Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design

Abstract

1. Introduction

2. Selection of Nuclear Fuel

2.1. Common Types and Characteristics of Nuclear Fuel

2.1.1. Classification by Compounds of Fission Heavy Nuclei

2.1.2. Classification by Fission Heavy Nuclei

2.1.3. Classification by Inert Matrix Fuel

2.2. Influencing Factors of Nuclear Fuel Selection

3. Selection of the Coolant

3.1. Characteristics of Lead-Based Coolants

3.2. Technical Problems Related to Lead-Based Coolants and the Progress of Solutions

4. Selection of Other Materials

4.1. Fuel Cladding and Core Structural Materials

4.2. Control Materials and Absorbing Materials

4.3. Reflective Material

4.4. Shielding Material

5. Design of Assembly Geometric Structure

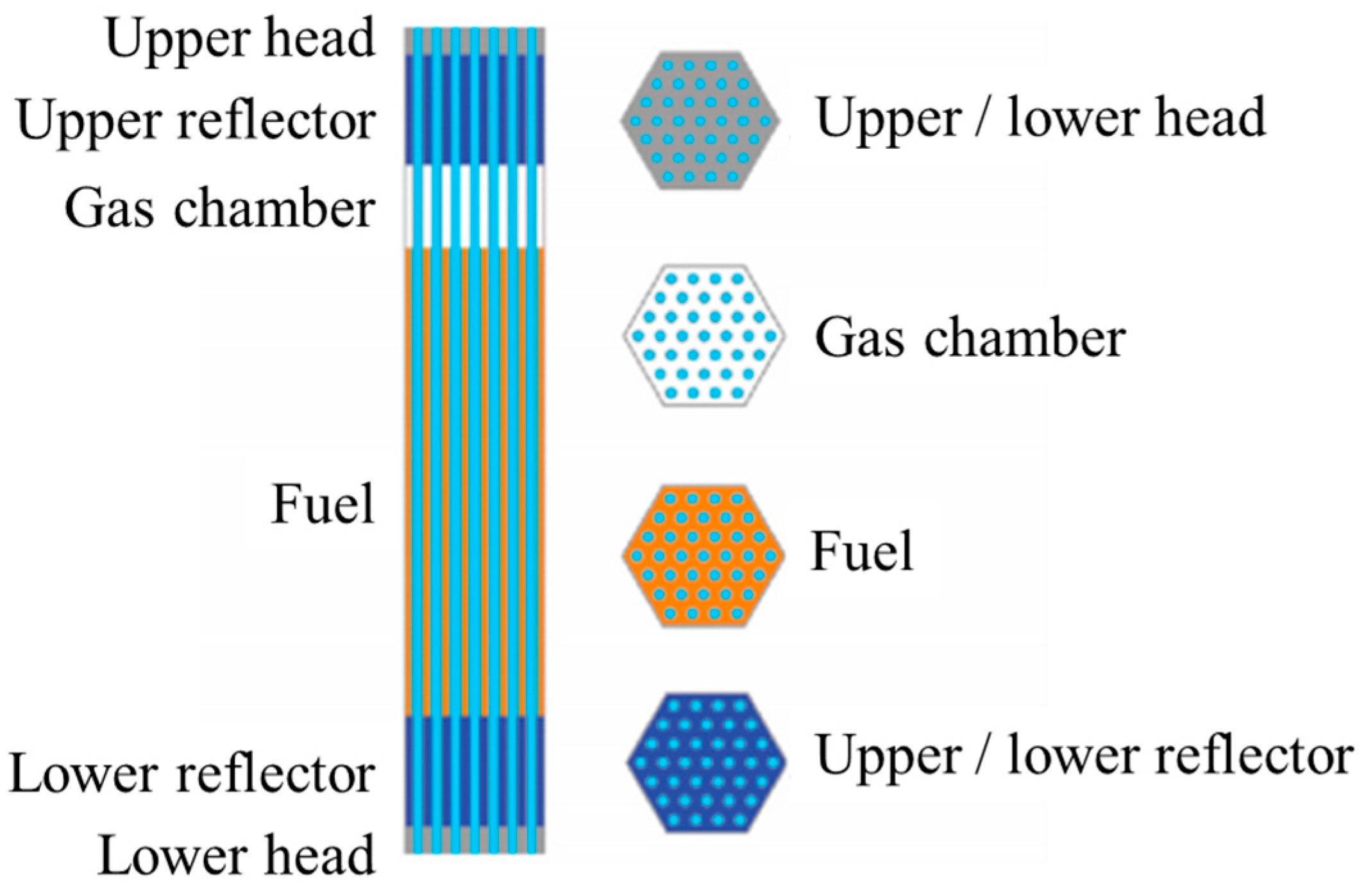

5.1. Geometric Structure Design of Fuel Assembly

5.1.1. Radial Geometric Structure Design of Fuel Assembly

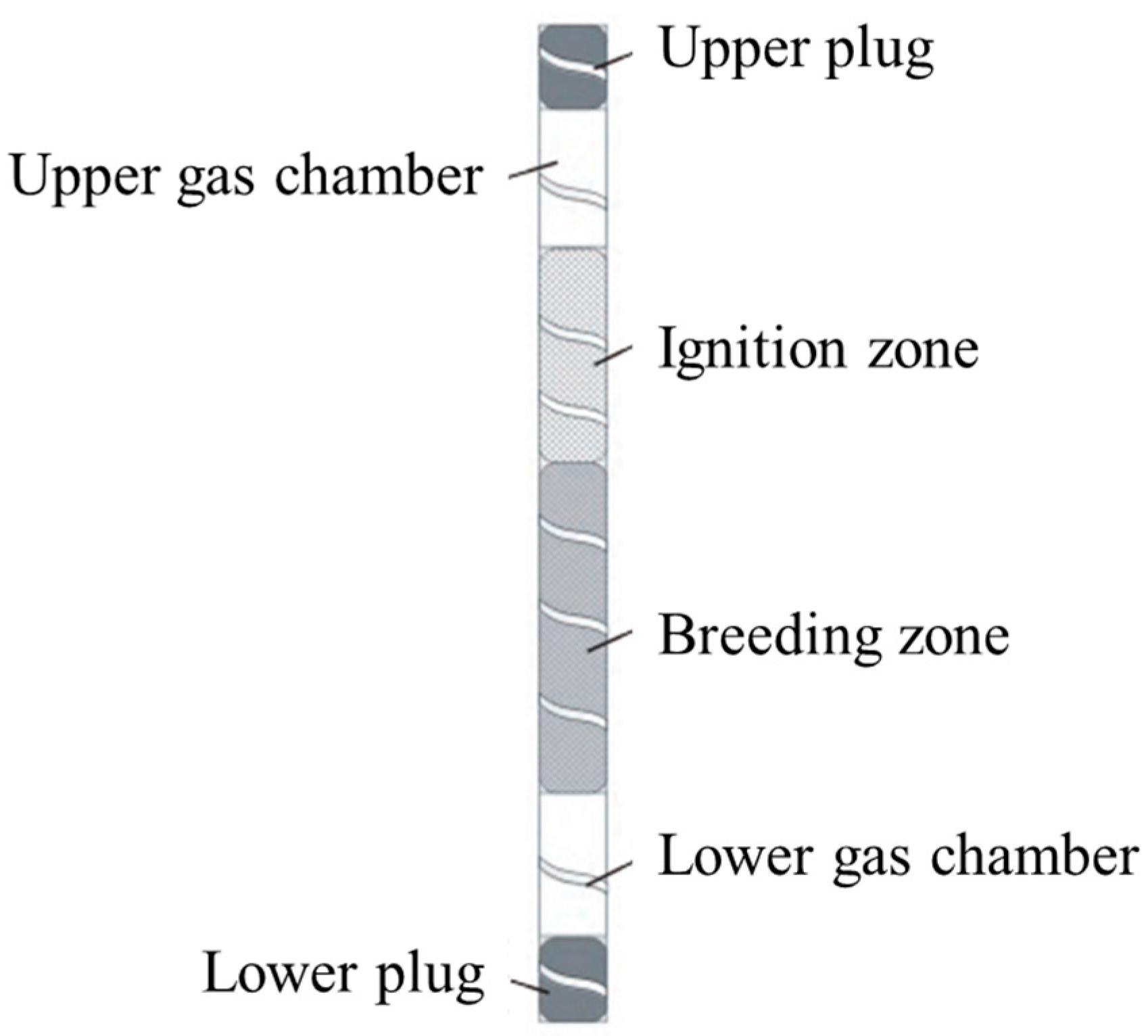

5.1.2. Axial Geometric Structure of Fuel Assembly

5.2. Geometric Structure of the Absorber/Control Assembly

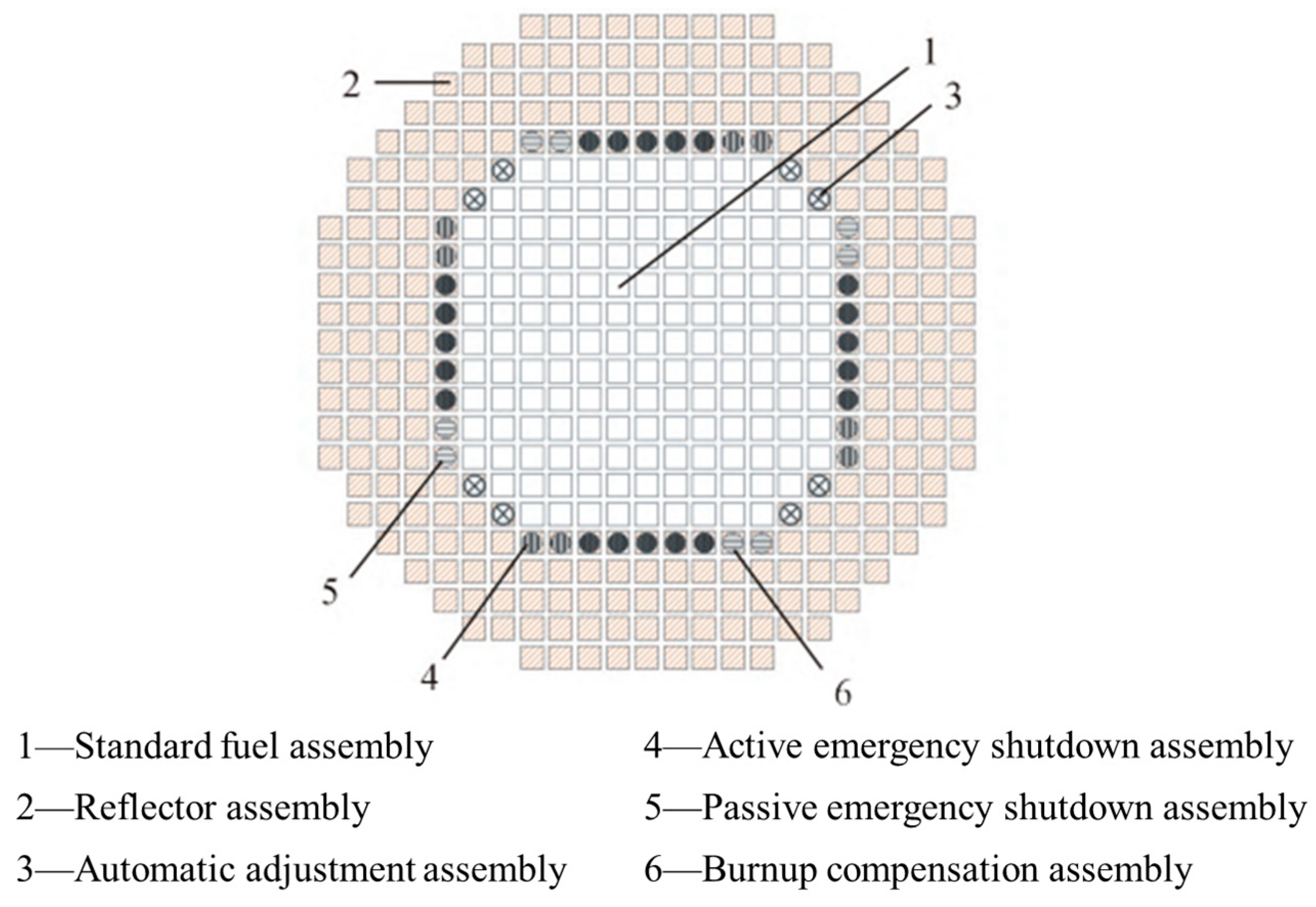

6. Core Geometric Structure

