Impact of Ammonia Energy Ratio on the Performance of an Ammonia/Diesel Dual-Fuel Direct Injection Engine Across Different Combustion Modes

Abstract

1. Introduction

2. Methodology

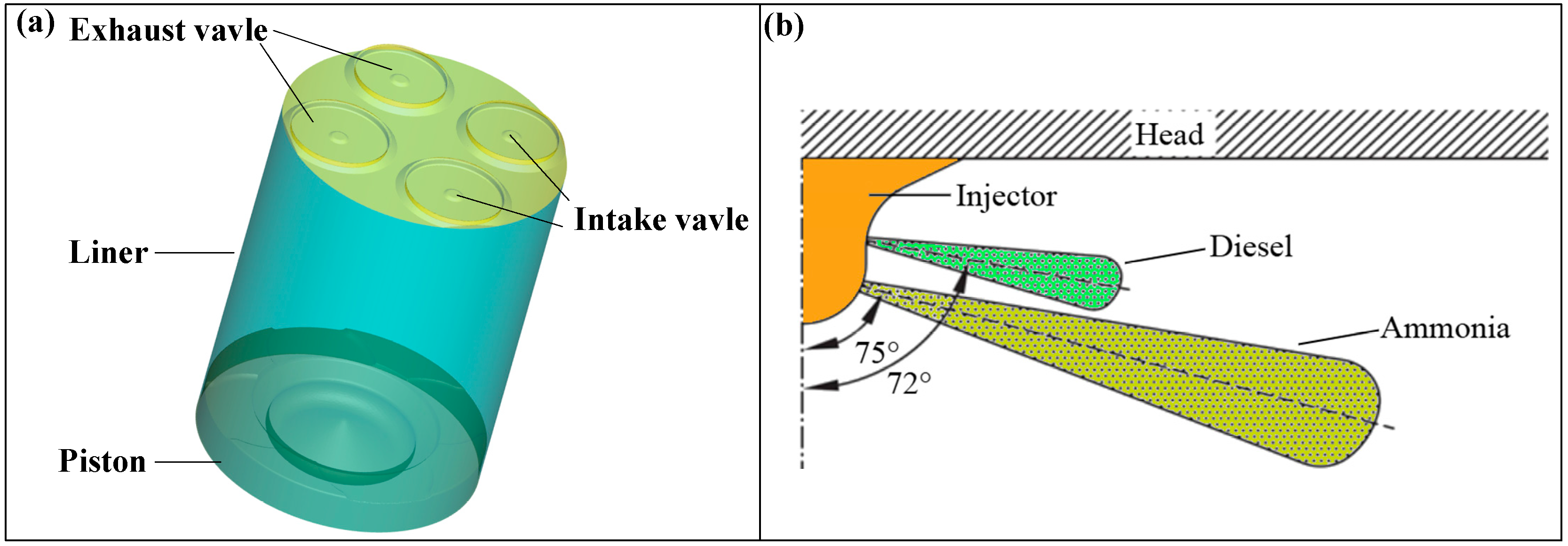

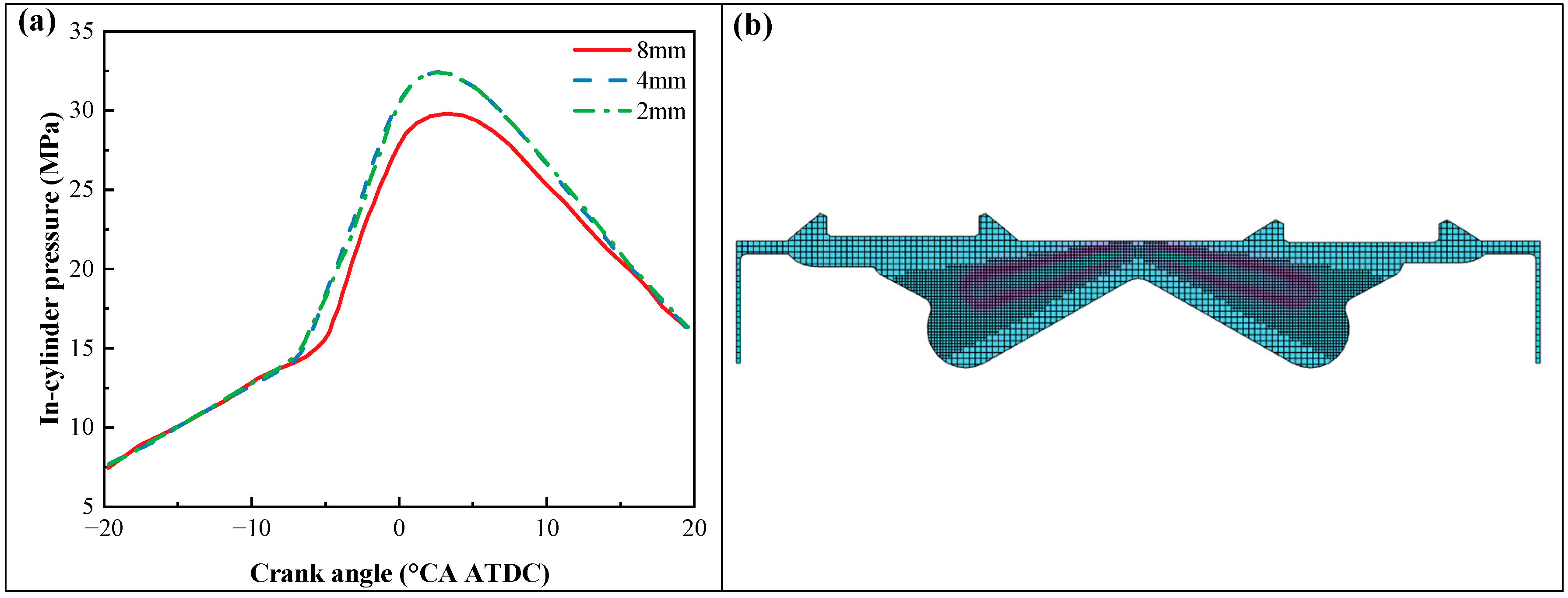

2.1. Construction of the Numerical Model

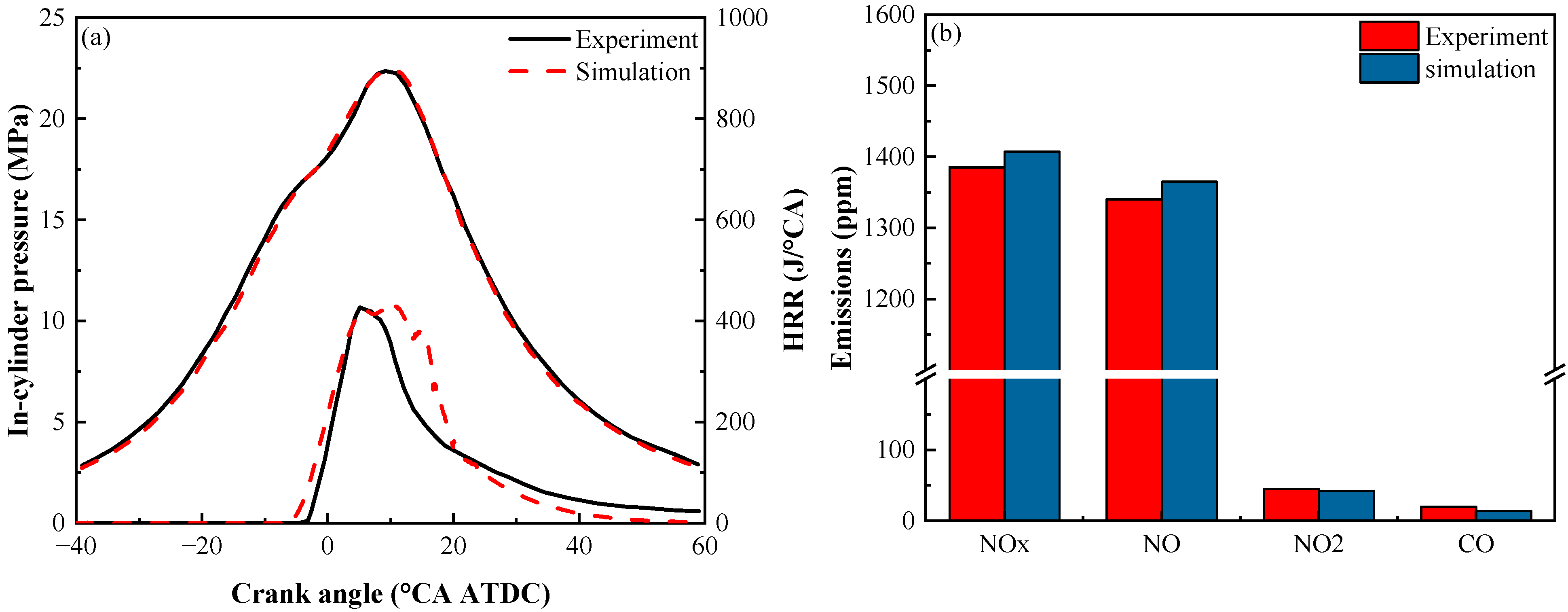

2.2. Validation of Numerical Model

