Early Medieval Iron Metallurgy in the Lučenec Basin, Slovakia

Abstract

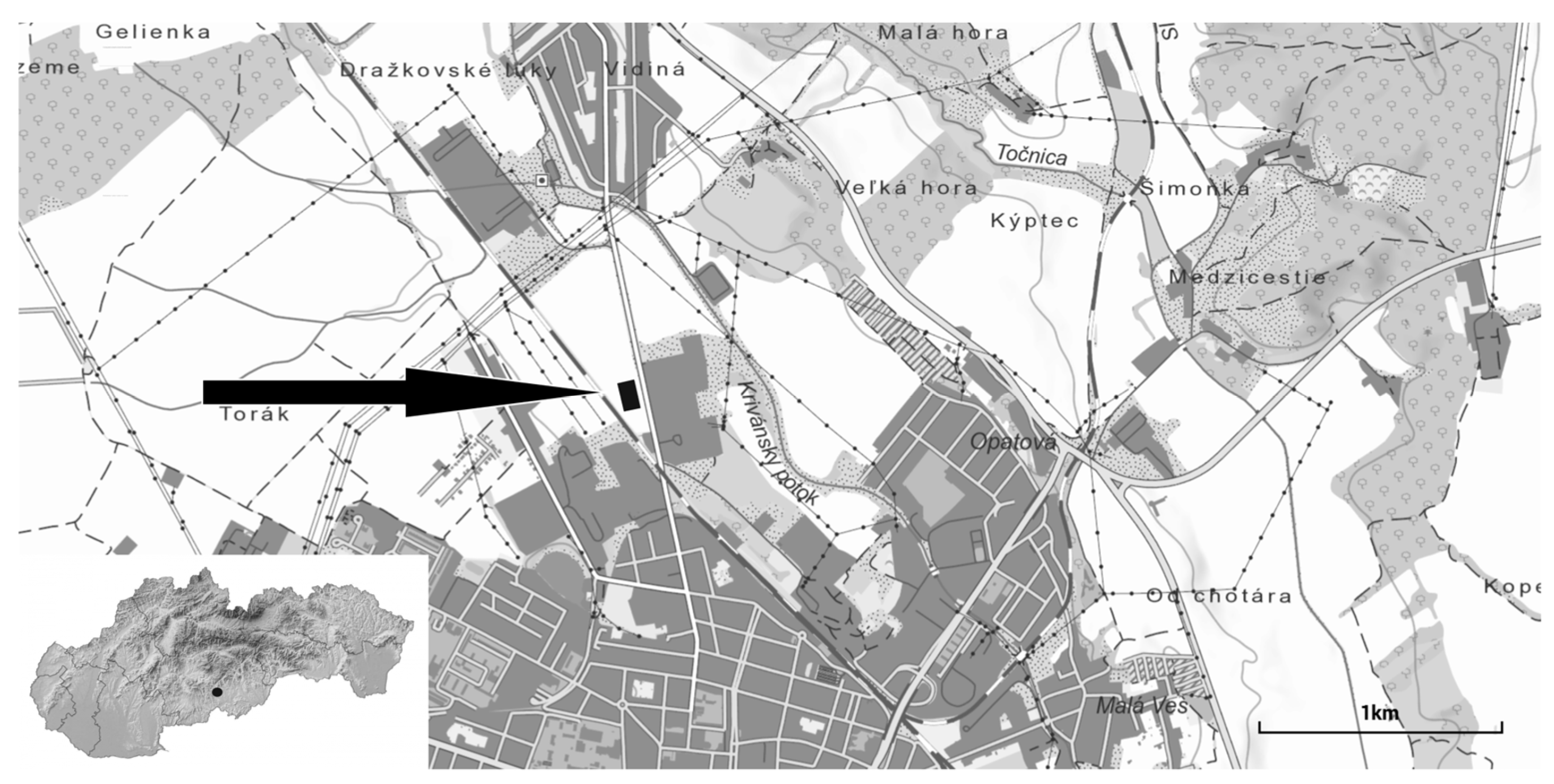

1. Introduction

2. Materials and Methods

3. Results and Discussion

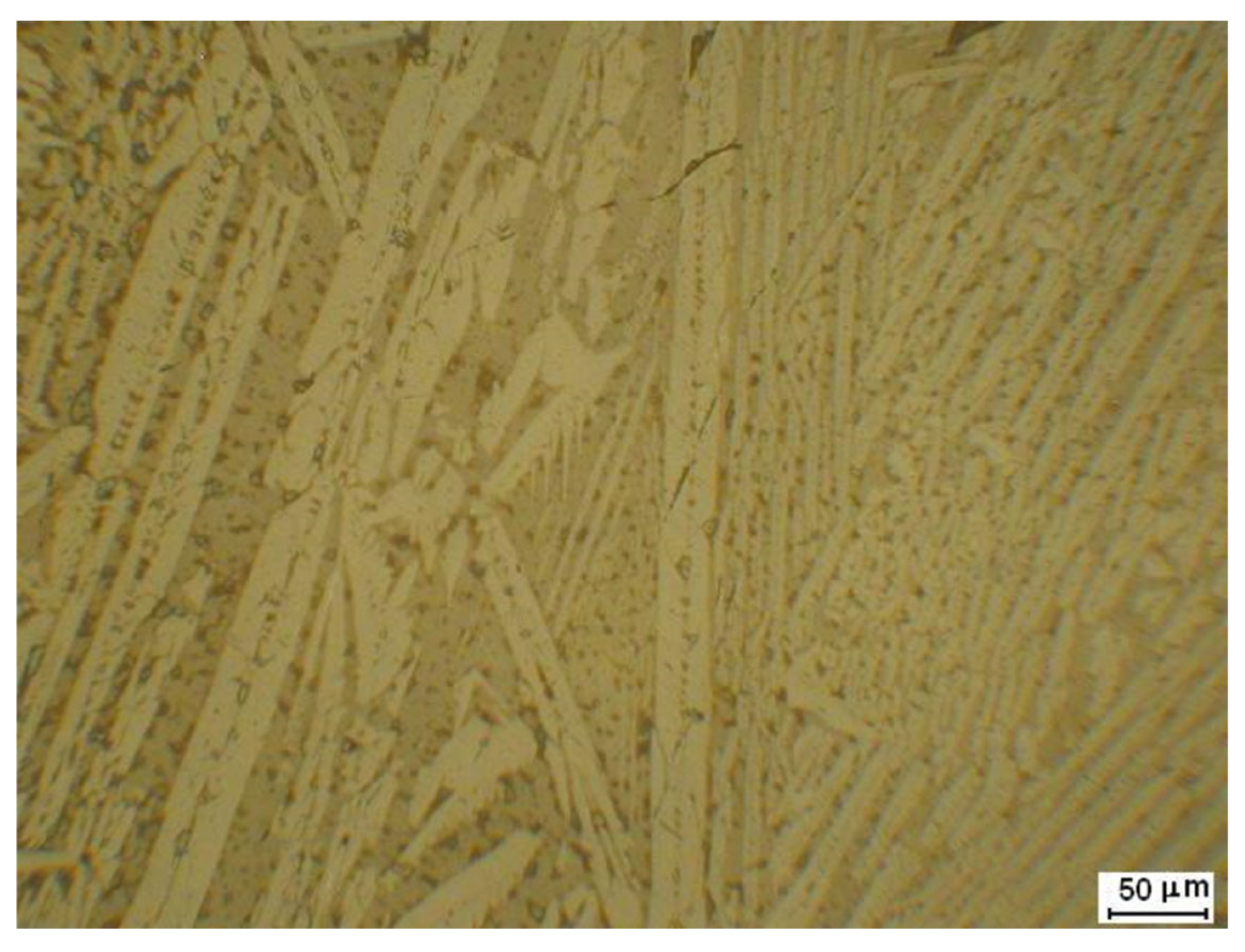

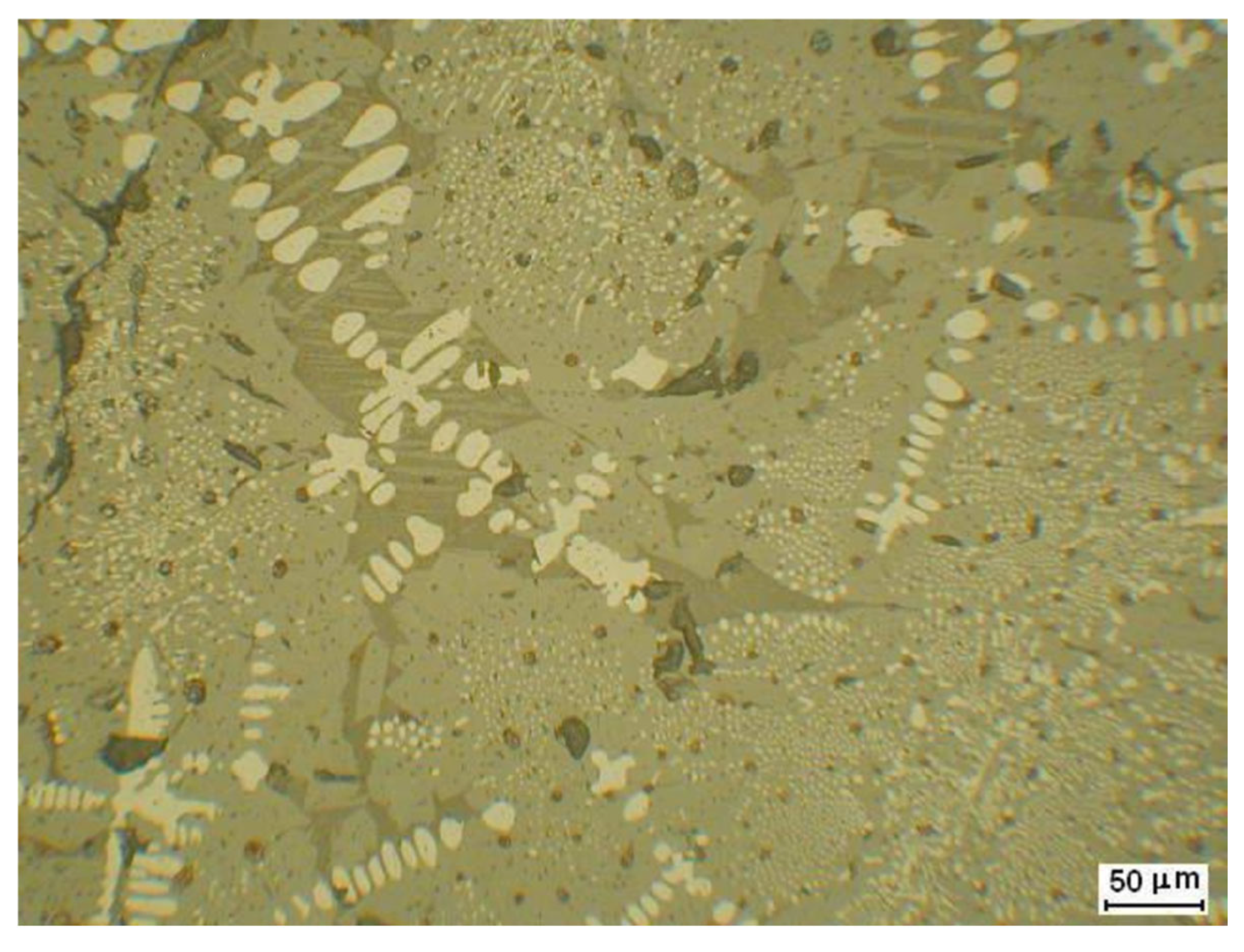

3.1. Slag from Direct Reduction the Iron Ore (Bloomery Slag)

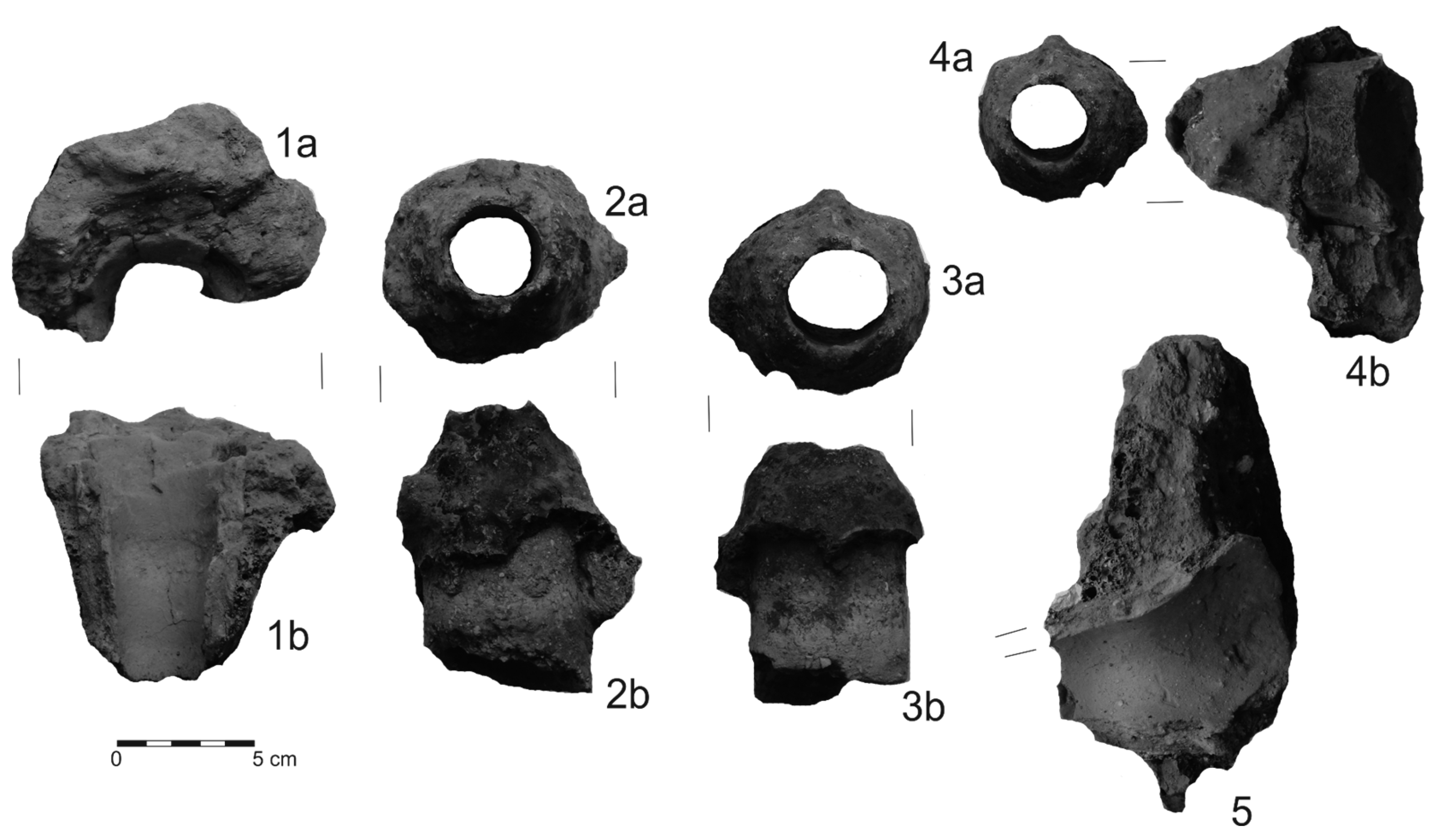

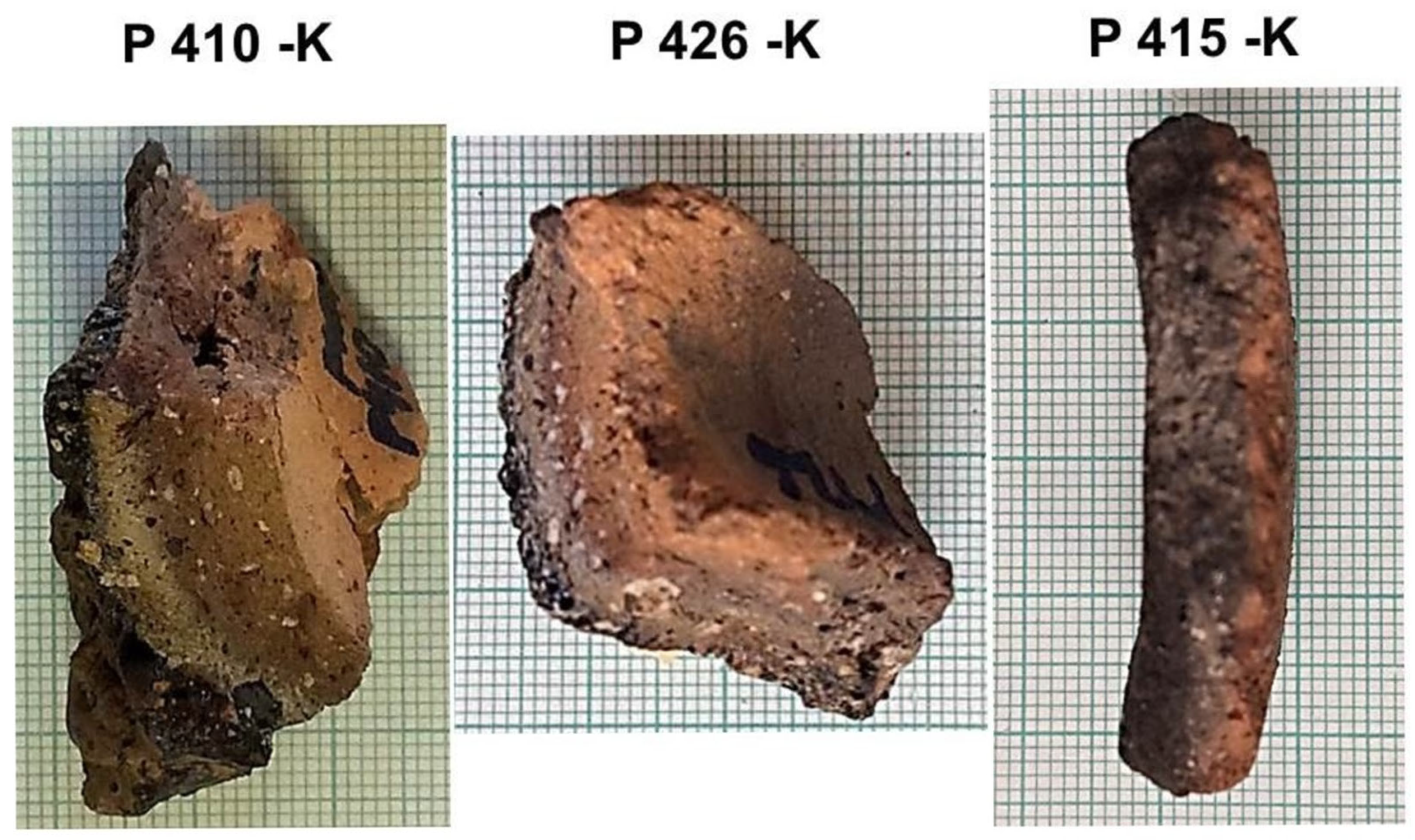

3.2. Technical Ceramic Material

3.3. Phosphorus

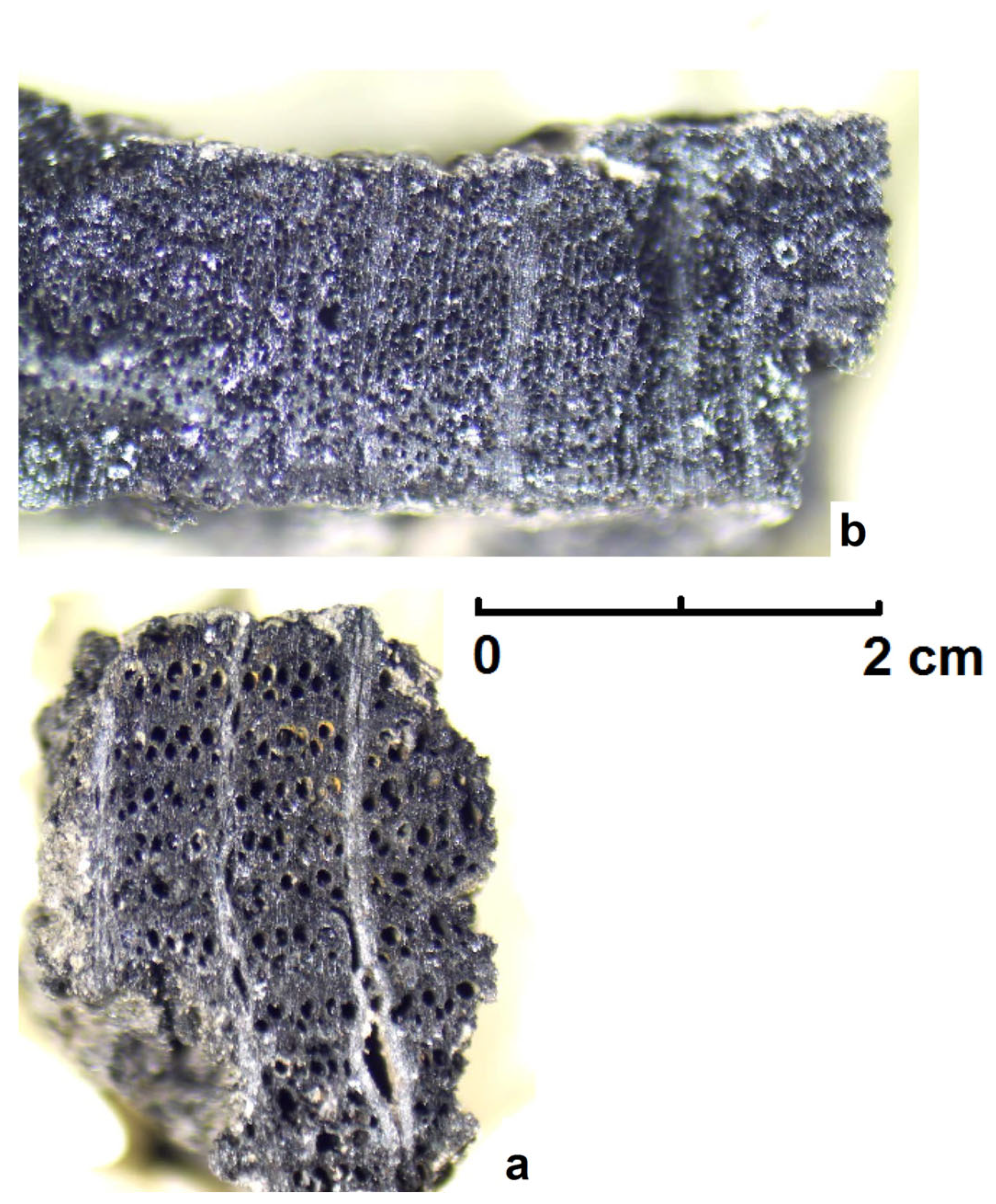

3.4. Charcoal Fuel and Reducing Agent

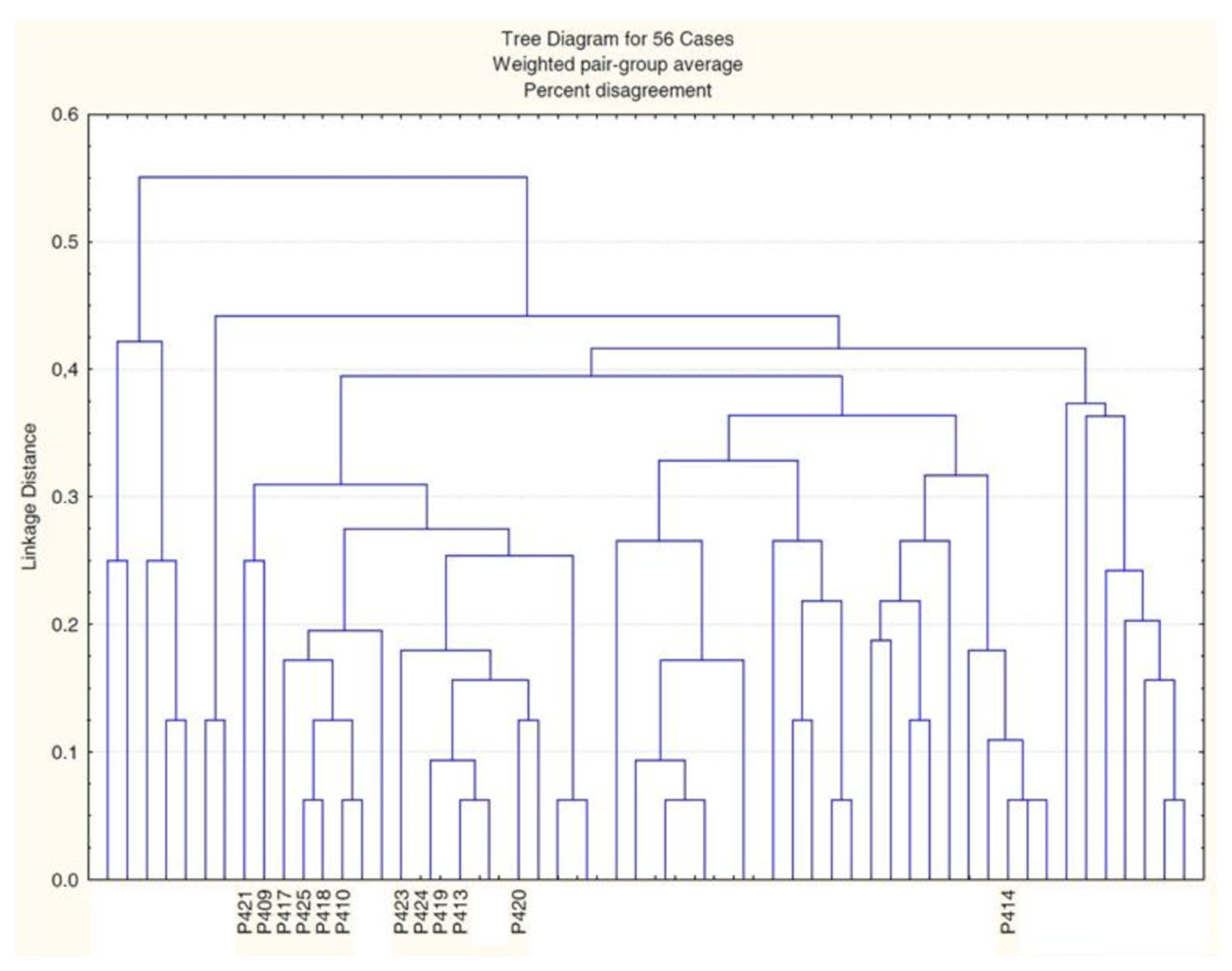

3.5. Cluster Analysis

4. Conclusions

- Based on the shapes of the ceramic fragments and their decoration, it was possible to chronologically date the structures from which the analyzed material originated to the early medieval period (probably the 9th or 10th century).

- Based on the analyses, it can be said that the production of iron in the locality took place by direct reduction. Local bog ores were most likely smelted, and the fuel was predominantly oak charcoal.

