1. Introduction

The global pursuit of carbon neutrality has intensified the exploration of alternative fuels that can replace conventional hydrocarbon fuels in internal combustion engines (ICEs). Among emerging zero-carbon fuels, ammonia (NH

3) and hydrogen (H

2) have attracted growing interest due to their complementary combustion properties, abundance, and potential for renewable production pathways [

1,

2]. Their combination has proven particularly promising in advanced combustion concepts, particularly in the context of homogeneous charge compression ignition (HCCI) engines, which hold high-efficiency and near-zero emission output profiles [

3,

4].

Ammonia stands out as a viable hydrogen carrier and carbon-free fuel, benefiting from an already established distribution infrastructure. However, its direct applicability in ICEs is constrained by several challenges: notably, a narrow flammability limit, low flame speed (≈0.07 m/s) and high autoignition temperature (≈651 °C) that lead to combustion instability and ammonia slip [

5]. These limitations are particularly pronounced in HCCI operation, which lacks a direct ignition source and relies on autoignition of a homogeneous mixture [

5,

6]. Hydrogen, on the other hand, features high diffusivity, fast flame speed, and low ignition energy, making it an ideal combustion enhancer for ammonia. Several studies confirm that blending H

2 with NH

3 significantly improves combustion stability, increases peak pressure, and reduces unburned ammonia emissions [

5,

7]. For instance, Pochet et al. demonstrated that NH

3/H

2 dual fueling in an HCCI engine with a 22:1 compression ratio (CR) expands the load range and increases combustion efficiency, although with a notable increase in NOx emissions that necessitates after-treatment such as exhaust gas recirculation (EGR) [

2]. Akram et al. also experimentally verified these trends in a diesel pilot-ignited engine operating on NH

3/H

2 mixtures [

5]. They found that increasing H

2 and diesel pilot content improved net indicated mean effective pressure at 720 °CA (IMEP720) and indicated efficiency yet introduced ammonia slip and high NOx levels, particularly under low-load conditions [

5]. Their findings support the role of hydrogen as a combustion enhancer for ammonia-based fuels in practical engine platforms.

While experimental investigations have shown the feasibility of NH

3/H

2 combustion in ICEs, detailed kinetic modeling provides critical insights into the complex ignition phenomena under HCCI conditions. More comprehensive simulation frameworks have evolved to capture the behavior of complex fuels in HCCI combustion. Kominionos and Rakopoulos reviewed various single-zone, multizone and multidimensional chemical kinetics models used to simulate HCCI operation with biofuels, hydrogen, and ammonia [

4]. They emphasized the need for detailed kinetic mechanisms to resolve ignition chemistry accurately and predict performance across operating conditions. Xu et al. applied direct numerical simulation (DNS) to explore the impact of temperature and composition stratification on NH

3/H

2 autoignition. Their results showed that temperature stratification is more effective than composition stratification in extending combustion duration and moderating peak heat release rates (HRR) [

6]. Stagni et al. have also investigated low- and intermediate-temperature NH

3/H

2 oxidation in a flow reactor using both experimental and wide-range kinetic modeling [

8]. Similarly, Guo et al. utilized detailed kinetic models to investigate the combustion of n-heptane in HCCI, highlighting how precise control over ignition delay and HRR is essential for optimizing performance and emissions [

9]. Challenges associated with the HCCI concept include achieving a consistent combustion phasing and controlling ignition timing under diverse engine operating conditions [

3]. Fast simulation models are employable in engine performance optimization, due to their high comparability, enabling rapid prototyping of robust engine models [

10]. This makes applied-level engine research possible, such as maximizing engine design concepts’ functioning limitations for technical advancement. HCCI simulation techniques vary by run-time constraint application, ranging from high-fidelity three-dimensional (3D) models to zero-dimensional (0D) models [

11]. Computational fluid dynamics (CFD) solves the Navier–Stokes equations in detail, making 0D an order of magnitude faster than CFD. Chemical kinetics is usually used to simulate HCCI combustion progress, regardless of the model fidelity [

10,

11]. This illustrates the reaction-driven nature of the phenomena for capturing ignition and combustion characteristics. To address LTC development needs, chemical kinetic solvers have been recently included in the commercial engine simulation toolchains like GT-Suite (v2022 onwards) [

12]. However, limited studies have validated the use of such solvers in 0–1D simulation, with unconventional fuels such as NH

3 and H

2 especially under HCCI conditions. This study aims to fill this gap by implementing a validated NH

3/H

2 kinetic mechanism in a 1D HCCI model in GT-Suite, assessing combustion and emissions across a wide range of operating conditions. Specifically, the study explores how blending ratio (BR), air–fuel equivalence ratio (ER), compression ratio (CR), and engine speed affect engine performance, combustion phasing and NOx emissions. In addition, cycle-to-cycle variability (CCV) is analyzed over six simulated cycles to quantify stability, a critical metric in HCCI combustion. By combining simulation accuracy with comprehensive parametric evaluation, this work contributes to the growing body of research on ammonia–hydrogen-fueled engines and highlights the opportunity and trade-offs inherent in transitioning towards carbon-free combustion.