6.1. Radial Cross-Section Geometric Structure of the Core

6.2. Geometric Structure of the Axial Cross-Section of the Core

7. Summary and Prospect

Author Contributions

Funding

Conflicts of Interest

References

- Yue, X.; Peng, M.Y.-P.; Anser, M.K.; Nassani, A.A.; Haffar, M.; Zaman, K. The role of carbon taxes, clean fuels, and renewable energy in promoting sustainable development: How green is nuclear energy? Renew. Energy 2022, 193, 167–178. [Google Scholar] [CrossRef]

- Imran, M.; Zaman, K.; Nassani, A.A.; Dinca, G.; Khan, H.u.R.; Haffar, M. Does nuclear energy reduce carbon emissions despite using fuels and chemicals? Transition to clean energy and finance for green solutions. Geosci. Front. 2024, 15, 101608. [Google Scholar] [CrossRef]

- Wang, G. A review of recent numerical and experimental research progress on CDA safety analysis of LBE-/lead-cooled fast reactors. Ann. Nucl. Energy 2017, 110, 1139–1147. [Google Scholar] [CrossRef]

- Tassone, F.; Ricotti, M.E.; Lorenzi, S.; Locatelli, G. Economics and finance of lead fast reactors: A systematic literature review. Prog. Nucl. Energy 2024, 174, 105298. [Google Scholar] [CrossRef]

