Drying of Grade-Out Cape Gooseberry (Physalis peruviana Linn.) with Mild Hydrostatic Osmotic Pretreatment Using Rotary Tray Dryer: A Case Study at Mae Hae Royal Project Development Center, Chiang Mai Province

Abstract

1. Introduction

2. Materials and Methods

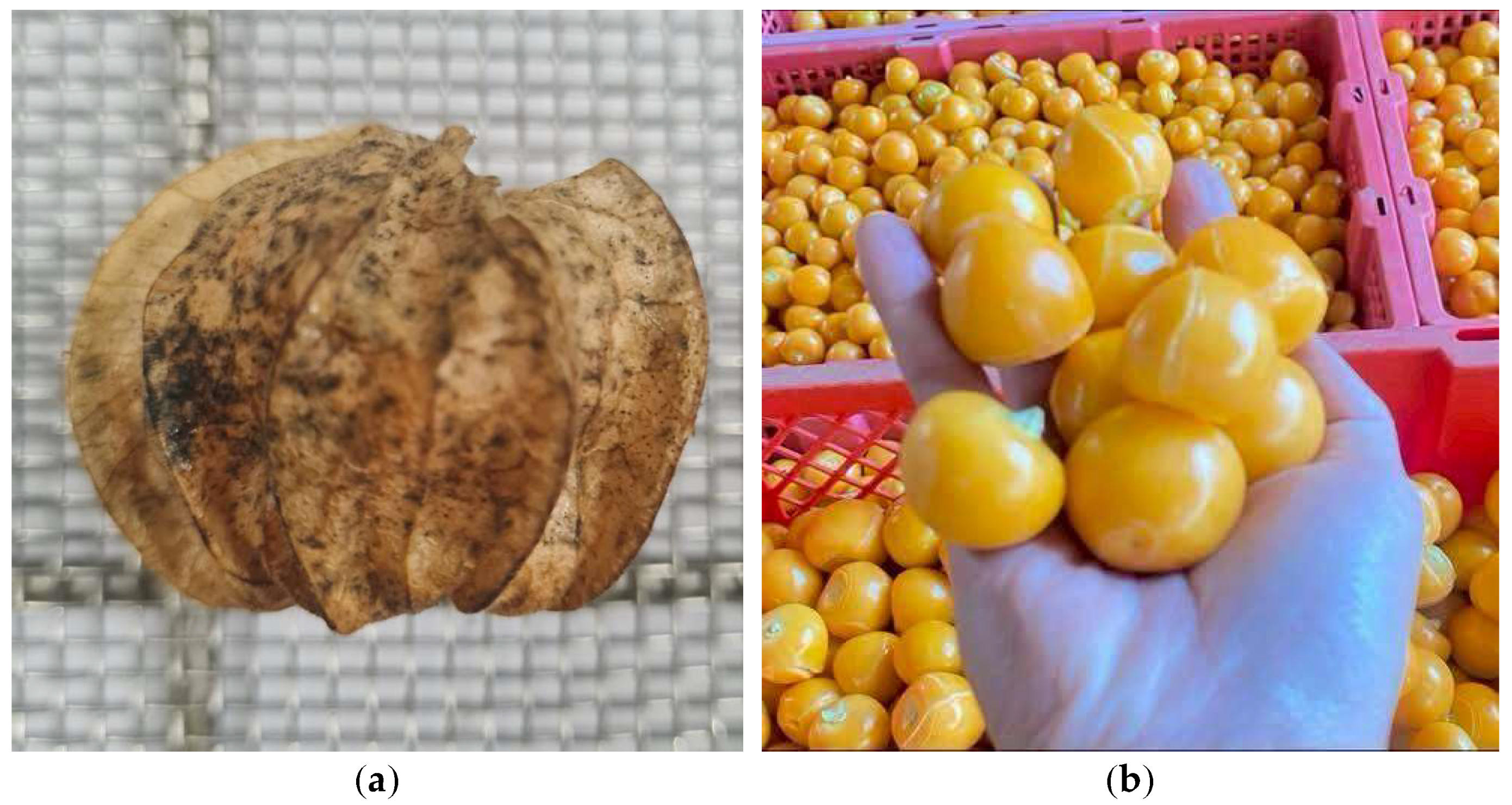

2.1. Materials

2.2. Hydrostatic Osmotic Pretreatment

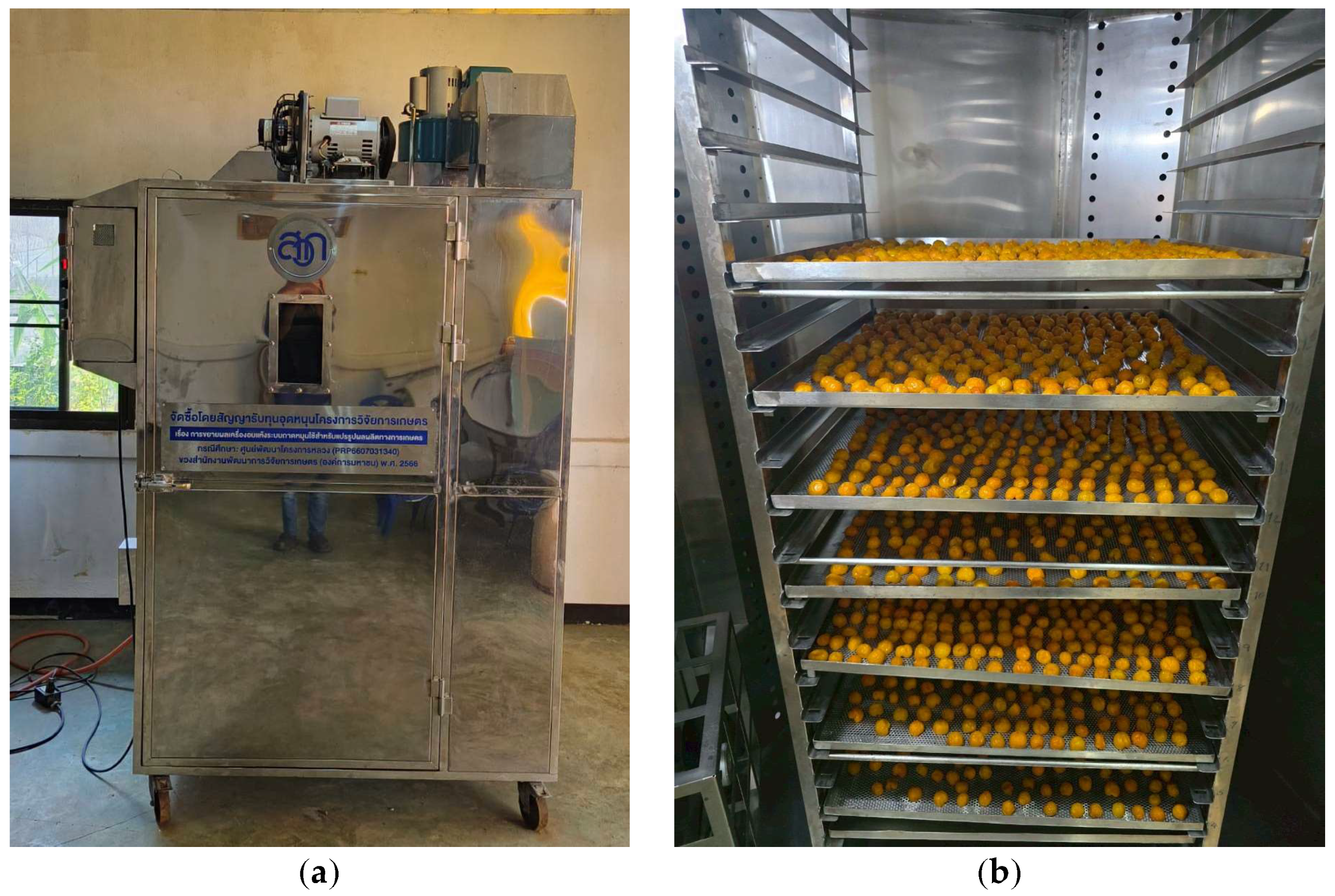

2.3. Rotary Tray Dryer

2.4. Drying Parameter

2.4.1. Moisture Content

2.4.2. Water Activity

2.4.3. Determination of Water Loss and Solid Gain

2.5. Optical Properties

2.6. Determination of Vitamin C, Total Phenolic Content, and Antioxidant Capacity

2.7. Microbiological Analysis

2.8. Cost Analysis

2.9. Statistical Analysis

3. Results

3.1. Efficacy of Hydrostatic Osmotic Pretreatment

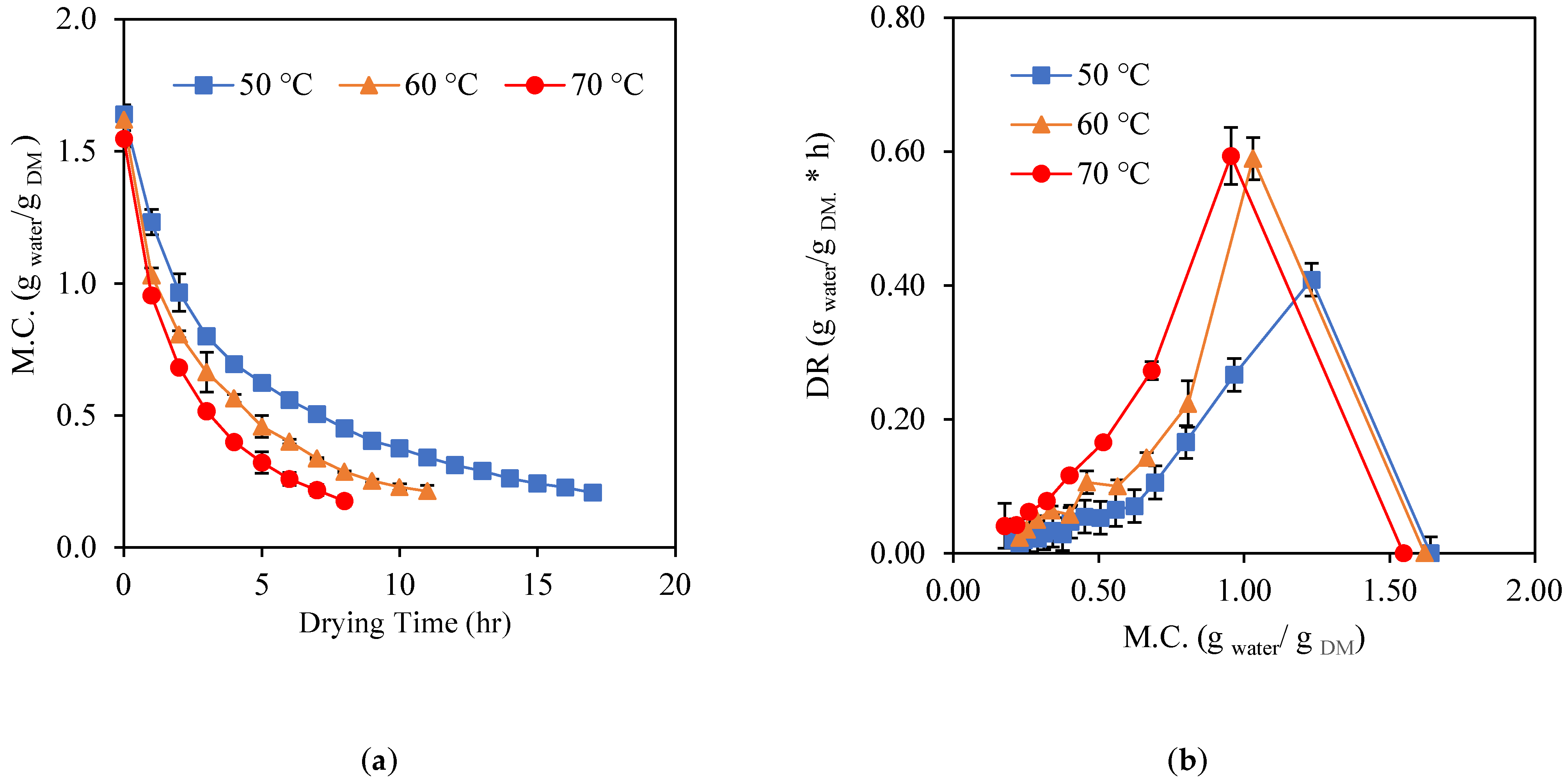

3.2. Characteristics of Drying Process

3.3. Temperature Affects Changes in Optical Properties

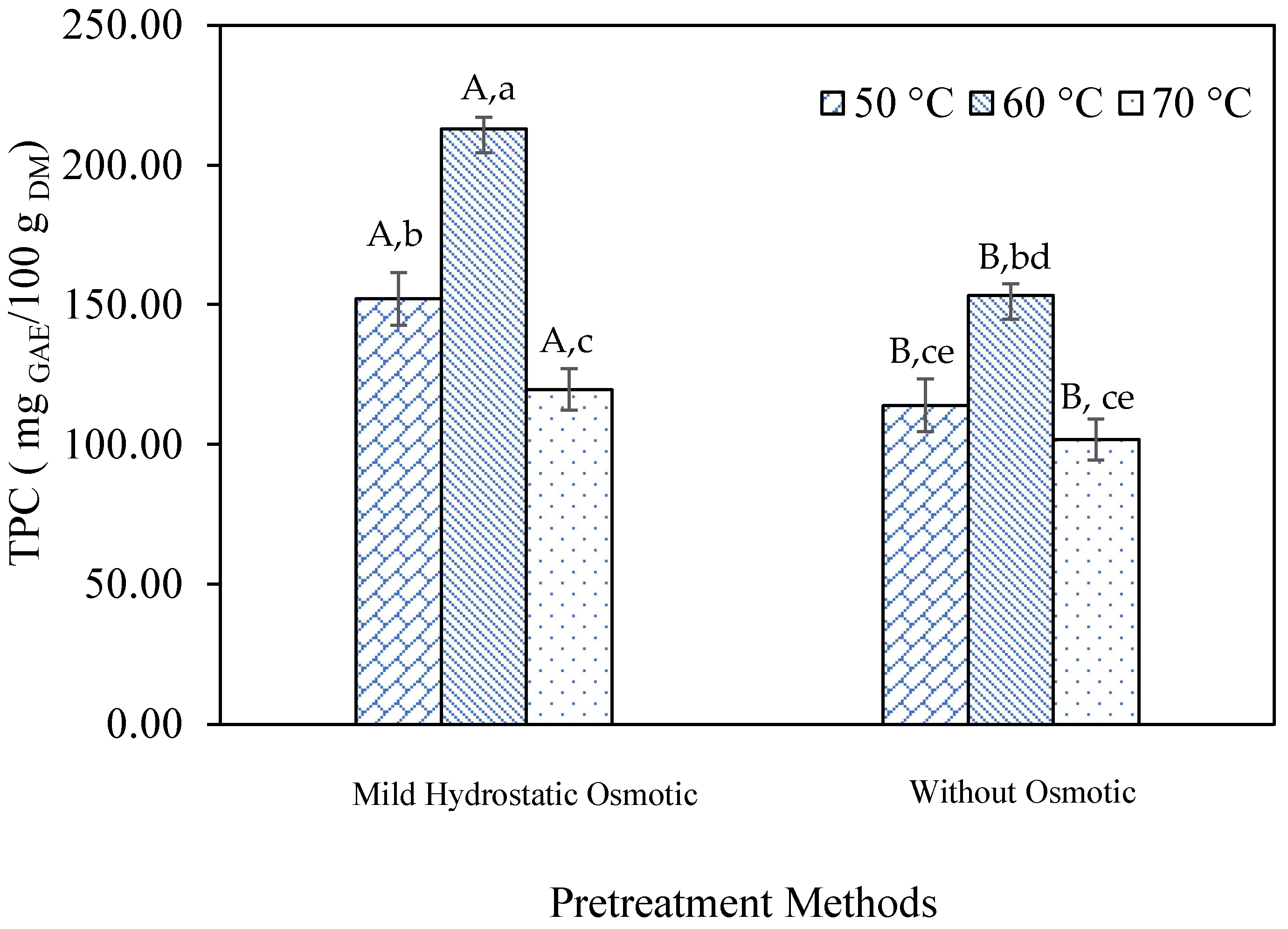

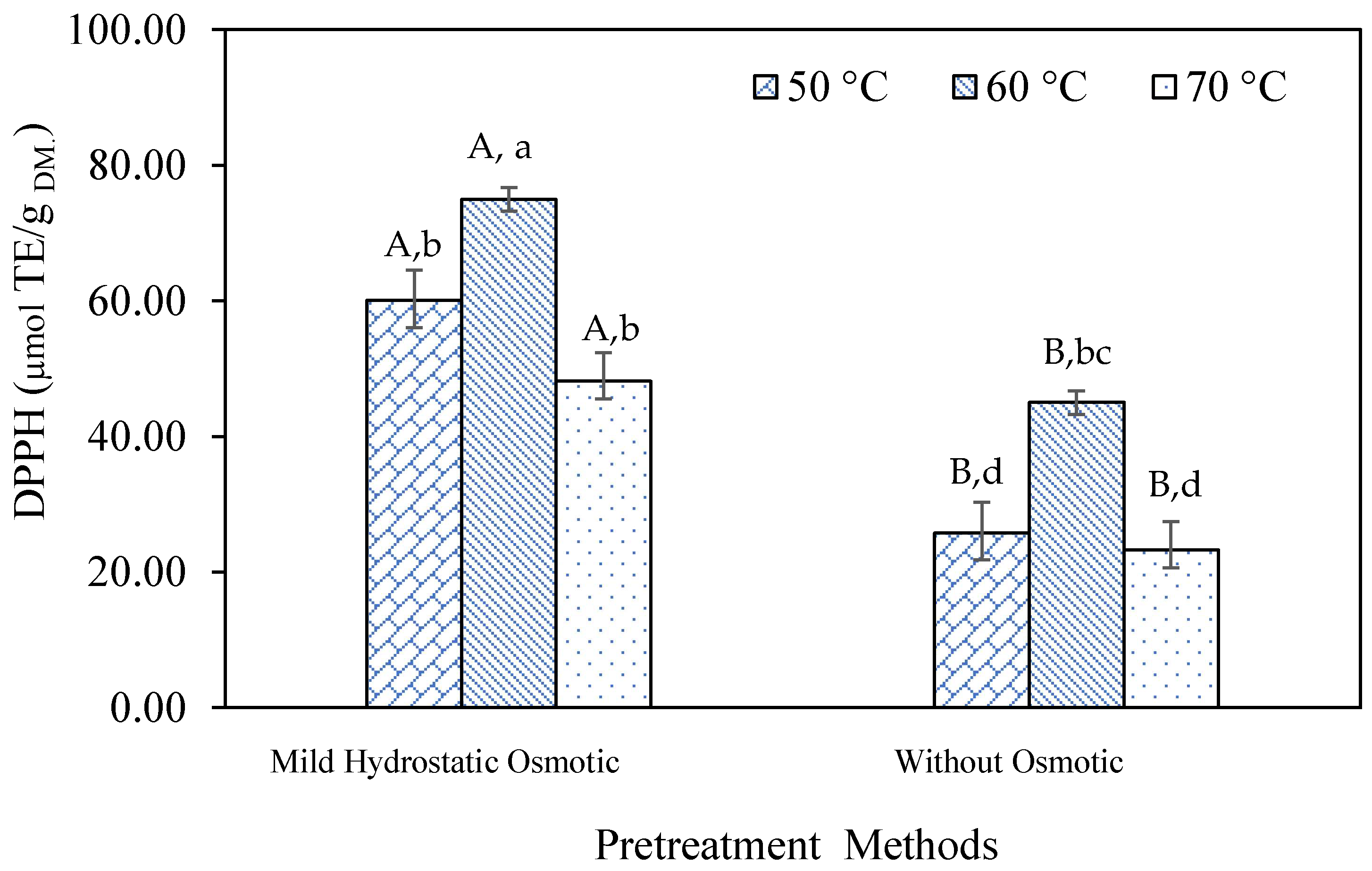