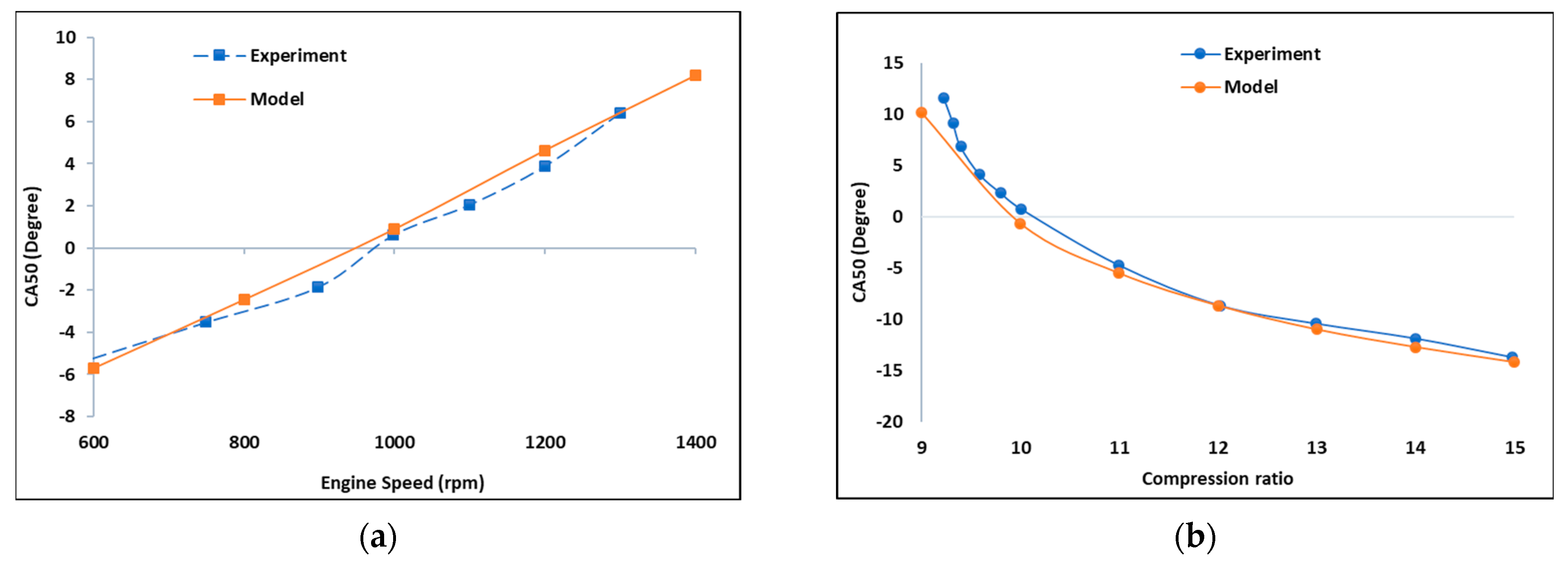

To this end, using an n-heptane-fueled single-cylinder HCCI engine, Guo et al. [

9] compared their experimental measurement with numerical simulations. They observed slight discrepancies in the HRR, in-cylinder pressure and other combustion parameters. This was predicted to be caused by the imperfect assumption of air/fuel homogenous mixing, combustion chamber wall temperature, reaction rates, uniform temperature and pressure, and fuel chemistry (level of detail of the applied chemical reaction mechanism) applied in modeling [

6,

9]. This led to increasing the inlet temperature by 30 K for modeling HCCI, as recommended by Yelvington et al. [

13]. They proposed that using 333 K as the inlet temperature for the modeled case would reduce the deviation of the HRR phasing between the experimental and numerical modeling result data. To this end, a baseline model with a suitable multi-component mechanism is validated over the experimental data available in the previously mentioned study by Guo et al. [

9]. The validated model is further extended with H

2 and NH

3 injectors and benchmarked for combustion and emission performance over a wide range of operating conditions.

