Characterization of Briquettes from Potato Stalk Residues for Sustainable Solid Biofuel Production

Abstract

1. Introduction

2. Materials and Methods

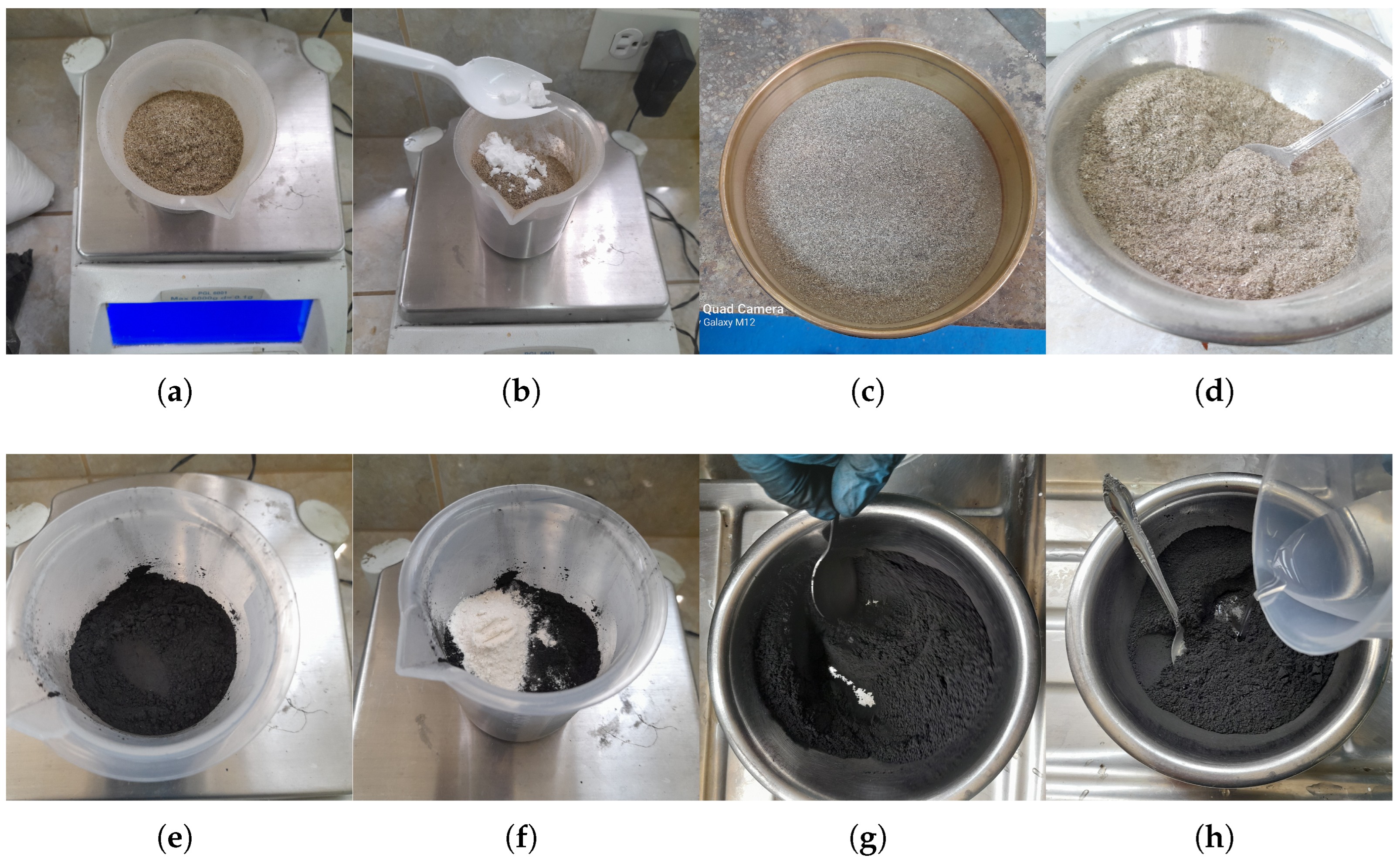

2.1. Biomass Preparation

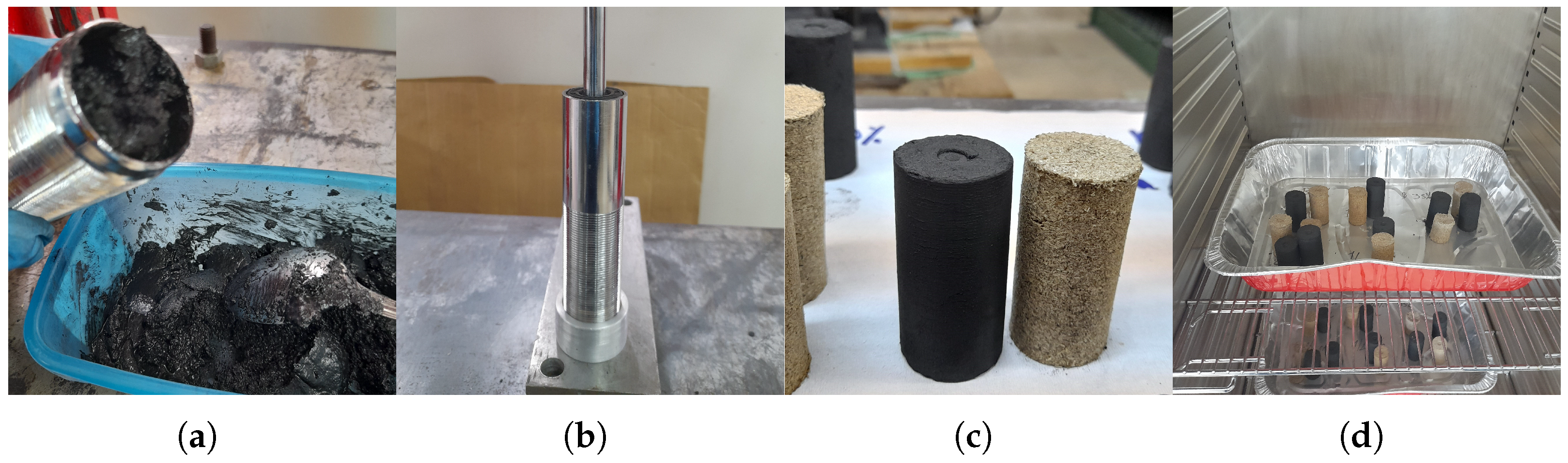

2.2. Briquette Production

2.3. Scanning Electron Microscopy (SEM)

- Accelerating voltage: 10 kV and 5 kV;

- Filament loading: 70.2%;

- Magnifications: 100X, 500X, and 1500X;

- Imaging mode: Standard conditions were applied to optimize contrast and resolution.

2.4. Raman Spectroscopy

- Excitation source: 532 nm laser wavelength;

- Laser power: 50 mW;

- Objective lens: 50X magnification;

- Focal aperture: 100 μm.

2.5. Thermogravimetric Analysis (TGA)

- Sample weight range: 5–30 mg;

- Temperature range/heating rate: 25–700 °C: 5 °C/min;

- Atmosphere: Inert nitrogen gas at 50 mL/min to both the sample and the microbalance.

2.6. Compression Test

2.7. Thermal Characterization

3. Results and Discussion

3.1. Morphology

3.2. Carbon Formation

3.3. Thermal Decomposition

- Moisture evaporation (0 °C–190 °C).

- Volatile matter decomposition (190 °C–380 °C).

- Charcoal zone (380 °C–700 °C).

3.4. Compression Strength

3.5. Higher Heating Value

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CB | Carbonized Biomass |

| NCB | Non-Carbonized Biomass |

| WC | Wood Charcoal |

| PS | Potato Stalk |

| SEM | Scanning Electron Microscopy |

| TGA | Thermogravimetric Analysis |

| HVV | Higher Heating Value |

| ASTM | American Society for Testing and Materials |

| IUPAC | International Union of Pure and Applied Chemistry |

References

- Ritchie, H.; Rosado, P.; Roser, M. Energy Production and Consumption. Our World in Data 2020. Available online: https://ourworldindata.org/energy-production-consumption (accessed on 3 January 2025).

