Potential, Efficiency, and Leakage Risk of CO2 Sequestration in Coal: A Review

Abstract

1. Introduction

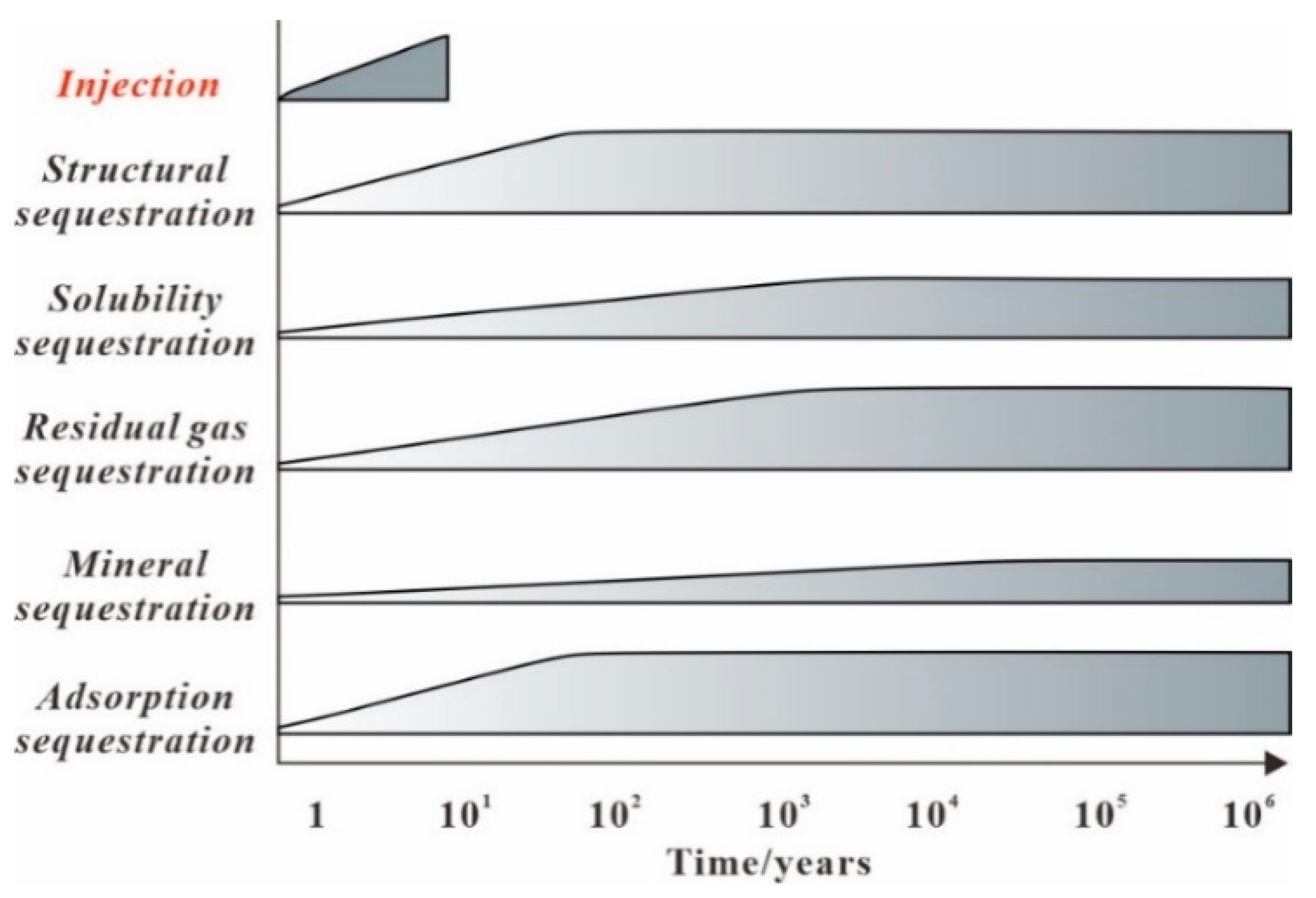

2. Potential of CO2 Sequestration in Coal

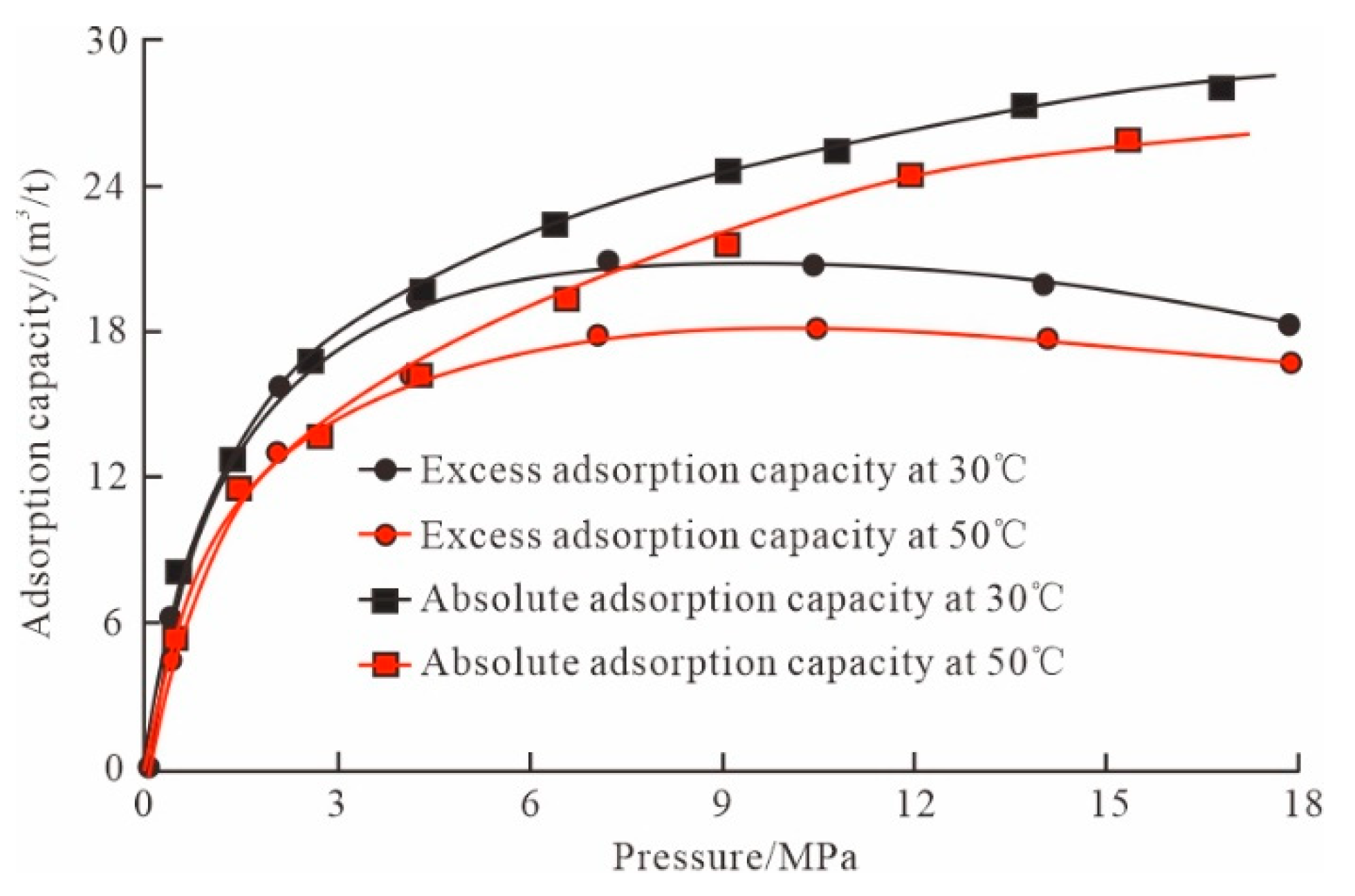

2.1. Mechanisms of CO2 Sequestration in Coal

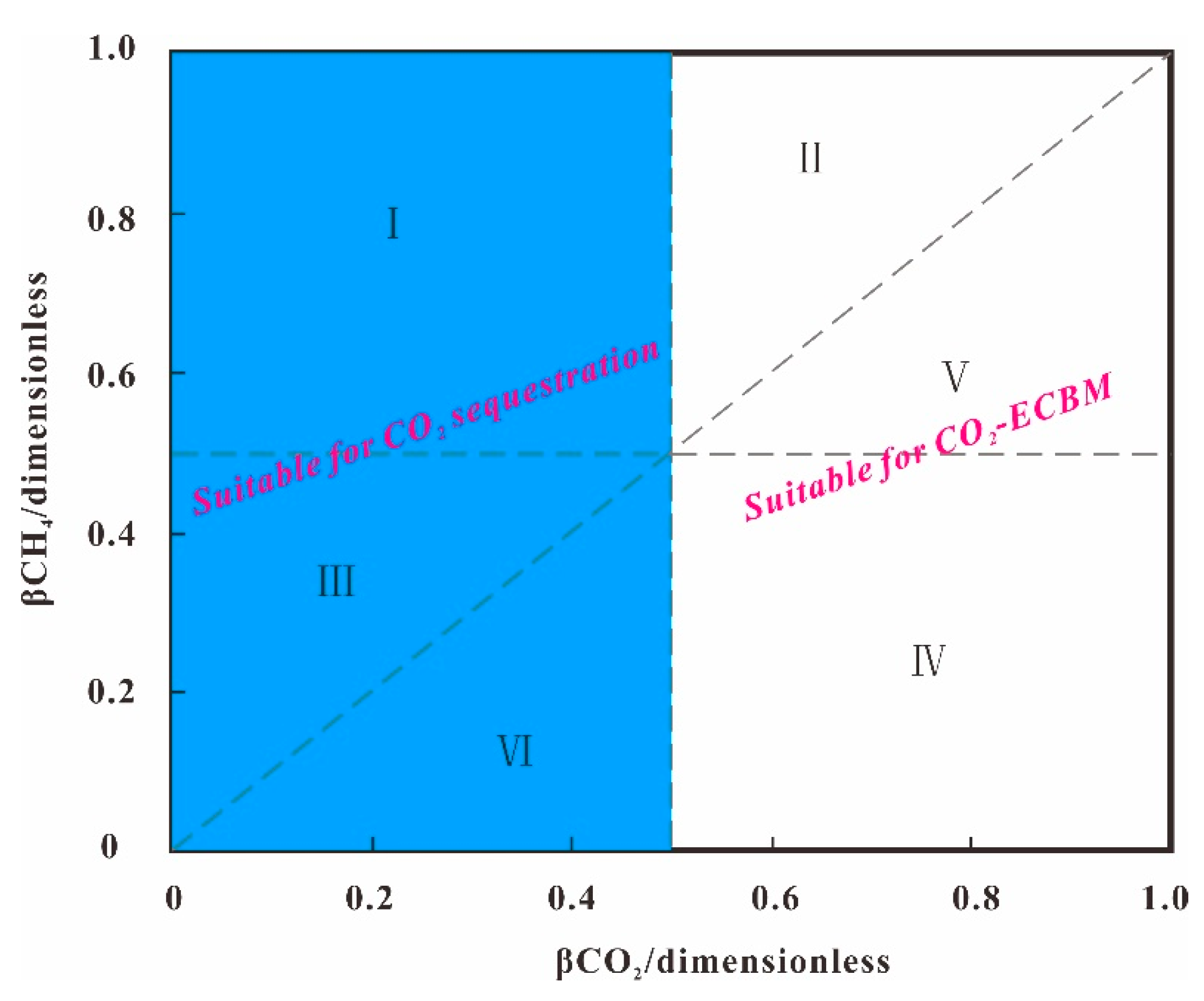

2.2. Differences Between CO2 Sequestration and CO2-ECBM

2.3. Estimation of CO2 Sequestration Capacity in Coal

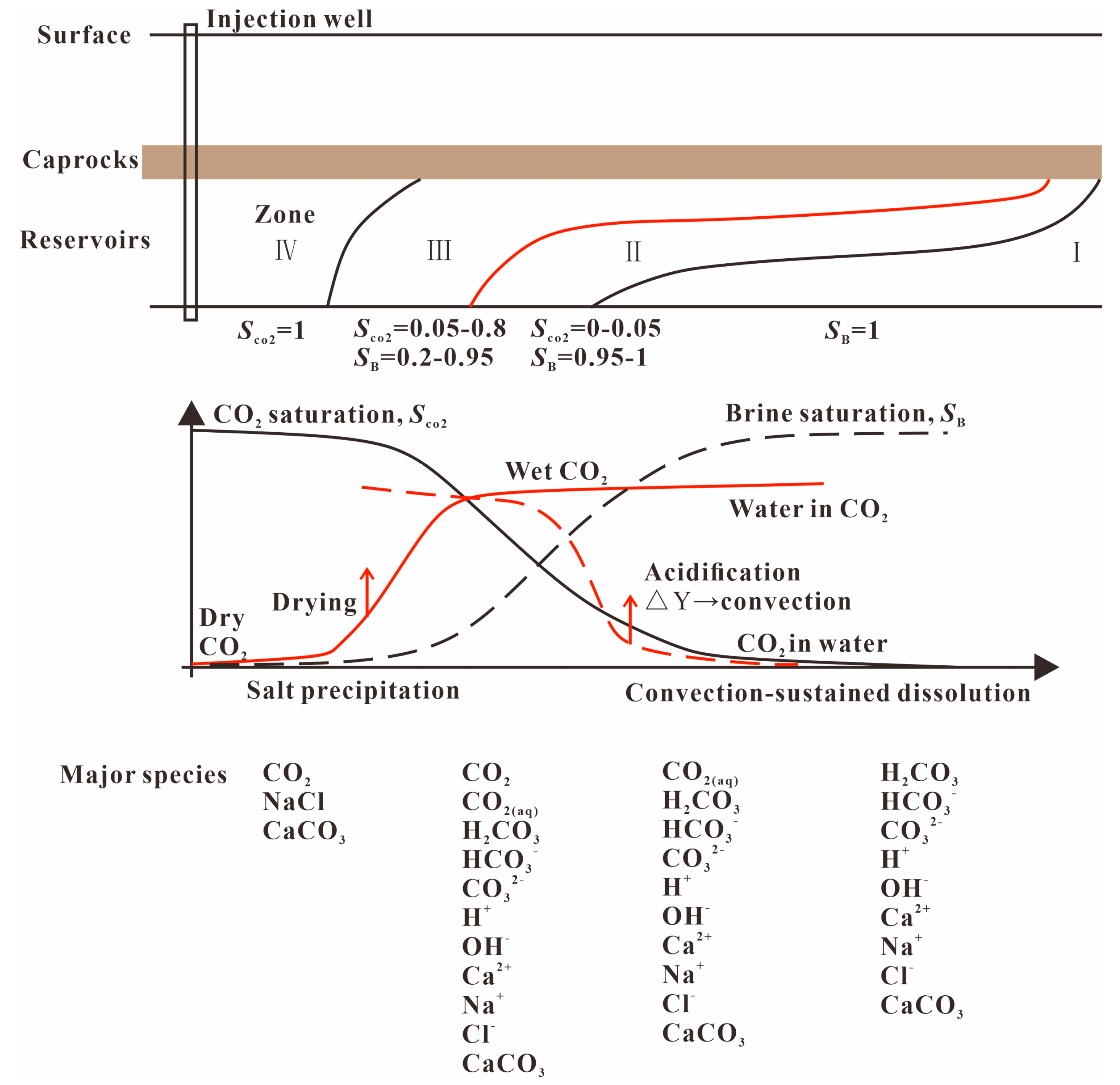

3. Comparisons of CO2 Sequestration in Coal and Saline Aquifers

4. Efficiency of CO2 Sequestration in Coal

4.1. Effects of Matrix Swelling Induced by CO2 Adsorption on Injection

4.2. Effects of CO2 Corrosion on Injection

4.3. Approaches to Enhance CO2 Injection Efficiency

4.3.1. Inhibiting the Reduction in Permeability

4.3.2. Inhibiting Corrosion

5. Leakage Risk of CO2 Sequestration in Coal

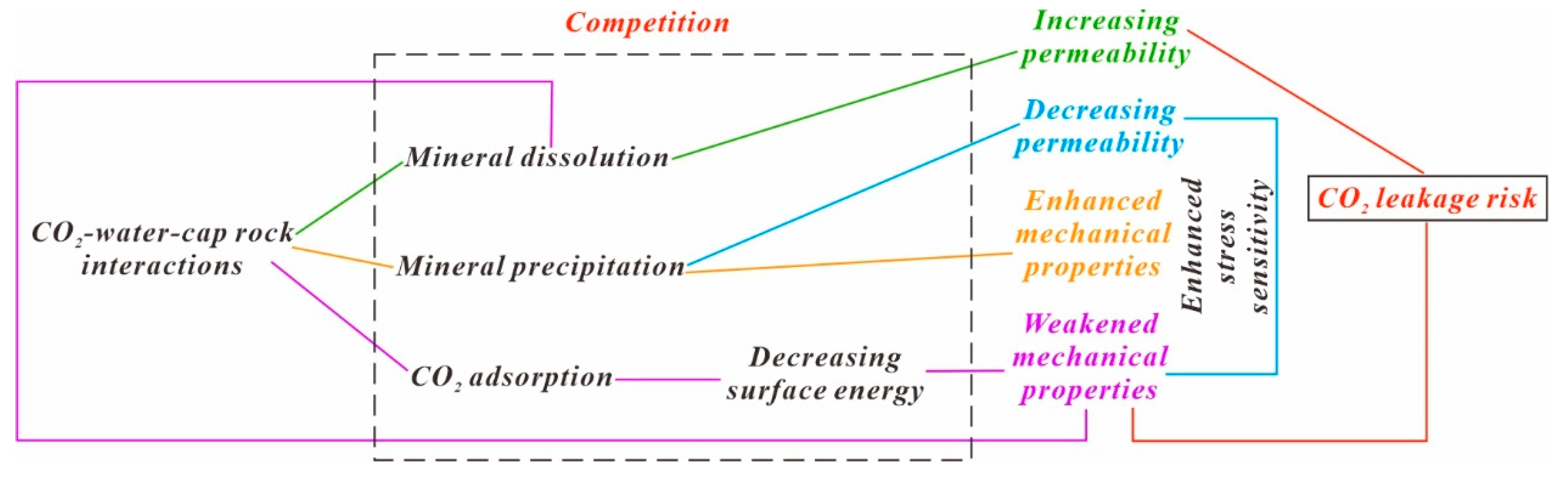

5.1. Changes in Integrity of Caprock Induced by CO2–Water Interactions

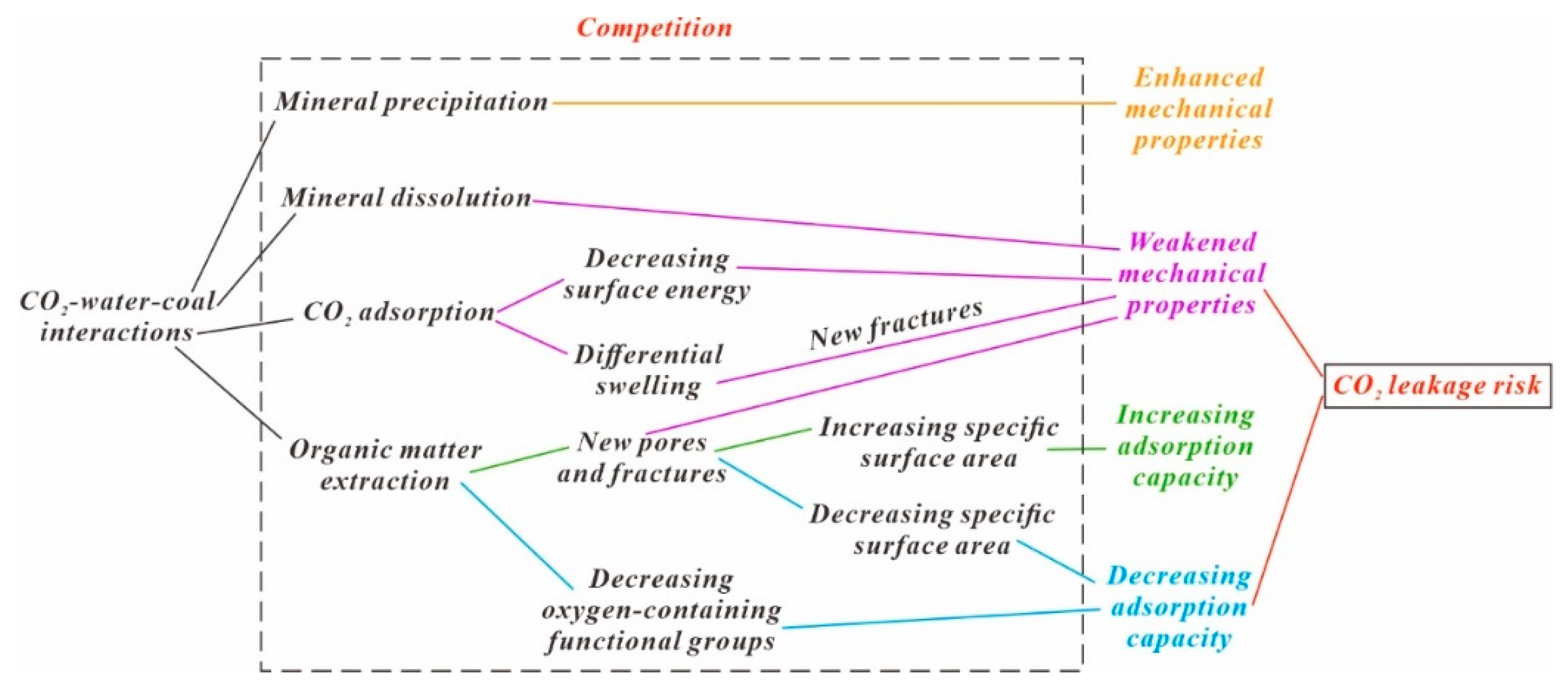

5.2. Changes in Coal Properties Induced by CO2–Water Interactions

6. Prospects for Future Studies

- (1)

- Increasing the CO2 adsorption capacity of coal

- (2)

- Establishing optimal approaches for enhancing CO2 injection efficiency

- (3)

- Predicting the long-term variations in coal/caprock properties induced by CO2–water interactions

7. Conclusions

- (1)

- Compared with saline aquifers, the superiority of CO2 sequestration in coal is rapid sequestration induced by adsorption and extra energy benefits.

- (2)

- The significant reduction in permeability induced by matrix swelling and corrosion inhibits the CO2 injection efficiency, and utilizing coatings, corrosion inhibitors, pre-fracturing, horizontal well injection, CO2 + N2 injection, delayed/cycled injection, and optimizing injection pressure are effective methods to increase the capacity of CO2 injection.

- (3)

- During long-term CO2–water–rock interaction, the decreasing adsorption capacity due to organic matter extraction and variations in caprock/reservoir integrity leads to the CO2 leakage risk.

