Evaluation of Mechanical Properties and Environmental Impact of Red Mud-Based Silty Soil Modified by Inorganic Binding Materials

Abstract

1. Introduction

2. Experimental Materials and Methods

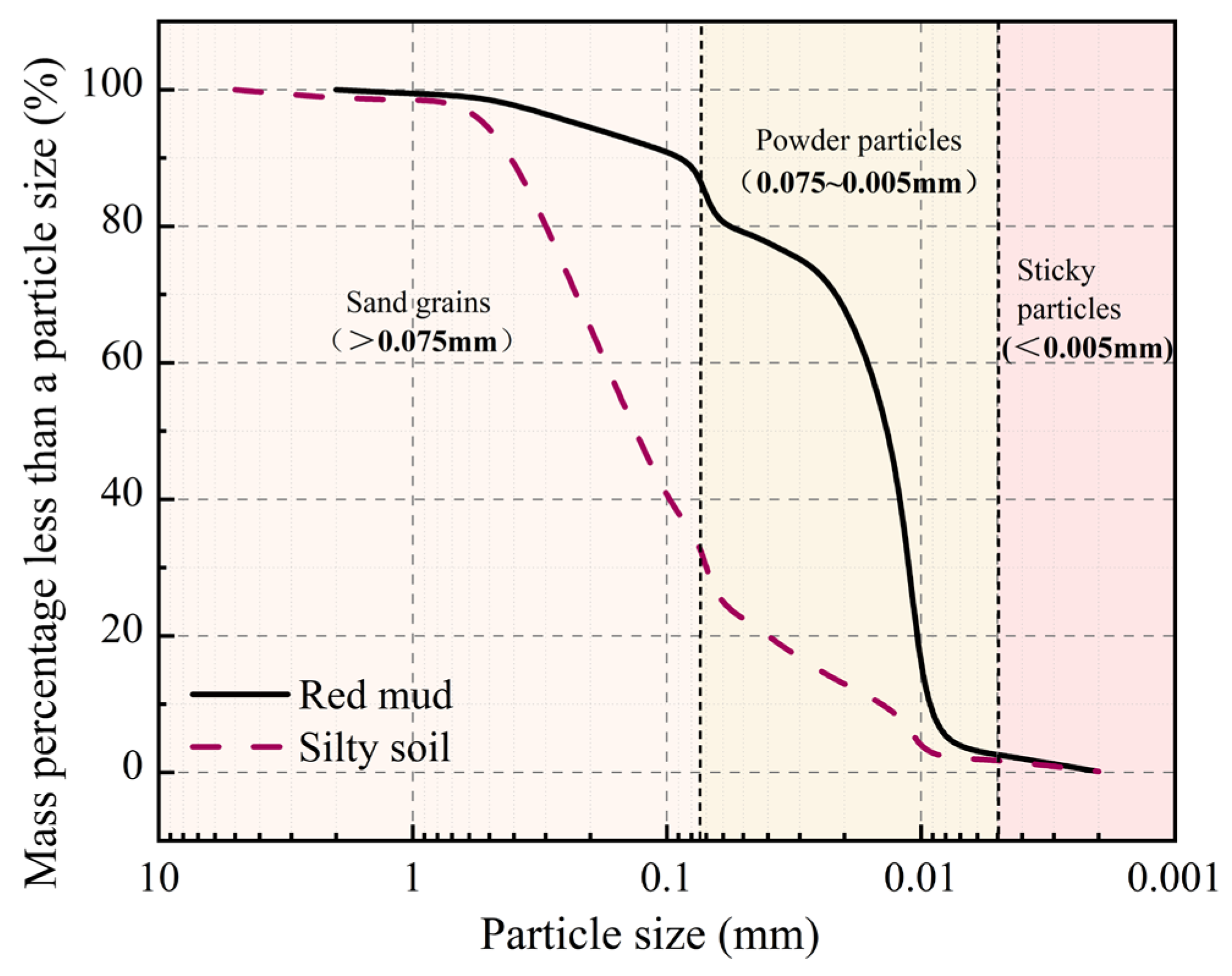

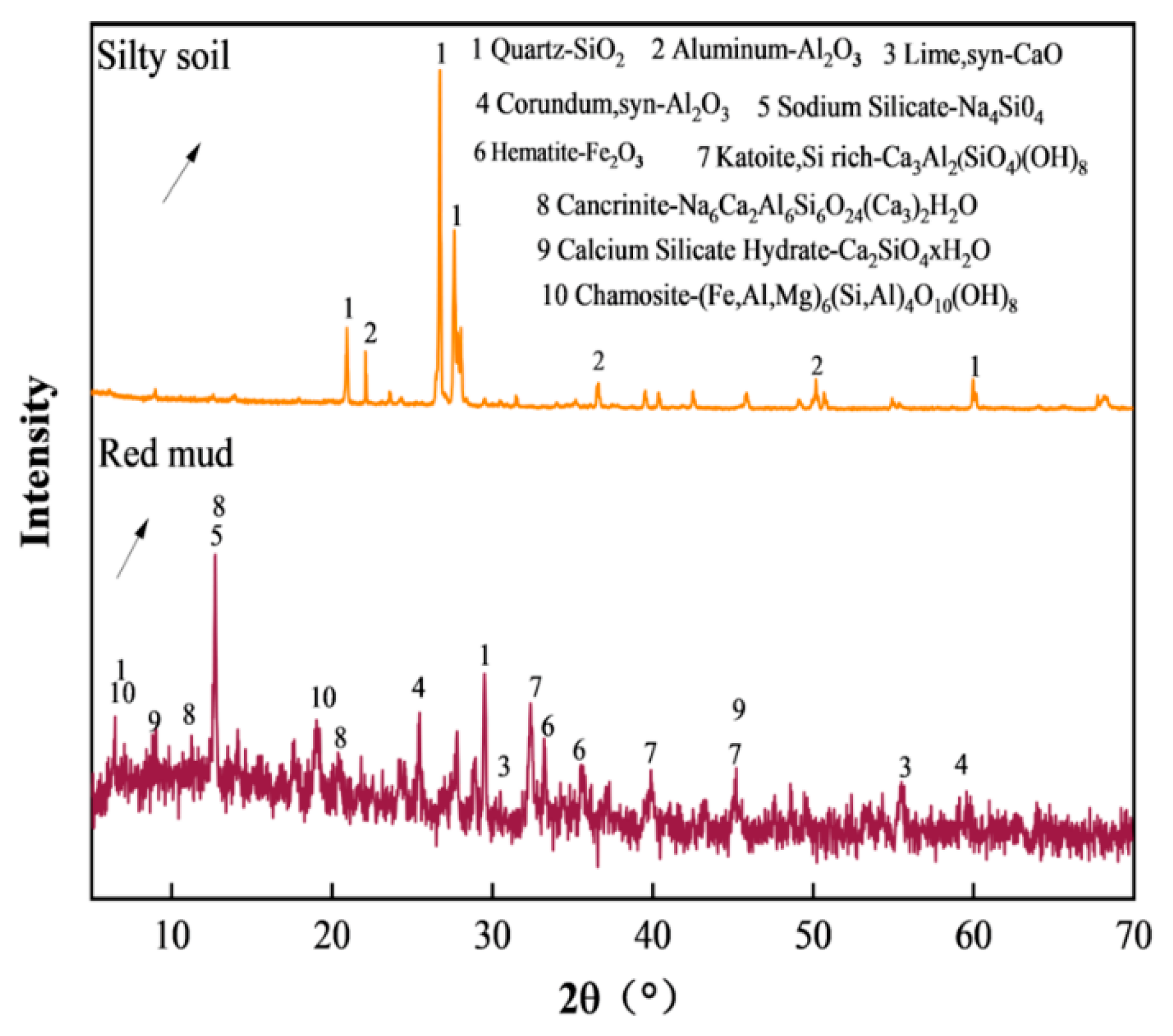

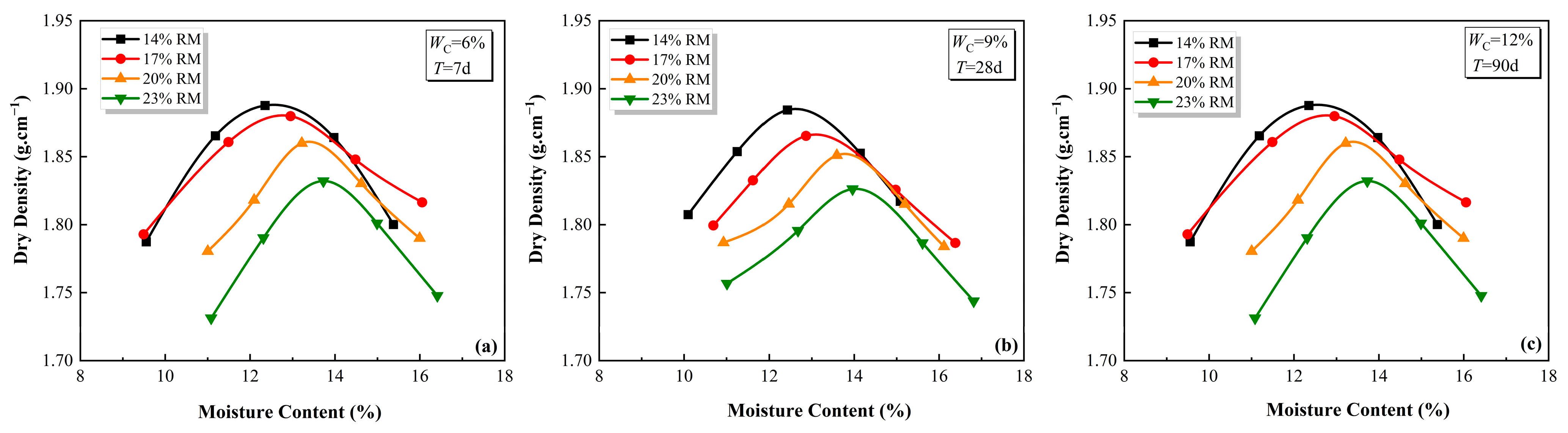

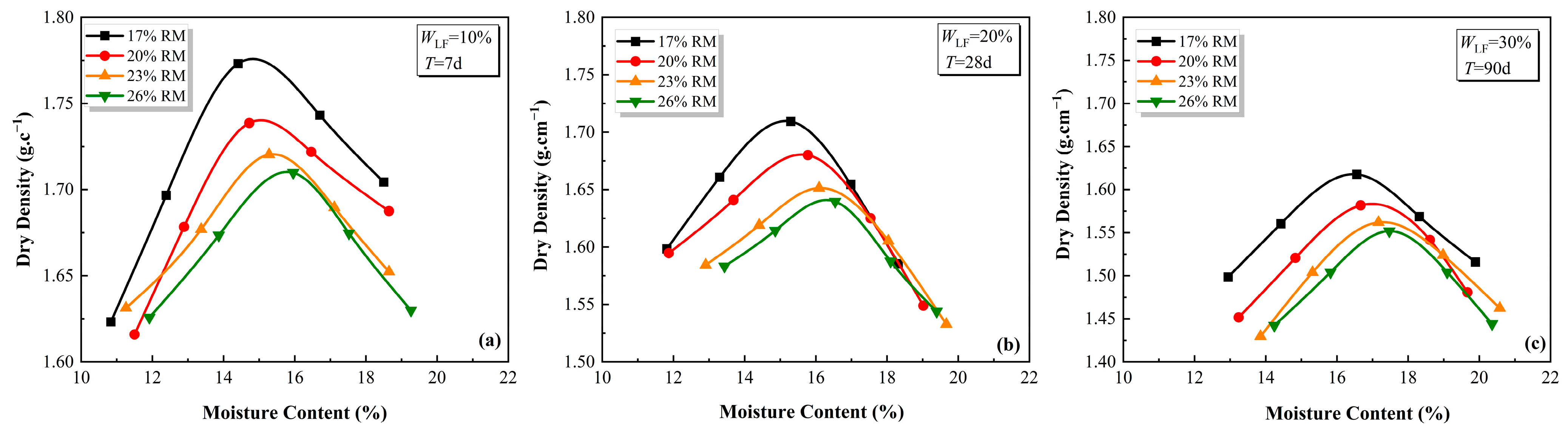

2.1. Experimental Materials

2.2. Experimental Method

2.2.1. Unconfined Compressive Strength Test

2.2.2. Splitting Tensile Strength Test

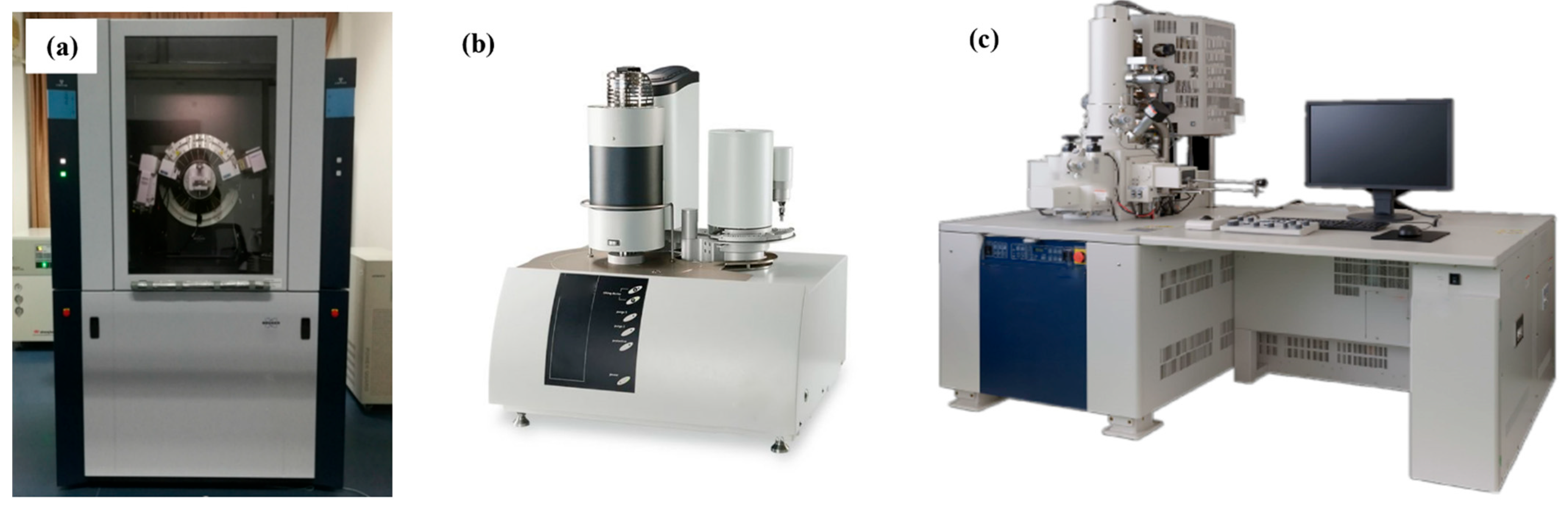

2.2.3. Microscopic Test

