Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination

Abstract

1. Introduction

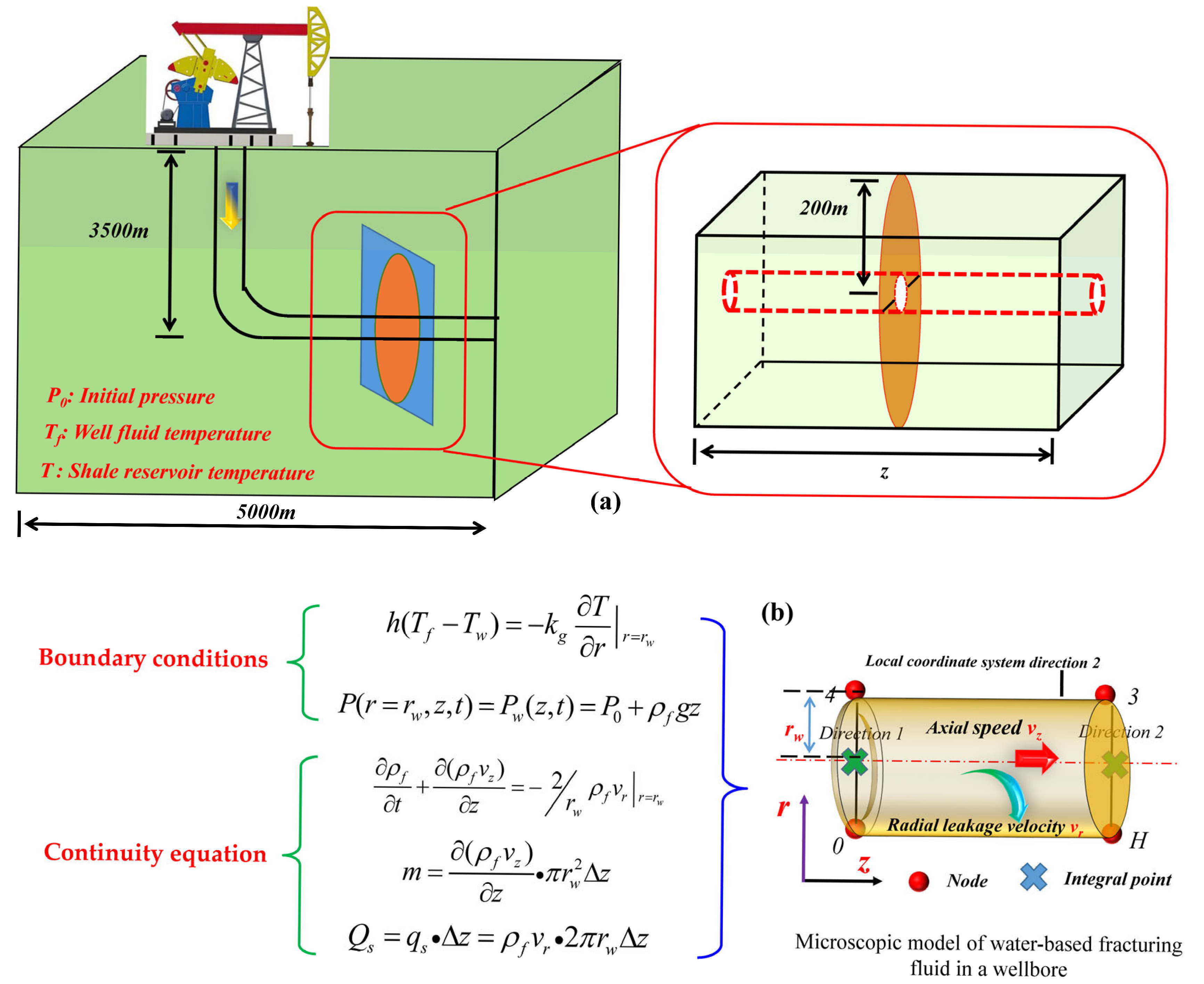

2. Numerical Model

2.1. Temperature Field of Wellbore Heat Transfer in Low-Permeability Shale Reservoirs

2.1.1. Heat-Transfer Equation for the Wellbore and Formation, Considering Seepage

2.1.2. Heat-Transfer Equation in a Wellbore, Considering Seepage

2.2. Continuity Equation for the Water-Based Fracturing Fluid in a Wellbore, Considering Seepage

2.3. Fluid Flow Field of Water-Based Fracturing Fluid in a Wellbore of a Low-Permeability Reservoir

2.4. Determination of the Physical Property Parameters of the Coupling Model

2.5. Model Geometry and Boundary Conditions

2.5.1. Temperature Boundary Conditions

2.5.2. Pressure Boundary Conditions

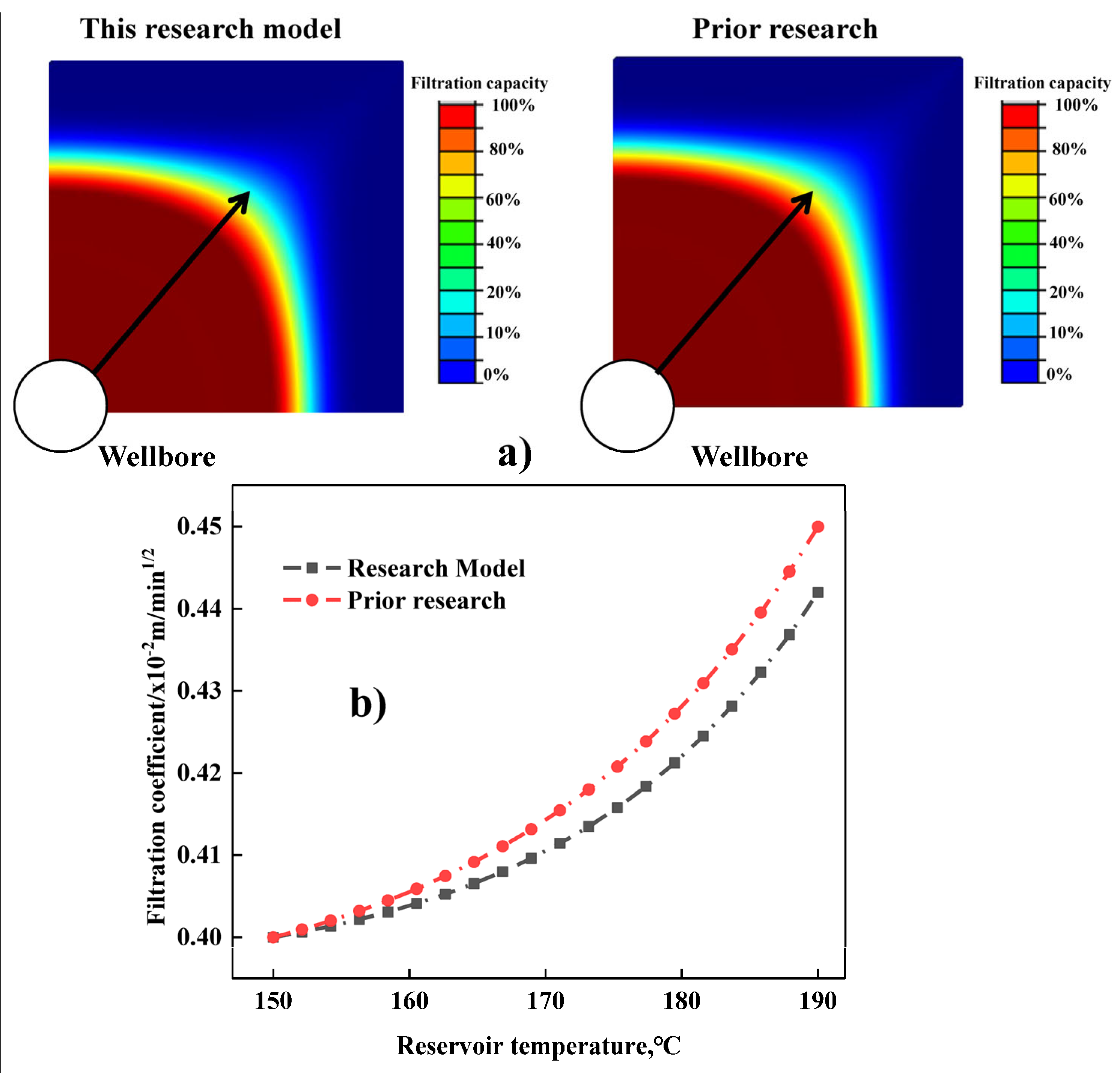

2.6. Model Decoupling, Solution, and Adaptability Validation of Investigation Methodology

2.6.1. Model Decoupling and Solution

2.6.2. Adaptability Validation of Investigation Methodology

3. Results and Discussion

3.1. Effects of the Wellbore Heat-Transfer Coefficient on the Filtration Behavior of Fracturing Fluid

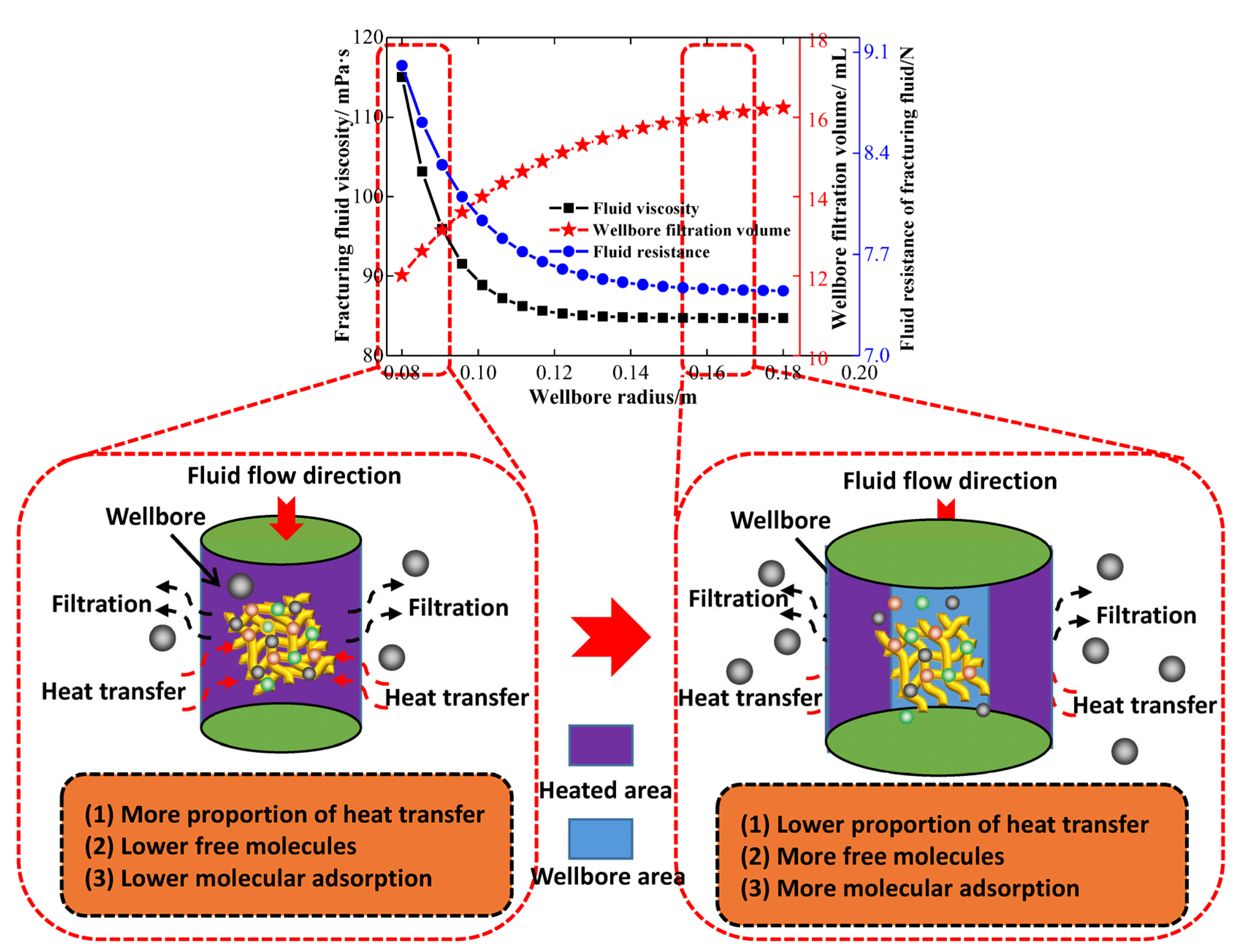

