Study of the Effects of Differences in Drill Pipe Materials, Drilling Fluids, and Formation Rock Types on the Drag Reduction Capacity of Hydraulic Oscillators

Abstract

1. Introduction

2. Theoretical Models

- (1)

- The drill string was modeled as an elastic rod with a circular cross-section.

- (2)

- The drill string was considered in uniform contact with the borehole wall and nonrotating.

- (3)

- Only axial vibrations were considered; lateral and torsional vibrations were neglected.

- (4)

- The Stribeck model was adopted to depict the dynamic friction between the drill string and the well-bore.

- (5)

- The damping effect of drill string materials and formation rocks on the drill pipe was represented by the friction damping term in the vibration equation. The friction damping coefficient was obtained through laboratory friction coefficient measurement experiments.

- (6)

- The damping effect of drilling fluid on the drill pipe was represented by the viscous damping term in the vibration equation. The viscous damping coefficient varied with the type of drilling fluid.

- (7)

- The hydraulic oscillator was simplified as a high-stiffness spring-mass-damping system, and the excitation effect of the tool was modeled as an equivalent resonant force.

- (8)

- The drill bit was considered a boundary with a known axial force, and its axial displacement was calculated as the system output.

2.1. Evaluation Index for Drag Reduction

2.2. Vibration Equation

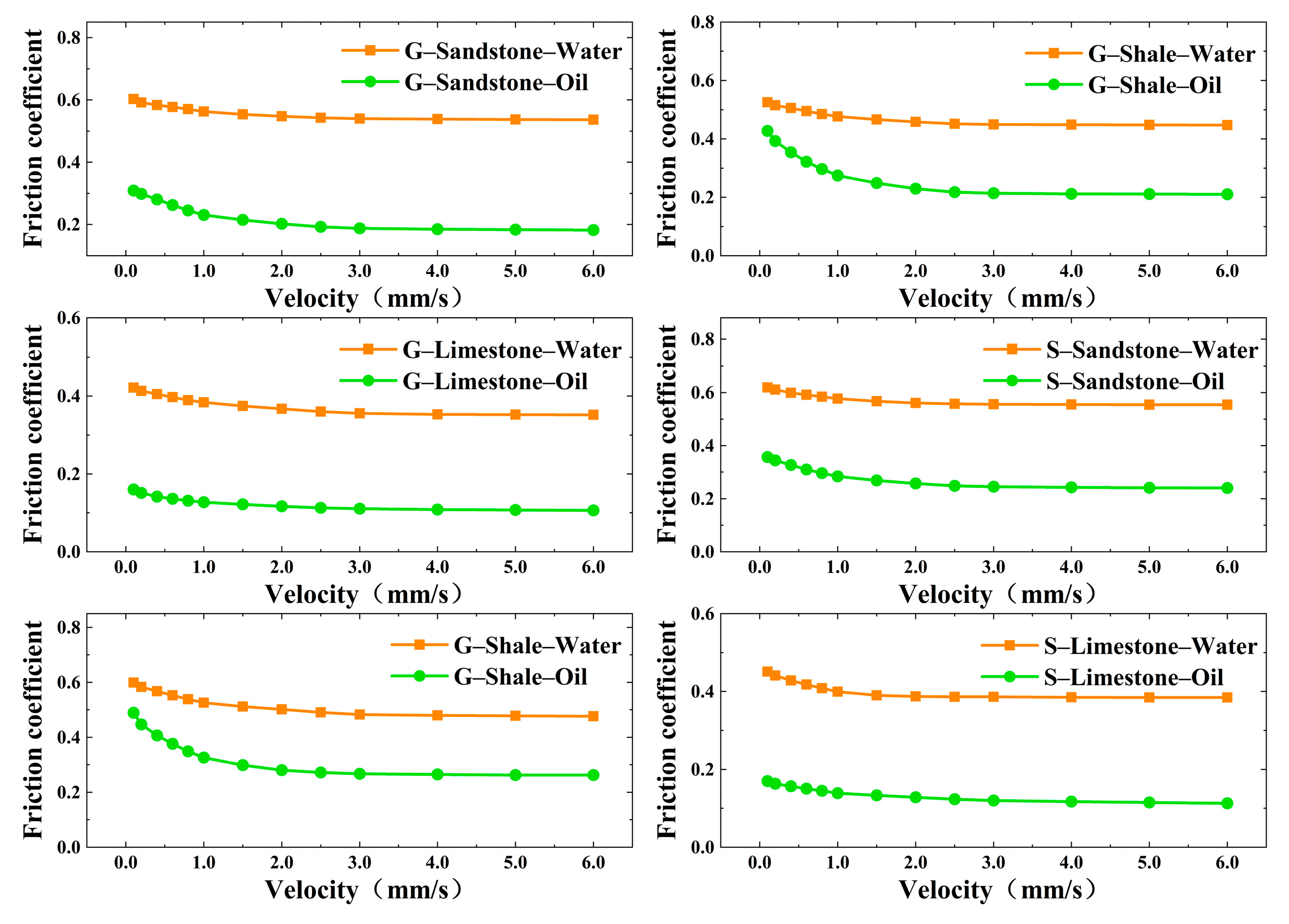

2.3. Friction Model

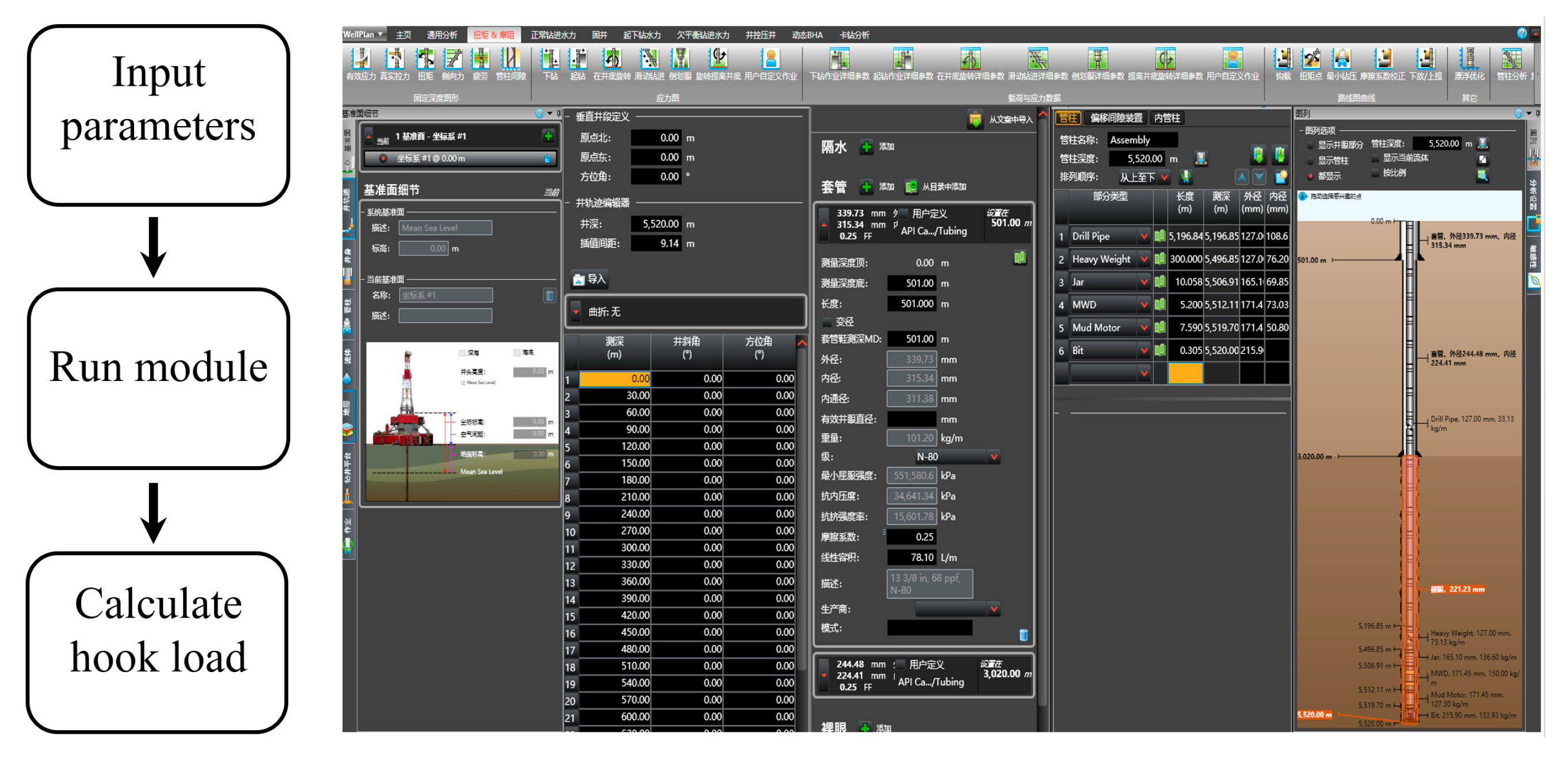

3. Numerical Method

3.1. Finite Difference Method

3.2. Boundary and Initial Conditions

3.3. Continuity Conditions

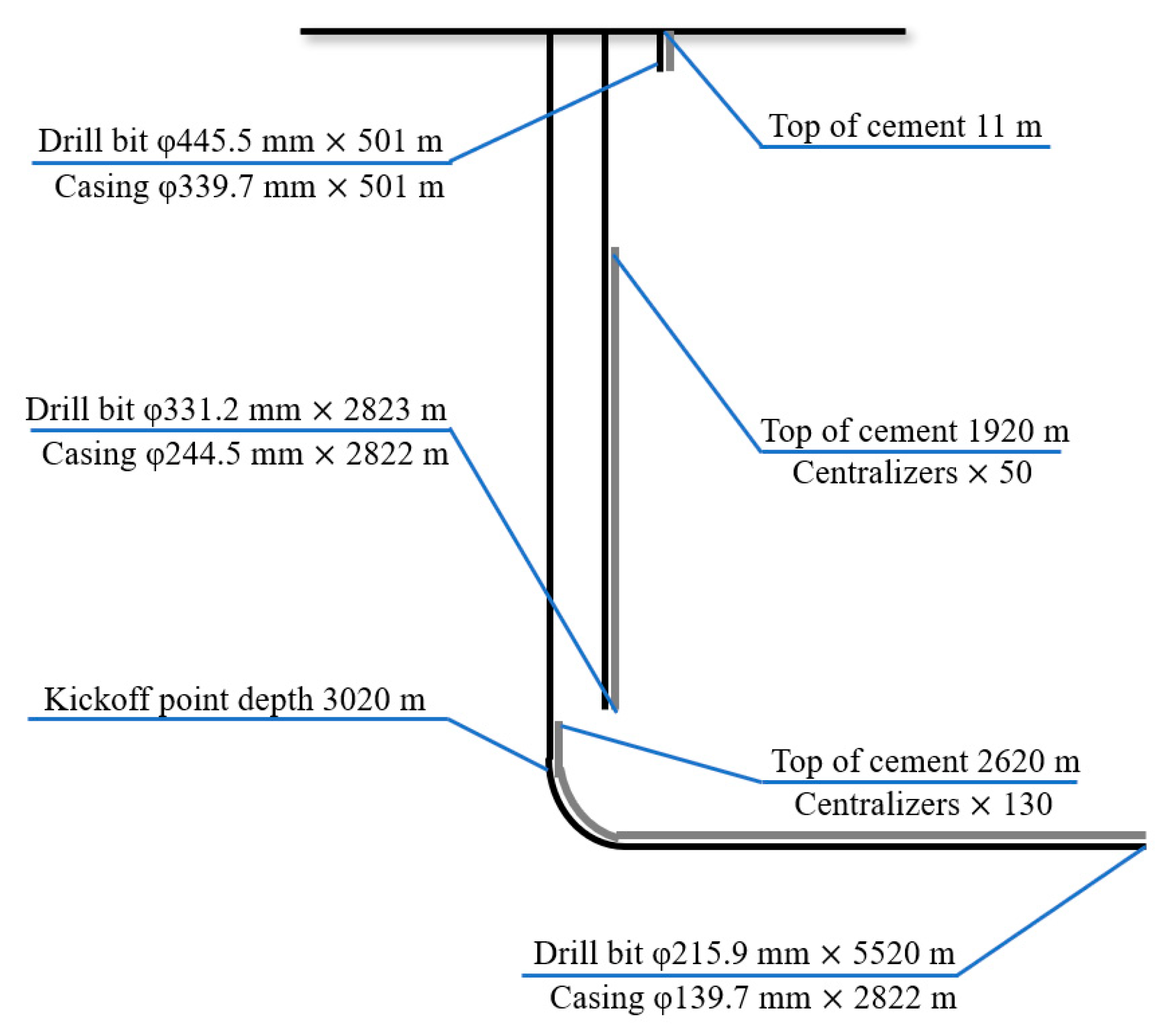

3.4. Model Validation

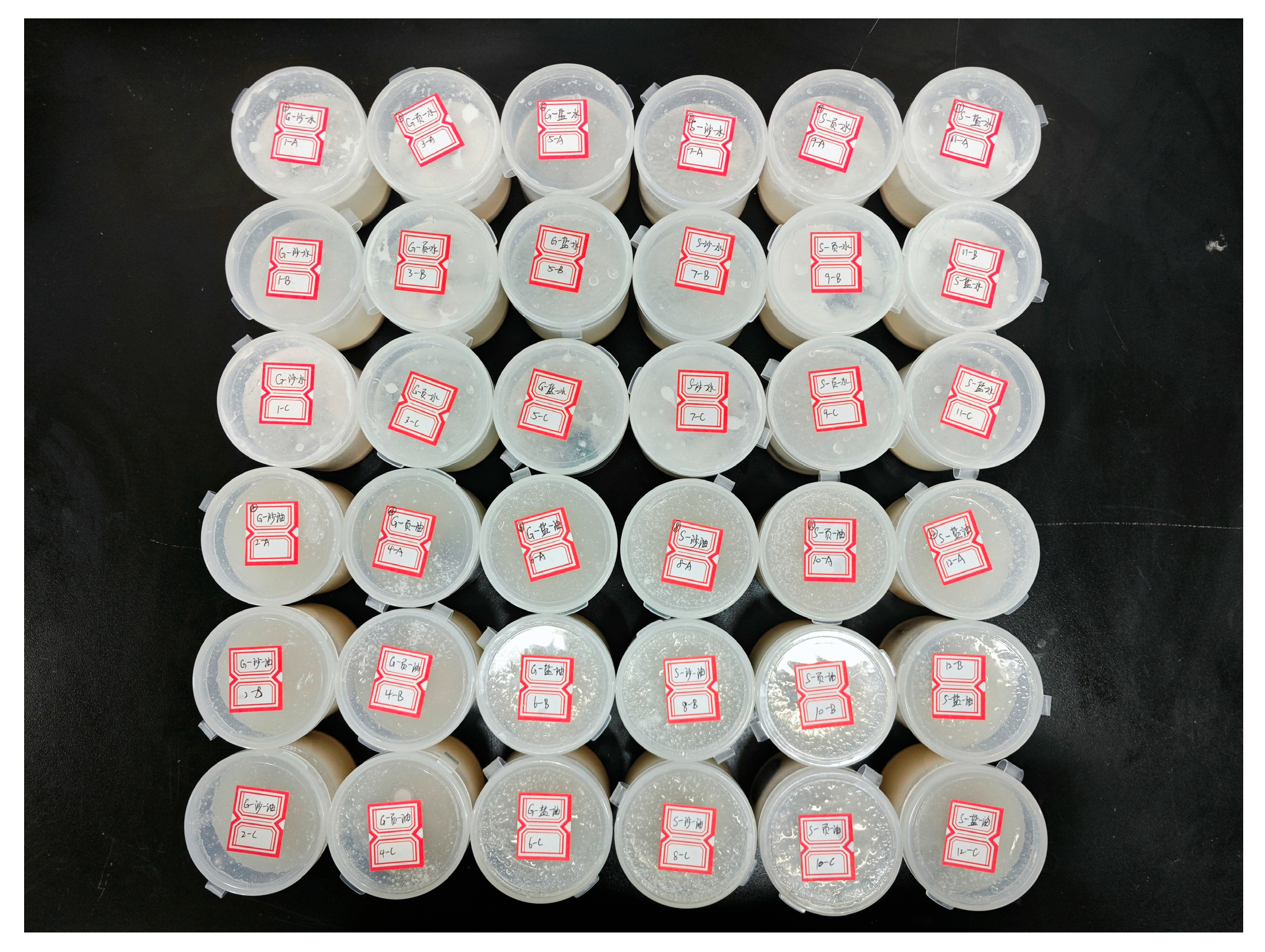

