1. Introduction

Generally, the air conditioners that we see in our daily life obtain a high COP by exchanging heat with outdoor air through an outdoor unit. On the other hand, an indirect geothermal heat pump system exchanges heat with a low-temperature heat source that exists 50 to 100 m underground, rather than with the outside air. This method has been reported to have a higher COP than ordinary air conditioners, and is being promoted in many countries around the world [

1,

2,

3].

To further improve the energy-saving performance of geothermal heat pumps, research into and development of a direct-expansion geothermal heat pump system is underway at the University of Yamanashi [

4,

5,

6,

7]. The biggest challenge regarding this system is reducing the cost of underground excavation. Although the direct expansion method has made it possible to reduce the excavation cost to a fraction of that with conventional systems, the cost is still high compared to that of conventional air conditioners.

In this study, we focused on the design of geothermal air conditioners with aims to reduce development costs and establish a system for long-term, large-scale demonstration operations. Conventional air conditioners have been in operation for several decades, and manufacturers and distributors have accumulated long-term operation data for their components. However, new air conditioners differ significantly from conventional models in terms of equipment configuration and control methods, and new failure factors may occur, making it essential to accumulate long-term operational data. In particular, long-term, large-scale demonstration runs are necessary to quickly identify and resolve low-frequency failure factors that may be overlooked in small-scale demonstrations. Therefore, it is desirable to conduct large-scale demonstration operations as soon as possible while minimizing design changes and reducing initial costs.

In recent years, the shortage of skilled workers due to the declining birthrate and aging population has become an issue for the entire industry, and building construction sites are no exception. Therefore, in the installation of geothermal air conditioners, it is necessary to devise a design that allows for the installation of the air conditioner and underground piping to be performed separately.