- Some slags have an increased phosphorus content, typical of slags from “consolidation”—i.e., repeated heating and forging of iron blooms into tradable form. This assumption is not supported by archeological findings showing production facilities, such as a blacksmith’s forge.

- As only parts of the slag-covered tips of the tuyere have been preserved, this confirms that the tuyeres used were made from unfired clay. The obtained construction material of the furnaces, due to its quantity and fragmentation, does not allow any reliable reconstruction of their shape and dimensions.

- The melting probably took place in a free-standing shaft furnace with manual blowing.

- The results of the analysis document the good quality of the metallurgical process in comparison with contemporary localities of iron production in Europe.

- Despite its existence in a very turbulent period, connected with the disintegration of the Great Moravian kingdom in parallel with the migration of Hungarian tribes to Central Europe, the site did not disappear by force. The cause of its extinction was the depletion of local iron ore.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mácelová, M. Slovanské sídlisko v Sliači na Horných zemiach v okrese Zvolen (Slavic settlement in Sliač in the Horné Zeme region in the Zvolen district). Stred. Slov. 1982, 2, 117–132. (In Slovak) [Google Scholar]

- Saltykov, S.A. Stereometričeskaja Metallografia (Stereometric Metallography); Metallurgija: Moskva, Russia, 1976. (In Russian) [Google Scholar]

- Halčinová, J.; Trebuňa, P. Cluster analysis in the software statistica. In Proceedings of the 15th International Scientific Conference: Trends and Inovative Approaches in Business Processes, Košice, Slovakia, 10–11 December 2012; TUKE: Košice, Slovakia, 2012; pp. 1–5. Available online: https://www.sjf.tuke.sk/umpadi/taipvpp/2012/index.files/clanky/41%20Jana%20HalCInovA%20Peter%20TrebuNa%20ZHLUKOVA.pdf (accessed on 16 August 2022). (In Slovak).

- Galbraith, S.; Daniel, J.A.; Vissel, B. A Study of Clustered Data and Approaches to Its Analysis. J. Neurosci. 2010, 30, 10601–10608. [Google Scholar] [CrossRef] [PubMed]

- Petrík, J.; Moravčíková, L. Stanovenie síry v muzejných artefaktoch (Determination of sulfur in museum artifacts). Múzeum 2006, 52, 7–11. (In Slovak) [Google Scholar]