3.4. Physicochemical Properties of Grade-Out Cape Gooseberry as Affected by Drying Temperature

3.4.1. Impact of Mild Hydrostatic Osmotic Pretreatment

3.4.2. Impact of Drying Temperature

3.5. Analysis of Drying Costs

4. Discussion

5. Conclusions

6. Patents

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz, P.; Parra, F.; Simirgiotis, M.J.; Sepúlveda Chavera, G.F.; Parra, C. Chemical Characterization, Nutritional and Bioactive Properties of Physalis peruviana Fruit from High Areas of the Atacama Desert. Foods 2021, 10, 2699. [Google Scholar] [CrossRef] [PubMed]

- Monroy-Velandia, D.; Coy-Barrera, E. Effect of Salt Stress on Growth and Metabolite Profiles of Cape Gooseberry (Physalis peruviana L.) along Three Growth Stages. Molecules 2021, 26, 2756. [Google Scholar] [CrossRef]

- Gómez Racines, L.; Buitrago Vera, J.M. Export of Organic Cape Gooseberry (Physalis peruviana) as an Alternative Illicit Crop Substitution: Survey of Consumers in Namur, Belgium. Sustainability 2023, 15, 16604. [Google Scholar] [CrossRef]

- Bhaktikul, K.; Aroonsrimorakot, S.; Laiphrakpam, M. Sustainable Low-Carbon Community Development: A Study Based on a Royal Project for Highland Community Development in Thailand. J. Community Dev. Res. (Humanit. Soc. Sci.) 2021, 14, 14–28. [Google Scholar]

- Nosten, M. Rotational Farming by the Karen People and Its Role in Livelihood Adaptive Capacity and Biocultural Conservation: A Case Study of Upland Community Forestry in Thailand. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2024. [Google Scholar]

- Assawarachan, R. Rotary Tray Hot-Air Dryer with Two-Stage Temperature Control System. Thai Petty Patent No. 18896, 2020, 14 December 2021. [Google Scholar]

- Ahmed, M.; Hasan, M.; Islam, M.N. Effect of osmotic dehydration pretreatment on drying kinetics and quality characteristics of fruits and vegetables: A review. J. Food Process. Preserv. 2021, 45, e15434. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, J.; Kumar, R.; Sunil; Chaudhary, V.; Singh, B. Effect of Drying Methods and Pretreatments on Dehydration and Rehydration Characteristics of Osmo-Dried Papaya Slices; Hind Agricultural Research and Training Institute: Meerut, India, 2025; Available online: https://www.cabidigitallibrary.org/doi/pdf/10.5555/20219982832 (accessed on 4 June 2025).

- Kroehnke, J.; Szadzińska, J.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G.; Mierzwa, D. Osmotic Dehydration and Convective Drying of Kiwifruit (Actinidia deliciosa)—The Influence of Ultrasound on Process Kinetics and Product Quality. Ultrason. Sonochem. 2021, 71, 105377. [Google Scholar] [CrossRef]

- Ahamad, S.; Sagar, V.R.; Asrey, R.; Islam, S.; Tomar, B.S.; Vinod, B.R.; Kumar, A. Nutritional Retention and Browning Minimisation in Dehydrated Onion Slices through Potassium Metabisulphite and Sodium Chloride Pre-Treatments. Int. J. Food Sci. Technol. 2024, 59, 5794–5805. [Google Scholar] [CrossRef]

- Luechai, N.; Khamsuk, T.; Aramkhiphai, S.; Keadsak, P.; Lungjitang, N. Effect of Temperature on Quality Change of Drying Cape Gooseberry (Physalis peruviana Linn.). Unpublished. Undergraduate Thesis, Bachelor of Engineering Program in Smart Farm and Agricultural Innovation. School of Renewable Energy, Maejo University, Chiang Mai, Thailand, 2025; p. 66. [Google Scholar]

- Bhat, T.A.; Rather, A.H.; Hussain, S.Z.; Naseer, B.; Qadri, T.; Nazir, N. Efficacy of Ascorbic Acid, Citric Acid, Ethylenediaminetetraacetic Acid, and 4-Hexylresorcinol as Inhibitors of Enzymatic Browning in Osmo-Dehydrated Fresh Cut Kiwis. J. Food Meas. Charact. 2021, 15, 4354–4370. [Google Scholar] [CrossRef]

- AOAC International. Official Method 920.151: Solids (Total) in Fruits and Fruit Products. In Official Methods of Analysis of AOAC International, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019. [Google Scholar]

- Torreggiani, D.; Bertolo, G. Osmotic Pre-Treatments in Fruit Processing: Chemical, Physical and Structural Effects. J. Food Eng. 2001, 49, 247–253. [Google Scholar] [CrossRef]

