1. Introduction

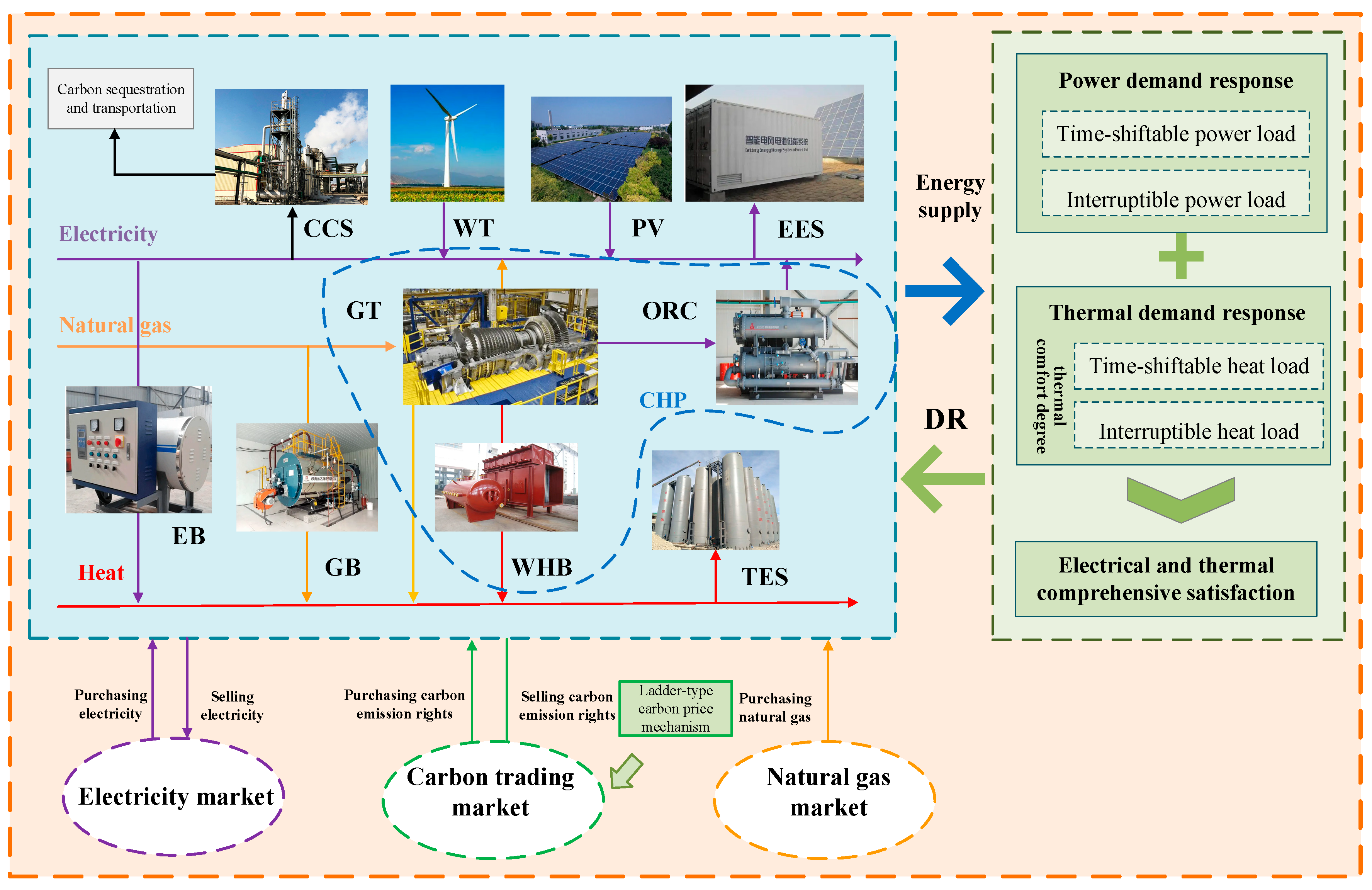

Under the pressure of energy scarcity and environmental degradation, distributed power generation sources such as wind turbines (WTs) and photovoltaic (PV) systems are an important mode of new energy development. However, owing to their scattered distribution, large number, and fluctuation [

1,

2], the grid connection of these distributed resources also impacts the safe and stable operation of power systems. Virtual power plants (VPPs) can aggregate user adjustable load, distribute renewable and controllable energy [

3], and utilize user load responsiveness to smooth out distributed renewable energy fluctuations and promote renewable energy consumption [

4]. In addition, under the global environmental pressure, VPPs can also adopt technologies such as carbon capture to achieve carbon reduction in the system while promoting renewable energy consumption. Therefore, the application of distributed resource coordination and carbon reduction technologies in VPPs will become a direction for low-carbon and efficient development of future energy systems [

5].

1.1. Literature Review

Most current studies consider demand response (DR) to enhance the low carbon and flexibility of VPPs. The reference [