- Chidumayo, E.N.; Gumbo, D.J. The environmental impacts of charcoal production in tropical ecosystems of the world: A synthesis. Energy Sustain. Dev. 2013, 17, 86–94. [Google Scholar] [CrossRef]

- Espinoza Tellez, T.; Bastías, J.; Quevedo, R.; Valencia, E.; Aburto, H.; Díaz-Guineo, D.; Ibarra-Garnica, M.; Diaz, O. Agricultural, forestry, textile and food waste used in the manufacture of biomass briquettes: A review. Sci. Agropecu. 2020, 11, 427–437. [Google Scholar] [CrossRef]

- Sampathkumar, V.; Manoj, S.; Nandhini, V.; Lakshmi, N.; Janani, S. Briquetting of Biomass for Low Cost Fuel using Farm Waste, Cow Dung and Cotton Industrial Waste. Int. J. Recent Technol. Eng. 2019, 8, 8349–8353. [Google Scholar] [CrossRef]

- Arévalo, J.; Quispe, G.; Raymundo, C. Sustainable Energy Model for the production of biomass briquettes based on rice husk in low-income agricultural areas in Peru. Energy Procedia 2017, 141, 138–145. [Google Scholar] [CrossRef]

- Baqir, M.; Kothari, R.; Singh, R. Fuel wood consumption, and its influence on forest biomass carbon stock and emission of carbon dioxide. A case study of Kahinaur, district Mau, Uttar Pradesh, India. Biofuels 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2019, 7, 1801011. [Google Scholar] [CrossRef]

- Mishra, R.; Mohanty, K. Characterization of non-edible lignocellulosic biomass in terms of their candidacy towards alternative renewable fuels. Biomass Convers. Biorefinery 2018, 8, 799–812. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Miranda, T.; Montero, I.; Sepúlveda Justo, F.; Arranz, J.I.; Rojas, C.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaták, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.; Hess, J.; Kenney, K. Erratum: A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 720. [Google Scholar] [CrossRef]

- Silos-Llamas, A.K.; Sudibyo, H.; Hernández-Montoya, V.; Meredith, W.; Durán-Jiménez, G. Fast pyrolysis of agricultural residues: Reaction mechanisms and effects of feedstock properties and microwave operating conditions on the yield and product composition. J. Anal. Appl. Pyrolysis 2023, 175, 106217. [Google Scholar] [CrossRef]

- Murni, S.W.; Setyoningrum, T.M.; Nur, M.M.A. Production of briquettes from Indonesia agricultural biomass waste by using pyrolysis process and comparing the characteristics. Eksergi 2021, 18, 13–17. [Google Scholar] [CrossRef]

- Setiawan, A.; Nugraha, A.; Cahyono, L.; Nindyapuspa, A.; Widiana, D.R.; Kusuma, S.A. The Study on Utilization of Agricultural Waste as an Alternative Fuel for Bio-briquettes. Int. J. Progress. Sci. Technol. 2023, 40, 44. [Google Scholar] [CrossRef]

- Patil, G. The possibility study of briquetting agricultural wastes for alternative energy. Indones. J. For. Res. 2019, 6, 133–139. [Google Scholar] [CrossRef]

- Kimura, L.M.; Santos, L.C.; Vieira, P.F.; Parreira, P.M.; Henrique, H.M. Biomass Pyrolysis: Use of Some Agricultural Wastes for Alternative Fuel Production. Mater. Sci. Forum 2010, 660–661, 259–264. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Öngen, A.; Karabağ, N.; Hunce, S.Y.; Özcan, H.K.; Özbaş, E.E.; Aydın, S. An Assessment of Pyrolysis Process for the Treatment of Agricultural and Forest Wastes. In Recycling and Reuse Approaches for Better Sustainability; Balkaya, N., Guneysu, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 97–110. [Google Scholar] [CrossRef]

- Kappler, G.; Hauschild, T.; Tarelho, L.A.; Moraes, C.A.M. Waste to energy and materials through pyrolysis: A review. Rev. Tecnol. Soc. 2022, 18, 281. [Google Scholar] [CrossRef]

- Tuquerrez, G.K.C.; Pavón, G.A.N.; Moya, J.C.E.; Park, C.H. Effect of use of Certified Seed to Increase Potato (Solanum Tuberosum) Production in Ecuador. Cienc. Lat. 2023, 7, 8310–8326. [Google Scholar] [CrossRef]