2.3. Case Setup

3. Results and Discussion

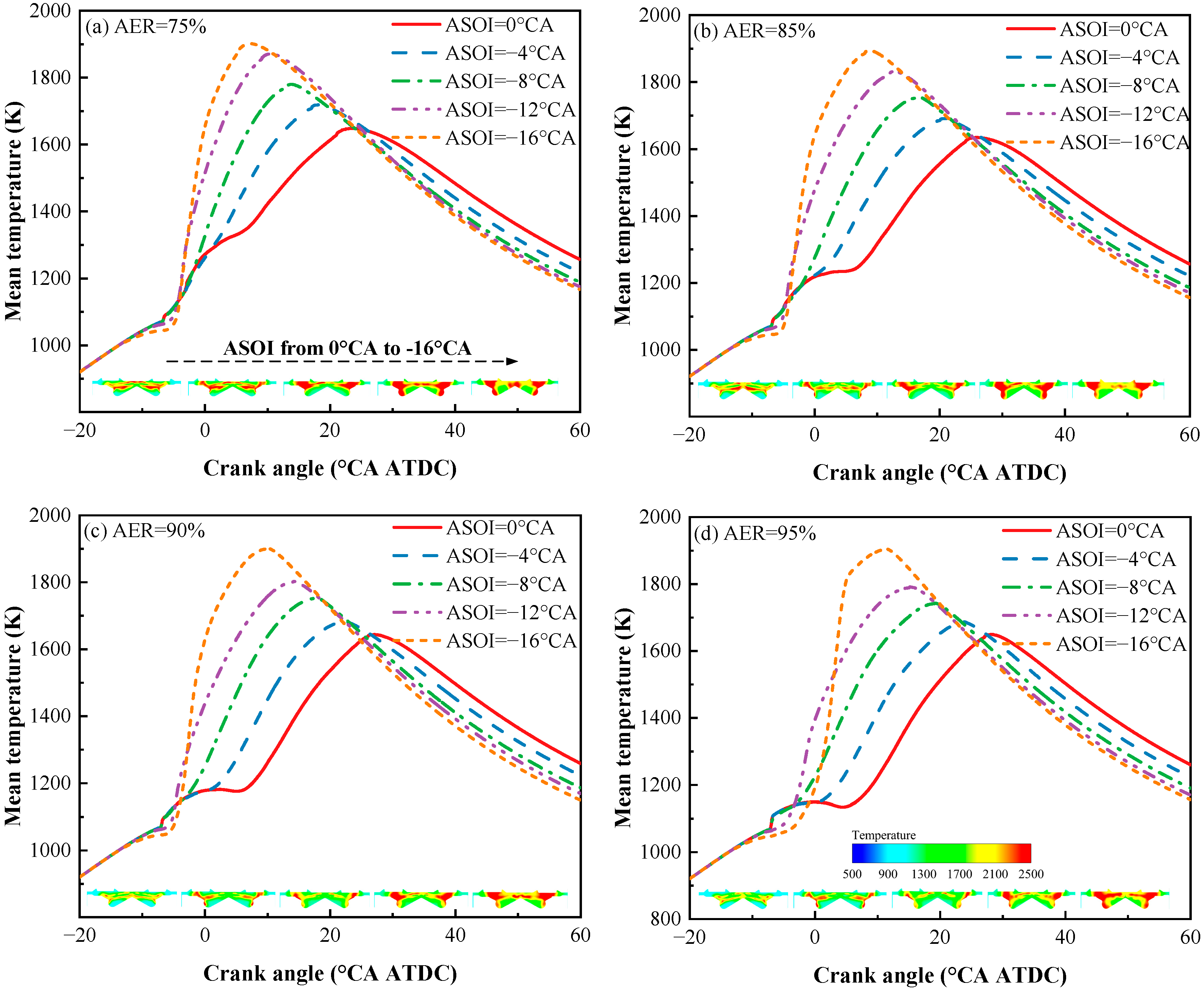

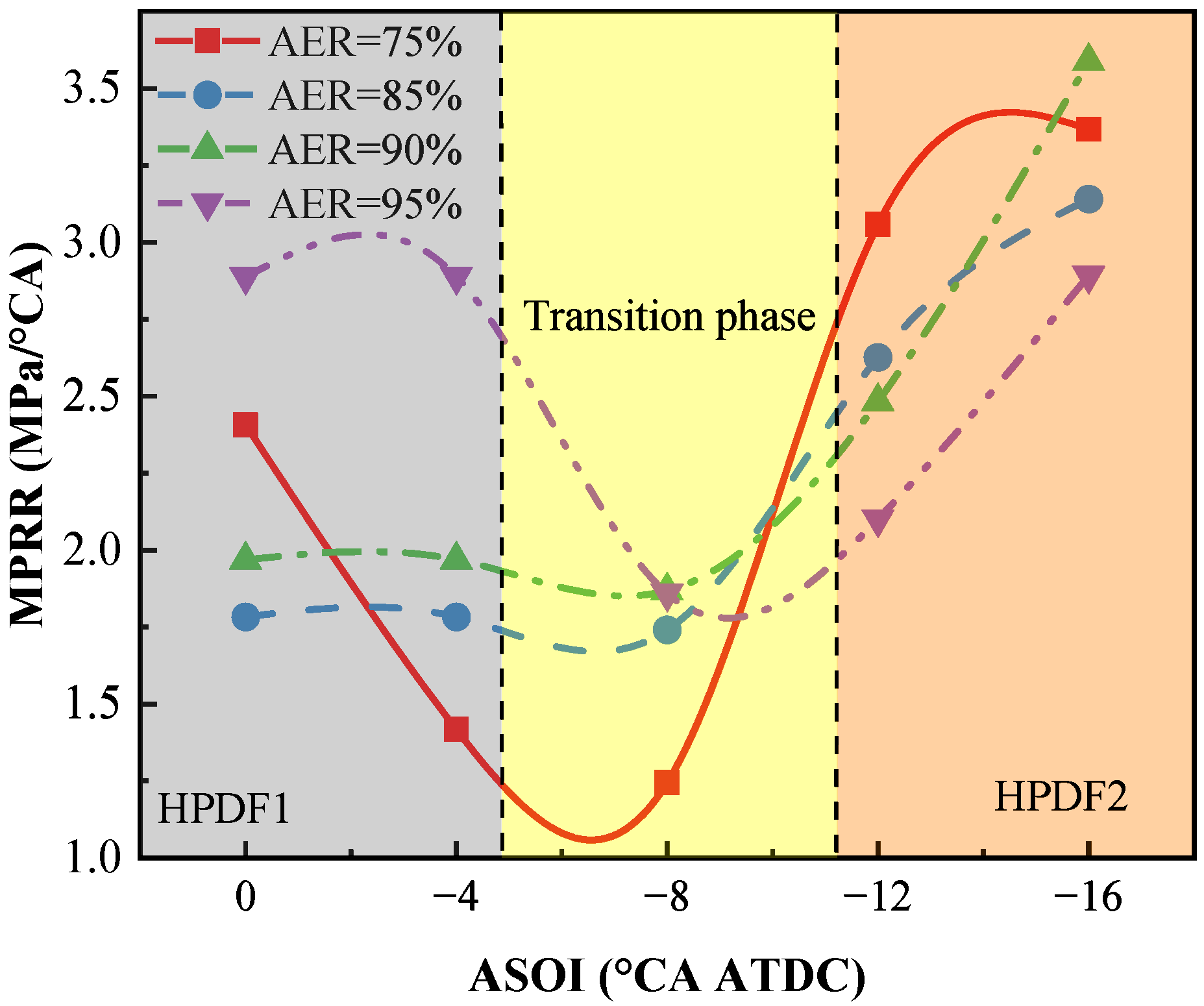

3.1. Combustion Characteristics

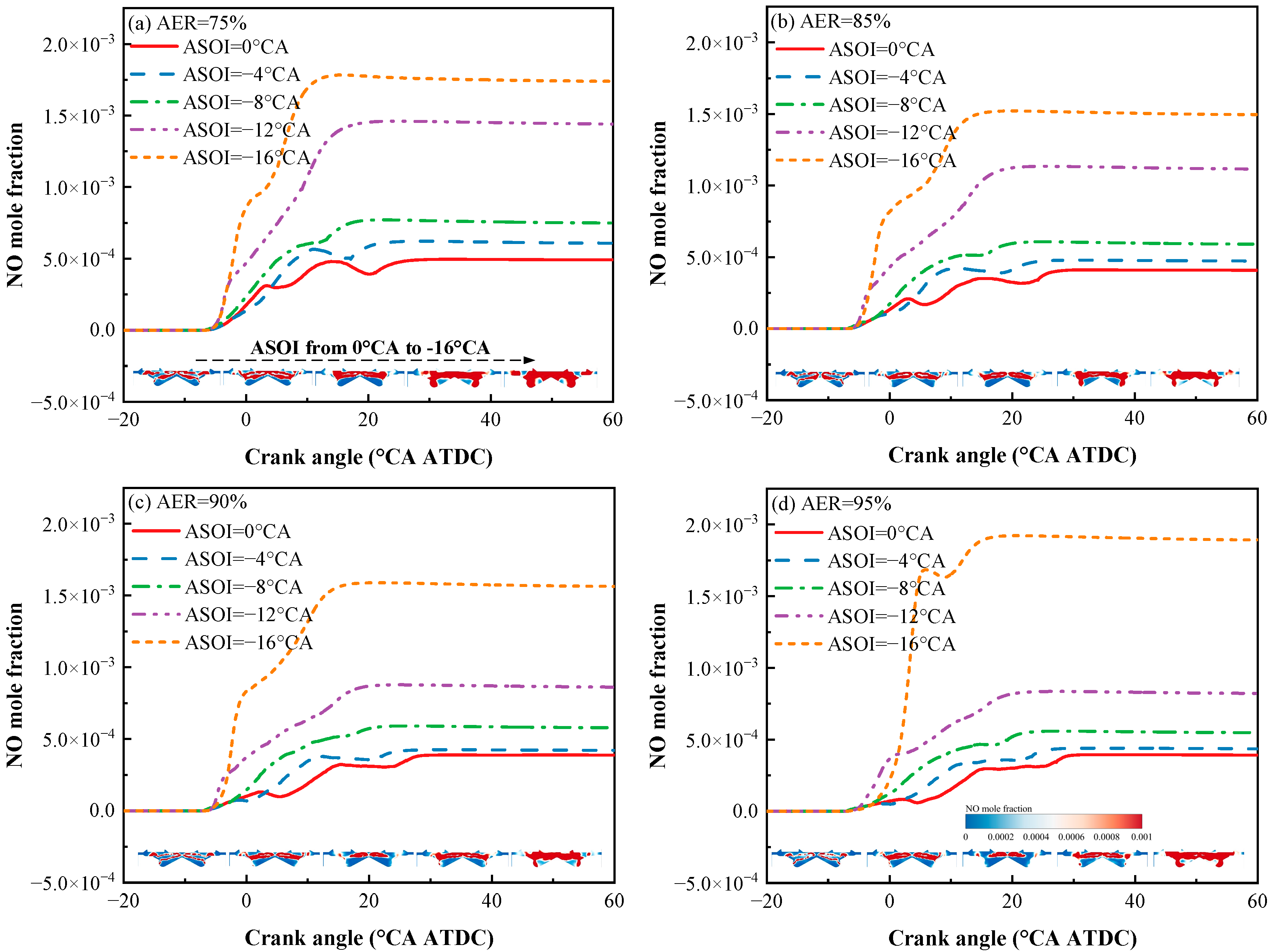