- (4)

- Increasing the CO2 adsorption capacity of coal, establishing optimal approaches for enhancing the CO2 injection efficiency, and predicting the long-term variations in coal/caprock properties are critical issues to be addressed, which can be facilitated by material surface engineering and AI-based predictive modeling.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Global warming of 1.5 °C. In Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2018; Volume 450. [Google Scholar]

- Sohail, A.; Du, J.; Abbasi, B.N.; Ahmed, Z. The nonlinearity and nonlinear convergence of CO2 emissions: Evidence from top 20 highest emitting countries. Environ. Sci. Pollut. Res. 2022, 29, 59466–59482. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, Y.; Cai, H.; Wang, B. Comparative analysis of regional carbon emissions accounting methods in China: Production-based versus consumption-based principles. J. Clean. Prod. 2018, 194, 12–22. [Google Scholar] [CrossRef]

- He, X.; Adebayo, T.S.; Kirikkaleli, D.; Umar, M. Consumption-based carbon emissions in Mexico: An analysis using the dual adjustment approach. Sustain. Prod. Consum. 2021, 27, 947–957. [Google Scholar] [CrossRef]

- Filonchyk, M.; Peterson, M.; Zhang, L.; Hurynovich, V.; He, Y. Greenhouse gases emissions and global climate change: Examining the influence of CO2, CH4, and N2O. Sci. Total Environ. 2024, 935, 173359. [Google Scholar] [CrossRef]

- Luo, A.; Li, Y.; Chen, X.; Zhu, Z.; Peng, Y. Review of CO2 sequestration mechanism in saline aquifers. Nat. Gas Ind. B 2022, 9, 383–393. [Google Scholar] [CrossRef]

- Arts, R.J.; Vandeweijer, V.P.; Hofstee, C.; Pluymaekers, M.P.D.; Loeve, D.; KoPP, A.; Plug, W.J. The feasibility of CO2 storage in the depleted P18-4 gas field offshore the Netherlands (the ROAD project). Int. J. Greenh. Gas Control 2012, 11, S10–S20. [Google Scholar] [CrossRef]

- Luo, D.; Dai, Y. Economic evaluation of coalbed methane production in China. Energy Policy 2009, 37, 3883–3889. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Zheng, T.; Liang, Y.; Wang, B.; Sun, H.; Zheng, J.; Li, D.; Chen, Y.; Shao, L.; Zhang, H. A two-stage improved genetic algorithm-particle swarm optimization algorithm for optimizing the pressurization scheme of coal bed methane gathering networks. J. Clean. Prod. 2019, 229, 941–955. [Google Scholar] [CrossRef]

- Li, Z.; Yu, H.; Bai, Y.; Wang, Y.; Hu, H.; Gao, Y.; Yan, F. Analysis of reservoir permeability evolution and influencing factors during CO2-Enhanced coalbed methane recovery. Energy 2024, 304, 132045. [Google Scholar] [CrossRef]

- Gunter, W.D.; Gentzis, T.; Rottenfusser, B.A.; Richardson, R.J.H. Deep coalbed methane in Alberta, Canada: A fuel resource with the potential of zero greenhouse gas emissions. Energy Convers. Manag. 1997, 38, S217–S222. [Google Scholar] [CrossRef]

- White, C.M.; Smith, D.H.; Jones, K.L.; Goodman, A.L.; Jikich, S.A.; LaCount, R.B.; DuBose, S.B.; Ozdemir, E.; Morsi, B.I.; Schroeder, K.T. Sequestration of carbon dioxide in coal with enhanced coalbed methane recovery a review. Energy Fuels 2005, 19, 659–724. [Google Scholar] [CrossRef]

- Gasparik, M.; Rexer, T.F.; Aplin, A.C.; Billemont, P.; De Weireld, G.; Gensterblum, Y.; Henry, M.; Krooss, B.M.; Liu, S.; Ma, X.; et al. First international inter-laboratory comparison of high-pressure CH4, CO2 and C2H6 sorption isotherms on carbonaceous shales. Int. J. Coal Geol. 2014, 132, 131–146. [Google Scholar] [CrossRef]

- Zhang, M.; Fu, X. Influence of reservoir properties on the adsorption capacity and fractal features of shales from Qinshui coalfield. J. Pet. Sci. Eng. 2019, 177, 650–662. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, X.; Yu, K.; Tian, F.; Deng, Z. Geochemical composition and microstructure of coal measure shale in the upper permian, western Guizhou, China: Implications for methane generation and storage. Energy Fuels 2022, 36, 10143–10154. [Google Scholar] [CrossRef]

- De Silva, P.N.K.; Ranjith, P.G. A study of methodologies for CO2 storage capacity estimation of saline aquifers. Fuel 2012, 93, 13–27. [Google Scholar] [CrossRef]

- Shukla Potdar, R.; Vishal, V. Trapping mechanism of CO2 storage in deep saline aquifers: Brief review. Geol. Carbon Sequestration Underst. Reserv. Behav. 2016, 47–58. [Google Scholar]

- Zhong, Y.; Li, Q.; Gao, W.; Wen, Y.; Zhang, Y. A review of microfluidic technology for CO2 sequestration in saline aquifers. J. Rock Mech. Geotech. Eng. 2025. [Google Scholar] [CrossRef]

- Zhang, B.B.; Song, X.C. Geological storage of CO2 to enhance coalbed methane production. Adv. Mater. Res. 2012, 524, 1173–1177. [Google Scholar] [CrossRef]

- Masoudian, M.S.; Airey, D.W.; El-Zein, A. Mechanical and flow behaviours and their interactions in coalbed geosequestration of CO2. Geomech. Geoengin. 2013, 8, 229–243. [Google Scholar] [CrossRef]

- Ozdemir, E.; Morsi, B.I.; Schroeder, K. CO2 adsorption capacity of argonne premium coals. Fuel 2004, 83, 1085–1094. [Google Scholar] [CrossRef]

- Pashin, J.C. Coal as a petroleum source rock and reservoir rock. In Applied Coal Petrology; Elsevier: Amsterdam, The Netherlands, 2008; Chapter 9; pp. 227–262. [Google Scholar] [CrossRef]

- Luo, C.; Zhang, D.; Lun, Z.; Zhao, C.; Wang, H.; Pan, Z.; Li, Y.; Zhang, J.; Jia, S. Displacement behaviors of adsorbed coalbed methane on coals by injection of SO2/CO2 binary mixture. Fuel 2019, 247, 356–367. [Google Scholar] [CrossRef]

- Mukherjee, M.; Misra, S. A review of experimental research on Enhanced Coal Bed Methane (ECBM) recovery via CO2 sequestration. Earth-Sci. Rev. 2018, 179, 392–410. [Google Scholar] [CrossRef]

- Busch, A.; Krooss, B.M.; Gensterblum, Y.; Van Bergen, F.; Pagnier, H.J.M. High-pressure adsorption of methane, carbon dioxideand their mixtures on coals with a special focus on the preferential sorption behaviour. J. Geochem. Explor. 2003, 78, 671–674. [Google Scholar] [CrossRef]

- Fitzgerald, J.E.; Pan, Z.; Sudibandriyo, M.; Robinson, R.L., Jr.; Gasem, K.A.M.; Reeves, S. Adsorption of methane, nitrogen, carbon dioxide and their mixtures on wet Tiffany coal. Fuel 2005, 84, 2351–2363. [Google Scholar] [CrossRef]

- Harpalani, S.; Prusty, B.K.; Dutta, P. Methane/CO2 sorption modeling for coalbed methane production and CO2 sequestration. Energy Fuels 2006, 20, 1591–1599. [Google Scholar] [CrossRef]

- Li, D.; Liu, Q.; Weniger, P.; Gensterblum, Y.; Busch, A.; Krooss, B.M. High-pressure sorption isotherms and sorption kinetics of CH4 and CO2 on coals. Fuel 2010, 89, 569–580. [Google Scholar] [CrossRef]

- Dutta, P.; Bhowmik, S.; Das, S. Methane and carbon dioxide sorption on a set of coals from India. Int. J. Coal Geol. 2011, 85, 289–299. [Google Scholar] [CrossRef]

- Gensterblum, Y.; Busch, A.; Krooss, B.M. Molecular concept and experimental evidence of competitive adsorption of H2O, CO2 and CH4 on organic material. Fuel 2014, 115, 581–588. [Google Scholar] [CrossRef]

- Siemons, N.; Busch, A. Measurement and interpretation of supercritical CO2 sorption on various coals. Int. J. Coal Geol. 2007, 69, 229–242. [Google Scholar] [CrossRef]

- Zhang, L.; Aziz, N.; Ren, T.X.; Wang, Z. Influence of temperature on coal sorption characteristics and the theory of coal surface free energy. Procedia Eng. 2011, 26, 1430–1439. [Google Scholar] [CrossRef]

- Abunowara, M.; Sufian, S.; Bustam, M.A.; Eldemerdash, U.; Suleman, H.; Bencini, R.; Assiri, M.A.; Ullah, S.; Al-Sehemi, A.G. Experimental measurements of carbon dioxide, methane and nitrogen high-pressure adsorption properties onto Malaysian coals under various conditions. Energy 2020, 210, 118575. [Google Scholar] [CrossRef]

- Tambaria, T.N.; Sugai, Y.; Nguele, R. Adsorption Factors in Enhanced Coal Bed Methane Recovery: A Review. Gases 2022, 2, 1–21. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Q.; Yuan, C.; Tao, Q.; Zhao, Y.; Zhang, G.; Liu, J. Influence of temperature on adsorption selectivity: Coal-based activated carbon for CH4 enrichment from coal mine methane. Powder Technol. 2019, 347, 42–49. [Google Scholar] [CrossRef]

- Mohamed, T.; Mehana, M. Coalbed methane characterization and modeling: Review and outlook. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–23. [Google Scholar] [CrossRef]

- Li, Z.W. Study on Microstructure Characteristics of Low Rank Coal and Its Control Mechanism on Gas Adsorption/Desorption. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2015. [Google Scholar]

- Day, S.; Sakurovs, R.; Weir, S. Supercritical gas sorption on moist coals. Int. J. Coal Geol. 2008, 74, 203–214. [Google Scholar] [CrossRef]

- Sun, X.; Yao, Y.; Liu, D. The behavior and efficiency of methane displaced by CO2 in different coals and experimental conditions. J. Nat. Gas Sci. Eng. 2021, 93, 104032. [Google Scholar] [CrossRef]

- Mastalerz, M.; Gluskoter, H.; Rupp, J. Carbon dioxide and methane sorption in high volatile bituminous coals from Indiana, USA. Int. J. Coal Geol. 2004, 60, 43–55. [Google Scholar] [CrossRef]

- Levy, J.H.; Day, S.J.; Killingley, J.S. Methane capacities of Bowen Basin coals related to coal properties. Fuel 1997, 76, 813–819. [Google Scholar] [CrossRef]

- Zhu, H.; He, X.; Xie, Y.; Guo, S.; Huo, Y.; Wang, W. A Study on the Effect of coal metamorphism on the adsorption characteristics of a binary component system: CO2 and N2. ACS Omega 2020, 6, 523–532. [Google Scholar] [CrossRef]

- Day, S.; Duffy, G.; Sakurovs, R.; Weir, S. Effect of coal properties on CO2 sorption capacity under supercritical conditions. Int. J. Greenh. Gas Control 2008, 2, 342–352. [Google Scholar] [CrossRef]

- Fathi, E.; Akkutlu, I.Y. Counter-diffusion and competitive adsorption effects during CO2 injection and coalbed methane production. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008; p. SPE-115482. [Google Scholar]

- Jiang, K.; Dou, H.E.; Shen, P.; Sun, T. China’s CCUS progresses and a new evaluation method of CO2 storage capacity in coalbed reservoirs. In Proceedings of the Carbon Management Technology Conference, Sugar Land, TX, USA, 17–19 November 2015; p. CMTC-440095. [Google Scholar]

- Goraya, N.S.; Rajpoot, N.; Marriyappan Sivagnanam, B. Coal bed methane enhancement techniques: A review. ChemistrySelect 2019, 4, 3585–3601. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, Z.; Zhu, W.; Zhao, T.; Liu, S.; Guo, Z.; Sun, C.; Bai, G. Effect of coal permeability evolution on CO2 storage capacity under phase partial pressure in ScCO2-ECBM processes. Energy 2024, 297, 131298. [Google Scholar] [CrossRef]

- Gunter, W.D.; Wiwehar, B.; Perkins, E.H. Aquifer disposal of CO2-rich greenhouse gases: Extension of the time scale of experiment for CO2-sequestering reactions by geochemical modelling. Mineral. Petrol. 1997, 59, 121. [Google Scholar] [CrossRef]

