Multiphysics Coupling Effects on Slope Deformation in Jiangte Xikeng Lithium Deposit Open-Pit Mining

Abstract

1. Introduction

2. Engineering Geological Features

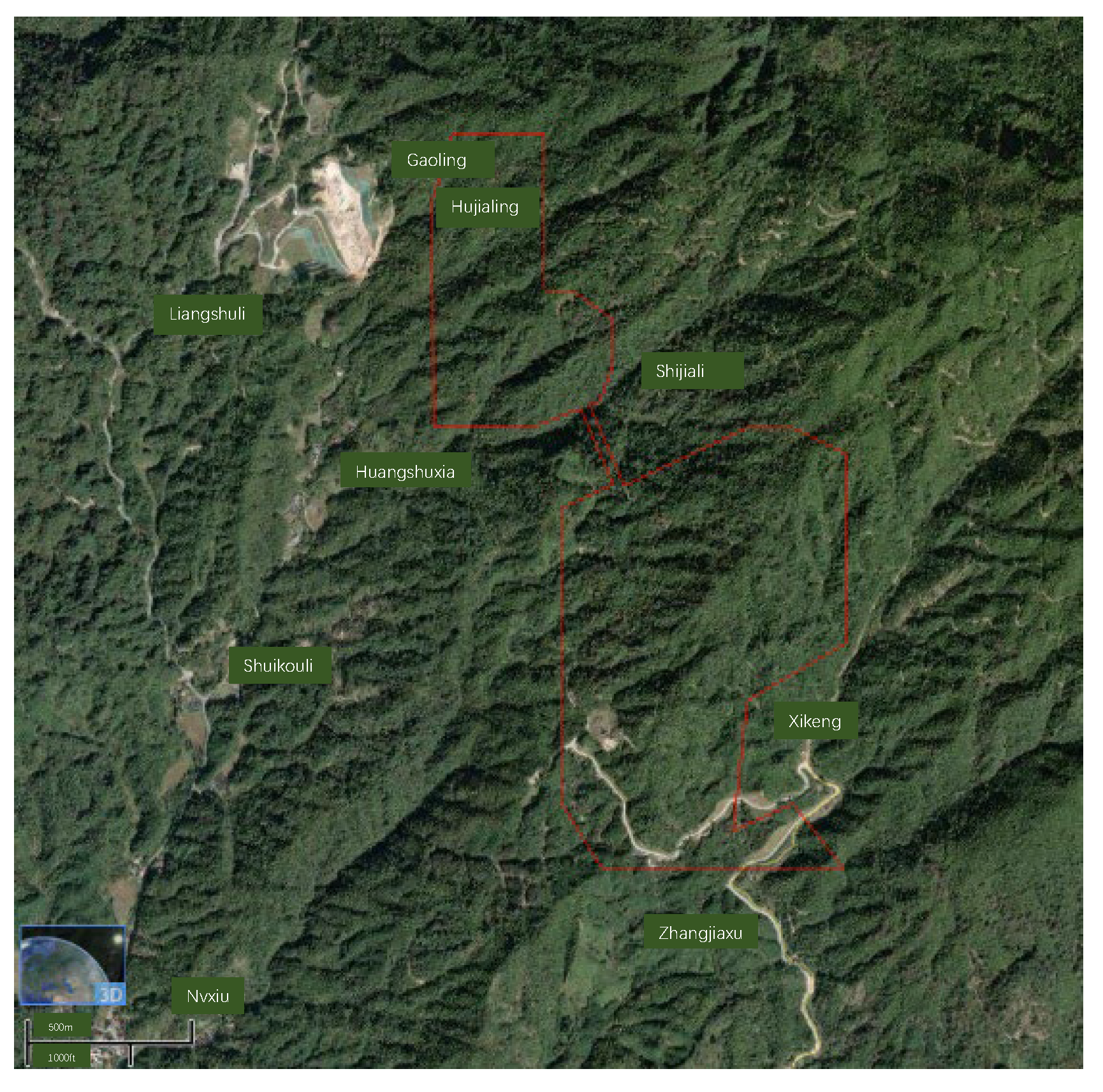

2.1. Engineering Geological Conditions of the Mine Area

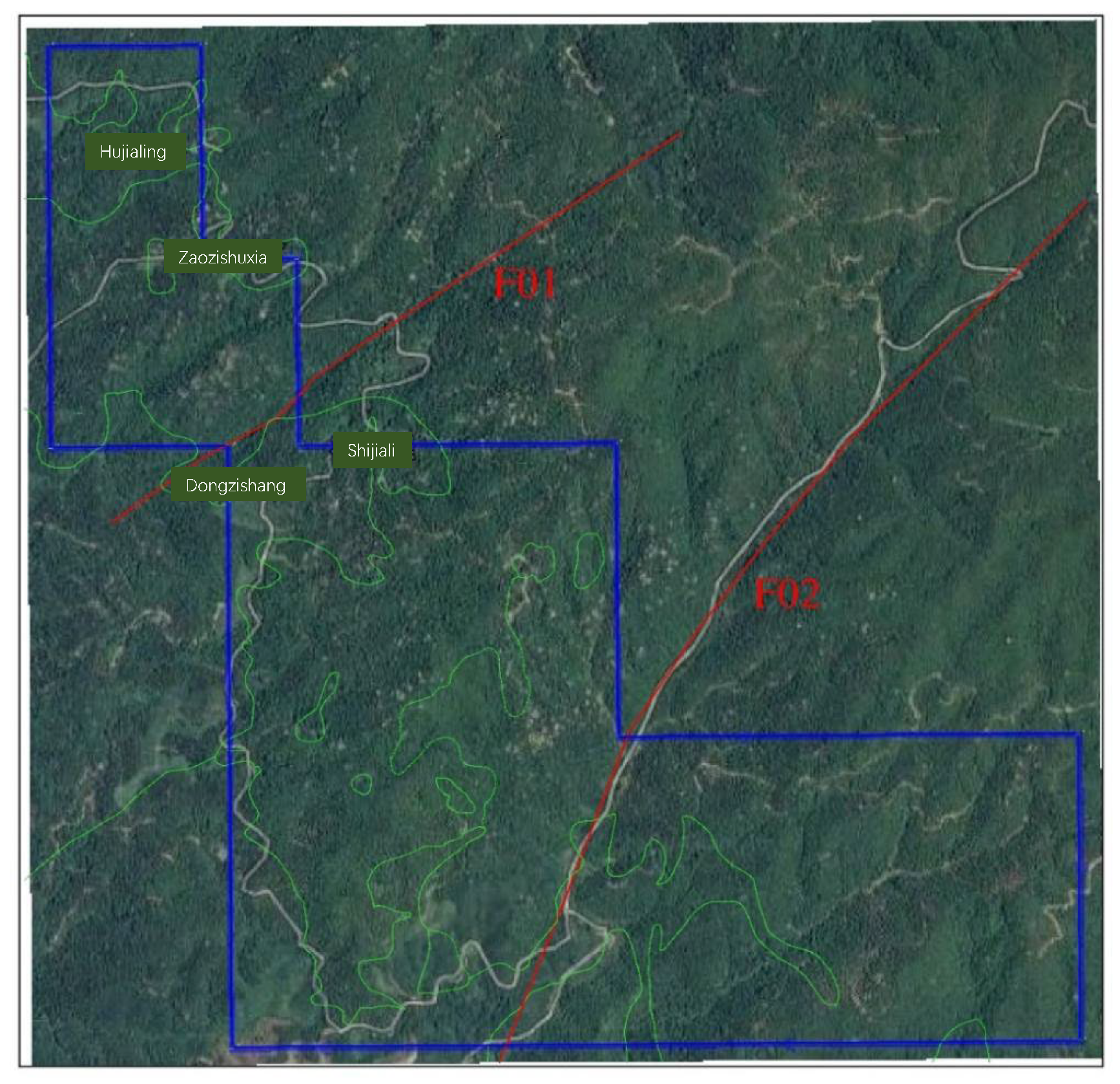

2.2. Geological Structures of the Mine Area

3. Three-Dimensional Slope Stability Analysis

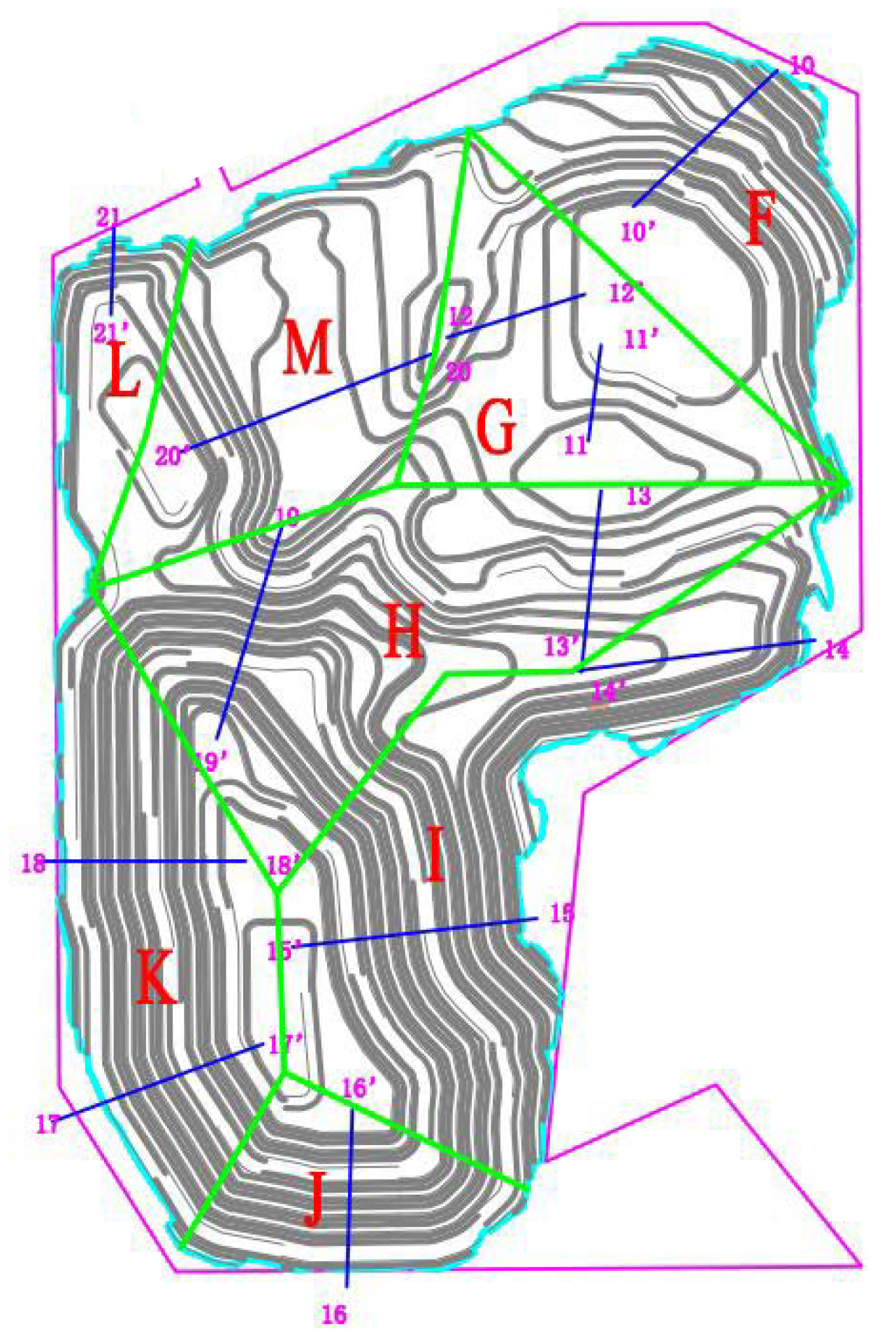

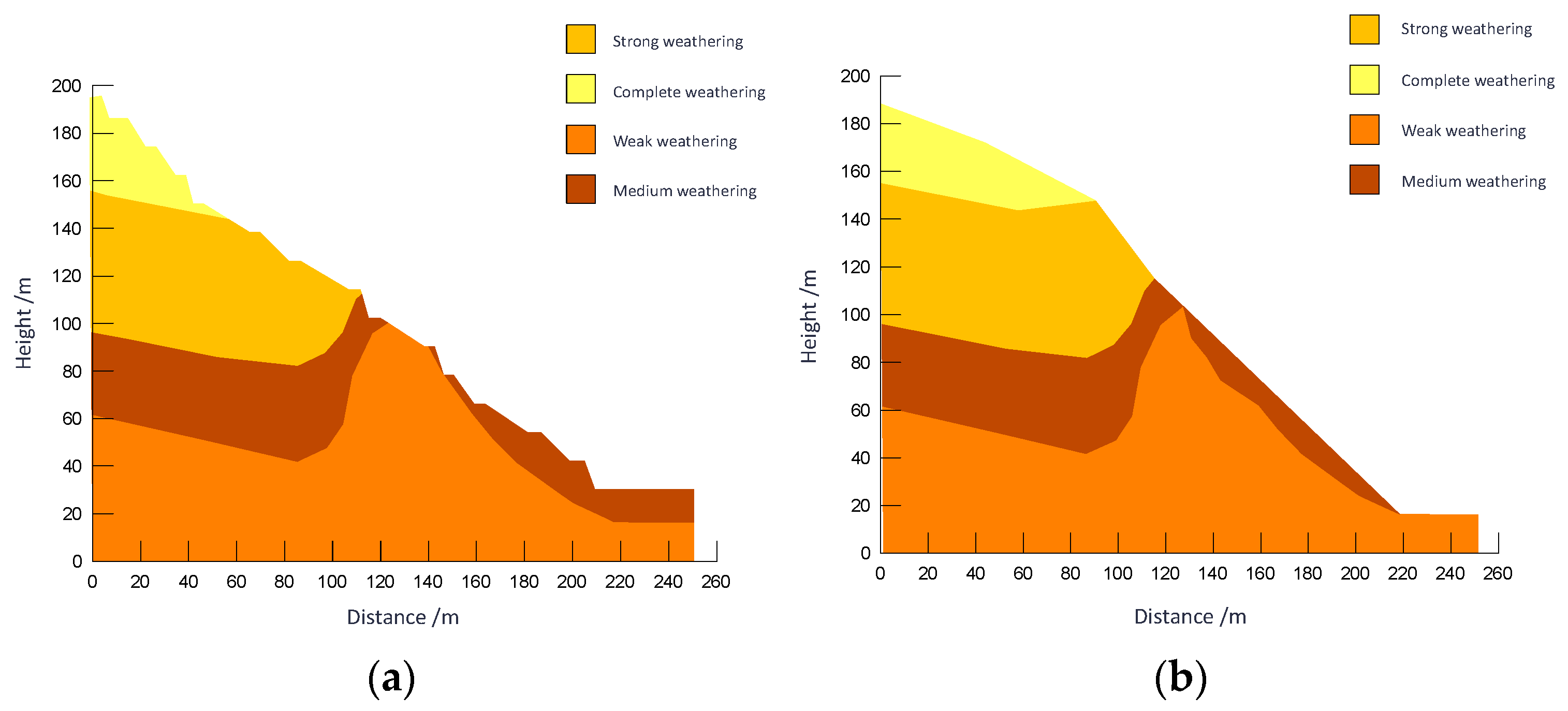

3.1. Slope Zoning