3.2. Effects of Wellbore Radius on Filtration Behavior of the Fracturing Fluid and Heat Conversion Efficiency

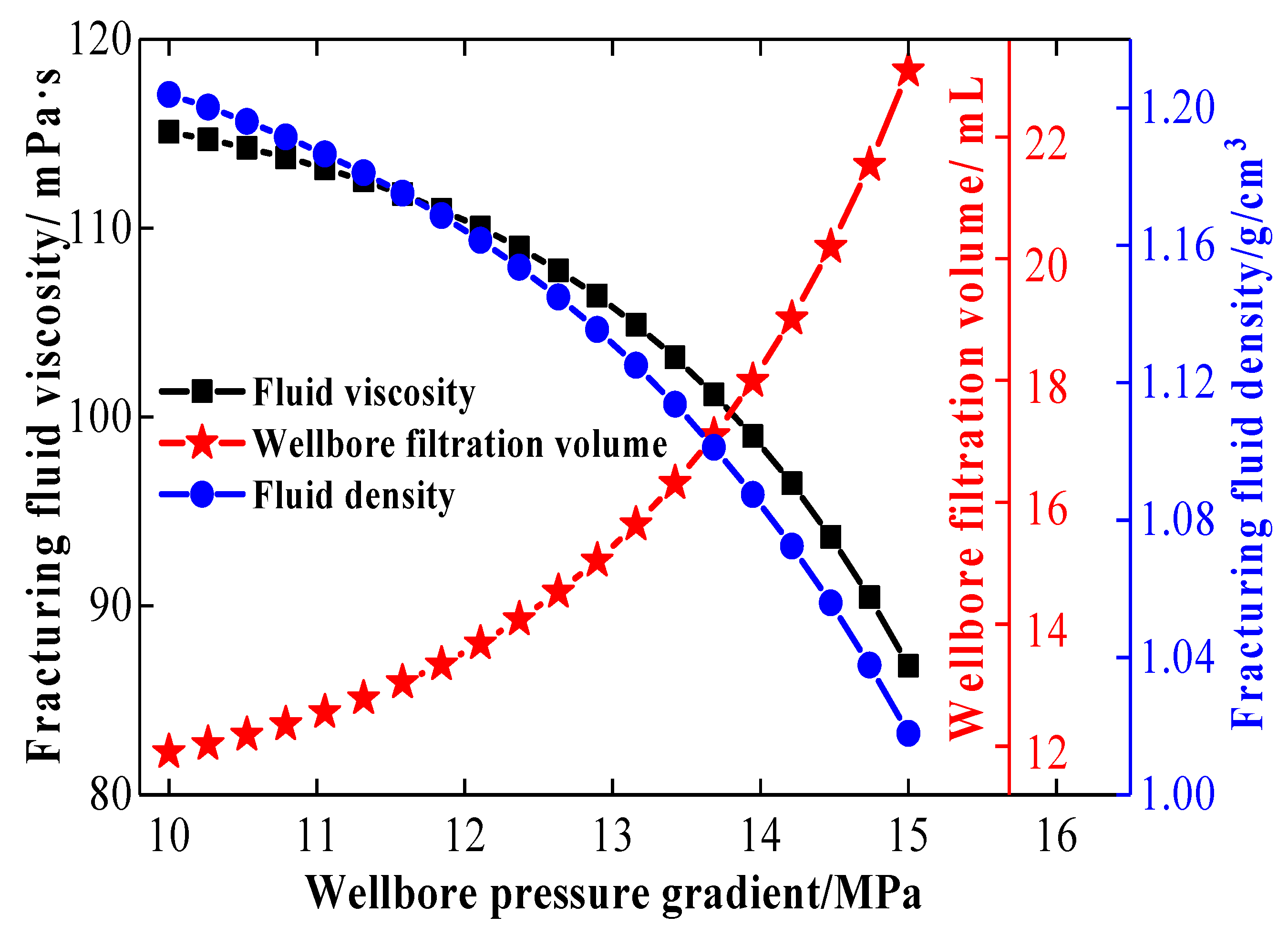

3.3. Effects of Wellbore Pressure Gradient on Filtration Behavior of the Fracturing Fluid and Heat Conversion Efficiency

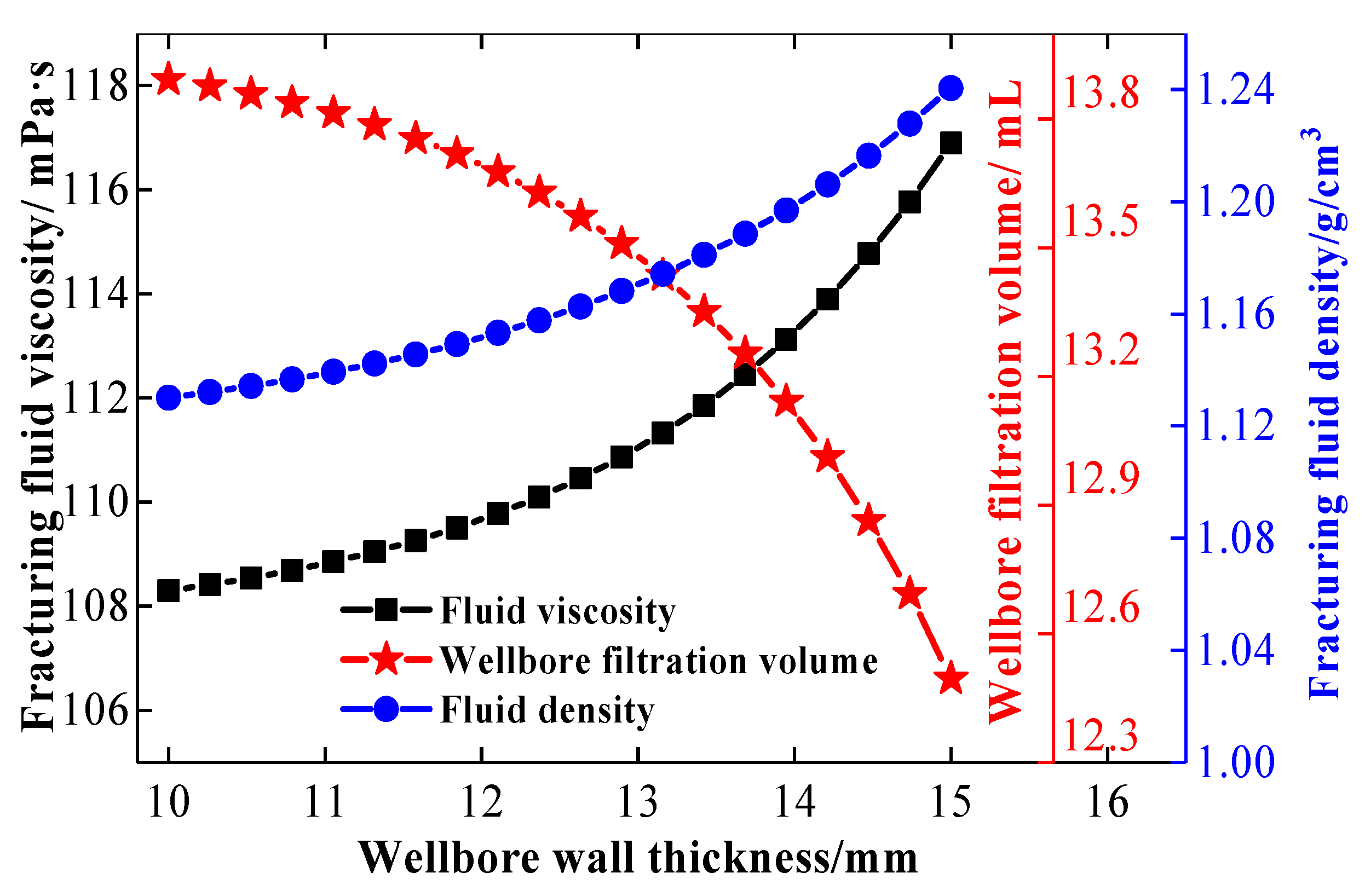

3.4. Effects of Wellbore Thickness on Filtration Behavior of the Fracturing Fluid and Crack Extension

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Hajri, S.; Negash, B.M.; Rahman, M.M.; Haroun, M.; Al-Shami, T.M. Perspective Review of polymers as additives in water-based fracturing fluids. ACS Omega 2022, 7, 7431–7443. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Liu, S.; Wang, G.; Cheng, W. Evaluating the changes of sorption and diffusion behaviors of Illinois coal with various water-based fracturing fluid treatments. Fuel 2021, 283, 118884. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Cheng, Y.; Li, Q.; Wang, F.; Wei, J.; Ansari, U. Numerical simulation of fracture reorientation during hydraulic fracturing in perforated horizontal well in shale reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1807–1813. [Google Scholar] [CrossRef]