- Alemberti, A.; Smirnov, V.; Smith, C.F.; Takahashi, M. Overview of lead-cooled fast reactor activities. Prog. Nucl. Energy 2014, 77, 300–307. [Google Scholar] [CrossRef]

- Sarkisov, A.A. Some Historical Lessons from the Development of Naval Nuclear Power Engineering in the Soviet Union/Russia. Her. Russ. Acad. Sci. 2021, 91, 311–326. [Google Scholar] [CrossRef]

- Cinotti, L.; Smith, C.F.; Sekimoto, H.; Mansani, L.; Reale, M.; Sienicki, J.J. Lead-cooled system design and challenges in the frame of Generation IV International Forum. J. Nucl. Mater. 2011, 415, 245–253. [Google Scholar] [CrossRef]

- Takada, Y.; Shimazu, Y.; Narabayashi, T.; Tsuji, M. A Study on Nuclear Characteristics of METMET Fuel. Proc. Annu./Fall Meet. At. Energy Soc. Jpn. 2010, 276. [Google Scholar] [CrossRef]

- Dragunov, Y.G.; Lemekhov, V.V.; Smirnov, V.S.; Chernetsov, N.G. Technical solutions and development stages for the BREST-OD-300 reactor unit. At. Energy 2012, 113, 70–77. [Google Scholar] [CrossRef]

- de Man, T.J.B.; Limbago, B.M. SSTAR, a Stand-Alone Easy-To-Use Antimicrobial Resistance Gene Predictor. Msphere 2016, 1, e00050-15. [Google Scholar] [CrossRef]