2.2.4. Environmental Index Detection Test

3. Results and Analysis

3.1. Comparative Analysis of Compressive Performance

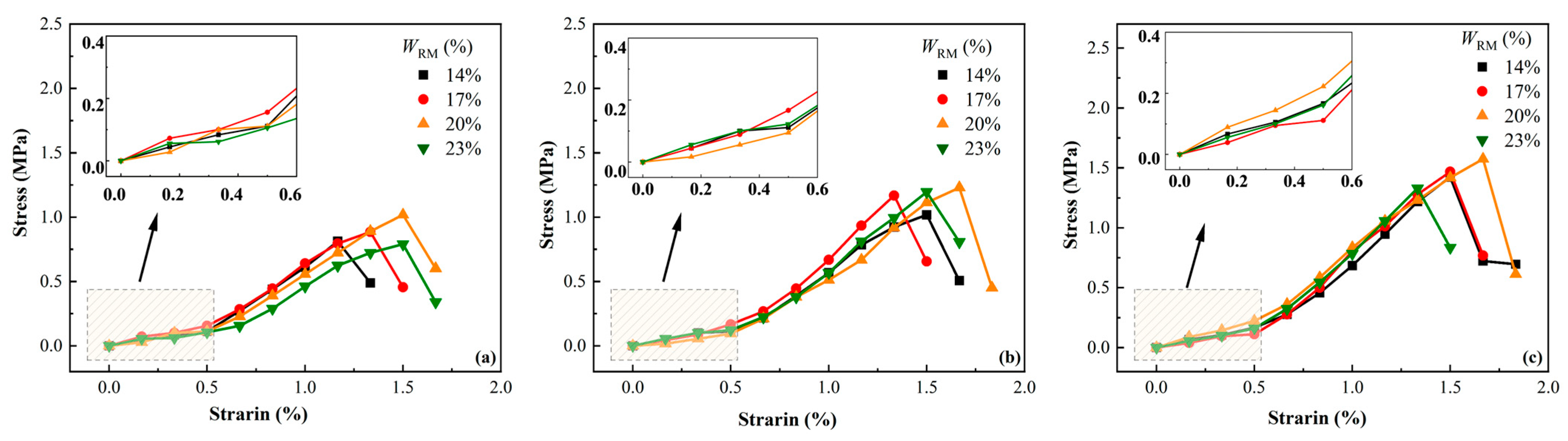

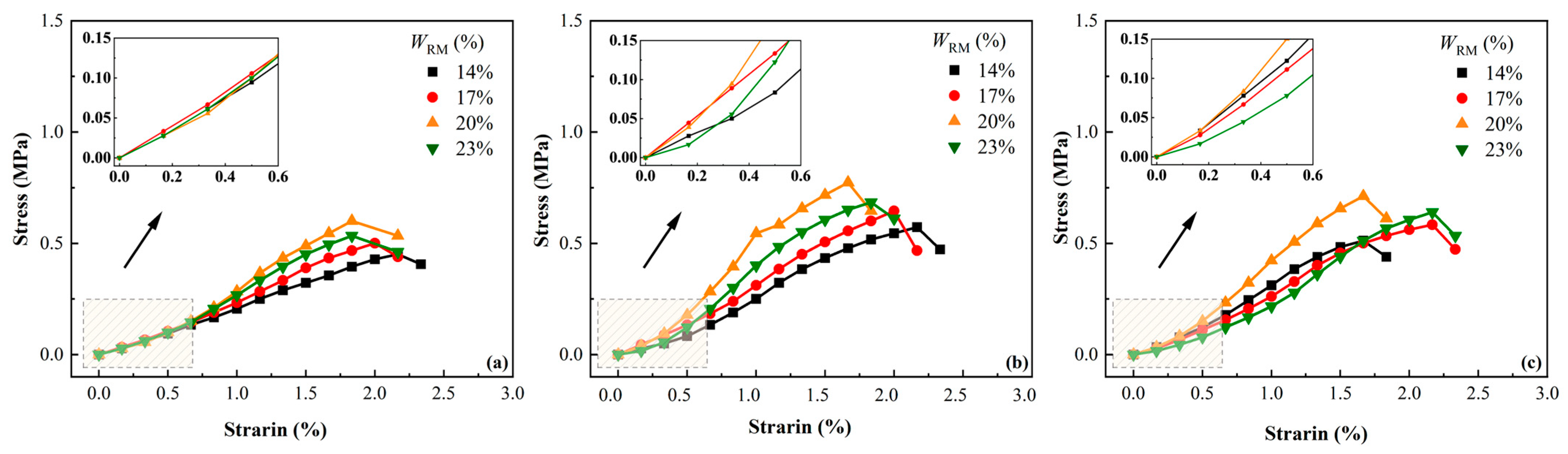

3.1.1. Axial Stress-Strain Relationship

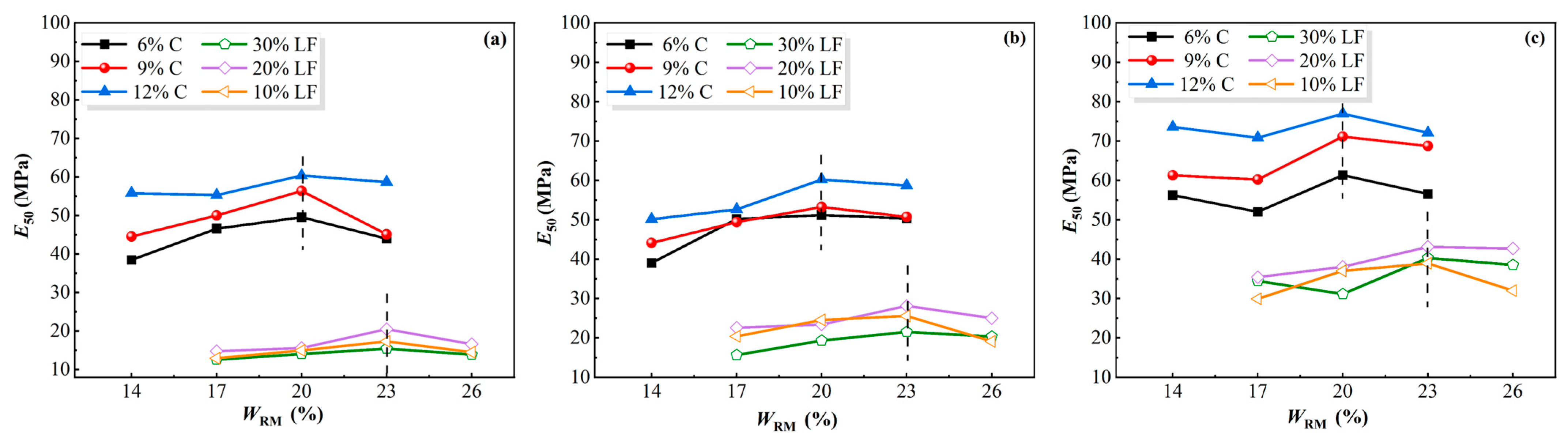

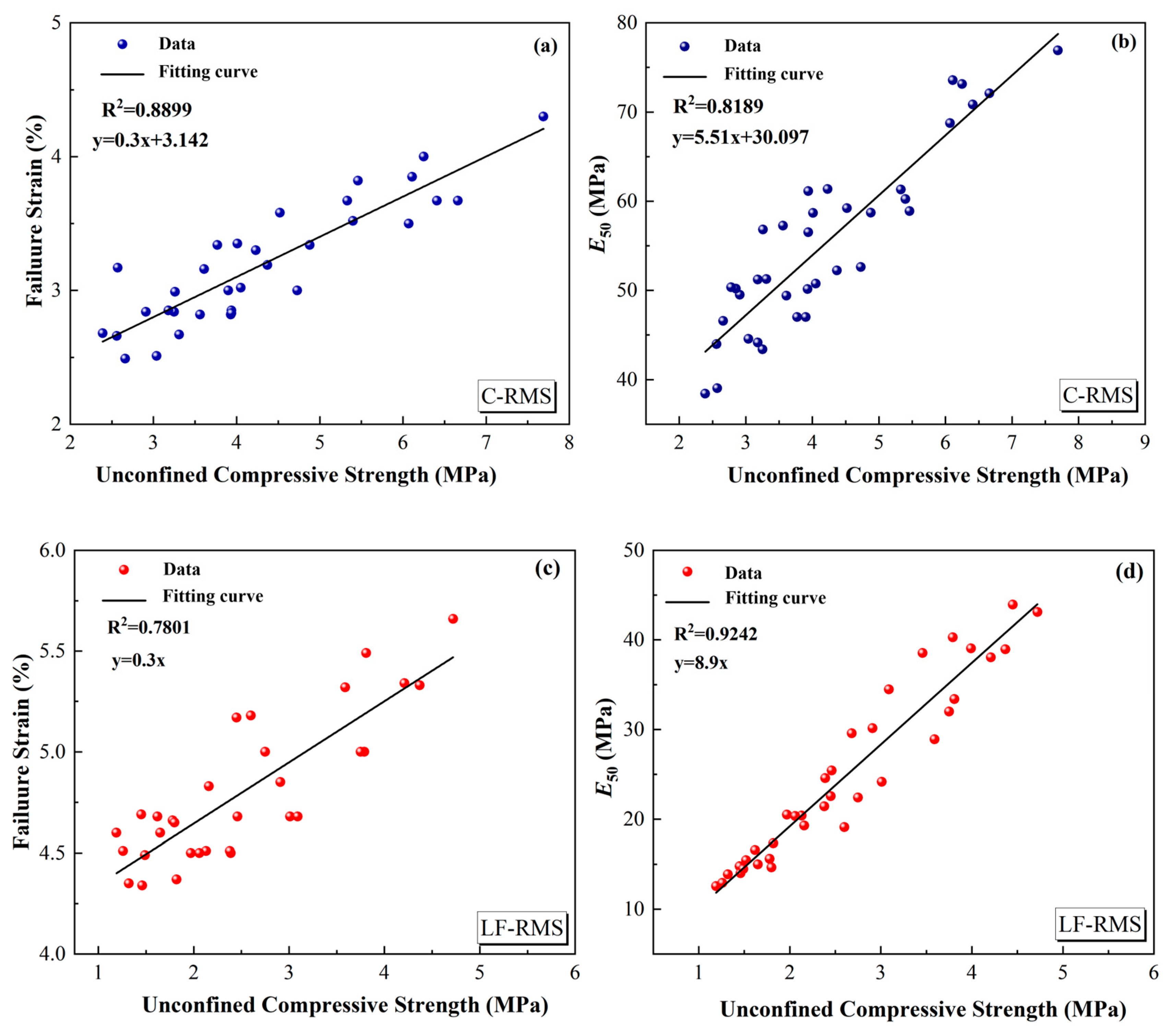

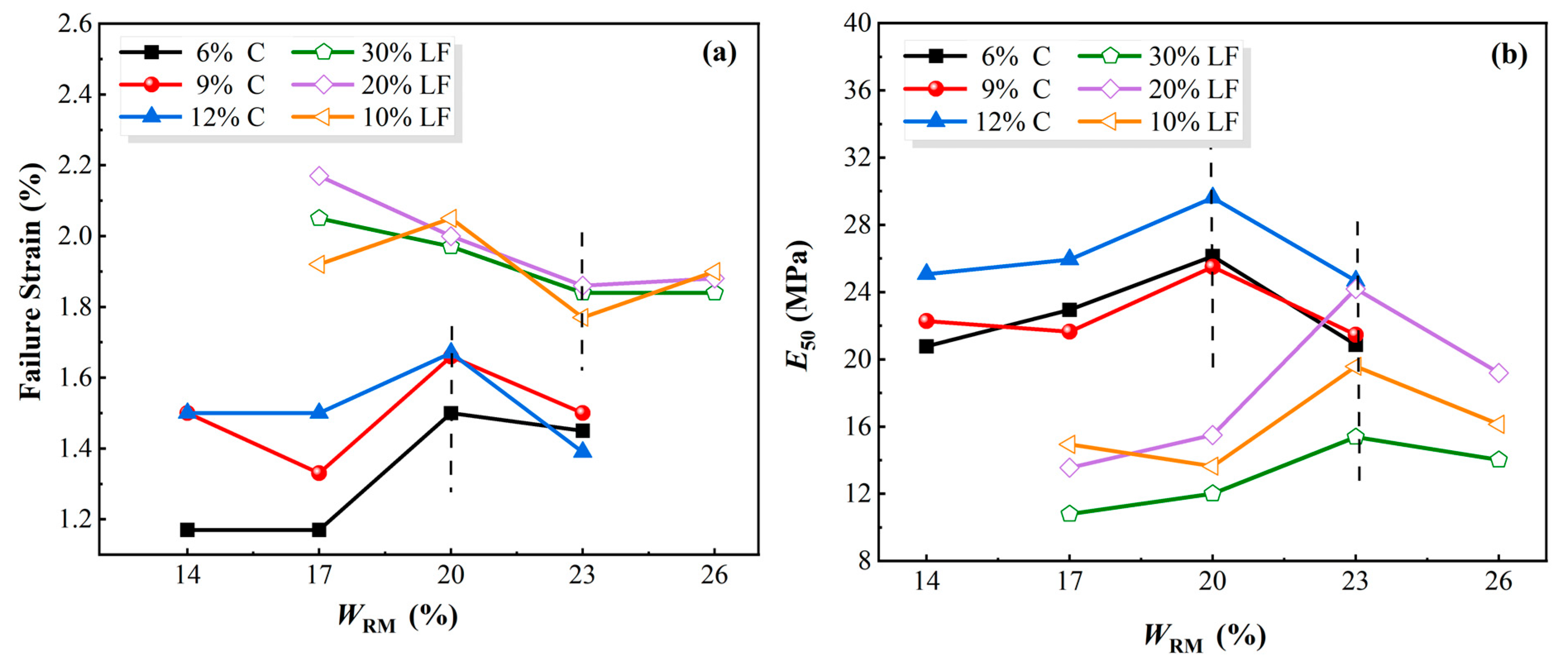

3.1.2. Deformation Characteristic Analysis

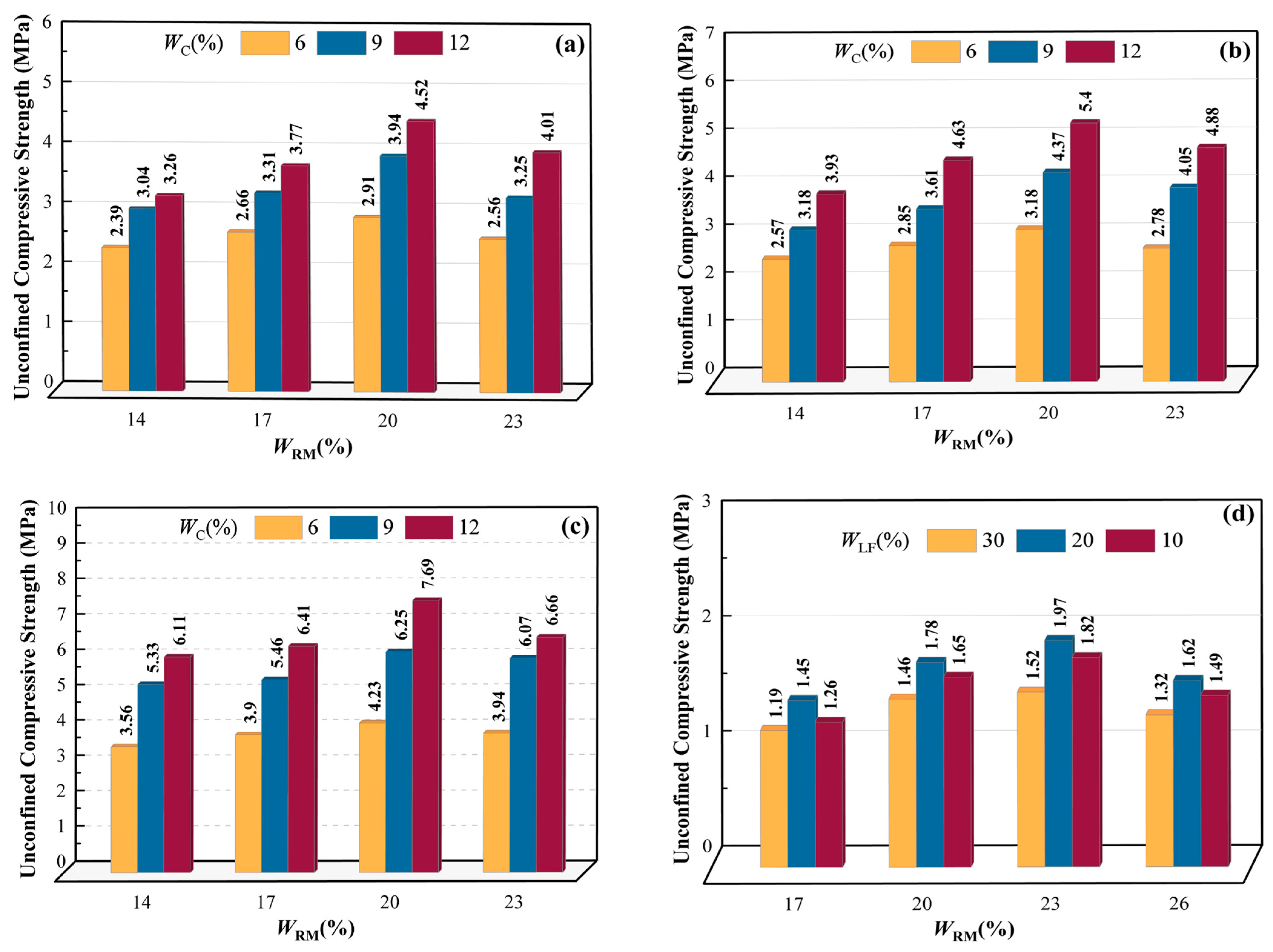

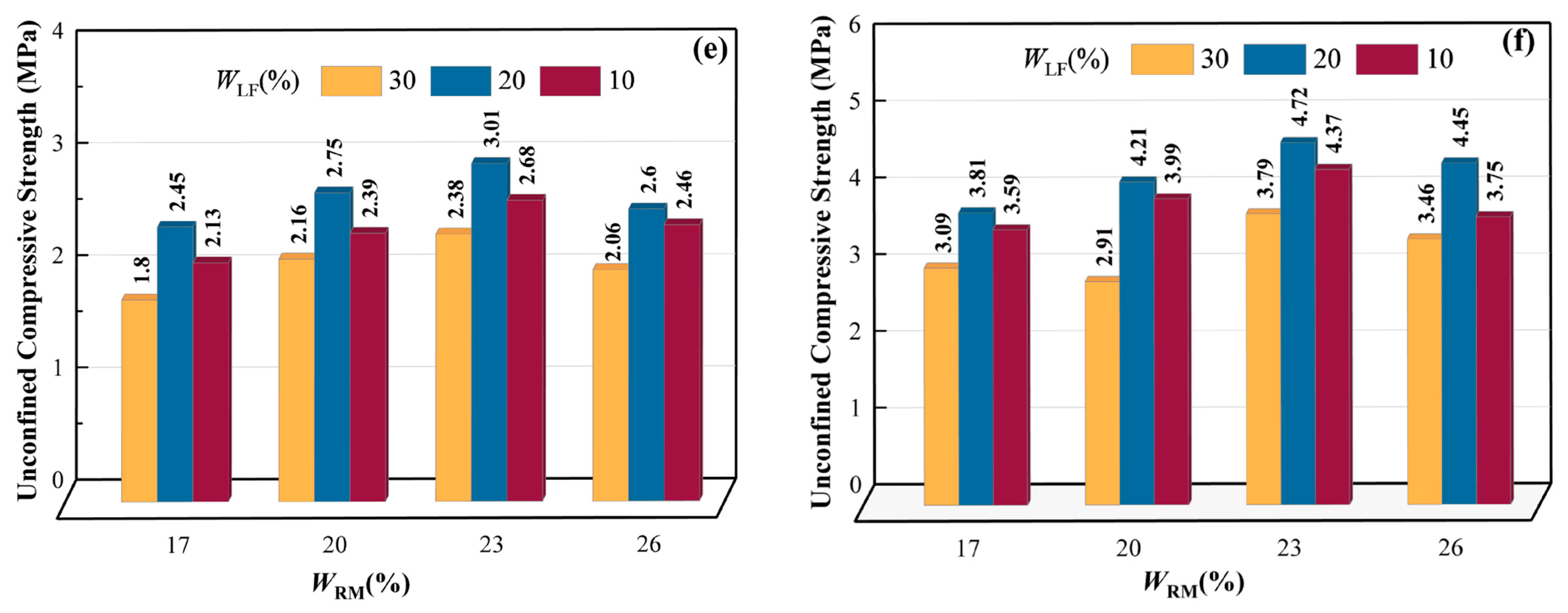

3.1.3. Compressive Strength

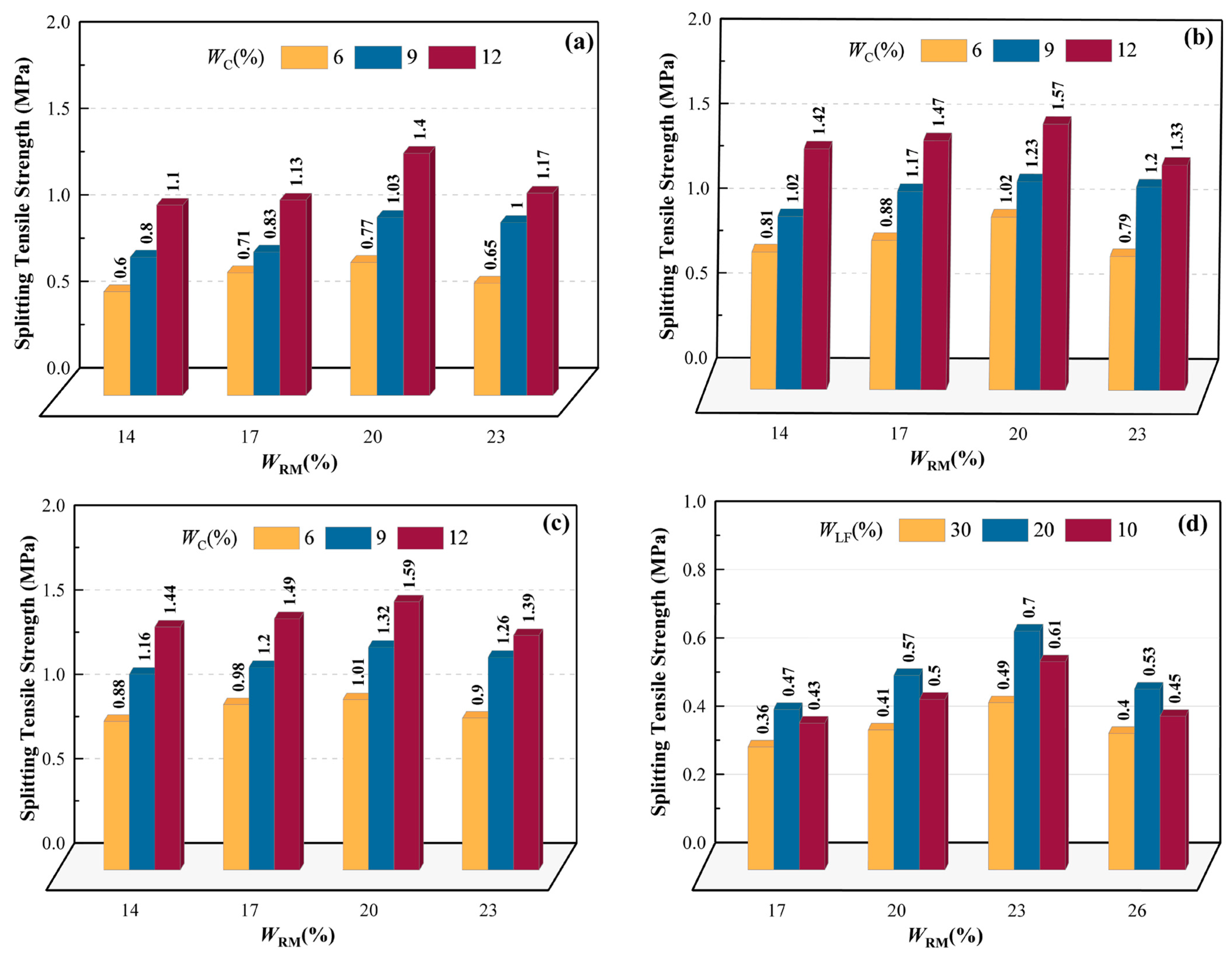