- Da, Q.A.; Yao, C.; Zhang, X.; Li, L.; Lei, G. Reservoir Damage Induced by Water-Based Fracturing Fluids in Tight Reservoirs: A Review of Formation Mechanisms and Treatment Methods. Energy Fuels 2024, 38, 18093–18115. [Google Scholar] [CrossRef]

- Wang, J.; Elsworth, D.; Wu, Y.; Liu, J.; Zhu, W.; Liu, Y. The influence of fracturing fluids on fracturing processes: A comparison between water, oil and SC-CO2. Rock Mech. Rock Eng. 2018, 51, 299–313. [Google Scholar] [CrossRef]

- Papavasileiou, K.D.; Michalis, V.K.; Peristeras, L.D.; Vasileiadis, M.; Striolo, A.; Economou, I.G. Molecular dynamics simulation of water-based fracturing fluids in kaolinite slit pores. J. Phys. Chem. C 2018, 122, 17170–17183. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control stratege. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Abdelaal, A.; Aljawad, M.S.; Alyousef, Z.; Almajid, M.M. A review of foam-based fracturing fluids applications: From lab studies to field implementations. J. Nat. Gas Sci. Eng. 2021, 95, 104236. [Google Scholar] [CrossRef]

- Zhang, C.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Zhao, J. Simulation of flow behaviour through fractured unconventional gas reservoirs considering the formation damage caused by water-based fracturing fluids. J. Nat. Gas Sci. Eng. 2018, 57, 100–121. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, R.; Wu, X. Multi-timescale capacity configuration optimization of energy storage equipment in power plant-carbon capture system. Appl. Therm. Eng. 2023, 227, 120371. [Google Scholar] [CrossRef]

- Kreipl, M.P.; Kreipl, A.T. Hydraulic fracturing fluids and their environmental impact: Then, today, and tomorrow. Environ. Earth Sci. 2017, 76, 160. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A numerical Investigation on Kick Control with Displacement Kill Method during Well Test in Deep-water Gas Reservoir: Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.; Li, Q.; Wang, F.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar]

- Li, H.; Shi, Y. Study on the performance degradation of sandstone under acidification. ACS Omega 2020, 5, 28333–28340. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The carrying behavior of water-based fracturing fluid in shale reservoir fractures and molecular dynamics of sand-carrying mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Gonzalez Perdomo, M.E.; Wan Madihi, S. Foam based fracturing fluid characterization for an optimized application in HPHT reservoir conditions. Fluids 2022, 7, 156. [Google Scholar] [CrossRef]