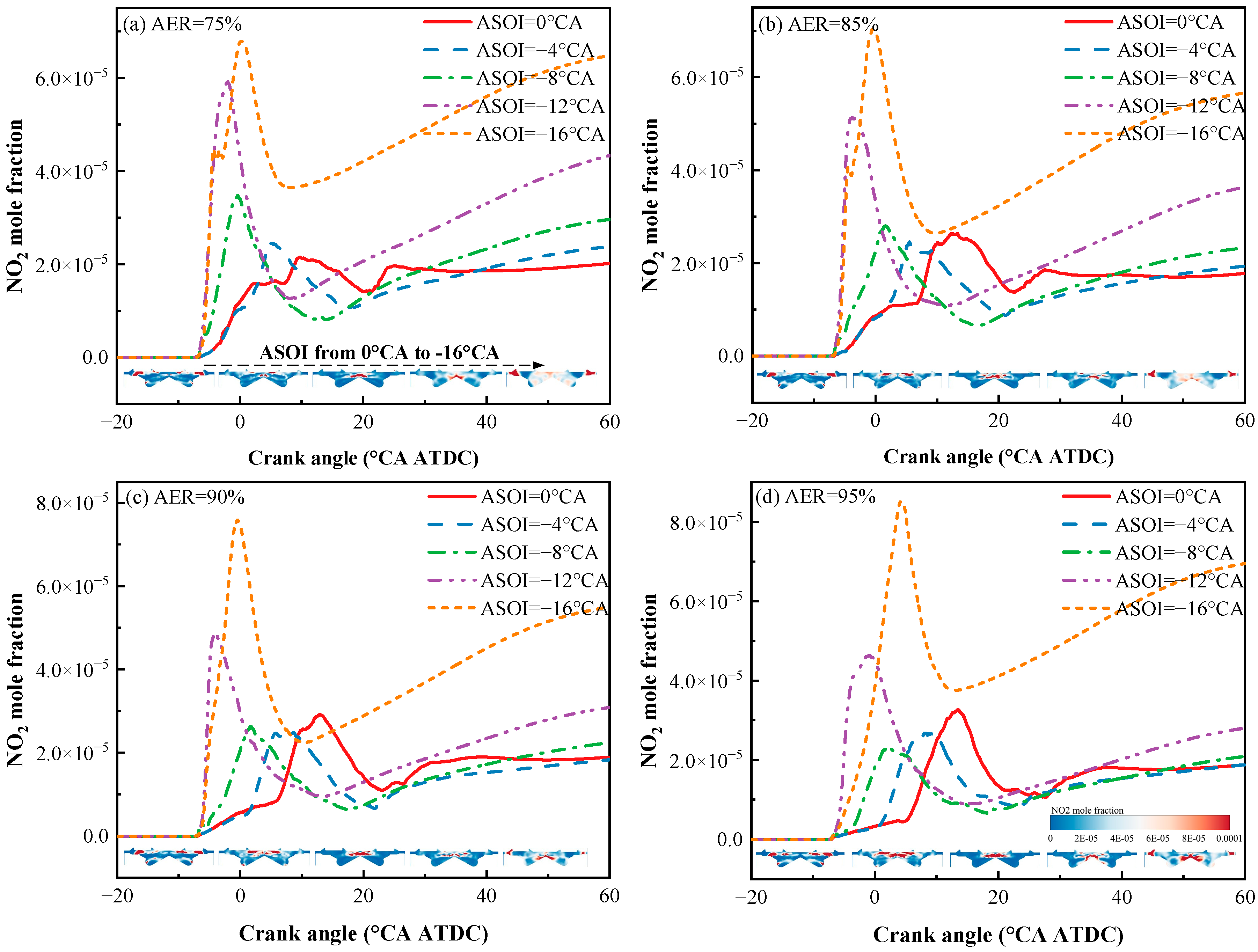

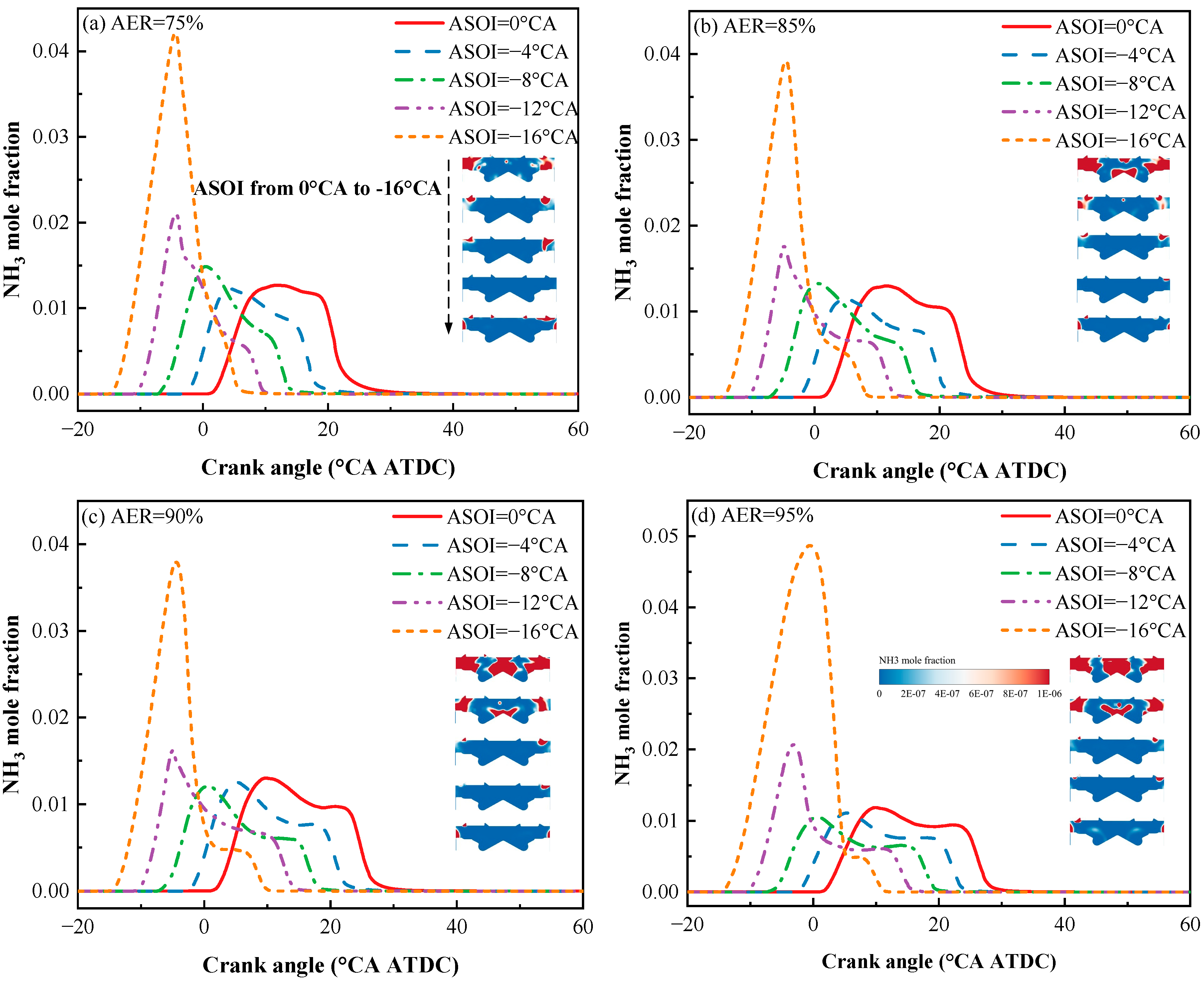

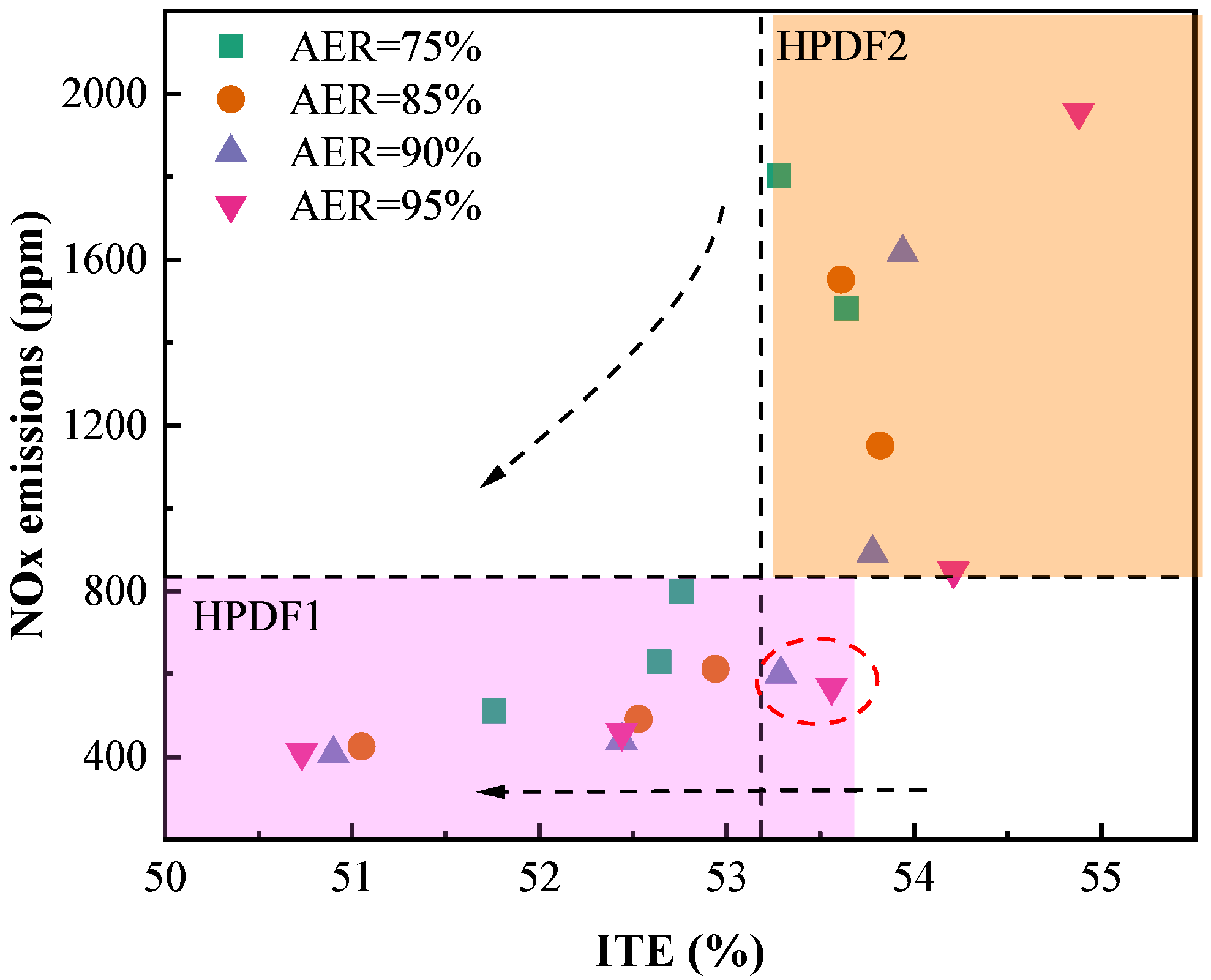

3.2. Emission Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dimitriou, P.; Javaid, R. A review of ammonia as a compression ignition engine fuel. Int. J. Hydrogen Energy 2020, 45, 7098–7118. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.; Lai, S.; Li, J.; Huang, H.; Kobayashi, N. Numerical simulation and spray model development of liquid ammonia injection under diesel-engine conditions. Energy 2024, 294, 130833. [Google Scholar] [CrossRef]