- Wolniewicz, P. Development of a Methodology for Detecting Coolant Void in Lead-cooled Fast Reactors by Means of Neu-Tron Measurements; Applied Nuclear Physics; Acta Universitatis Upsaliensis: Uppsala, Sweden, 2014. [Google Scholar]

- Liu, B.; Han, J.; Liu, F.; Sheng, J.; Li, Z. Minor actinide transmutation in the lead-cooled fast reactor. Prog. Nucl. Energy 2020, 119, 103148. [Google Scholar] [CrossRef]

- Allen, T.R.; Sridharan, K.; Tan, L.; Windes, W.E.; Cole, J.I.; Crawford, D.C.; Was, G.S. Materials Challenges for Generation IV Nuclear Energy Systems. Nucl. Technol. 2008, 162, 342–357. [Google Scholar] [CrossRef]

- Mcfarlane, H. Generation-IV Nuclear Energy Systems. In Proceedings of the 10th Annual Meeting of the Northwest Section of APS, Portland, OR, USA, 15–17 May 2008; American Physical Society: Washington, DC, USA, 2008. [Google Scholar]

- Bruvoll, V.; Kristoffersen, Y.; Coakley, B.J.; Hopper, J.R. Hemipelagic deposits on the Mendeleev and northwestern Alpha submarine Ridges in the Arctic Ocean: Acoustic stratigraphy, depositional environment and an inter-ridge correlation calibrated by the ACEX results. Mar. Geophys. Res. 2010, 31, 149–171. [Google Scholar] [CrossRef]

- Ekdal, E.; Karali, I.; Saç, M.M. 210Po and 210Pb in soils and vegetables in Kucuk Menderes basin of Turkey. Radiat. Meas. 2006, 41, 72–77. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Wang, F.; Zhou, W.; He, M.; Lu, W.; Wang, W.; Chu, D. Experimental study on corrosion compatibility of laser-welded ODS steel with liquid lead lithium. Nucl. Eng. Technol. 2025, 57, 103359. [Google Scholar] [CrossRef]

- Smith, C.F.; Halsey, W.G.; Brown, N.W.; Sienicki, J.J.; Moisseytsev, A.; Wade, D.C. SSTAR: The US lead-cooled fast reactor (LFR). J. Nucl. Mater. 2008, 376, 255–259. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, P.; Jin, Y.; Zhang, C.; Li, W.; Gao, C.; Xiang, Y. Performance analysis of a small lead-cooled fast reactor coupled with a copper-chloride cycle hydrogen production system. Int. J. Hydrogen Energy 2024, 49, 1538–1549. [Google Scholar] [CrossRef]

- Xu, C.; Khan, M.S.; Kong, F.; Yu, D.; Yu, J.; Li, T. Conceptual design and optimization of cogeneration system based on small modular lead-cooled fast reactor. Energy Sci. Eng. 2021, 9, 1688–1702. [Google Scholar] [CrossRef]

- Popov, A.V.; Kulakov, E.N.; Proukhin, A.V.; Tarasenko, R.S.; Denisova, I.B.; Esin, S.B.; Sukhorukov, Y.G. Development of Technical Solutions to Improve the Reliability of the Condensate-Feed Pipeline of the BREST-OD-300 Power Unit. Power Technol. Eng. 2023, 57, 445–451. [Google Scholar] [CrossRef]

- Fedorovich, D.; Paramonova, I. Convective Heat Transfer in the Brest-Od-300 Nuclear Reactor Fuel Rod. In Proceedings of the CONV-22: International Symposium on Convective Heat and Mass Transfer, Izmir, Turkey, 5–10 June 2022. [Google Scholar]

- Wu, Y.; Bal, Y.; Song, Y.; Huang, Q. Conceptual Design of China Lead-based Research Reactor, CLEAR-I. Nucl. Sci. Eng. 2014, 34, 8. (In Chinese) [Google Scholar]

- Zhu, G.; Bai, Y.; Huang, T.; Huang, Q.; Shen, J.; Nagasaka, T. Effect of Y2Ti2O7 on microstructure and tensile properties of ODS-CLAM steel. J. Nucl. Mater. Mater. Asp. Fission Fusion 2024, 599, 155208. [Google Scholar] [CrossRef]

- Abderrahim, H.A.; d’Hondt, P. MYRRHA: A European Experimental ADS for R&D Applications Status at Mid-2005 and Prospective towards Implementation. J. Nucl. Sci. Technol. 2007, 44, 491–498. [Google Scholar]

- Biarrotte, J.L.; Mueller, A.C.; Klein, H.; Pierini, P.; Vandeplassche, D. Accelerator reference design for the MYRRHA European ADS demonstrator. In Proceedings of the Linear Accelerator Conference LINAC2010, Tsukuba, Japan, 12–17 September 2010. [Google Scholar]

- Mcauliffe, M. X-energy’s Xe-100 reactor design advances in review by Canada regulator. Inside NRC 2024, 46. Available online: https://www.nstl.gov.cn/paper_detail.html?id=3abe170119dc3009d5645077aa070f90 (accessed on 1 March 2025).