- Wilkins, R.; Menefee, A.H.; Clarens, A.F. Environmental life cycle analysis of water and CO2-based fracturing fluids used in unconventional gas production. Environ. Sci. Technol. 2016, 50, 13134–13141. [Google Scholar] [CrossRef]

- Akpan, E.U.; Enyi, G.C.; Nasr, G.; Yahaya, A.A.; Ahmadu, A.A.; Saidu, B. Water-based drilling fluids for high-temperature applications and water-sensitive and dispersible shale formations. J. Pet. Sci. Eng. 2019, 175, 1028–1038. [Google Scholar] [CrossRef]

- Huang, R.; Lei, Q.; Chen, J.; Weng, D.; Wang, X.; Liang, H. Gas content prediction model of water-sensitive shale based on gas–water miscible competitive adsorption. Pet. Sci. Technol. 2024, 42, 1841–1863. [Google Scholar] [CrossRef]

- Wu, G.; Pan, J.; Anwaier, M.; Wu, J.; Xiao, P.; Zheng, L.; Wang, W.; Meng, X.; Wang, P.; Liu, J.; et al. Effect of nano-SiO2 on the flowback-flooding integrated performance of water-based fracturing fluids. J. Mol. Liq. 2023, 379, 121686. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Rathnaweera, T.D.; Zhang, D.C.; Zhang, C. Investigation of effects of fracturing fluid on hydraulic fracturing and fracture permeability of reservoir rocks: An experimental study using water and foam fracturing. Eng. Fract. Mech. 2018, 194, 117–135. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhang, C.P.; Zhang, Z.Y. Experimental study of fracturing behaviour in ultralow permeability formations: A comparison between CO2 and water fracturing. Eng. Fract. Mech. 2019, 217, 106541. [Google Scholar] [CrossRef]

- Sinclair, A.R. Heat Transfer effects in deep well fracturing. J. Pet. Technol. 1971, 23, 1484–1492. [Google Scholar] [CrossRef]

- Liu, B.; Suzuki, A.; Ito, T. Numerical analysis of different fracturing mechanisms between supercritical CO2 and water-based fracturing fluids. Int. J. Rock Mech. Min. Sci. 2020, 132, 104385. [Google Scholar] [CrossRef]

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Wei, Z.; He, Y.; Gu, S.; Shi, Y.; Yang, X.; Cai, J. Experimental study on water-based drilling fluid for horizontal wells. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 13351–13370. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Wu, J.; Usman Tahir, M.; Li, Q.; Liu, Z. Effect of thickener and reservoir parameters on the filtration property of CO2 fracturing fluid. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1705–1715. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Sepehrnoori, K.; Zheng, Y.; Yan, W. Calculation of the wellbore temperature and pressure distribution during supercritical CO2 fracturing flowback process. Int. J. Heat Mass Transf. 2019, 139, 10–16. [Google Scholar] [CrossRef]

- Zhao, X.; Qiu, Z.; Wang, M.; Huang, W.; Zhang, S. Performance evaluation of a highly inhibitive water-based drilling fluid for ultralow temperature wells. J. Energy Resour. Technol. 2018, 140, 012906. [Google Scholar] [CrossRef]

- Yang, L.L.; Li, B.; Chen, X.D.; Yu, L.; Jing, F.M.; Zhang, D. Experimental and numerical study of the rheological characteristics and flow law of water-based drilling fluids in high-temperature and high-pressure wellbores. J. Hydrodyn. 2024, 36, 954–967. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Ridha, S.; Mohshim, D.F.; Yusuf, M.; Kamyab, H.; Krishna, S.; Maoinser, M.A. A comprehensive review of nanoparticles: Effect on water-based drilling fluids and wellbore stability. Chemosphere 2022, 308, 136274. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, F.; Wang, Y.; Zhang, J.; Yu, X.; Zhao, M.; Li, W. Influence of organoboron cross-linker and reservoir characteristics on filtration and reservoir residual of guar gum fracturing fluid in low-permeability shale gas reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 82975–82985. [Google Scholar] [CrossRef] [PubMed]

- Bongole, K.; Sun, Z.; Yao, J.; Mehmood, A.; Yueying, W.; Mboje, J.; Xin, Y. Multifracture response to supercritical CO2-EGS and water-EGS based on thermo-hydro-mechanical coupling method. Int. J. Energy Res. 2019, 43, 7173–7196. [Google Scholar]

- Li, Q.; Cheng, Y.; Li, Q.; Ansari, U.; Liu, Y.; Yan, C.; Lei, C. Development and verification of the comprehensive model for physical properties of hydrate sediment. Arab. J. Geosci. 2018, 11, 325. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.; Zhao, J. Experimental investigation of water sensitivity effects on microscale mechanical behavior of shale. Int. J. Rock Mech. Min. Sci. 2021, 145, 104837. [Google Scholar] [CrossRef]

- Song, W.; Shi, X.; Wang, C.; Xu, J.; Chen, S.; Chen, Z. Predicting the radial heat transfer in the wellbore of cryogenic nitrogen fracturing: Insights into stimulating underground reservoir. Energy Sci. Eng. 2020, 8, 582–591. [Google Scholar] [CrossRef]

- Zhao, X.; Li, D.; Zhu, H.; Ma, J.; An, Y. Advanced developments in environmentally friendly lubricants for water-based drilling fluid: A review. RSC Adv. 2022, 12, 22853–22868. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, Y.; San, J.; Li, Q.; Foster, G. Synthetic process on hydroxyl-containing polydimethylsiloxane as a thickener in CO2 fracturing and thickening performance test. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1137–1143. [Google Scholar] [CrossRef]

- Gong, Q.; Xu, Z.G.; Wang, M.Q.; Qin, J. Numerical investigation on wellbore temperature and pressure during carbon dioxide fracturing. Appl. Therm. Eng. 2019, 157, 113675. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Wang, H.; Tian, S.; Song, X.; Lu, P.; Wang, M. A unified model for wellbore flow and heat transfer in pure CO2 injection for geological sequestration, EOR and fracturing operations. Int. J. Greenh. Gas Control 2017, 57, 102–115. [Google Scholar] [CrossRef]

