Advances in the Research on the Properties and Applications of Micro-Nano Bubbles

Abstract

1. Introduction

2. Characteristics of Micro-Nano Bubbles

2.1. Physicochemical Properties of Micro-Nano Bubbles

2.1.1. Small Size

2.1.2. Large Specific Surface Area

2.1.3. Slow Rising Velocity in Water

2.1.4. High Bubble Surface Zeta Potential

2.1.5. Easy Self-Pressurization and Dissolution

2.1.6. Strong Mass Transfer Efficiency

2.2. Measurement Methods for Micro-Nano Bubbles

3. Generation Devices for Micro-Nano Bubbles

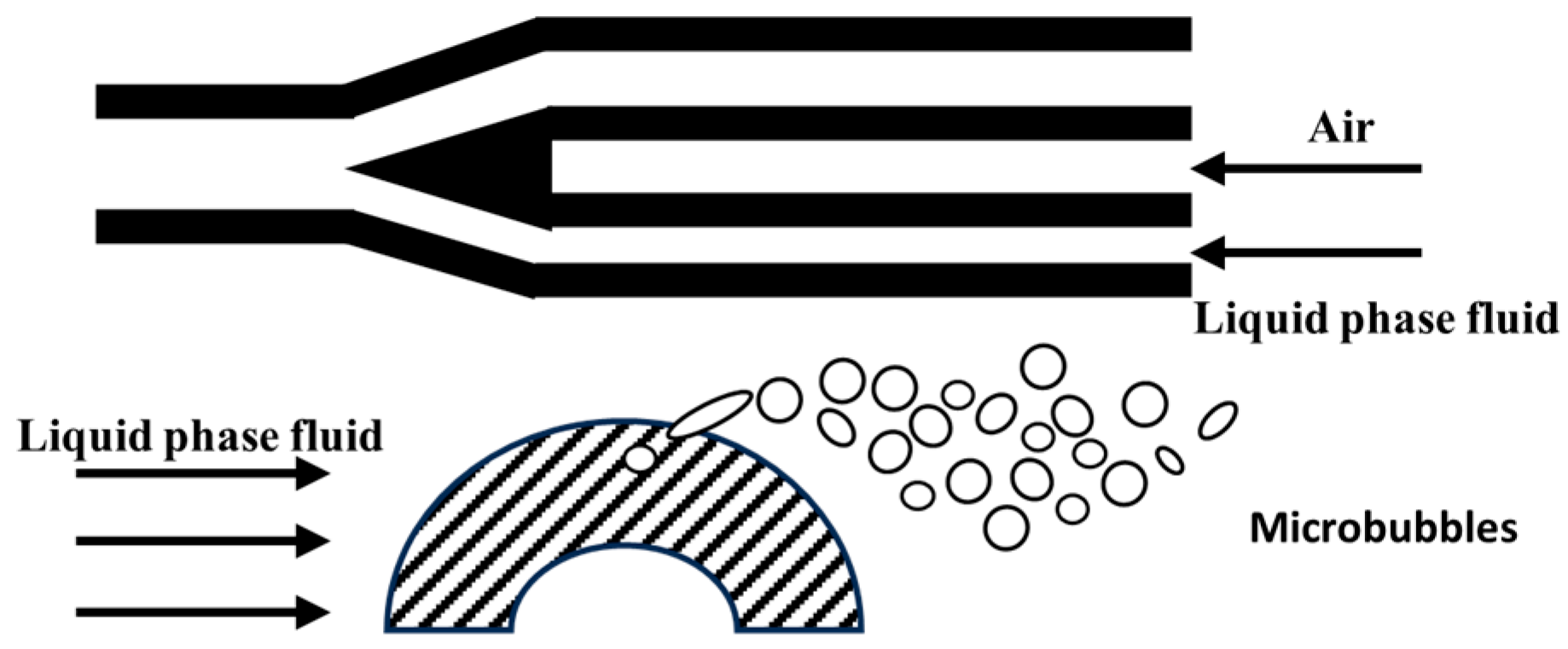

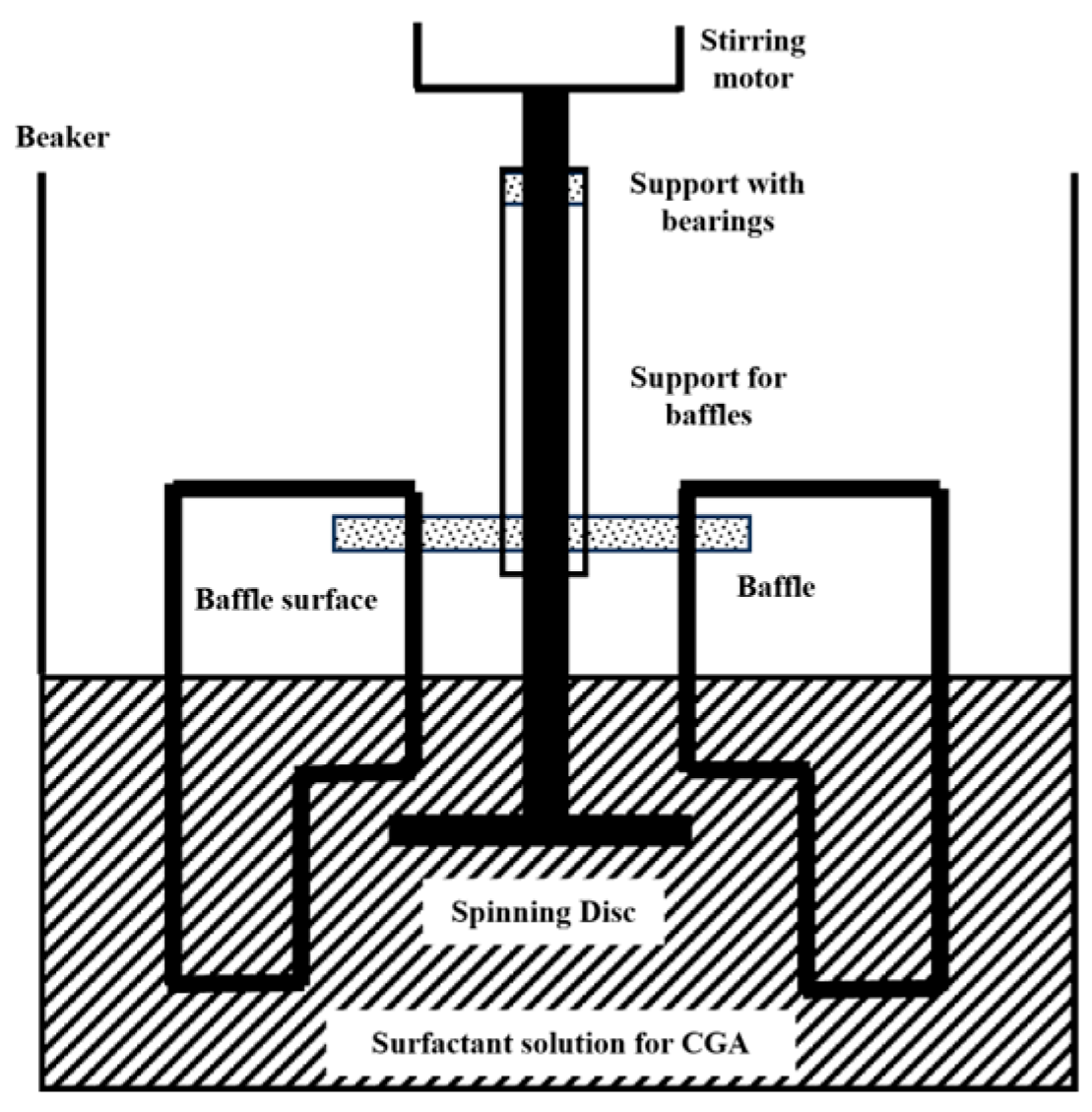

3.1. Mechanical Shearing Methods

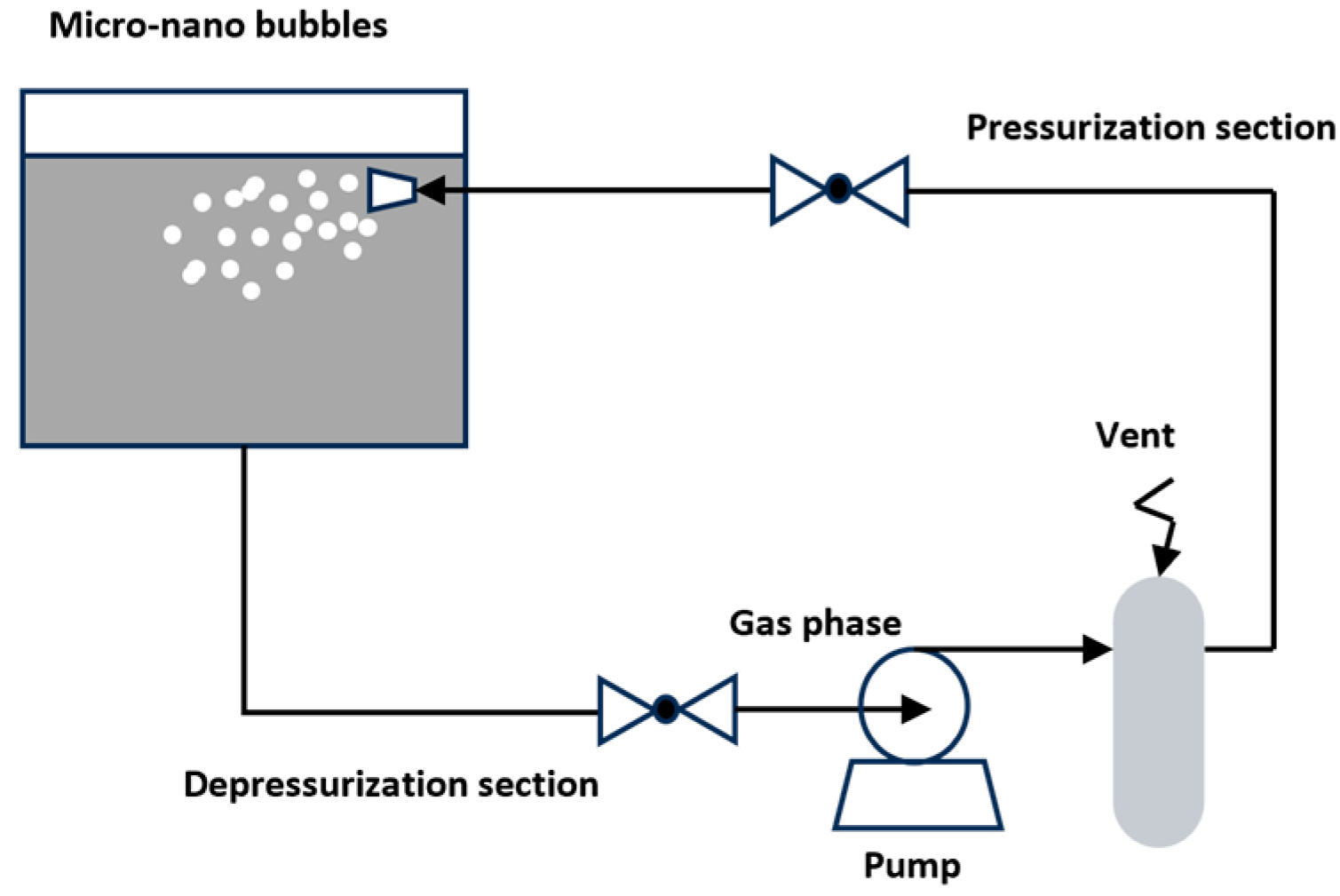

3.2. Pressurized Gas Dissolution Methods