- Hervás, B.; Rejas, L. Analysis and Validation of the Main Control Room Staffing of the Xe-100 SMR; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Powers, J.J.; Wirth, B.D. A review of TRISO fuel performance models. J. Nucl. Mater. 2010, 405, 74–82. [Google Scholar] [CrossRef]

- Singh, G.; Jiang, W.; Hales, J.; Novascone, S.; Evans, J.A. Impact of anisotropy on TRISO fuel performance. Nucl. Eng. Des. 2024, 430, 113637. [Google Scholar] [CrossRef]

- Mansani, L.; Alemberti, A.; Frogheri, M.; Bubelis, E.; Schikorr, M. The European Lead Fast Reactor: Design, Safety Approach and Safety Characteristics. In Proceedings of the Technical Meeting on Impact of Fukushima Event on Current & Future Fr Designs, Dresden, Germany, 19–23 March 2012. [Google Scholar]

- Tsujimoto, K.; Oigawa, H.; Ouchi, N.; Kikuchi, K.; Kurata, Y.; Mizumoto, M.; Sasa, T.; Saito, S.; Nishihara, K.; Umeno, M. Research and Development Program on Accelerator Driven Subcritical System in JAEA. J. Nucl. Sci. Technol. 2007, 44, 483–490. [Google Scholar] [CrossRef]

- Shahbunder, H.; Pyeon, C.H.; Misawa, T. Subcritical multiplication factor and source efficiency in accelerator-driven system. Ann. Nucl. Energy 2010, 37, 1214–1222. [Google Scholar] [CrossRef]

- Lim, J.Y.; Pyeon, C.H.; Yagi, T.; Misawa, T. Subcritical Multiplication Parameters of the Accelerator-Driven System with 100 MeV Protons at the Kyoto University Critical Assembly. Sci. Technol. Nucl. Install. 2012, 2012, 347. [Google Scholar] [CrossRef]

- Marie, N.; Billebaud, A.; Kochetkov, A.; Lecouey, J.L.; Messaoudi, N.; Vittiglio, G.; Wagemans, J. Comparison of 238U and 235U Fission Chambers for Monitoring the Reactivity of the VENUS-F Accelerator-Driven Subcritical Reactor Using the Cur-rent-to-Flux Method. Nucl. Sci. Eng. 2025, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Meng, L.; Huang, Z.; Li, S.; Wang, D.; Liu, B.; Zhang, Y.P.; Zhang, L.; Jiang, W. Study on the Effects from Spacer Wires on Coolant Flow within a Ciads Fuel Assembly. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, Z.; Zhu, Z.L.; Xue, Z.H.; Wang, X.W. Multi-frequency Point Supported LLRF Front-end for CiADS Wide-bandwidth Application. Nucl. Sci. Tech. 2020, 31, 71–78. [Google Scholar] [CrossRef]

- Yao, C.; Huang, Q.; Zhu, Z.; Li, Y.; He, J. Data acquisition and control system for lead-bismuth loop KYLIN-II-M. Nucl. Sci. Tech. 2015, 26, 28–35. [Google Scholar]

- Zhou, M.; Zhang, G.; Xia, Z. Radiological Characterization Study for Decommissioning of the ADSSub-Critical Experimental Assembly. J. Oflsotopes 2025, 38, 87–94. (In Chinese) [Google Scholar]

- Zhu, Q.; Zhou, Q.; Liang, S. Venus-I Dual-core Zero Power Reactor. At. Energy Sci. Technol. 2019, 53, 1842–1849. (In Chinese) [Google Scholar]

- Liang, S.; Zhu, Q.; Shi, Y. Sub-critical Reactivity Dynamic Characteristic Measured by Source jerk Method on VENUS-II. At. Energy Sci. Technol. 2018, 52, 302–306. (In Chinese) [Google Scholar]

- Fernandez, A.F.; Ooms, H.; Brichard, B.; Coeck, M.; Decreton, M. SCK·CEN Gamma Irradiation Facilities for Radiation Tolerance Assessment. In Radiation Effects Data Workshop; IEEE: Washington, DC, USA, 2002. [Google Scholar]

- Zrodnikov, A.V.; Toshinsky, G.I.; Komlev, O.G.; Dragunov, Y.G.; Stepanov, V.S.; Klimov, N.N.; Kopytov, I.I.; Krushelnitsky, V.N. Nuclear power development in market conditions with use of multi-purpose modular fast reactors SVBR-75/100. Nucl. Eng. Des. 2005, 236, 1490–1502. [Google Scholar] [CrossRef]

- Zrodnikov, A.V.; Toshinsky, G.I.; Komlev, O.G.; Dragunov, Y.G.; Krushelnitsky, V.N. Use of Multi-Purpose Modular Fast Reactors SVBR-75/100 in Market Conditions. In Proceedings of the ICAPP’06: Proceedings of the 2006 International Congress on Advances in Nuclear Power Plants, Reno, NV, USA, 4–8 June 2006. [Google Scholar]

- Christensen, J.A. Thermal Performance Limits for Fast Reactor Oxide Fuels. 1971. Available online: https://www.semanticscholar.org/paper/THERMAL-PERFORMANCE-LIMITS-FOR-FAST-REACTOR-OXIDE-Christensen/85b2d6e71ab290ff84f32f1675da4c3648797406 (accessed on 1 March 2025).