- Ahmed, A.; Alsaihati, A.; Elkatatny, S. An overview of the common water-based formulations used for drilling onshore gas wells in the Middle East. Arab. J. Sci. Eng. 2021, 46, 6867–6877. [Google Scholar] [CrossRef]

- Xiao, C.; Ni, H.; Shi, X. Unsteady model for wellbore pressure transmission of carbon dioxide fracturing considering limited-flow outlet. Energy 2022, 239, 122289. [Google Scholar] [CrossRef]

- Song, H.; Liu, J. Effects of Modified Cross-Linkers on the Rheology of Water-Based Fracturing Fluids and Reservoir Water Environment. Processes 2024, 12, 2896. [Google Scholar] [CrossRef]

- Wang, M.; Wu, W.; Ni, Q.; Gao, Z.; Li, T.; Yang, Y. Experimental evaluation of self-generated heat-enhanced fracturing fluid for low-temperature and low-pressure shallow reservoirs. Phys. Fluids 2024, 36, 096621. [Google Scholar] [CrossRef]

- Chen, H.; Tomac, I. Technical review on coaxial deep borehole heat exchanger. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 120. [Google Scholar] [CrossRef]

- Xiao, F.; Salimzadeh, S.; Zhang, Q.B. A 3D coupled numerical simulation of energised fracturing with CO2: Impact of CO2 phase on fracturing process. Int. J. Rock Mech. Min. Sci. 2024, 182, 105863. [Google Scholar] [CrossRef]

- Li, C.; Mao, X. Correction of the circulation depth of geothermal water based on temperature variation in the discharge section of geothermal system. Environ. Earth Sci. 2024, 83, 552. [Google Scholar] [CrossRef]

- Cha, M.; Yin, X.; Kneafsey, T.; Johanson, B.; Alqahtani, N.; Miskimins, J.; Patterson, T.; Wu, Y.S. Cryogenic fracturing for reservoir stimulation–Laboratory studies. J. Pet. Sci. Eng. 2014, 124, 436–450. [Google Scholar] [CrossRef]

- Lu, X.; Tong, X.; Du, X.; Xiao, Y.; Deng, J. Effect of wellbore layout and varying flow rate on fluid flow and heat transfer of deep geothermal mining system. Therm. Sci. Eng. Prog. 2023, 42, 101870. [Google Scholar] [CrossRef]

- Guo, Y.; Li, X.; Huang, L.; Dyskin, A.; Pasternak, E. Insight into the dynamic tensile behavior of deep anisotropic shale reservoir after water-based working fluid cooling. Int. J. Rock Mech. Min. Sci. 2024, 182, 105875. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Meng, S.; Duan, Y. Fracturing with carbon dioxide: Application status and development trend. Pet. Explor. Dev. 2014, 41, 513–519. [Google Scholar] [CrossRef]

- Pruess, K. Enhanced geothermal systems (EGS) using CO2 as working fluid—A novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 376, 121394. [Google Scholar] [CrossRef]

- Ren, K.; Cai, C. Numerical investigation into the distributions of temperature and stress around wellbore during the injection of cryogenic liquid nitrogen into hot dry rock reservoir. Math. Probl. Eng. 2021, 2021, 9913321. [Google Scholar] [CrossRef]

- Mahmoodpour, S.; Singh, M.; Bär, K.; Sass, I. Thermo-hydro-mechanical modeling of an enhanced geothermal system in a fractured reservoir using carbon dioxide as heat transmission fluid-A sensitivity investigation. Energy 2022, 254, 124266. [Google Scholar] [CrossRef]

- Zhang, F.Z.; Jiang, P.X.; Xu, R.N. System thermodynamic performance comparison of CO2-EGS and water-EGS systems. Appl. Therm. Eng. 2013, 61, 236–244. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: Evolution and mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, B.; Sun, X. Calculation of temperature in fracture for carbon dioxide fracturing. SPE J. 2016, 21, 1491–1500. [Google Scholar] [CrossRef]

- Shi, Y.; Bai, Z.; Feng, G.; Tian, H.; Bai, H. Performance analysis of medium-depth coaxial heat exchanger geothermal system using CO 2 as a circulating fluid for building heating. Arab. J. Geosci. 2021, 14, 1308. [Google Scholar] [CrossRef]

- Huang, X.; Liu, F.; Zhang, P.; Wei, Z.; Sun, J.; Lv, K.; Li, J. Application of microgel latex in water-based drilling fluid to stabilize the fractured formation. Geoenergy Sci. Eng. 2023, 228, 212016. [Google Scholar] [CrossRef]

- Tang, S.; Wang, J.; Chen, P. Theoretical and numerical studies of cryogenic fracturing induced by thermal shock for reservoir stimulation. Int. J. Rock Mech. Min. Sci. 2020, 125, 104160. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Liu, X. Performance analysis of pinnate horizontal well in enhanced geothermal system. Appl. Therm. Eng. 2022, 201, 117799. [Google Scholar] [CrossRef]

- He, Y.; Bu, X. Performance of a hybrid heating system based on enhanced deep borehole heat exchanger and solar energy. Geotherm. Energy 2022, 10, 25. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Yang, H.; Han, J.; Zhu, M.; Dong, S.; Yu, Z. A new rough fracture permeability model of coal with injected water based on damaged tree-like branching network. Fractals 2024, 32, 2450057. [Google Scholar] [CrossRef]

- Xiao, D.; Hu, Y.; Wang, Y.; Deng, H.; Zhang, J.; Tang, B.; Xi, J.; Tang, S.; Li, G. Wellbore cooling and heat energy utilization method for deep shale gas horizontal well drilling. Appl. Therm. Eng. 2022, 213, 118684. [Google Scholar] [CrossRef]

- Wen, H.; Yang, R.; Huang, Z.; Hu, X.; Hong, C.; Song, G. Flow and heat transfer of nitrogen during liquid nitrogen fracturing in coalbed methane reservoirs. J. Pet. Sci. Eng. 2022, 209, 109900. [Google Scholar] [CrossRef]