3.2. Comparative Analysis of Tensile Properties

3.2.1. Stress-Strain Curve

3.2.2. Deformation Characteristic Analysis

3.2.3. Tensile Strength

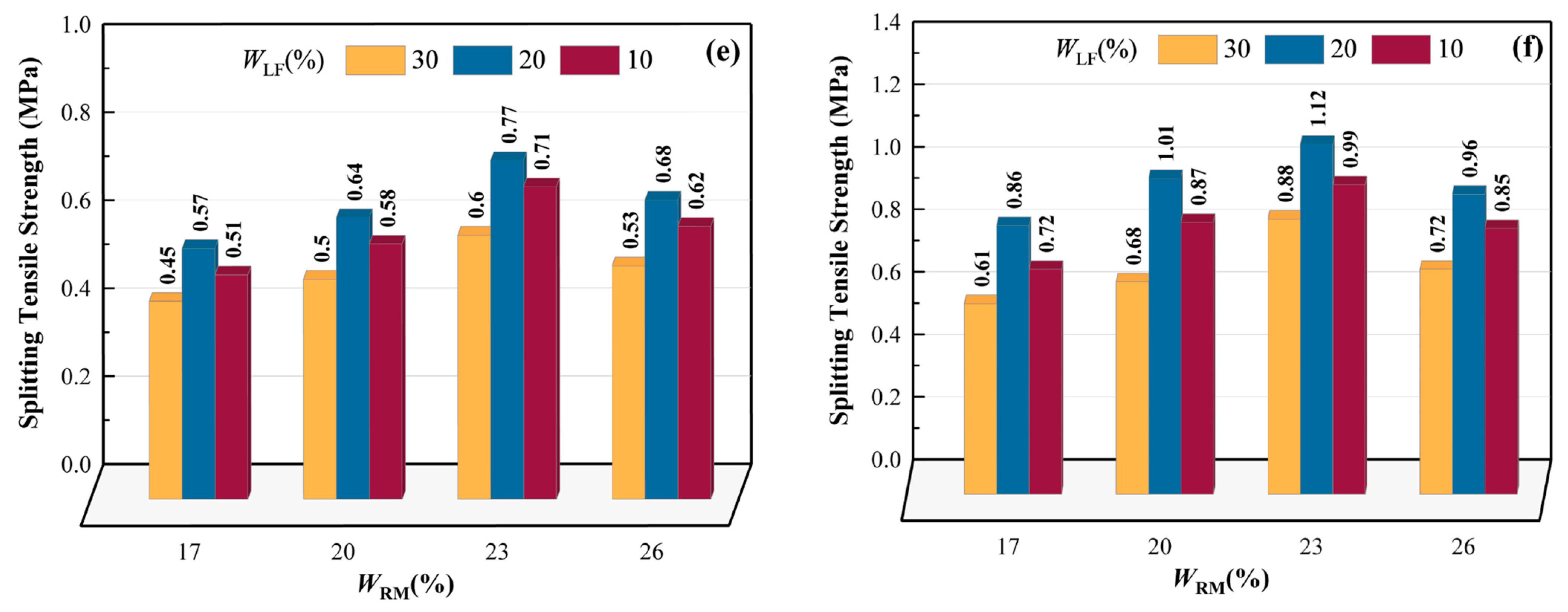

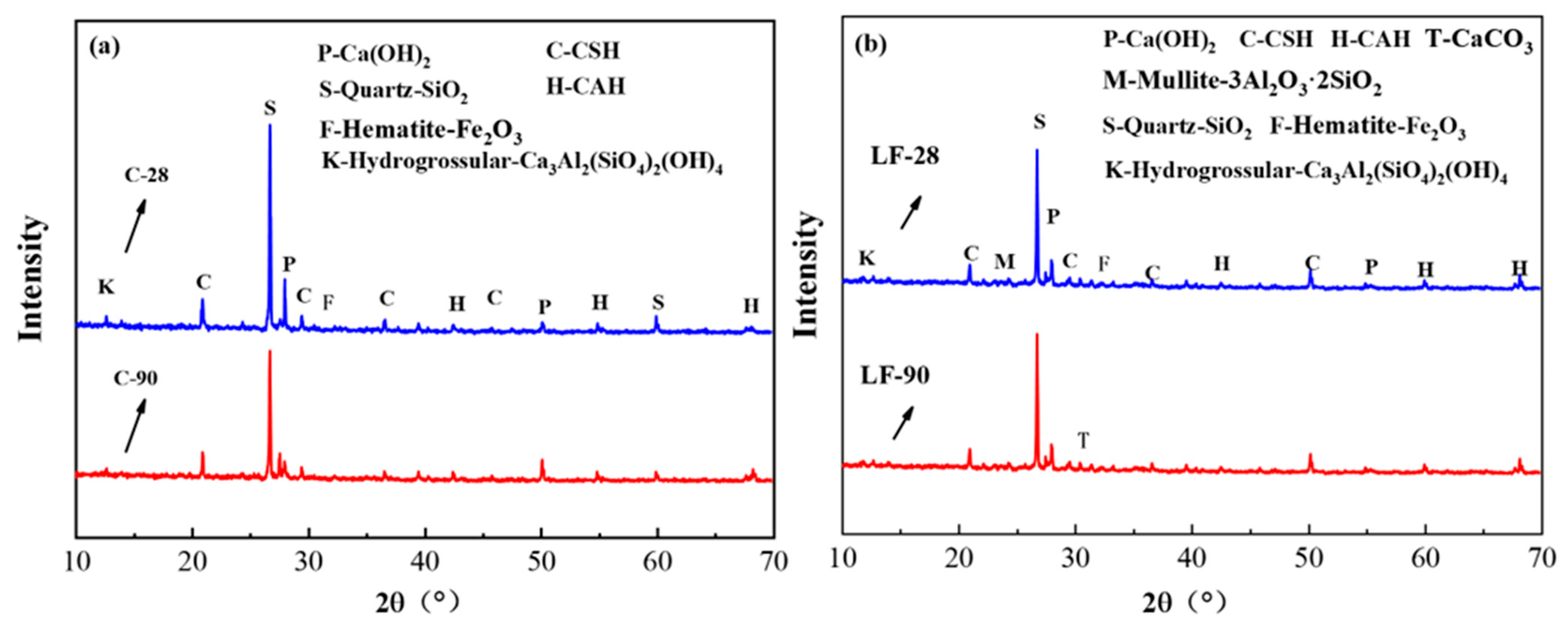

3.3. Comparative Analysis of Microscopic Experiments

3.3.1. Hydration Product Analysis

3.3.2. Thermogravimetric Analysis

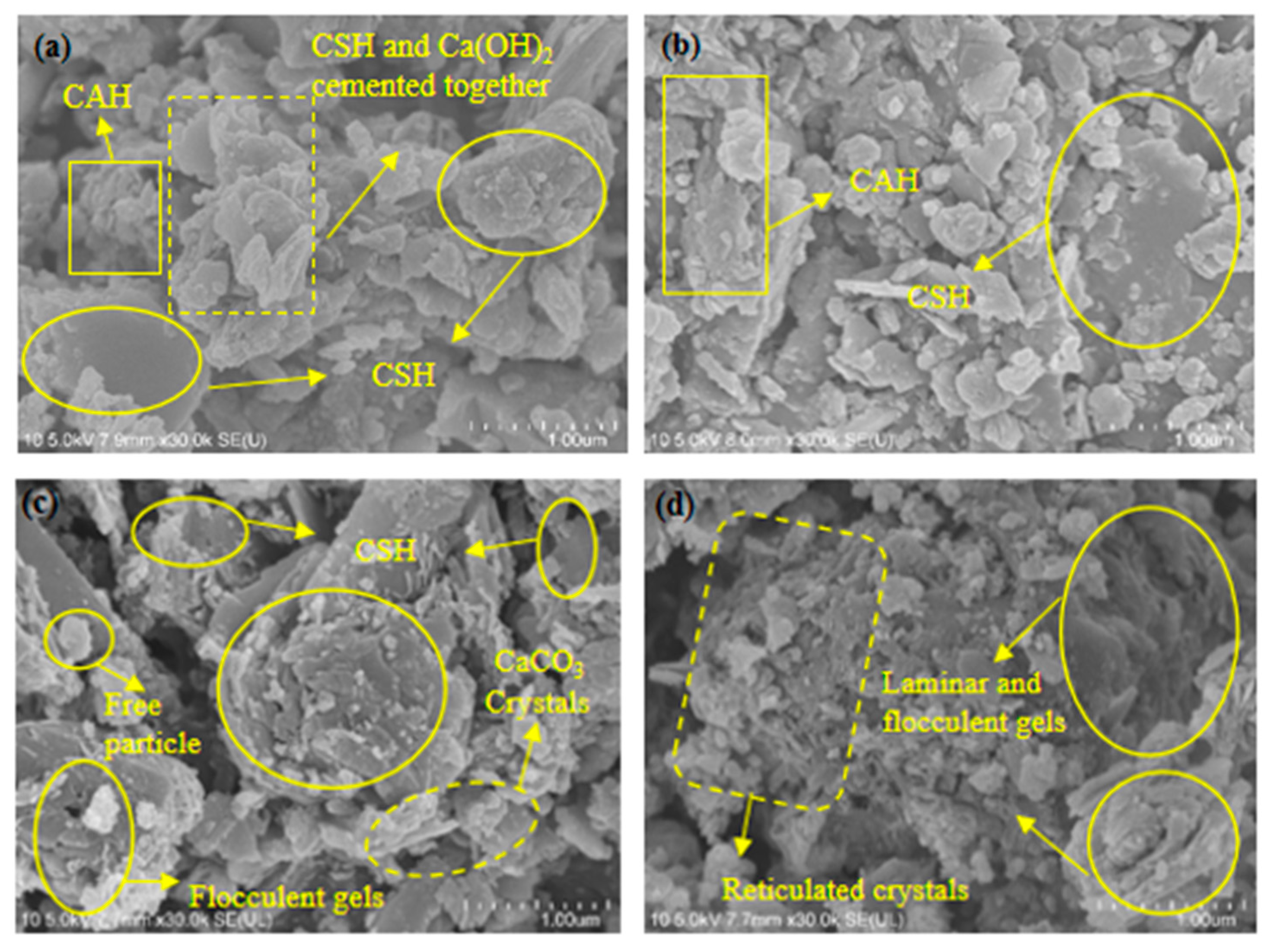

3.3.3. Microscopic Morphology Analysis

3.4. Environmental Impact Assessment

4. Conclusions

- (1)