- D-Lab. Charcoal Press Build-It Teachers Notes; D-Lab: Singapore, 2024. [Google Scholar]

- Ujjinappa, S.; Sreepathi, L. Evaluation of Physico-Mechanical-Combustion Characteristics of Fuel Briquettes made from blends of Areca Nut Husk, Simarouba Seed Shell and Black Liquor. Int. J. Renew. Energy Dev. 2018, 7, 131. [Google Scholar] [CrossRef]

- Khlifi, S.; Lajili, M.; Belghith, S.; Mezlini, S.; Tabet, F.; Jeguirim, M. Briquettes Production from Olive Mill Waste under Optimal Temperature and Pressure Conditions: Physico-Chemical and Mechanical Characterizations. Energies 2020, 13, 1214. [Google Scholar] [CrossRef]

- Sawadogo, M.; Tchini Tanoh, S.; Sidibé, S.; Kpai, N.; Tankoano, I. Cleaner production in Burkina Faso: Case study of fuel briquettes made from cashew industry waste. J. Clean. Prod. 2018, 195, 1047–1056. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Ruíz-García, V.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G. Exploitation of Wood Waste of Pinus spp for Briquette Production: A Case Study in the Community of San Francisco Pichátaro, Michoacán, Mexico. Appl. Sci. 2020, 10, 2933. [Google Scholar] [CrossRef]

- Singh, A.K.; Sharma, M.; Singh, M. SEM and reflected light petrography: A case study on natural cokes from seam XIV, Jharia coalfield, India. Fuel 2013, 112, 502–512. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A.; Muhairwe, F.; Kihedu, J. Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renew. Energy 2020, 148, 1002–1016. [Google Scholar] [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- BS EN 14918:2009; Solid Biofuels—Determination of Calorific Value. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- Trubetskaya, A.; Leahy, J.J.; Yazhenskikh, E.; Müller, M.; Layden, P.; Johnson, R.; Ståhl, K.; Monaghan, R.F. Characterization of woodstove briquettes from torrefied biomass and coal. Energy 2019, 171, 853–865. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Abdul Salam, P. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Florentino-Madiedo, L.; Díaz-Faes, E.; Barriocanal, C. Reactivity of biomass containing briquettes for metallurgical coke production. Fuel Process. Technol. 2019, 193, 212–220. [Google Scholar] [CrossRef]

- Niño, A.; Arzola, N.; Araque, O. Experimental Study on the Mechanical Properties of Biomass Briquettes from a Mixture of Rice Husk and Pine Sawdust. Energies 2020, 13, 1060. [Google Scholar] [CrossRef]

- Kpalo, S.; Zainuddin, M.; Halim, H.; Ahmad, F.; Abbas, Z. Physical characterization of briquettes produced from paper pulp and Mesua ferrea mixtures. Biofuels 2019, 13, 1–8. [Google Scholar] [CrossRef]

- Fazlitdinova, A.; Tyumentsev, V. Study of Structural Transformation of High-Sulfur Carbon Materials During Graphitization by Raman Spectroscopy and X-Ray Diffraction Analysis. ChemChemTech 2024, 67, 114–121. [Google Scholar] [CrossRef]

- Deiana, C.; Gimenez, M.; Sardella, M.; Sapag, K.; Masseo, A.; Teixeira, A.; Araujo, M.; Lago, R. Catalytic Oxidation of Aqueous Sulfide Promoted by Oxygen Functionalities on the Surface of Activated Carbon Briquettes Produced from Viticulture Wastes. J. Braz. Chem. Soc. 2014, 25, 2392–2398. [Google Scholar] [CrossRef]

- Flores Jerónimo, G.; Guerrero Salazar, C.A.; González González, V.A.; Guerrero Salas, T. Química verde en la síntesis de rGO partiendo de la exfoliación electroquímica del grafito. Ingenierías 2019, 22, 54–65. [Google Scholar]

