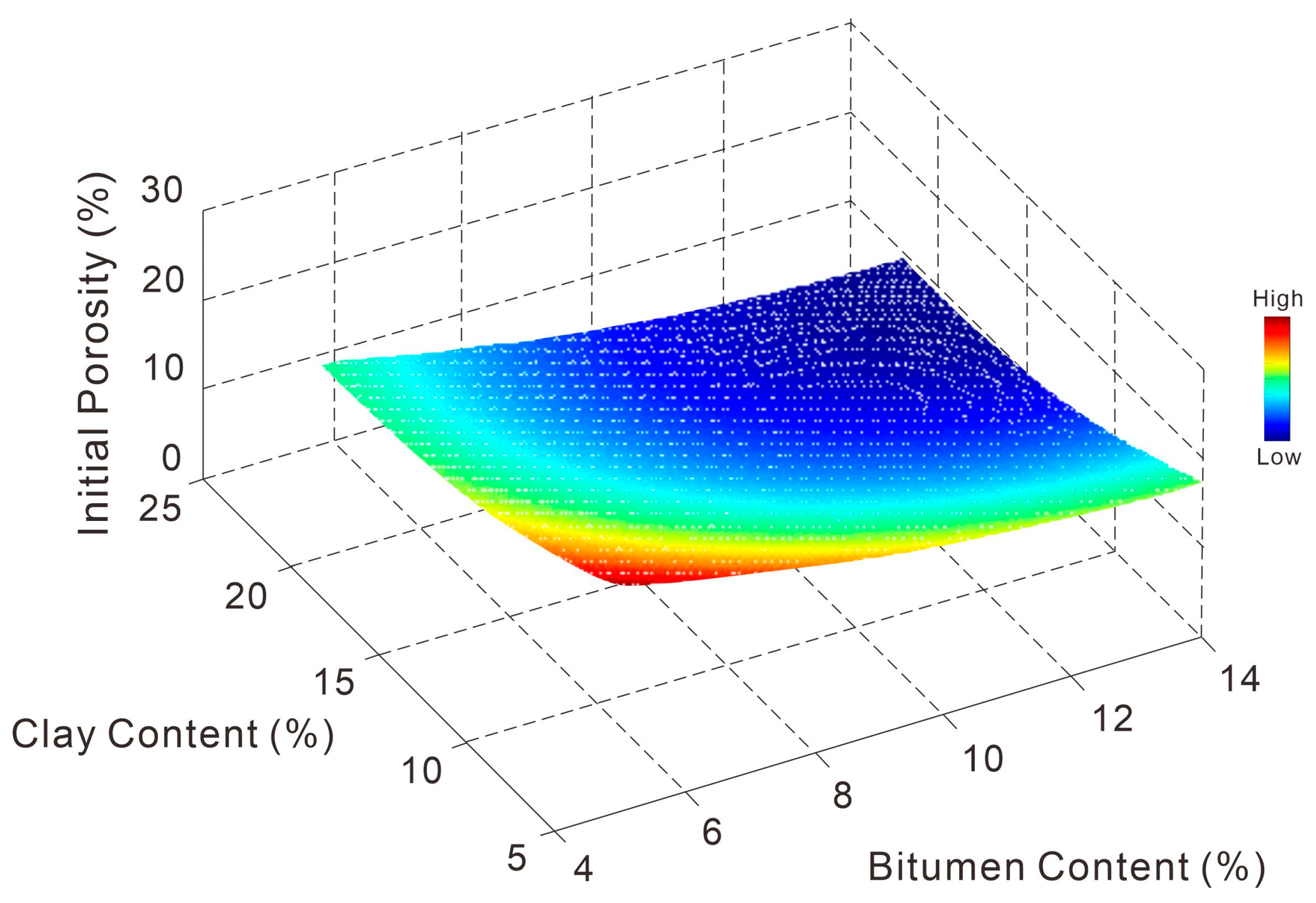

- Relationship between asphaltene content, clay content, and initial porosity.

- (3)

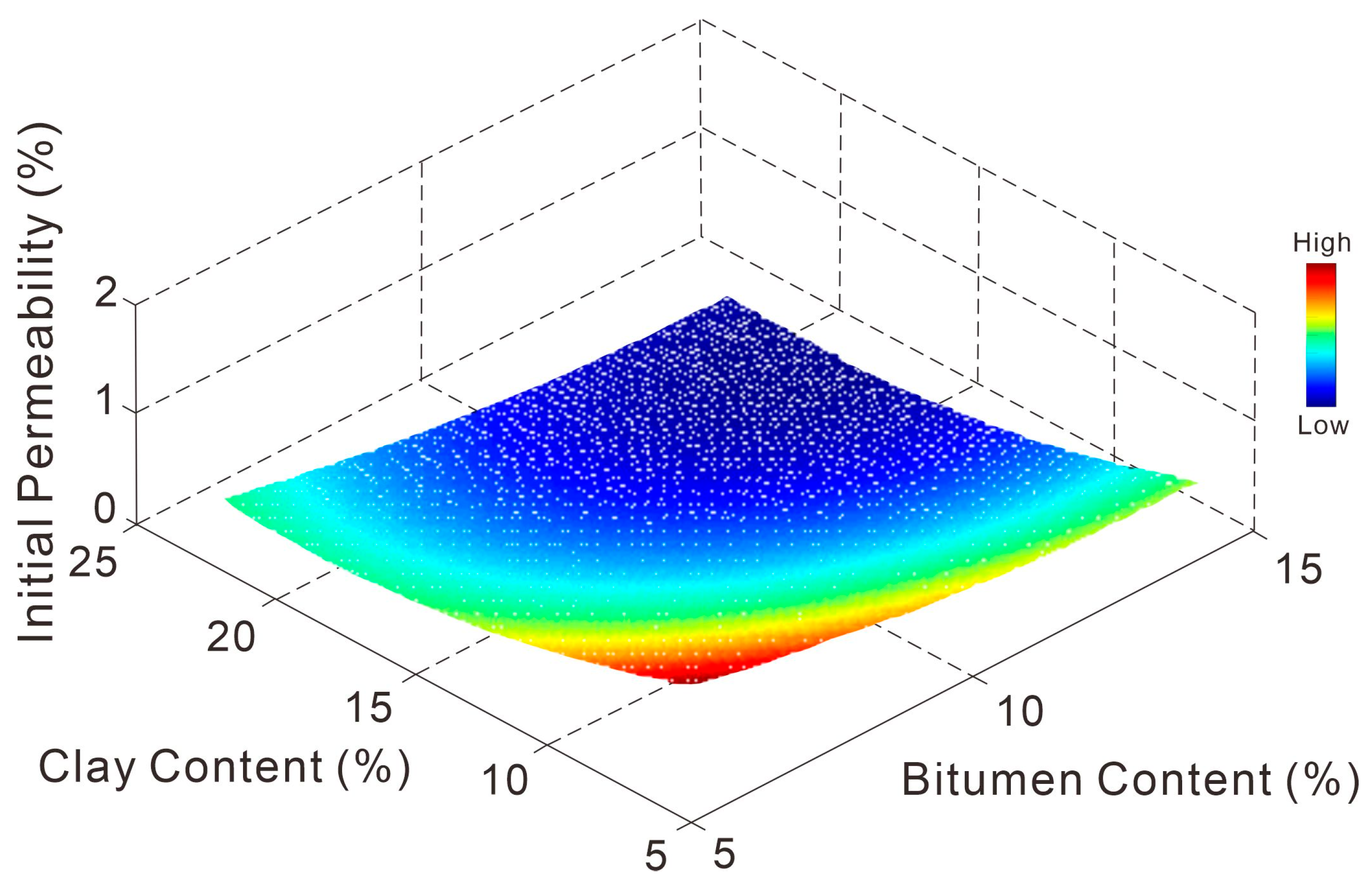

- Relationship between asphaltene content, clay content, and initial permeability.