- Kloužková, A.; Zemenová, P.; Kohoutková, M.; Kloužek, J. Hydrothermal rehydroxylation of kaolinite studied by thermal Analysis. Ceram.—Silikáty 2013, 57, 342–347. [Google Scholar]

- ISO 540:2008; Hard Coal and Coke—Determination of Ash Fusibility. ISO: Geneva, Switzerland, 2008.

- Choma, M. Xylotomické Analýza Uhlíkov z Archeologického Výskumu Lučenec—Merkury, Výskumná Dokumentácia č. 1-2018 (Xylotomy Analysis of Carbons from Archaeological Research Lučenec—Merkury, Research Documentation No. 1-2018); ADendro: Piešt’any, Slovakia, 2018. (In Slovak) [Google Scholar]

- Merico, P.; Faccoli, M.; LaCorte, D.; Cornacchia, G. Archaeometallurgical Characterization of Two Lombard EarlyMedieval Bloomery Slags fromPonte di Val Gabbia I Site (Northern Italy). Metals 2023, 13, 984. [Google Scholar] [CrossRef]

- Mihok, Ľ.; Cengel, P.; Wyderko, M. Hodnotenie štruktúry zvárkových trosiek (Evaluation of the structure of bloomery slag). Hut. Listy 1987, 42, 371–374. (In Slovak) [Google Scholar]

- Mihok, Ľ.; La Salvia, V.; Roth, P. Research of medieval smithy slags. In Archaeometallurgy. Proceedings of the 10th International Symposium Metalography’98; Stará Lesná: Košice, Slovakia, 1998; pp. 475–477. [Google Scholar]