- Talapatra, A.; Halder, S.; Chowdhury, A.I. Enhancing coal bed methane recovery: Using injection of nitrogen and carbon dioxide mixture. Pet. Sci. Technol. 2021, 39, 49–62. [Google Scholar] [CrossRef]

- Katyal, S.; Valix, M.; Thambimuthu, K. Study of parameters affecting enhanced coal bed methane recovery. Energy Sources Part A 2007, 29, 193–205. [Google Scholar] [CrossRef]

- Hall, F.E.; Zhou, C.; Gasem, K.A.M.; Robinson, R.L., Jr.; Dan, Y. Adsorption of pure methane, nitrogen, carbon dioxide and their mixtures on wet Fruitland coal. SPE East. Reg. Meet. 1994, 29, 329–344. [Google Scholar]

- Jessen, K.; Tang, G.Q.; Kovscek, A.R. Laboratory and simulation investigation of enhanced coalbed methane recovery by gas injection. Transp. Porous Media 2008, 73, 141–159. [Google Scholar] [CrossRef]

- Zhang, B.; Ye, J.; Li, Y.; Han, X.; Shen, J.; Cao, C. Simulation of key parameters in CO2 injection for enhanced coalbed methane recovery in a deep well group. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 2219–2226. [Google Scholar]

- Huang, K.; Du, X.; Li, K.; Zhou, J.; Zhang, D.; Abbas, N.; Cheng, Y.; Wu, T.; Liu, G.; He, C. Competitive adsorption of CO2/CH4 on coal: Insights from thermodynamics. Alex. Eng. J. 2024, 97, 114–126. [Google Scholar] [CrossRef]

- Tambach, T.J.; Mathews, J.P.; Van Bergen, F. Molecular exchange of CH4 and CO2 in coal: Enhanced coalbed methane on a nanoscale. Energy Fuels 2009, 23, 4845–4847. [Google Scholar] [CrossRef]

- Stevens, S.H.; Kuuskraa, J.A.; Schraufnagel, R.A. Technology spurs growth of US coalbed methane. Oil Gas J. 1996, 94, 56–63. [Google Scholar]

- Koperna, G.J., Jr.; Oudinot, A.Y.; McColpin, G.R.; Liu, N.; Heath, J.E.; Wells, A.; Young, G.B. CO2-ECBM/storage activities at the San Juan Basin’s pump Canyon test site. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; p. SPE-124002. [Google Scholar]

- Grigg, R.; McPherson, B.; Lee, R. Southwest Regional Partnership on Carbon Sequestration (SWP) Phase II Final Scientific/Technical Report; The U.S. Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2012; DOE Cooperative Agreement; No. DE-FC26-05NT42591.

- Gunter, W.D.; Mavor, M.J.; Robinson, J.R. CO2 storage and enhanced methane production: Field testing at Fenn-Big Valley, Alberta, Canada, with application. Greenh. Gas Control Technol. 2005, 7, 413–421. [Google Scholar]

- Deng, X.; Mavor, M.; Macdonald, D.; Gunter, B.; Wong, S.; Faltinson, J.; Li, H. ECBM technology development at Alberta Research Council. In Proceedings of the Sixth International Forum on Geological Sequestration of CO2 in Deep, Unmineable Coalseams, Houston, TX, USA, 10–11 April 2008. [Google Scholar]

- Fujioka, M. Field Experiment of CO2-ECBMR in Ishikari Basin of Japan. In Proceedings of the Coal-Seq VI, Houston, TX, USA, 10–11 April 2008. [Google Scholar]

- Ye, J.; Feng, S.; Fan, Z.; Wang, G.; Gunter, W.D.; Wong, S.; Robinson, J.R. Micro-pilot test for enhanced coalbed methane recovery by injecting carbon dioxide in south part of Qinshui Basin. Acta Pet. Sin. 2007, 28, 77. [Google Scholar]

- Connell, L.D.; Pan, Z.; Camilleri, M.; Meng, S.; Down, D.; Carras, J.; Zhang, W.; Fu, X.; Guo, B.; Briggs, C.; et al. Description of a CO2 enhanced coal bed methane field trial using a multi-lateral horizontal well. Int. J. Greenh. Gas Control 2014, 26, 204–219. [Google Scholar] [CrossRef]

- Pan, Z.; Ye, J.; Zhou, F.; Tan, Y.; Connell, L.D.; Fan, J. CO2 storage in coal to enhance coalbed methane recovery: A review of field experiments in China. Coal Geol. China 2020, 224–246. [Google Scholar]

- Hamelinck, C.N.; Faaij, A.P.C.; Turkenburg, W.C.; Van Bergen, F.; Pagnier, H.J.M.; Barzandji, O.H.M.; Wolf, K.-H.; Ruijg, G. CO2 enhanced coalbed methane production in the Netherlands. Energy 2002, 27, 647–674. [Google Scholar] [CrossRef]

- Reeves, S.; Oudinot, A. The Allison Unit CO2-ECBM pilot–a reservoir and economic analysis. In Proceedings of the International coalbed Methane Symposium, Tuscaloosa, AL, USA, 17–19 May 2005; pp. 16–20. [Google Scholar]

- Kumar, H.; Elsworth, D.; Mathews, J.P.; Liu, J.; Pone, D. Effect of CO2 injection on heterogeneously permeable coalbed reservoirs. Fuel 2014, 135, 509–521. [Google Scholar] [CrossRef]

- Vishal, V.; Mahanta, B.; Pradhan, S.P.; Singh, T.N.; Ranjith, P.G. Simulation of CO2 enhanced coalbed methane recovery in Jharia coalfields, India. Energy 2018, 159, 1185–1194. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Elsworth, D.; Liu, D.; Cai, Y. Dynamic fluid interactions during CO2-enhanced coalbed methane and CO2 sequestration in coal seams. Part 1: CO2–CH4 interactions. Energy Fuels 2020, 34, 8274–8282. [Google Scholar] [CrossRef]

- Liu, X.; Sang, S.; Zhou, X.; Wang, Z. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM. Energy 2023, 262, 125306. [Google Scholar] [CrossRef]

- Xu, H.; Ni, J.; Ding, H.; Dai, W.; Gou, B.; Zhu, Y.; Liu, H.; Fang, H. Methane adsorption/desorption and carbon dioxide replacement in low permeable coal using LF-NMR-experiments on cylindrical sample under apparent adsorption equilibrium condition. Int. J. Greenh. Gas Control 2024, 132, 104076. [Google Scholar] [CrossRef]

- Zhang, D.; Li, S.; Cui, Y.; Song, W.; Lin, W. Displacement behavior of methane adsorbed on coal by CO2 injection. Ind. Eng. Chem. Res. 2011, 50, 8742–8749. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, C.; Zhang, X.; Li, F.; Wang, X.; Qiao, L. Numerical study of CO2-enhanced coalbed methane recovery. Int. J. Greenh. Gas Control 2018, 76, 12–23. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, S.; Han, J.; Liu, X.; Han, L.; Fu, C. Numerical simulation of the effect of injected CO2 temperature and pressure on CO2-enhanced coalbed methane. Appl. Sci. 2020, 10, 1385. [Google Scholar]

- Bai, G.; Su, J.; Fu, S.; Li, X.; Zhou, X.; Wang, J.; Liu, Z.; Zhang, X. Effect of CO2 injection on the gas desorption and diffusion kinetics: An experimental study. Energy 2024, 288, 129921. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Chen, Z.; Elsworth, D.; Pone, D. A dual poroelastic model for CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2011, 86, 177–189. [Google Scholar] [CrossRef]

- Ranathunga, A.S.; Perera, M.S.A.; Ranjith, P.G.; Wei, C.H. An experimental investigation of applicabilityy of CO2 enhanced coal bed methane recovery to low rank coal. Fuel 2017, 189, 391–399. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Y.; Wang, Y.; Wang, L.; Li, W. Experimental investigation of CO2 injection into coal seam reservoir at in-situ stress conditions for enhanced coalbed methane recovery. Fuel 2019, 236, 709–716. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Liu, S. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery. J. Pet. Sci. Eng. 2019, 181, 106177. [Google Scholar] [CrossRef]

- Ma, Q.; Li, H.; Ji, K.; Huang, F. Thermal-hydraulic-mechanical coupling simulation of CO2 enhanced coalbed methane recovery with regards to low-rank but relatively shallow coal seams. Appl. Sci. 2023, 13, 2592. [Google Scholar] [CrossRef]

- Fan, C.; Yang, L.; Sun, H.; Luo, M.; Zhou, L.; Yang, Z.; Li, S. Recent Advances and Perspectives of CO2-Enhanced Coalbed Methane: Experimental, Modeling, and Technological Development. Energy Fuels 2023, 37, 3371–3412. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Wei, Z.; Zhang, D. A fully coupled multiphase multicomponent flow and geomechanics model for enhanced coalbed-methane recovery and CO2 storage. SPE J. 2013, 18, 448–467. [Google Scholar] [CrossRef]

- Han, H.; Liang, S.; Liang, Y.; Fu, X.; Kang, J.; Yu, L.; Tang, C. The role of coal mechanical characteristics on reservoir permeability evolution and its effects on CO2 sequestration and enhanced coalbed methane recovery. Geofluids 2020, 2020, 1–28. [Google Scholar] [CrossRef]

- Talapatra, A. A study on the carbon dioxide injection into coal seam aiming at enhancing coal bed methane (ECBM) recovery. J. Pet. Explor. Prod. Technol. 2020, 10, 1965–1981. [Google Scholar] [CrossRef]

- Wong, S.; Gunter, W.D.; Mavor, M.J. Economics of CO2 sequestration in coalbed methane reservoirs. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Houston, TX, USA, 20–22 June 2020; p. SPE-59785. [Google Scholar]

- Serikov, G.; Wang, L.; Asif, M.; Hazlett, R. Simulation evaluation of CO2-ECBM potential in Karaganda Coal Basin in Kazakhstan. In Proceedings of the SPE EuropEC-Europe Energy Conference featured at the 83rd EAGE Annual Conference & Exhibition, Madrid, Spain, 5–9 June 2022. [Google Scholar]

- Sams, W.N.; Bromhal, G.; Jikich, S.; Ertekin, T.; Smith, D.H. Field-project designs for carbon dioxide sequestration and enhanced coalbed methane production. Energy Fuels 2005, 19, 2287–2297. [Google Scholar] [CrossRef]

- Zhang, X.; Ranjith, P.G. Experimental investigation of effects of CO2 injection on enhanced methane recovery in coal seam reservoirs. J. CO2 Util. 2019, 33, 394–404. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Li, B.; Kong, X.; Xu, J.; Peng, S.; Chen, Y. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy 2023, 262, 125473. [Google Scholar] [CrossRef]

- Bustin, M. Research activities on CO2, H2S, and SO2 sequestration at UBC. In Proceedings of the Coal-Seq I, Houston, TX, USA, 14–15 March 2002; pp. 14–15. [Google Scholar]

- Zhang, R.; Liu, S. Experimental and theoretical characterization of methane and CO2 sorption hysteresis in coals based on Langmuir desorption. Int. J. Coal Geol. 2017, 171, 49–60. [Google Scholar] [CrossRef]

- Song, Y.; Wang, N. Exploring temporal and spatial evolution of global coal supply-demand and flow structure. Energy 2019, 168, 1073–1080. [Google Scholar] [CrossRef]

- Zhang, R.; Yin, X.; Winterfeld, P.H.; Wu, Y.S. A fully coupled thermal-hydrological-mechanical-chemical model for CO2 geological sequestration. J. Nat. Gas Sci. Eng. 2016, 28, 280–304. [Google Scholar] [CrossRef]

- Vangkilde-Pedersen, T.; Anthonsen, K.L.; Smith, N.; Kirk, K.; van der Meer, B.; Le Gallo, Y.; Bossie-Codreanu, D.; Wojcicki, A.; Nindre, Y.L.; Hendriks, C.; et al. Assessing European capacity for geological storage of carbon dioxide–the EU GeoCapacity project. Energy Procedia 2009, 1, 2663–2670. [Google Scholar] [CrossRef]