- Rodriguez, P. Mixed plutonium-uranium carbide fuel in fast breeder test reactor. Bull. Mater. Sci. 1999, 22, 215–220. [Google Scholar] [CrossRef]

- Ekberg, C.; Ribeiro Costa, D.; Hedberg, M.; Jolkkonen, M. Nitride fuel for Gen IV nuclear power systems. J. Radioanal.-Cal Nucl. Chem. 2018, 318, 1713–1725. [Google Scholar] [CrossRef]

- Aitkaliyeva, A. Recent trends in metallic fast reactor fuels research. J. Nucl. Mater. 2021, 558, 153377. [Google Scholar] [CrossRef]

- Mei, H.; Wu, Q.; Han, Q.; Chen, J.; Wu, Y. Selection and analysis of transmutation fuel in lead-bismuth cooled reactor. Nucl. Tech. 2015, 38, 57–63. [Google Scholar]

- Max, A.; Mason, T. Past and future of uranium production. Atw. Atomwirtsch. Atomtech. 1996, 41, 79–84. [Google Scholar]

- Guzman, J.R.; Espinosa-Paredes, G.; Francois, J.L.; Martin-Del-Campo, C. A novel method for transuranic fuel design. Prog. Nucl. Energy 2010, 52, 689–697. [Google Scholar] [CrossRef]

- Carr, W.H.; Sumner, W.B.; Thomas, L.L. Transuranic waste from reprocessing of nuclear fuel. Nucl. Chem. Waste Manag. 1983, 4, 25–33. [Google Scholar] [CrossRef]

- Zorzoli, G.B. Uranium-plutonium fuel cycle for thermal and fast-reactors. Energ. Nucl. 1971, 18, 719. [Google Scholar]

- Bergel’Son, B.R.; Tikhomirov, G.V. Expanded 233U Breeding in the Heavy-Water Blanket of an Electronuclear System. At. Energy 2001, 91, 610–616. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, P.; Ren, G.; Ke, G.; Yu, T.; Xie, J.; Chen, Z.; He, L.; Xie, Q.; Zeng, H. Fuel Selection of Long Life Small Natural Circulation Lead-based Fast Reactor. At. Energy Sci. Technol. 2020, 54, 944–953. [Google Scholar]

- Stanisz, P.; Oettingen, M.; Cetnar, J. Development of a Trajectory Period Folding Method for Burnup Calculations. Energies 2022, 15, 2245. [Google Scholar] [CrossRef]

- Stanisz, P.; Cetnar, J.; Oettingen, M. Radionuclide neutron source trajectories in the closed nuclear fuel cycle. Nukl. Orig. Ed. 2019, 64, 3–9. [Google Scholar] [CrossRef]

- Stanisz, P.; Cetnar, J.; Domanska, G. Modeling minor actinide multiple recycling in a lead-cooled fast reactor to demonstrate a fuel cycle without long-lived nuclear waste. Nukleonika 2015, 60, 581–590. [Google Scholar] [CrossRef]

- Oettingen, M.; Stanisz, P. Monte Carlo modelling of Th-Pb fuel assembly with californium neutron source. Nukl. Orig. Ed. 2018, 63, 87–91. [Google Scholar] [CrossRef]

- Oettingen, M.; Stanisz, P. Monte Carlo methods for numerical simulations of the Lead-Cooled Fast Reactor. IOP Conf. Ser. Earth Environ. Sci. 2021, 642, 012004. [Google Scholar] [CrossRef]

- Stanisz, P.; Oettingen, M.; Cetnar, J. Monte Carlo modeling of Lead-Cooled Fast Reactor in adiabatic equilibrium state. Nucl. Eng. Des. 2016, 301, 341–352. [Google Scholar] [CrossRef]

- Zagra, L.; Ceroni, R.G. Ceramic–ceramic coupling with big heads: Clinical outcome. Eur. J. Orthop. Surg. Traumatol. 2007, 17, 247–251. [Google Scholar] [CrossRef]

- Esquivel-Upshaw, J.F.; Clark, A.E.; Shuster, J.J.; Anusavice, K.J. Randomized Clinical Trial of Implant-Supported Ceramic-Ceramic and Metal-Ceramic Fixed Dental Prostheses: Preliminary Results. J. Prosthodont.-Implant. Esthet. Reconstr. Dent. 2014, 23, 73–82. [Google Scholar] [CrossRef]

- Bonnet, M.; Baldi, S.; Porta, J. Progress in core and cermet fuel modelling to calculate severe accidents. Prog. Nucl. Energy 2000, 38, 387–390. [Google Scholar] [CrossRef]

- Concetta, F. Handbook on Lead-Bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermal-Hydraulics and Technologies: 2015 Edition—Introduction; OECD: Paris, France, 2015. [Google Scholar]

- Xing, M.; Fan, J.; Shen, F.; Lu, D.; Li, L.; Yu, H.; Fan, J. Comparative Analysis on the Characteristics of Liquid Lead and Lead-Bismuth Eutectic as Coolants for Fast Reactors. Energies 2025, 18, 596. [Google Scholar] [CrossRef]

- Yu, Q.; Xiao, H.; Liu, Z. A coolant suitable for small long life natural circulation lead-based fast reactor. Nucl. Tech. 2022, 45, 030601. [Google Scholar]