- Ferrari, A. Resonant Raman Spectroscopy of Disordered, Amorphous, and Diamondlike Carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Singh, A.; Yasri, N.; Karan, K.; Roberts, E. Electrocatalytic Activity of Functionalized Carbon Paper Electrodes and Their Correlation to the Fermi Level Derived from Raman Spectra. ACS Appl. Energy Mater. 2019, 2, 2324–2336. [Google Scholar] [CrossRef]

- Navalta, C.J.L.G.; Banaag, K.G.C.; Raboy, V.A.O.; Go, A.W.; Cabatingan, L.K.; Ju, Y.H. Solid fuel from Co-briquetting of sugarcane bagasse and rice bran. Renew. Energy 2020, 147, 1941–1958. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Ioannidou, O. Evaluation of utilization of corn stalks for energy and carbon material production by using rapid pyrolysis at high temperature. Fuel 2008, 87, 834–843. [Google Scholar] [CrossRef]

- Sánchez, C.M.; Marie, T. TGA-MS Studies of the Pyrolysis of Corn Stover for Charcoal Production. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2016. [Google Scholar]

- Rudolfsson, M. Characterization and Densification of Carbonized Lignocellulosic Biomass. Ph.D. Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2016. [Google Scholar]

- Sinha, S.; Jhalani, A.; M R, R.; Ray, A. Modeling of pyrolysis in wood: A review. Sol. Energy Soc. India 2000, 10, 41–62. [Google Scholar]

- Ungureanu, N.; Vladut, V.; Voicu, G.; Dinca, M.; Zabava, B.-S. Influence of biomass moisture content on pellet properties—Review. In Proceedings of the Enginering for Rural Development, Jelgava, Latvia, 23–25 May 2018. [Google Scholar] [CrossRef]

- Tabasso, S.; Grillo, G.; Mariatti, F.; Cravotto, G. Alternative Techniques and Sustainable Methods for the Valorisation of Lignocellulosic Biomass. In Biomass Burning in Sub-Saharan Africa: Chemical Issues and Action Outreach; Springer: Dordrecht, The Netherlands, 2020; pp. 83–91. [Google Scholar] [CrossRef]

- Yank, A.; Ngadi, M.; Kok, R. Physical properties of rice husk and bran briquettes under low pressure densification for rural applications. Biomass Bioenergy 2016, 84, 22–30. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubík, H.; Brožek, M. Bamboo Fiber and Sugarcane Skin as a Bio-Briquette Fuel. Energies 2018, 11, 2186. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, S.; Wang, C.; Mu, C.; Huang, X. High-strength charcoal briquette preparation from hydrothermal pretreated biomass wastes. Fuel Process. Technol. 2018, 171, 293–300. [Google Scholar] [CrossRef]

- Mohd Faizal, A.; Mohd-Shaid, M.; Ahmad Zaini, M.A. Solid fuel briquette from biomass: Recent trends. Ovidius Univ. Ann. Chem. 2022, 33, 150–155. [Google Scholar] [CrossRef]

- Sanchez, P.D.; Aspe, M.; Sindol, K. An Overview on the Production of Bio-briquettes from Agricultural Wastes: Methods, Processes, and Quality. J. Agric. Food Eng. 2022, 3. [Google Scholar] [CrossRef]

- Falemara, B.C.; Joshua, V.I.; Aina, O.O.; Nuhu, R.D. Performance Evaluation of the Physical and Combustion Properties of Briquettes Produced from Agro-Wastes and Wood Residues. Recycling 2018, 3, 37. [Google Scholar] [CrossRef]

- Rago, Y.P.; Collard, F.X.; Görgens, J.F.; Surroop, D.; Mohee, R. Torrefaction of biomass and plastic from municipal solid waste streams and their blends: Evaluation of interactive effects. Fuel 2020, 277, 118089. [Google Scholar] [CrossRef]

- Berge, N.; Ro, K.; Mao, J.; Flora, J.; Chappell, M.; Bae, S. Hydrothermal Carbonization of Municipal Waste Streams. Environ. Sci. Technol. 2011, 45, 5696–5703. [Google Scholar] [CrossRef]

- Yuan, H.; Yang, Q.; Wang, Y.; Gu, J.; He, M.; Sun, F. Impact of Torrefaction on the Fuel Properties and Combustion Characteristics of Compost of Food Waste and Sawdust. Energy Fuels 2018, 32, 3469–3476. [Google Scholar] [CrossRef]