- The brittle failure characteristics of C-RMS are evident. The maximum strength, optimal toughness, and deformation resistance of the specimen occur at a red mud content of 20%. In contrast, LF-RMS exhibits stronger plastic damage properties, with maximum strength and better deformation properties at 23% red mud content and 20% lime-fly ash content.

- (2)

- Although LF-RMS has lower strength compared to C-RMS, it has better toughness and can utilize more red mud, resulting in greater economic and environmental efficiency. Therefore, it is recommended to prioritize LF-RMS for low-grade highways with lower road strength requirements.

- (3)

- In the splitting tensile test, all specimens of the modified red mud-based silty soil display typical splitting tensile failure patterns, with a 90° vertical direction and an uneven fracture surface. Furthermore, the tensile failure strength and deformation characteristics of the modified red mud-based silty soil are consistent with those observed in their unconfined compressive strength tests.

- (4)

- According to the Technical Instructions for highway pavement base construction (JTG/TF20-2015), it is found that C-RMS can be used for the base of secondary and sub-secondary highways (3.5 MPa~4.5 MPa) or the base of expressways and first-class highways (2.5 MPa~3.5 MPa). LF-RMS can be used on the base of highways and primary roads (≥1.1 MPa) or the bottom base (≥0.8 MPa).

- (5)

- The primary hydration products of C-RMS and LF-RMS are calcium silicate hydrate (CSH), calcium aluminate hydrate (CAH), and Ca(OH)2. In the LF-RMS at a curing age of 90 days, some CaCO3 crystals are present. At a curing age of 90 days, both C-RMS and LF-RMS are most fully hydrated, producing the greatest amount of gel.