3.2. Determination of Physical and Mechanical Parameters

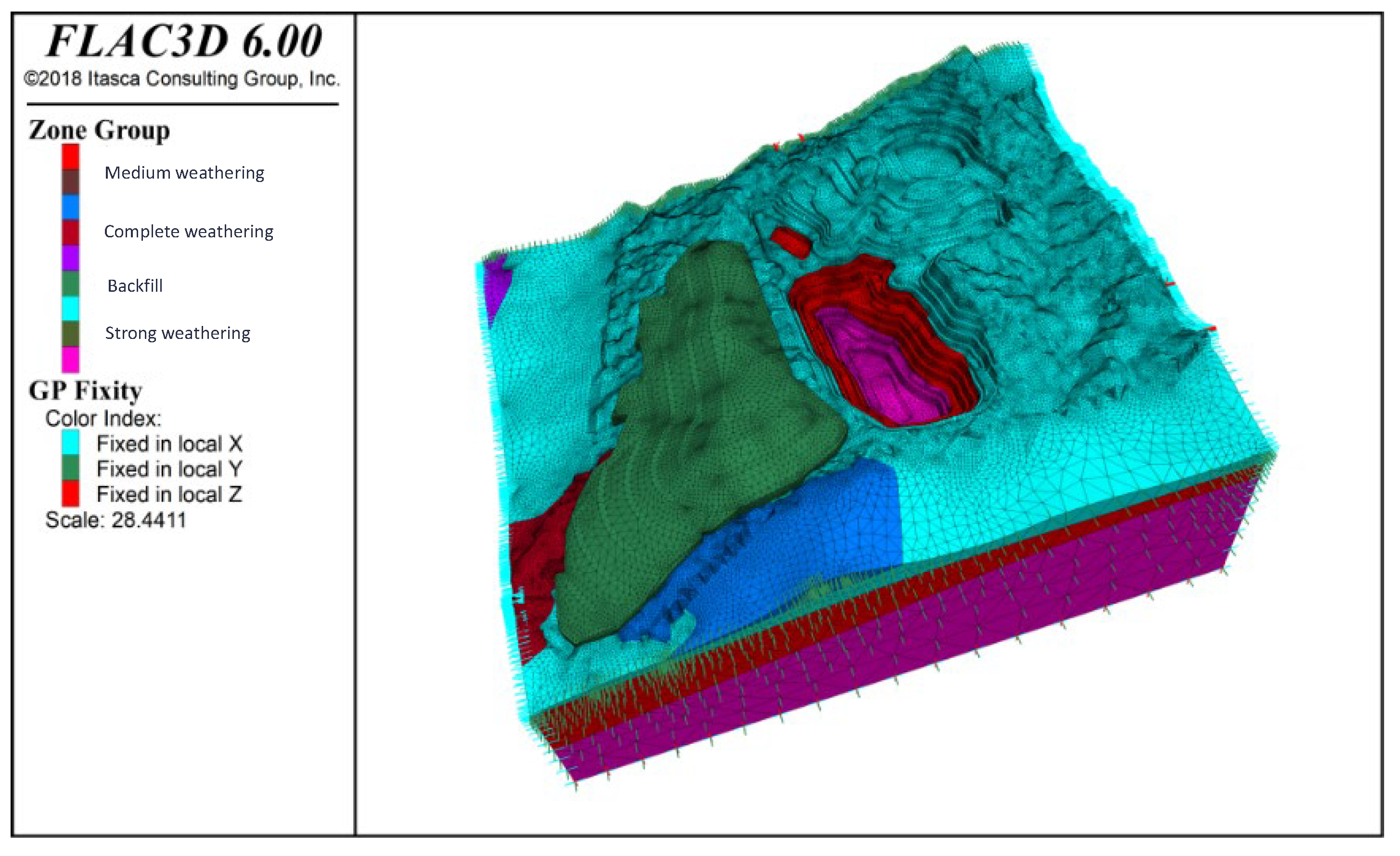

3.3. Calculation Model and Boundary Conditions

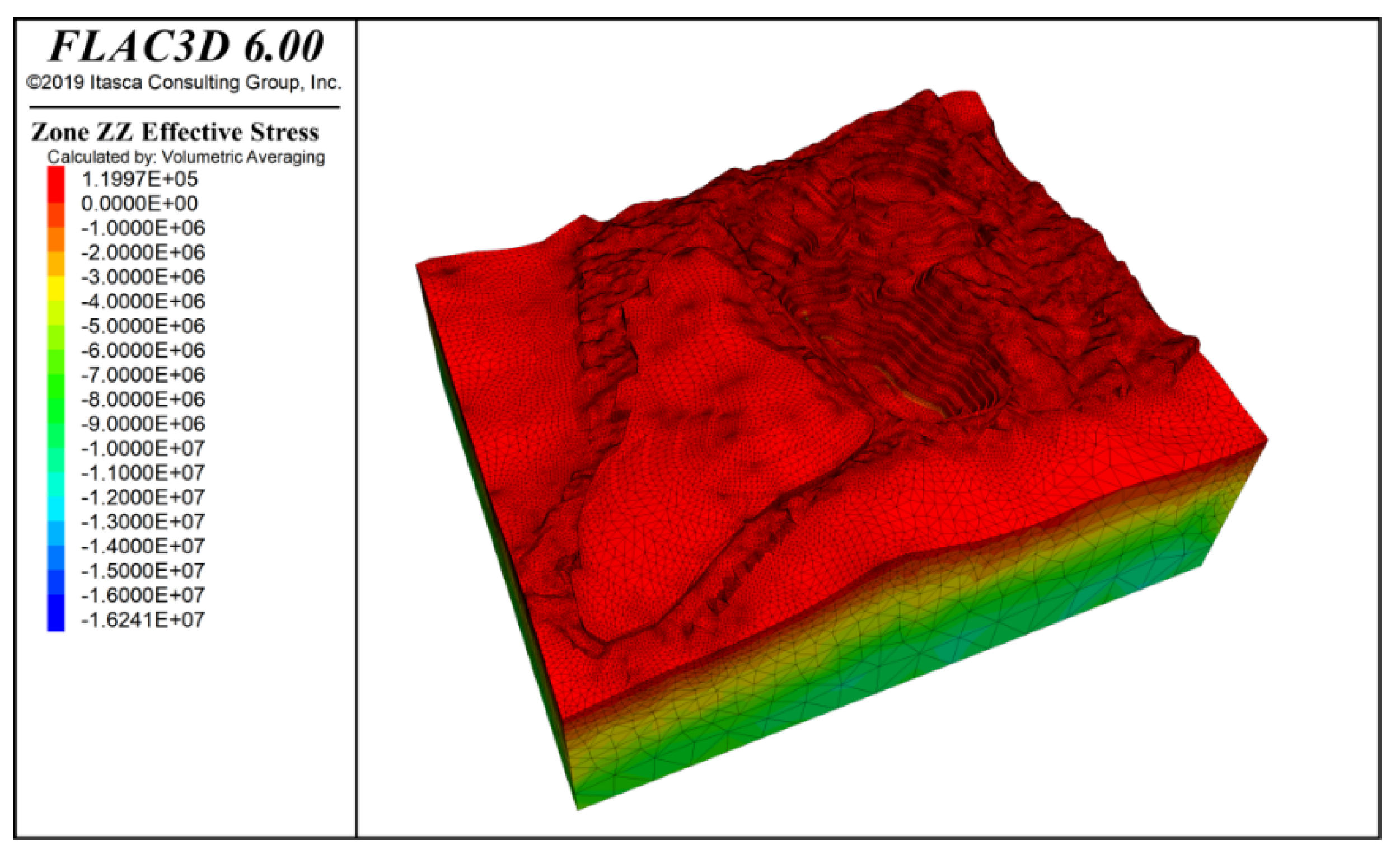

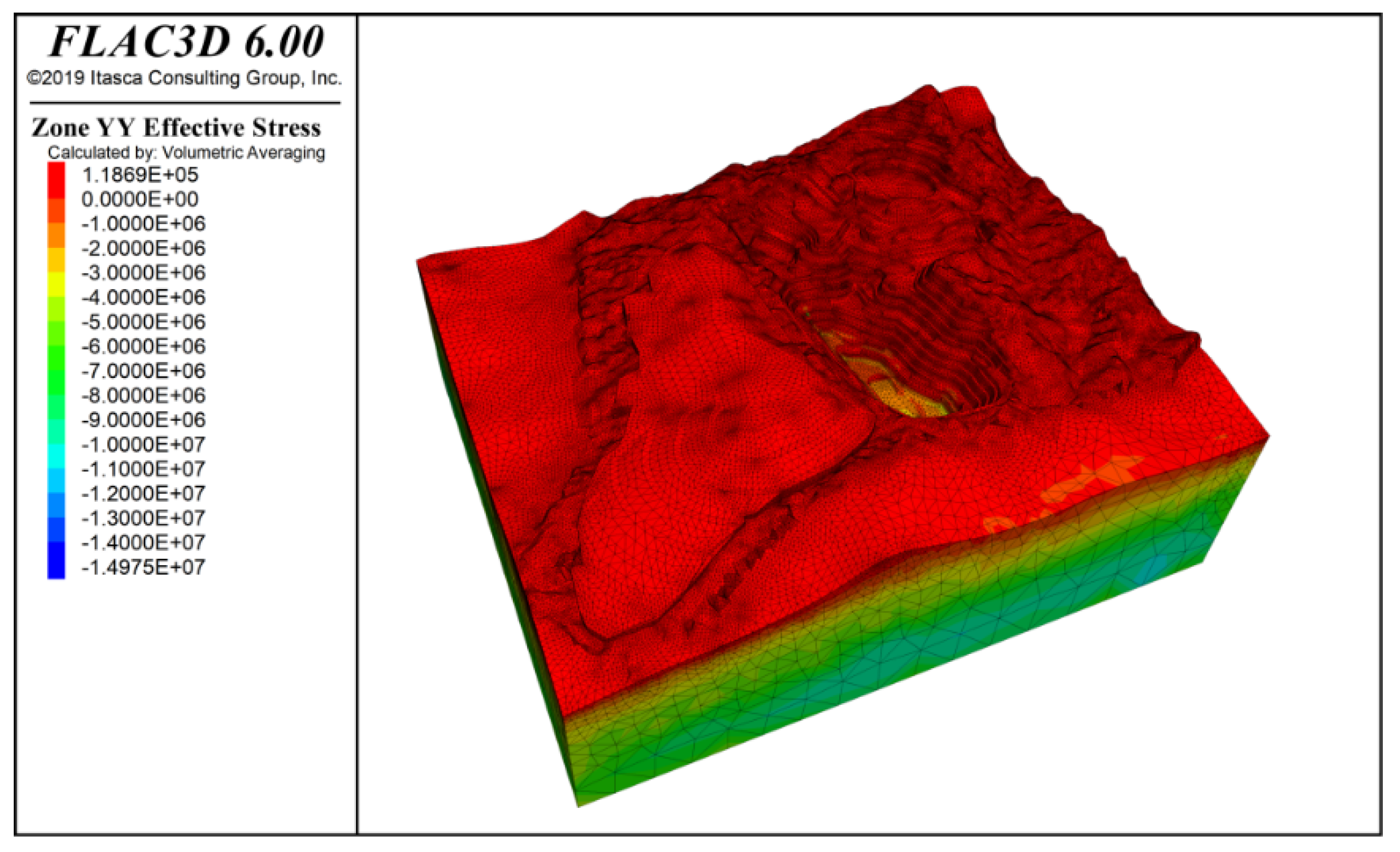

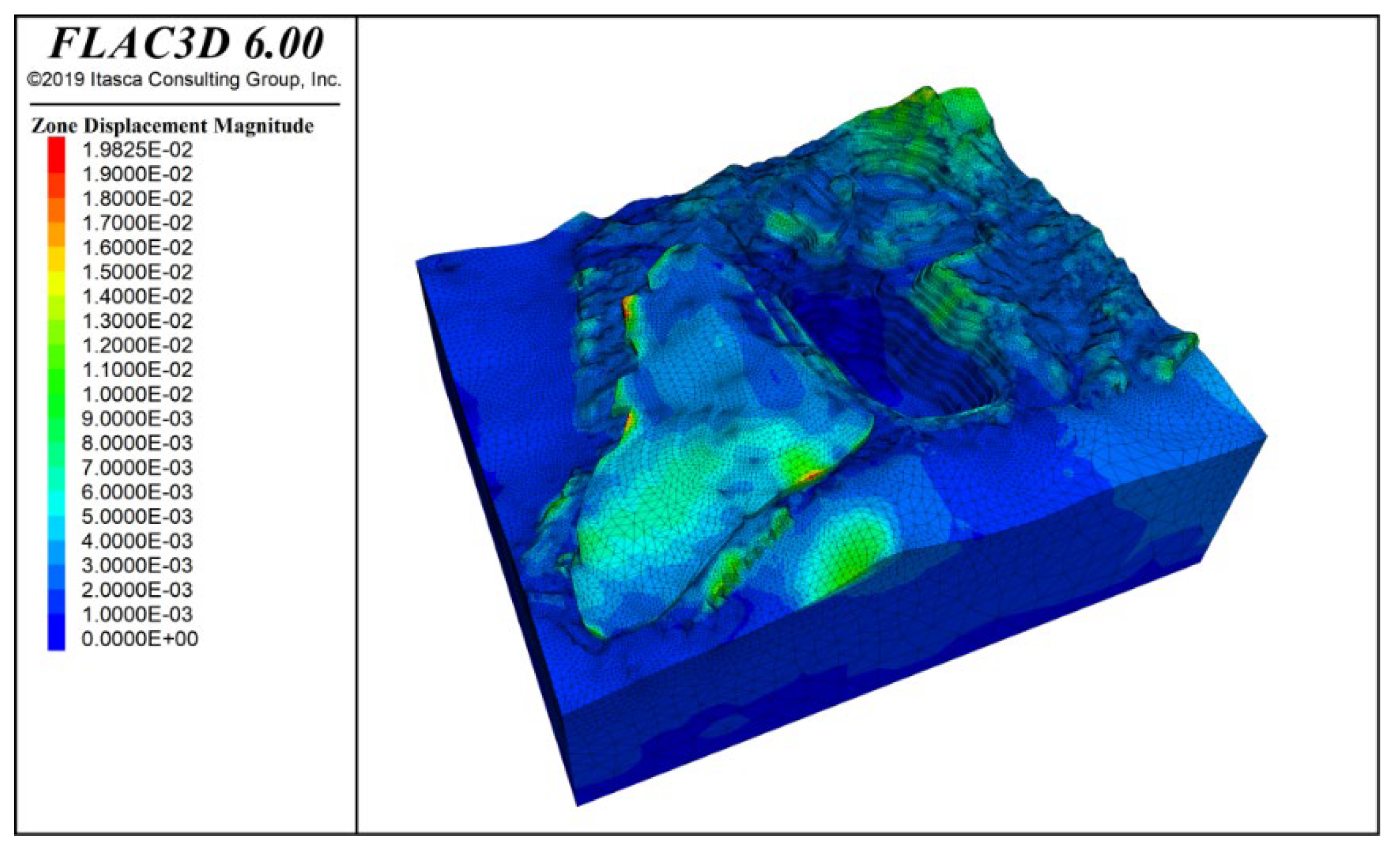

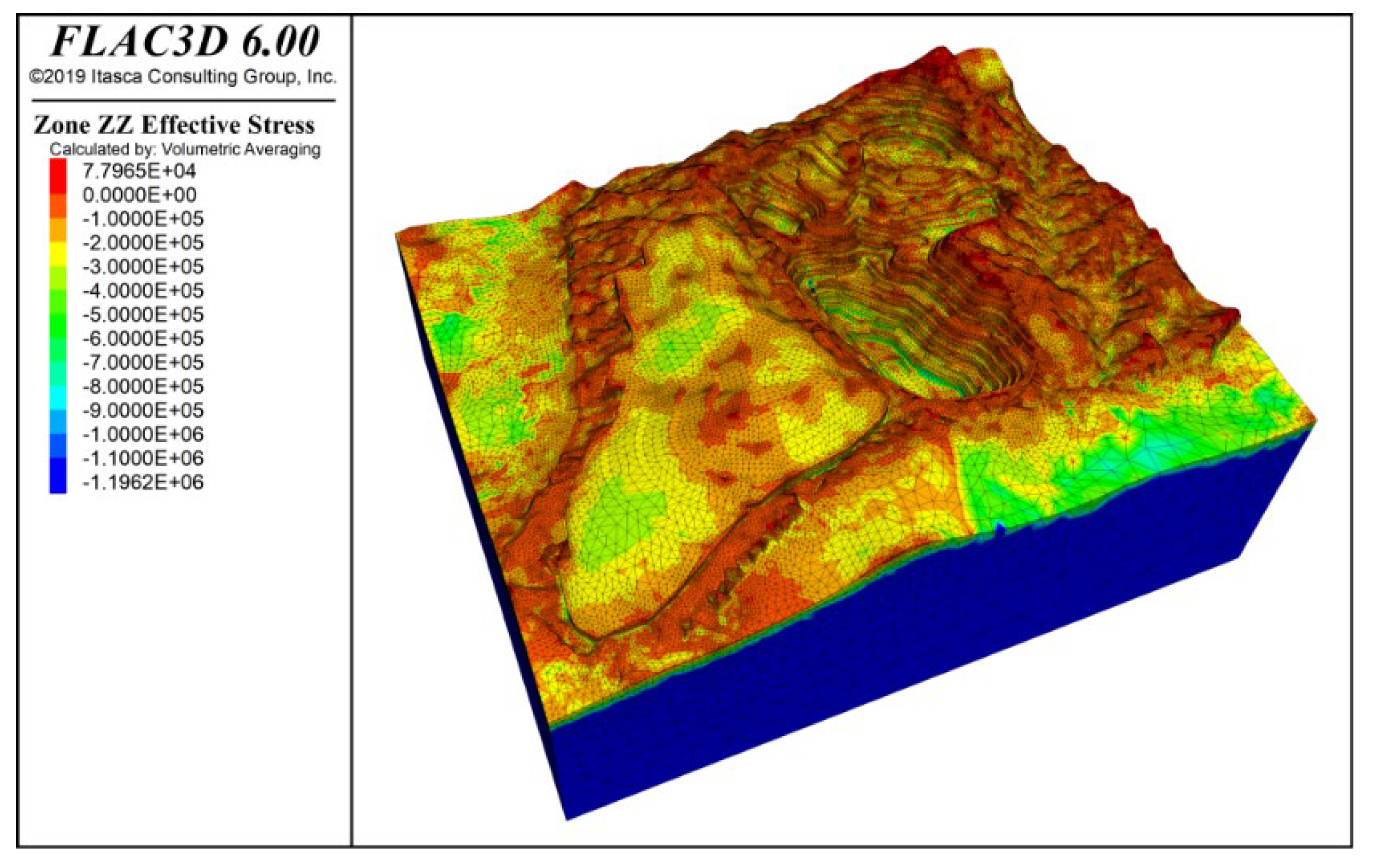

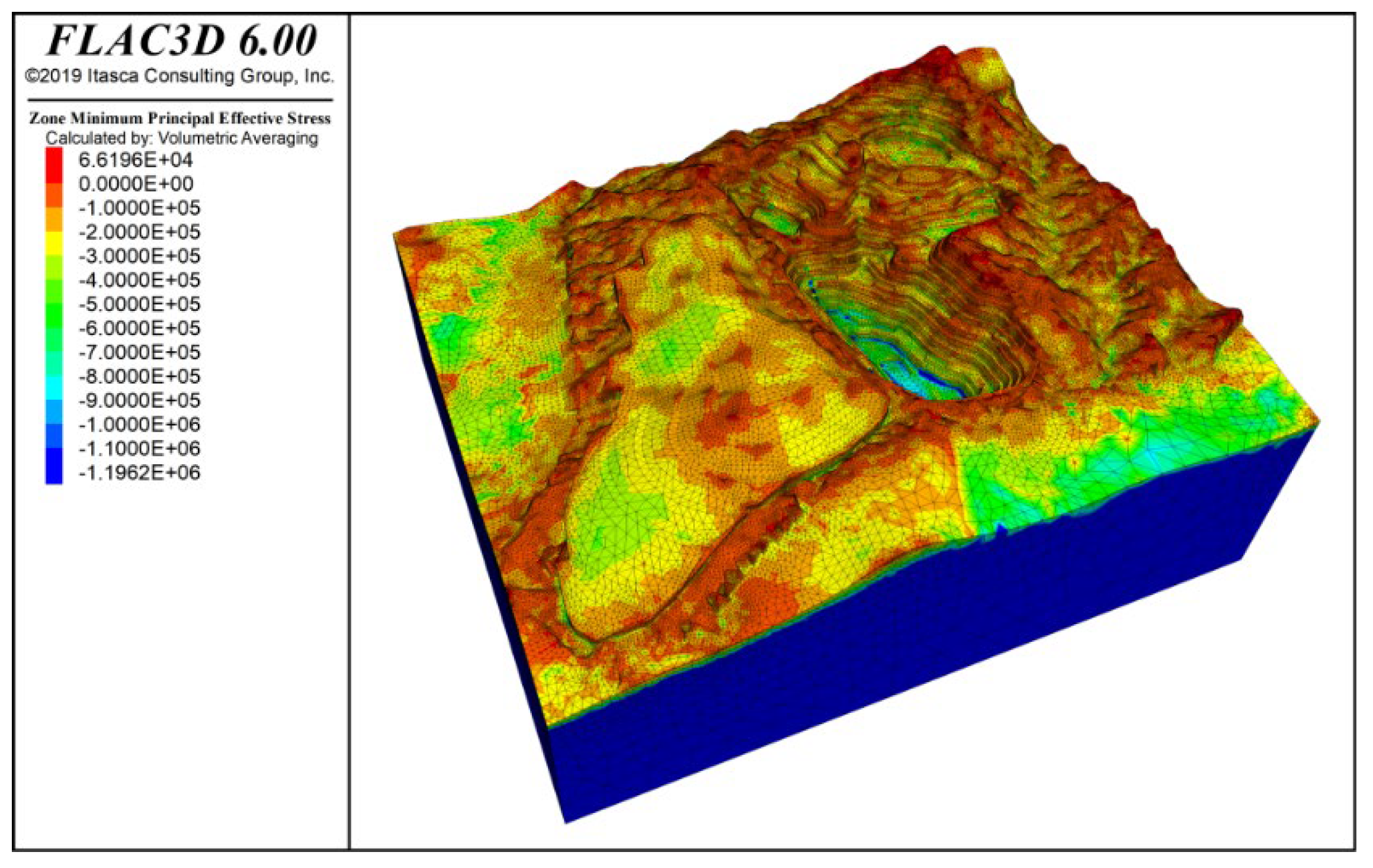

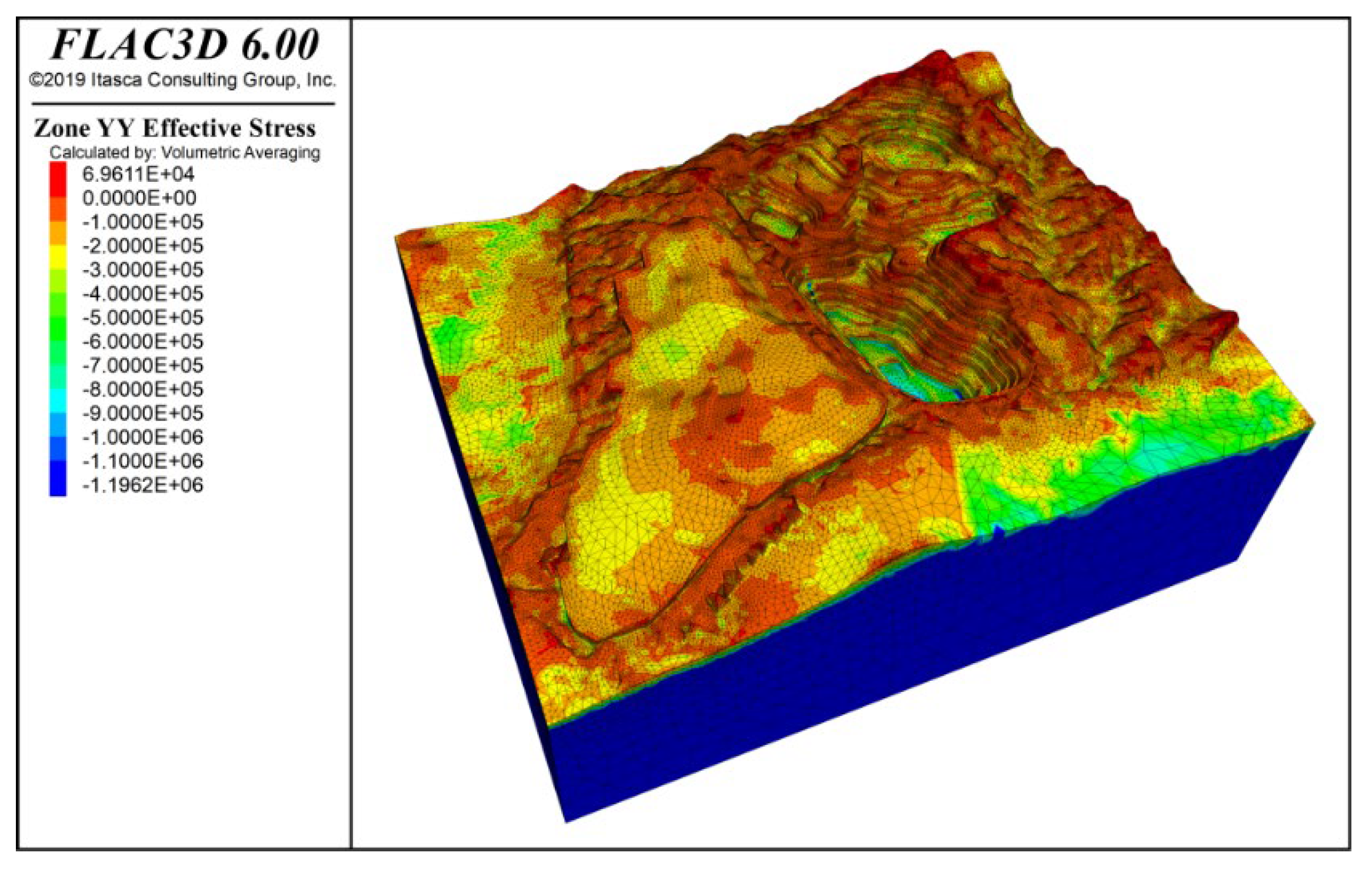

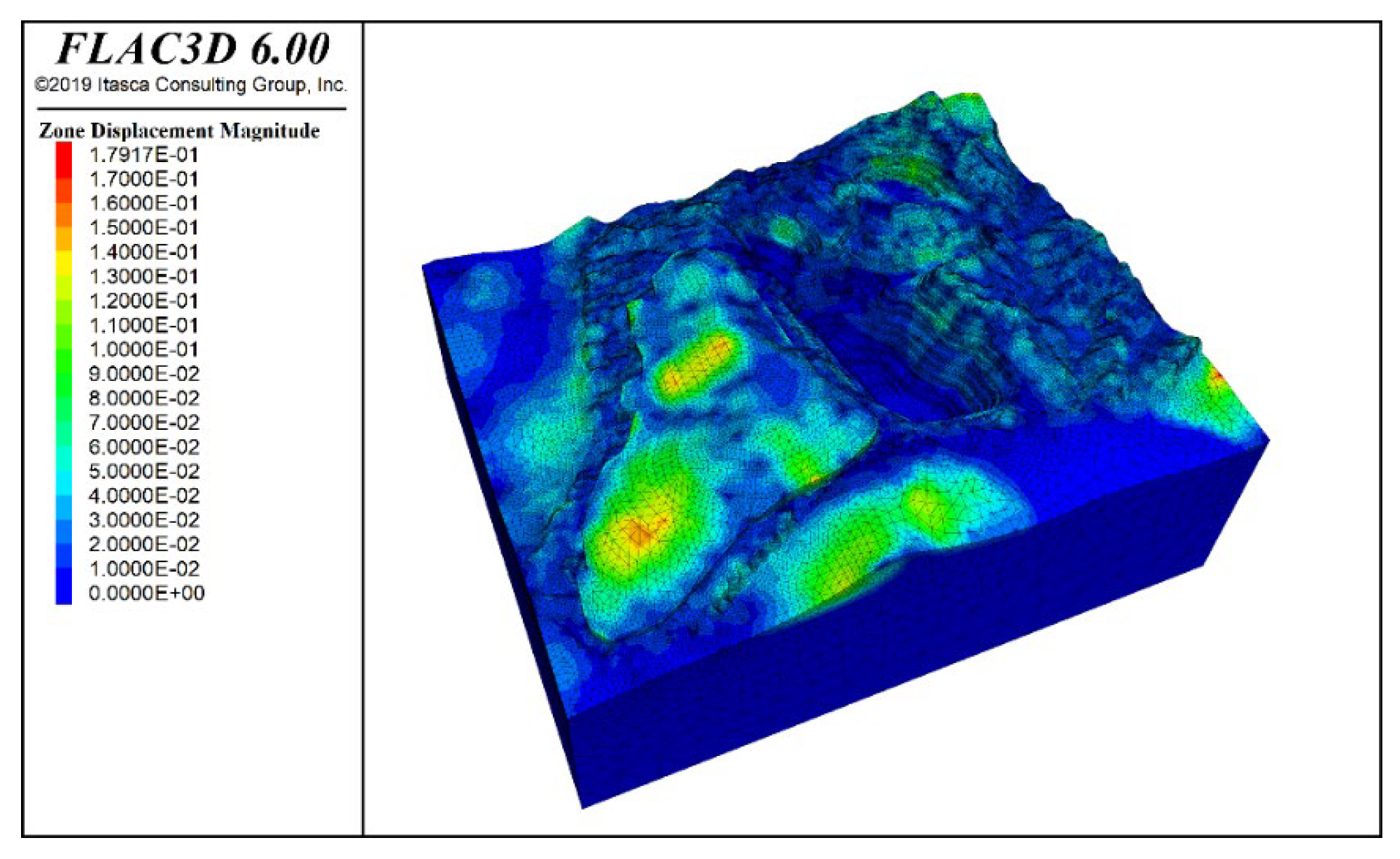

3.4. Results and Analysis

3.4.1. Analysis of Slope Deformation and Failure Characteristics