- AOAC International. Official Method 967.21: Ascorbic Acid in Vitamin Preparations and Juices. In Official Methods of Analysis of AOAC International, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2023. [Google Scholar]

- Osorio-Arias, J.; Delgado-Arias, S.; Cano, L.; Zapata, S.; Quintero, M.; Nuñez, H.; Ramírez, C.; Simpson, R.; Vega-Castro, O. Sustainable Management and Valorization of Spent Coffee Grounds through the Optimization of Thin Layer Hot Air-Drying Process. Waste Biomass Valorization 2019, 11, 5015–5026. [Google Scholar] [CrossRef]

- Ignat, I.; Volf, I.; Popa, V.I. A Critical Review of Methods for Characterization of Polyphenolic Compounds in Fruits and Vegetables. Food Chem. 2011, 126, 1821–1835. [Google Scholar] [CrossRef] [PubMed]

- TIS 919–2532; Dried Fruit Products. Thai Industrial Standards Institute: Bangkok, Thailand, 1989. Available online: https://fic.nfi.or.th/law/upload/file1/TH_358.pdf (accessed on 20 May 2025).

- Santana, P.A.; de Carvalho Lopes, D.; Neto, A.J.S. Economic Analysis of Low-Temperature Grain Drying. Emir. J. Food Agric. 2019, 31, 930–936. [Google Scholar] [CrossRef]

- Pise, V.H. Techno-Economic Evaluation for Cost-Effective Drying of Different Fruit Products. In Dried Fruit Products; CRC Press: Boca Raton, FL, USA, 2024; pp. 206–233. [Google Scholar]

- Goula, A.M.; Adamopoulos, K.G.; Chatzitakis, P.C.; Nikas, V.A. Prediction of lycopene degradation during a drying process of tomato pulp. J. Food Eng. 2006, 74, 37–46. [Google Scholar] [CrossRef]

- Garcia-Noguera, J.; Oliveira, F.I.P.; Gallão, M.I.; Weller, C.L.; Rodrigues, S.; Fernandes, F.A.N. Ultrasound-Assisted Osmotic Dehydration of Strawberries: Effect of Pretreatment Time and Ultrasonic Frequency. Dry. Technol. 2010, 28, 294–303. [Google Scholar] [CrossRef]

- Shi, J.; Le Maguer, M. Osmotic Dehydration of Foods: Mass Transfer and Modeling Aspects. Food Rev. Int. 2002, 18, 305–335. [Google Scholar] [CrossRef]

- Nowacka, M.; Tylewicz, U.; Laghi, L.; Dalla Rosa, M.; Witrowa-Rajchert, D. Effect of Ultrasound Treatment on the Water State in Kiwifruit during Osmotic Dehydration. Food Chem. 2014, 144, 18–25. [Google Scholar] [CrossRef]

- Yulni, T.; Agusta, W.; Jayanegara, A.; Alfa, M.N.; Hartono, L.K.; Mariastuty, T.E.P.; Lintang, M.M.J. Unveiling the Influence of Osmotic Pretreatment on Dried Fruit Characteristics: A Meta-Analysis Approach. Prev. Nutr. Food Sci. 2024, 29, 178–189. [Google Scholar] [CrossRef]

- Nudar, J.; Roy, M.; Ahmed, S. Combined osmotic pretreatment and hot air drying: Evaluation of drying kinetics and quality parameters of adajamir (Citrus assamensis). Heliyon 2023, 9, e19545. [Google Scholar] [CrossRef]

- Boateng, I.D. Thermal and Nonthermal Assisted Drying of Fruits and Vegetables: Underlying Principles and Role in Physicochemical Properties and Product Quality. Food Eng. Rev. 2023, 15, 113–155. [Google Scholar] [CrossRef]

- Araújo, A.L.D.; Pena, R.D.S. Combined Pulsed Vacuum Osmotic Dehydration and Convective Air-Drying Process of Jambolan Fruits. Foods 2023, 12, 1785. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, M.; Sun, Q.; Mujumdar, A.S.; Yu, D. Effects of Ultrasonic-Assisted Osmotic Pretreatment on Convective Air-Drying Assisted Radio Frequency Drying of Apple Slices. Dry. Technol. 2025, 43, 467–482. [Google Scholar] [CrossRef]

- Leelapattana, W.; Assawarachan, R. Enhancing technology transfer and innovation for processing of dried yellow chrysanthemum (Chrysanthemum indicum) flowers: A case study of the Mae Wang Lao Community Enterprise Group, Chiang Rai Province. J. Food Process. Preserv. 2025, 2025, 3541701. [Google Scholar] [CrossRef]

- Osae, R.; Adjonu, R.; Apaliya, M.T.; Engmann, F.N.; Owusu-Ansah, P.; Fauzia, A.S.; Alolga, R.N. Freeze-Thawing and Osmotic Dehydration Pretreatments on Physicochemical Properties and Quality of Orange-Fleshed Sweet Potato Slice during Hot Air Drying. Food Chem. Adv. 2024, 5, 100843. [Google Scholar] [CrossRef]