- Daniel Tang, K.H. Climate change policies of the four largest global emitters of greenhouse gases: Their similarities, differences and way forward. J. Energy Res. Rev. 2022, 10, 19–35. [Google Scholar] [CrossRef]

- Akal, D.; Öztuna, S.; Büyükakın, M.K. A review of hydrogen usage in internal combustion engines (gasoline-lpg-diesel) from combustion performance aspect. Int. J. Hydrogen Energy 2020, 45, 35257–35268. [Google Scholar] [CrossRef]

- Wang, W.; Fan, L.W.; Zhou, P. Evolution of global fossil fuel trade dependencies. Energy 2022, 238, 121924. [Google Scholar] [CrossRef]

- Serrano, R.; Uriondo, Z.; Del Portillo, L.; Basterretxea, A. A study on the optimal adjustment of a turbocharged marine compression-ignition engine with double pilot fuel injection operating under a diesel—h2 dual fuel. Appl. Therm. Eng. 2025, 270, 126233. [Google Scholar] [CrossRef]

- Kojima, Y.; Yamaguchi, M. Ammonia as a hydrogen energy carrier. Int. J. Hydrogen Energy 2022, 47, 22832–22839. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.D.K.A.; Okafor, E.C. Science and technology of ammonia combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Cheng, Q.; Muhammad, A.; Kaario, O.; Ahmad, Z.; Martti, L. Ammonia as a sustainable fuel: Review and novel strategies. Renew. Sustain. Energy Rev. 2025, 207, 114995. [Google Scholar] [CrossRef]

- Chiong, M.-C.; Chong, C.T.; Ng, J.-H.; Mashruk, S.; Chong, W.W.F.; Samiran, N.A.; Mong, G.R.; Valera-Medina, A. Advancements of combustion technologies in the ammonia-fuelled engines. Energy Convers. Manag. 2021, 244, 114460. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, D.; Yang, W.; Qian, Y.; Mao, Y.; Lu, X. Investigation on the potential of using carbon-free ammonia in large two-stroke marine engines by dual-fuel combustion strategy. Energy 2023, 263, 125748. [Google Scholar] [CrossRef]

- Khateeb, A.A.; Guiberti, T.F.; Zhu, X.; Younes, M.; Jamal, A.; Roberts, W.L. Stability limits and no emissions of technically-premixed ammonia-hydrogen-nitrogen-air swirl flames. Int. J. Hydrogen Energy 2020, 45, 22008–22018. [Google Scholar] [CrossRef]

- Zi, Z.; Jin, S.; Shi, T.; Zhu, L.; Wu, B. Effect of ammonia energy fraction and diesel injection strategy on load extension and greenhouse gas reduction potential of ammonia-diesel premixed-charge compression ignition engine. Fuel 2025, 398, 135351. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Dev, S.; Liko, B.; Lafrance, S. Effects of ammonia energy fraction and diesel injection timing on combustion and emissions of an ammonia/diesel dual-fuel engine. Fuel 2022, 314, 122723. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Dev, S.; Lafrance, S.; Liko, B. A study on split diesel injection on thermal efficiency and emissions of an ammonia/diesel dual-fuel engine. Fuel 2022, 316, 123412. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, D.; Jin, S.; Gu, Y.; Wu, C.; Wu, B. A quantitative study on the combustion and emission characteristics of an ammonia-diesel dual-fuel (addf) engine. Fuel Process. Technol. 2023, 250, 107906. [Google Scholar] [CrossRef]

- Yang, R.; Yue, Z.; Zhang, S.; Yu, Z.; Wang, H.; Liu, H.; Yao, M. A novel approach of in-cylinder nox control by inner selective non-catalytic reduction effect for high-pressure direct-injection ammonia engine. Fuel 2025, 381, 133349. [Google Scholar] [CrossRef]

- Li, T.; Zhou, X.; Wang, N.; Wang, X.; Chen, R.; Li, S.; Yi, P. A comparison between low- and high-pressure injection dual-fuel modes of diesel-pilot-ignition ammonia combustion engines. J. Energy Inst. 2022, 102, 362–373. [Google Scholar] [CrossRef]

- Scharl, V.; Sattelmayer, T. Ignition and combustion characteristics of diesel piloted ammonia injections. Fuel Commun. 2022, 11, 100068. [Google Scholar] [CrossRef]

- Zhou, X.; Li, T.; Wang, N.; Wang, X.; Chen, R.; Li, S. Pilot diesel-ignited ammonia dual fuel low-speed marine engines: A comparative analysis of ammonia premixed and high-pressure spray combustion modes with cfd simulation. Renew. Sustain. Energy Rev. 2023, 173, 113108. [Google Scholar] [CrossRef]

- Zhang, Z.; Long, W.; Dong, P.; Tian, H.; Tian, J.; Li, B.; Wang, Y. Performance characteristics of a two-stroke low speed engine applying ammonia/diesel dual direct injection strategy. Fuel 2023, 332, 126086. [Google Scholar] [CrossRef]

- Bjørgen, K.O.P.; Emberson, D.R.; Løvås, T. Combustion of liquid ammonia and diesel in a compression ignition engine operated in high-pressure dual fuel mode. Fuel 2024, 360, 130269. [Google Scholar] [CrossRef]

- Zuo, Q.; Chen, L.; Chen, W.; Zhu, G.; Wang, Z.; Ma, Y.; Shen, Z.; Lu, C. Performance analysis of ammonia energy ratio on an ammonia-diesel engine in different fuel supply modes. Fuel 2025, 384, 134038. [Google Scholar] [CrossRef]