- Shi, D.; Cheng, S.; Wang, Q.; Liu, D.; Yin, F.; Xu, X.; Guo, X.; Weng, Z. Comparative Analysis and Application of Mass and Heat Transfer Simulation in Fractured Reservoirs Based on Two Fracture Models. Processes 2024, 12, 2399. [Google Scholar] [CrossRef]

- Wu, L.; Hou, Z.; Luo, Z.; Xiong, Y.; Zhang, N.; Luo, J.; Fang, Y.; Chen, Q.; Wu, X. Numerical simulations of supercritical carbon dioxide fracturing: A review. J. Rock Mech. Geotech. Eng. 2023, 15, 1895–1910. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Zhou, C.; Chen, J.; Forson, K.; Miao, R.; Su, Y.; Zhang, J. Effect of reservoir characteristics and chemicals on filtration property of water-based drilling fluid in unconventional reservoir and mechanism disclosure. Environ. Sci. Pollut. Res. 2023, 30, 55034–55043. [Google Scholar] [CrossRef]

- Li, M.; Liu, G.; Li, J. Thermal effect on wellbore stability during drilling operation with long horizontal section. J. Nat. Gas Sci. Eng. 2015, 23, 118–126. [Google Scholar] [CrossRef]

- Guerrero, F.J.; Santoyo, E. A heat mining strategy for the potential Enhanced Geothermal System of the Acoculco Caldera Complex, Puebla (Mexico): A numerical approach based on Multiple Interacting Continua. Appl. Therm. Eng. 2024, 253, 123743. [Google Scholar] [CrossRef]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Hartmann–sprenger energy separation effect for the quasi-isothermal pressure reduction of natural gas: Feasibility analysis and numerical simulation. Energies 2024, 17, 2010. [Google Scholar] [CrossRef]

- He, Z.; Yang, Y.; Qi, J.; Lin, X.; Wang, N.; Wang, L.; Dai, H.; Lu, H. Hyperbranched polymer nanocomposite as a potential shale stabilizer in water-based drilling fluids for improving wellbore stability. J. Mol. Liq. 2024, 395, 123903. [Google Scholar] [CrossRef]

- Cong, L.; Lu, S.; Jiang, P.; Zheng, T.; Yu, Z.; Lü, X. Research Progress on CO2 as Geothermal Working Fluid: A Review. Energies 2024, 17, 5415. [Google Scholar] [CrossRef]

- Tang, M.; Zhang, G.; He, S.; Kong, L.; Deng, F.; Lei, H. Analysis of seepage and temperature fields and their influence on collapse pressure while drilling in shale oil reservoirs. Geoenergy Sci. Eng. 2023, 231, 212410. [Google Scholar] [CrossRef]

- Cha, M.; Alqahtani, N.B.; Yin, X.; Kneafsey, T.J.; Yao, B.; Wu, Y.S. Laboratory system for studying cryogenic thermal rock fracturing for well stimulation. J. Pet. Sci. Eng. 2017, 156, 780–789. [Google Scholar] [CrossRef]

- Hou, Z.; Yuan, Y.; Chen, Y.; Feng, J.; Wang, H.; Zhang, X. A review of supercritical CO2 fracturing technology in shale gas reservoirs. Processes 2024, 12, 1238. [Google Scholar] [CrossRef]

- Ribeiro, L.H.; Sharma, M.M. A new 3D compositional model for hydraulic fracturing with energized fluids. SPE Prod. Oper. 2013, 28, 259–267. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Li, Q.; Zhang, C.; Ansari, U.; Song, B. Establishment and evaluation of strength criterion for clayey silt hydrate-bearing sediments. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 742–750. [Google Scholar] [CrossRef]

- Yao, B.; Wang, L. Modeling of cryogenic fracturing processes. In Hydraulic Fracture Modeling; Gulf Professional Publishing: Oxford, UK, 2018; pp. 393–410. [Google Scholar]

- Li, H.; Xiang, Y.; Luo, H.; Yu, H.; Zhang, Q.; Li, Y.; Jiang, B.; Zhang, N. Study on temperature distribution prediction of horizontal wells during fracturing treatment. J. Nat. Gas Geosci. 2022, 7, 49–57. [Google Scholar] [CrossRef]

- Mao, H.; Yang, Y.; Zhang, H.; Zhang, J.; Huang, Y. A critical review of the possible effects of physical and chemical properties of subcritical water on the performance of water-based drilling fluids designed for ultra-high temperature and ultra-high pressure drilling applications. J. Pet. Sci. Eng. 2020, 187, 106795. [Google Scholar] [CrossRef]

- Yang, R.; Hong, C.; Wen, H.; Huang, Z.; Li, G.; Lan, T.; Wang, H.; Dubinya, N. Cyclic liquid nitrogen fracturing performance on coal with various coal ranks: Laboratory investigation and mechanism analysis. Spe J. 2023, 28, 1706–1728. [Google Scholar] [CrossRef]

- Jin, Y.; Haixiong, T.; Zhengli, L.; Liping, Y.; De, Y.A.N.; Ruirui, T.I.A.N. Prediction model of casing annulus pressure for deepwater well drilling and completion operation. Pet. Explor. Dev. 2013, 40, 661–664. [Google Scholar]

- Kumari, W.G.P.; Ranjith, P.G. Sustainable development of enhanced geothermal systems based on geotechnical research–A review. Earth-Sci. Rev. 2019, 199, 102955. [Google Scholar] [CrossRef]

- Xie, B.; Ting, L.; Zhang, Y.; Liu, C. Rheological properties of bentonite-free water-based drilling fluids with novel polymer viscosifier. J. Pet. Sci. Eng. 2018, 164, 302–310. [Google Scholar] [CrossRef]

- Albooyeh, M.; Kivi, I.R.; Ameri, M. Promoting wellbore stability in active shale formations by water-based muds: A case study in Pabdeh shale, Southwestern Iran. J. Nat. Gas Sci. Eng. 2018, 56, 166–174. [Google Scholar] [CrossRef]