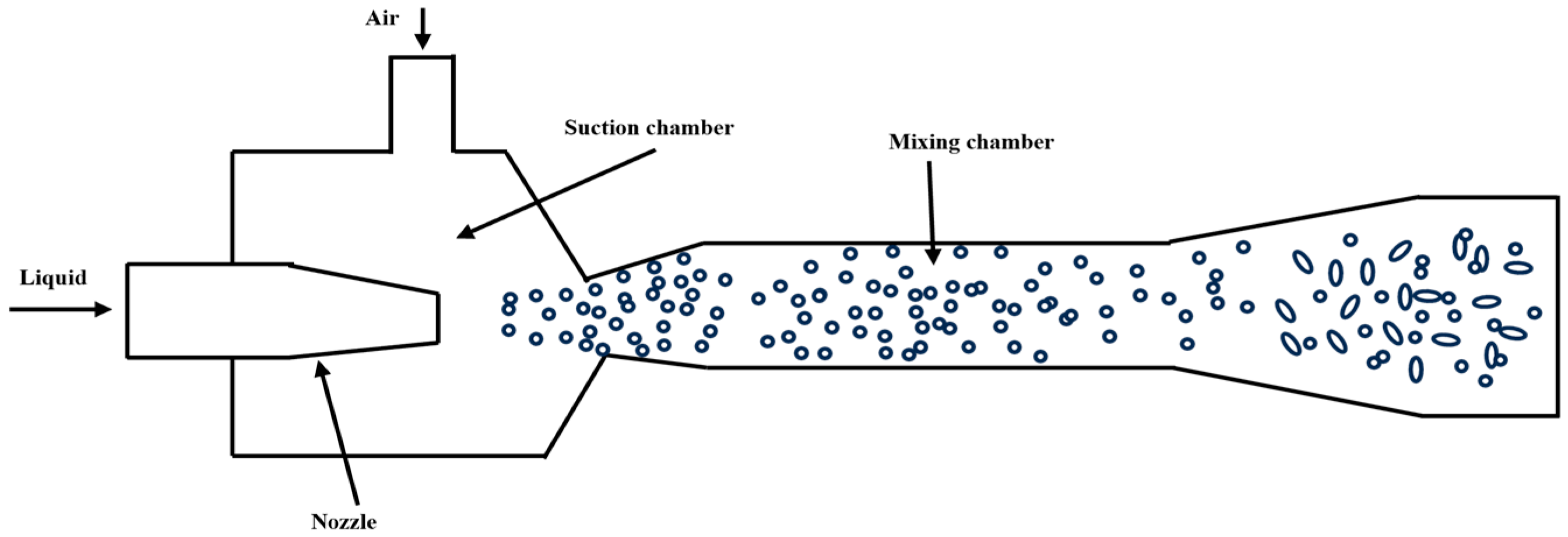

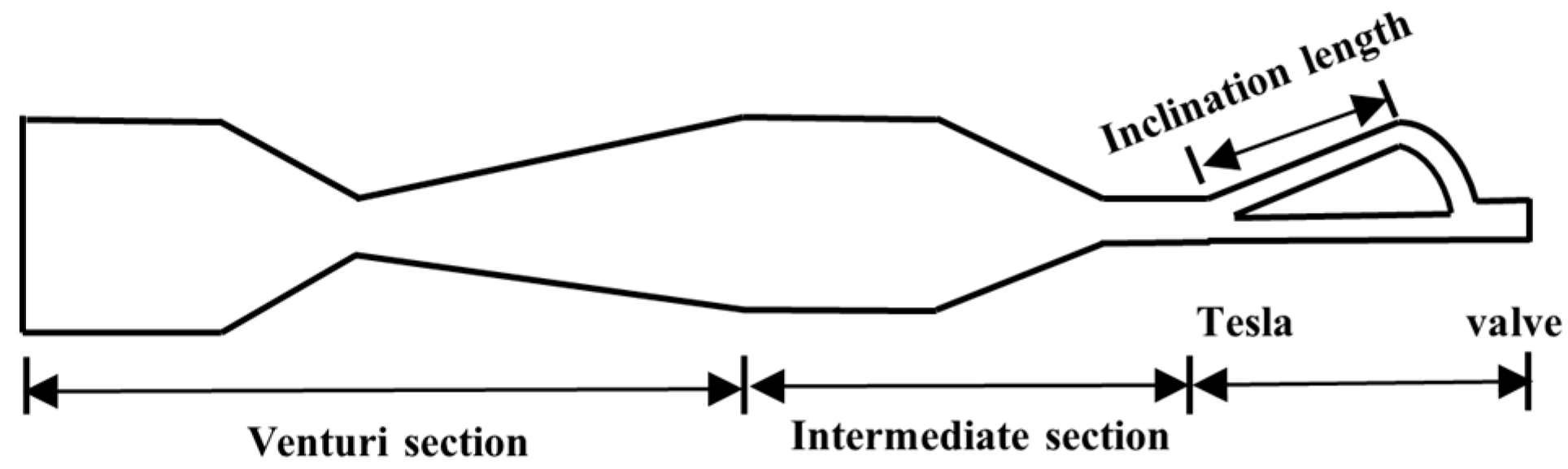

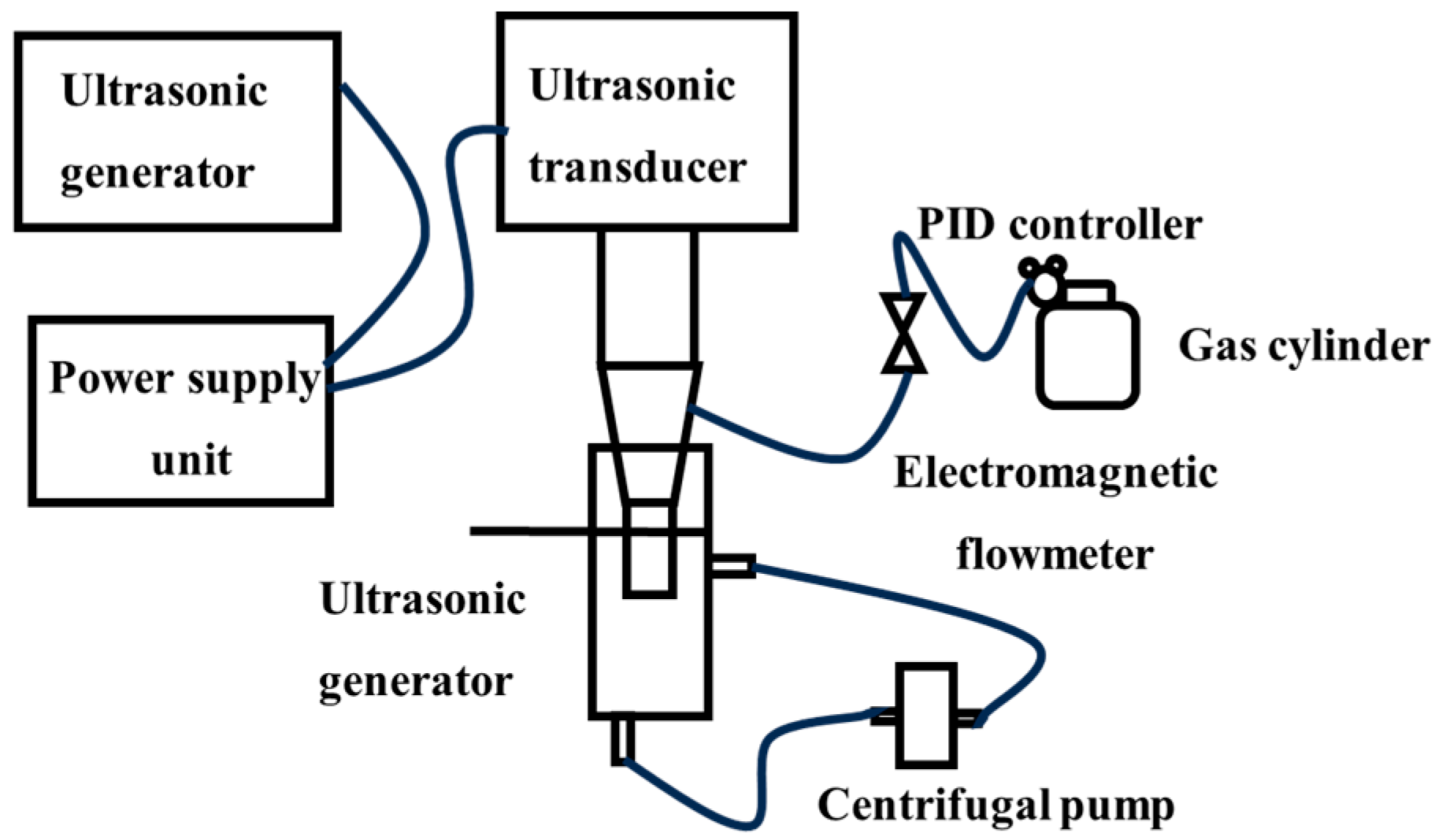

3.3. Cavitation Effect Methods

3.4. Electrochemical Methods

3.5. Micro-Porous Dispersion Methods

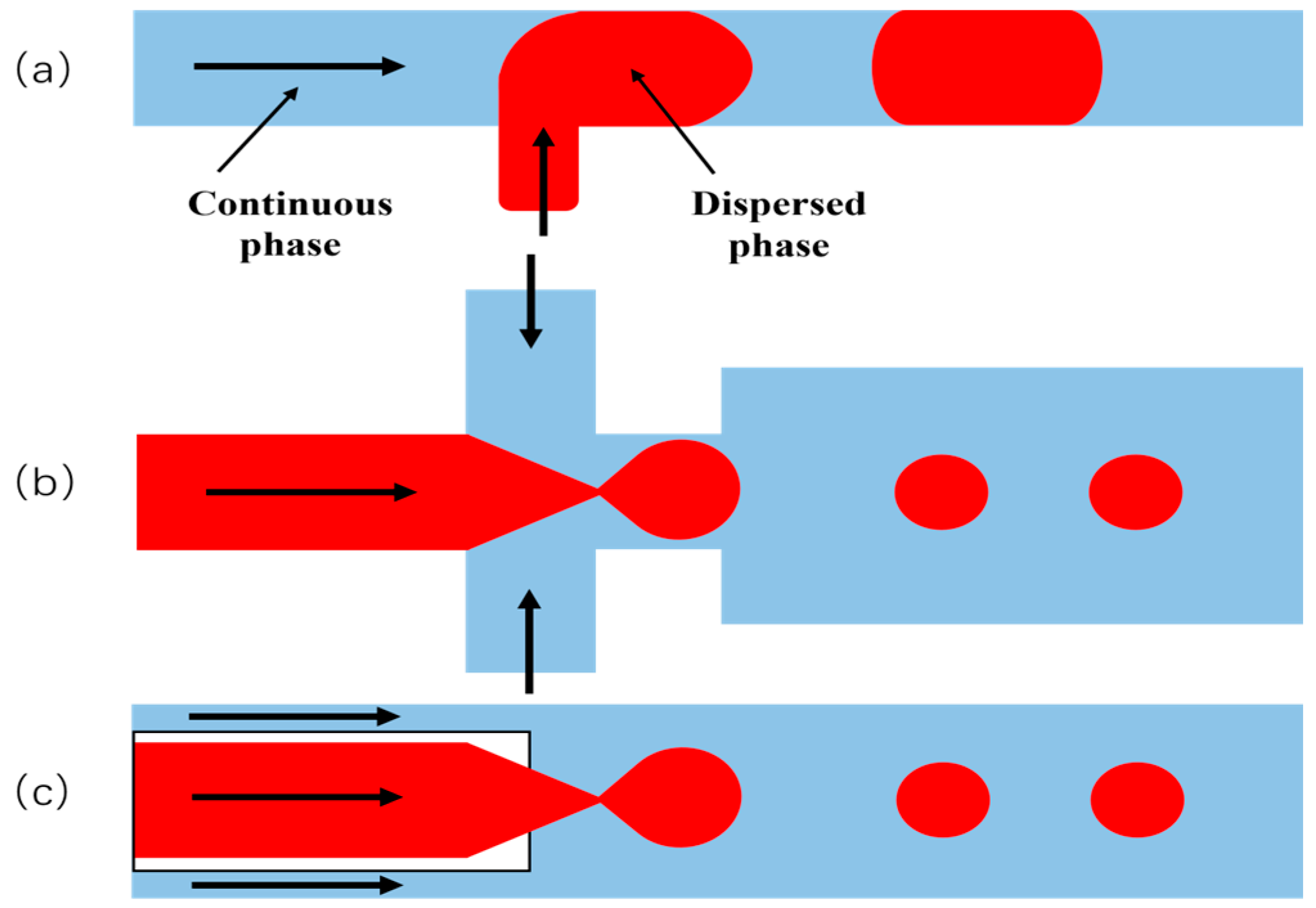

3.6. Microfluidic Technology

3.7. Summary

4. Applications of Micro-Nano Bubbles

4.1. Water Pollution Control

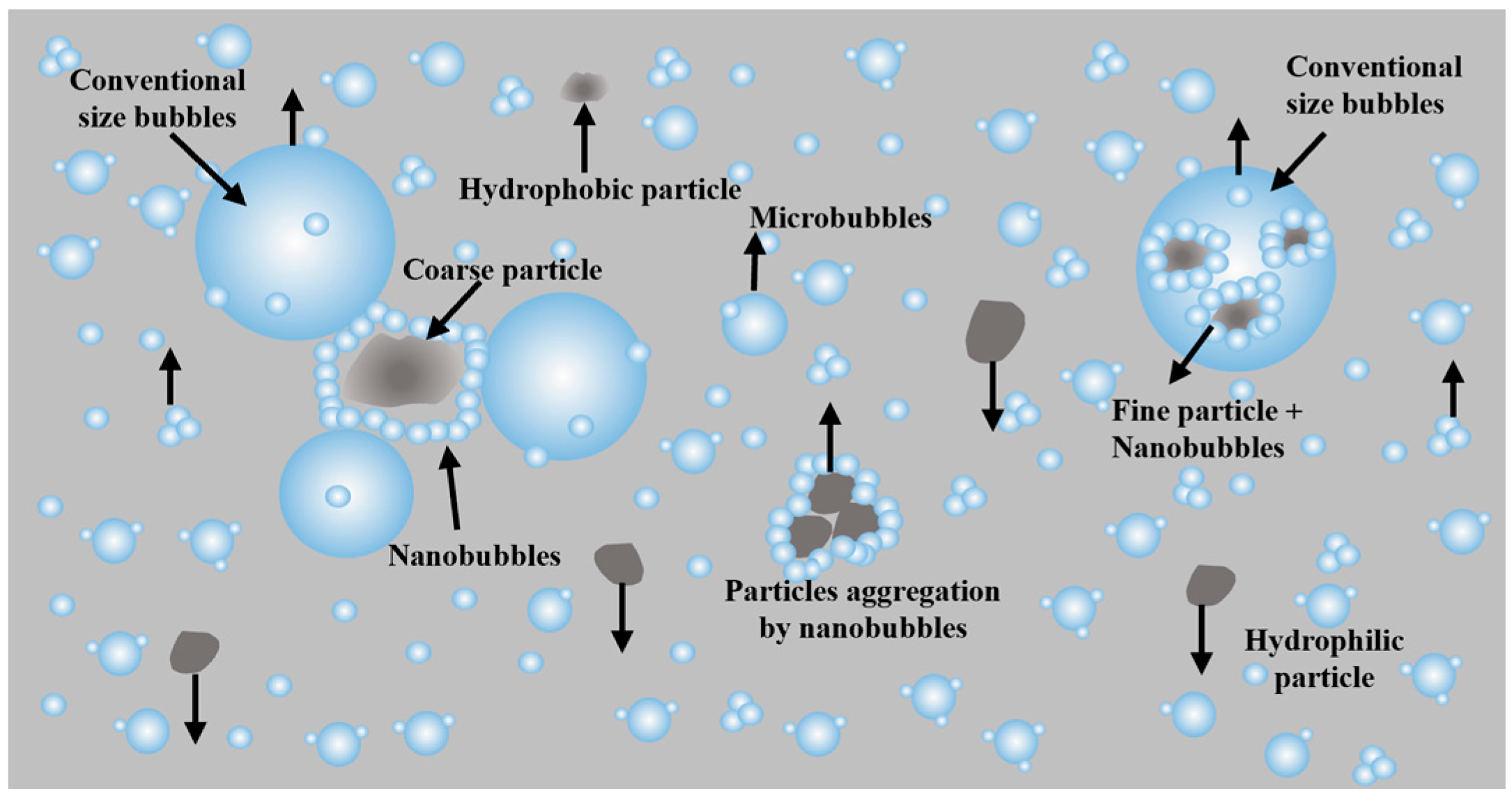

4.2. Mineral Flotation

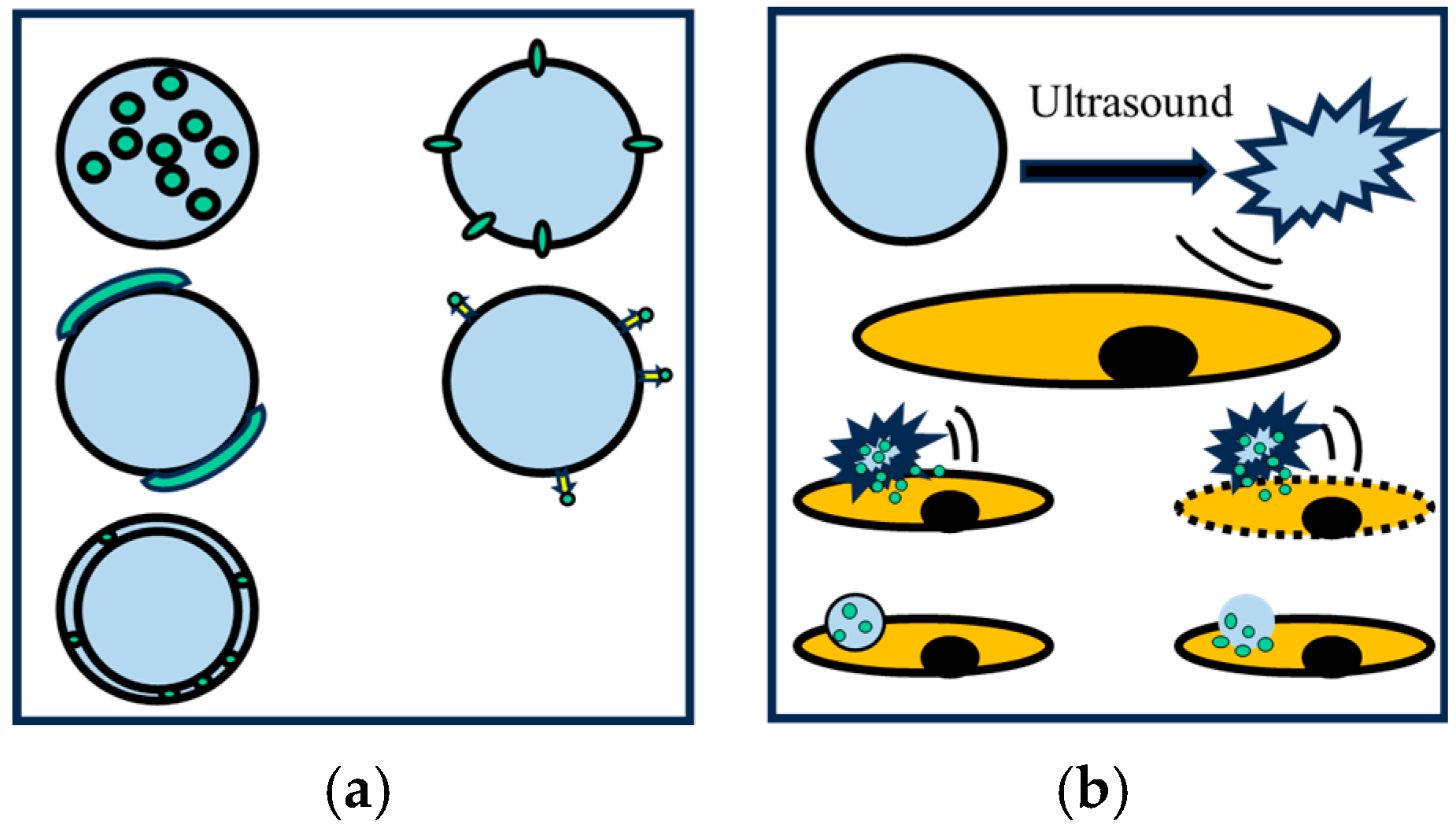

4.3. Medical Field

4.4. Crop Yield Enhancement

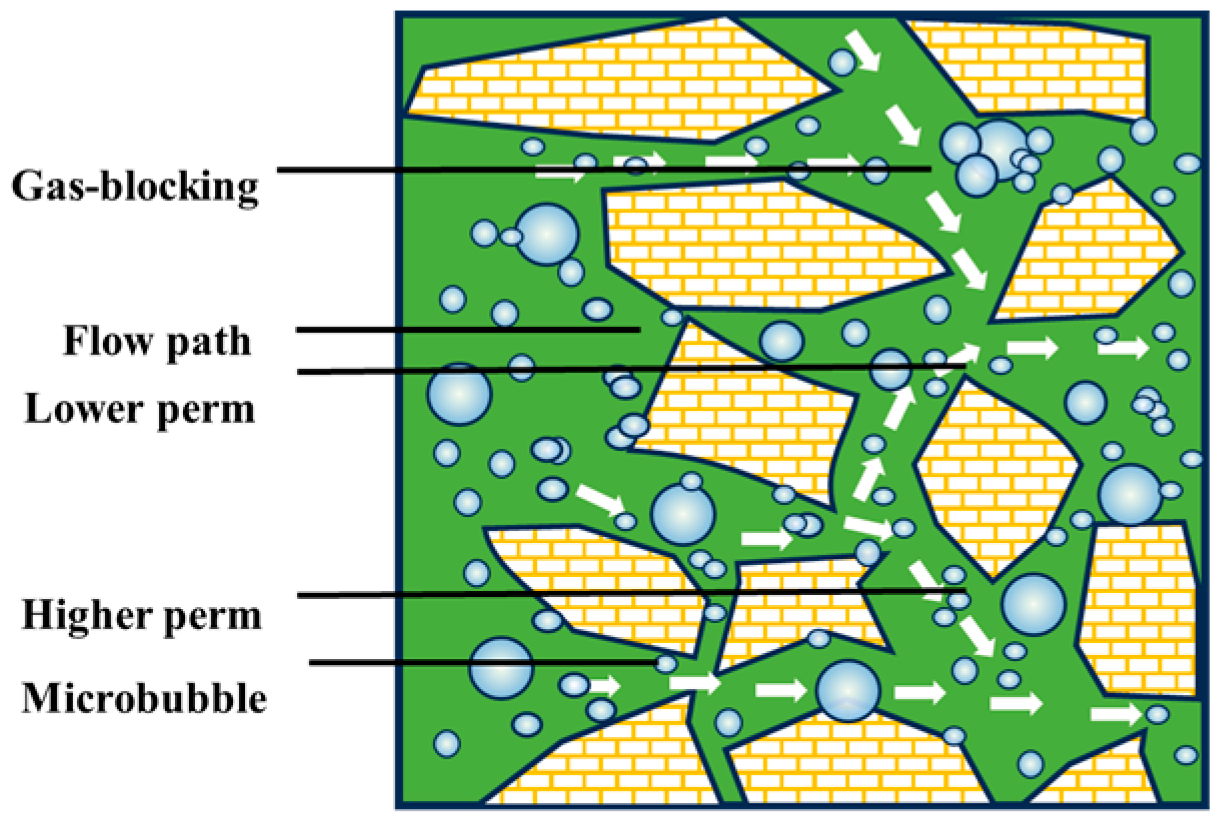

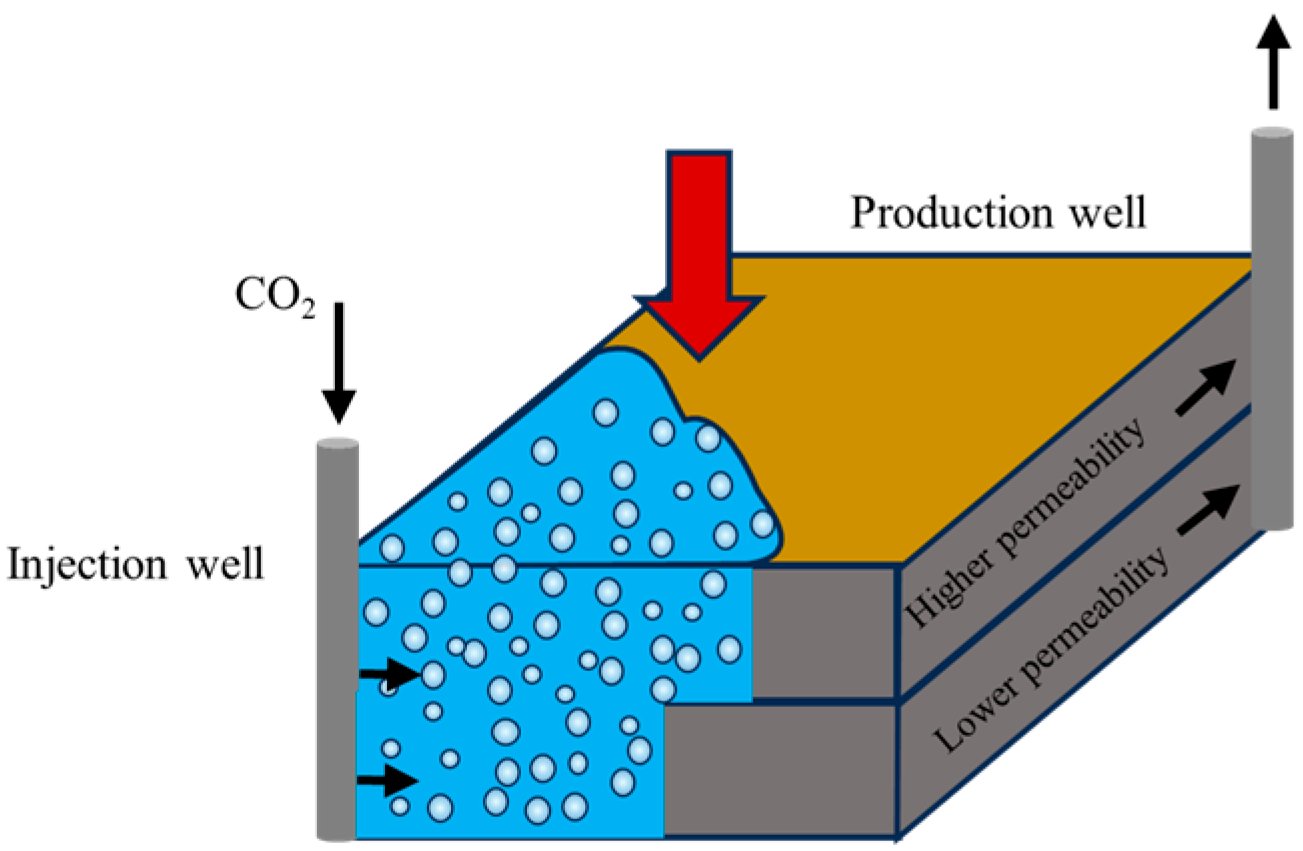

4.5. Enhanced Oil Recovery

5. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, A.; Ng, W.J.; Liu, Y. Principle and Applications of Microbubble and Nanobubble Technology for Water Treatment. Chemosphere 2011, 84, 1175–1180. [Google Scholar] [CrossRef] [PubMed]

- Bowonder, B.; Kumar, R. Studies in Bubble Formation - IV: Bubble Formation at Porous Discs. Chem. Eng. Sci. 1970, 25, 25–32. [Google Scholar] [CrossRef]

- Takahashi, T.; Miyahara, T.; Mochizuki, H. Fundamental-Study of Bubble Formation in Dissolved Air-Pressure Flotation. J. Chem. Eng. Jpn. 1979, 12, 275–280. [Google Scholar] [CrossRef]

- Ketkar, D.R.; Mallikarjunan, R.; Venkatachalam, S. Electroflotation of Quartz Fines. Int. J. Miner. Process. 1991, 31, 127–138. [Google Scholar] [CrossRef]

- Ding, G.D.; Chen, J.Q.; Wang, C.S.; Chao, S. Structural Design and Numerical Simulation of Axial-Swirling Type Micro-Bubble Generator. Chin. J. Process Eng. 2018, 18, 934–941. [Google Scholar]

- Azevedo, A.; Oliveira, H.; Rubio, J. Bulk Nanobubbles in the Mineral and Environmental Areas: Updating for Research and Applications. Adv. Colloid Interface Sci. 2019, 271, 101992. [Google Scholar] [CrossRef]

- Li, H.; Hu, L.; Xia, Z. Impact of Groundwater Salinity on Bioremediation Enhanced by Micro-Nano Bubbles. Materials 2013, 6, 3676–3687. [Google Scholar] [CrossRef]

- Swart, B.; Zhao, Y.; Khaku, M.; Che, E.; Maltby, R.; Chew, Y.M.J.; Wenk, J. In Situ Characterisation of Size Distribution and Rise Velocity of Microbubbles by High-Speed Photography. Chem. Eng. Sci. 2020, 225, 115836. [Google Scholar] [CrossRef]

- Huang, B.; Wang, H.; Gu, G.H. Zeta Potential of Air Bubble. Appl. Chem. Ind. 2014, 43, 142–145. [Google Scholar]

- Ahmed, A.K.A.; Sun, C.; Hua, L.; Zhang, Z.; Zhang, Y.; Zhang, W.; Marhaba, T. Generation of Nanobubbles by Ceramic Membrane Filters: The Dependence of Bubble Size and Zeta Potential on Surface Coating, Pore Size and Injected Gas Pressure. Chemosphere 2018, 203, 327–335. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kwak, D.-H. Effect of Zeta Potential on Collision-Attachment Coefficient and Removal Efficiency for Dissolved Carbon Dioxide Flotation. Environ. Eng. Sci. 2017, 34, 272–280. [Google Scholar] [CrossRef]