- De Silva, P.N.K.; Ranjith, P.G.; Choi, S.K. A study of methodologies for CO2 storage capacity estimation of coal. Fuel 2012, 91, 1–15. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; De Coninck, H.C.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Gale, J.; Freund, P. Coal-bed methane enhancement with CO2 sequestration worldwide potential. Environ. Geosci. 2001, 8, 210–217. [Google Scholar] [CrossRef]

- Stevens, S.H.; Spector, D.; Riemer, P. Enhanced coalbed methane recovery using CO2 injection: Worldwide resource and CO2 sequestration potential. In Proceedings of the SPE International Oil and Gas Conference and Exhibition in China, Beijing, China, 2–6 November 1998; p. SPE-48881. [Google Scholar]

- Sander, R.; Allinson, W.G.; Connell, L.D.; Neal, P.R. Methodology to determine the economics of CO2 storage in coal seams with enhanced coalbed methane recovery. Energy Procedia 2011, 4, 2129–2136. [Google Scholar] [CrossRef]

- Mastalerz, M.; Rupp, J.; Drobniak, A.; Harpalani, S.; Anderson, A.; Korose, C.; Frailey, S.; Morse, D. Assessment of CO2 sequestration and enhanced coalbed methane potential in unminable coal seams of the Illinois Basin. In book: Carbon Dioxide Sequestration Geol. Media-State Sci. AAPG Stud. Geol. 2009, 59, 149–171. [Google Scholar]

- Robertson, E.P. Enhanced Coal Bed Methane Recovery and CO2 Sequestration in the Powder River Basin; Idaho National Lab.: Idaho Falls, ID, USA, 2010. [Google Scholar]

- Stevens, S.H.; Kuuskraa, V.A.; Spector, D.; Riemer, P. CO2 sequestration in deep coal seams: Pilot results and worldwide potential. In Greenhouse Gas Control Technologies; Elsevier Science: Oxford, UK, 1999. [Google Scholar]

- Reeves, S.R. Enhanced CBM recovery, coalbed CO2 sequestration assessed. Oil Gas J. 2003, 101, 49. [Google Scholar]

- Yu, H.; Zhou, G.; Fan, W.; Ye, J. Predicted CO2 enhanced coalbed methane recovery and CO2 sequestration in China. Int. J. Coal Geol. 2007, 71, 345–357. [Google Scholar] [CrossRef]

- Zhou, L.; Feng, Q.; Chen, Z.; Liu, J. Modeling and upscaling of binary gas coal interactions in CO2 enhanced coalbed methane recovery. Procedia Environ. Sci. 2012, 12, 926–939. [Google Scholar] [CrossRef]

- Barzandji, O.H.; Wolf, K.H.A.A.; Bruining, J. Combination of laboratory experiments and field simulations on the improvement of CBM production by CO2 injection. In Proceedings of the Second International Conference on Methane Mitigation, Novosibirsk, Russia, 18–23 June 2000; pp. 325–336. [Google Scholar]

- Hamelinck, C.N.; Schreurs, H.; Faaij, A.P.C.; Ruijg, G.J.; Jansen, D.; Pagnier, H.; van Bergen, F.; Wolf, K.-H.; Barzandji, O.; Bruining, H. Potential for CO2 Sequestration and Enhanced Coalbed Methane Production in the Netherlands; Utrecht University Repository: Utrecht, The Netherlands, 2006; Available online: https://dspace.library.uu.nl/handle/1874/8062 (accessed on 20 May 2025).

- Prabu, V.; Mallick, N. Coalbed methane with CO2 sequestration: An emerging clean coal technology in India. Renew. Sustain. Energy Rev. 2015, 50, 229–244. [Google Scholar] [CrossRef]

- Kalkreuth, W.; Holz, M.; Levandowski, J.; Kern, M.; Casagrande, J.; Weniger, P.; Krooss, B. The coalbed methane (CBM) potential and CO2 storage capacity of the Santa Terezinha Coalfield, Paraná Basin, Brazil–3D modelling, and coal and carbonaceous shale characteristics and related desorption and adsorption capacities in samples from exploration borehole CBM001-ST-RS. Energy Explor. Exploit. 2013, 31, 485–527. [Google Scholar]

- Michael, K.; Golab, A.; Shulakova, V.; Ennis-King, J.; Allinson, G.; Sharma, S.; Aiken, T. Geological storage of CO2 in saline aquifers-A review of the experience from existing storage operations. Int. J. Greenh. Gas Control 2010, 4, 659–667. [Google Scholar] [CrossRef]

- Izadpanahi, M.; Blunt, M.; Kumar, N.; Ali, M.; Tassinari, C.; Sampaio, M. A review of carbon storage in saline aquifers: Mechanisms, prerequisites, and key considerations. Fuel 2024, 369, 131744. [Google Scholar] [CrossRef]

- Law, D.H.S.; Van der Meer, L.G.H.; Gunter, W.D. Numerical simulator comparison study for enhanced coalbed methane recovery processes, part I: Pure carbon dioxide injection. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, AB, Canada, 5–7 November 2002; p. SPE-75669. [Google Scholar]

- Zhang, B.; Fu, X.; Deng, Z.; Shen, Y.; Hao, M. A comparative study on the deformation of unconfined coal during the processes of methane desorption with successively decreasing outlet pressure and with constant outlet pressure. J. Pet. Sci. Eng. 2020, 195, 107531. [Google Scholar] [CrossRef]

- Mitra, A.; Harpalani, S. Modeling incremental swelling of coal matrix with CO2 injection in coalbed methane reservoirs. In Proceedings of the SPE Eastern Regional Meeting, Lexington, KY, USA, 17–19 October 2007; p. SPE-111184. [Google Scholar]

- Harpalani, S.; Mitra, A. Impact of CO2 injection on flow behavior of coalbed methane reservoirs. Transp. Porous Media 2010, 82, 141–156. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, Z.; Liu, L.; Ye, J.; McPherson, B.J.; McLennan, J.D. Modeling CH4 displacement by CO2 in deformed coalbeds during enhanced coalbed methane recovery. Energy Fuels 2018, 32, 1942–1955. [Google Scholar] [CrossRef]

- Staib, G.; Sakurovs, R.; Gray, E.M. Kinetics of coal swelling in gases: Influence of gas pressure, gas type and coal type. Int. J. Coal Geol. 2014, 132, 117–122. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Liu, J.; Pone, D.; Mathews, J.P. Optimizing enhanced coalbed methane recovery for unhindered production and CO2 injectivity. Int. J. Greenh. Gas Control 2012, 11, 86–97. [Google Scholar] [CrossRef]

- Pan, J.; Meng, Z.; Hou, Q.; Ju, Y.; Cao, Y. Coal strength and Young’s modulus related to coal rank, compressional velocity and maceral composition. J. Struct. Geol. 2013, 54, 129–135. [Google Scholar] [CrossRef]

- Li, S.; Ni, G.; Wang, H.; Xun, M.; Xu, Y. Effects of acid solution of different components on the pore structure and mechanical properties of coal. Adv. Powder Technol. 2020, 31, 1736–1747. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, G.; Shu, Z.; Tong, Y. Study on key influencing factors of competitive adsorption of coalbed methane by carbon dioxide displacement. Front. Chem. 2022, 10, 998592. [Google Scholar] [CrossRef]

- Syed, A.; Durucan, S.; Shi, J.Q.; Korre, A. Flue gas injection for CO2 storage and enhanced coalbed methane recovery: Mixed gas sorption and swelling characteristics of coals. Energy Procedia 2013, 37, 6738–6745. [Google Scholar] [CrossRef]

- Wang, G.X.; Massarotto, P.; Rudolph, V. An improved permeability model of coal for coalbed methane recovery and CO2 geosequestration. Int. J. Coal Geol. 2009, 77, 127–136. [Google Scholar] [CrossRef]

- Ma, T.; Rutqvist, J.; Oldenburg, C.M.; Liu, W. Coupled thermal–hydrological–mechanical modeling of CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2017, 179, 81–91. [Google Scholar] [CrossRef]

- Guo, R.; Akkutlu, K.M.; Kantzas, A. Laboratory investigation on the permeability of coal during primary and enhanced coalbed methane production. J. Can. Pet. Technol. 2008, 47, PETSOC-08-10-27. [Google Scholar] [CrossRef]

- Pini, R.; Storti, G.; Mazzotti, M. A model for enhanced coal bed methane recovery aimed at carbon dioxide storage: The role of sorption, swelling and composition of injected gas. Adsorption 2011, 17, 889–900. [Google Scholar] [CrossRef]

- Fan, C.; Yang, L.; Xiao, B.; Zhou, L.; Wen, H.; Sun, H. Reasonable start time of carbon dioxide injection in enhanced coalbed methane recovery involving thermal-hydraulic-mechanical couplings. Front. Earth Sci. 2023, 17, 832–843. [Google Scholar] [CrossRef]

- Syahrial, E. Coalbed Methane Simulator Development for Improved Recovery of Coalbed Methane and CO2 Sequestration. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 4 April 2005; p. SPE-93160. [Google Scholar]

- Fazal, B.R.; Becker, T.; Kinsella, B.; Lepkova, K. A review of plant extracts as green corrosion inhibitors for CO2 corrosion of carbon steel. NPJ Mater. Degrad. 2022, 6, 5. [Google Scholar] [CrossRef]

- Dougherty, J.A. A review of the effect of organic acids on CO2 corrosion. In Proceedings of the Nace Corrosion, New Orleans, LA, USA, 28 March 2004; p. NACE-04376. [Google Scholar]

- Moiseeva, L.S. Carbon dioxide corrosion of oil and gas field equipment. Prot. Met. 2005, 41, 76–83. [Google Scholar] [CrossRef]

- Koornneef, J.; Spruijt, M.; Molag, M.; Ramírez, A.; Turkenburg, W.; Faaij, A. Quantitative risk assessment of CO2 transport by pipelines-a review of uncertainties and their impacts. J. Hazard. Mater. 2010, 177, 12–27. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Lateef, H.M.; Abbasov, V.M.; Aliyeva, L.I.; Ismayilov, T.A. Corrosion protection of steel pipelines against CO2 corrosion-a review. Chem. J. 2012, 2, 52–63. [Google Scholar]

- Al-Janabi, Y.T. An overview of corrosion in oil and gas industry: Upstream, midstream, and downstream sectors. In Corrosion Inhibitors in the Oil and Gas Industry, 1st ed.; Part I; Wiley-VCHVerlagGmbH&Co.KGaA: Hoboken, NJ, USA, 2020; pp. 1–39. [Google Scholar] [CrossRef]

- Bai, M.; Sun, J.; Song, K.; Li, L.; Qiao, Z. Well completion and integrity evaluation for CO2 injection wells. Renew. Sustain. Energy Rev. 2015, 45, 556–564. [Google Scholar] [CrossRef]

- Askari, M.; Aliofkhazraei, M.; Jafari, R.; Hamghalam, P.; Hajizadeh, A. Downhole corrosion inhibitors for oil and gas production—A review. Appl. Surf. Sci. Adv. 2021, 6, 100128. [Google Scholar] [CrossRef]

- Nešić, S. Key issues related to modelling of internal corrosion of oil and gas pipelines—A review. Corros. Sci. 2007, 49, 4308–4338. [Google Scholar] [CrossRef]

- Choi, Y.S.; Young, D.; Nešić, S.; Gray, L.G. Wellbore integrity and corrosion of carbon steel in CO2 geologic storage environments: A literature review. Int. J. Greenh. Gas Control 2013, 16, S70–S77. [Google Scholar] [CrossRef]

- Niu, Q.; Cao, L.; Sang, S.; Zhou, X.; Wang, W.; Yuan, W.; Ji, Z.; Wang, H.; Nie, Y. Study on the anisotropic permeability in different rank coals under influences of supercritical CO2 adsorption and effective stress and its enlightenment for CO2 enhance coalbed methane recovery. Fuel 2020, 262, 116515. [Google Scholar] [CrossRef]

- Omotilewa, O.J.; Panja, P.; Vega-Ortiz, C.; McLennan, J. Evaluation of enhanced coalbed methane recovery and carbon dioxide sequestration potential in high volatile bituminous coal. J. Nat. Gas Sci. Eng. 2021, 91, 103979. [Google Scholar] [CrossRef]

- Syed, A.; Shi, J.Q.; Durucan, S. Permeability and injectivity improvement in CO2 enhanced coalbed methane recovery: Thermal stimulation of the near wellbore region. Energy Procedia 2011, 4, 2137–2143. [Google Scholar] [CrossRef]

- Niu, Q.; Hu, M.; Leng, B.; He, X.; Su, W.; Wang, W.; Wang, Q.; Chang, J.; Ji, Z.; Qi, X. Experimental and numerical model of anisotropic permeability and CO2 injectivity of coal during CO2 enhanced coalbed methane recovery process. Front. Earth Sci. 2023, 10, 1042477. [Google Scholar] [CrossRef]

- van Bergen, F.; Tambach, T.; Pagnier, H. The role of CO2-enhanced coalbed methane production in the global CCS strategy. Energy Procedia 2011, 4, 3112–3116. [Google Scholar] [CrossRef]

- Li, X.; Fang, Z.M. Current status and technical challenges of CO2 storage in coal seams and enhanced coalbed methane recovery: An overview. Int. J. Coal Sci. Technol. 2014, 1, 93–102. [Google Scholar] [CrossRef]

- Reeves, S.; Taillefert, A.; Pekot, L.; Clarkson, C. Allison Unit CO2-ECBM Pilot: A Reservoir Modeling Study. Topical Report; U.S. Department of Energy: Washington, DC, USA, 2003; Award Number DE-FC26-0NT40924.