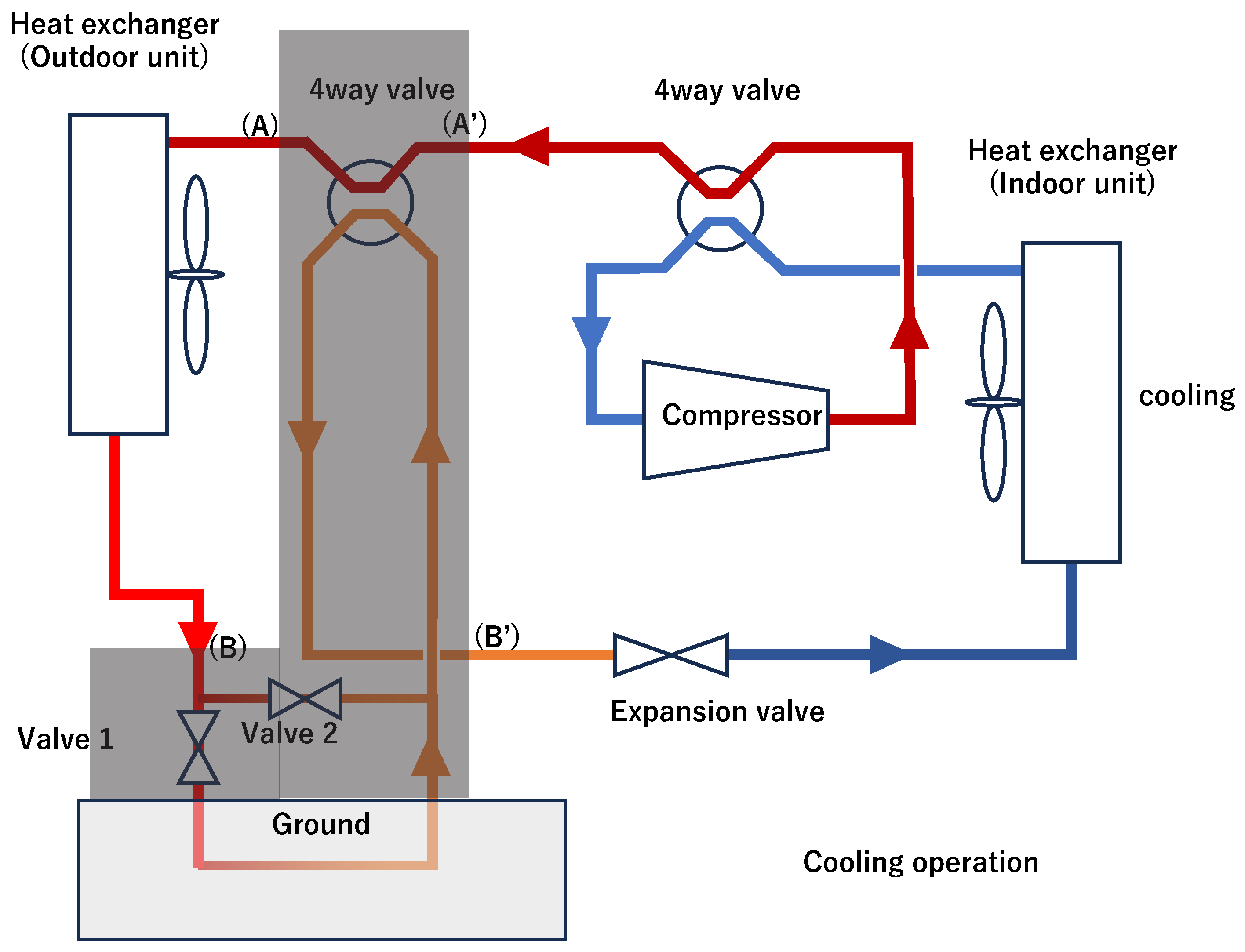

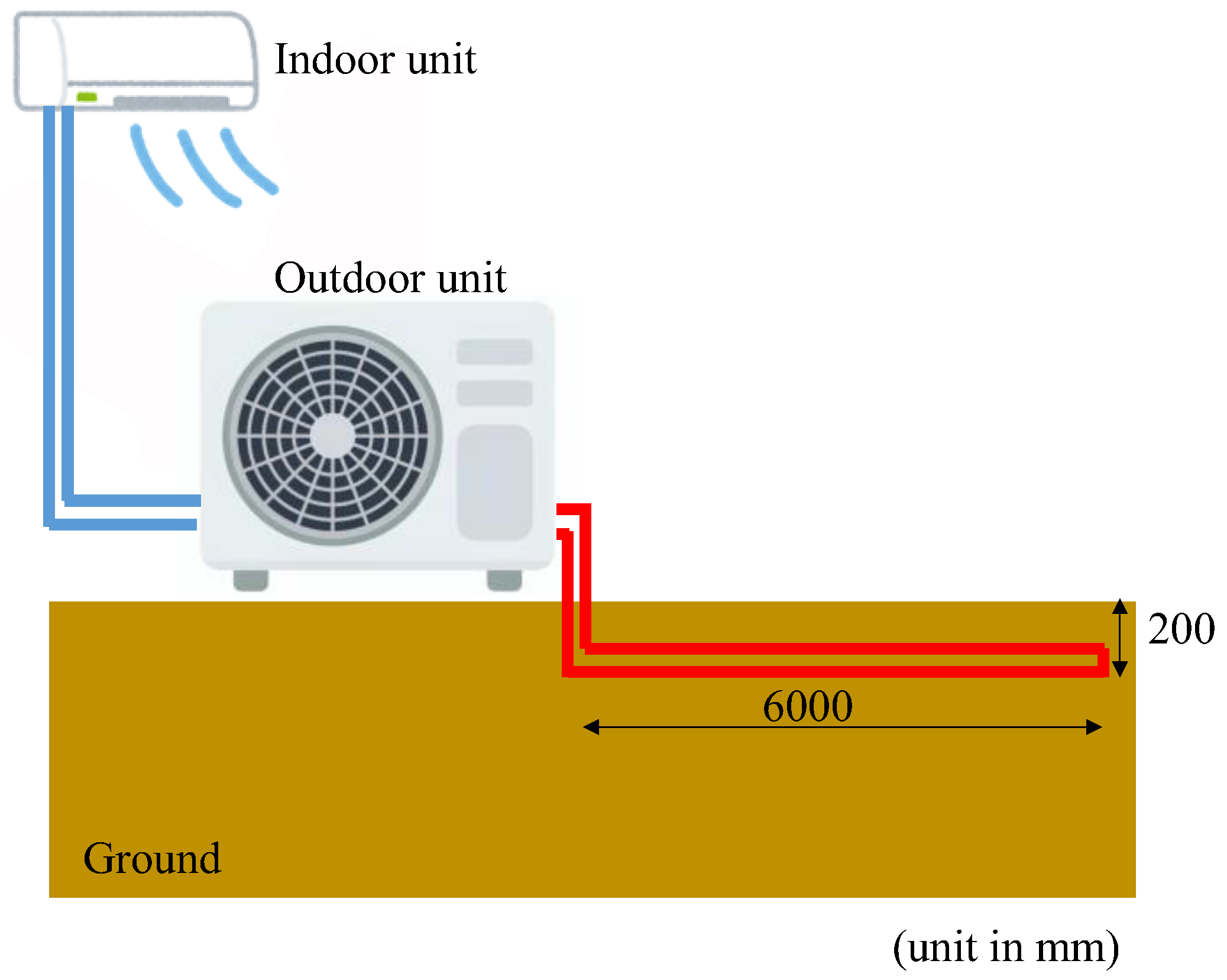

Therefore, a hybrid geothermal air conditioner (

Figure 1) that (1) does not change the control system of a conventional air conditioner, (2) achieves geothermal heat exchange with a minimum specification change of bypassing two points of refrigerant piping, and (3) can be commissioned without underground piping in the same way as a conventional air conditioner is proposed.

Figure 1 illustrates the hybrid system, showing the bypass flow paths and four-way valve integrating the ground heat exchanger. The purpose of this study is to evaluate the performance of the hybrid geothermal air conditioner (

Figure 1) and to identify any associated issues. A geothermal air conditioner in this configuration is still unprecedented, and the authors plan to prove its performance according to the milestones shown in

Figure 2.

The risk factors related to the long-term reliability of the direct expansion method are instability in oil return to the compressor and instability in refrigerant flow [

8]. Compressor oil circulates within the refrigeration cycle, but there is a possibility that it may accumulate at the deepest part of the refrigerant pipe buried underground. If the flow of compressor oil passing through the compressor becomes unstable and the oil flow becomes extremely insufficient, there is a risk of damage to the compressor. Unstable refrigerant flow can cause an alternating over-supply and under-supply of refrigerant due to the accumulation of liquid refrigerant at the deepest part of the refrigerant pipe, potentially reducing compressor capacity. These risk factors will be subject to detailed evaluation and countermeasures in Phases 2 and 3 of this research project (

Figure 2).

2. Geothermal Heat Exchange Downstream from the Outdoor Unit

The purpose of geothermal heat exchange is to ensure an appropriate refrigerant temperature to achieve a high COP. It is widely known that COP can be improved in conventional air–thermal air conditioners by lowering (during cooling) or raising (during heating) the refrigerant temperature at the outlet of the outdoor unit heat exchanger [

9,

10]. Therefore, it is only necessary to reach the target refrigerant temperature downstream from the heat exchanger, and it is not necessary to bury the entire extent of refrigerant piping underground. This study investigated a method for enhancing outdoor heat exchange by adding underground piping at the downstream end of the outdoor heat exchanger. However, in conventional air and geothermal air conditioners, the flow of refrigerant differs between cooling and heating operations, so simply adding geothermal piping at the bottom of the air conditioner is not suitable.

To solve this problem, in this study, as shown in

Figure 1, a bypass flow path is provided between (A)-(A′) and (B)-(B′) of the outdoor unit piping of a conventional air conditioner, and a four-way valve is installed at (A)-(A′). The ground heat exchanger can be placed after the outdoor unit heat exchanger during both cooling and heating operations. This flow path structure allows the geothermal heat exchanger to be placed after the outdoor unit heat exchanger in both cooling and heating modes by simply bypassing two conventional air conditioner pipes and adding geothermal piping. Most of the installation cost of geothermal air conditioners is the cost of borehole excavation. In the geothermal air conditioner proposed in this study, most of the heat exchange volume is borne by the outdoor unit heat exchanger, so the heat exchange volume borne by the geothermal heat exchanger is relatively small. Therefore, the borehole length required for heat exchange is short and cost reduction can be achieved.

The underground heat exchanger allows the compressor to operate at a load equivalent to that of a typical air conditioner installed on the second floor because the piping length is only 12 m for a round trip. When burying the underground piping, it is sufficient to install steel pipes of about 6 m in length and drill holes about 1 m3 in size, making the cost of excavation relatively low. Furthermore, the control board of a conventional air conditioner can be used without modification, enabling the mass production of prototype units at low cost while keeping initial costs down. This makes it possible to conduct long-term operational tests using a large number of demonstration units from the initial development stage, which is beneficial for identifying and resolving failure factors.