- Yang, M.; Luo, D.; Chen, Y.; Li, G.; Tang, D.; Meng, Y. Establishing a practical method to accurately determine and manage wellbore thermal behavior in high-temperature drilling. Appl. Energy 2019, 238, 1471–1483. [Google Scholar] [CrossRef]

- Yang, R.; Hong, C.; Huang, Z.; Wen, H.; Li, X.; Huang, P.; Liu, W.; Chen, J. Liquid nitrogen fracturing in boreholes under true triaxial stresses: Laboratory investigation on fractures initiation and morphology. SPE J. 2021, 26, 135–154. [Google Scholar] [CrossRef]

- Sudharsan, J.; Khare, S.K. Pore pressure transmission test as measure of shale inhibition performance of nanoparticle additives in water based drilling fluids–A comprehensive review. Mater. Today Proc. 2023, 99, 8–14. [Google Scholar] [CrossRef]

- Wang, C.L.; Cheng, W.L.; Nian, Y.L.; Yang, L.; Han, B.B.; Liu, M.H. Simulation of heat extraction from CO2-based enhanced geothermal systems considering CO2 sequestration. Energy 2018, 142, 157–167. [Google Scholar] [CrossRef]

- Ai, E.; Li, Q.; Liu, Z.; Zhang, B.; Wang, L.; Ma, C. Advanced Trends in Shale Mechanical Inhibitors for Enhanced Wellbore Stability in Water-Based Drilling Fluids. Minerals 2024, 14, 1197. [Google Scholar] [CrossRef]

- Wu, G.D.; Wang, L.K.; Zhao, C.Y.; Zhang, Z.J.; Yin, J.Y.; Anwaier, M.; Zhu, D.Y. Experimental study of reservoir damage of water-based fracturing fluids prepared by different polymers. Pet. Sci. 2024, 21, 3298–3306. [Google Scholar] [CrossRef]

- Xue, S.; Huang, Q.; Wang, G.; Bing, W.; Li, J. Experimental study of the influence of water-based fracturing fluids on the pore structure of coal. J. Nat. Gas Sci. Eng. 2021, 88, 103863. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, S.; Cheng, W.; Wang, G. Fracture permeability damage and recovery behaviors with fracturing fluid treatment of coal: An experimental study. Fuel 2020, 282, 118809. [Google Scholar] [CrossRef]

- Fan, M.; Lai, X.; Tang, M.; Li, J.; Wang, L.; Gao, J. Preparation and properties of a clean, low-damage waterproof locking damage multifunctional integrated water-based fracturing fluid. J. Appl. Polym. Sci. 2022, 139, e53207. [Google Scholar] [CrossRef]

- Budiman, O.; Alajmei, S. Seawater-based fracturing fluid: A review. ACS Omega 2023, 8, 41022–41038. [Google Scholar] [CrossRef]

- Zhang, Q.; Mao, J.; Qu, X.; Liao, Y.; Du, A.; Zhang, H.; Liu, B.; Xiao, Y.; Zhang, Y.; Lin, C.; et al. Application of fumed silica-enhanced polymeric fracturing fluids in highly mineralized water. J. Mol. Liq. 2023, 375, 120835. [Google Scholar] [CrossRef]

- Cao, M.; Wang, R.; Li, Y.; Dai, C.; Yan, X.; Zhang, L.; Wu, Y. Nanoparticle-enhanced water-based-emulsion fracturing fluid for improved imbibition recovery in unconventional reservoirs: Performance and mechanism. SPE J. 2024, 29, 3732–3747. [Google Scholar] [CrossRef]

- Nalla, R.K.; Balooch, M.; Ager Iii, J.W.; Kruzic, J.J.; Kinney, J.H.; Ritchie, R.O. Effects of polar solvents on the fracture resistance of dentin: Role of water hydration. Acta Biomater. 2005, 1, 31–43. [Google Scholar] [CrossRef]

- Bondarenko, A.V.; Islamov, S.R.; Ignatyev, K.V.; Mardashov, D.V. Laboratory studies of polymer compositions for well-kill under increased fracturing. Perm J. Pet. Min. Eng. 2020, 20, 37–48. [Google Scholar] [CrossRef] [PubMed]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

| Factor Type | Factor Range | Fluid Viscosity (mPa·s) | Proportional Relationship | Sensitivity |

|---|---|---|---|---|

| Crack diameter | 8 mm–18 mm | −32 | Inverse | Strength |

| Reservoir pressure | 10 MPa–15 MPa | −16 | Inverse | Medium |

| Wellbore thickness | 10 mm–15 mm | +11 | Proportional | Medium |

| Reservoir pressure/MPa | 10 | 12 | 14 | 15 |

| Bond length/nm | 74 | 72 | 67 | 61 |

| Bond energy/×10−3 J/mol | 3.8 | 4.0 | 4.4 | 5.1 |

| Fracturing fluid type | 150 °C | 160 °C | 170 °C | 180 °C |

| Water-based fracturing fluid | 0.4 | 0.405 | 0.415 | 0.43 |

| CO2-based fracturing fluid | 0.63 | 0.65 | 0.68 | 0.74 |

| Foam-based fracturing fluid | 0.48 | 0.49 | 0.505 | 0.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y.; Jin, J. Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination. Processes 2025, 13, 1747. https://doi.org/10.3390/pr13061747

Li Q, Li Q, Wang F, Wu J, Wang Y, Jin J. Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination. Processes. 2025; 13(6):1747. https://doi.org/10.3390/pr13061747

Chicago/Turabian StyleLi, Qiang, Qingchao Li, Fuling Wang, Jingjuan Wu, Yanling Wang, and Jiafeng Jin. 2025. "Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination" Processes 13, no. 6: 1747. https://doi.org/10.3390/pr13061747

APA StyleLi, Q., Li, Q., Wang, F., Wu, J., Wang, Y., & Jin, J. (2025). Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination. Processes, 13(6), 1747. https://doi.org/10.3390/pr13061747