3.4.2. Slope Rainfall Seepage Simulation

3.4.3. Slope Structure Parameter Optimization

4. Conclusions

- (1)

- The stratigraphic distribution in the Xikeng Lithium Mine area is relatively simple. The artificial fill primarily consists of strongly weathered granite fragments, gravelly and sandy granite, with minor amounts of sandy soil-like granite. The colluvium is mainly composed of sandy clay with rock debris, occasionally containing gravel, coarse sandy clay, or interbedded spheroidal weathered bodies. Structural development in the area is not significant, with two principal fault sets that have not caused any notable damage to the ore body. The F01 fault has a strike of 137° and a dip of 75° and is mainly characterized by silicification and fragmentation. The fault zone is narrow with significant variability; it contains abundant fracture fillings, exhibits small openings, and has poor permeability and water-bearing capacity. The F02 fault, with a strike of 113° and a dip of 60°, comprises a series of parallel and densely spaced compressive shear fractures. This fault zone displays relatively good permeability but similarly poor water-bearing capacity.

- (2)

- The open-pit slope is divided into eight zones, with the predominant failure modes being circular and compound failures. Based on the degree of weathering, the rocks are classified into four types: slightly weathered, moderately weathered, heavily weathered, and fully weathered. With increasing weathering, parameters such as rock density and strength gradually decline.

- (3)

- Slope stability analyses were performed under the combined effects of self-weight, seismic forces, and rainfall. The results indicate that under all load scenarios, the most critical zones for slope stability are near the slope crests in Zones F and I. These areas require local optimization or the addition of structural support. Following the accumulation of the No. 1 waste dump on the western side of the site, the displacement in the K zone slope increases significantly, highlighting the need for enhanced safety monitoring in this area.