- Jia, W.; Ren, S.; Hu, B. Effect of Water Chemistry on Zeta Potential of Air Bubbles. Int. J. Electrochem. Sci. 2013, 8, 5828–5837. [Google Scholar] [CrossRef]

- Smoluchowski, M.V. Drei Vortrage Uber Diffusion, Brownsche Molekularbewegung Und Koagulation von Kolloidteilchen. Z. Physik. 1916, 17, 585–599. [Google Scholar]

- Takahashi, M. ξ Potential of Microbubbles in Aqueous Solutions: Electrical Properties of the Gas-Water Interface. J. Phys. Chem. B 2005, 109, 21858–21864. [Google Scholar] [CrossRef] [PubMed]

- Hewage, S.A.; Kewalramani, J.; Meegoda, J.N. Stability of Nanobubbles in Different Salts Solutions. Colloids Surf. A-Physicochem. Eng. Asp. 2021, 609, 125669. [Google Scholar] [CrossRef]

- Matsumoto, M.; Tanaka, K. Nano Bubble-Size Dependence of Surface Tension and inside Pressure. Fluid Dyn. Res. 2008, 40, 546–553. [Google Scholar] [CrossRef]

- Nock, W.J.; Heaven, S.; Banks, C.J. Mass Transfer and Gas-Liquid Interface Properties of Single CO2 Bubbles Rising in Tap Water. Chem. Eng. Sci. 2016, 140, 171–178. [Google Scholar] [CrossRef]

- Bao, Y.; Jia, J.; Tong, S. A Review on Single Bubble Gas-Liquid Mass Transfer. Chin. J. Chem. Eng. 2020, 28, 2707–2722. [Google Scholar] [CrossRef]

- Parkinson, L.; Sedev, R.; Fornasiero, D.; Ralston, J. The Terminal Rise Velocity of 10–100 Microm Diameter Bubbles in Water. J Colloid Interface Sci 2008, 322, 168–172. [Google Scholar] [CrossRef]

- Yang, C.; Dabros, T.; Li, D.; Czarnecki, J.; Masliyah, J.H. Measurement of the Zeta Potential of Gas Bubbles in Aqueous Solutions by Microelectrophoresis Method. J. Colloid Interface Sci. 2001, 243, 128–135. [Google Scholar] [CrossRef]

- Sebba, F. An Improved Generator for Micron-Sized Bubbles. Chem. Ind. 1985, 91–92. [Google Scholar]

- Zhang, W.; Li, Z.H.; Agblevor, F.A. Microbubble Fermentation of Recombinant Pichia pastoris for Human Serum Albumin Production. Process Biochem. 2005, 40, 2073–2078. [Google Scholar] [CrossRef]

- Xu, Q.; Nakajima, M.; Ichikawa, S. A Comparative Study of Microbubble Generation by Mechanical Agitation and Sonication. Innov. Food Sci. Emerg. Technol. 2008, 9, 489–494. [Google Scholar] [CrossRef]

- Etchepare, R.; Oliveira, H.; Azevedo, A. Nanobubbles: Generation Using a Multiphase Pump, Properties and Features in Flotation. Miner. Eng. 2017, 112, 19–26. [Google Scholar] [CrossRef]

- Shi, Y.L.; Wang, S.F.; Wu, G.; Chen, X. Study on the Mechanism of the Micro-Bubble Formation of Pressure Dissolved Air Flotation and Application. Ind. Water Treat. 2012, 32, 20–23. [Google Scholar]

- Azevedo, A.; Etchepare, R.; Calgaroto, S.; Rubio, J. Aqueous Dispersions of Nanobubbles: Generation, Properties and Features. Miner. Eng. 2016, 94, 29–37. [Google Scholar] [CrossRef]

- Zhai, L.; Cui, Y.; Li, C.; Shi, X.; Gao, J.; Lan, X. Research and Application Process of Microbubble Generator. Chem. Ind. Eng. Prog. 2024, 43, 111–123. [Google Scholar]

- Li, J.; Song, Y.; Yin, J.; Wang, D. Investigation on the Effect of Geometrical Parameters on the Performance of a Venturi Type Bubble Generator. Nucl. Eng. Des. 2017, 325, 90–96. [Google Scholar] [CrossRef]

- Wang, X.; Shuai, Y.; Zhou, X.; Huang, Z.; Yang, Y.; Sun, J.; Zhang, H.; Wang, J.; Yang, Y. Performance Comparison of Swirl-Venturi Bubble Generator and Conventional Venturi Bubble Generator. Chem. Eng. Process. 2020, 154, 108022. [Google Scholar] [CrossRef]

- Li, X. Research on the Characteristics of a New Microbubble Generator Based on the Venturi Tube. Chem. Eng. Process. 2024, 31, 109876. [Google Scholar] [CrossRef]

- Levitsky, I.; Tavor, D.; Gitis, V. Generation of Two-Phase Air-Water Flow with Fine Microbubbles. Chem. Eng. Technol. 2016, 39, 1537–1544. [Google Scholar] [CrossRef]

- Xu, X.; Ge, X.; Qian, Y. Effect of Nozzle Diameter on Bubble Generation with Gas Self-Suction through Swirling Flow. Chem. Eng. Res. Des. 2018, 138, 13–20. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.; Han, M.; Kim, T. Generation of Sub-Micron (Nano) Bubbles and Characterization of Their Fundamental Properties. Environ. Eng. Res. 2018, 24, 382–388. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, H.; Song, X. Experimental and Numerical Study on the Bubble Dynamics and Flow Field of a Swirl Flow Microbubble Generator with Baffle Internals. Chem. Eng. Sci. 2022, 263, 118066. [Google Scholar] [CrossRef]

- Wu, M.; Song, H.; Liang, X.; Huang, N.; Li, X. Generation of Micro-Nano Bubbles by Self-Developed Swirl-Type Micro-Nano Bubble Generator. Chem. Eng. Process. 2022, 181, 109136. [Google Scholar] [CrossRef]

- Li, Z.K.; Zhang, Z.H.; Guo, S. Research on the Jet Bubble Generator for Microbubble Flotation. Min. Res. Dev. 2007, 5, 54–56. [Google Scholar] [CrossRef]

- Hui, H.L.; Qiu, X.Q.; Zhang, J.W.; Zhao, Z.B. Experimental Study on Optimization of Throat-Nozzle Distance for Jet Bubble Generator. Energy Conserv. 2011, 30, 5. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, B.; Wu, C.; Xu, X.; Xue, M.; Zheng, X. Numerical Simulation and Structural Optimization of Swirl Flow Micro-Nano Bubble Generator. Coatings 2023, 13, 1468. [Google Scholar] [CrossRef]

- Tian, H.; Pi, S.; Feng, Y.; Zhou, Z.; Zhang, F.; Zhang, Z. One-Dimensional Drift-Flux Model of Gas Holdup in Fine-Bubble Jet Reactor. Chem. Eng. J. 2020, 386, 121222. [Google Scholar] [CrossRef]

- Li, X.; Su, W.; Liu, Y.; Yan, X.; Wang, L.; Zhang, H. Comparison of Bubble Velocity, Size, and Holdup Distribution between Single- and Double-Air Inlet in Jet Microbubble Generator. Asia-Pac. J. Chem. Eng. 2021, 16, e2611. [Google Scholar] [CrossRef]

- Yasui, K. Acoustic Cavitation and Bubble Dynamics; Springer Briefs in Molecular Science; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-68236-5. [Google Scholar]

- Ma, Y.L.; Shen, S.L.; Chen, J.L.; Xu, Y.L. Ultrasonic Assisted Removal of Micro-Bubbles in Water. Chem. Ind. Eng. 2024, 41, 131–137. [Google Scholar]

- Makuta, T.; Suzuki, R.; Nakao, T. Generation of Microbubbles from Hollow Cylindrical Ultrasonic Horn. Ultrasonics 2013, 53, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.N.; Chen, W.Z.; Huang, W. High-Precision Measurement Techniques for Stable Acoustic Cavitation Bubbles. Chin. Sci. Bull. 2005, 50, 2458–2462. [Google Scholar] [CrossRef]

- Mo, C.R. Study on the Generation Method and Properties of Nanobubbles Based on Ultrasonic Cavitation. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2019. [Google Scholar]

- Chandran, P.; Bakshi, S.; Chatterjee, D. Study on the Characteristics of Hydrogen Bubble Formation and Its Transport during Electrolysis of Water. Chem. Eng. Sci. 2015, 138, 99–109. [Google Scholar] [CrossRef]