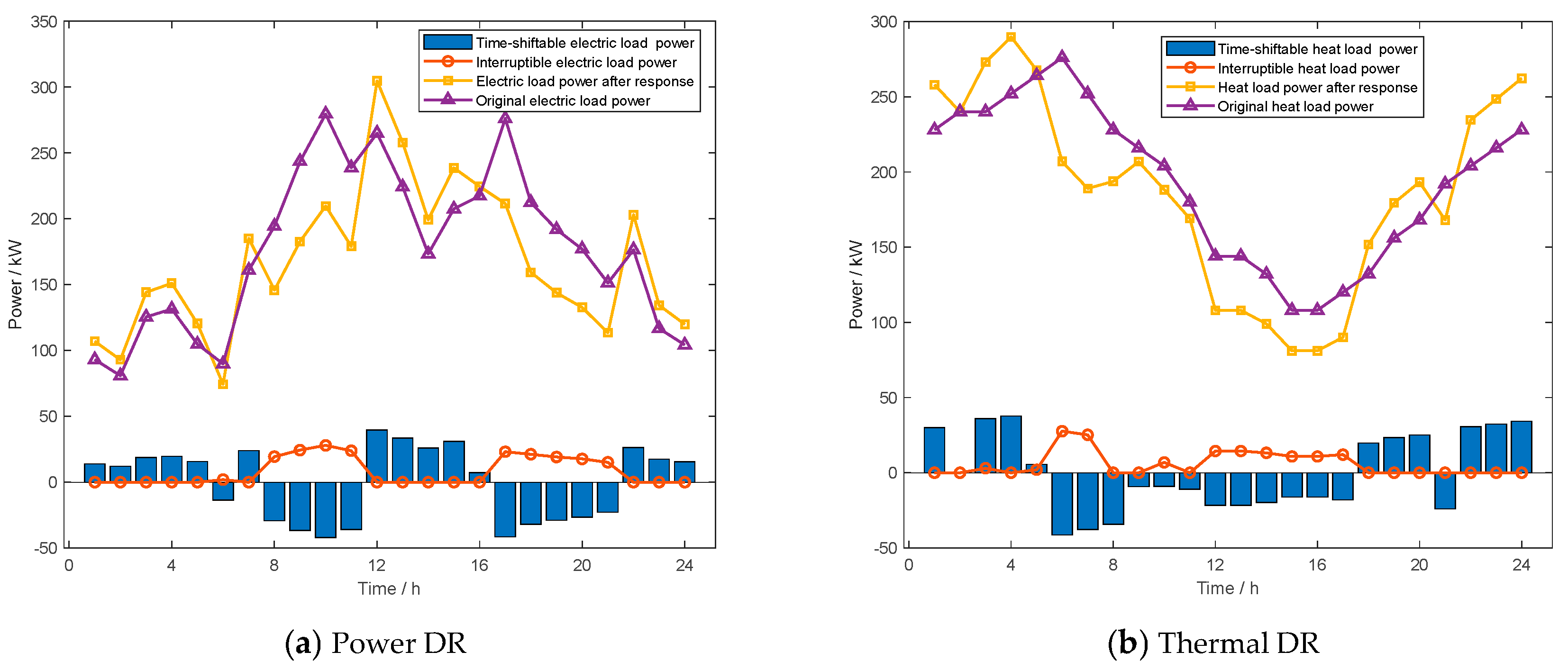

6] divides the resources of the load-side DR of VPPs into vertical demand response, including time-shiftable and interruptible loads, and horizontal demand response, including mutually substitutable resources of electricity and natural gas. Reference [

7] proposed a microgrid operation model with IDR resources involved in two-stage robust dispatch optimization before and during the day, in which a cooling, heating, and power triple-supply system is used to provide multiple energy demands to customers. Reference [

8] considered electricity and heat DRs to shift their demand in the micro-energy hub from peak to off-peak hours, reducing the total system operating cost by 3.9%. The above studies proposed IDR mechanisms based on multiple energy alternatives, which can more effectively relieve the pressure on the energy side. The above studies propose IDR mechanisms based on multiple energy alternatives that can more effectively relieve the source-side peaking pressure. However, these studies only consider the physical characteristics of the load or the demand response potential and fail to consider the willingness of users to participate. The reference [

9] introduces the regret-matching mechanism (RMM) to characterize the willingness of customers to participate in demand response, which results in the amount of DR that can be provided by customers at each time. However, this reference fails to consider IDR and only considers a single-power DR. In addition, user thermal comfort is also an important factor affecting the implementation of integrated demand response [

10,

11], and the above studies have not yet been combined with user comfort for optimization analysis.