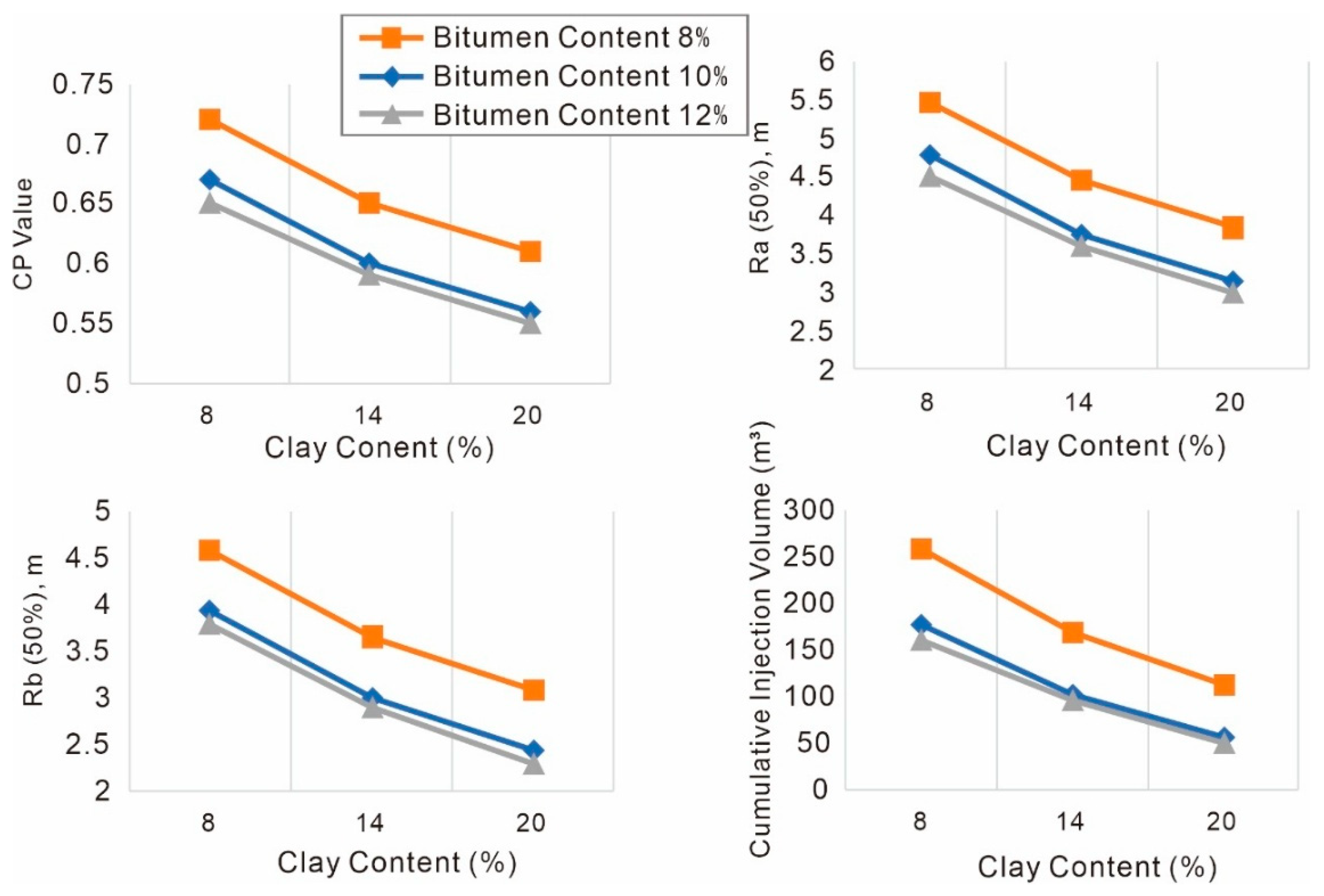

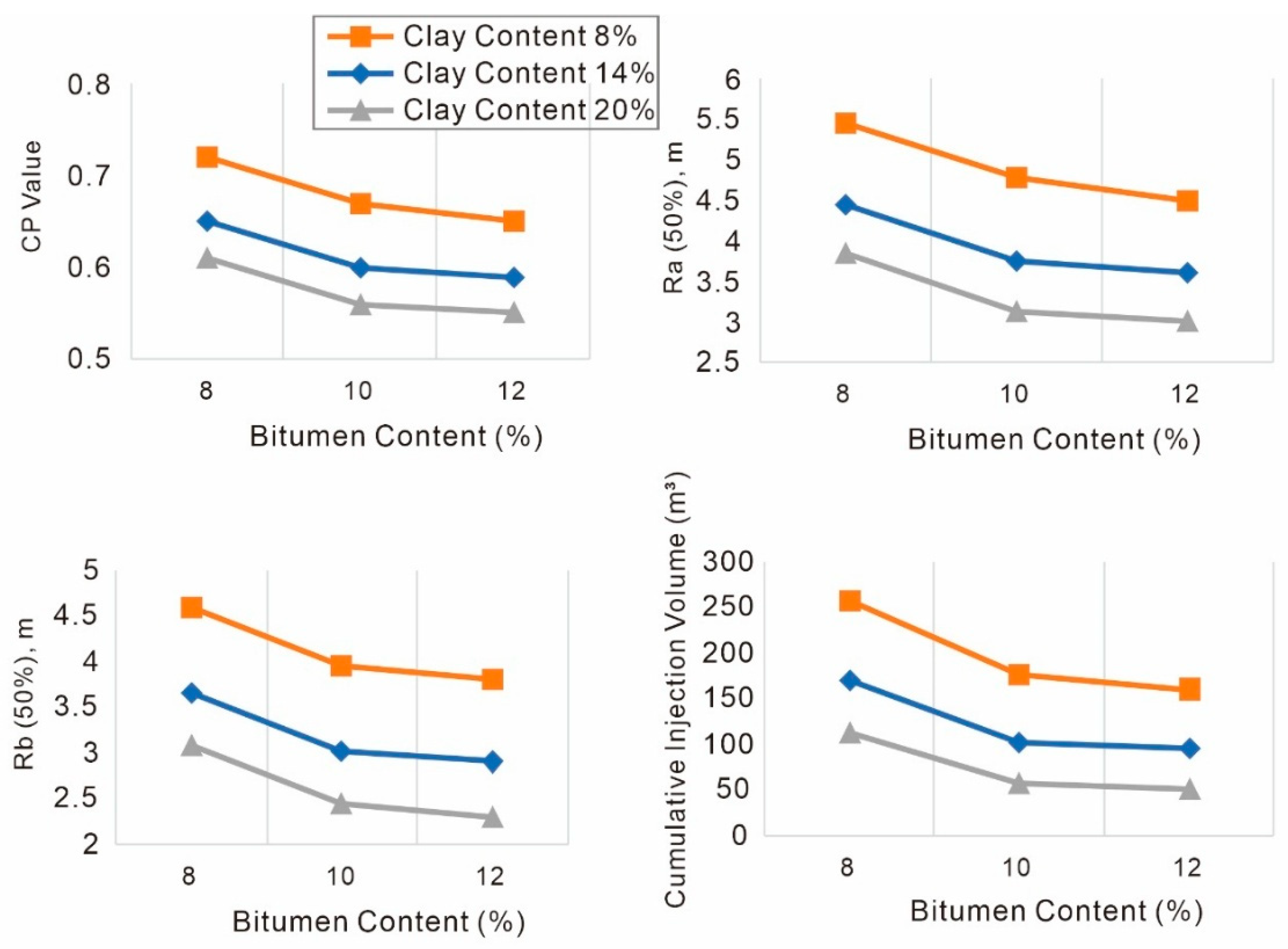

3.1.2. Case Analysis of Asphaltene and Clay Content Impacts on Stimulation Effectiveness

3.2. Effects of Heavy Oil Viscosity

3.2.1. Temperature–Viscosity Curve of Heavy Oil

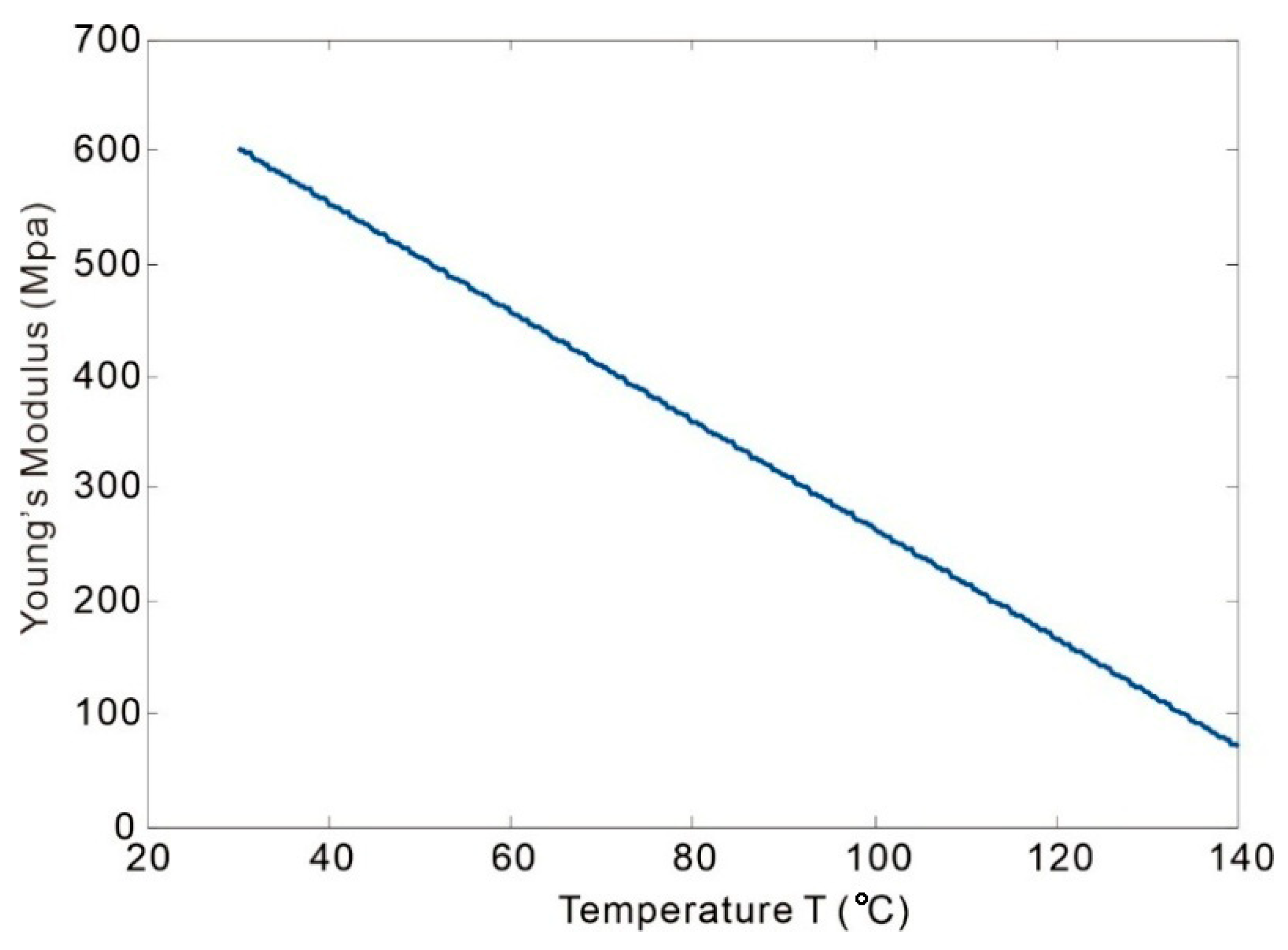

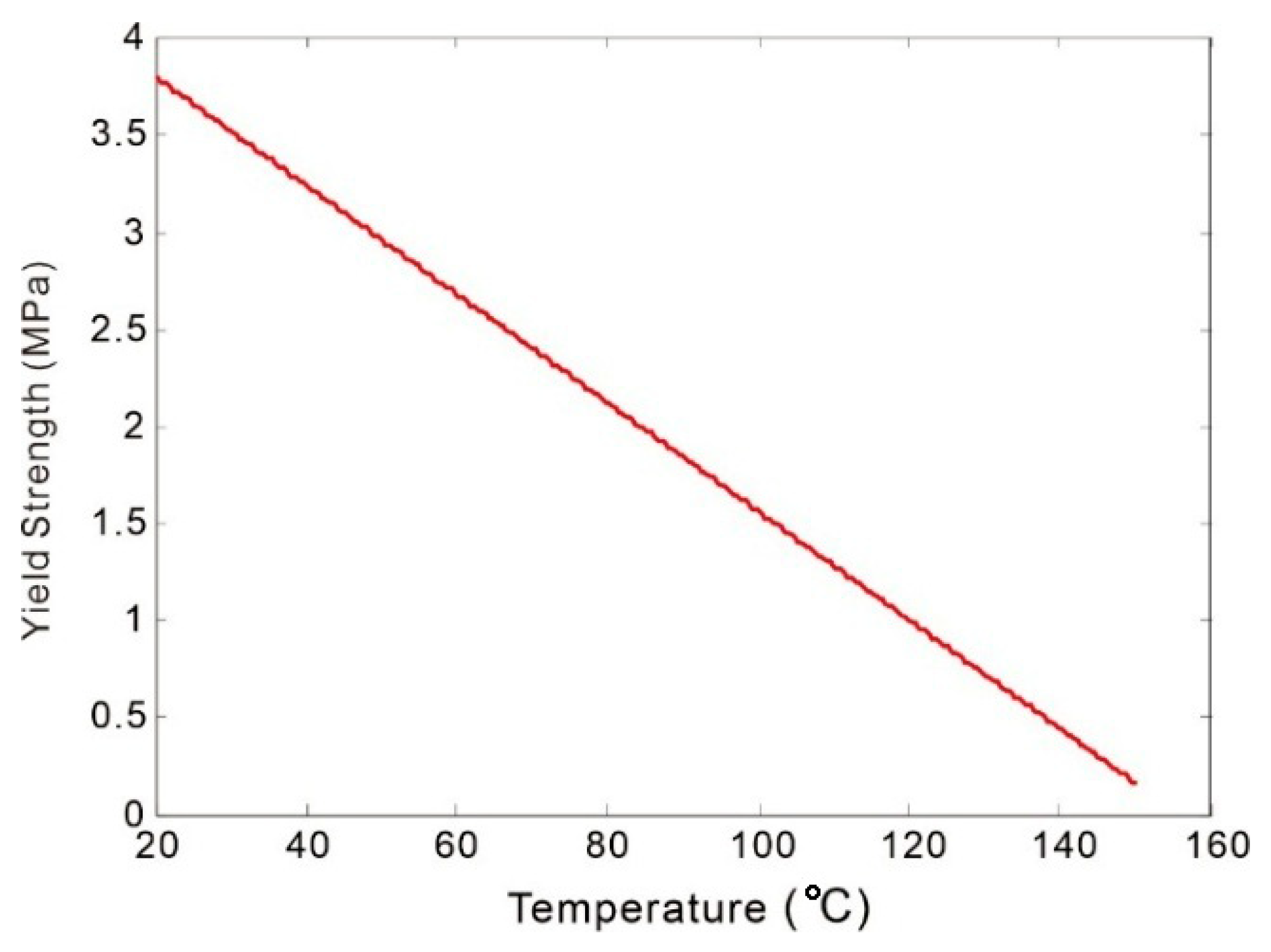