- Torres, J.A.; Abdel-Kader, A.Y.; Karel, M. Osmotic dehydration of fruits: Mass transfer and quality. In Handbook of Food Preservation; CRC Press: Boca Raton, FL, USA, 2006; pp. 447–469. [Google Scholar]

- Mayor, L.; Sereno, A.M. Modelling Shrinkage during Convective Drying of Food Materials: A Review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Norouzi, S.; Orsat, V.; Yeasmen, N.; Dumont, M.J. Osmotic Dehydration of Waxy Skinned Berries—A Review. Dry. Technol. 2024, 42, 1270–1294. [Google Scholar] [CrossRef]

- Huerta-Vera, K.; Flores-Andrade, E.; Contreras-Oliva, A.; Villegas-Monter, Á.; Chavez-Franco, S.; Arévalo-Galarza, M. Incorporation of Bioactive Compounds in Fruit and Vegetable Products through Osmotic Dehydration: A Review. Rev. Mex. Cienc. Agríc. 2023, 14, 8. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Clydesdale, F.M. Color as a factor in food choice. Crit. Rev. Food Sci. Nutr. 1993, 33, 83–101. [Google Scholar] [CrossRef]

- Valente, A.; Albuquerque, T.G.; Sanches-Silva, A.; Costa, H.S. Ascorbic Acid Content in Exotic Fruits: A Contribution to Produce Quality Data for Food Composition Databases. Food Res. Int. 2011, 44, 2237–2242. [Google Scholar] [CrossRef]

- Avendaño, W.A.; Muñoz, H.F.; Leal, L.J.; Deaquiz, Y.A.; Castellanos, D.A. Physicochemical characterization of cape gooseberry (Physalis peruviana L.) fruits ecotype Colombia during preharvest development and growth. J. Food Sci. 2022, 87, 2583–2598. [Google Scholar] [CrossRef]

- Mousa, E.A.; Ali, M.I.K.; Hassan, N.A.; Elbassiony, K.R. Effect of Osmo-Dehydration and Gamma Irradiation on Nutritional Characteristics of Dried Fruit. Egypt. J. Food Sci. 2024, 52, 1. [Google Scholar] [CrossRef]

- Haneef, N.; Hanif, N.; Hanif, T.; Raghavan, V.; Garièpy, Y.; Wang, J. Food fortification potential of osmotic dehydration and the impact of osmo-combined techniques on bioactive component saturation in fruits and vegetables. Braz. J. Food Technol. 2024, 27, e2023028. [Google Scholar] [CrossRef]

- Ladika, G.; Tsiaka, T.; Stavropoulou, N.A.; Strati, I.F.; Sinanoglou, V.J. Enhancing the Nutritional Value and Preservation Quality of Strawberries through an Optimized Osmotic Dehydration Process. Appl. Sci. 2024, 14, 9211. [Google Scholar] [CrossRef]

- Li, T.; Shen, P.; Liu, W.; Liu, C.; Liang, R.; Yan, N.; Chen, J. Major Polyphenolics in Pineapple Peels and Their Antioxidant Interactions. Int. J. Biol. Macromol. 2018, 121, 238–247. [Google Scholar] [CrossRef]

- Agudelo-Sánchez, S.; Mosquera-Palacios, Y.; David-Úsuga, D.; Cartagena-Montoya, S.; Duarte-Correa, Y. Effect of processing methods on the postharvest quality of cape gooseberry (Physalis peruviana L.). Horticulturae 2023, 9, 1158. [Google Scholar] [CrossRef]

- Gallon Bedoya, M.; Cortes Rodriguez, M.; Gil, J.H. Physicochemical stability of colloidal systems using the cape gooseberry, strawberry, and blackberry for spray drying. J. Food Process. Preserv. 2020, 44, e14705. [Google Scholar] [CrossRef]

- Rinaldi, B.J.D.; Montanher, P.F.; Johann, G. Brewing of craft beer enriched with freeze-dried cape gooseberry: A promising source of antioxidants. Braz. J. Food Technol. 2022, 25, e2022019. [Google Scholar] [CrossRef]

- Pretty, J. Agricultural sustainability: Concepts, principles and evidence. Philos. Trans. R Soc. B Biol. Sci. 2008, 363, 447–465. [Google Scholar] [CrossRef]

- Royal Project Foundation. Official Letter Requesting Permission to Propose a Project to the Royal Project Foundation; (Doc. No. ล.02/1251/2566); Royal Project Foundation: Chiang Mai, Thailand, 2023. [Google Scholar]

| Optical Properties in CIE-L*a*b* | l*-Value | a*-Value | b*-Value | ΔE |

|---|---|---|---|---|

| Grade-out cape gooseberry fresh fruit | 43.52 ± 2.71 A | 13.14 ± 1.55 A | 34.43 ± 3.82 A | |

| Grade-out cape gooseberry after a 12 h hydrostatic osmotic pretreatment | 39.59 ± 1.08 A | 12.28 ± 1.22 A | 32.61 ± 1.49 A | 4.86 ± 1.52 A,a |