- Mori, M. Core Design Analysis of the Supercritical Water Fast Reactor. Ph.D. Thesis, Universitat of Stuttgart: Stuttgart, Germany, 2005. [Google Scholar] [CrossRef]

- Okunev, V.S. The concept of a compact and safe high-power lead-cooled fast reactor. AIP Conf. Proc. 2024, 3184, 7. [Google Scholar]

- Aurelio, L.C.; Stanislaw, S.P.; Luca, A.; Haileyesus, T.; Martorell, S.; Verdu, G. Development of a three-dimensional thermohy-draulic-neutronic coupling scheme for transient analysis of liquid metal cooled fast reactor technologies using the system code TRACE-PARCS. 2013. [Google Scholar]

- Guang Ming, C.; Liang Cheng, R. Solving point reactor neutron kinetic equations by using generation of neutron time method. Nucl. Sci. Eng. 2012. [Google Scholar] [CrossRef]

- Ibrahim, A. Comparative analysis of fuel burnup calculations of fourth-generation European fast reactors. Kerntechnik 2023, 88, 11. [Google Scholar] [CrossRef]

- Lynn, J.E.; Trela, W.J.; Meggers, K. Neutron Doppler broadening studies of tantalum and tungsten metal. Nucl. Inst Methods Phys. Res. B 2002, 192, 318–330. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, T.; Zhou, T.; Wang, Z. Performance of the new ferritic/martensitic steel SIMP against liquid lead-bismuth eutectic corrosion: Comparison with T91 and 316L steels. Mater. Corros.-Werkst. Korros. 2023, 74, 221–232. [Google Scholar] [CrossRef]

- Wang, L.; Chai, L.; Xu, S.; Liu, S.; Gan, S.; Chen, L.; He, X.; Polcar, T.; Daghbouj, N.; Li, B. Study on the corrosion behavior of laser surface remelted and laser cladding of ferritic/martensitic steels after exposure to lead-bismuth eutectic at 700 °C. J. Nucl. Mater. 2024, 590, 154888. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, B.; Fu, X.; Long, B. Influence of Surface State on the Corrosion Behavior of Si-Reinforced F/M Steels under Solid-Phase Oxygen-Controlled Static Liquid LBE Environment. Metals 2024, 14, 810. [Google Scholar] [CrossRef]

- Ji, X.; Liu, X.; Zhang, T.; He, H. Numerical investigation on the Multi-Physics coupling characteristics of Lead-Bismuth reactor fuel assembly based on oxidation corrosion behaviors. Nucl. Eng. Des. 2024, 428, 113519. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Yun, D. Cladding Failure Modelling for Lead-Based Fast Reactors: A Review and Prospects. Metals 2023, 13, 24. [Google Scholar] [CrossRef]

- Liao, Q.; Li, B.; Ge, F.; Zhang, H.; Shen, T.; Mao, X.; Wang, R.; Sheng, Y.; Chang, H.; Wang, Z. Stability and corrosion behavior of AlOx coating on T91 steel and SIMP steel in static LBE at 600 °C. Acta Phys. Sin. 2022, 71, 156103. [Google Scholar] [CrossRef]

- Hashim, M.; Cao, L.; Zhou, S.; Ma, R.; Shao, Y.; Chen, R. SPARK-NC: A Lead-Bismuth-Cooled Small Modular Fast Reactor with Natural Circulation and Load Following Capabilities. Energies 2020, 13, 5410. [Google Scholar] [CrossRef]

- Meli, A.; Bassini, S.; Ciantelli, C.; Fiore, A. Preliminary Characterization of Alumina-Forming Austenitic–Type Advanced Alloys as Structural Materials for LFRs. Nucl. Technol. 2024, 210, 758–771. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, R.; Shao, Y.; Cao, L.; Bai, B.; Wu, H. Conceptual core design study of an innovative small transportable lead-bismuth cooled fast reactor (SPARK) for remote power supply. Int. J. Energy Res. 2018, 42, 3672–3687. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Zheng, Y.; Wang, K. Neutronics studies on the feasibility of developing fast breeder reactor with flexible breeding ratio. J. Nucl. Sci. Technol. 2016, 53, 129–138. [Google Scholar] [CrossRef]

- Qin, T.; Xia, B.; Li, Q.; Li, S.; Zhang, C.; Lu, D. Study on Reactivity Variation and Its Influencing Factors of Lead-cooled Traveling Wave Reactor. Nucl. Power Eng. 2022, 43, 206–212. (In Chinese) [Google Scholar]

- Xia, B.; Xu, C.; Qin, T.; Li, Q. Study on Loading Pattern for Long-cycle Lead-cooled Fast Reactor Core. Nu-Clear Power Eng. 2023, 44, 260–265. (In Chinese) [Google Scholar]

- Zhang, X.; Zeng, F.; Zhao, P. Study on non-uniform circumferential temperature distribution of annular fuel in the tight lattice configuration of a lead-bismuth cooled fast reactor. Prog. Nucl. Energy 2024, 176, 10. [Google Scholar] [CrossRef]