- Reeves, S.R. The Coal-Seq Project: Key Results from Field, Laboratory, and Modeling Studies. In Proceedings of the Greenhouse Gas Control Technologies: Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5–9 September 2005; Volume 1, p. 1399. [Google Scholar]

- Durucan, S.; Shi, J.Q. Improving the CO2 well injectivity and enhanced coalbed methane production performance in coal seams. Int. J. Coal Geol. 2009, 77, 214–221. [Google Scholar] [CrossRef]

- Zhou, F.; Hussain, F.; Cinar, Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation. Int. J. Coal Geol. 2013, 116, 53–62. [Google Scholar] [CrossRef]

- Kang, J.; Fu, X.; Liang, S.; Zhou, F.; Li, Y. Experimental study of changes in fractures and permeability during nitrogen injection and sealing of low-rank coal. J. Nat. Gas Sci. Eng. 2018, 57, 21–30. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, X.; Li, G.; Deng, Z.; Shen, Y.; Hao, M. An experimental study on the effect of nitrogen injection on the deformation of coal during methane desorption. J. Nat. Gas Sci. Eng. 2020, 83, 103529. [Google Scholar] [CrossRef]

- Schepers, K.; Oudinot, A.; Ripepi, N. Enhanced gas recovery and CO2 storage in coal bed methane reservoirs: Optimized injected gas composition for mature basins of various coal rank. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010. [Google Scholar]

- Perera, M.S.A.; Ranjith, P.G.; Ranathunga, A.S.; Koay, A.Y.J.; Zhao, J.; Choi, S.K. Optimization of enhanced coal-bed methane recovery using numerical simulation. J. Geophys. Eng. 2015, 12, 90–107. [Google Scholar] [CrossRef]

- Oudinot, A.Y.; Riestenberg, D.E.; Koperna, G.J., Jr. Enhanced gas recovery and CO2 storage in coal bed methane reservoirs with N2 co-injection. Energy Procedia 2017, 114, 5356–5376. [Google Scholar] [CrossRef]

- Reeves, S.R. Geological sequestration of CO2 in deep, unmineable coalbeds: An integrated research and commerical-scale field demonstration project. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017; p. SPE-71749. [Google Scholar]

- Sayyafzadeh, M.; Keshavarz, A.; Alias, A.R.M.; Dong, K.A.; Manser, M. Investigation of varying-composition gas injection for coalbed methane recovery enhancement: A simulation-based study. J. Nat. Gas Sci. Eng. 2015, 27, 1205–1212. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G. Enhanced coal bed methane recovery: Using injection of nitrogen and carbon dioxide mixture. In Handbook of Clean Energy Systems; Wiley: Hoboken, NJ, USA, 2015; pp. 1–19. [Google Scholar]

- Fan, C.; Elsworth, D.; Li, S.; Chen, Z.; Luo, M.; Song, Y.; Zhang, H. Modelling and optimization of enhanced coalbed methane recovery using CO2/N2 mixtures. Fuel 2019, 253, 1114–1129. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Mu, Y.; Wang, T. Numerical study on enhancing coalbed methane recovery by injecting N2/CO2 mixtures and its geological significance. Energy Sci. Eng. 2020, 8, 1104–1119. [Google Scholar] [CrossRef]

- Sayyafzadeh, M.; Keshavarz, A. Optimisation of gas mixture injection for enhanced coalbed methane recovery using a parallel genetic algorithm. J. Nat. Gas Sci. Eng. 2016, 33, 942–953. [Google Scholar] [CrossRef]

- Su, E.; Liang, Y.; Zou, Q.; Niu, F.; Li, L. Analysis of effects of CO2 injection on coalbed permeability: Implications for coal seam CO2 sequestration. Energy Fuels 2019, 33, 6606–6615. [Google Scholar] [CrossRef]

- Fan, Z.; Fan, G.; Zhang, D.; Zhang, L.; Zhang, S.; Liang, S.; Yu, W. Optimal injection timing and gas mixture proportion for enhancing coalbed methane recovery. Energy 2021, 222, 119880. [Google Scholar] [CrossRef]

- Le, T.D.; Ha, Q.D.; Panfilov, I.; Moyne, C. Multiscale model for flow and transport in CO2-enhanced coalbed methane recovery incorporating gas mixture adsorption effects. Adv. Water Resour. 2020, 144, 103706. [Google Scholar] [CrossRef]

- Gao, C.; Liu, D.; Vandeginste, V.; Cai, Y.; Sun, F. Effects of CO2 injection pressure and confining pressure on CO2-enhanced coalbed methane recovery: Experimental observations at various simulated geological conditions. Chem. Eng. J. 2024, 483, 149207. [Google Scholar] [CrossRef]

- Zhao, L.; Guanhua, N.; Yongzan, W.; Hehe, J.; Yixin, L.; Qiming, H.; Wanpeng, H. Analysis of permeability evolution mechanism during CO2 enhanced coalbed methane recovery based on impact factor method. Fuel 2021, 304, 121389. [Google Scholar] [CrossRef]

- Su, E.; Liang, Y.; Zou, Q.; Xu, M.; Sasmito, A.P. Numerical analysis of permeability rebound and recovery during coalbed methane extraction: Implications for CO2 injection methods. Process Saf. Environ. Prot. 2021, 149, 93–104. [Google Scholar] [CrossRef]

- Tan, Y.J.; Bailey, S.; Kinsella, B. An investigation of the formation and destruction of corrosion inhibitor films using electrochemical impedance spectroscopy (EIS). Corros. Sci. 1996, 38, 1545–1561. [Google Scholar] [CrossRef]

- Olvera-Martínez, M.E.; Mendoza-Flores, J.; Genesca, J. CO2 corrosion control in steel pipelines. Influence of turbulent flow on the performance of corrosion inhibitors. J. Loss Prev. Process Ind. 2015, 35, 19–28. [Google Scholar] [CrossRef]

- Lewis, R.E.; Barbin, D.K. Selecting Internal Coatings For Gas Well Tubulabs. In Proceedings of the Nace Corrosion, New Orleans, LA, USA, 9–14 March 1997; p. NACE-97070. [Google Scholar]

- Sharif, Q.J.; Esmail, O.J.; Radhakrishnan, G.; Simpson, J.A.; Bremner, M.R. Experience with Fiberglass GRE Lined Carbon Steel Tubular for Corrosion Protection for Oil Production Applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 10 October 2012; p. SPE-160236. [Google Scholar]

- Wei, L.; Zhang, Y.; Pang, X.; Gao, K. Corrosion behaviors of steels under supercritical CO2 conditions. Corros. Rev. 2015, 33, 151–174. [Google Scholar] [CrossRef]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced coalbed methane recovery. J. Supercrit. Fluids 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Wo, S.; Liang, J.T. Simulation assessment of N2/CO2 contact volume in coal and its impact on outcrop seepage in N2/CO2 injection for enhanced coalbed methane recovery. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 24–28 April 2004; p. SPE-89344. [Google Scholar]

- Ross, H.E.; Hagin, P.; Zoback, M.D. CO2 storage and enhanced coalbed methane recovery: Reservoir characterization and fluid flow simulations of the Big George coal, Powder River Basin, Wyoming, USA. Int. J. Greenh. Gas Control 2009, 3, 773–786. [Google Scholar] [CrossRef]

- Jamshidi, M.; Jessen, K. Water production in enhanced coalbed methane operations. J. Pet. Sci. Eng. 2012, 92, 56–64. [Google Scholar] [CrossRef]

- Pashin, J.C.; Clark, P.E.; McIntyre-Redden, M.R.; Carroll, R.E.; Esposito, R.A.; Oudinot, A.Y.; Koperna, G.J., Jr. SECARB CO2 injection test in mature coalbed methane reservoirs of the Black Warrior Basin, Blue Creek Field, Alabama. Int. J. Coal Geol. 2015, 144, 71–87. [Google Scholar] [CrossRef]

- Toews, K.L.; Shroll, R.M.; Wai, C.M.; Smart, N.G. pH-defining equilibrium between water and supercritical CO2. Influence on SFE of organics and metal chelates. Anal. Chem. 1995, 67, 4040–4043. [Google Scholar] [CrossRef]

- Carroll, S.A.; McNab, W.W.; Dai, Z.; Torres, S.C. Reactivity of Mount Simon sandstone and the Eau Claire shale under CO2 storage conditions. Environ. Sci. Technol. 2013, 47, 252–261. [Google Scholar] [CrossRef]

- Gaus, I. Role and impact of CO2–rock interactions during CO2 storage in sedimentary rocks. Int. J. Greenh. Gas Control 2010, 4, 73–89. [Google Scholar] [CrossRef]

- Busch, A.; Alles, S.; Krooss, B.M.; Stanjek, H.; Dewhurst, D. Effects of physical sorption and chemical reactions of CO2 in shaly caprocks. Energy Procedia 2009, 1, 3229–3235. [Google Scholar] [CrossRef]

- Kaszuba, J.P.; Janecky, D.R.; Snow, M.G. Experimental evaluation of mixed fluid reactions between supercritical carbon dioxide and NaCl brine: Relevance to the integrity of a geologic carbon repository. Chem. Geol. 2005, 217, 277–293. [Google Scholar] [CrossRef]

- Wang, K.; Xu, T.; Tian, H.; Wang, F. Impacts of mineralogical compositions on different trapping mechanisms during long-term CO2 storage in deep saline aquifers. Acta Geotech. 2016, 11, 1167–1188. [Google Scholar] [CrossRef]

- Kim, S.; Santamarina, J.C. CO2 geological storage: Hydro-chemo-mechanical analyses and implications. Greenh. Gases: Sci. Technol. 2014, 4, 528–543. [Google Scholar] [CrossRef]

- Hol, S.; Zoback, M.D. Creep behavior of coal and shale related to adsorption of reservoir fluids. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013; p. ARMA-2013. [Google Scholar]

- Zhou, J.; Tian, S.; Zhou, L.; Xian, X.; Yang, K.; Jiang, Y.; Zhang, C.; Guo, Y. Experimental investigation on the influence of sub-and super-critical CO2 saturation time on the permeability of fractured shale. Energy 2020, 191, 116574. [Google Scholar] [CrossRef]