| Cape gooseberry (without pretreatment) | ||||

| 50 °C | 18.23 ± 0.64 B,g | 28.87 ± 1.42 B,f | 14.11 ± 1.35 B,e | 36.09 ± 0.37 B,f |

| 60 °C | 22.11 ± 2.09 B,f | 21.93 ± 4.89 B,g | 15.33 ± 2.26 B,e | 30.39 ± 1.08 B,e |

| 70 °C | 9.65 ± 0.82 B,e | 31.97 ± 1.69 B,f | 12.93 ± 1.47 B,e | 44.34 ± 1.46 B,g |

| Mild hydrostatically osmotic pretreatment | ||||

| 50 °C | 23.43 ± 2.87 A,b | 16.97 ± 1.68 A,ab | 20.61 ± 3.22 A,b | 20.67 ± 1.18 A,c |

| 60 °C | 36.29 ± 1.47 A,a | 13.37 ± 0.59 A,a | 24.18 ± 4.29 A,b | 9.12 ± 2.67 A,b |

| 70 °C | 16.82 ± 4.62 A,b | 21.13 ± 2.14 A,c | 20.25 ± 0.91 A,b | 27.38 ± 2.89 A,d |

| Physicochemical Properties | Fresh Grade-Out Cape Gooseberry | Mild Hydrostatic Osmotic |

|---|---|---|

| aw | 0.88 ± 0.06 A | 0.46 ± 0.04 A |

| Vitamin C (mg/100 g FW) | 26.93 ± 2.41 A | 34.92 ± 1.48 B |

| TPC (mg GAE/100 g FW) | 49.97 ± 1.38 A | 50.43 ± 2.95 A |

| ABTS (µmol TE/g FW) | 24.73 ± 2.11 A | 22.21 ± 1.93 A |

| DPPH (µmol TE/g FW) | 23.81 ± 1.35 A | 21.27 ± 0.42 A |

| Total Plate Count (CFU/g) | <1 | |

| Yeast and Mold (CFU/g) | <1 |

| Category | Amount Used | Unit Price | Estimated Cost |

|---|---|---|---|

| Raw Materials | |||

| Grade-out cape gooseberry (1500 kg) | 0.33 | USD/kg | 495 |

| Osmotic solution | |||

| Sucrose (150 kg) | 1 | USD/kg | 150 |

| Citric acid (0.5 kg) | 10 | USD/kg | 5 |

| Glycerin (30 kg) | 2 | USD/kg | 60 |

| CaCl2 (0.5 kg) | 10 | USD/kg | 5 |

| Potassium metabisulfite (0.5 kg) | 15 | USD/kg | 5 |

| Soft water (1200 L) | 0.05 | USD/L | 60 |

| Pretreatment Process | |||

| Heat energy (LPG = 15 kg) | 15 | USD | 15 |

| Electricity for air compressor (80 kW-h) | 0.25 | USD/kW-h | 20 |

| Equipment depreciation | |||

| Drying Process | |||

| Electricity for rotary tray dryer (Total = 350 kW-h) | 0.25 | USD/kW-h | 87.5 |

| Heat energy (LPG = 96 kg) | 80 | USD | 80 |

| Maintenance and cleaning (20 time) | 3 | USD/times | 60 |

| Equipment depreciation (0.1% per times) | 7.35 | USD | 148 |

| Labor Costs | |||

| Labor for pretreatment (20 time × 2 person × 2 h) | 1 | USD/h | 80 |

| Labor for drying & Packaging (20 time × 3 person × 4 h) | 1 | USD/h | 240 |

| Total Cost Components of Processing | 1510.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assawarachan, R. Drying of Grade-Out Cape Gooseberry (Physalis peruviana Linn.) with Mild Hydrostatic Osmotic Pretreatment Using Rotary Tray Dryer: A Case Study at Mae Hae Royal Project Development Center, Chiang Mai Province. Processes 2025, 13, 1790. https://doi.org/10.3390/pr13061790

Assawarachan R. Drying of Grade-Out Cape Gooseberry (Physalis peruviana Linn.) with Mild Hydrostatic Osmotic Pretreatment Using Rotary Tray Dryer: A Case Study at Mae Hae Royal Project Development Center, Chiang Mai Province. Processes. 2025; 13(6):1790. https://doi.org/10.3390/pr13061790

Chicago/Turabian StyleAssawarachan, Rittichai. 2025. "Drying of Grade-Out Cape Gooseberry (Physalis peruviana Linn.) with Mild Hydrostatic Osmotic Pretreatment Using Rotary Tray Dryer: A Case Study at Mae Hae Royal Project Development Center, Chiang Mai Province" Processes 13, no. 6: 1790. https://doi.org/10.3390/pr13061790

APA StyleAssawarachan, R. (2025). Drying of Grade-Out Cape Gooseberry (Physalis peruviana Linn.) with Mild Hydrostatic Osmotic Pretreatment Using Rotary Tray Dryer: A Case Study at Mae Hae Royal Project Development Center, Chiang Mai Province. Processes, 13(6), 1790. https://doi.org/10.3390/pr13061790