5. Conclusions

This study explored the combustion performance and emission behavior of NH3/H2 blends in an HCCI engine using a detailed 0D single-zone simulation model implemented in GT-Suite. A validated chemical kinetics mechanism was applied to systematically assess the influence of BR, air–fuel ER, CR, and engine speed on thermal efficiency, NOx emissions, and combustion stability. The study allowed us to draw the following conclusions:

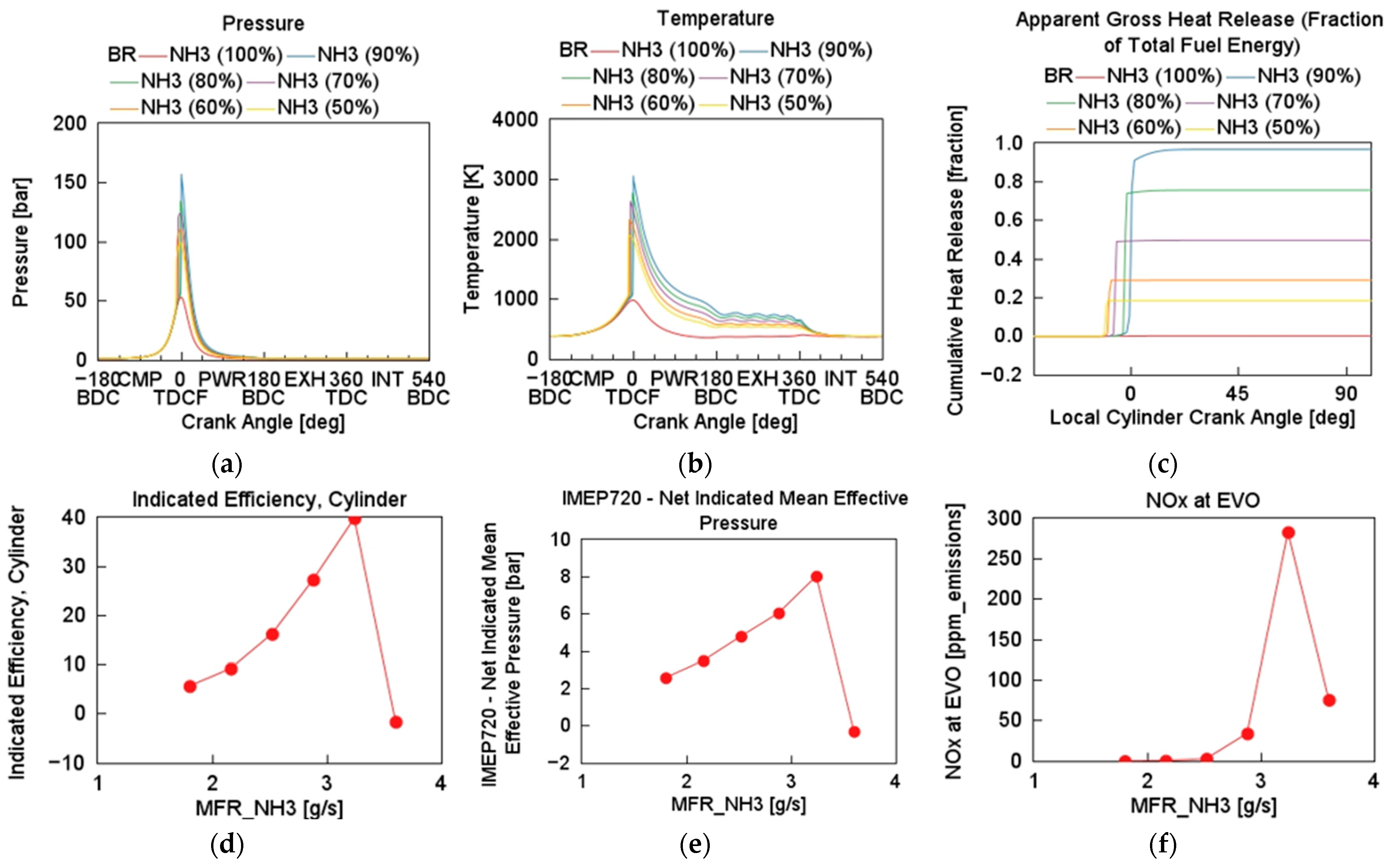

As little as 10 w/w% of H2 in the fuel blend improved the autoignition properties of NH3, although higher hydrogen fractions reduced cumulative heat release due to faster combustion and dilution effects.