- Yang, B.; Wang, H.; Wang, B.; Yi, Y.; Zhao, C.; Tian, G. Effect of supercritical CO2-water/brine-rock interaction on microstructures and mechanical properties of tight sandstone. Transp. Porous Media 2022, 1–29. [Google Scholar] [CrossRef]

- Dewhurst, D.N.; Raven, M.D.; Shah, S.S.B.M.; Ali, S.S.B.M.; Giwelli, A.; Firns, S.; Josh, M.; White, C. Interaction of super-critical CO2 with mudrocks: Impact on composition and mechanical properties. Int. J. Greenh. Gas Control 2020, 102, 103163. [Google Scholar] [CrossRef]

- Sun, Y.; Aman, M.; Espinoza, D.N. Assessment of mechanical rock alteration caused by CO2 water mixtures using indentation and scratch experiments. Int. J. Greenh. Gas Control 2016, 45, 9–17. [Google Scholar] [CrossRef]

- Major, J.R.; Eichhubl, P.; Dewers, T.A.; Olson, J.E. Effect of CO2–brine–rock interaction on fracture mechanical properties of CO2 reservoirs and seals. Earth Planet. Sci. Lett. 2018, 499, 37–47. [Google Scholar] [CrossRef]

- Zou, Y.; Li, S.; Ma, X.; Zhang, S.; Li, N.; Chen, M. Effects of CO2–brine–rock interaction on porosity/permeability and mechanical properties during supercritical-CO2 fracturing in shale reservoirs. J. Nat. Gas Sci. Eng. 2018, 49, 157–168. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Zoback, M.D. Permeability evolution of fractures in shale in the presence of supercritical CO2. J. Geophys. Res. Solid Earth 2021, 126, e2021JB022266. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Xing, H.; Zou, Y. CO2–brine–rock interactions altering the mineralogical, physical, and mechanical properties of carbonate-rich shale oil reservoirs. Energy 2022, 256, 124608. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, G.; Huang, Z.; Zhao, J.; Wang, L.; Qiu, R. Changes in microstructure and mechanical properties of shales exposed to supercritical CO2 and brine. Int. J. Rock Mech. Min. Sci. 2022, 160, 105228. [Google Scholar] [CrossRef]

- Sheng, J.; Zhao, J.; Yue, P. An Experimental Study of the Effect of CO2 Water-Mancos Shale Interactions on Permeability. Int. J. Earth Sci. Knowl. Appl. 2022, 4, 26–31. [Google Scholar]

- Niu, Q.; Wang, Q.; Wang, W.; Chang, J.; Chen, M.; Wang, H.; Cai, N.; Fan, L. Responses of multi-scale microstructures, physical-mechanical and hydraulic characteristics of roof rocks caused by the supercritical CO2-water-rock reaction. Energy 2022, 238, 121727. [Google Scholar] [CrossRef]

- Yang, K.; Zhou, J.; Xian, X.; Zhou, L.; Zhang, C.; Tian, S.; Lu, Z.; Zhang, F. Chemical-mechanical coupling effects on the permeability of shale subjected to supercritical CO2-water exposure. Energy 2022, 248, 123591. [Google Scholar] [CrossRef]

- Tian, S.; Zhou, J.; Xian, X.; Gan, Q.; Yang, K.; Zheng, Y.; Deng, G.; Zhang, F. Impact of supercritical CO2 exposure time on the porosity and permeability of dry and wet shale: The influence of chemo-mechanical coupling effects. Energy 2023, 270, 126905. [Google Scholar] [CrossRef]

- Li, N.; Jin, Z.; ZHANG, S.; Wang, H.; Yang, P.; Zou, Y.; Zhou, T. Micro-mechanical properties of shale due to water/supercritical carbon dioxide-rock interaction. Pet. Explor. Dev. 2023, 50, 1001–1012. [Google Scholar] [CrossRef]

- Yang, K.; Zhou, J.; Xian, X.; Zhang, C.; Gan, Q.; Dong, Z. Effect of supercritical CO2-water-shale interaction on mechanical properties of shale and its implication for carbon sequestration. Gas Sci. Eng. 2023, 111, 204930. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, J.; Xian, X.; Jiang, Y.; Lu, Z.; Tan, J.; Liu, G. Experimental study of the effects of sub-and super-critical CO2 saturation on the mechanical characteristics of organic-rich shales. Energy 2017, 132, 84–95. [Google Scholar] [CrossRef]

- Lyu, Q.; Ranjith, P.G.; Long, X.; Ji, B. Experimental investigation of mechanical properties of black shales after CO2-water-rock interaction. Materials 2016, 9, 663. [Google Scholar] [CrossRef]

- Zhang, S.; Xian, X.; Zhou, J.; Zhang, L. Mechanical behaviour of Longmaxi black shale saturated with different fluids: An experimental study. RSC Adv. 2017, 7, 42946–42955. [Google Scholar] [CrossRef]

- Zhou, J.; Tian, S.; Zhou, L.; Xian, X.; Zhang, C.; Yang, K.; Dong, Z.; Lu, Z. Effect of sub-/super-critical CO2 and brine exposure on the mechanical and acoustic emission characteristics of shale. J. Nat. Gas Sci. Eng. 2021, 90, 103921. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, K.; Zhou, L.; Jiang, Y.; Xian, X.; Zhang, C.; Tian, S.; Fan, M.; Lu, Z. Microstructure and mechanical properties alterations in shale treated via CO2/CO2-water exposure. J. Pet. Sci. Eng. 2021, 196, 108088. [Google Scholar] [CrossRef]

- Amann-Hildenbrand, A.; Bertier, P.; Busch, A.; Krooss, B.M. Experimental investigation of the sealing capacity of generic clay-rich caprocks. Int. J. Greenh. Gas Control 2013, 19, 620–641. [Google Scholar] [CrossRef]

- Al-Yaseri, A.; Zhang, Y.; Ghasemiziarani, M.; Sarmadivaleh, M.; Lebedev, M.; Roshan, H.; Iglauer, S. Permeability evolution in sandstone due to CO2 injection. Energy Fuels 2017, 31, 12390–12398. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Wang, Z.; Bai, B.; Xiao, D.; Tang, M. Application of nanoindentation technology for characterizing the mechanical properties of shale before and after supercritical CO2 fluid treatment. J. CO2 Util. 2020, 37, 158–172. [Google Scholar] [CrossRef]

- Chen, X.; Eichhubl, P.; Olson, J.E.; Dewers, T.A. Effect of water on fracture mechanical properties of shales. J. Geophys. Res. Solid Earth 2019, 124, 2428–2444. [Google Scholar] [CrossRef]

- Rathnaweera, T.D.; Ranjith, P.G.; Perera, M.S.A.; Haque, A.; Lashin, A.; Al Arifi, N.; Chandrasekharam, D.; Yang, S.; Xu, T.; Wang, S.; et al. CO2-induced mechanical behaviour of Hawkesbury sandstone in the Gosford basin: An experimental study. Mater. Sci. Eng. A 2015, 641, 123–137. [Google Scholar] [CrossRef]

- Jayasekara, D.W.; Ranjith, P.G.; Wanniarachchi, W.A.M.; Rathnaweera, T.D.; Chaudhuri, A. Effect of salinity on supercritical CO2 permeability of caprock in deep saline aquifers: An experimental study. Energy 2020, 191, 116486. [Google Scholar] [CrossRef]

- Goodman, A.; Kutchko, B.; Sanguinito, S.; Natesakhawat, S.; Cvetic, P.; Haljasmaa, I.; Spaulding, R.; Crandall, D.; Moore, J.; Burrows, L.C. Reactivity of CO2 with Utica, Marcellus, Barnett, and Eagle Ford Shales and impact on permeability. Energy Fuels 2021, 35, 15894–15917. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Liu, A.; Kang, Y. Determination of Mechanical Property Evolutions of Shales by Nanoindentation and High-Pressure CO2 and Water Treatments: A Nano-to-Micron Scale Experimental Study. Rock Mech. Rock Eng. 2022, 55, 7629–7655. [Google Scholar] [CrossRef]

- Zhang, M.; Spiers, C.J.; Hangx, S.J.T. Effect of CO2-H2O-Smectite Interactions on Permeability of Clay-Rich Rocks Under CO2 Storage Conditions. Rock Mech. Rock Eng. 2023, 56, 3451–3474. [Google Scholar] [CrossRef]

- Hangx, S.; van der Linden, A.; Marcelis, F.; Bauer, A. The effect of CO2 on the mechanical properties of the Captain Sandstone: Geological storage of CO2 at the Goldeneye field (UK). Int. J. Greenh. Gas Control 2013, 19, 609–619. [Google Scholar] [CrossRef]

- Bielinski, A. Numerical Simulation of CO2 Sequestration in Geological Formations. Ph.D. Dissertation, Universität Stuttgart, Stuttgart, Germany, 2007. [Google Scholar]

- Hao, Y.; Smith, M.; Sholokhova, Y.; Carroll, S. CO2-induced dissolution of low permeability carbonates. Part II: Numerical modeling of experiments. Adv. Water Resour. 2013, 62, 388–408. [Google Scholar] [CrossRef]

- Xiao, T.; Xu, H.; Moodie, N.; Esser, R.; Jia, W.; Zheng, L.; Rutqvist, J.; McPherson, B. Chemical-mechanical impacts of CO2 intrusion into heterogeneous caprock. Water Resour. Res. 2020, 56, e2020WR027193. [Google Scholar] [CrossRef]

- Fan, Z.; Xu, T.; Yang, B.; Zhang, H.; Zhu, H. Numerical Simulation of Thermo-Hydro-Mechanical-Chemical Response Caused by CO2 Injection into Saline Geological Formations: A Case Study from the Ordos Project, China. Acta Geol. Sin.-Engl. Ed. 2023, 97, 889–910. [Google Scholar] [CrossRef]

- Diersch, H.J.; Kolditz, O. Variable-density flow and transport in porous media: Approaches and challenges. Adv. Water Resour. 2002, 25, 899–944. [Google Scholar] [CrossRef]

- Xu, T.; Pruess, K. On fluid flow and mineral alteration in fractured caprock of magmatic hydrothermal systems. J. Geophys. Res. Solid Earth 2001, 106, 2121–2138. [Google Scholar] [CrossRef]

- Xu, T.; Pruess, K. Coupled Modeling of Non-Isothermal Multiphase flow, Solute Transport And reactive Chemistry in Porous and Fractured Media: 1. Model Development and Validation; Lawrence Berkeley National Laboratory Report LBNL-42050; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1998. [Google Scholar]

- Parkhurst, D.L.; Appelo, C.A.J. User’s guide to PHREEQC (Version 2): A computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Water-Resour. Investig. Rep. 1999, 99, 312. [Google Scholar]

- Ates, Y.; Barron, K. The effect of gas sorption on the strength of coal. Min. Sci. Technol. 1988, 6, 291–300. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Ranjith, P.G.; Perera, M.S.A. A comprehensive review of structural alterations in CO2-interacted coal: Insights into CO2 sequestration in coal. Energy Fuels 2020, 34, 13369–13383. [Google Scholar] [CrossRef]

- Mirzaeian, M.; Hall, P.J. The interactions of coal with CO2 and its effects on coal structure. Energy Fuels 2006, 20, 2022–2027. [Google Scholar] [CrossRef]

- Ettinger, I.L.; Lamba, E.G. Gas medium in coal-breaking processes. Fuel 1957, 36, 298–306. [Google Scholar]

- Green, T.K.; Pan, W.P.; Clark, M. Glass transition temperature of modified coals. Papers of the American Chemical Society. Fuel 1991, 201, 110. [Google Scholar]

- Masoudian, M.S.; Airey, D.W.; El-Zein, A. Experimental investigations on the effect of CO2 on mechanics of coal. Int. J. Coal Geol. 2014, 128, 12–23. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Perera, M.S.A.; Li, D.Y.; Ranjith, P.G.; Matthai, S.K. Evaluation of the mechanical behaviour of brine+CO2 saturated brown coal under mono-cyclic uni-axial compression. Eng. Geol. 2019, 263, 105312. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Nie, B.; Zhang, C.; Song, D.; Yang, T.; Ma, Z. Mechanical response and mineral dissolution of anthracite induced by supercritical CO2 saturation: Influence of saturation time. Fuel 2022, 319, 123759. [Google Scholar] [CrossRef]