- Abdulyekeen, K.A.; Umar, A.A.; Patah, M.F.A.; Daud, W.M.A.W. Torrefaction of biomass: Production of enhanced solid biofuel from municipal solid waste and other types of biomass. Renew. Sustain. Energy Rev. 2021, 150, 111436. [Google Scholar] [CrossRef]

| Biomass Type | Designation | Binder Fraction (%) | Compaction Time (s) |

|---|---|---|---|

| Carbonized | CB–PS10–I | 10 | 30 |

| CB–PS10–II | 10 | 60 | |

| CB–PS20–I | 20 | 30 | |

| CB–PS20–II | 20 | 60 | |

| CB–AS10–I | 10 | 30 | |

| CB–AS10–II | 10 | 60 | |

| CB–AS20–I | 20 | 30 | |

| CB–AS20–II | 20 | 60 | |

| Non-Carbonized | NCB–PS10–I | 10 | 30 |

| NCB–PS10–II | 10 | 60 | |

| NCB–PS20–I | 20 | 30 | |

| NCB–PS20–II | 20 | 60 | |

| NCB–AS10–I | 10 | 30 | |

| NCB–AS10–II | 10 | 60 | |

| NCB–AS20–I | 20 | 30 | |

| NCB–AS20-II | 20 | 60 | |

| Carbonized | CB–PS35–II | 35 | 60 |

| CB–PS50–II | 50 | ||

| CB–AS35–II | 35 | ||

| CB–AS50–II | 50 | ||

| Non-Carbonized | NCB–PS35–II | 35 | 60 |

| NCB–PS50–II | 50 | ||

| NCB–AS35–II | 35 | ||

| NCB–AS50–II | 50 | ||

| PS | – | ||

| Carbonized | WC1 | – | – |

| WC2 | – | – |

| Sample | Parameter | D-Band | G-Band | ID/IG |

|---|---|---|---|---|

| CB-PS10-II | Position (cm−1) | 1328.68 | 1585.04 | 0.91 |

| Intensity ( | 0.90701 | 1 | ||

| CB-PS20-II | Position (cm−1) | 1350.79 | 1594.29 | 0.80 |

| Intensity ( | 0.79632 | 1 | ||

| CB-PS35-II | Position (cm−1) | 1356.06 | 1589.67 | 0.78 |

| Intensity ( | 0.77500 | 1 | ||

| CB-PS50-II | Position (cm−1) | 1357.13 | 1589.67 | 0.70 |

| Intensity ( | 0.70363 | 1 | ||

| CB-AS10-II | Position (cm−1) | 1352.18 | 1589.67 | 0.76 |

| Intensity ( | 0.76442 | 1 | ||

| CB-AS20-II | Position (cm−1) | 1353.76 | 1592.57 | 0.81 |

| Intensity ( | 0.81187 | 1 | ||

| CB-AS35-II | Position (cm−1) | 1360.10 | 1592.57 | 0.75 |

| Intensity ( | 0.74644 | 1 | ||

| CB-AS50-II | Position (cm−1) | 1334.84 | 1584.85 | 0.82 |

| Intensity ( | 0.82092 | 1 | ||

| WCI | Position (cm−1) | 1376.13 | 1595.83 | 0.72 |

| Intensity ( | 0.72097 | 1 |

| Sample | Moisture Evaporation (%) | Volatile Matter (%) | Lignin and Thermally Resistant Materials (%) | Fixed Carbon (%) |

|---|---|---|---|---|

| NCB-PS10-II | 12.35 | 57.58 | 9.49 | 20.58 |

| NCB-PS20-II | 12.14 | 58.50 | 9.08 | 20.28 |

| NCB-AS10-II | 13.32 | 57.19 | 10.72 | 10.77 |

| NCB-AS20-II | 13.06 | 56.26 | 9.23 | 21.45 |

| CB-PS10-II | 7.55 | 11.60 | 5.85 | 69.11 |

| CB-PS20-II | 7.73 | 17.31 | 5.55 | 69.41 |

| CB-AS10-II | 7.69 | 11.81 | 6.60 | 73.9 |

| CB-AS20-II | 7.89 | 18.16 | 4.53 | 69.42 |

| PS | 10.55 | 63.85 | 8.47 | 17.13 |

| Sample | Moisture Evaporation (%) | Volatile Matter (%) | Fixed Carbon (%) | Reference |