- (4)

- Under a daily rainfall of 300 mm, the mechanical response analysis after 24 h of rainfall shows that infiltration has a limited impact on the open-pit slopes under heavy rain conditions. For a specific profile in Zone F, the overall slope angle of rock layers and the local slope angle of soil layers were optimized. The recommended slope angles are 42° for rock masses and 27° for soil layers. Other profiles may be optimized based on site-specific conditions during the mining process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salunkhe, D.P.; Bartakke, R.N.; Chvan, G.; Kothavale, P.R.; Digvijay, P. An overview on methods for slope stability analysis. Int. J. Eng. Res. Technol. 2017, 6, 528–535. [Google Scholar]

- Christian, J.T.; Ladd, C.C.; Baecher, G.B. Reliability applied to slope stability analysis. J. Geotech. Eng. 1994, 120, 2180–2207. [Google Scholar] [CrossRef]

- Azarafza, M.; Akgün, H.; Ghazifard, A.; Asghari-Kaljahi, E.; Rahnamarad, J.; Derakhshani, R. Discontinuous rock slope stability analysis by limit equilibrium approaches—A review. Int. J. Digit. Earth 2021, 14, 1918–1941. [Google Scholar] [CrossRef]

- Kardani, N.; Zhou, A.; Nazem, M.; Shen, S.L. Improved prediction of slope stability using a hybrid stacking ensemble method based on finite element analysis and field data. J. Rock Mech. Geotech. Eng. 2021, 13, 188–201. [Google Scholar] [CrossRef]

- Shiau, J.; Keawsawasvong, S. Multivariate adaptive regression splines analysis for 3D slope stability in anisotropic and heterogenous clay. J. Rock Mech. Geotech. Eng. 2023, 15, 1052–1064. [Google Scholar] [CrossRef]

- Meng, J.; Mattsson, H.; Laue, J. Three-dimensional slope stability predictions using artificial neural networks. Int. J. Numer. Anal. Methods Geomech. 2021, 45, 1988–2000. [Google Scholar] [CrossRef]

- Jiang, S.H.; Zhu, G.Y.; Wang, Z.Z.; Huang, Z.T.; Huang, J. Data augmentation for CNN-based probabilistic slope stability analysis in spatially variable soils. Comput. Geotech. 2023, 160, 105501. [Google Scholar] [CrossRef]

- Zhang, W.G.; Meng, F.S.; Chen, F.Y.; Liu, H.L. Effects of spatial variability of weak layer and seismic randomness on rock slope stability and reliability analysis. Soil Dyn. Earthq. Eng. 2021, 146, 106735. [Google Scholar] [CrossRef]

- Yang, Y.; Xia, Y.; Zheng, H.; Liu, Z. Investigation of rock slope stability using a 3D nonlinear strength-reduction numerical manifold method. Eng. Geol. 2021, 292, 106285. [Google Scholar] [CrossRef]

- Azarafza, M.; Hajialilue Bonab, M.; Derakhshani, R. A novel empirical classification method for weak rock slope stability analysis. Sci. Rep. 2022, 12, 14744. [Google Scholar] [CrossRef]

- Spiekermann, R.I.; McColl, S.; Fuller, I.; Dymond, J.; Burkitt, L.; Smith, H.G. Quantifying the influence of individual trees on slope stability at landscape scale. J. Environ. Manag. 2021, 286, 112194. [Google Scholar] [CrossRef] [PubMed]

- Ramhmachhuani, R.; Mozumder, R.A. Impact of building topologies on hill slope stability in Aizawl city. Results Eng. 2024, 23, 102744. [Google Scholar]

- Liu, L.L.; Wang, Y. Quantification of stratigraphic boundary uncertainty from limited boreholes and its effect on slope stability analysis. Eng. Geol. 2022, 306, 106770. [Google Scholar] [CrossRef]

- Unigwe, C.O.; Igwe, O.; Onwuka, O.S.; Egbueri, J.C.; Omeka, M.E. Roles of hydro-geotechnical and slope stability characteristics in the erosion of Ajali and Nanka geologic formations in southeastern Nigeria. Arabian J. Geosci. 2022, 15, 1492. [Google Scholar] [CrossRef]

- Demir, S.; Sahin, E.K. Application of state-of-the-art machine learning algorithms for slope stability prediction by handling outliers of the dataset. Earth Sci. Inform. 2023, 16, 2497–2509. [Google Scholar] [CrossRef]

- Huang, R.Q.; Zhang, Z.Y.; Wang, S.T. Study on the current status and development prospects of high slope stability. Adv. Earth Sci. 1991, 6, 12–20. [Google Scholar]

- Shi, B.T.; Zhang, Y.; Zhang, W. Strength reduction method for slope stability analysis. J. Geotech. Eng. 2016, 38, 1678–1684. [Google Scholar]

- Wang, Y.; Li, Z.Y.; Shi, H.P.; Wang, P.Q. Progress in slope stability analysis methods. Sichuan Cement 2021, 43, 89–94. [Google Scholar]

- Qi, X.J.; Gao, X.X.; Ji, C.; Yu, J. Discussion on slope stability and landslide treatment in geological hazard projects. Value Eng. 2024, 43, 61–63. [Google Scholar]

- Wang, W. A brief discussion on the research progress of loess slope stability and prevention technology. Sci. Tech. Inf. Dev. Econ. 2009, 19, 102–105. [Google Scholar]

- Wang, L. BIM 3D Geological Modeling Technology in Slope Stability Analysis. Bachelor’s Dissertation, Chang’an University, Xi’An, China, 2020. [Google Scholar]

- Xia, Y.Y. Research status and prospects of slope stability analysis methods. Rock Soil Mech. 2007, 28, 621–628. [Google Scholar]

- Ji, J.; Wang, C.W.; Cui, H.Z.; Li, X.Y.; Song, J.; Gao, Y. A simplified nonlinear coupled Newmark displacement model with degrading yield acceleration for seismic slope stability analysis. Int. J. Numer. Anal. Methods Geomech. 2021, 45, 1303–1322. [Google Scholar] [CrossRef]

- Rusydy, I.; Fathani, T.F.; Al-Huda, N.; Sugiarto; Iqbal, K.; Jamaluddin, K.; Meilianda, E. Integrated approach in studying rock and soil slope stability in a tropical and active tectonic country. Environ. Earth Sci. 2021, 80, 58. [Google Scholar] [CrossRef]

- Wang, W.; Wang, P.; Zhang, Z. Study on gravel soil strength degradation and its influence on slope stability in reservoir bank fluctuating zone. Eng. Fail. Anal. 2022, 134, 105980. [Google Scholar] [CrossRef]

- Mafi, R.; Javankhoshdel, S.; Cami, B.; Jamshidi Chenari, R.; Gandomi, A.H. Surface altering optimisation in slope stability analysis with non-circular failure for random limit equilibrium method. Georisk 2021, 15, 260–286. [Google Scholar] [CrossRef]

- Thomas, J.; Gupta, M.; Srivastava, P.K.; Petropoulos, G.P. Assessment of a dynamic physically based slope stability model to evaluate timing and distribution of rainfall-induced shallow landslides. ISPRS Int. J. Geo-Inf. 2023, 12, 105. [Google Scholar] [CrossRef]

- Chen, M.L.; Zhou, J.W.; Yang, X.G. A novel approach for slope stability evaluation considering landslide dynamics and its application to reservoir landslide. Nat. Hazards 2024, 120, 3589–3621. [Google Scholar] [CrossRef]

- Xiong, Z.T. Optimization study of slope stability prediction model based on machine learning. Kunming Univ. Sci. Technol. 2023, 9, 93. [Google Scholar] [CrossRef]

- Shi, Y.X.; Zhang, Q.; Meng, X.W. Application of distributed optical fiber sensing technology in landslide monitoring. J. Jilin Univ. 2008, 38, 820–824. [Google Scholar] [CrossRef]

- Yan, H.Q.; Song, C.J.; Zhou, Y.F. Application of prestressed anchor cable technology in slope reinforcement. Highway 2003, 8 (Suppl. S1), 46–50. [Google Scholar]

- Griffiths, D.V.; Lane, P.A. Slope stability analysis by finite elements. Geotechnique 1999, 49, 387–403. [Google Scholar] [CrossRef]

- Mikkelsen, P.E. Advances in inclinometer data analysis. In Proceedings of the 6th International Symposium on Field Measurements in Geomechanics, Oslo, Norway, 23–26 September 2003; pp. 555–567. [Google Scholar]

- Jones, C.J.F.P.; Clarke, D. The stabilization of slopes using soil nailing. Geotech. Eng. 2007, 160, 167–177. [Google Scholar]