4. Friction Coefficient Measurement Experiments

4.1. Experimental Apparatus

4.2. Experimental Materials

4.3. Experimental Design

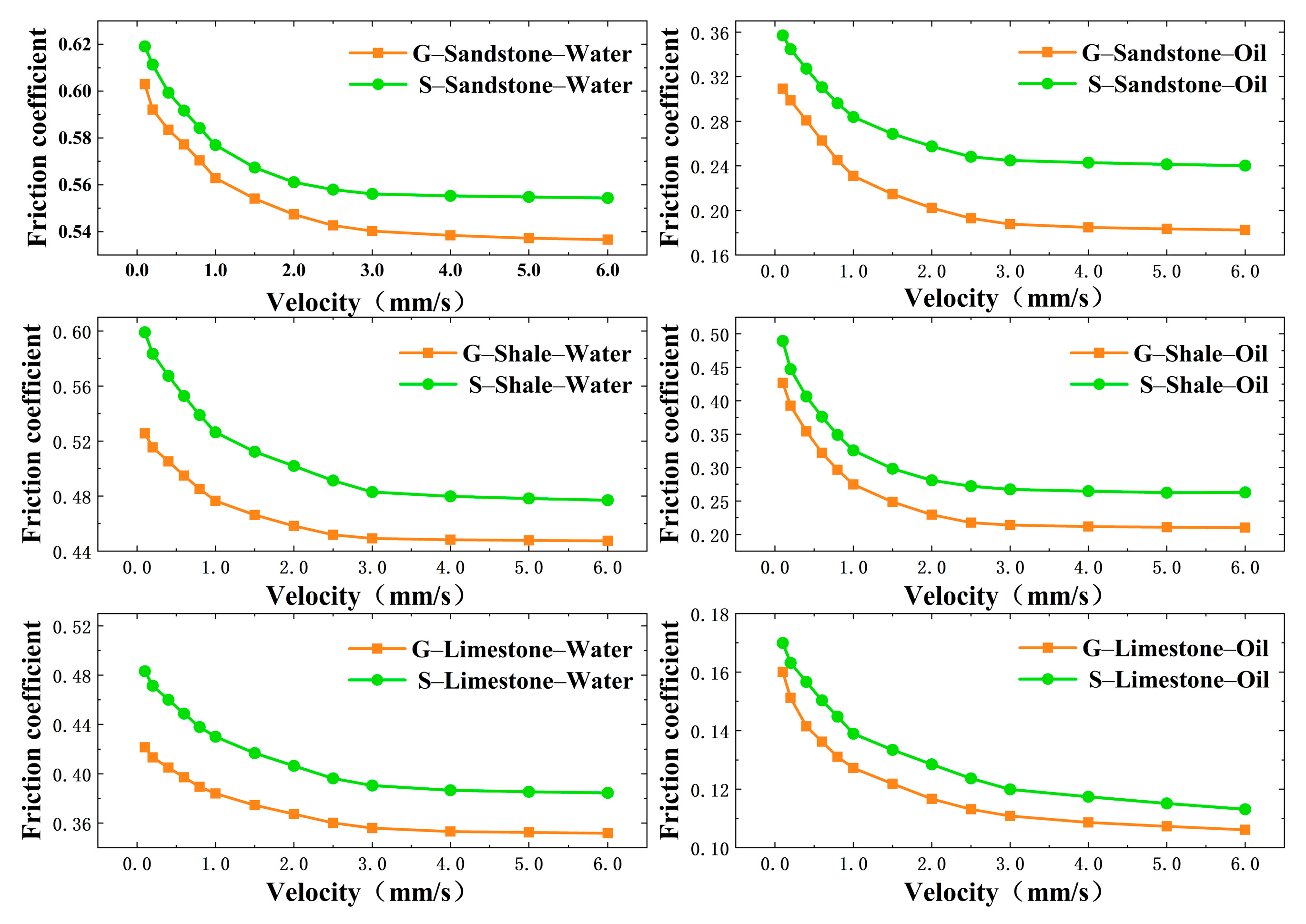

5. Results and Discussion

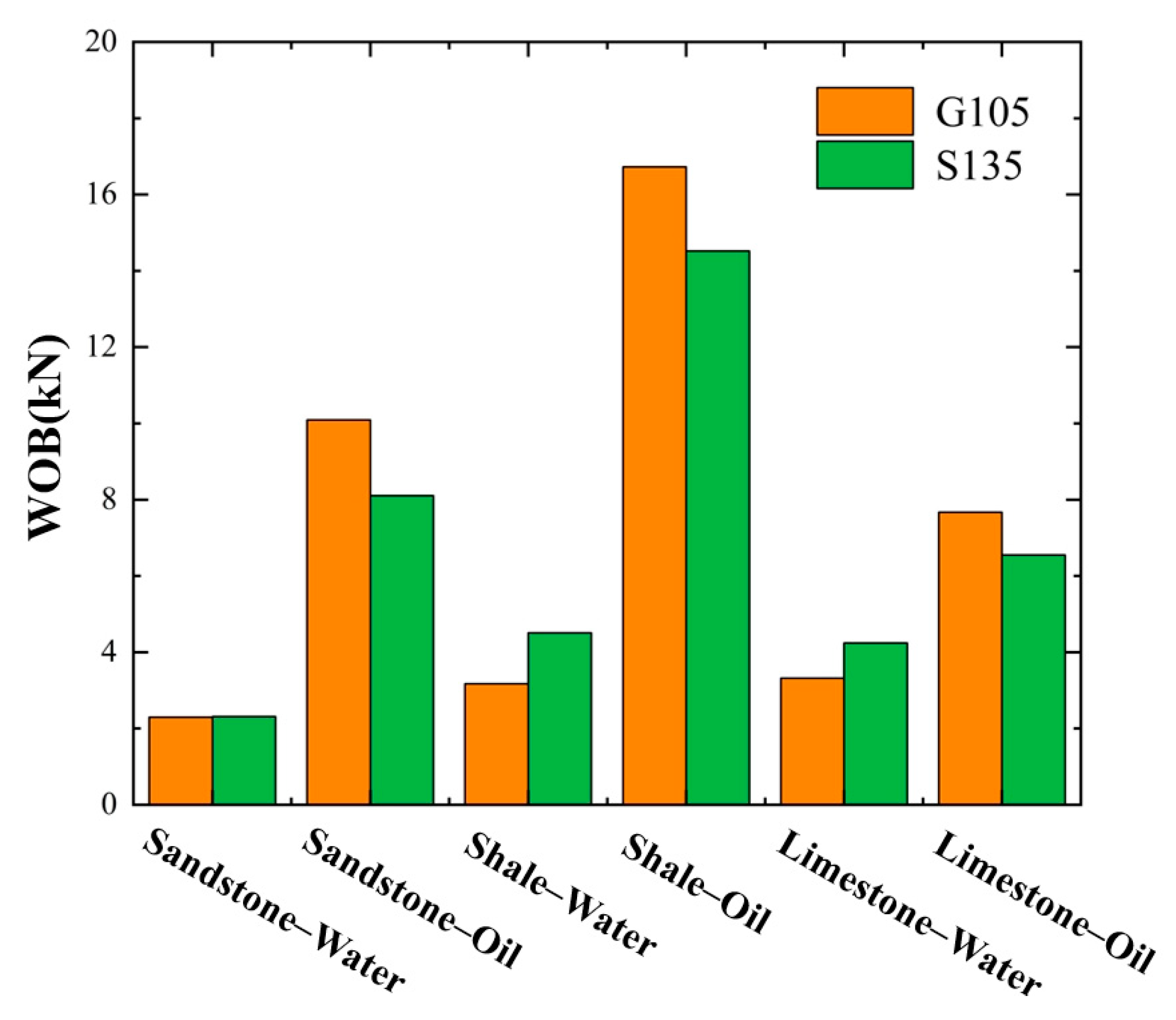

5.1. Effects of Drill String Material

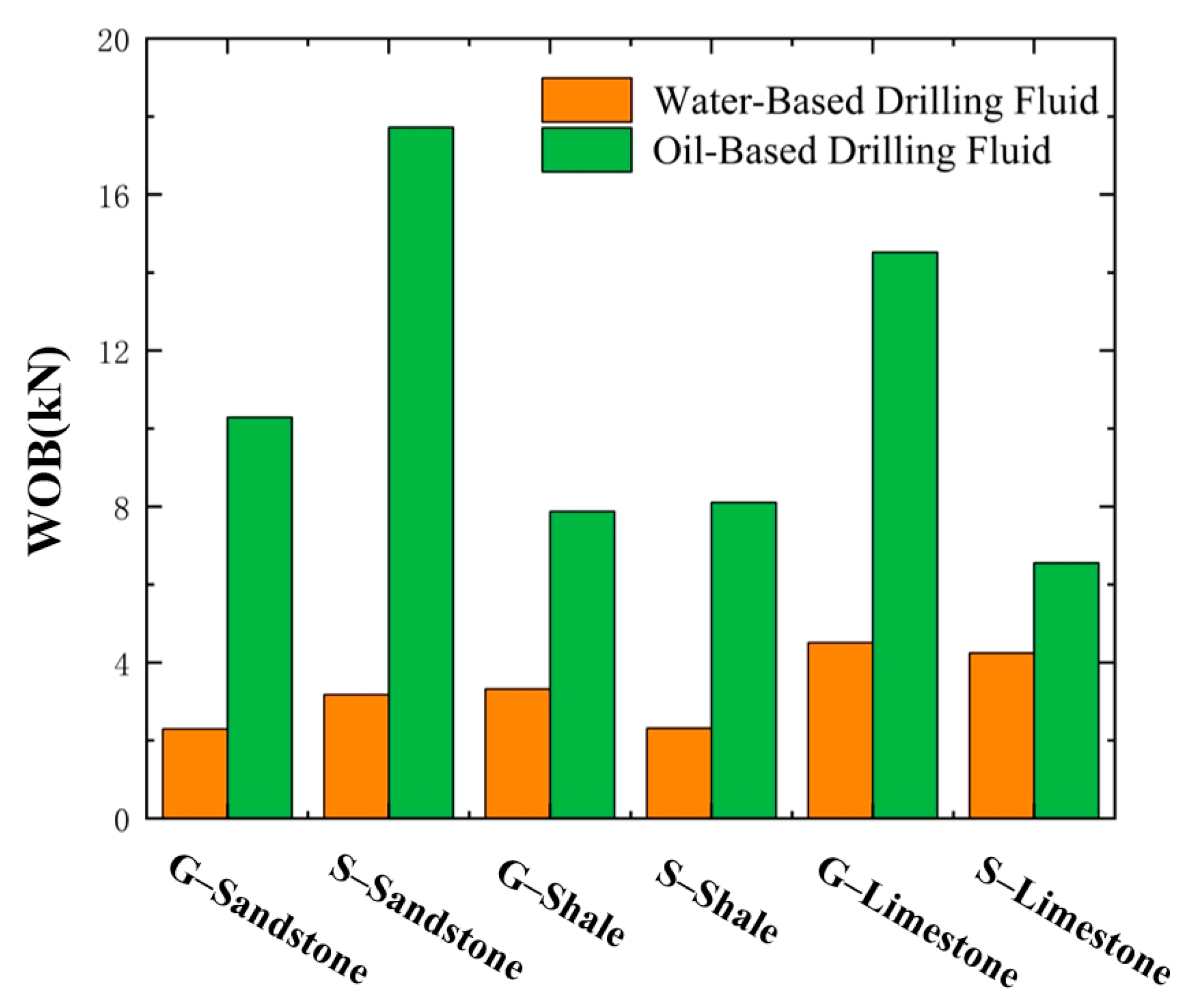

5.2. Effects of Drilling Fluid Type

5.3. Effects of Rock Type

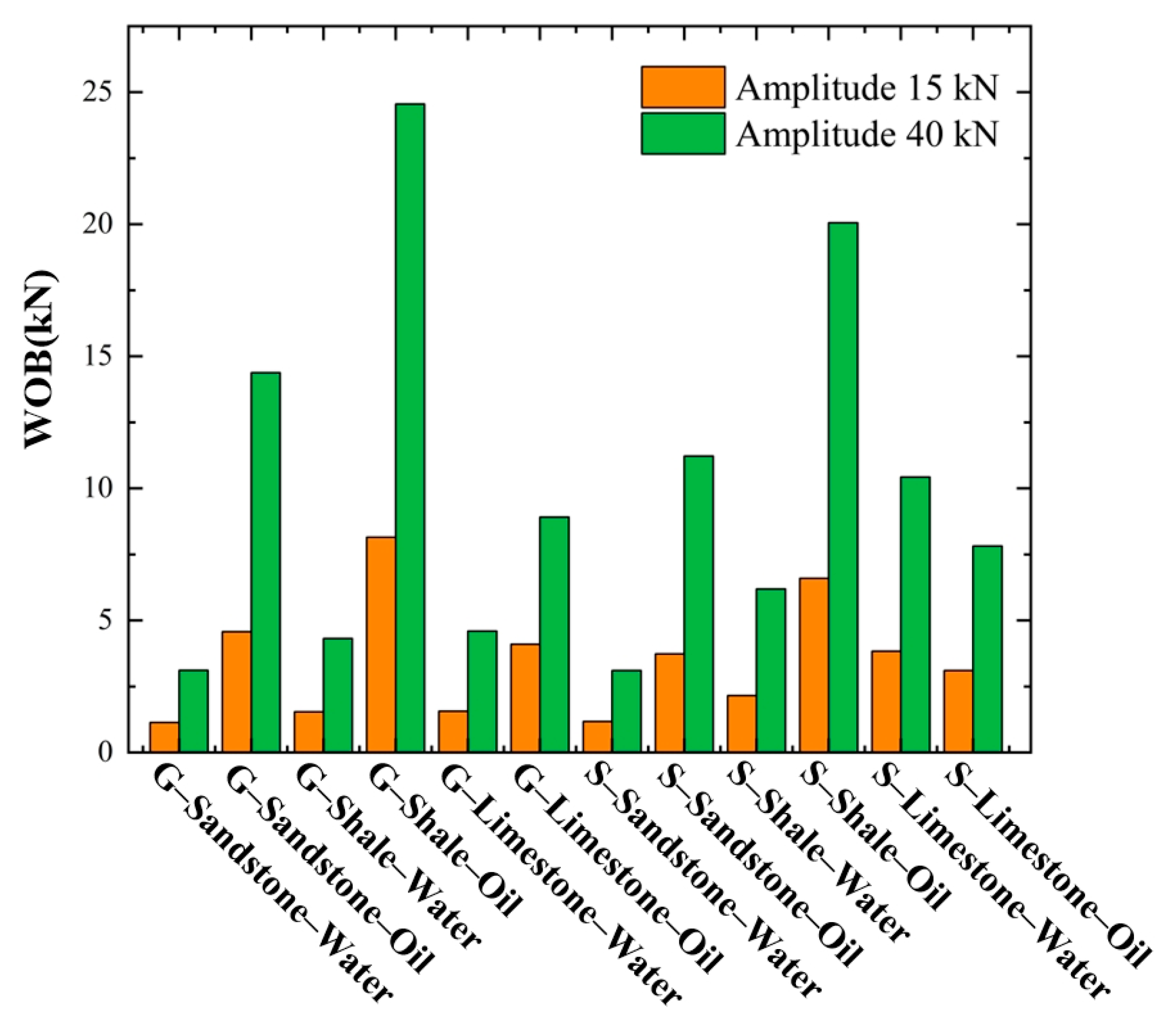

5.4. Effects of Vibration Frequency and Amplitude

6. Conclusions

- (1)

- A mechanical model of a hydraulic-oscillator-equipped drill string incorporating nonlinear friction behavior was established. Integrated with experimental friction data, the effects of drill string material, drilling fluid type, rock type, and tool vibration parameters on the hydraulic oscillator’s friction reduction capability were systematically analyzed.

- (2)