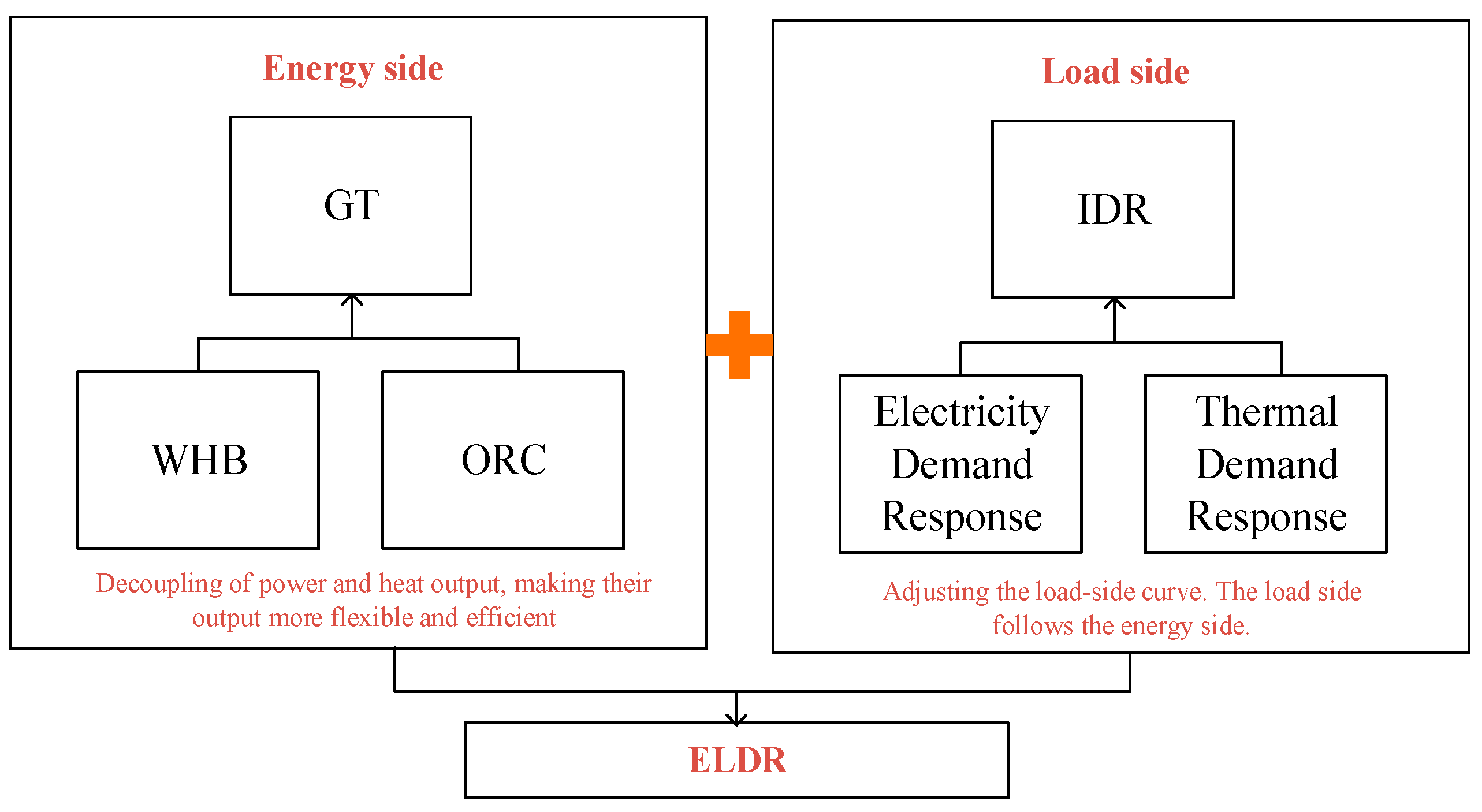

In addition to tapping the load-side flexibility regulation potential, the system supply side also has response potential. To meet the electricity and heat demand of customers, many studies [

12,

13] have configured gas boilers (GB) as electricity supply and introduced combined heat and power (CHP) units for energy supply. However, the application of CHP “with heat to determine electricity“ or “with electricity to determine heat” in the system leads to energy waste because of the staggered nature of the electric and thermal loads on the customer side. The system flexibility can be enhanced and energy waste can be reduced to some extent by deploying electric energy storage (EES), thermal energy storage (TES), and an electric boiler (EB) on the source side [

14,

15]. Energy storage has a limited role in storing electricity and heat in the system due to its own energy storage constraint, and studies have indicated that a large amount of energy is discharged through waste heat when internal combustion engines and gas turbines (GTs) supply energy, resulting in waste. However, the addition of a waste heat recovery system can increase the system energy utilization efficiency by 80%. The organic Rankine cycle (ORC) and waste heat boiler (WHB), which are waste heat recovery devices, were introduced into CHP and proved able to decouple it and improve system energy efficiency [

16,

17]. However, few studies on VPPs have considered both load-side demand response and the introduction of waste heat recovery devices on the energy side of the system.

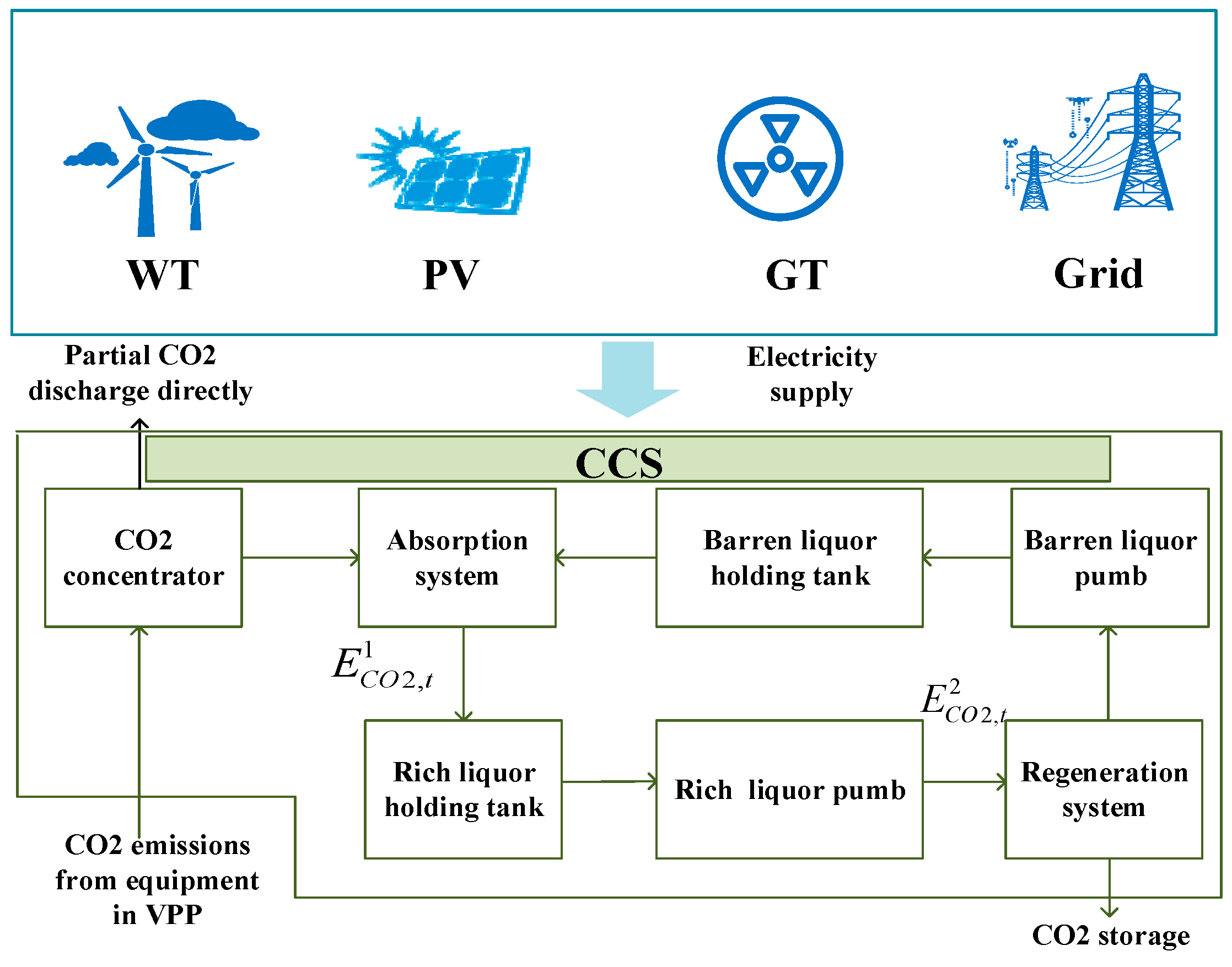

In addition to improving the new energy penetration and system efficiency of VPPs by coordinating the energy side containing new energy and load-side resources with DR, carbon capture technology can also be used to absorb CO