- Pleiner, R. Iron in Archaeology. The European Bloomery Smelters; Archeologický Ústav AVČR: Praha, Czech Republic, 2000. [Google Scholar]

- Šarudyová, M. Topografia Železiarnína Slovensku v 19. Storočí (Topography of Ironworks in Slovakia in the 19th Century), 1st ed.; Východoslovenské Vydavateľsvo: Košice, Slovakia, 1989. (In Slovak) [Google Scholar]

- Dungworth, D. The Possible Water-Powered Bloomery at Goscote (Rushall), Walsall, West Midlands; Historical Metallurgy: Kent, UK, 2010; Volume 44, pp. 15–20. [Google Scholar]

- Mihok, L.; Cengel, P. Štúdium dokladov starej slovanskej výroby železa v Blatných Remetách (Study of documents of old Slavic iron production in Blatné Remety). In Zborník Vedeckých Prác; Vysoká Škola Technická v Košiciach, Ed.; Slovenské Vydavateľstvo Technickej Literatúry: Košice, Slovakia, 1983; pp. 313–323. (In Slovak) [Google Scholar]

- Souchopová, V. Hutnictví Železa v 8.—11. Století na Západní Moravě (Iron Metallurgy in the 8th–11th Centuries in Western Moravia); Academia: Praha, Czech Republic, 1986. (In Czech) [Google Scholar]