- The influence of drill string material on the drag reduction performance of the hydraulic oscillator was limited. When applied to horizontal wells, the tool exhibited slightly better performance with G105 steel drill strings than with those made of S135 steel.

- (3)

- The type of drilling fluid significantly affected the drag reduction capability of the hydraulic oscillator; oil-based drilling fluids form more stable lubricating films and are preferred in horizontal well sections with high frictional resistance.

- (4)

- The type of rock had a pronounced impact on the drag reduction efficiency of the hydraulic oscillator. In sandstone formations, the use of oil-based fluids combined with high-excitation hydraulic oscillators is recommended. In shale formations, tools with medium excitation intensity are sufficient to achieve effective drag reduction. For limestone formations, oil-based fluids with high excitation parameters can enhance drag reduction, though energy consumption should also be considered.

- (5)

- Vibration parameters strongly influenced the tool’s drag reduction performance, with increases in amplitude contributing significantly more to efficiency improvements than increases in frequency. Therefore, when designing tool vibration parameters, priority should be given to increasing amplitude to achieve better drag reduction outcomes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References and Note

- Roper, D.L. Reduction of the Frictional Coefficient in a Borehole by the Use of Vibration. U.S. Patent 4,398,594, 16 August 1983. [Google Scholar]

- Sola, K.-I.; Lund, B. New downhole tool for coiled tubing extended reach. In Proceedings of the SPE/ICoTA Coiled Tubing Roundtable, Houston, TX, USA, 5–6 April 2000. [Google Scholar]