2 emitted by fossil energy generation units in the system [

18,

19]. Currently, the application of carbon capture systems (CCSs) in the optimal dispatch of VPPs has attracted significant attention. In previous studies, CCS plants retrofitted from coal-fired power plants were integrated into VPPs, and a dispatch optimization model was constructed to maximize economic efficiency, verifying that the system’s environmental friendliness was improved after the introduction of CCS plants [

20]. However, the combined operation of CCS and thermal power units in these studies significantly reduced the operating output of thermal power units due to the high power of carbon capture operation. Additionally, they required thermal power units to increase coal consumption to supply carbon capture equipment operation, which further increased the proportion of fossil energy generation in the system and failed to fully exploit the carbon reduction effect of CCSs. If carbon capture is considered with the surplus power, including new energy generation in VPPs, it can simultaneously promote new energy consumption and enhance the flexibility and low carbon of the system. In addition, carbon capture technology is in the developmental stage, and as the level and total amount of carbon capture increases, the cost of VPPs will also increase accordingly. Reference [

21] indicated that introducing the carbon market mechanism can promote the application of carbon capture technology in energy power systems. The current carbon market mechanism mostly incorporates carbon emissions into the system operation benefits as costs by setting carbon emission cost factors or carbon allowance trading average prices. Compared with the uniform type of carbon price mechanism, the ladder-type carbon price mechanism has proven to be more effective in enhancing the low-carbon economy of system operation [

22]. Reference [

23] investigated the impact of carbon price on the carbon emissions of power systems with the introduction of CCSs, and suggested that the ladder-type carbon price mechanism can control the VPP’s carbon emissions without significantly increasing its cost.

1.2. Contribution

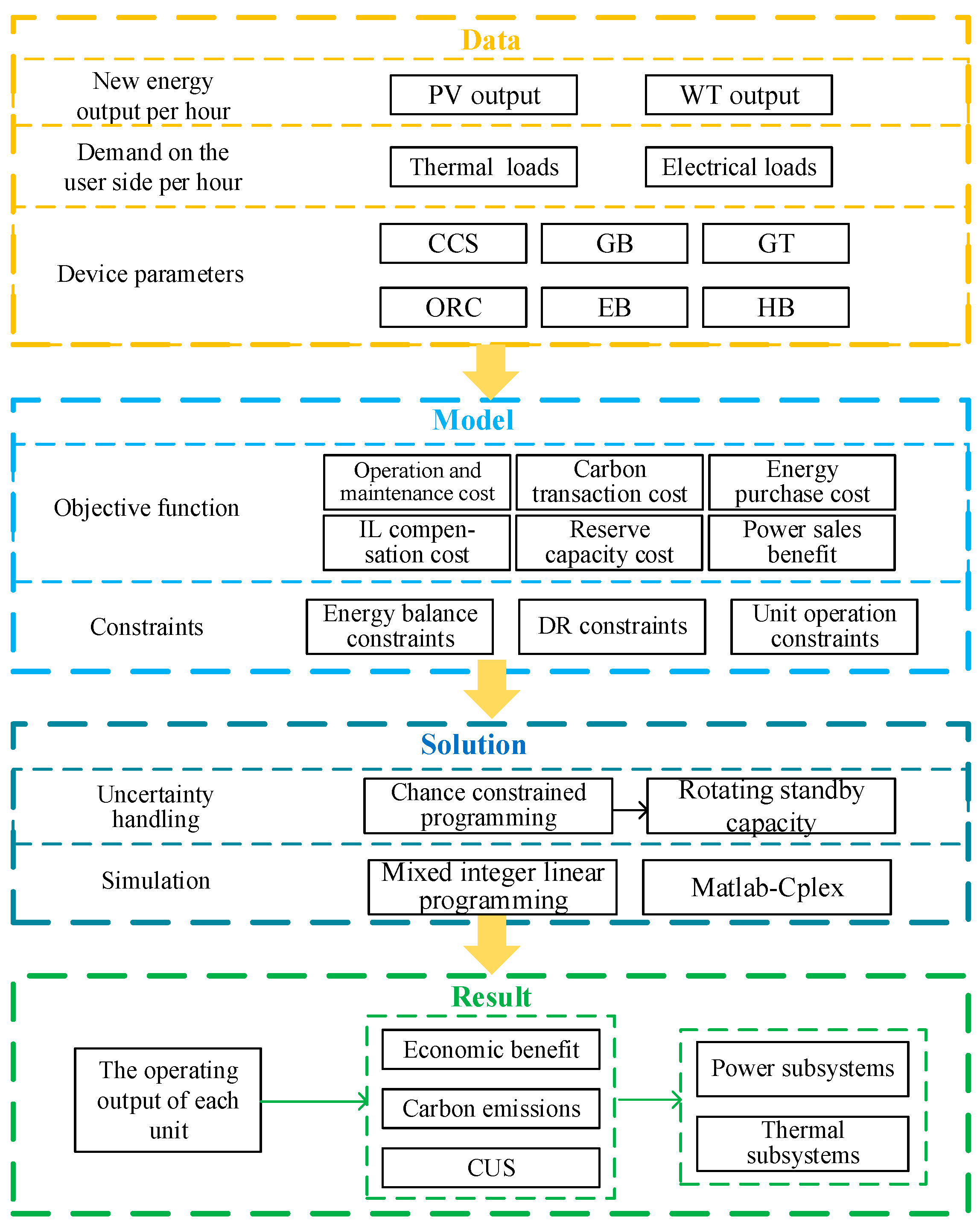

The analysis of the above studies shows that the current basic VPP economic dispatch problem has been solved. However, they mostly consider waste heat recovery devices on the energy side or IDR on the load side in isolation and have not yet combined them organically. They consider waste heat recovery devices on the energy side or IDR on the load side in isolation and have not yet combined them organically. Furthermore, CCS technology operates mostly through thermal power supply in VPPs, and less consideration is given to coordinating new energy generation in the system to supply CCS operation. Therefore, in this study, a source-load dual response (ELDR) mechanism is proposed by introducing ORC-WHB on the source side while considering the electro-thermal IDR. On this basis, the CCS is set in the system for carbon capture, and thus, a VPP low-carbon economic dispatch model is constructed. Finally, the model is solved and validated by an opportunity-constrained planning method based on sequential operations. The main contributions of this paper are as follows.