- Heckenast, G.; Nováky, G.; Vastagh, G.; Zoltay, E. A Magyarországi Vaskohászat Története a Korai Középkorban (a Honfoglalástól a XIII. Századközepéig) (The History of Hungarian Iron Metallurgy in the Middle Ages. From the Occupation of the Homeland to the 13th Century); Akadémiai Kiadó: Budapest, Hungary, 1968. (In Hungarian) [Google Scholar]

- Füryová, K.; Miček, M.; Mihok, Ľ.; Tomčo, Š. Začiatky železiarstva vo východnej časti Gemera v stredoveku (The beginnings of ironwork in the eastern part of Gemer in the Middle Ages). Ann. Musei Natl. Slovaci 1990, 85, 107–144. (In Slovak) [Google Scholar]

- Petrík, J.; Mihok, Ľ.; Soják, M.; Roth, P. Rozbor archeometalurgických materiálov z oblasti Hôrka—Jánovce (Analysis of archaeometallurgical materials from the Hôrka—Jánovce area). Z Dějin Hutnictví. Rozpr. NTM Praha 2000, 29, 31–41. (In Slovak) [Google Scholar]

- Espelund, A. The Evidence and the Secrets of Ancient Bloomery Ironmaking in Norway: With an Extension to the Beginning of the Industrial Period; Arketype Forlag: Trondheim, Norway, 2013. [Google Scholar]

- Espelund, A.; Stenvik, L.F. 1993: Ironmaking during the Roman iron age in Mid-Norway. The Bloomery site Storbekken I in Budalen. In Bloomery Ironmaking During 2000 Years; Seminar in Budalen 1991; Espelund, A., Ed.; Budalseminaret: Trondheim, Norway; Volume III, pp. 123–148.

- Kolchin, B.A. Chernaya Metallurgiya i Metalloobrabotka v Drevney Rusi (Ferrous Metallurgy and Metal Processing in Ancient Russia); Izdatelstvo AN SSSR: Moscow, Russia, 1953. (In Russian) [Google Scholar]

- Mameli, P.; Mongelli, G.; Oggiano, G.; Rovina, D. First Finding of Early Medieval Iron Slags in Sardinia (Italy): A Geochemical-Mineralogical Approach to Insights into Ore Provenance and Work Activity: First finding of early medieval iron slags in Sardinia (Italy). Archaeometry 2014, 56, 406–430. [Google Scholar] [CrossRef]

- Mace, T.C. Investigations of Medieval Slag from Gotland, Sweden. Master’s Thesis, University of Idaho, Moscow, ID, USA, 2012. Available online: http://www.gafs.me/MaceThesis.pdf (accessed on 16 December 2021).

- Portillo-Blanco, H.; Zuluaga, M.C.; Ortega, L.A.; Alonso-Olazabal, A.; Cepeda-Ocampo, J.J.; Martínez Salcedo, A. Mineralogical Characterization of Slags from the Oiola Site (Biscay, Spain) to Assess the Development in Bloomery Iron Smelting Technology from the Roman Period to the Middle Ages. Minerals 2020, 10, 321. [Google Scholar] [CrossRef]

- Joosen, I. Technology of Early Historical Iron Production in the Netherlands: Academisch Proefschrift ter Verkrijging van de Graad van Doctor aan de Vrije Universiteit Amsterdam; Geoarchaeological and Bioarchaeological Studies (Amsterdam); Vrije Universiteit Amsterdam: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Kronz, A. Self-mixing melt compositions in fayalitic slags—A key in understanding early metal production? In Applied Mineralogy: Research, Economy, Technology, Ecology and Culture, Proceedings of the Sixth International Congress on Applied Mineralogy, ICAM 2000, Göttingen, Germany, 17–19 July 2000; International Congress on Applied Mineralogy, Ed.; A.A. Balkema: Rotterdam, Netherlands, 2000. [Google Scholar]

- Török, B.; Kovács, A.; Gallina, Z.S. Iron metallurgy of the Pannonian Avars of the 7th–9th century based on excavations and material examinations. In Proceedings of the Archaeometallurgy in Europe III: 3rd International Conference, Deutsches Bergbau-Museum Bochum, Bochum, Germany, 29 June–1 July 2011; pp. 229–238. Available online: https://www.researchgate.net/publication/285494399_Iron_metallurgy_of_the_Pannonian_Avars_of_the_7th_-_9th_century_based_on_excavations_and_material_examinations (accessed on 10 June 2025).

- Selskienė, A. Examination of smelting and smithing slags formed in bloomery iron-making process. Chemija 2007, 18, 22–28. [Google Scholar]

- Labuda, J.; Mihok, Ľ.; Fröhlichová, M. Stredoveké železiarske objekty v Banskej Štiavnici (Medieval ironworks in Banská Štiavnica). In Študijné Zvesti Archeologického Ústavu SAV 3; Mačala, P., Němejcová-Pavúková, V., Rajtár, J., Eds.; SAV: Nitra, Slovakia, 1995; pp. 249–263. (In Slovak) [Google Scholar]

- Ustohal, V.; Mazač, L.; Stránský, K. Doubravník—Nejstarší železná huť Českomoravské vysočiny (Doubravník—The oldest iron smelter in the Bohemian-Moravian Highlands). Hut. Listy 1989, 44, 520–526. (In Czech) [Google Scholar]

- Stránský, K.; Rek, A.; Salaš, M.; Stránsky, K. Analýza halštatské železářské strusky z Radslavic u Vyškova na Moravě (Analysis of Hallstatt iron slag from Radslavice near Vyškov in Moravia). Archeol. Tech. 1992, 7, 129–130. (In Czech) [Google Scholar]

- Dungworth, D. Iron Bloom. In Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993–5; Atkinson, M., Preston, S.J., Eds.; Internet Archaeology 40; University of York: Toronto, ON, Canada, 2015. [Google Scholar] [CrossRef]

- Tylecote, R.F. A History of Metallurgy; The Institute of Materials: London, UK, 2002. [Google Scholar]

- Pleiner, R. Základy Slovanského Železářskeho Hutnictví v Českých Zemích—Grundlagen der Slavischen Eisenindustrie in den Böhmischen Ländern (The Foundations of Slavic Iron and Steel Industry in the Czech Lands); Nakladatelství SAV: Praha, Czech Republic, 1958; (In Czech and German). [Google Scholar]

- Werkelin, J.; Skrifvars, B.-J.; Hupa, M. Ash-forming elements in four Scandinavian wood species. Part 1: Summer harvest. Biomass Bioenergy 2005, 29, 451–466. [Google Scholar] [CrossRef]