- Lee, J. Conceptual Neutronic Design of Inverted Core for Lead-Bismuth Cooled Small Modular Reactor. Doctoral Dissertation, Graduate School of Seoul National University, Seoul, Republic of Korea, 2017. [Google Scholar]

- Zeng, Y.; Ming, P.; Li, F.; Zhang, H. Thermal hydraulic characteristics of spiral cross rod bundles in a lead–bismuth-cooled fast reactor. Ann. Nucl. Energy 2021, 167, 108850. [Google Scholar] [CrossRef]

- Lei, C.; Wu, H.; Cao, L.; Zhou, S.; Shao, Y. Core Design Study of Small Transportable Long-life Lead-bismuth Cooled Fast Reactor. At. Energy Sci. Technol. 2019, 53, 1451–1458. (In Chinese) [Google Scholar]

- Zhang, K.; Wang, W.; Chen, L.H. SUMMER: A small modular lead-bismuth-cooled fast reactor for mobile energy sup-ply. Prog. Nucl. Engergy 2023, 164, 104860.1–104860.10. [Google Scholar]

- Li, J. Physical Design and Performance Research of Heat Pipe Cooled Reactor Core; South China University of Technology: Guangzhou, China, 2023. (In Chinese) [Google Scholar]

- Yang, Q.; Pan, Q.; Liu, X. Burnup-control drum coupling characteristics investigation of lead–bismuth eutectic-cooled solid re-actor. Ann. Nucl. Energy 2023, 193, 110018. (In Chinese) [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Q.; Liu, X. Conceptual design and thermal-hydraulic analysis of a megawatt-level lead-bismuth cooling re-actor for deep-sea exploration. Prog. Nucl. Energy 2022, 145, 104125. (In Chinese) [Google Scholar] [CrossRef]

- Nguyen, T.D.C.; Khandaq, M.F.; Jeong, E.; Choe, J.; Lee, D.; Fynan, D.A. MicroURANUS: Core design for long-cycle lead-bismuth-cooled fast reactor for marine applications. Int. J. Energy Res. 2021, 45, 12426–12448. [Google Scholar] [CrossRef]

| Physical Parameters | Oxide Fuel | Carbide Fuel | Nitride Fuel | Metallic Fuel |

|---|---|---|---|---|

| Density, g/cm3 | 10.28 | 12.18 | 12.92 | 14.17 |

| Melting point, K | 3000 | 2575 | 3035 | 1350 |

| Thermal conductivity, W/(m·K) | 2.3 | 20 | 26 | 16 |

| Thermal expansion coefficient, K−1 | 1.2 × 10−5 | 1.2 × 10−5 | 1.0 × 10−5 | 1.7 × 10−5 |

| Heat capacity, J/(g·K) | 34 | 26 | 26 | 17 |

| Type of Fuel | Material Components | Core Advantages | Key Challenges |

|---|---|---|---|

| cercer |

|

|

|

| cermet |

|

|

|

| metmet |

|

|

|

| Physical Parameters | Lead | Lead-Bismuth Eutectic (LBE) | Sodium |

|---|---|---|---|

| Absorption cross-section, 10−28 m2 | 0.17 | 0.0946 | 0.530 |

| Moderating power, m−1 | 3.48 × 10−5 | 2.88 × 10−5 | 8.62 × 10−5 |

| Moderating ratio | 0.58 | 1.58 | 0.66 |

| Melting point, °C | 327.5 | 125 | 98 |

| Boiling point, °C | 1750 | 1670 | 883 |

| Density, kg/m3 | 10,480 | 10,150 | 847 |

| Heat capacity, kJ/(kg·K) | 0.15 | 0.15 | 1.3 |

| Thermal conductivity, W/(m·K) | 16 | 13 | 70 |

| Thermal expansion coefficient, 10−6/K | 108 | 123 | 71 |

| Material Type | Advantages | Disadvantages | Applicable Scenarios |

|---|---|---|---|

| Ferritic/Martensitic Steel | Excellent resistance to irradiation swelling, good toughness, and stable thermophysical properties. | The problem of liquid metal corrosion is significant. | Medium-high temperature (≥450 °C), intense irradiation environment. |

| Austenitic steel | It has good corrosion resistance, excellent cold-working performance, and good high-temperature stability. | The dissolution corrosion is severe, and the liquid metal embrittlement phenomenon is prominent at low temperatures. | Medium temperature (450–600 °C). |

| Ceramic material | It has excellent high-temperature stability, stable chemical properties, high strength, and good wear and corrosion resistance. | It has poor toughness and high processing difficulty. | High-temperature (≥600 °C), strong-corrosion environment. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Chen, L.; Zhang, Y.; Li, S. Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design. Processes 2025, 13, 1773. https://doi.org/10.3390/pr13061773

Zhang C, Chen L, Zhang Y, Li S. Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design. Processes. 2025; 13(6):1773. https://doi.org/10.3390/pr13061773

Chicago/Turabian StyleZhang, Cong, Ling Chen, Yongfa Zhang, and Song Li. 2025. "Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design" Processes 13, no. 6: 1773. https://doi.org/10.3390/pr13061773

APA StyleZhang, C., Chen, L., Zhang, Y., & Li, S. (2025). Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design. Processes, 13(6), 1773. https://doi.org/10.3390/pr13061773