- Lu, N.; Şener-Kaya, B.; Wayllace, A.; Godt, J.W. Analysis of rainfall-induced slope instability using a field of local factor of safety. Water Resour. Res. 2012, 48, 9524. [Google Scholar] [CrossRef]

- Wang, X.; Wang, K.; Hu, K. Analysis of Slope Stability Induced by Changes in Water Content Using Local Stability Field Coefficient Method. Water Resour. Hydropower Eng. 2016, 47, 110–113+121. [Google Scholar]

- Zhu, Y.; Ishikawa, T.; Subramanian, S.S.; Luo, B. Simultaneous Analysis of Slope Instabilities on a Small Catchment-Scale Using Coupled Surface and Subsurface Flows. Eng. Geol. 2020, 275, 105750. [Google Scholar] [CrossRef]

- Ma, S. Study on the Stability of Infinite Slopes Under Heavy Rainfall Using the Green-Ampt Infiltration Model. Master’s Thesis, Zhejiang University, Hangzhou, China, 2014. [Google Scholar]

- Li, M.; Cai, G.; Li, H.; Yang, B.; Zhao, C. Stability Analysis of Unsaturated Soil Infinite Slopes Considering Tensile Strength and Shear Failure. J. Geotech. Eng. 2020, 42, 705–713. [Google Scholar]

- Michalowski, R.L. Failure Potential of Infinite Slopes in Soils with Tensile Strength Cutoff. Can. Geotech. J. 2017, 55, 477–485. [Google Scholar] [CrossRef]

- Ma, C.; Liu, Z. Horizontal Displacement and Stability Analysis of Infinite Slopes under Rainfall Infiltration. Rock Soil Mech. 2007, 28 (Suppl. S1), 563–568. [Google Scholar]

- Zhang, M.M.; Liang, L.X.; Liu, X.J. Analysis of the Influence of Different Rock Shear Failure Criteria on Wellbore Collapse Pressure. Chin. J. Rock Mech. Eng. 2017, 36 (Suppl. S1), 3485–3491. [Google Scholar]

- Zhang, M.; Fan, X.; Zhang, Q.; Yang, B.; Zhao, P.; Yao, B.; He, L. Influence of Multi-Planes of Weakness on Unstable Zones Near Wellbore Wall in a Fractured Formation. J. Nat. Gas Sci. Eng. 2021, 93, 104026. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, X.; Zhang, Q.; Yang, B.; Zhao, P.; Yao, B.; Ran, J. Parametric Sensitivity Study of Wellbore Stability in Transversely Isotropic Medium Based on Poly-Axial Strength Criteria. J. Pet. Sci. Eng. 2021, 197, 108078. [Google Scholar] [CrossRef]

- Zhang, M.; Li, D.; Liu, J.; Zhang, D.; Zhang, Y.; Cui, K. Modification of the Mohr-Coulomb Criterion Based on Shape Function and Determination of Undetermined Parameters. Mech. Mater. 2023, 185, 104772. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, C.; Tang, H.; Wen, T.; Tannant, D.D.; Zhang, B. Input-Parameter Optimization Using an SVR-Based Ensemble Model to Predict Landslide Displacements in a Reservoir Area: A Comparative Study. Appl. Soft Comput. 2024, 150, 111107. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, H.; Tan, Q.; Mao, M.; Zhou, B.; Zhang, Y. A Generalized Early Warning Criterion for Landslide Risk Assessment: Deformation Probability Index (DPI). Acta Geotech. 2024, 19, 2607–2627. [Google Scholar] [CrossRef]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Chen, G.; Zhang, Y. A novel method for automatic quantification of different pore types in shale based on SEM-EDS calibration. Mar. Pet. Geol. 2025, 173, 107278. [Google Scholar] [CrossRef]

- Wu, W.; Wang, T.; Bai, J.; Liu, J.; Wang, X.; Xu, H.; Feng, G. Failure Characteristics and Cooperative Control Strategies for Gob-Side Entry Driving Near an Advancing Working Face: A Case Study. Processes 2024, 12, 1398. [Google Scholar] [CrossRef]

- Fu, J.; Song, W.; Du, J. Transient Volume Water Content Analysis of Unsaturated Soil Slopes Under Two-Dimensional Rainfall Infiltration. J. Eng. Sci. 2015, 37, 407–413. [Google Scholar]

- Das, T.; Rao, V.D.; Choudhury, D. Numerical Investigation of the Stability of Landslide-Affected Slopes in Kerala, India, under Extreme Rainfall Event. Nat. Hazards 2022, 114, 751–785. [Google Scholar] [CrossRef]

- Wang, J.; Xi, H.; Li, B.; Yang, X. Study and Analysis of Factors Affecting Slope Stability under Rainfall Infiltration Field Distribution. J. Lanzhou Univ. Technol. 2022, 48, 142–147. [Google Scholar]

- Gu, Y.; Yuan, Y.; Li, X. The Influence of Soil Anisotropic Permeability on Slope Stability under Rainfall Conditions. Chin. Saf. Sci. Technol. 2023, 19 (Suppl. S1), 43–49. [Google Scholar]

- Fan, Z.; Song, X.; Wang, D.; Ayasrah, M.; Li, S. Poroelastic Solutions of a Semi-Permeable Borehole Under Non-Hydrostatic in Situ Stresses Within Transversely Isotropic Media. Int. J. Geomech. 2025, 25, 04024342. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of ground fracturing with horizontal fracture plane on rock breakage characteristics and mine pressure control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Gao, R.; Dou, B.; Bin, Y.; Yang, T.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- GB 51016-2014; Technical Code for Non-Coal Open-Pit Mine Slope Engineering. Standards Press of China (SPC): Beijing, China, 2014.

| Geotechnical Layer | Dry Density ρd/(g/cm3) | Wet Density ρ/(g/cm3) | Cohesion c/kPa | Friction Angle φ/° |

|---|---|---|---|---|

| Completely Weathered Granite | 1.51 | 1.75 | 143.00 | 24.00 |

| Rock Classification | Water Absorption ω/% | Wet Density frk/g/cm3 | Natural Compressive Strength frk/MPa | Elastic Modulus Eav/GPa | Cohesion c/MPa | Friction Angle φ/° | Poisson’s Ratio μ |

|---|---|---|---|---|---|---|---|

| Highly Weathered Granite | 2.06 | 2.50 | 23.32 | 7.54 | 8.33 | 47.58 | 0.28 |

| Moderately Weathered Granite | 0.44 | 2.56 | 74.49 | 13.62 | 19.78 | 49.72 | 0.34 |

| Slightly Weathered Granite | 0.29 | 2.59 | 106.12 | 15.51 | 21.60 | 51.60 | 0.32 |

| Profile | Loading Combination | Safety Factor | Specification Value | ||

|---|---|---|---|---|---|

| Bishop Method | M-P Method | Optional Value | |||

| Profile X in Zone F | I | 1.373 | 1.376 | 1.373 | Loading combination I: 1.25; Loading combination II: 1.23 |

| II | 1.306 | 1.308 | 1.306 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Yu, Z.; Wen, J.; Gan, F.; Shu, C. Multiphysics Coupling Effects on Slope Deformation in Jiangte Xikeng Lithium Deposit Open-Pit Mining. Processes 2025, 13, 1686. https://doi.org/10.3390/pr13061686

Yin Y, Yu Z, Wen J, Gan F, Shu C. Multiphysics Coupling Effects on Slope Deformation in Jiangte Xikeng Lithium Deposit Open-Pit Mining. Processes. 2025; 13(6):1686. https://doi.org/10.3390/pr13061686

Chicago/Turabian StyleYin, Yongming, Zhengxing Yu, Jinglin Wen, Fangzhi Gan, and Couxian Shu. 2025. "Multiphysics Coupling Effects on Slope Deformation in Jiangte Xikeng Lithium Deposit Open-Pit Mining" Processes 13, no. 6: 1686. https://doi.org/10.3390/pr13061686

APA StyleYin, Y., Yu, Z., Wen, J., Gan, F., & Shu, C. (2025). Multiphysics Coupling Effects on Slope Deformation in Jiangte Xikeng Lithium Deposit Open-Pit Mining. Processes, 13(6), 1686. https://doi.org/10.3390/pr13061686