3.2.2. The Temperature Sensitivity of Rock Mechanical Parameters

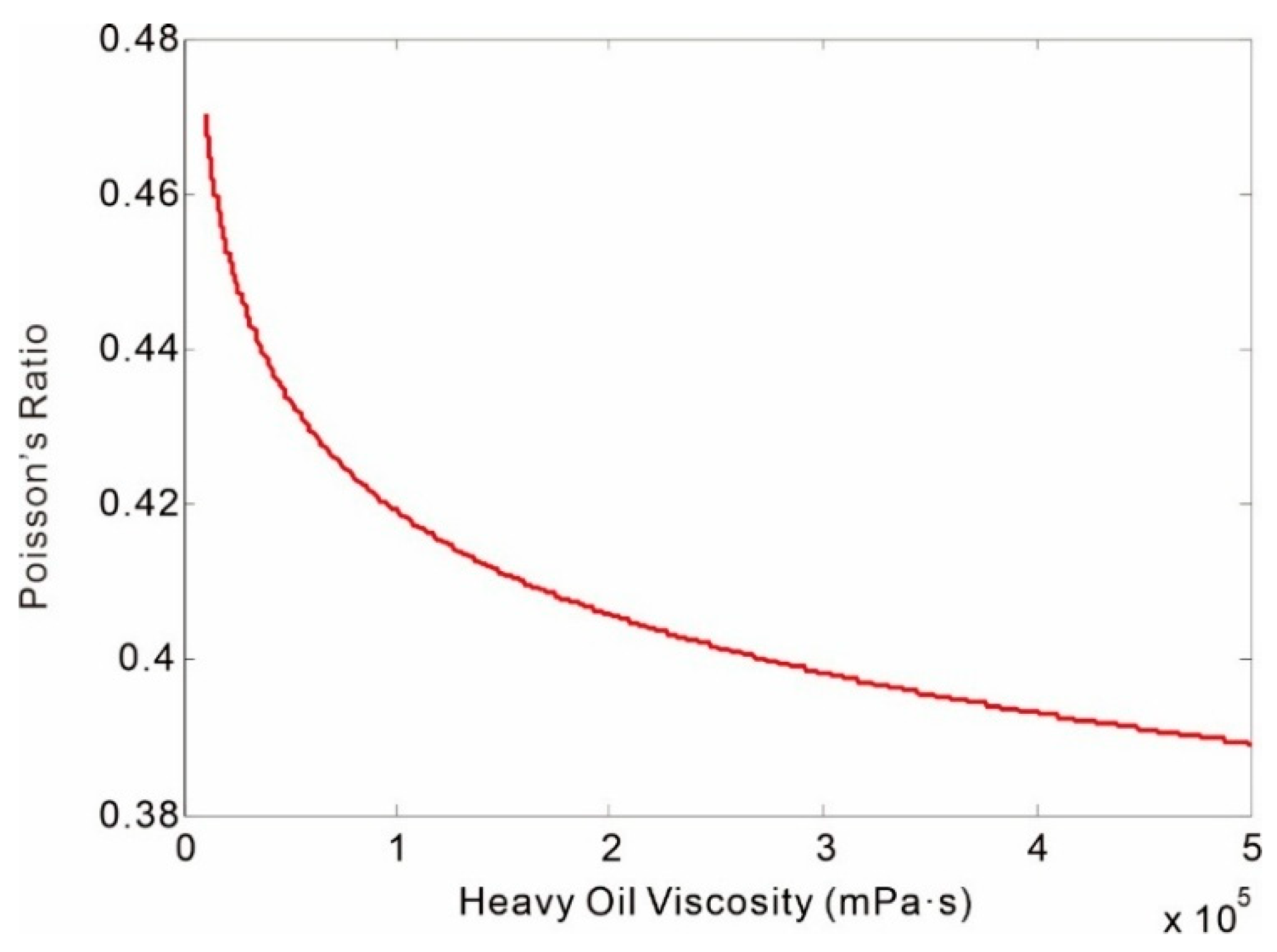

3.2.3. Effects of Heavy Oil Viscosity on Rock Mechanical Parameters

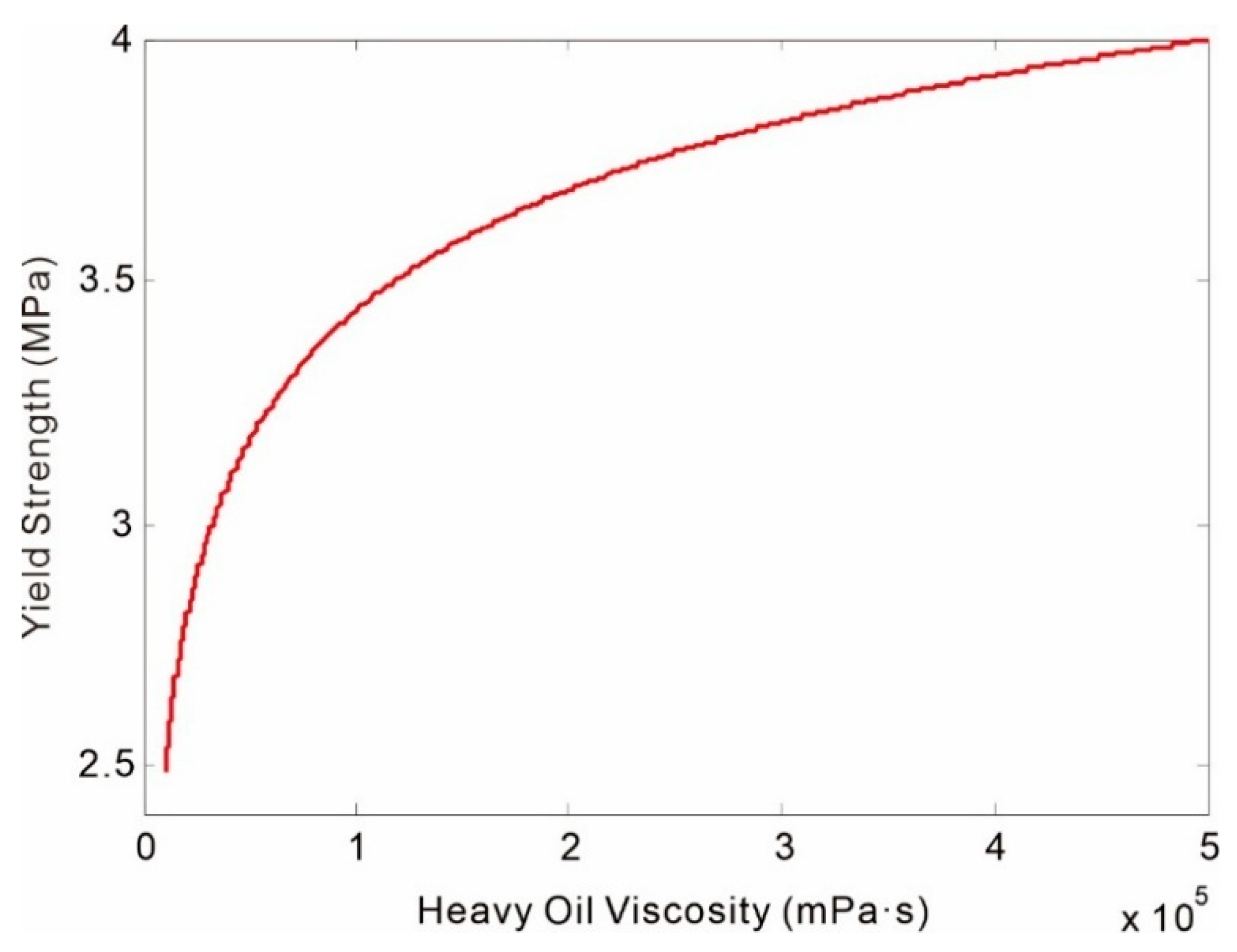

3.2.4. Case Analysis of Heavy Oil Viscosity Effects on Dilation Behavior