- Symanowicz, B.; Becher, M.; Jaremko, D.; Skwarek, K. Possibilities for the Use of Wood Ashes in Agriculture. J. Ecol. Eng. 2018, 19, 191–196. [Google Scholar] [CrossRef] [PubMed]

- Petrík, J.; Mihok, Ľ.; Javorský, F.; Fröhlich, L.; Vadász, P.; Soláriková, M. The analysis of the slags from the south Spiš. Acta Metall. Slovaca 2001, 7, 66–79. [Google Scholar]

- Paynter, S. Regional veriations in bloomey smelting salg of the iron age and romano-british period. Archaeometry 2006, 48, 271–292. [Google Scholar] [CrossRef]

- Straka, T.J. Charcoal as a Fuel in the Ironmaking and Smelting Industries. Adv. Hist. Stud. 2017, 6, 56–64. [Google Scholar] [CrossRef]

- Rożaňsky, W.; Słomska, I. Suitability of charcoal mixtures for iron smelting in early furnaces front Holy Cross Mountains area as revealed by investigation of their reactivity. Kwart. HTN 1980, 25, 379–386. [Google Scholar]

- Opravil, E. Dřevěné uhlí ze slovanských železářských dílen na Blanensku (Charcoal from Slavic ironworks in Blanensko). Sborník Okr. Vlast. Mus. V Blansku 1973, 5, 236–254. (In Czech) [Google Scholar]

- Forest Portal o Lesoch Slovenska. Lesné Vegetačné Stupne (Forest Portal About the Forests of Slovakia. Forest Vegetation Levels). (In Slovak). Available online: https://www.forestportal.sk/les-pre-verejnost/informacie-o-lesoch/lesne-vegetacne-stupne-2/ (accessed on 10 May 2025).

- Kropilák, M.; Strhan, M.; Hudák, J. Vlastivedný Slovník Obcí na Slovensku II (The Dictionary of Municipalities in Slovakia); Veda: Bratislava, Slovakia, 1972. (In Slovak) [Google Scholar]

- Lukniš, M. Slovensko–Príroda (Slovakia–Nature); Obzor: Bratislava, Slovakia, 1972. (In Slovak) [Google Scholar]

- Ščipák, J. Atlas ČSSR (Atlas of CSSR); Slovenská Kartografia: Bratislava, Slovakia, 1980; pp. 10–11. (In Slovak) [Google Scholar]

- Krippel, E. Postglaciálny Vývoj Vegetácie Slovenska (Postglacial Development of Vegetation in Slovakia); Veda: Bratislava, Slovakia, 1986. (In Slovak) [Google Scholar]

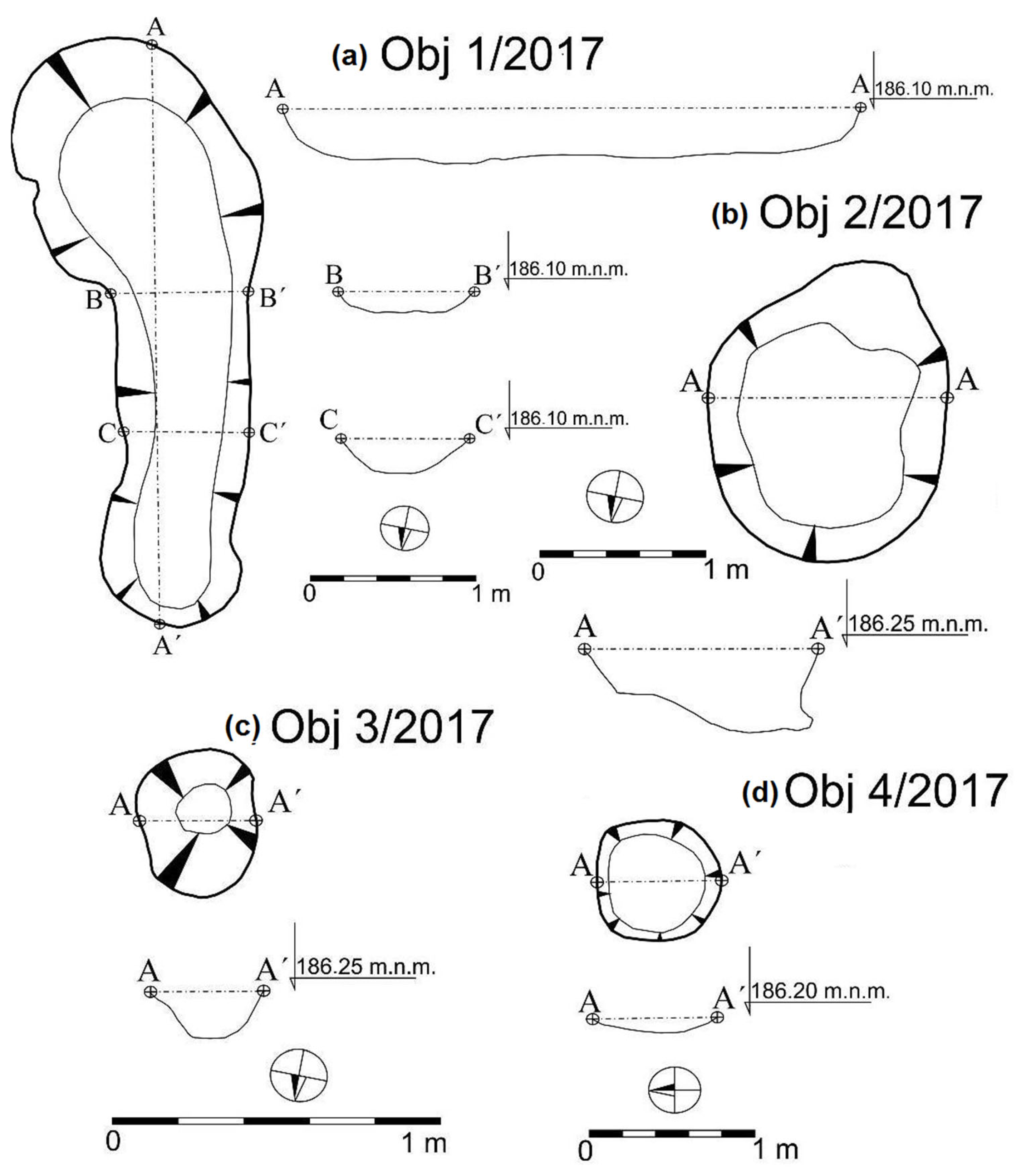

| Structure No. (Figure 3) | Stratigraphic Unit (SJ) | Dimensions Length × Max. Width × Depth | Orientation of the Structure |