- Sakai, O.; Kimura, M.; Shirafuji, T.; Tachibana, K. Underwater Microdischarge in Arranged Microbubbles Produced by Electrolysis in Electrolyte Solution Using Fabric-Type Electrode. Appl. Phys. Lett. 2008, 93, 231501. [Google Scholar] [CrossRef]

- Liu, J.L. Research on Micro-Nano Bubbles Generation Device. Master’s Thesis, Zhejiang University, Hangzhou, China, 2012. [Google Scholar]

- Rameshkumar, C.; Lakshmi Sankar, S.; Senthilkumar, G. Characterisation of Seed Germination Using Nanaobubbled Water. Int. J. Ambient Energy 2019, 43, 745–748. [Google Scholar] [CrossRef]

- Liu, M.; Guo, X.-F.; Wang, J.-M.; Jiang, L. Behavior of Bubbles on Electrodes with Hierarchical Microporous Structures and Different Wettability. Acta Phys.-Chim. Sin. 2012, 28, 2931–2938. [Google Scholar] [CrossRef]

- Xu, T.D.; Pang, M.J.; Fei, T. Experimental Study on Microbubble Generation by Electrolysis Method. Lab. Sci. 2015, 18, 5. [Google Scholar]

- Tanaka, Y.; Kikuchi, K.; Saihara, Y.; Ogumi, Z. Bubble Visualization and Electrolyte Dependency of Dissolving Hy-drogen in Electrolyzed Water Using Solid-Polymer-Electrolyte. Electrochim. Acta 2005, 50, 5229–5236. [Google Scholar] [CrossRef]

- Kukizaki, M.; Goto, M. Size Control of Nanobubbles Generated from Shirasu-Porous-Glass (SPG) Membranes. J. Membr. Sci. 2006, 281, 386–396. [Google Scholar] [CrossRef]

- Wu, S.J.; Fang, W.M.; Zhao, H.W.; Chang, C. Research on Microbubbles Formation by High-Speed Cross-Flow. Technol. Water Treat. 2009, 35, 44–48. [Google Scholar]

- Khirani, S.; Kunwapanitchakul, P.; Augier, F.; Guigui, C.; Guiraud, P.; Hebrard, G. Microbubble Generation through Porous Membrane under Aqueous or Organic Liquid Shear Flow. Ind. Eng. Chem. Res. 2012, 51, 1997–2009. [Google Scholar] [CrossRef]

- Zheng, C.; Tan, J.; Wang, K.; Luo, G.S. Stability and Pressure Drop of Gas-Liquid Micro-Dispersion Flows through a Capillary. Chem. Eng. Sci. 2016, 140, 134–143. [Google Scholar] [CrossRef]

- Xu, Z.H.; Zhao, H.W.; Fang, W.M.; Zhong, B.H. Research on Microbubbles Generation by Metal Microporous Tube. Tech. Equip. Environ. Pollut. Control 2006, 7, 78–82. [Google Scholar]

- Fujikawa, S.; Zhang, R.S.; Hayama, S.; Peng, G.Y. The Control of Micro-Air-Bubble Generation by a Rotational Porous Plate. Int. J. Multiph. Flow 2003, 29, 1221–1236. [Google Scholar] [CrossRef]

- Sadatomi, M.; Kawahara, A.; Matsuura, H.; Shikatani, S. Micro-Bubble Generation Rate and Bubble Dissolution Rate into Water by a Simple Multi-Fluid Mixer with Orifice and Porous Tube. Exp. Therm. Fluid Sci. 2012, 41, 23–30. [Google Scholar] [CrossRef]

- Juwana, W.E.; Widyatama, A.; Dinaryanto, O.; Budhijanto, W.; Indarto; Deendarlianto. Hydrodynamic Characteristics of the Microbubble Dissolution in Liquid Using Orifice Type Microbubble Generator. Chem. Eng. Res. Des. 2019, 141, 436–448. [Google Scholar] [CrossRef]

- Xie, B.Q.; Zhou, C.J.; Sang, L.; Ma, X.D.; Zhang, J.S. Preparation and Characterization of Microbubbles with a Porous Ceramic Membrane. Chem. Eng. Process. 2021, 159, 108213. [Google Scholar] [CrossRef]

- Sun, L.; Fan, M.; Xu, B.; Yu, H.; Wang, Y.; Zhang, Y.; Li, P. Growth Characteristic of Microbubble in a T-Junction Microchannel in Microfluidic Chip. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 042146. [Google Scholar] [CrossRef]

- Lee, M.; Lee, E.; Lee, D.; Park, B. Stabilization and Fabrication of Microbubbles: Applications for Medical Purposes and Functional Materials. Soft Matter 2015, 11, 2067–2079. [Google Scholar] [CrossRef]

- Lin, H.; Chen, J.; Chen, C. A Novel Technology: Microfluidic Devices for Microbubble Ultrasound Contrast Agent Generation. Med. Biol. Eng. Comput. 2016, 54, 1317–1330. [Google Scholar] [CrossRef] [PubMed]

- van Hoeve, W.; Dollet, B.; Gordillo, J.M.; Versluis, M.; van Wijngaarden, L.; Lohse, D. Bubble Size Prediction in Co-Flowing Streams. EPL 2011, 94, 64001. [Google Scholar] [CrossRef][Green Version]

- Mehrabi, M.; Isfahani, A.H.M. A New Micro Pump for Rapid and Accurate Microscale Droplet Manipulation Using Thermo-Viscous Actuation. Sci. Iran. 2022, 29, 2279–2289. [Google Scholar] [CrossRef]

- Jenkins, K.; Michelsen, D.; Novak, J. Application of Oxygen Microbubbles for In-Situ Biodegradation of P-Xylene-Contaminated Groundwater in a Soil Column. Biotechnol. Prog. 1993, 9, 394–400. [Google Scholar] [CrossRef]

- Dacheng, B. Water Purification in Wide Enclosed Water Areas Using Microbubble Generation Technology. Multiph. Flow 1997, 11, 263–266. [Google Scholar] [CrossRef][Green Version]

- Ghadimkhani, A.; Zhang, W.; Marhaba, T. Ceramic Membrane Defouling (Cleaning) by Air Nano Bubbles. Chemosphere 2016, 146, 379–384. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H. Surface Nanobubbles and Their Roles in Flotation of Fine Particles-A Review. J. Ind. Eng. Chem. 2022, 106, 37–51. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H. A Review of Bulk Nanobubbles and Their Roles in Flotation of Fine Particles. Powder Technol. 2022, 395, 618–633. [Google Scholar] [CrossRef]

- Yoon, R.H.; Luttrell, G.H. The Effect of Bubble Size on Fine Particle Flotation. Miner. Process. Extr. Metall. Rev. 1989, 5, 101–122. [Google Scholar] [CrossRef]

- Rosa, A.F.; Rubio, J. On the Role of Nanobubbles in Particle-Bubble Adhesion for the Flotation of Quartz and Apatitic Minerals. Miner. Eng. 2018, 127, 178–184. [Google Scholar] [CrossRef]

- Calgaroto, S.; Azevedo, A.; Rubio, J. Flotation of Quartz Particles Assisted by Nanobubbles. Int. J. Miner. Process. 2015, 137, 64–70. [Google Scholar] [CrossRef]

- Zhang, H.-F.; Chen, L.; Santosh, M.; Menzies, M.A. Construction and Destruction of Cratons: Preface. Gondwana Res. 2013, 23, 1–3. [Google Scholar] [CrossRef]

- Liu, Y.; Miyoshi, H.; Nakamura, M. Encapsulated Ultrasound Microbubbles: Therapeutic Application in Drug/Gene Delivery. J. Control. Release 2006, 114, 89–99. [Google Scholar] [CrossRef] [PubMed]

- Vilela, D.; Cossio, U.; Parmar, J.; Martinez-Villacorta, A.M.; Gomez-Vallejo, V.; Llop, J.; Sanchez, S. Medical Imaging for the Tracking of Micromotors. ACS Nano 2018, 12, 1220–1227. [Google Scholar] [CrossRef]

- Tamagawa, M.; Yamanoi, I.; Ishimatsu, N.; Suetsugu, S. Prototype of Microcapsule for Shock Wave Drug Delivery Systems and Analysis of Deformation Process of a Bubble in a Capsule Model; Kim, S., Suh, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 14, pp. 3236–3237. [Google Scholar]

- Prajapati, J.V.; Agrawal, Y.K. Synthesis, Characterization and Application of Microbubbles: A Review. Int. J. Pharm. L Sci. Res. 2012, 3, 1532–1543. [Google Scholar] [CrossRef]