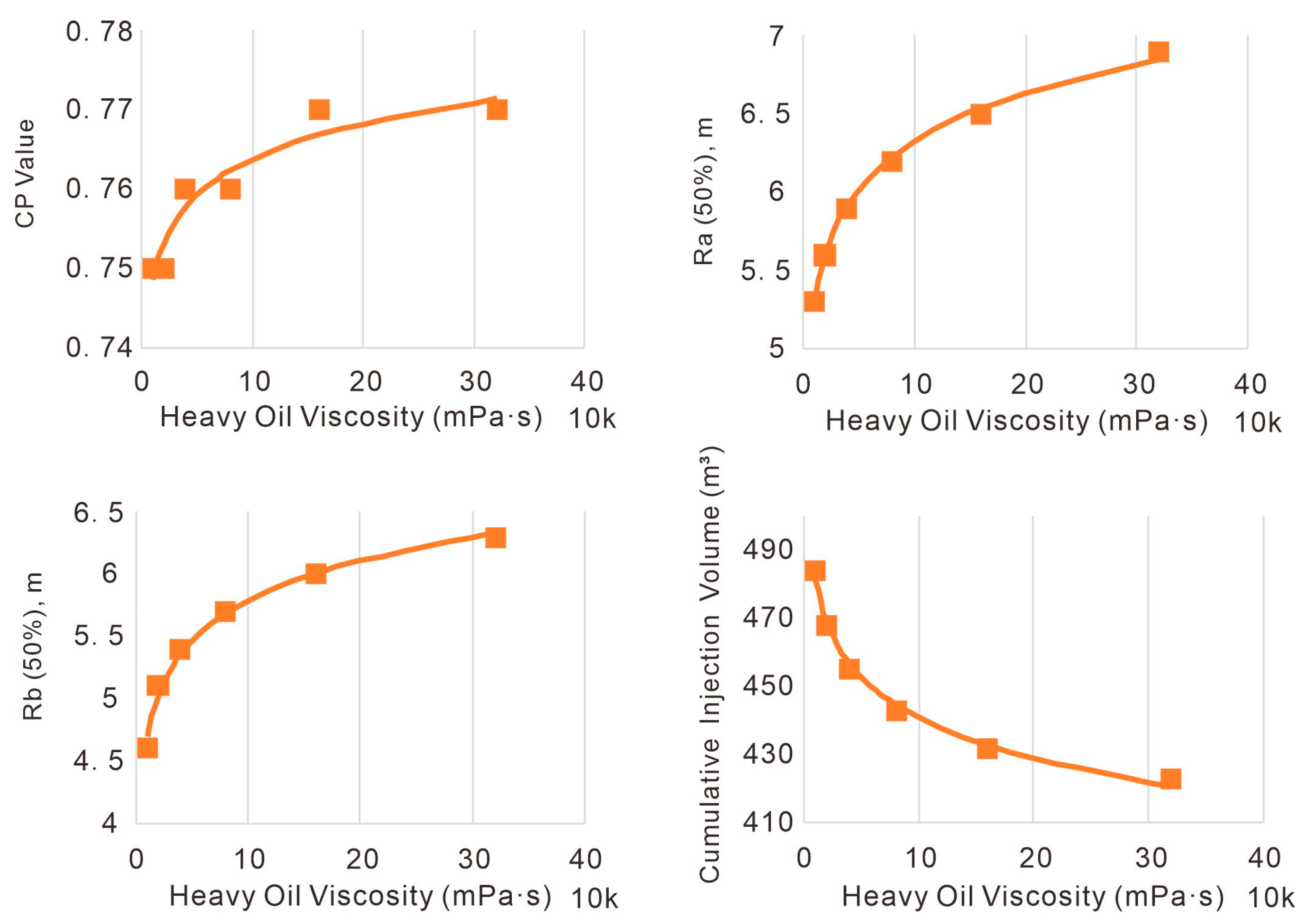

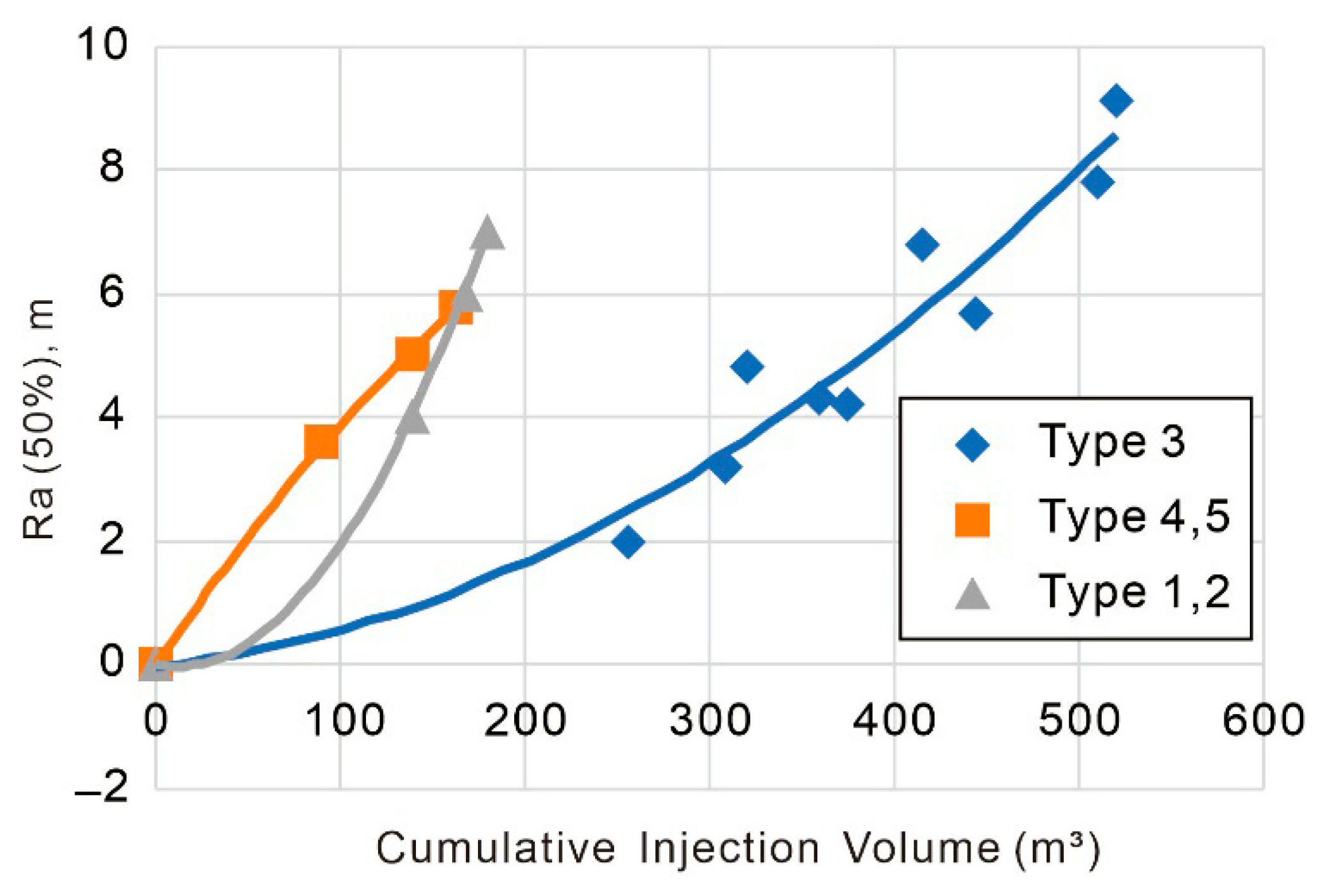

4. Optimization Objectives and Strategies

- CP = hydraulic connectivity coefficient (dimensionless)

- R = dilation radius (m)

- Q = cumulative injection volume (m3)

- a, b, m, n = material constants dependent on oil sand type (or reservoir properties)