- Newman, K.; Burnett, T.; Pursell, J.; Gouasmia, O. Modeling the affect of a downhole vibrator. In Proceedings of the SPE/ICoTA Coiled Tubing & Well Intervention Conference and Exhibition, The Woodlands, TX, USA, 31 March–1 April 2009; p. SPE-121752-MS. [Google Scholar]

- Zhang, H.; Yu, W.; Chen, Z.-S.; Cai, W. Development of hydropulse axial-oscillation friction-reduce tool. Oil Field Equip. 2014, 43, 73–77. [Google Scholar]

- Wang, P.; Ni, H.; Wang, R. A novel vibration drilling tool used for reducing friction and improving the penetration rate of petroleum drilling. J. Pet. Sci. Eng. 2018, 165, 436–443. [Google Scholar] [CrossRef]

- Wang, P.; Ni, H.; Wang, X.; Wang, R. Modelling the load transfer and tool surface for friction reduction drilling by vibrating drill-string. J. Pet. Sci. Eng. 2018, 164, 333–343. [Google Scholar] [CrossRef]

- Liu, H.; Fu, Q.; Zhou, J.; Wu, X.; Zhao, P.; Wang, J. Vibration frequency analysis of jetting hydraulic oscillator. China Pet. Mach. 2016, 44, 20–24. [Google Scholar]

- Nie, Y.; Zhang, Y.; Fan, X.; Zhao, C.; Zhang, H. Development and application of self-excited vortex control hydraulic oscillator. Pet. Drill. Tech. 2019, 47, 74–79. [Google Scholar]

- Wang, W.; Li, G.; Li, J.; Zha, C.; Chen, T. Structural design and performance parameters of valve-type hydraulic oscillator. China Pet. Mach. 2022, 50, 17–23. [Google Scholar]

- Wang, J.; Zhang, F.; Yang, C.; Liu, H.; Yu, C.; Zhang, Z. Development and test of low-pressure high energy and long life hydraulic oscillator. Oil Field Equip. 2024, 53, 30–35. [Google Scholar]

- Bo, L. Development and pilot test of hydro-oscillator. Pet. Drill. Tech. 2014, 42, 111–113. [Google Scholar]

- Baker, H.D.; Cook, W.; Fuller, D.D. In Proceedings of the First U.S. National Congress of Applied Mechanics Held at Illinois Institute of Technology, Chicago, IL, USA, 11–16 June 1951.