|---|---|---|---|

| 1/2017 (a) | 1003/5000 | 550 cm × 200 cm × 40 cm | N–S |

| 2/2017 (b) | 1004/5001 | 175 cm × 124 cm × 42 cm | NE–SW |

| 3/2017 (c) | 1005/5002 | 45 cm × 36 cm × 12 cm | NE–SW |

| 4/2017 (d) | 1006/5003 | ∅ 75 cm × 14 cm | - |

| SJ | Sample No. | Oxide Content in Analyzed Slags [wt.%] | B | |||||

|---|---|---|---|---|---|---|---|---|

| FeO | SiO2 | CaO | MgO | Al2O3 | MnO | |||

| 1003/5000 | P413 | 79.12 | 11.35 | 3.00 | 0.40 | 2.06 | 0.60 | 0.30 |

| 1003/5000 | P414 | 67.45 | 22.65 | 4.6 | 0.30 | 4.08 | 0.54 | 0.22 |

| 1004/5001 | P418 | 48.06 | 30.64 | 2.01 | 0.55 | 9.58 | 3.06 | 0.08 |

| 1004/5001 | P419 | 55.55 | 25.68 | 2.57 | 0.58 | 6.43 | 2.32 | 0.12 |

| 1004/5001 | P420 | 59.57 | 21.00 | 1.55 | 0.33 | 9.07 | 0.68 | 0.09 |

| 1004/5001 | P423 | 56.10 | 17.70 | 2.04 | 0.43 | 3.80 | 0.55 | 0.14 |

| 1004/5001 | P424 | 66.80 | 9.42 | 1.78 | 0.50 | 2.02 | 0.40 | 0.24 |

| SJ | Sample No. | Content in Analyzed Slags [wt.%] | ||

|---|---|---|---|---|

| P2O5 | S | K2O | ||

| 1003/5000 | P409 | 1.33 | 0.070 | N |

| 1003/5000 | P417 | 1.04 | 0.060 | N |

| 1004/5001 | P418 | 0.88 | 0.056 | 0.62 |

| 1004/5001 | P421 | 1.00 | 0.290 | N |

| 1004/5001 | P425 | 1.62 | 0.081 | 0.68 |

| Sample No. | Minor Elements (0.01–1%) | Trace Elements (0.0001–0.01%) |

|---|---|---|

| P409 | Mn Cu Ag Zn Sb Mo V Cr | Ni Co Sn |

| P410 | Mn Zn Pb V | Cu Ni Co Ag Sn |

| P413 | Mn Cu V | Ag Sn Zn |

| P414 | Mn Cu V | Ag Zn |

| P417 | Mn Zn V Cr | Cu Ni Co Ag |

| P418 | Mn Zn V | Cu Ni Co Ag Sn Cr |

| P419 | Mn Cu Zn V | Ag Sn |

| P420 | Mn Cu Zn V | Ag Sn Mo |

| P421 | Mn Cu Ag Zn | Ni Co Sn V |

| P423 | Mn Cu Zn V | Co Ag Sn Pb |

| P424 | Mn Cu Zn V | Ag Sn |

| P425 | Mn Zn V | Cu Ni Co Ag Sn |

| SJ | Sample No. | Process Attribution | Wüstite [vol.%] | Metallic Iron [vol.%] | Magnetic Properties |

|---|---|---|---|---|---|

| 1003/5000 | P406 | Bloomery | Low/absent | - | No |

| 1003/5000 | P412 | Bloomery | Low/absent | - | No |

| 1003/5000 | P414 | Bloomery | 2.9 | - | No |

| 1004/5001 | P418 | Bloomery | Low/absent | - | No |

| 1004/5001 | P420 | Bloomery | 11.1 | - | No |

| 1003/5000 | P408 | Bloomery | 18.8 | - | No |

| 1003/5000 | P409 | Bloomery | 9.5–20.3 | - | No |

| 1003/5000 | P411 | Bloomery | 9.5–20.3 | - | No |

| 1003/5000 | P417 | Bloomery | 9.5–20.3 | - | No |

| 1004/5001 | P419 | Bloomery | 1.8 | - | No |

| 1004/5001 | P422 | Bloomery | 17.6 | - | No |

| 1004/5001 | P423 | Bloomery | 18.9 | - | No |

| 1003/5000 | P413 | Reheating | 63.3 | - | Yes |

| 1004/5001 | P421 | Reheating | 44.6 | 2.0 | Yes |

| 1004/5001 | P424 | Reheating | 19–35 | - | Yes |

| 1004/5001 | P425 | Reheating | 13–41 | - | Yes |

| Sample No. | Representation of Fe and Oxides in Analyzed Slag [wt.%] | |||||||

|---|---|---|---|---|---|---|---|---|

| Fetotsl | SiO2 | CaO | MgO | Al2O3 | K2O | P2O5 | S | |

| P410 | 14.7 | 55.9 | 2 | 1.5 | 8.2 | 2.1 | 0.93 | 0.054 |

| Sample No. | Representation of Oxides in Ceramic Fragments [wt.%] | Loss on Ignition [wt.%] | ||||||

|---|---|---|---|---|---|---|---|---|

| Fe2O3 | SiO2 | CaO | MgO | Al2O3 | Na2O | K2O | ||

| P410-K | 9.3 | 60.3 | 2.2 | 0.5 | 19.8 | 0.4 | 1.2 | 6.3 |

| P415-K | 6.3 | 63.3 | 5.3 | 0.9 | 16.3 | 0.6 | 1.4 | 5.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrík, J.; Futáš, P.; Plešingerová, B.; Blaško, P.; Pribulová, A.; Vadasz, P. Early Medieval Iron Metallurgy in the Lučenec Basin, Slovakia. Processes 2025, 13, 2104. https://doi.org/10.3390/pr13072104

Petrík J, Futáš P, Plešingerová B, Blaško P, Pribulová A, Vadasz P. Early Medieval Iron Metallurgy in the Lučenec Basin, Slovakia. Processes. 2025; 13(7):2104. https://doi.org/10.3390/pr13072104

Chicago/Turabian StylePetrík, Jozef, Peter Futáš, Beatrice Plešingerová, Peter Blaško, Alena Pribulová, and Pavol Vadasz. 2025. "Early Medieval Iron Metallurgy in the Lučenec Basin, Slovakia" Processes 13, no. 7: 2104. https://doi.org/10.3390/pr13072104

APA StylePetrík, J., Futáš, P., Plešingerová, B., Blaško, P., Pribulová, A., & Vadasz, P. (2025). Early Medieval Iron Metallurgy in the Lučenec Basin, Slovakia. Processes, 13(7), 2104. https://doi.org/10.3390/pr13072104