Based on the characteristics of supply-side WHB-ORC and load-side IDR, an ELDR mechanism is proposed to achieve energy use coordination and optimization between the energy and load sides, and the improved RMM is introduced to characterize the behavioral choices of users’ participation in IDR, thus quantifying more rationally the extent of users’ participation in IDR within VPPs.

A new carbon capture operation mode is proposed, in which new energy and lower-priced power from the grid can be supplied to CCS operation, improving energy utilization and system operation economy while reducing system carbon emissions.

The introduction of a ladder-type carbon trading mechanism in the low-carbon economic dispatch optimization model increases the penalty for excessive carbon emissions from the system, which can effectively promote the application and development of carbon capture technology and low-carbon economic VPP operation.

5. Solution Method Based on Chance-Constrained Planning

For optimization models containing uncertain constraints, chance-constrained planning is an effective way to solve them. Chance-constrained planning was proposed by Charnes and Cooper [

27], and its main principle is to use probabilistic constraints to describe uncertain constraints to seek the optimal solution of the model. The output of WT and PV units in this study was constructed as random variables. We used chance-constrained planning to describe the uncertainty of WT and PV output in the model and generate probabilistic sequences according to the cumulative probability distribution of WT and PV output and used convolution calculations to form probabilistic sequences of common outputs, so that the chance constraint was transformed into a deterministic constraint. The general form of the chance-constrained planning can be expressed as:

where

is the objective function,

is the random parameter vector,

is the constraint, and

is the probability of the event holding.

and

are the pre-given confidence levels.

is the traditional deterministic constraint;

is the minimum value of the objective function

at a probability level no lower than

.

(1) Probabilistic serialization of random variables

The output of WT and PV units in period

t is a random variable, and the corresponding probabilistic sequences

and

can be obtained from their probability distributions, which are a discretization of the probability distribution of the WT and PV unit output continuity. The length of the probabilistic sequence

of the PV output is:

where

is the maximum integer not exceeding

,

is the maximum PV output in period

t, and

is the discretization step, and owing to the rounding of the sequence length, there is a certain probability remaining when

, which is included in

. The PV output and its corresponding probabilistic sequence are shown in

Table 1.

The expected value of the probabilistic series is:

According to the WT and PV probability distribution, to calculate the common output of the two, we can obtain their probabilistic sequences

and

. Their sequence lengths are defined as

and

, respectively, and the calculation process is as follows:

The probabilistic series of WT, PV, and the electric load power with the discretization compensation of q for each time period can be obtained by Equations (57) and (58). And their power expectation for each time period can be calculated by Equation (56), where the net electric load power expectation is:

The WT, PV joint out power probabilistic sequence

has sequence length

, and its sequence probability can be calculated as follows:

Let the probability of the electric load sequence in time period t be

; the length of the sequence is

, and the probability of the net electric load sequence in time period

t can be calculated from

and

by the following equation.

Table 2 shows the correspondence between the probabilistic sequence of the net electric load power

and the step size

and length

:

Equation (53) contains

,

, and

, three random variables with different distributions. To transform Equation (53) into the equivalence class of deterministic constraints, we must find the distribution of the random variable

. To facilitate the description, we introduce the variable

. The probability distribution of

can be described as:

In this paper, is the probability density of the WT and PV outputs, respectively; is the probability density function of the load demand; and is the maximum value of electric load power. They can be obtained by inverse transformation, thus transforming the chance constraint into a deterministic constraint. However, because the function form is complex, difficult to find, and may not be unique, it usually needs to be processed by means of stochastic simulation. In this study, we used the theory of sequential operations to discretize the probability distribution of random variables to achieve the conversion of the deterministic constraint.

Here, the 0–1 variable

is defined as:

Combining with

Table 2, (53) can be transformed into

By transforming the chance constraint into a deterministic constraint through Equation (64), not only is the influence brought by the uncertainty factor in the operation of the VPP solved, but the drawbacks of the traditional chance-constraint solution can also be avoided.

(3) Constraint linearization

where

is a large positive number. Equation (65) is equivalent to (64), and the linearization of Equation (53) is realized by Equations (64) and (65). As a result, the optimization model constructed in this study is transformed into a mixed-integer linear programming solvable form.