- (6)

- The environmental indices of modified red mud-based silty soil meet the requirements for roadbed filling. Although the environmental indices of LF-RMS are slightly inferior to those of C-RMS, the red mud-based modified silty soil shows significant improvement in environmental impact compared to pure red mud.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Patangia, J.; Saravanan, T.J.; Kabeer, K.S.A.; Bisht, K. Study on the utilization of red mud (bauxite waste) as a supplementary cementitious material: Pathway to attaining sustainable development goals. Constr. Build. Mater. 2023, 375, 131005. [Google Scholar] [CrossRef]

- Babisk, M.P.; Amaral, L.F.; da Silva Ribeiro, L.; Vieira, C.M.F.; do Prado, U.S.; Gadioli, M.C.B.; da Costa Garcia Filho, F.J. Evaluation and application of sintered red mud and its incorporated clay ceramics as materials for building construction. Mater. Res. Technol. 2020, 9, 2186–2195. [Google Scholar] [CrossRef]

- Agrawal, V.; Paulose, R.; Arya, R.; Rajak, G.; Giri, A.; Bijanu, A.; Salammal, S.T. Green conversion of hazardous red mud into diagnostic X-ray shielding tiles. J. Hazard. Mater. 2022, 424, 127507. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.; Wu, H.; Lv, Z.; Yu, H.; Tu, G. Recovery of valuable metals from red mud: A comprehensive review. Sci. Total Environ. 2023, 904, 166686. [Google Scholar] [CrossRef] [PubMed]

- Khanna, R.; Konyukhov, Y.V.; Burmistrov, I.; Cayumil, R.; Belov, V.A.; Rogachev, S.O.; Mukherjee, P.S. An innovative route for valorising iron and aluminium oxide rich industrial wastes: Recovery of multiple metals. J. Environ. Manag. 2021, 295, 113035. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Development and sustainability of industrial waste-based red mud hybrid composites. J. Clean. Prod. 2019, 30, 862–868. [Google Scholar] [CrossRef]

- Arroyo, F.; Luna-Galiano, Y.; Leiva, C.; Vilches, L.F.; Fernández-Pereira, C. Environmental risks and mechanical evaluation of recycling red mud in bricks. Environ. Res. 2020, 186, 109537. [Google Scholar] [CrossRef]

- Leiva, C.; Arroyo-Torralvo, F.; Luna-Galiano, Y.; Villegas, R.; Vilches, L.F.; Fernández Pereira, C. Valorization of Bayer red mud in a circular economy process: Valuable metals recovery and further brick manufacture. Processes 2022, 10, 2367. [Google Scholar] [CrossRef]

- Taneez, M.; Hurel, C. A review on the potential uses of red mud as amendment for pollution control in environmental media. Environ. Sci. Pollut. Res. 2019, 26, 22106–22125. [Google Scholar] [CrossRef]

- Kryvenko, P.; Rudenko, I.; Sikora, P.; Sanytsky, M.; Konstantynovskyi, O.; Kropyvnytska, T. Alkali-activated cements as sustainable materials for repairing building construction: A review. J. Build. Eng. 2024, 90, 109399. [Google Scholar] [CrossRef]

- Roy, S.K.; Nayak, D.; Rath, S.S. A review on the enrichment of iron values of low-grade Iron ore resources using reduction roasting-magnetic separation. Powder Technol. 2020, 367, 796–808. [Google Scholar] [CrossRef]

- Habibi, H.; Pirouzan, D.; Shakibania, S.; Pourkarimi, Z.; Mokmeli, M. Physical and chemical separation of Ti, rare earth elements, Fe, and Al from red mud by carbothermal reduction, magnetic separation, and leaching. Environ. Sci. Pollut. Res. 2022, 29, 62952. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, S.; Dhawan, N. Hydrogen reduction of red mud for extraction of metallic values. J. Sustain. Metall. 2023, 9, 386–397. [Google Scholar] [CrossRef]

- Agrawal, S.; Dhawan, N. Microwave acid baking of red mud for extraction of titanium and scandium values. Hydrometallurgy 2021, 4, 105704. [Google Scholar] [CrossRef]

- Loebsack, G.; Kang, K.; Klinghoffer, N.B.; Yeung, K.K.C.; Torsello, D.; Gerbaldo, R.; Berruti, F. Adsorption mechanisms and optimal production of magnetic biochar composites from red mud and soft wood biomass. J. Anal. Appl. Pyrol. 2024, 177, 106340. [Google Scholar] [CrossRef]

- Zhang, D.; Yan, K.; Liu, Y.; Naidu, R. Effects of phosphate, red mud, and biochar on As, Cd, and Cu immobilization and enzymatic activity in a Co-Contaminated soil. Processes 2022, 10, 1127. [Google Scholar] [CrossRef]

- Oprčkal, P.; Mladenovič, A.; Zupančič, N.; Ščančar, J.; Milačič, R.; Serjun, V.Z. Remediation of contaminated soil by red mud and paper ash. J. Clean. Prod. 2020, 256, 120440. [Google Scholar] [CrossRef]

- Xiao, R.; Nie, Q.; Dai, X.; Wan, Z.; Zhong, J.; Ma, Y.; Huang, B. Developing alkali-activated controlled low-strength material (CLSM) using urban waste glass and red mud for sustainable construction. J. Build. Eng. 2024, 98, 111202. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Fořt, J.; Klapiszewska, I.; Thomas, M.; Klapiszewski, Ł.; Černý, R.A. literature review of the latest trends and perspectives regarding alkali-activated materials in terms of sustainable development. J. Mater. Res. Technol. 2023, 25, 5394–5425. [Google Scholar] [CrossRef]

- Wang, C.; Liu, H.; Wu, D.; Liu, X. Engineering and environmental evaluation of red mud amended volcanic ash as a sustainable subgrade material. J. Clean. Prod. 2023, 393, 136353. [Google Scholar] [CrossRef]

- Singh, V.; Bano, S.; Chauhan, V.B.; Pal, P.; Kumar, A.; Srivastava, J.B. Red mud as a sustainable road construction material: An experimental investigation. Constr. Build. Mater. 2024, 411, 134549. [Google Scholar] [CrossRef]

- Salim, M.U.; Mosaberpanah, M.A.; Danish, A.; Ahmad, N.; Khalid, R.A.; Moro, C. Role of bauxite residue as a binding material and its effect on engineering properties of cementitious Composites: A review. Constr. Build. Mater. 2023, 409, 133844. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, A.; Sitharam, T.G. Experimental study on strength, durability, hydraulic and toxicity characteristics of soil treated with mine tailings based geopolymers for sustainable road subgrade application. Constr. Build. Mater. 2024, 414, 134894. [Google Scholar] [CrossRef]

- Saranya, V.; Karthiyaini, S.; Stone, D. Enhancement of strength and microstructural characterization in red mud-iron carbonate binders: Effects of CO2 sequestration and oxalic acid concentration. Results Eng. 2025, 25, 104539. [Google Scholar] [CrossRef]

- Du, Z.; Sheng, S.; Guo, J. Effect of composite activators on mechanical properties, hydration activity and microstructure of red mud-based geopolymer. J. Mater. Res. Technol. 2023, 24, 8077–8085. [Google Scholar] [CrossRef]

- Chandra, K.S.; Krishnaiah, S.; Reddy, N.G.; Hossiney, N.; Peng, L. Strength development of geopolymer composites made from red mud–fly ash as a subgrade material in road construction. J. Hazard. Toxic. Radio 2021, 1, 04020068. [Google Scholar] [CrossRef]

- Koshy, N.; Dondrob, K.; Hu, L.; Wen, Q.; Meegoda, J.N. Mechanical properties of geopolymers synthesized from fly ash and red mud under ambient conditions. Crystals 2019, 9, 572. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Li, Y.; Cao, W. Strength properties of Bayer red mud stabilized by lime-fly ash using orthogonal experiments. Constr. Build. Mater. 2018, 166, 554–563. [Google Scholar] [CrossRef]

- Panda, S.; Pradhan, M.; Panigrahi, S.K. Optimal Red Mud Replacement Level Evaluation in Conventional Concrete Based on Fresh and Hardened Concrete Characteristics. J. Sustain. Metall. 2024, 10, 835–850. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Z.; Yin, S.; Yan, P.; Wang, Y.; Li, X. Experimental study on the mixing ratio of cement and red mud to improve silty soil. Light. Met. 2023, 4, 13–20. [Google Scholar] [CrossRef]

- Suo, C.; Yao, X.; Song, Z.; Dong, X. Mechanical and leaching characteristics of red mud residue solidified/stabilized high Cu (II)-contaminated soil. Environ. Earth Sci. 2022, 81, 9. [Google Scholar] [CrossRef]

- Aziman, E.S.; Ismail, A.F.; Jubri, S.F.; Rahmat, M.A.; Idris, W.M.R. Environmental impact assessment of post illegal mining activities in Chini Lake with regards to natural radionuclides and heavy metals in water and sediment. J. Radioanal. Nucl. Chem. 2021, 330, 667–683. [Google Scholar] [CrossRef]