- Pohlman, R.; Lehfeldt, E. Influence of ultrasonic vibration on metallic friction. Ultrasonics 1966, 4, 178–185. [Google Scholar] [CrossRef]

- Pance, R.; Hassan, A. A study of the buckling of rotary drilling strings. AIAA J. 1971, 9, 1385–1390. [Google Scholar]

- Barakat, E.R.; Miska, S.; Yu, M.; Takach, N. The effect of hydraulic vibrations on initiation of buckling and axial force transfer for helically buckled pipes at simulated horizontal wellbore conditions. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 20–22 February 2007; p. SPE-105123-MS. [Google Scholar]

- Wicks, N.; Pabon, J.; Zheng, A. Modeling and field trials of the effective tractoring force of axial vibration tools. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 10–11 September 2014; p. SPE D021S014R004. [Google Scholar]

- Liu, Y.; Chen, P.; Wang, X.; Ma, T. Modeling friction-reducing performance of an axial oscillation tool using dynamic friction model. J. Nat. Gas Sci. Eng. 2016, 33, 397–404. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, H.; Li, G.; Song, X.; Zhao, H. Mechanism analysis of friction reduction in coiled tubing drilling with axial vibratory tool. J. Pet. Sci. Eng. 2019, 175, 324–337. [Google Scholar] [CrossRef]

- Zheng, X.; Agarwal, V.; Liu, X.; Balachandran, B. Nonlinear instabilities and control of drill-string stick-slip vibrations with consideration of state-dependent delay. J. Sound Vib. 2020, 473, 115235. [Google Scholar] [CrossRef]

- Shi, X.; Huang, W.; Gao, D. Mechanical models of drillstrings with drag reduction oscillators and optimal design methods of vibration parameters in horizontal drilling. Geoenergy Sci. Eng. 2023, 224, 211585. [Google Scholar] [CrossRef]

- Shi, X.; Huang, W.; Gao, D.; Zhu, N. Optimal design of drag reduction oscillators by considering drillstring fatigue and hydraulic loss in sliding drilling. J. Pet. Sci. Eng. 2022, 208, 109572. [Google Scholar] [CrossRef]

- Shi, X.; Huang, W.-J.; Gao, D.-L. Mechanical behavior of drillstring with drag reduction oscillators and its effects on sliding drilling limits. Pet. Sci. 2021, 18, 1689–1697. [Google Scholar] [CrossRef]

- Li, C.; Pavelescu, D. The friction-speed relation and its influence on the critical velocity of stick-slip motion. Wear 1982, 82, 277–289. [Google Scholar]

- Armstrong, B. Friction: Experimental determination, modeling and compensation. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988. [Google Scholar]

- Canudas de Wit, C.; Carrillo, J. A modified EW-RLS algorithm for systems with bounded disturbances. Automatica 1990, 26, 599–606. [Google Scholar] [CrossRef]

- Ge, S.S.; Hang, L.T.; Ren, S.X. Adaptive friction compensation of servo mechanisms. Int. J. Syst. Sci. 2001, 32, 523–532. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Liu, G.; Chen, T.; Li, J.; Wang, W.; Li, S.; Wang, L. Study of the Effects of Differences in Drill Pipe Materials, Drilling Fluids, and Formation Rock Types on the Drag Reduction Capacity of Hydraulic Oscillators. Processes 2025, 13, 1918. https://doi.org/10.3390/pr13061918

He X, Liu G, Chen T, Li J, Wang W, Li S, Wang L. Study of the Effects of Differences in Drill Pipe Materials, Drilling Fluids, and Formation Rock Types on the Drag Reduction Capacity of Hydraulic Oscillators. Processes. 2025; 13(6):1918. https://doi.org/10.3390/pr13061918

Chicago/Turabian StyleHe, Xin, Gonghui Liu, Tian Chen, Jun Li, Wei Wang, Shichang Li, and Lincong Wang. 2025. "Study of the Effects of Differences in Drill Pipe Materials, Drilling Fluids, and Formation Rock Types on the Drag Reduction Capacity of Hydraulic Oscillators" Processes 13, no. 6: 1918. https://doi.org/10.3390/pr13061918

APA StyleHe, X., Liu, G., Chen, T., Li, J., Wang, W., Li, S., & Wang, L. (2025). Study of the Effects of Differences in Drill Pipe Materials, Drilling Fluids, and Formation Rock Types on the Drag Reduction Capacity of Hydraulic Oscillators. Processes, 13(6), 1918. https://doi.org/10.3390/pr13061918