The impact of air temperature changes on surface and subsurface temperatures is an important topic in the evaluation of geothermal applications and urban environments. Studies have shown that while the surface temperature is highly correlated with the air temperature, the subsurface temperature varies with depth in terms of the degree of influence of temperature change, with short-term changes affecting only shallow layers and long-term climate change extending to deeper levels [

11,

12,

13,

14]. Surface and air temperatures are closely related, and many studies have shown the correlation. A high correlation (correlation coefficient of 0.97) exists between daily mean surface temperature and air temperature, and a quantitative relationship is evident: a 1 °C increase in daily mean surface temperature corresponds to a daily mean air temperature increase of about 0.85 °C. It has been observed that the diurnal ground surface temperature is affected by solar radiation and other factors, and shows the same pattern of change as air temperature. However, although a time difference between surface temperature and air temperature may be observed in intraday variations, when organized as daily averages, surface temperature and air temperature show almost the same trend. Surface temperature changes propagate to the subsurface by heat conduction. An important characteristic of this process is that the amplitude of the temperature change attenuates with increasing depth. The attenuation is particularly significant for short-period variations, which tend to disappear before reaching depth. Subsurface temperature distribution is affected by the combined effects of natural groundwater flow, anthropogenic pumping, and surface temperature changes. Underground heat transfer is mainly affected by two mechanisms: heat conduction and heat transport (advection) by groundwater. Studies in Japan have shown that the effects of daily changes in temperature are limited to shallow underground layers. Specifically, the influence of daily changes reaches from a depth of 20 cm to 80 cm. Subterranean temperatures at a depth of 10 cm show similar changes to air and surface temperatures, and are directly affected by solar radiation and other factors. The effects of solar radiation and other meteorological factors on subsurface temperatures at depths of 30 cm and deeper are small and almost negligible.

Figure 2 shows the milestones of this research project. This paper introduces the results of Phase 1, and we plan to work on Phase 2 and beyond in the future.

3. Preliminary Performance Evaluation by 1D-CAE

The performance of the geothermal heat pump system developed in this study was estimated through one-dimensional simulation (1D-CAE) of the refrigeration cycle using Matlab. In this study, a comprehensive model was developed to numerically simulate the behavior of air conditioning systems using differential equations based on first principles [

15,

16,

17,

18,

19,

20,

21]. In particular, a general model was employed for the unsteady-state behavior of the major components such as the compressor, heat exchanger, and expansion valve. The modeling of the heat exchanger reproduced the heat transfer process with phase change. The entire mathematical model consisted of a system of differential equations based on the conservation of mass, energy, and momentum laws, which were solved numerically to predict the transient response of the air conditioner operation. It should be noted, however, that the purpose of the 1D-CAE in this study was to evaluate whether or not the addition of a ground heat exchanger downstream from the outdoor unit heat exchanger was effective, and not for the purpose of rigorous numerical analysis.

The following system of differential equations is derived as the basic equations describing the refrigerant flow and heat transfer in an air conditioning system:

- (1)

Energy conservation equation

where

is the refrigerant density,

is the specific heat at constant pressure, T is the temperature,

is the velocity vector,

is the thermal conductivity, and

is the viscous dissipation term.

- (2)

- (3)

Momentum conservation equation

The change in state of the refrigerant inside the compressor can be approximated by the following isentropic process equation:

Here, and are the temperature and pressure before compression, and are the temperature and pressure after compression, and is the specific heat ratio.

The mass flow rate of the refrigerant through the expansion valve can be expressed using the flow coefficient

, as follows:

Here, A is the valve opening area, is the pressure difference before and after the valve, and is the refrigerant density.

The heat transfer phenomena in a heat exchanger are described by the following differential equations:

Here, is the refrigerant temperature, is the air temperature, is the wall surface temperature, and are the refrigerant and air velocity, respectively, and are parameters related to the heat transfer coefficient at the refrigerant side and air side, respectively, and and are parameters related to heat transfer at the wall surface.

The analytical conditions are described in the following. R32, widely used in residential air conditioners, was used as the refrigerant; the physical properties of R32 were calculated using REFPLOP [

22]. Summer cooling operation (outdoor temperature 38 °C, set temperature 26 °C) was set as the boundary condition. Cooling mode was prioritized due to its relevance to extreme heat conditions, with heating mode analysis planned for future work. The length of the geothermal piping was 6 m on the outward route and 6 m on the return route, for a total of 12 m. Each pipe was divided into 50 sections for analysis. The ground temperature was set at 20 °C.