- Harvey, C.J.; Blomley, M.J.K.; Eckersley, R.J.; Cosgrove, D.O. Developments in Ultrasound Contrast Media. Eur. Radiol. 2001, 11, 675–689. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Wang, T.; Pan, J.; Zhou, B.; Muhammad, T.; Zhou, C.; Li, Y. Micro-Nano Bubble Water Oxygation: Synergistically Improving Irrigation Water Use Efficiency, Crop Yield and Quality. J. Clean Prod. 2019, 222, 835–843. [Google Scholar] [CrossRef]

- Minamikawa, K.; Makino, T. Oxidation of Flooded Paddy Soil through Irrigation with Water Containing Bulk Oxygen Nanobubbles. Sci. Total Environ. 2020, 709, 136323. [Google Scholar] [CrossRef]

- Liu, S.; Kawagoe, Y.; Makino, Y.; Oshita, S. Effects of Nanobubbles on the Physicochemical Properties of Water: The Basis for Peculiar Properties of Water Containing Nanobubbles. Chem. Eng. Sci. 2013, 93, 250–256. [Google Scholar] [CrossRef]

- Wang, P. Research Status of CO2 Enhanced Oil Recovery Technology. China Chem. Trade 2014, 32. [Google Scholar] [CrossRef]

- Hao, M.; Song, Y.C. Research Status of CO2 Enhanced Oil Recovery Technology. Drill. Prod. Technol. 2010, 33, 59–63. [Google Scholar] [CrossRef]

- Microbubble Technology Boosts Enhanced Oil Recovery. Petrochem. Ind. Appl. 2018, 37, 147–148.

- Jiang, L.; Xue, Z.; Park, H. Enhancement of CO2 Dissolution and Sweep Efficiency in Saline Aquifer by Micro Bubble CO2 Injection. Int. J. Heat Mass Transf. 2019, 138, 1211–1221. [Google Scholar] [CrossRef]

- Patmonoaji, A.; Zhang, Y.; Xue, Z.; Park, H.; Suekane, T. Experimental and Numerical Simulation of Supercritical CO2 Microbubble Injection into a Brine-Saturated Porous Medium. Int. J. Greenh. Gas Control 2019, 91, 102830. [Google Scholar] [CrossRef]

- Le, N.N.H.; Sugai, Y.; Vo-Thanh, H. Experimental Investigation on Plugging Performance of CO2 Microbubbles in Porous Media. J. Pet. Sci. Eng. 2022, 211, 110187. [Google Scholar] [CrossRef]

- Adamova, T.P.; Skiba, S.S.; Manakov, A.Y.; Kutateladze, S.Y.M. Growth Rate of CO2 Hydrate Film on Water-Oil and Water-Gaseous CO2 Interface. Chin. J. Chem. Eng. 2023, 56, 266–272. [Google Scholar] [CrossRef]

- Microbubble Carbon Dioxide Injection for Enhanced Dissolution in Geological Sequestration and Improved Oil Recovery. Energy Procedia 2014, 63, 7939–7946. [CrossRef]

- Xue, Z.; Park, H.; Ueda, R.; Nakano, M.; Nishii, T.; Inagaki, S. Microbubble CO2 Injection for Enhanced Oil Recovery and Geological Sequestration in Heterogeneous and Low Permeability Reservoirs. In Proceedings of the 14th International Conference on Greenhouse Gas Control Technologies, GHGT-14, Melbourne, Australia, 21–25 October 2018. [Google Scholar]

- Xue, Z.; Tsuji, S.; Kameyama, H. Development of Carbon Dioxide Microbubble Sequestration into Saline Aquifer and CO2-EOR Reservoirs. Energy Procedia 2013, 37, 4628–4634. [Google Scholar] [CrossRef]

- Xue, Z.; Yamada, T.; Matsuoka, T.; Kameyama, H.; Nishio, S. Carbon Dioxide Microbubble Injection–Enhanced Dissolution in Geological Sequestration. Energy Procedia 2011, 4, 4307–4313. [Google Scholar] [CrossRef]

- Akai, T.; Xue, Z.; Yamashita, Y.; Yoshizawa, M. Application of CO2 Micro Bubble for the Innovative CO2-EOR. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 10 November 2015; SPE: Richardson, TX, USA, 2015; p. D021S034R002. [Google Scholar]

- Savitski, N.V.V. Findings of Experimental and Field Research into Oil Displacement by Means of Finely Dispersed Water-Gas Mixtured (FDWGM). In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 25–29 October 2020; SPE: Richardson, TX, USA, 2010; p. SPE-138067-MS. [Google Scholar]

- Shi, X.Y.; Kuai, J.W.; Wang, G.H.; Ding, M.C. Laboratory Experiment on Enhancing Conventional Heavy Oil Recovery by Microbubble-Enhanced S/P Binary Flooding. China Offshore Oil Gas 2024, 36, 84–90. [Google Scholar]

| Factors | Zeta Potential (mV) | Reference | |

|---|---|---|---|

| Pressure | 138 | −0.3 | Ahmed [10] |

| 207 | −3.8 | ||

| 345 | −15.2 | ||

| PH | 5 | −18.2 | Kim [11] |

| 7 | −21.8 | ||

| 9 | −28.1 | ||

| Anionic surfactant concentration (ppm) | 50 | −37.8 | Jia, W. [12] |

| 100 | −42.0 | ||

| 150 | −64.1 | ||

| Measurement Object | Main Methods | Features | Reference |

|---|---|---|---|

| Bubble Size | Laser Diffraction (nm–100 µm) Electron Microscopy | Fast, non-contact, requires transparent samples, High precision, but cannot be used for real-time detection | Swart [8] |

| Rising Velocity | High-Speed Camera + Image Analysis Laser Doppler Velocimetry | Suitable for 10 µm mm level, limited accuracy High precision, complex equipment | Parkinson [19] |

| Zeta Potential | Electrophoretic Light Scattering | High sensitivity, requires homogeneous samples | Yang, C [20] |

| Preparation Techniques | Bubble Size and Key Parameters | Related Parameters and Their Corresponding Impacts | References |

|---|---|---|---|

| Mechanical Shearing Methods | 10–200 μm High throughput | Higher rotational speed increases shear force, leading to smaller bubble size, while reduced surface tension inhibits bubble coalescence | Xu, Q. [23] Ramiro Etchepare [24] |

| Pressurized Gas Dissolution Methods | 30–100 μm High gas Transfer efficiency | The increase in saturation pressure and depressurization rate leads to a smaller bubble size, while a higher gas–liquid ratio may promote bubble coalescence | Shi, Y. et al. [25] Azevedo, A. et al. [26] |

| Cavitation Effect Methods | 50 nm–10 μm High nanobubble yield | Higher cavitation intensity and increased frequency promote the generation of micro-nano bubbles | Li, J. et al. [28] Wang, X. et al. [29] |

| Electrochemical Methods | 50 nm–50 μm Precise size control | The increase in current density and electrolyte concentration enhances the bubble generation rate | Sakai, Q. [47] Liu, M. et al. [50] |

| Micro-Porous Dispersion Methods | 100 nm–50 μm Superior monodispersity | Smaller membrane pore size yields smaller bubble size, but it may reduce bubble generation efficiency | Wu, S.J. et al. [54] Khirani, S. [55] |

| Microfluidic technology | 50 nm-500 μm Multistage structure regulation | Narrower main channel width and increased shear gradient reduce bubble size, while higher gas flow ratio enlarges bubble diameter but decreases generation frequency. Elevated fluid viscosity diminishes bubble production efficiency | Lee, M. et al. [63] Mehrabi, M.and Isfahani, A.H.M. [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Wu, J.; Li, Y. Advances in the Research on the Properties and Applications of Micro-Nano Bubbles. Processes 2025, 13, 2106. https://doi.org/10.3390/pr13072106

Zhao S, Wu J, Li Y. Advances in the Research on the Properties and Applications of Micro-Nano Bubbles. Processes. 2025; 13(7):2106. https://doi.org/10.3390/pr13072106

Chicago/Turabian StyleZhao, Shuke, Jiazhong Wu, and Yisong Li. 2025. "Advances in the Research on the Properties and Applications of Micro-Nano Bubbles" Processes 13, no. 7: 2106. https://doi.org/10.3390/pr13072106

APA StyleZhao, S., Wu, J., & Li, Y. (2025). Advances in the Research on the Properties and Applications of Micro-Nano Bubbles. Processes, 13(7), 2106. https://doi.org/10.3390/pr13072106