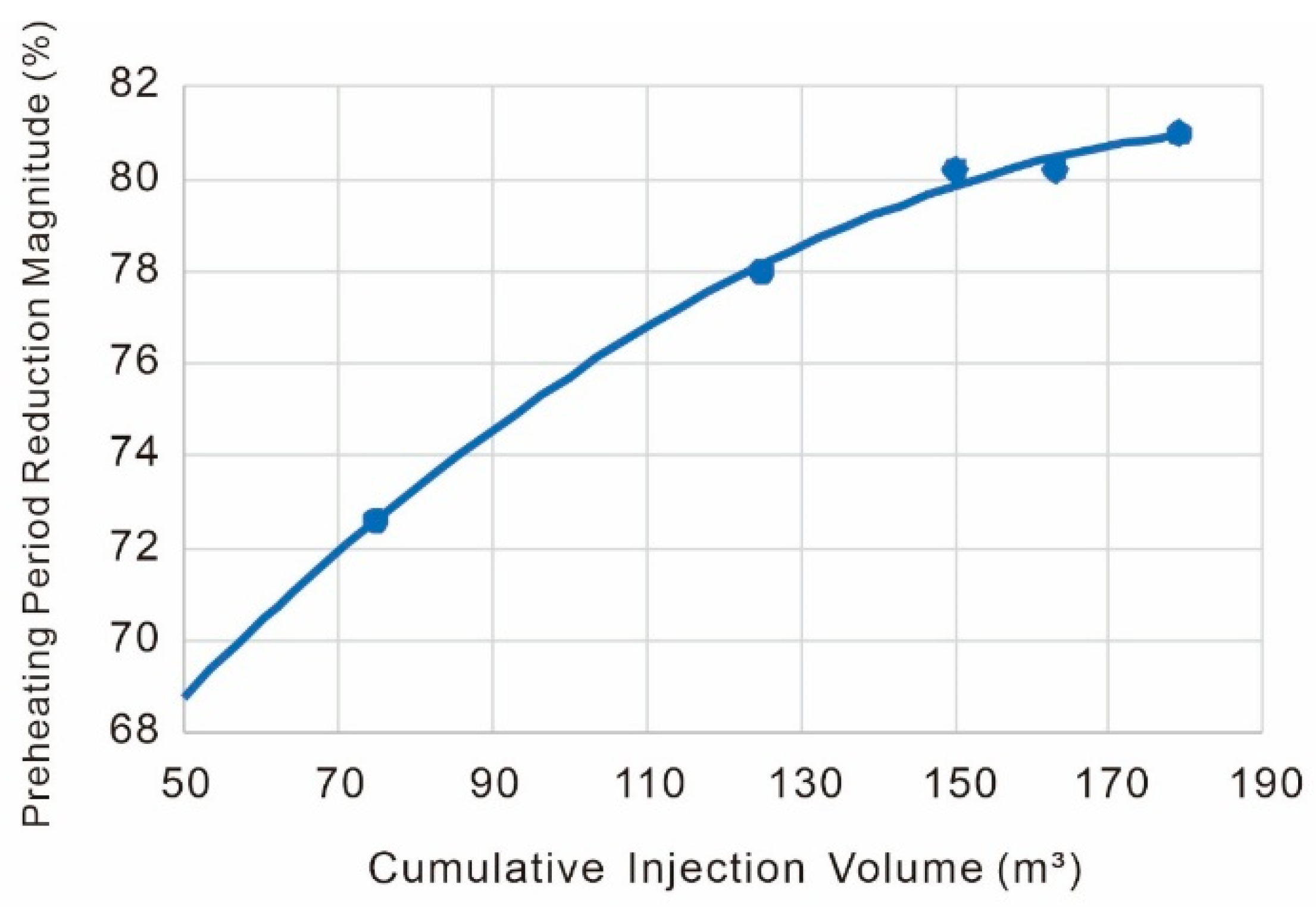

5. Prediction of Preheating Period Reduction Magnitude

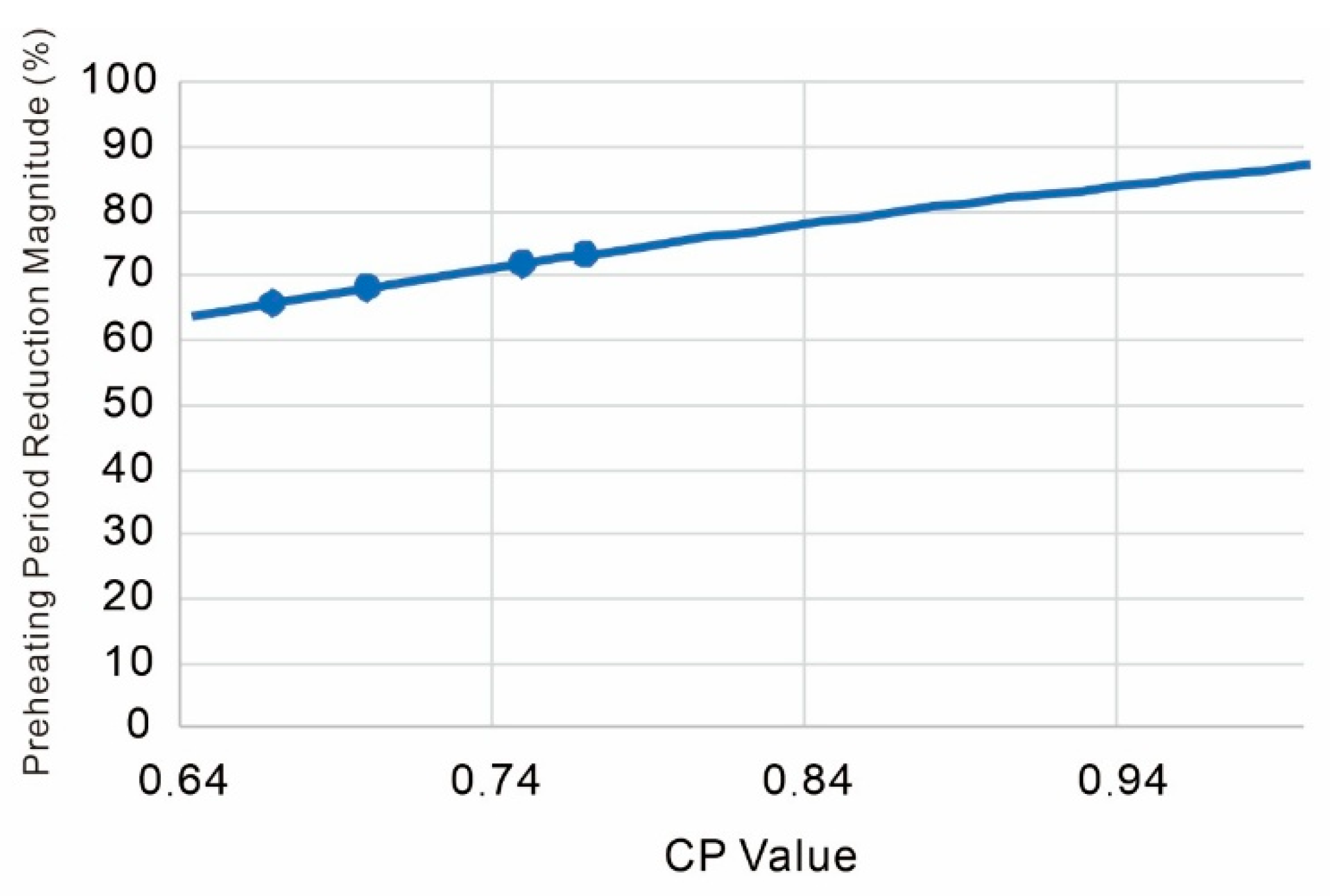

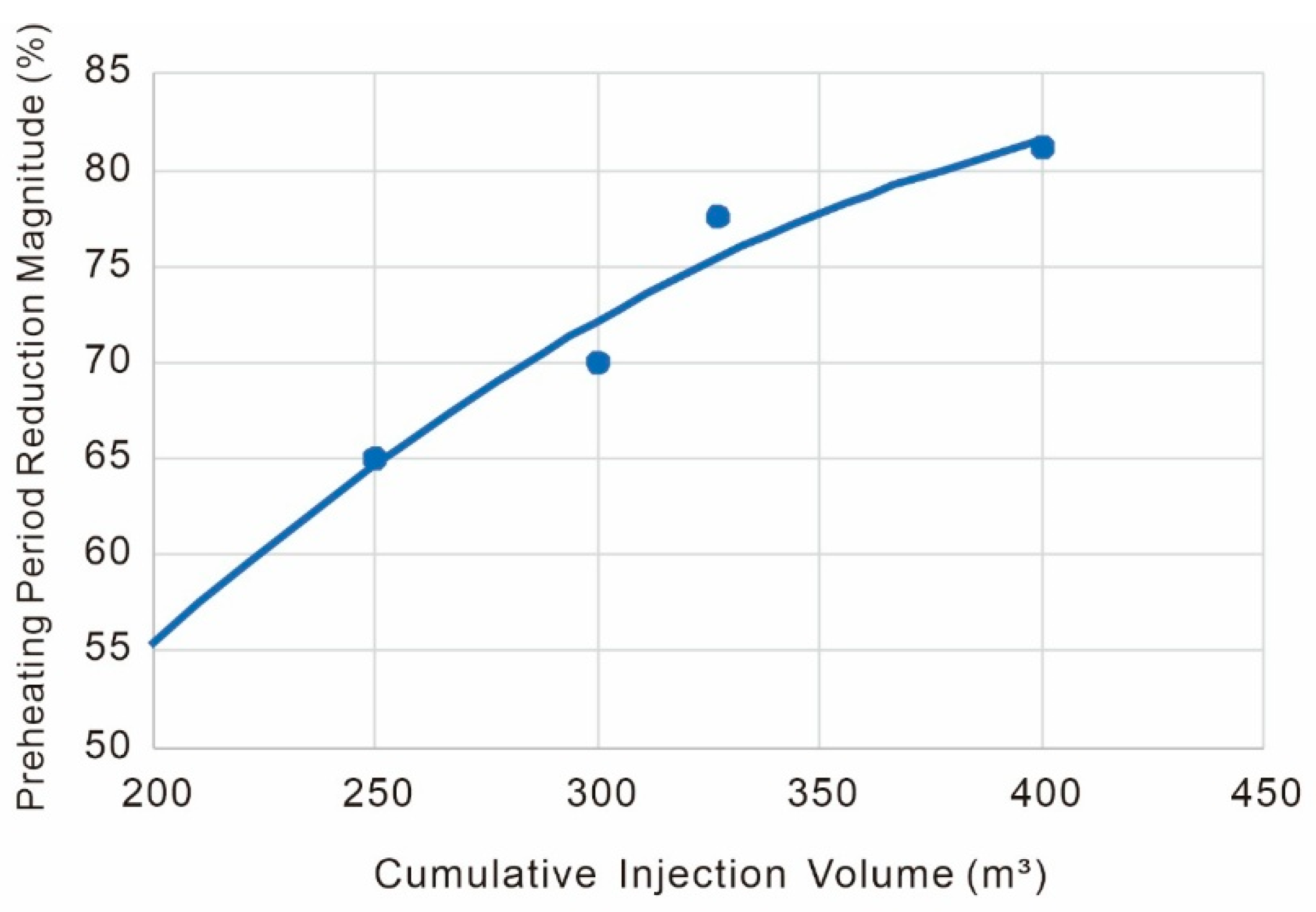

5.1. Prediction of Preheating Period Reduction Magnitude for Conventional Oil Sands

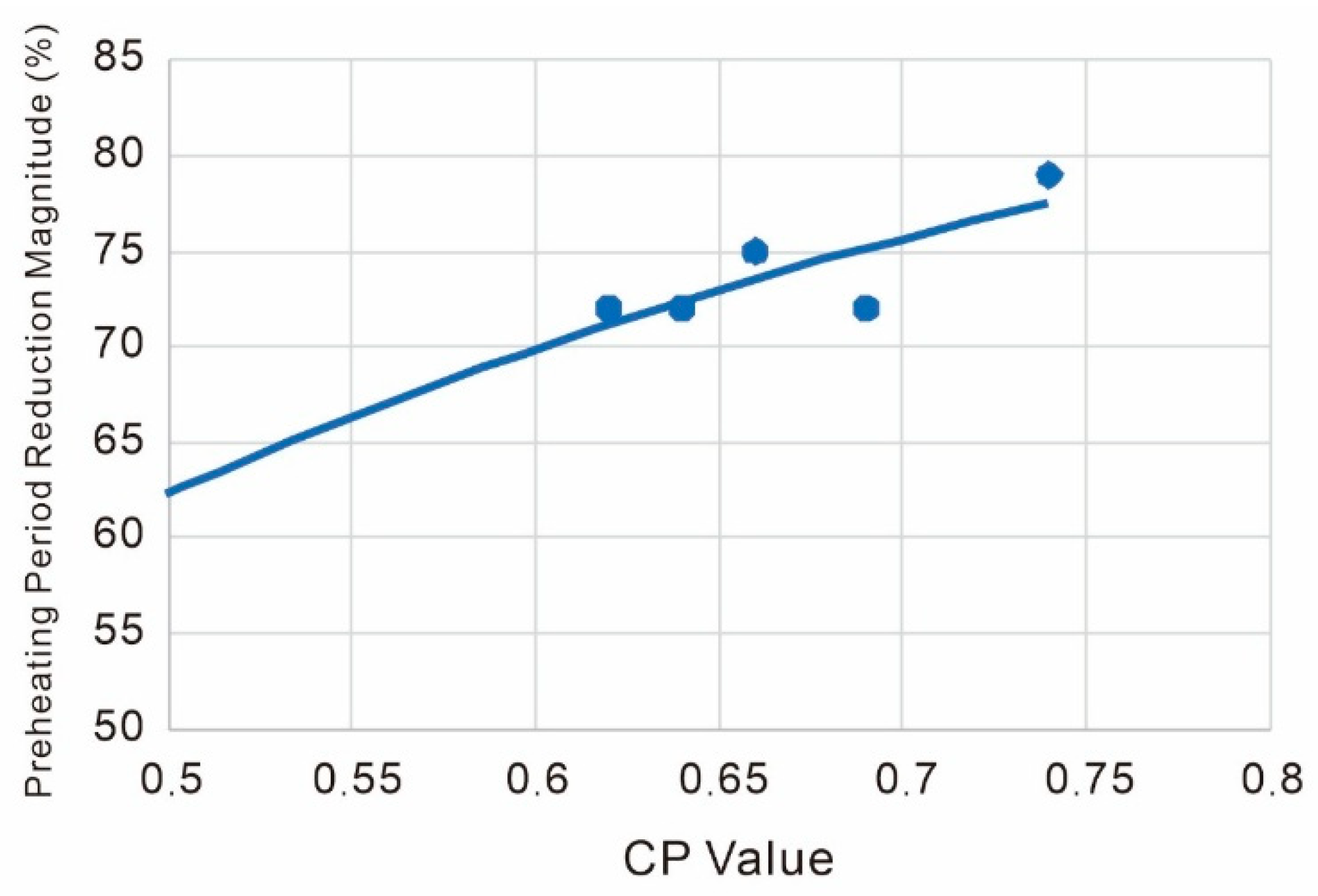

5.2. Prediction of Preheating Period Reduction Magnitude for Unconventional Oil Sands

6. Conclusions and Recommendations

- (1)

- As bitumen content increases, the dilation effectiveness of micro-fracturing in oil sands progressively deteriorates, with more pronounced deterioration trends observed in low-clay-content formations. Field operation recommendations: For low-bitumen oil sands (e.g., conventional oil sands), micro-fracturing demonstrates significant dilation effects; while for high-bitumen oil sands, it still achieves satisfactory dilation performance.

- (2)

- Increasing clay content reduces micro-fracturing effectiveness, particularly in high-bitumen oil sands. Field recommendation: Implement multi-stage pressure elevation protocols for clay-rich oil sands (e.g., argillaceous oil sands) during operations.

- (3)

- Elevated heavy oil viscosity enhances hydraulic connectivity coefficient and dilation radius while moderately reducing cumulative injection volume. Field implication: Higher viscosity reservoirs exhibit superior micro-fracturing response. The Fengcheng oil sands (with in situ viscosity >106 mPa·s at reservoir temperature) in particular demonstrate the necessity of micro-fracturing.

- (4)

- Under identical injection volumes, the dilation radius follows the order of (clay-rich) argillaceous > (oil-rich) bituminous > conventional oil sands, consistent with CP value trends. For conventional oil sands, preheating period reduction magnitude increases with injection volume, achieving 70–75% reduction at the hydraulic connectivity threshold (270–350 m3 cumulative injection).