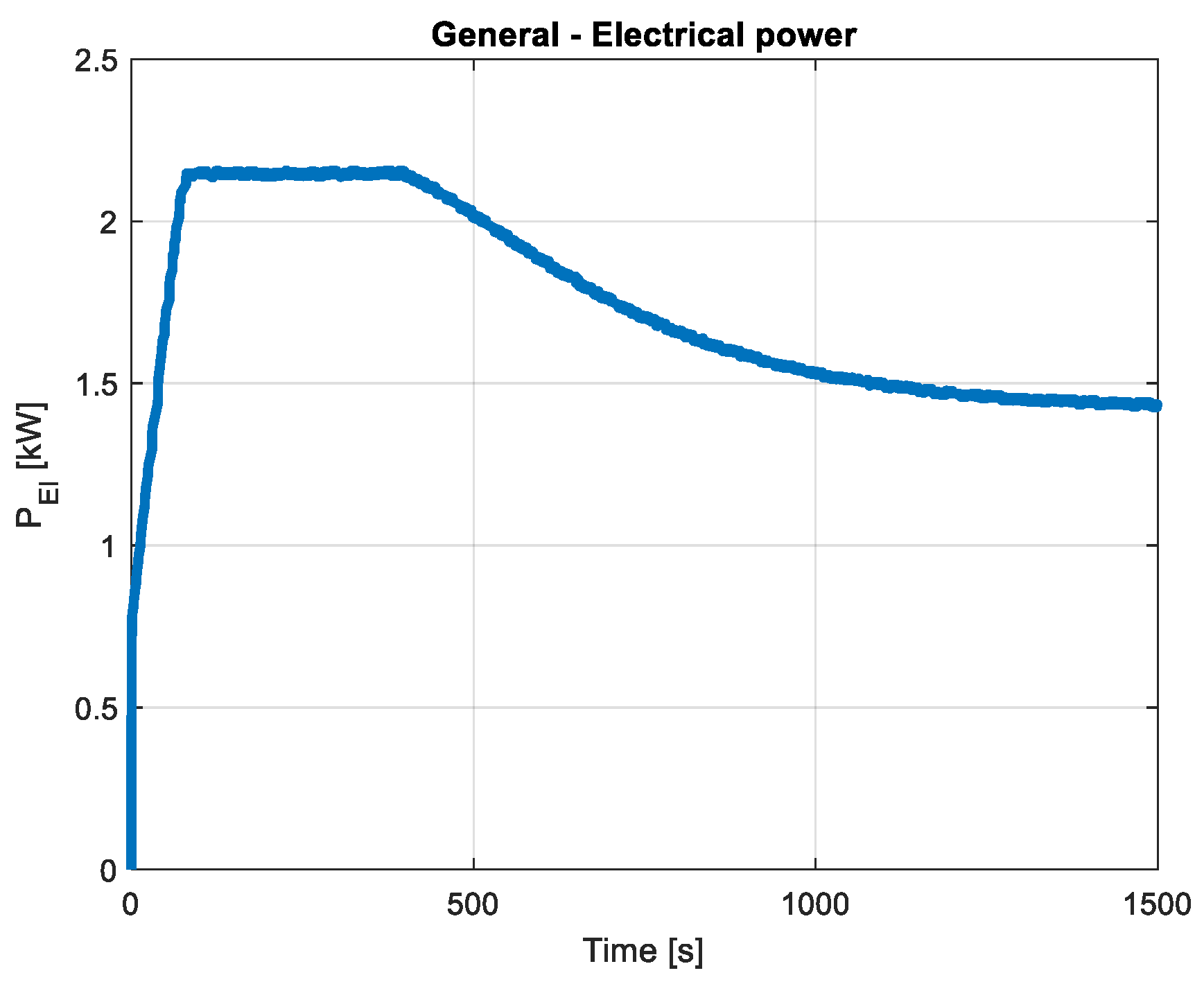

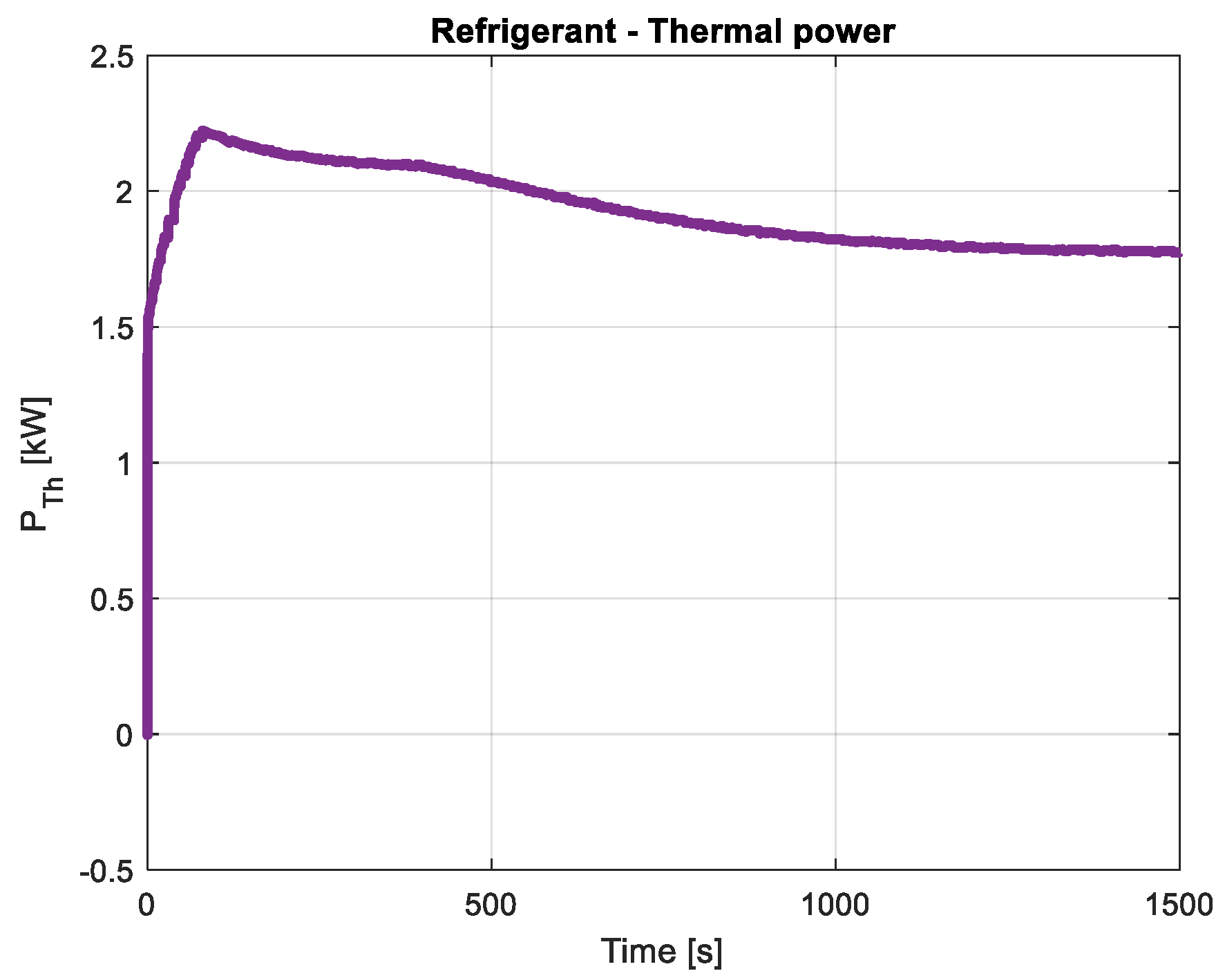

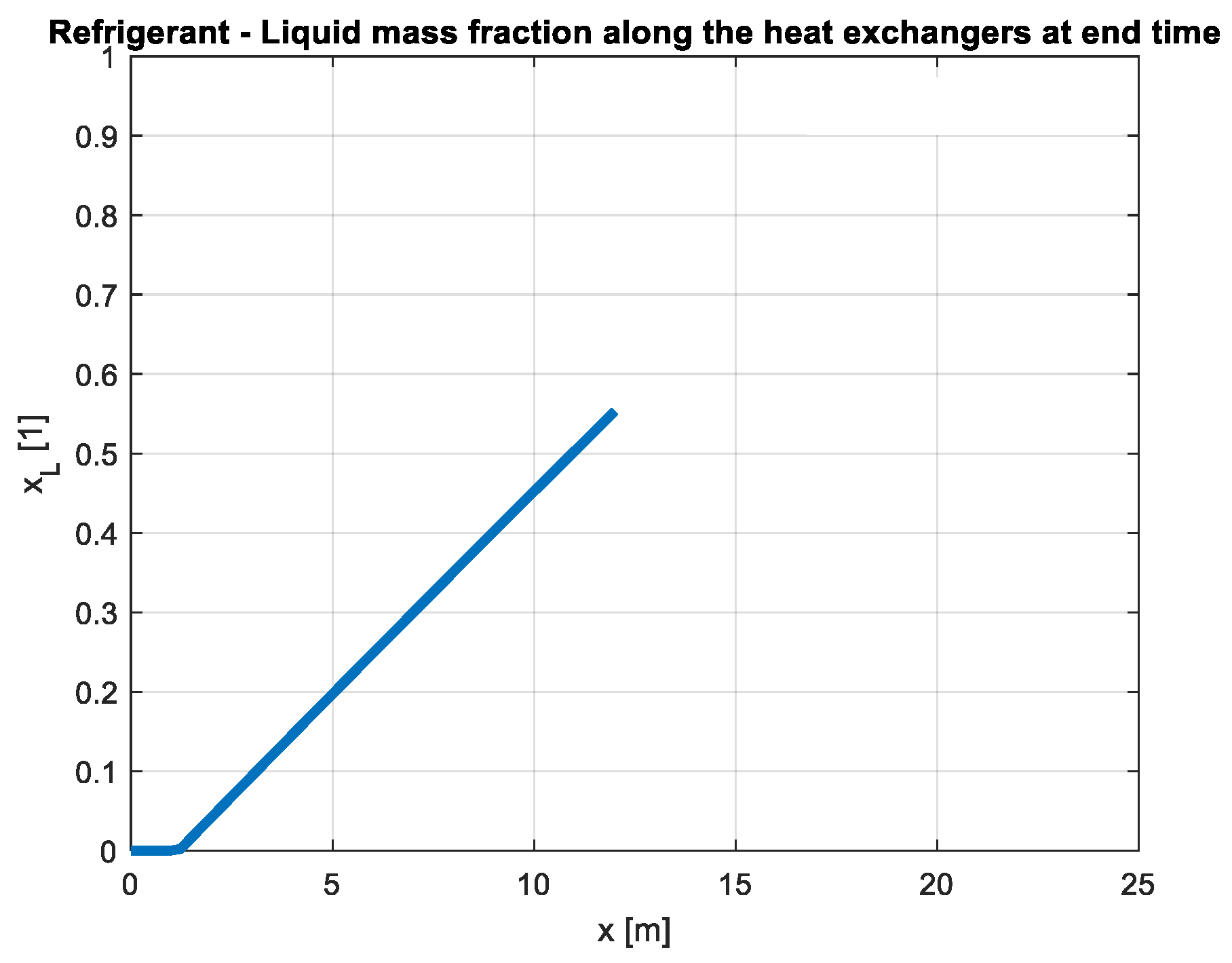

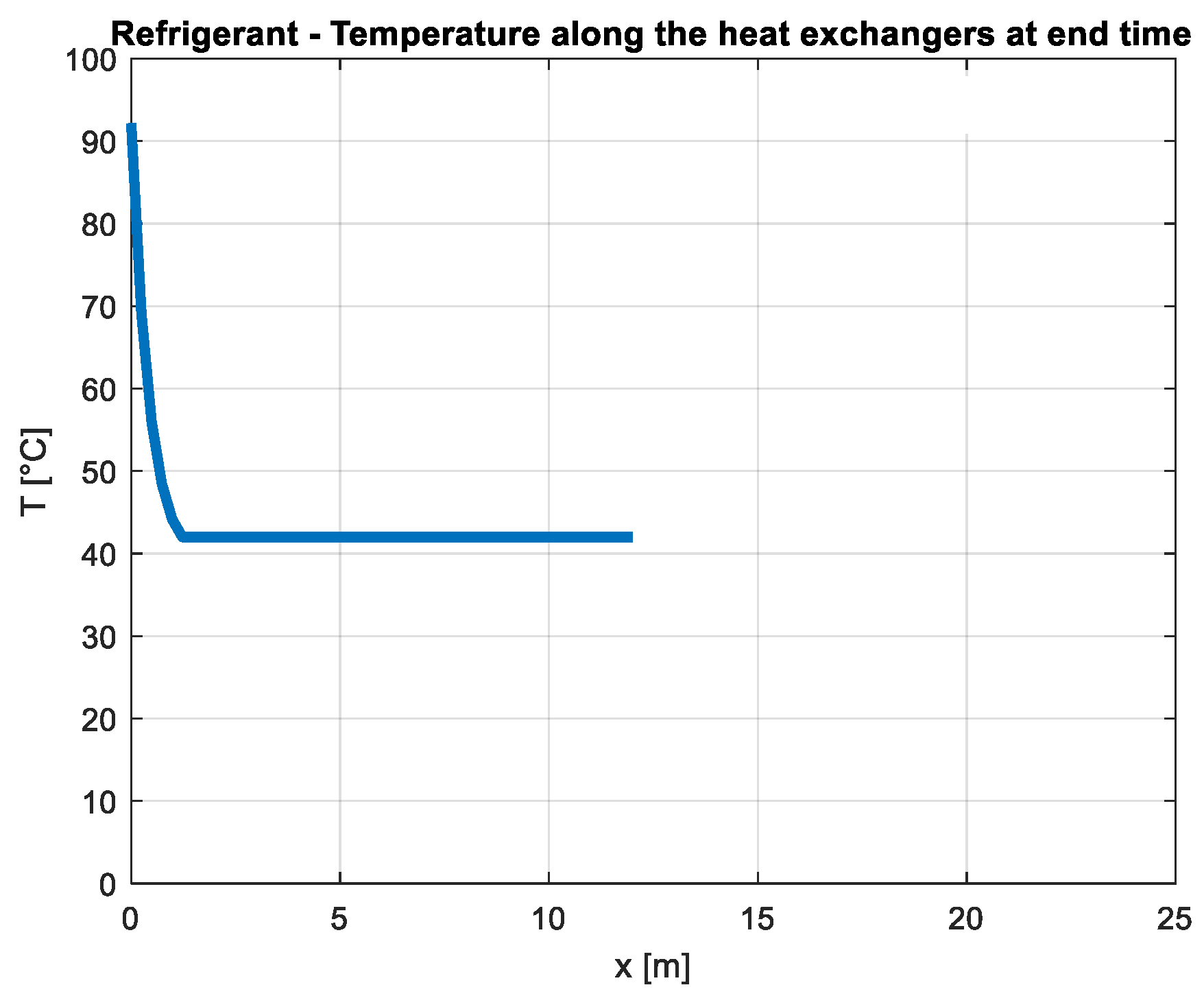

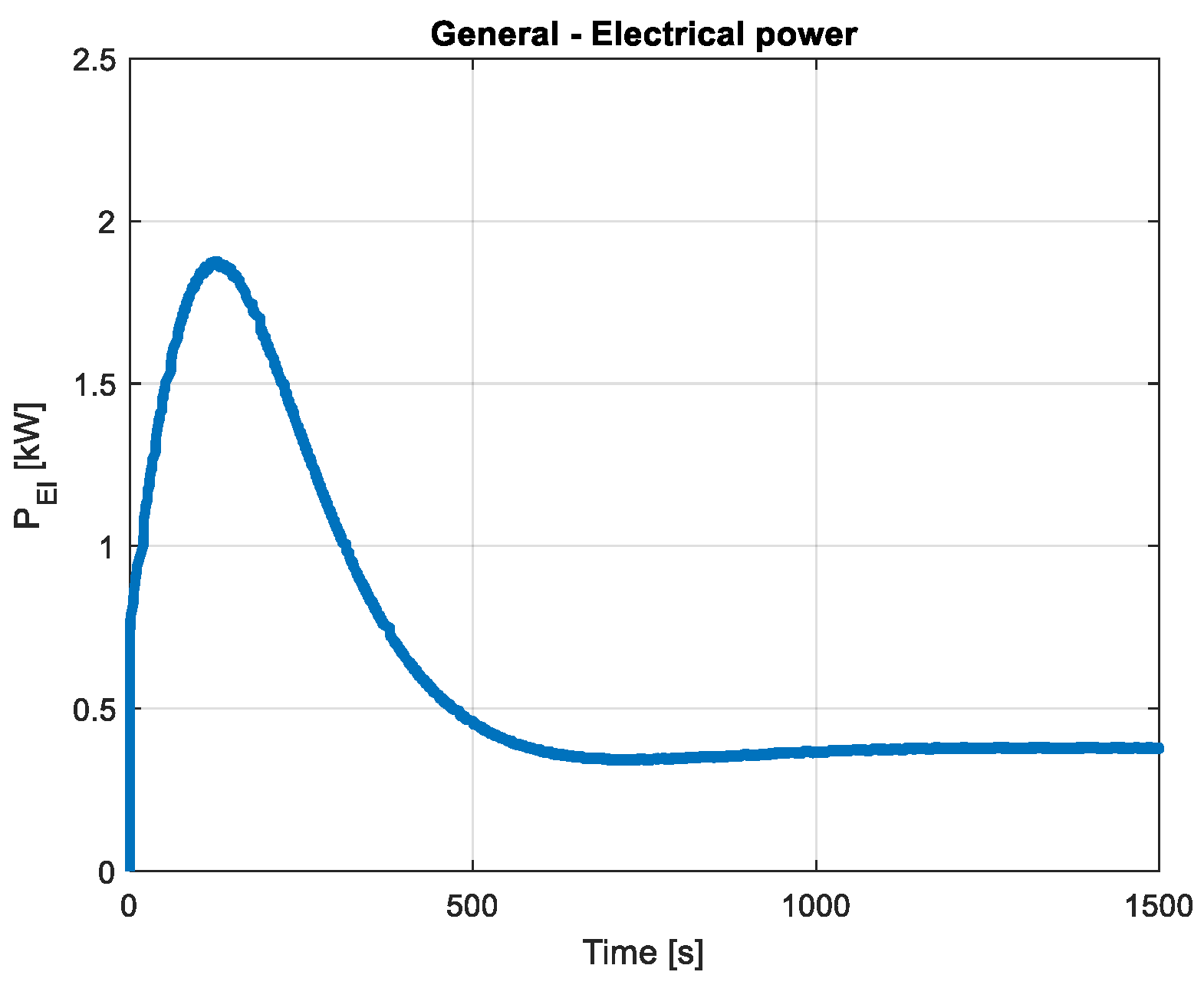

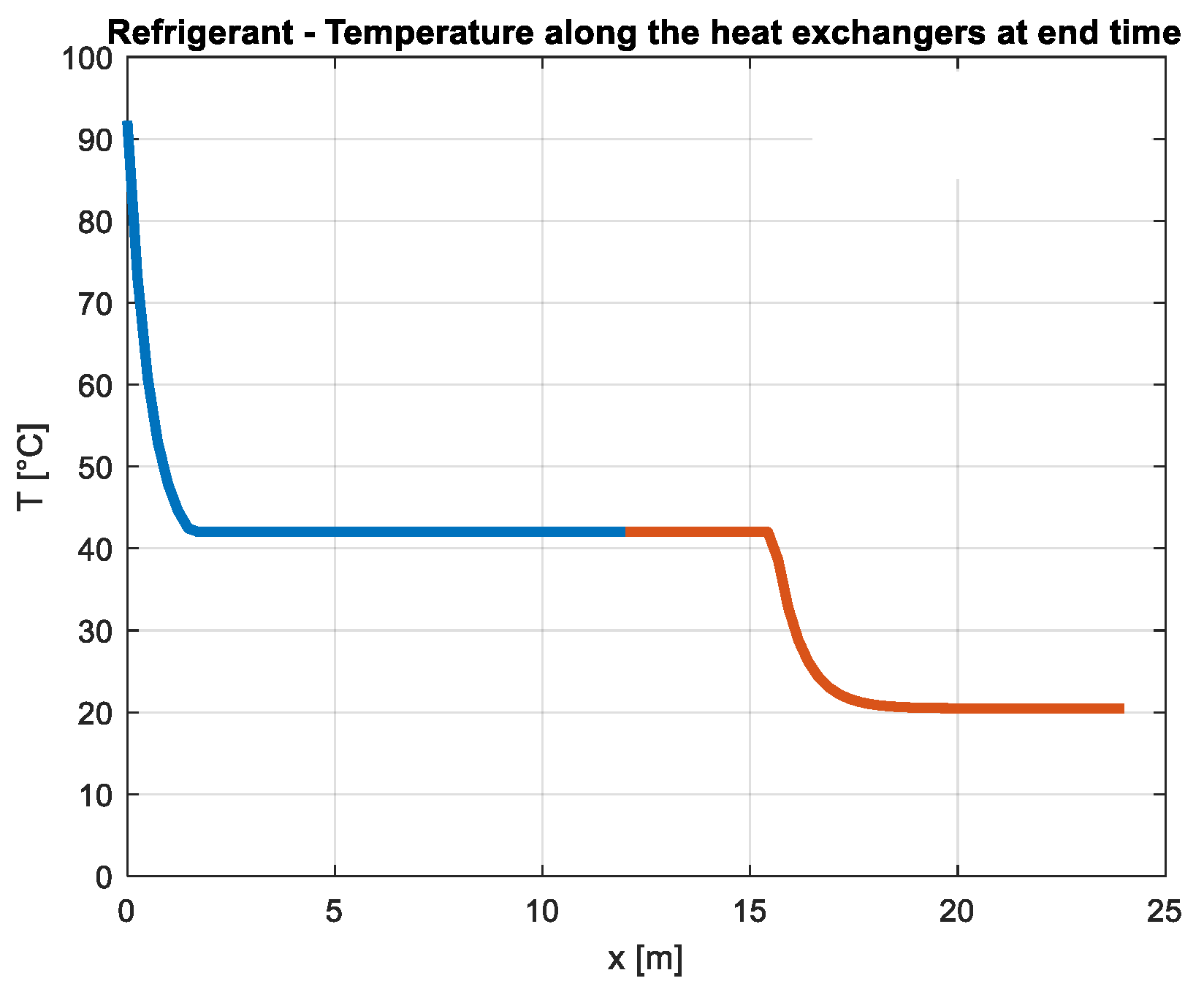

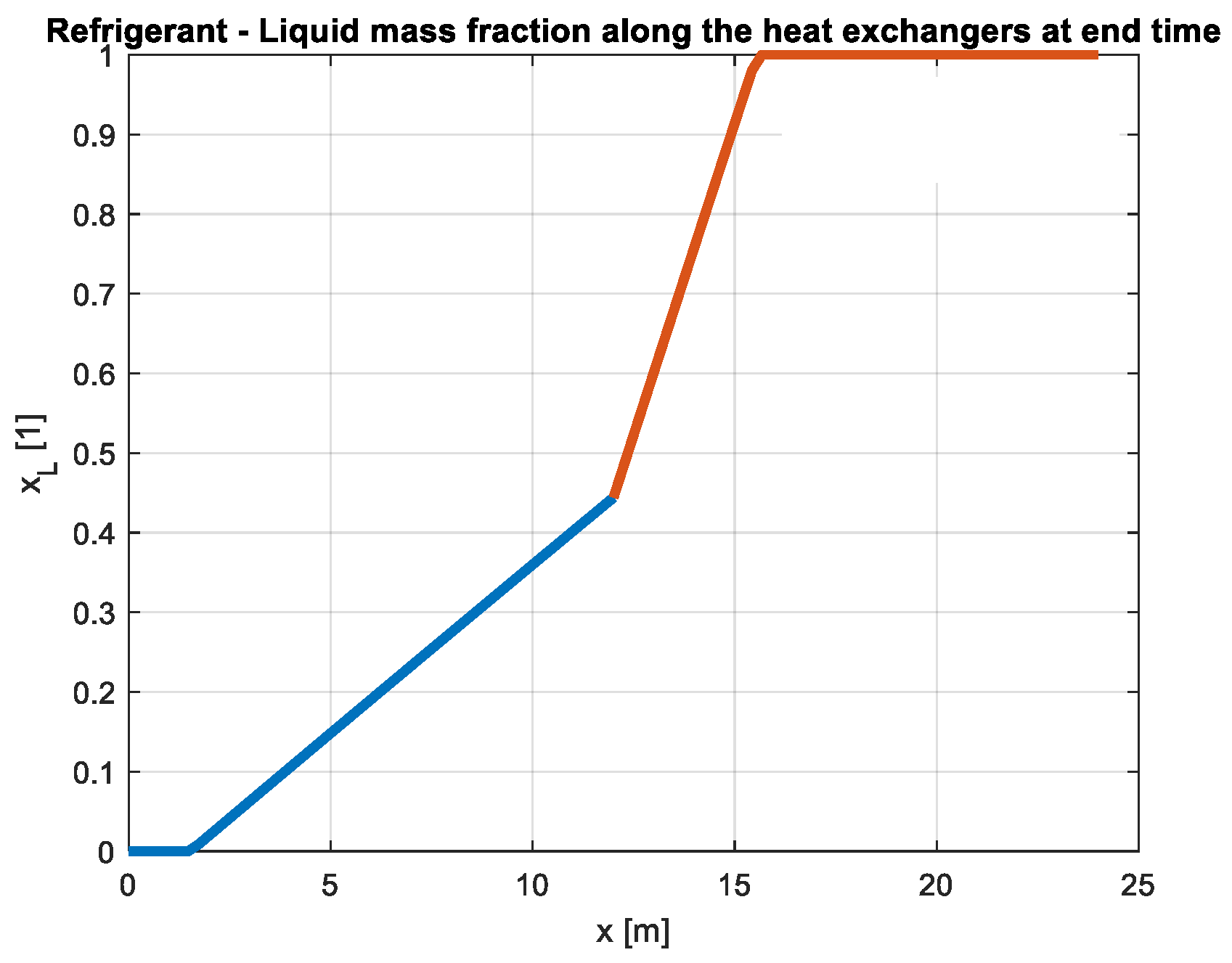

The analysis was conducted for two types of air conditioners: a conventional air conditioner without a ground heat exchanger (

Figure 3,

Figure 4,

Figure 5 and

Figure 6) and a hybrid air conditioner using ground heat (

Figure 7,

Figure 8,

Figure 9 and

Figure 10). As a result, it was confirmed that the indoor temperatures of both types of air conditioners stabilized at around 26 °C by 1500 s after the start of operation. Therefore, the power consumption and cooling output at 1500 s after the start of operation were used to evaluate the energy-saving performance.

Simulation results for a conventional air conditioner show that on a very hot day with an outdoor temperature of 38 °C, heat exchange was insufficient when using only the air heat exchanger, and that only about 50% of refrigerant condensation was achieved by the air heat exchanger (

Figure 5). As a result, the load on the compressor increased, resulting in a higher power consumption of 1.44 kW (