- Tastan, E.O.; Edil, T.B.; Benson, C.H.; Aydilek, A.H. Stabilization of organic soils with fly ash. J. Geotech. Geoenviron. 2011, 137, 819–833. [Google Scholar] [CrossRef]

- Somlai, J.; Jobbagy, V.; Kovacs, J.; Tarján, S.; Kovács, S.T. Radiological aspects of the usability of red mud as building material additive. J. Hazard. Mater. 2008, 150, 541–545. [Google Scholar] [CrossRef]

- Ozden, B.; Brennan, C.; Landsberger, S. Environmental assessment of red mud by determining natural radionuclides using neutron activation analysis. Environ. Earth Sci. 2019, 78, 114. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Bui, T.H.; Pham, V.T.H.Q.; Do, M.Q.; Hoang, M.D.; Le, V.Q. Leaching behavior and immobilization of heavy metals in geopolymer synthesized from red mud and fly ash. Key Eng. Mater. 2018, 777, 518–522. [Google Scholar] [CrossRef]

- Żak, R.; Deja, J. Spectroscopy study of Zn, Cd, Pb and Cr ions immobilization on C–S–H phase. Spectrochim. Acta A 2015, 134, 614–620. [Google Scholar] [CrossRef]

- Król, M.; Florek, P.; Marzec, M.; Wójcik, S.; Dziża, K.; Mozgawa, W. Structural studies of calcium silicate hydrate modified with heavy metal cations. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 321, 124681. [Google Scholar] [CrossRef]

- Król, M.; Florek, P.; Dziża, K.; Mozgawa, W. Spectroscopic studies of heavy metal cations influence on the structure of synthetic hydrated calcium aluminosilicates. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 294, 122559. [Google Scholar] [CrossRef]

- Yang, F.; Pang, F.; Xie, J.; Wang, W.; Wang, W.; Wang, Z. Leaching and solidification behavior of Cu2+, Cr3+ and Cd2+ in the hydration products of calcium sulfoaluminate cement. J. Build. Eng. 2020, 46, 103696. [Google Scholar] [CrossRef]

| Materials | Mass Fraction (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | Fe2O3 | CaO | TiO2 | K2O | MgO | Na2O | SO3 | Others | |

| Red mud | 20.10 | 13.28 | 3.32 | 32.02 | 3.81 | 0.35 | 1.16 | 10.90 | / | 15.06 |

| Silty soil | 9.58 | 67.89 | 5.97 | 3.04 | 2.86 | 1.75 | 2.82 | / | 0.46 | 5.63 |

| Lime | / | / | / | 95.6 | / | / | 0.96 | / | 0.06 | 3.38 |

| Fly ash | 36.3 | 42.6 | 1.95 | 4.6 | 1.15 | 0.52 | / | / | 0.06 | 12.88 |

| Materials | Specific Area (m2·kg−1) | Cl (%) | SO3 (%) | MgO (%) | Loss-on-Ignition (%) | Initial Setting Time (min) | Final Setting Time (min) | Stability |

|---|---|---|---|---|---|---|---|---|

| Cement | 352 | 0.043 | 2.77 | 3.51 | 3.51 | 209 | 291 | qualified |

| Fly ash | 326 | / | 0.06 | / | 15.2 | / | / | qualified |

| Test Items | Limiting Value (mg/L) | RM Test Result (mg/L) |

|---|---|---|

| Cu | 100 | 0.0441 |

| Zn | 100 | 0.00315 |

| Cd | 1 | 0.000042 |

| Pb | 5 | 0.000533 |

| Cr | 15 | 0.0371 |

| Cr (VI) | 5 | 0.000029 |

| Hg | 0.1 | 0.000099 |

| Be | 0.02 | / |

| Ba | 100 | 0.0319 |

| Ni | 5 | 0.00246 |

| Ag | 5 | / |

| As | 5 | 0.0109 |

| Se | 1 | 0.0258 |

| FL | 100 | 0.9 |

| Radionuclides | 226Ra | 232U | 40K |

|---|---|---|---|

| Radioactive specific activity/Bq·kg−1 | 508 | 265 | 1050 |

| Test Object | Red Mud Content WRM (%) | Cement Content Wc (%) | Lime-Fly Ash Content WLF (%) | Curing Age (d) |

|---|---|---|---|---|

| C-RMS | 14, 17, 20, 23 | 6, 9, 12 | 0 | 7, 28, 90 |

| LF-RMS | 17, 20, 23, 26 | 0 | 10, 20, 30 |

| Test Specimen | Specimen Number |

|---|---|

| 12% P + 20% RM (28 d) | C-1 |

| 9% P + 20% RM (28 d) | C-2 |

| 9% P + 23% RM (28 d) | C-3 |

| 9% P + 20% RM (90 d) | C-4 |

| 20% LF + 26% RM (28 d) | LF-1 |

| 30% LF + 23% RM (28 d) | LF-2 |

| 20% LF + 23% RM (28 d) | LF-3 |

| 20% LF + 23% RM (90 d) | LF-4 |

| Equipment Name | Model | Manufacturer | Sensitivity/Accuracy |

|---|---|---|---|

| Unconfined Compressive Strength Test | YYW-2 | Zhengzhou, Henan Province, China | The axial strain rate is 1 mm/min |

| X-ray diffraction analysis | Bruker D8 Advance | Munich, Germany | The working voltage is 20 to 60 kV, the current is 10 to 300 mA, the constant step size is 0.002° to 90°, and the scanning rate is 0.002 to 100°/min |

| Synchronous thermal analyzer | STA 499 F5 | Munich, Germany | The output pressure of the protective gas is 0.04 MPa, the heating rate is 20 °C/min, and the temperature range is 0–1000 °C |

| Scanning electron microscope. | SU8100 | Tokyo, Japan | The resolution is 1.3 nm/1.0 kV |

| γ spectrometer | FP-90041 | Zhengzhou, Henan Province, China | Its expanded uncertainty is less than 15%, the energy resolution is less than 7%, and the measurable range of nuclide activity is 10 Bq to 2 kBq |

| Functional Module | Detailed Description | Characteristics |

|---|---|---|

| Support for dark mode | Supports dark mode independent of system themes, provides multiple built-in dark themes, and allows for the customization of chart background colors | Enhance visual comfort and be suitable for long-term use |

| Interactively adjust the axis scale | Click and drag the red dot at the end of the axis to set the start and end values, supporting real-time drawing effects | Convenient operation and real-time feedback |

| Browser graph based on worksheet | Data can be selected from multiple worksheets for plotting, facilitating quick chart updates | Improve the visualization efficiency of multiple datasets |

| Interactive data extraction | Data can be interactively selected on the chart and extracted to a new worksheet | Facilitate the further analysis of the data |

| Radionuclides | 226Ra | 232U | 40K |

|---|---|---|---|

| RM (Bq·kg−1) | 508 | 265 | 1050 |

| C-RMS (Bq·kg−1) | 103 | 52 | 198 |

| LF-RMS (Bq·kg-1) | 181 | 97 | 332 |

| Test Item | C-RMS Toxicity Reduction (%) | LF-RMS Toxicity Reduction (%) |

|---|---|---|

| Cu | 97.3 | 80.5 |

| Zn | 87.2 | 75 |

| Cd | 45.5 | 90 |

| Pb | 97 | 95.5 |

| Cr | 98 | 75.6 |

| Cr (VI) | 100 | 62.8 |

| Hg | 100 | 88 |

| Ba | 99 | 96 |

| Ni | 100 | 98 |

| As | 90.5 | 50 |

| Se | 87 | 85.5 |

| FL | 51.1 | 41.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Li, Y.; Li, X.; Wang, P.; Wang, Z.; Wang, Y. Evaluation of Mechanical Properties and Environmental Impact of Red Mud-Based Silty Soil Modified by Inorganic Binding Materials. Processes 2025, 13, 1955. https://doi.org/10.3390/pr13071955

Yin S, Li Y, Li X, Wang P, Wang Z, Wang Y. Evaluation of Mechanical Properties and Environmental Impact of Red Mud-Based Silty Soil Modified by Inorganic Binding Materials. Processes. 2025; 13(7):1955. https://doi.org/10.3390/pr13071955

Chicago/Turabian StyleYin, Song, Yuru Li, Xinming Li, Ping Wang, Zhiliu Wang, and Yulong Wang. 2025. "Evaluation of Mechanical Properties and Environmental Impact of Red Mud-Based Silty Soil Modified by Inorganic Binding Materials" Processes 13, no. 7: 1955. https://doi.org/10.3390/pr13071955

APA StyleYin, S., Li, Y., Li, X., Wang, P., Wang, Z., & Wang, Y. (2025). Evaluation of Mechanical Properties and Environmental Impact of Red Mud-Based Silty Soil Modified by Inorganic Binding Materials. Processes, 13(7), 1955. https://doi.org/10.3390/pr13071955