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Stratum | Asphaltene Content | Clay Content | Elastic Parameters | Plastic Parameters | Hardening (or Softening) Shape | Petrophysical Parameters | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional Oil Sands | 8.5 | 8.2 | E (MPa) | 652 | β | 45 | σy (MPa) | 2.047 | εp | 0 | φ0 | 0.25 |

| ν | 0.3 | K | 1.0 | 3.746 | 0.0064 | k0 (mD) | 0.977 | |||||

| ψ | 25 | 2.624 | 0.04 | |||||||||

| Clay-Rich Oil Sands | 9.1 | 21.5 | E (MPa) | 255 | β | 45 | σy (MPa) | 2.047 | εp | 0 | φ0 | 0.17 |

| ν | 0.3 | K | 1.0 | 3.746 | 0.0064 | k0 (mD) | 0.121 | |||||

| ψ | 25 | 2.624 | 0.04 | |||||||||

| Bitumen-Rich Oil Sands | 13.7 | 6.7 | E (MPa) | 652 | β | 45 | σy (MPa) | 2.047 | εp | 0 | φ0 | 0.23 |

| ν | 0.4 | K | 1.0 | 3.746 | 0.0064 | k0 (mD) | 0.295 | |||||

| ψ | 25 | 2.624 | 0.04 | |||||||||

| Argillaceous Content | Asphaltene Content | Initial Permeability |

|---|---|---|

| 5 | 6 | 1.13 |

| 5 | 10 | 0.82 |

| 5 | 14 | 0.72 |

| 10 | 6 | 0.76 |

| 10 | 10 | 0.45 |

| 10 | 14 | 0.35 |

| 15 | 6 | 0.55 |

| 15 | 10 | 0.24 |

| 15 | 14 | 0.14 |

| 20 | 6 | 0.53 |

| 20 | 10 | 0.22 |

| 20 | 14 | 0.12 |

| Experimental Serial Number | Bitumen Content (%) | Clay Content (%) | Elastic Parameters | Petrophysical Parameters | ||

|---|---|---|---|---|---|---|

| Elastic Modulus (MPa) | Poisson’s Ratio | Initial Porosity (%) | Initial Permeability (mD) | |||

| 1 | 8 | 8 | 679 | 0.3 | 17.55 | 0.60 |

| 2 | 8 | 14 | 950 | 0.23 | 15.61 | 0.67 |

| 3 | 8 | 20 | 1221 | 0.20 | 10.89 | 0.29 |

| 4 | 10 | 8 | 568 | 0.32 | 20.04 | 0.75 |

| 5 | 10 | 14 | 839 | 0.25 | 18.10 | 0.82 |

| 6 | 10 | 20 | 1110 | 0.23 | 13.37 | 0.43 |

| 7 | 12 | 8 | 457 | 0.35 | 19.98 | 0.68 |

| 8 | 12 | 14 | 728 | 0.28 | 18.04 | 0.74 |

| 9 | 12 | 20 | 999 | 0.25 | 13.31 | 0.36 |

| Pressure Application Method and Injection Time | Wellhead Pressure of I-Well and P-Well (kPa) | ||