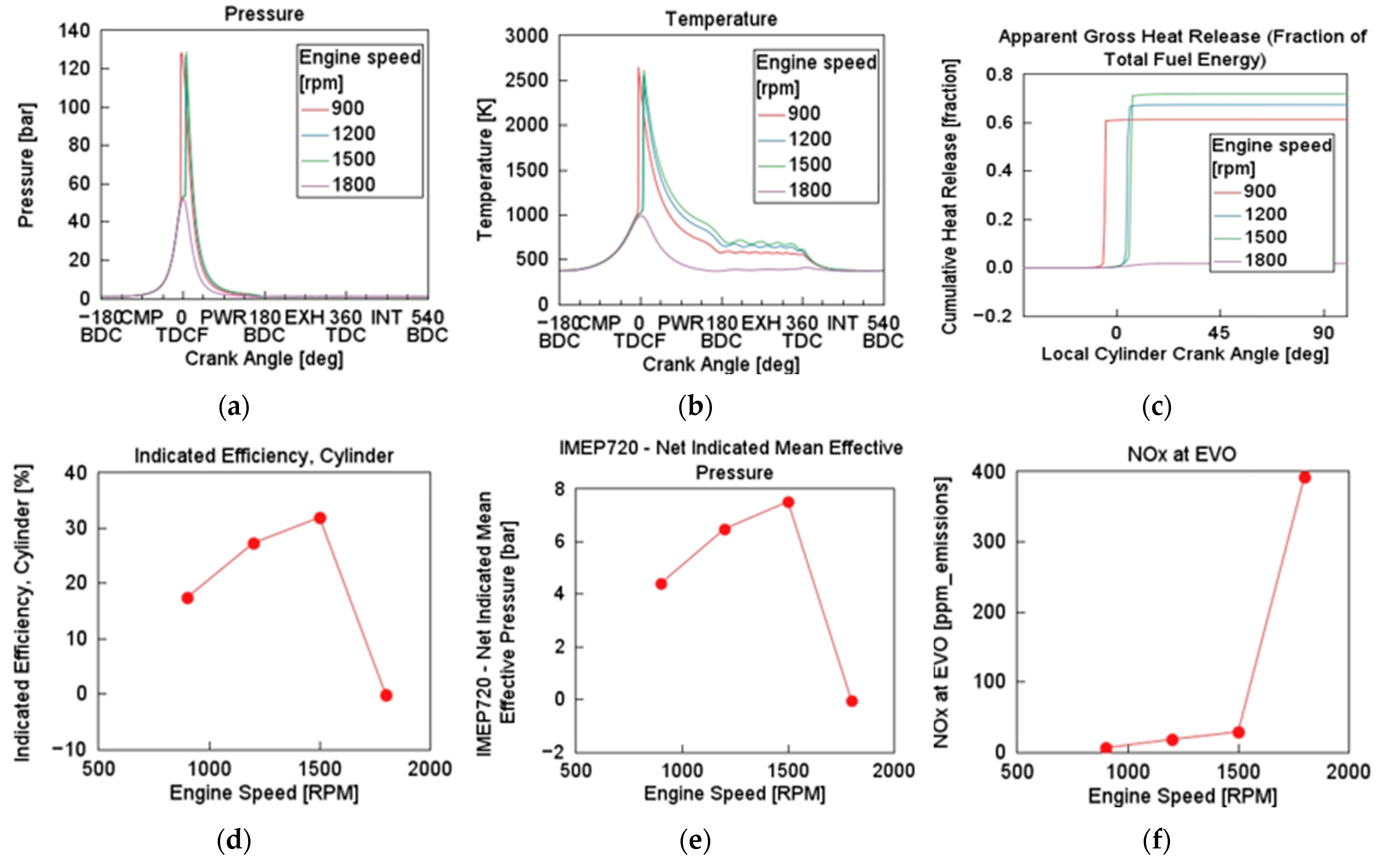

Engine speed significantly impacts combustion phasing and engine efficiency. The study identified 1500 rpm as the optimal speed for the modeled NH3/H2-fueled HCCI engine, proving stable combustion and improved thermal efficiency.

CR between 20 and 22 was found to be optimal for NH3/H2-fueled engines, balancing combustion efficiency and mechanical reliability. Lower CR values resulted in incomplete combustion, while higher CR values caused excessive peaks in pressure.

Air–fuel ER significantly influenced engine behavior. While efficiency improved with ER up to 1.4, NOx emissions increased exponentially beyond this limit. Leaner mixtures (air–fuel ER between 1.2 and 1.4) provided the best compromise between efficiency and emissions.

Cycle-to-cycle variability testing proved that the NH3/H2 engine model achieved combustion stability after few cycles, even though more cycles are needed for full statistical robustness of the simulation approach under varying operating conditions.

Despite the limitations of the single-zone model, especially the absence of spatial stratification and real-time temperature gradients, the results demonstrated strong alignment with the experimental and theoretical literature, validating the use of detailed chemical kinetics in engine concept modeling. Future work should include implementing multizone or 3D CFD models. Likewise, experimental validation for this model will be conducted for ammonia combustion with hydrogen blends using the rapid compression and expansion machine (RCEM) to further investigated the proposed model and operating parameters in engine-like conditions. The experiment will validate the simulations for further applicability in the design of ammonia–hydrogen-fueled HCCI practical solutions.