- Qian, F.; Zhang, S.; Wang, J.; Zhu, N.; Bao, X.; Yang, H.; Xu, X.; Alshahrani, W.A.; Helal, M.H.; Guo, Z. Ammonia Energy Fraction Effect on the Combustion and Reduced NOX Emission of Ammonia/Diesel Dual Fuel. Environ. Res. 2024, 261, 119530. [Google Scholar] [CrossRef]

- Wu, B.; Zi, Z.; Jin, S.; Pei, Y.; Wang, D. Effect of diesel injection strategy and ammonia energy fraction on ammonia-diesel premixed-charge compression ignition combustion and emissions. Fuel 2024, 357, 129785. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J. Experimental investigation of the effect of ammonia substitution ratio on an ammonia-diesel dual-fuel engine performance. J. Clean. Prod. 2024, 434, 140274. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, Q.; Liu, H.; Yang, R.; Yao, M. Numerical investigation and optimization of the ammonia/diesel dual fuel engine combustion under high ammonia substitution ratio. J. Energy Inst. 2024, 117, 101797. [Google Scholar] [CrossRef]

- Mi, S.; Wu, H.; Pei, X.; Liu, C.; Zheng, L.; Zhao, W.; Qian, Y.; Lu, X. Potential of ammonia energy fraction and diesel pilot-injection strategy on improving combustion and emission performance in an ammonia-diesel dual fuel engine. Fuel 2023, 343, 127889. [Google Scholar] [CrossRef]

- Han, Z.; Reitz, R.D. Turbulence modeling of internal combustion engines using rng κ-ε models. Combust. Sci. Technol. 1995, 106, 267–295. [Google Scholar] [CrossRef]

- Wang, H.; Ji, C.; Wang, D.; Wang, Z.; Yang, J.; Meng, H.; Shi, C.; Wang, S.; Wang, X.; Ge, Y.; et al. Investigation on the potential of using carbon-free ammonia and hydrogen in small-scaled wankel rotary engines. Energy 2023, 283, 129166. [Google Scholar] [CrossRef]

- Reitz, R.D.; Beale, J.C. Modeling spray atomization with the kelvin-helmholtz/rayleigh-taylor hybrid model. At. Sprays 1999, 9, 623–650. [Google Scholar] [CrossRef]

- Schmidt, D.P.; Rutland, C.J. A new droplet collision algorithm. J. Comput. Phys. 2000, 164, 62–80. [Google Scholar] [CrossRef]

- Wang, B.; Wang, H.; Yang, C.; Hu, D.; Duan, B.; Wang, Y. Effect of different ammonia/methanol ratios on engine combustion and emission performance. Appl. Therm. Eng. 2024, 236, 121519. [Google Scholar] [CrossRef]

- Reitz, R. Development and testing of diesel engine cfd models. Prog. Energy Combust. Sci. 1995, 21, 173–196. [Google Scholar] [CrossRef]

- Wang, B.; Yang, C.; Wang, H.; Hu, D.; Wang, Y. Effect of diesel-ignited ammonia/hydrogen mixture fuel combustion on engine combustion and emission performance. Fuel 2023, 331, 125865. [Google Scholar] [CrossRef]

- Xu, L.; Chang, Y.; Treacy, M.; Zhou, Y.; Jia, M.; Bai, X.S. A skeletal chemical kinetic mechanism for ammonia/n-heptane combustion. Fuel 2023, 331, 125830. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Bore (mm) | 138 |

| Stroke (mm) | 165 |

| Connecting rod (mm) | 258.5 |

| Compression ratio | 22.69 |

| Speed (r/min) | 1100 |

| Intake valve close (°CA ATDC) | −166 |

| Exhaust valve open (°CA ATDC) | 134 |

| No. diesel injector hole × diameter (mm) | 10 × 0.213 |

| No. ammonia injector hole × diameter (mm) | 10 × 0.3 |

| Injection pressure (MPa) | 80 (diesel)/80 (ammonia) |

| Item | Value |

|---|---|

| Initial pressure (bar) | 2.66 |

| Initial temperature (K) | 370 |

| Piston temperature (K) | 550 |

| Cylinder wall temperature (K) | 500 |

| Cylinder head temperature (K) | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Yang, S.; Li, Y. Impact of Ammonia Energy Ratio on the Performance of an Ammonia/Diesel Dual-Fuel Direct Injection Engine Across Different Combustion Modes. Processes 2025, 13, 1953. https://doi.org/10.3390/pr13071953

Li C, Yang S, Li Y. Impact of Ammonia Energy Ratio on the Performance of an Ammonia/Diesel Dual-Fuel Direct Injection Engine Across Different Combustion Modes. Processes. 2025; 13(7):1953. https://doi.org/10.3390/pr13071953

Chicago/Turabian StyleLi, Cheng, Sheng Yang, and Yuqiang Li. 2025. "Impact of Ammonia Energy Ratio on the Performance of an Ammonia/Diesel Dual-Fuel Direct Injection Engine Across Different Combustion Modes" Processes 13, no. 7: 1953. https://doi.org/10.3390/pr13071953

APA StyleLi, C., Yang, S., & Li, Y. (2025). Impact of Ammonia Energy Ratio on the Performance of an Ammonia/Diesel Dual-Fuel Direct Injection Engine Across Different Combustion Modes. Processes, 13(7), 1953. https://doi.org/10.3390/pr13071953