Figure 3). At the same time, the cooling output was 1.78 kW (

Figure 4) and the COP was as low as 1.24. These results suggest that the energy-saving performance of conventional air conditioners on extremely hot days is low. In conventional air conditioners, the amount of heat exchange in the condenser is insufficient, and desuperheating and complete condensation are not performed.

On the other hand, in the hybrid geothermal air conditioner, the ground heat exchanger provided supplemental cooling in situations where the heat exchange in the atmospheric heat exchanger was insufficient, enabling the refrigerant temperature to be lowered to 20 °C, equivalent to the ground temperature (

Figure 9). This result demonstrates the effectiveness of the design of this system, in which only the downstream portion of the heat exchange is cooled by the ground heat exchanger. As a result, the load on the compressor was reduced and the power consumption was significantly reduced to 0.37 kW (

Figure 7). The cooling output was 1.67 kW (

Figure 8), and a COP of 4.51 was recorded. The hybrid system’s slightly lower cooling output is offset by its significantly reduced power consumption, yielding a higher COP. Furthermore, this system is expected to be able to withstand long-term continuous operation because the ground heat exchange is performed only during extremely hot weather when the capacity of the air heat exchanger is insufficient, thus minimizing the effect on the ground temperature. When comparing total heat rejection, conventional air conditioners generate 3.22 kW, while hybrid geothermal air conditioners generate 2.04 kW. It is presumed that the energy savings achieved by hybrid geothermal air conditioners are mainly due to improved condensation efficiency, but this will be verified through experiments and simulations under the same conditions in the future.

4. Performance Evaluation Experiment of a Hybrid Geothermal Air Conditioner

Prior to the full-scale installation of the geothermal heat exchanger underground, a trial run was conducted with the geothermal heat exchanger buried at a depth of 20 cm below the ground surface (

Figure 11). The operation mode was the cooling operation, and a Mitsubishi Electric MSZ-GV2223-W indoor and outdoor unit was used. The pipe material of the ground source heat exchanger is a 12 m-long 1/4-inch copper pipe (thermal conductivity: 372

), installed downstream from the piping that was used as the outdoor unit heat exchanger. Thermophysical properties of the surrounding soil are a thermal conductivity of 1.69

and a thermal resistance of 0.08 K/W. No backfill material was used.

The only modification was the installation of a ground heat exchanger between the outdoor unit and the compressor. The geographical coordinates of the test site are 35.67805 degrees longitude and 138.57379 degrees latitude. The experiment was conducted from 9:00 a.m. to 5:00 p.m. on 26 June 2024. The highest temperature during the measurement period was 33.2 °C, the lowest temperature was 26.2 °C, the weather was cloudy, and the amount of sunlight was about half that of a sunny day. A switch valve was used to switch between an operation mode similar to that of a conventional air conditioner and a hybrid operation mode with ground heat exchange, and the COP values were compared based on the cooling output and power consumption of each. The cooling output was calculated by the air enthalpy method. However, the duct length of the exhaust port of the indoor unit was not long enough, and thermometers, hygrometers, and anemometers were installed at different points on the intake and exhaust sides.