|---|---|---|---|---|

| PS | 10.55 | 63.85 | 17.13 | – |

| NCB-AS10-II | 13.32 | 57.19 | 10.77 | – |

| Wheat husk | 5.98 | 69.19 | 12.72 | [48] |

| Rice husk | 4.65 | 68.89 | 17.17 | [48] |

| Corn straw | 6.10 | 76.00 | 13.20 | [49] |

| Wheat straw | 4.39 | 67.36 | 19.32 | [49] |

| Wood branch | 4.39 | 82.96 | 10.51 | [49] |

| Torrefied pelletized sawdust | 5.50 | 75.60 | 24.00 | [50] |

| Sample | Load (N) | Strength (MPa) |

|---|---|---|

| CB-PS10-I | 30.00 | 0.09 |

| CB-PS20-I | 11.11 | 0.03 |

| CB-AS10-I | 11.94 | 0.03 |

| CB-AS20-I | 10.28 | 0.03 |

| CB-PS10-II | 25.28 | 0.07 |

| CB-PS20-II | 18.33 | 0.05 |

| CB-AS10-II | 19.45 | 0.05 |

| CB-AS20-II | 16.11 | 0.05 |

| NCB-PS10-I | 446.90 | 1.35 |

| NCB-PS20-I | 426.05 | 1.30 |

| NCB-AS10-I | 420.84 | 1.28 |

| NCB-AS20-I | 566.47 | 1.70 |

| NCB-PS10-II | 368.36 | 1.10 |

| NCB-PS20-II | 436.88 | 1.39 |

| NCB-AS10-II | 513.93 | 1.55 |

| NCB-AS20-II | 582.39 | 1.78 |

| Sample | Higher Heating Value (MJ/kg) | Sample | Higher Heating Value (MJ/kg) |

|---|---|---|---|

| CB-PS10-I | 15.03 | NCB-PS10-I | 15.22 |

| CB-PS10-II | 15.76 | NCB-PS10-II | 15.16 |

| CB-PS20-I | 15.52 | NCB-PS20-I | 15.08 |

| CB-PS20-II | 15.52 | NCB-PS20-II | 15.20 |

| CB-AS10-I | 15.40 | NCB-AS10-I | 15.07 |

| CB-AS10-II | 14.52 | NCB-AS10-II | 14.99 |

| CB-AS20-I | 15.26 | NCB-AS20-I | 14.98 |

| CB-AS20-II | 15.31 | NCB-AS20-II | 14.95 |

| CB-PS35-II | 15.04 | NCB-PS35-II | 14.96 |

| CB-AS35-II | 14.96 | NCB-AS35-II | 15.09 |

| PS | 15.44 | WCI | 30.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piarpuezán Enríquez, M.A.; Zapata Hidalgo, D.R.; Pantoja-Suárez, F. Characterization of Briquettes from Potato Stalk Residues for Sustainable Solid Biofuel Production. Processes 2025, 13, 1851. https://doi.org/10.3390/pr13061851

Piarpuezán Enríquez MA, Zapata Hidalgo DR, Pantoja-Suárez F. Characterization of Briquettes from Potato Stalk Residues for Sustainable Solid Biofuel Production. Processes. 2025; 13(6):1851. https://doi.org/10.3390/pr13061851

Chicago/Turabian StylePiarpuezán Enríquez, Marlon Andrés, Daniel Roberto Zapata Hidalgo, and Fernando Pantoja-Suárez. 2025. "Characterization of Briquettes from Potato Stalk Residues for Sustainable Solid Biofuel Production" Processes 13, no. 6: 1851. https://doi.org/10.3390/pr13061851

APA StylePiarpuezán Enríquez, M. A., Zapata Hidalgo, D. R., & Pantoja-Suárez, F. (2025). Characterization of Briquettes from Potato Stalk Residues for Sustainable Solid Biofuel Production. Processes, 13(6), 1851. https://doi.org/10.3390/pr13061851