|---|---|---|---|

| Pressure Application Method | Injection Time (min) | I-well | P-well |

| Continuous steady pressure | 3780 | 1800 | 1600 |

| Experimental Serial Number | Influencing Factors | Evaluation Metrics for Reservoir Stimulation | ||||||

|---|---|---|---|---|---|---|---|---|

| Bitumen Content (%) | Clay Content (%) | Hydraulic Connectivity Coefficient | Stimulation Radius | Cumulative Injection Volume (m3) | ||||

| Ra | Rb | |||||||

| Ra (50%) | Ra (70%) | Rb (50%) | Rb (70%) | |||||

| 1 | 8 | 8 | 0.72 | 5.46 | 2.8 | 4.58 | 2.51 | 257 |

| 2 | 8 | 14 | 0.65 | 4.46 | 2.61 | 3.66 | 2.08 | 169 |

| 3 | 8 | 20 | 0.61 | 3.84 | 2.49 | 3.09 | 1.82 | 112 |

| 4 | 10 | 8 | 0.67 | 4.78 | 2.67 | 3.95 | 2.22 | 176 |

| 5 | 10 | 14 | 0.6 | 3.75 | 2.48 | 3.01 | 1.78 | 102 |

| 6 | 10 | 20 | 0.56 | 3.14 | 2.36 | 2.44 | 1.51 | 57 |

| 7 | 12 | 8 | 0.65 | 4.5 | 2.83 | 3.8 | 2.58 | 160 |

| 8 | 12 | 14 | 0.59 | 3.6 | 2.64 | 2.9 | 2.14 | 95 |

| 9 | 12 | 20 | 0.55 | 3 | 2.52 | 2.3 | 1.87 | 50 |

| Test ID | Heavy Oil Viscosity at 50 °C (mPa·s) | Elastic Modulus E (MPa) | Poisson’s Ratio | Yield Strength (MPa) |

|---|---|---|---|---|

| 1 | 10,000 | 425 | 0.47 | 2.48 |

| 2 | 20,000 | 479 | 0.45 | 2.79 |

| 3 | 40,000 | 529 | 0.44 | 3.08 |

| 4 | 80,000 | 576 | 0.42 | 3.35 |

| 5 | 160,000 | 620 | 0.41 | 3.61 |

| 6 | 320,000 | 661 | 0.40 | 3.85 |

| Pressure Application Method and Injection Duration | Wellhead Pressure at I-Well and P-Well (kPa) | ||

|---|---|---|---|

| Pressure Application Method | Injection Duration (min) | I-Well | P-Well |

| Stepwise Pressure increase | 0–1440 | 700 | 700 |

| 1440–2820 | 1680 | 1680 | |

| 2820–3780 | 2016 | 2016 | |

| 3780–4580 | 2620.8 | 2620.8 | |

| Test ID | Heavy Oil Viscosity (mPa·s) | Hydraulic Connectivity Coefficient | Dilation Radius | Cumulative Injection Volume (m3) | |