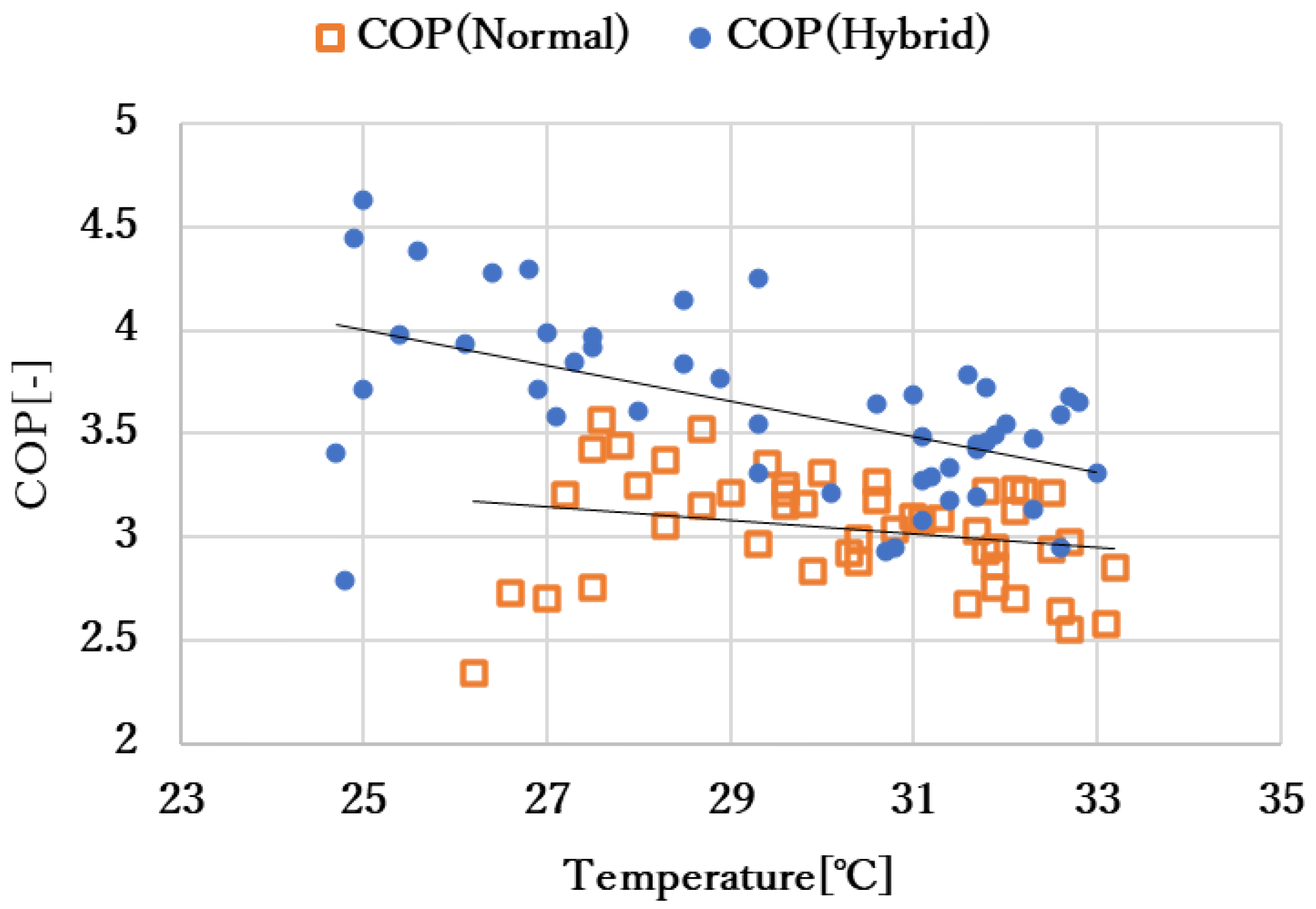

Figure 12 shows the results of a comparison of COP values calculated from cooling output and power consumption. The COP of the hybrid type was approximately 20% higher than that of the conventional type, regardless of the ambient temperature, indicating the superiority of the air/geothermal hybrid air conditioner.

Figure 10 shows the hybrid system’s COP advantage, consistent across 25–33 °C ambient temperatures. In the future, when the ground heat exchanger is buried at a depth of several meters, a larger COP improvement effect is expected to be obtained.

In addition, as a characteristic of conventional air conditioners, a tendency for COP to decrease as the outside temperature rises was confirmed. A similar tendency was also observed in the hybrid type that combines air heat exchange and ground heat exchange. In this regard, it is clear that the characteristics of the geothermal heat pump are different from those of the direct expansion-type geothermal heat pump, in which all heat exchange takes place deep underground and is almost unaffected by outdoor air temperatures.

5. Conclusions

This study proposed and evaluated a hybrid geothermal air conditioning system designed to enhance the performance of conventional air conditioners through the integration of a ground heat exchanger. The key findings and their implications are summarized as follows:

- (1)

Enhanced Performance and Efficiency:

The core innovation, placing a geothermal heat exchanger downstream from the outdoor unit’s heat exchanger, was demonstrated to improve both cooling performance and the coefficient of performance (COP). Preliminary performance evaluations using 1D-CAE indicated a significantly higher COP for the hybrid system compared to conventional units, especially under high ambient temperatures (e.g., 38 °C). Furthermore, initial experimental results, utilizing an underground heat exchanger buried at a shallow depth of 20 cm, corroborated these findings by confirming a reduction in refrigerant temperature, which directly contributed to an improved COP. This trend suggests a viable pathway to boosting air conditioner efficiency, particularly in hot climates.

- (2)

Practical Advantages and Feasibility:

Beyond performance gains, the proposed system offers considerable practical advantages. It is designed for integration into existing air conditioning systems with minimal modifications, which, coupled with its potential for low initial installation costs, supports wider adoption and long-term operational benefits. A significant design feature is the independent installation capability of the air conditioner and the underground piping. This modularity addresses a common practical challenge: the shortage of specialized technicians required for complex geothermal installations, thereby streamlining the implementation process. These results suggest potential for retrofitting existing air conditioners with ground heat exchangers.

- (3)

Future Research and Pathways to Practical Application:

To realize the full potential of this hybrid geothermal air conditioning technology, further research is essential. Key future work includes optimizing the burial depth of the ground heat exchanger to maximize its thermal exchange efficiency. Moreover, comprehensive long-term demonstration tests are necessary to rigorously assess the system’s durability, sustained operational efficiency, and overall reliability in real-world conditions. Successfully addressing these research areas will be critical milestones toward the practical deployment and commercialization of hybrid geothermal air conditioners, offering a more sustainable and efficient cooling solution.