7. Conclusions

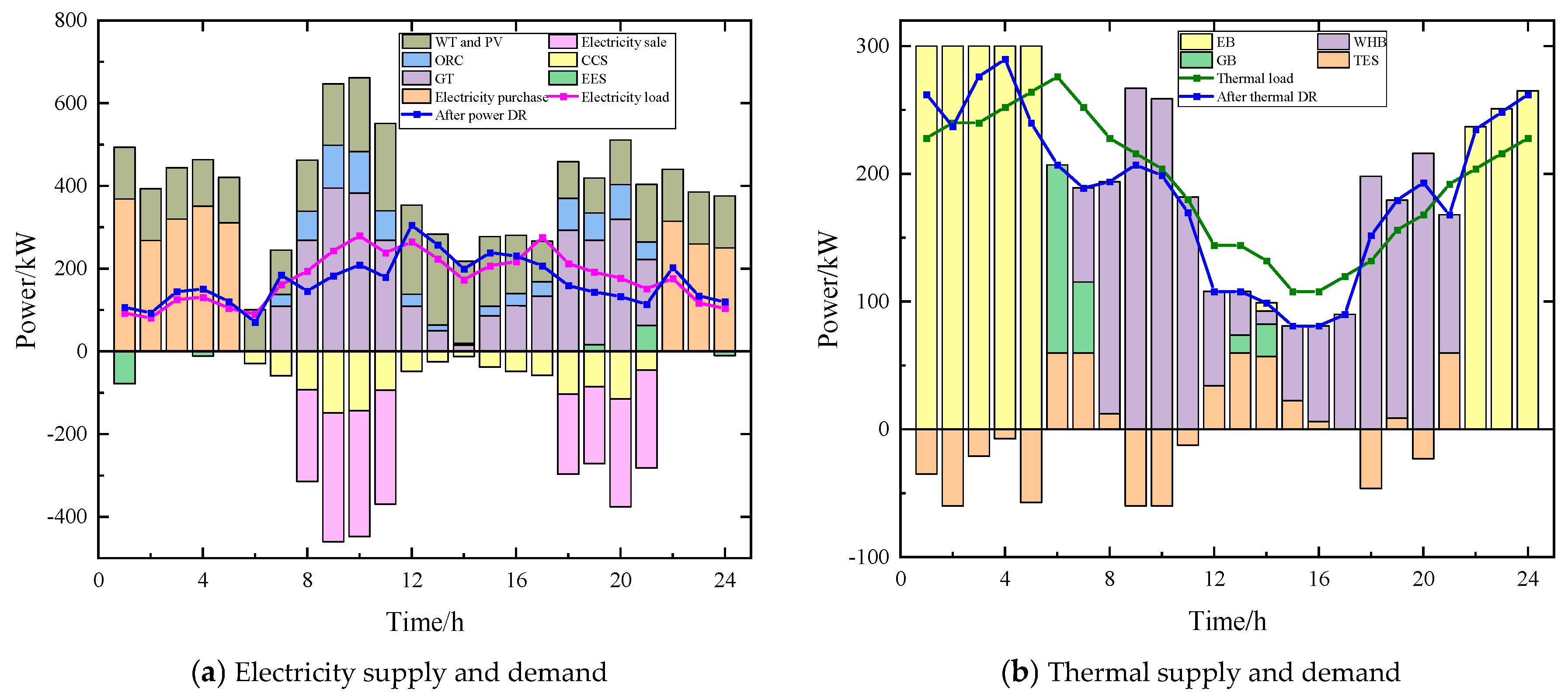

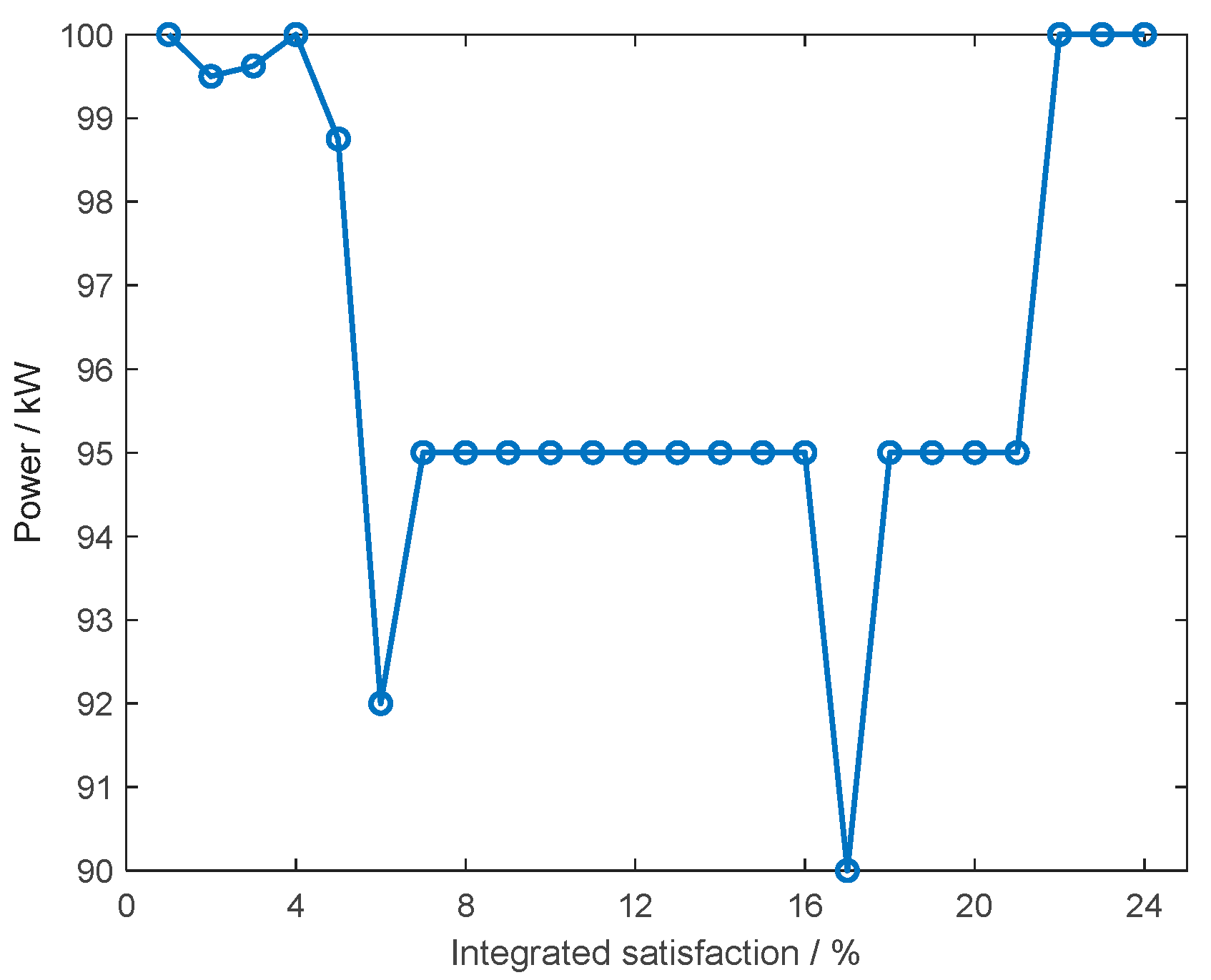

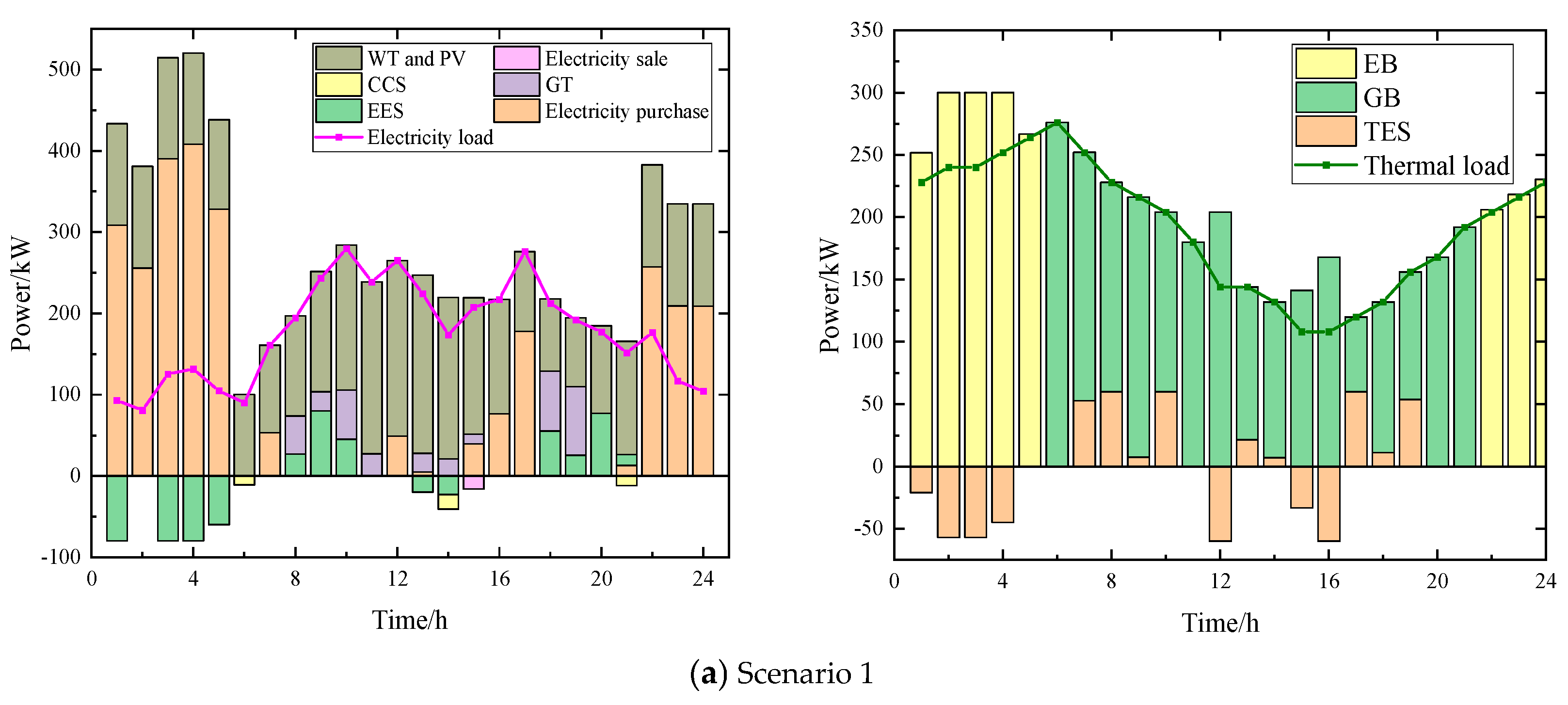

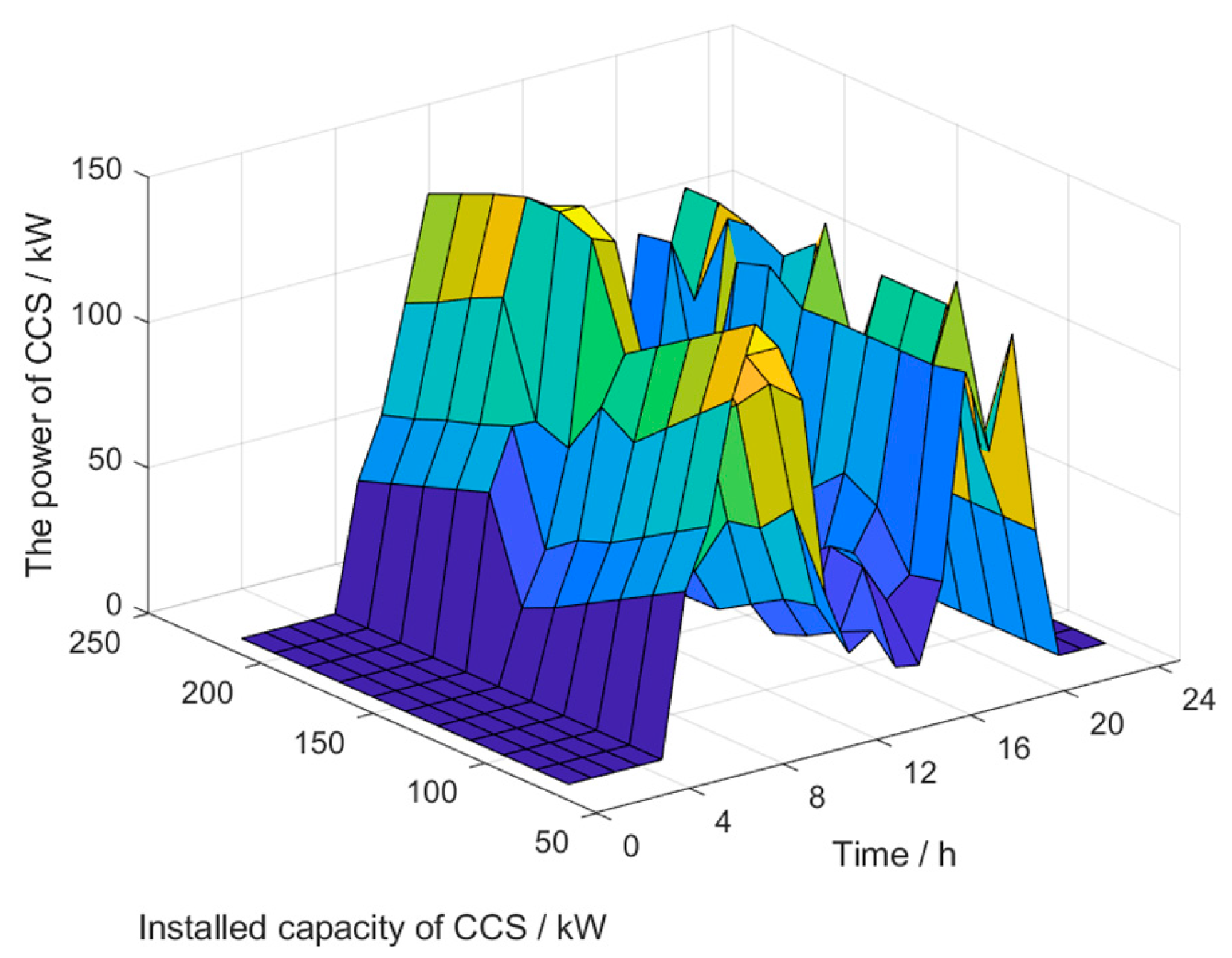

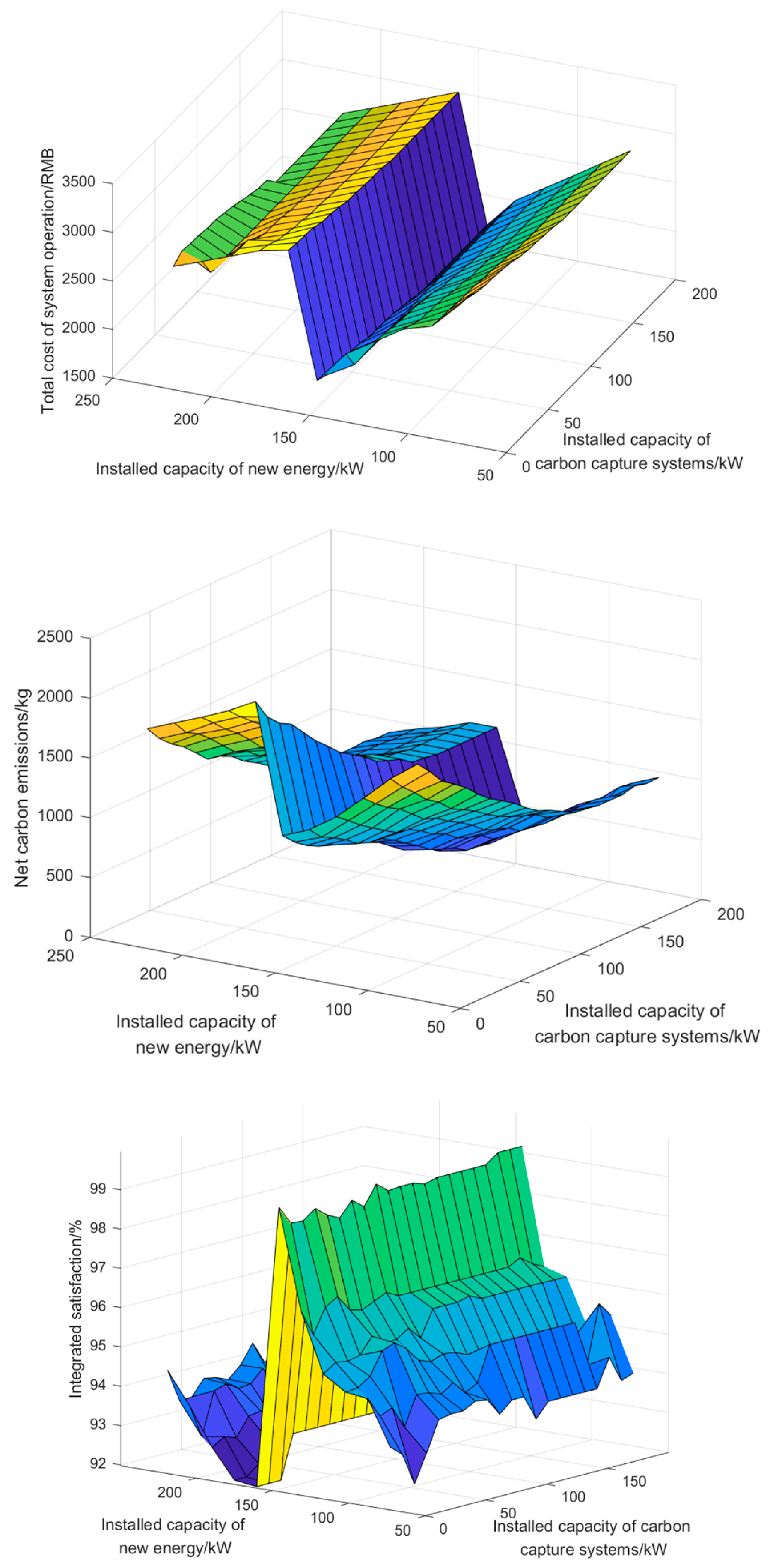

This study constructs an integrated optimization framework for the VPP incorporating carbon capture systems under the ELDR mechanism, with a particular focus on the synergistic optimization of economic efficiency, environmental performance, and user comfort CUS. Through comprehensive scenario analysis, the proposed model demonstrates substantial potential in balancing operational costs, carbon mitigation, and energy flexibility. The implementation of ORC-WHB units effectively decouples CHP generation, achieving 27.46% cost reduction and 45.28% emission reduction through peak shaving and waste heat recovery. The CCS technology exhibits time-dependent operational characteristics, primarily engaging during peak demand periods to offset CHP-related emissions while maintaining economic viability.

Despite the valuable insights provided by the current model under stationary operational conditions, several critical research avenues warrant exploration. First, while the marginal emission reduction benefits of the CCS plateau beyond a 120 kW capacity in our case study, and system economic/environmental performance deteriorates when renewable capacity exceeds optimal thresholds, future implementations must determine the optimal sizing of the CCS and renewable energy installations within VPPs to maximize overall system benefits. Second, detailed investigations into CCS performance across varied CHP operational regimes are essential, particularly regarding trade-offs between energy penalties and emission reduction targets. From a policy perspective, refined quantitative evaluations of interactions between carbon pricing mechanisms and ELDR incentives are needed to inform regulatory framework designs. Furthermore, advancements in predicting integrated demand response behaviors at the user level—through integration of machine learning techniques—could significantly enhance accuracy in forecasting electricity/heat demand responses under dynamic incentive structures. These extensions would not only enhance practical applicability but also contribute to developing more resilient and sustainable decentralized energy systems.