|---|---|---|---|---|---|

| Ra (50%) | Rb (50%) | ||||

| 1 | 10,000 | 0.75 | 5.3 | 4.6 | 484 |

| 2 | 20,000 | 0.75 | 5.6 | 5.1 | 468 |

| 3 | 40,000 | 0.76 | 5.9 | 5.4 | 455 |

| 4 | 80,000 | 0.76 | 6.2 | 5.7 | 443 |

| 5 | 160,000 | 0.77 | 6.5 | 6.0 | 432 |

| 6 | 320,000 | 0.77 | 6.9 | 6.3 | 423 |

| Block | Well ID | Reservoir Type | Rapid Cyclic Preheating Period (days) | Conventional Preheating Period (days) | Reduction Percentage (%) |

|---|---|---|---|---|---|

| Zhong-1 Well Block | FHW325U | Oil-rich | 36 | 211 | 82.93 |

| FHW327 | Oil-rich | 48 | 77.25 | ||

| Zhong-18 Well Block | FHW3055 | Conventional | 68 | 303 | 77.55 |

| FHW3061 | Clay-rich | 83 | 72.60 | ||

| FHW3076 | Argillaceous | 60 | 80.19 | ||

| FHW3077 | Conventional | 132 | 56.43 | ||

| FHW3078 | Conventional | 93 | 69.30 | ||

| FHW3079 | Conventional | 57 | 81.18 | ||

| FHW3080 | Conventional | 145 | 52.14 | ||

| FHW3083 | Argillaceous | 93 | 69.30 | ||

| FHW3099 | Argillaceous | 60 | 80.19 |

References

- Yuan, Y.; Yang, B.; Xu, B. Fracturing in the Oil-Sands Reservoirs. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 15–17 November 2011. [Google Scholar]

- Yuan, X.; Dou, S.; Zhang, J.; Chen, S.; Xu, B. Consideration of geomechanics for in-situ bitumen recovery in Xinjiang, China. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11 June 2013. [Google Scholar]

- Lin, B.; Jin, Y.; Chen, S. A criterion for evaluating the efficiency of water injection in oil sand reservoirs. J. Pet. Sci. Eng. 2017, 149, 322–330. [Google Scholar] [CrossRef]

- Xu, B.; Wong, R.C.K. Coupled finite-element simulation of injection well testing in unconsolidated oil sands reservoir. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 3131–3149. [Google Scholar] [CrossRef]

- Sun, X.; Xu, B.; Qian, G.; Li, B. The application of geomechanical SAGD dilation startup in a Xinjiang oil field heavy-oil reservoir. J. Petrol. Sci. Eng. 2021, 196, 107670. [Google Scholar] [CrossRef]

- Azad, A.; Chalaturnyk, R.J. A mathematical improvement to SAGD using geomechanical modelling. J. Can. Pet. Technol. 2010, 49, 53–64. [Google Scholar] [CrossRef]

- Lin, B.; Jin, Y.; Pang, H.; Cerato, A.B. Experimental investigation on dilation mechanics of land-facies Karamay oil sand reservoirs under water injection. Rock Mech. Rock Eng. 2016, 49, 1425–1439. [Google Scholar] [CrossRef]

- Li, P.; Chalaturnyk, R.J. History match of the UTF phase A project with coupled reservoir geomechanical simulation. J. Can. Pet. Technol. 2009, 48, 29–35. [Google Scholar] [CrossRef]

- Wong, R.C.K.; Barr, W.E.; Kry, P.R. Stress-strain response of Cold Lake oil sands. Can. Geotech. J. 1993, 30, 220–235. [Google Scholar] [CrossRef]

- Huang, L.; Liu, C.; Wang, Z.; Zhou, Y.; He, F.; Liu, Y.; Huang, Y. An alternative formation mechanism for strike-slip fault in stable intracratonic basin. J. Struct. Geol. 2025, 191, 105292. [Google Scholar] [CrossRef]

- Deutsch, C.V. Geostatistical Reservoir Modeling; Oxford University Press: New York, NY, USA, 2010. [Google Scholar]

- Fung, L.S.; Buchanan, L.; Wan, R.G. Coupled geomechanical-thermal simulation for deforming heavy-oil reservoirs. J. Can. Pet. Technol. 1994, 33, 22–28. [Google Scholar] [CrossRef]

- Ahmadi, S.; Khormali, A.; Kazemzadeh, Y.; Razmjooie, A. Enhancing dehydration/desalting efficiency of crude oil emulsions through experimental and computational insights. Results Eng. 2024, 12, 103094. [Google Scholar] [CrossRef]

- Fei, K.; Zhang, J. Application of ABAQUS in Geotechnical Engineering; China Water & Power Press: Beijing, China, 2010. [Google Scholar]

- Gao, Y.; Wang, X.; Jiang, H.; Ding, S. Numerically coupled thermo-hydro-mechanical analyses of ultra-heavy oil reservoirs during the micro-fracturing stage. Energies 2022, 15, 3677. [Google Scholar] [CrossRef]

- Nouri, A.; Vaziri, H.; Belhaj, H.; Islam, R. Sand production prediction in oil sands: A new model. SPE J. 2006, 11, 230–238. [Google Scholar]

- Shao, H.; Wang, W.; Sun, Y.; Zhang, L.; Kolditz, O. OpenGeoSys-MATLAB: A unified framework for coupled thermo-hydro-mechanical simulation of energy geostructures. Results Eng. 2024, 22, 103094. [Google Scholar]

- Gao, Y.; Chen, M.; Lin, B.; Jin, Y. Experimental investigation on compressibility of Karamay oil sands under water injection. In Proceedings of the 51st U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017. ARMA-2017-0597. [Google Scholar]

- Huang, L.; Liu, C.; Wang, Z.; Zhou, Y.; Liu, Y.; Li, X.; Yang, L. Abrupt structural deformation changes from the boundary to the interior of a craton basin: Implications for the long-term stability of cratonic blocks. Geol. Soc. Am. Bull. 2025, 137, 825–840. [Google Scholar] [CrossRef]

- Helwany, S. Applied Soil Mechanics: With ABAQUS Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 978-0-471-79107-2. [Google Scholar]

- Fjar, E.; Holt, R.M.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier Science: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Chalaturnyk, R.; Scott, J.D. Geomechanics issues of steam assisted gravity drainage. In Proceedings of the SPE International Heavy Oil Symposium, Calgary, AB, Canada, 19–21 June 1995. SPE-30280-MS. [Google Scholar]

- GB/T 23561.9-2009; Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 9: Determination Method of Rock Point Load Strength Index. Standards Press of China: Beijing, China, 2009.

- Tian, H.; Kempka, T.; Yu, S.; Ziegler, M. Mechanical Properties of Sandstones Exposed to High Temperature. Rock Mech. Rock Eng. 2016, 49, 321–327. [Google Scholar] [CrossRef]

- Pang, H.; Jin, Y.; Gao, Y. Evaluation of elastic property changes in Karamay oil sand reservoir during thermal stimulation. Energy Sci. Eng. 2019, 7, 1233–1253. [Google Scholar] [CrossRef]

- Lin, B.; Chen, S.; Jin, Y. Evaluation of reservoir deformation induced by water injection in SAGD wells considering formation anisotropy, heterogeneity and thermal effect. J. Pet. Sci. Eng. 2017, 157, 767–779. [Google Scholar] [CrossRef]

- Huang, L.; Liu, C.; Liu, Y.; Zhou, Y.; He, F.; Wang, Z.; Zhang, Y.; Guo, B.; Liang, C. Development model of vertical stratification for the strike-slip fault in the Ordos Basin and its significance. Sci. China Earth Sci. 2025, 68, 1497–1510. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, Y.; Li, W.; Cheng, J.; Zhao, J.; Zheng, C.; Zhang, Y.; Wang, R.; Li, D.; Gao, Y. Impact of Reservoir Properties on Micro-Fracturing Stimulation Efficiency and Operational Design Optimization. Processes 2025, 13, 2137. https://doi.org/10.3390/pr13072137

Wang S, Wang Y, Li W, Cheng J, Zhao J, Zheng C, Zhang Y, Wang R, Li D, Gao Y. Impact of Reservoir Properties on Micro-Fracturing Stimulation Efficiency and Operational Design Optimization. Processes. 2025; 13(7):2137. https://doi.org/10.3390/pr13072137

Chicago/Turabian StyleWang, Shaohao, Yuxiang Wang, Wenkai Li, Junlong Cheng, Jianqi Zhao, Chang Zheng, Yuxiang Zhang, Ruowei Wang, Dengke Li, and Yanfang Gao. 2025. "Impact of Reservoir Properties on Micro-Fracturing Stimulation Efficiency and Operational Design Optimization" Processes 13, no. 7: 2137. https://doi.org/10.3390/pr13072137

APA StyleWang, S., Wang, Y., Li, W., Cheng, J., Zhao, J., Zheng, C., Zhang, Y., Wang, R., Li, D., & Gao, Y. (2025). Impact of Reservoir Properties on Micro-Fracturing Stimulation Efficiency and Operational Design Optimization. Processes, 13(7), 2137. https://doi.org/10.3390/pr13072137