- Reucroft, P.E.; Patel, H. Gas-induced swelling in coal. Fuel 1986, 65, 816–820. [Google Scholar] [CrossRef]

- Stacy, W.O.; Jones, J.C. The swelling and adsorption characteristics of Victorian brown coals. Fuel 1986, 65, 1171–1173. [Google Scholar] [CrossRef]

- Walker, P.L., Jr.; Verma, S.K.; Rivera-Utrilla, J.; Khan, M.R. A direct measurement of expansion in coals and macerais induced by carbon dioxide and methanol. Fuel 1988, 67, 719–726. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Perera, M.S.A.; Ranjith, P.G.; Matthai, S.K.; Dong-yin, L. Qualitative and quantitative evaluation of the alteration of micro-fracture characteristics of supercritical CO2-interacted coal. J. Supercrit. Fluids 2019, 147, 90–101. [Google Scholar] [CrossRef]

- Li, Z.; Wang, F.; Shu, C.M.; Wen, H.; Wei, G.; Liang, R. Damage effects on coal mechanical properties and micro-scale structures during liquid CO2-ECBM process. J. Nat. Gas Sci. Eng. 2020, 83, 103579. [Google Scholar] [CrossRef]

- Massarotto, P.; Golding, S.D.; Bae, J.S.; Iyer, R.; Rudolph, V. Changes in reservoir properties from injection of supercritical CO2 into coal seams-A laboratory study. Int. J. Coal Geol. 2010, 82, 269–279. [Google Scholar] [CrossRef]

- Dawson, G.K.W.; Golding, S.D.; Massarotto, P.; Esterle, J.S. Experimental supercritical CO2 and water interactions with coal under simulated in situ conditions. Energy Procedia 2011, 4, 3139–3146. [Google Scholar] [CrossRef]

- Xu, T.; Pruess, K. Reactive transport modeling to study fluid-rock interactions in enhanced geothermal systems (EGS) with CO2 as working fluid. In Proceedings of the Proceedings, World Geothermal Congress, Bali, Indonesia, 25–30 April 2010; p. 20. [Google Scholar]

- Beni, A.N.; Kühn, M.; Meyer, R.; Clauser, C. Numerical modeling of a potential geological CO 2 sequestration site at Minden (Germany). Environ. Model. Assess. 2012, 17, 337–351. [Google Scholar] [CrossRef]

- Pearce, J.K.; Dawson, G.K.; Law, A.C.; Biddle, D.; Golding, S.D. Reactivity of micas and cap-rock in wet supercritical CO2 with SO2 and O2 at CO2 storage conditions. Appl. Geochem. 2016, 72, 59–76. [Google Scholar] [CrossRef]

- Liu, A.; Liu, S. Mechanical property alterations across coal matrix due to water-CO2 treatments: A micro-to-nano scale experimental study. Energy 2022, 248, 123575. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Jia, L.; Wang, H.; Yuan, J.; Wang, X. CO2–H2O–coal interaction of CO2 storage in coal beds. Int. J. Min. Sci. Technol. 2013, 23, 525–529. [Google Scholar] [CrossRef]

- Masoudian-Saadabad, M.; Airey, D.W.; Gainey, A.; Morris, T.; Berger, J. The mechanical properties of CO2-saturated coal specimens. In Proceedings of the ISRM Congress, Beijing, China, 18–21 October 2011; ISRM: London, UK, 2011; p. ISRM-12CONGRESS. [Google Scholar]

- Viete, D.R.; Ranjith, P.G. The effect of CO2 on the geomechanical and permeability behaviour of brown coal: Implications for coal seam CO2 sequestration. Int. J. Coal Geol. 2006, 66, 204–216. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Sang, S.; Ranjith, P.G.; Yu, X.; Sun, Y.; Cong, Y.; Tang, W.; Zheng, Y. Brittleness evolution of different rank coals under the effects of cyclic liquid CO2 during the coalbed methane recovery process. Energy Fuels 2021, 35, 17651–17662. [Google Scholar] [CrossRef]

- Zhang, X.G.; Ranjith, P.G.; Ranathunga, A.S.; Li, D.Y. Variation of mechanical properties of bituminous coal under CO2 and H2O saturation. J. Nat. Gas Sci. Eng. 2019, 61, 158–168. [Google Scholar] [CrossRef]

- Xue, Y.; Ranjith, P.G.; Chen, Y.; Cai, C.; Gao, F.; Liu, X. Nonlinear mechanical characteristics and damage constitutive model of coal under CO2 adsorption during geological sequestration. Fuel 2023, 331, 125690. [Google Scholar] [CrossRef]

- Liu, X.; Jia, X.; Liu, W.; Nie, B.; Zhang, C.; Song, D. Mechanical strength and porosity changes of bituminous coal induced by supercritical CO2 interactions: Influence of saturation pressure. Geoenergy Sci. Eng. 2023, 225, 211691. [Google Scholar] [CrossRef]

- Zhang, G.; Ranjith, P.G.; Li, Z.; Gao, M.; Ma, Z. Long-term effects of CO2-water-coal interactions on structural and mechanical changes of bituminous coal. J. Pet. Sci. Eng. 2021, 207, 109093. [Google Scholar] [CrossRef]

- Yang, Y.; Xing, P.; Dai, L.; Liu, X.; Nie, B. Coal microstructural and mechanical alterations induced by supercritical CO2 exposure: Role of water. Fuel 2023, 352, 128952. [Google Scholar] [CrossRef]

- Liu, T.; Li, M.; Li, J.; Chen, M.; Shi, Y.; Lin, B. Interactions of CO2–H2O-coal and its impact on micro mechanical strength of coal. Geoenergy Sci. Eng. 2023, 227, 211915. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Sun, D.; Lin, C.; Yu, X.; Hou, F.; Bai, Z. Permeability evolution of deep-buried coal based on NMR analysis: CO2 adsorption and water content effects. Energy 2024, 289, 129877. [Google Scholar] [CrossRef]

- Zhang, X.; Ranjith, P.G.; Lu, Y.; Ranathunga, A.S. Experimental investigation of the influence of CO2 and water adsorption on mechanics of coal under confining pressure. Int. J. Coal Geol. 2019, 209, 117–129. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Liu, X.; Wu, C.; Zhao, K. Feasibility and applicability analysis of CO2-ECBM technology based on CO2–H2O–coal interactions. Energy Fuels 2017, 31, 9268–9274. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Elsworth, D.; Liu, D.; Cai, Y. Dynamic fluid interactions during CO2-ECBM and CO2 sequestration in coal seams. Part 2: CO2-H2O wettability. Fuel 2020, 279, 118560. [Google Scholar] [CrossRef]

- Zhao, W.; Su, X.; Xia, D.; Hou, S.; Wang, Q.; Zhou, Y. Enhanced coalbed methane recovery by the modification of coal reservoir under the supercritical CO2 extraction and anaerobic digestion. Energy 2022, 259, 124914. [Google Scholar] [CrossRef]

- Du, Q.; Liu, X.; Wang, E.; Zuo, J.; Wang, W.; Zhu, Y. Effects of CO2-water interaction with coal on mineral content and pore characteristics. J. Rock Mech. Geotech. Eng. 2020, 12, 326–337. [Google Scholar] [CrossRef]

- Iwai, Y.; Murozono, T.; Koujina, Y.; Arai, Y.; Sakanishi, K. Physical properties of low rank coals dried with supercritical carbon dioxide. J. Supercrit. Fluids 2000, 18, 73–79. [Google Scholar] [CrossRef]

- Zhang, D.; Gu, L.; Li, S.; Lian, P.; Tao, J. Interactions of supercritical CO2 with coal. Energy Fuels 2013, 27, 387–393. [Google Scholar] [CrossRef]

- Zhang, K.; Cheng, Y.; Jin, K.; Guo, H.; Liu, Q.; Dong, J.; Li, W. Effects of supercritical CO2 fluids on pore morphology of coal: Implications for CO2 geological sequestration. Energy Fuels 2017, 31, 4731–4741. [Google Scholar] [CrossRef]

- Hu, Z.; Li, C.; Zhang, D. Interactions of dynamic supercritical CO2 fluid with different rank moisture-equilibrated coals: Implications for CO2 sequestration in coal seams. Chin. J. Chem. Eng. 2021, 35, 288–301. [Google Scholar] [CrossRef]

- Jiang, R.; Yu, H. Interaction between sequestered supercritical CO2 and minerals in deep coal seams. Int. J. Coal Geol. 2019, 202, 1–13. [Google Scholar] [CrossRef]

- Chen, K.; Liu, X.; Nie, B.; Zhang, C.; Song, D.; Wang, L.; Yang, T. Mineral dissolution and pore alteration of coal induced by interactions with supercritical CO2. Energy 2022, 248, 123627. [Google Scholar] [CrossRef]

- Gathitu, B.B.; Chen, W.Y.; McClure, M. Effects of coal interaction with supercritical CO2: Physical structure. Ind. Eng. Chem. Res. 2009, 48, 5024–5034. [Google Scholar] [CrossRef]

- Su, E.; Liang, Y.; Li, L.; Zou, Q.; Niu, F. Laboratory study on changes in the pore structures and gas desorption properties of intact and tectonic coals after supercritical CO2 treatment: Implications for coalbed methane recovery. Energies 2018, 11, 3419. [Google Scholar] [CrossRef]

- Giraldo, L.J.; Medina, O.E.; Ortiz-Perez, V.; Franco, C.A.; Cortés, F.B. Enhanced Carbon Storage Process from Flue Gas Streams Using Rice Husk Silica Nanoparticles: An Approach in Shallow Coal Bed Methane Reservoirs. Energy Fuels 2023, 37, 2945–2959. [Google Scholar] [CrossRef]

- Gorucu, F.B.; Jikich, S.A.; Bromhal, G.S.; Sams, W.N.; Ertekin, T.; Smith, D.H. Effects of matrix shrinkage and swelling on the economics of enhanced-coalbed-methane production and CO2 sequestration in coal. SPE Reserv. Eval. Eng. 2007, 10, 382–392. [Google Scholar] [CrossRef]

- Mohammadpoor, M.; Qazvini Firouz, A.R.; Torabi, F. Implementing simulation and artificial intelligence tools to optimize the performance of the CO2 sequestration in coalbed methane reservoirs. In Proceedings of the Carbon Management Technology Conference, Orlando, FL, USA, 7–9 February 2012; p. CMTC-151307. [Google Scholar]

- Roy, D.G.; Singh, T.N. Regression and soft computing models to estimate young’s modulus of CO2 saturated coals. Measurement 2018, 129, 91–101. [Google Scholar]

- Sampath, K.H.S.M.; Perera, M.S.A.; Ranjith, P.G.; Matthai, S.K.; Tao, X.; Wu, B. Application of neural networks and fuzzy systems for the intelligent prediction of CO2-induced strength alteration of coal. Measurement 2019, 135, 47–60. [Google Scholar] [CrossRef]

| Areas | Capacity | References | |

|---|---|---|---|

| USA | Illinois Basin | 4.00 Gt | [102] |

| Powder River Basin | 21.25 t/m2 | [103] | |

| San Juan, Uinta and Raton Basins | 8.50 Gt | [104] | |

| San Juan Basin | 90.00 Gt | [105] | |

| China | 142.67 Gt | [106] | |

| China | Qinshui Basin | 0.19 t/m2 | [107] |

| Russia | Kuznetsk Basin | 13.60 Gt | [104] |

| Netherlands | 3.00 Gt | [108] | |

| Netherlands | Zuid Limburg, Peel, Achterhoek, and Zeeland | 8.00 Gt | [109] |

| India | 0.76 Gt | [110] | |

| India | Cambay Basin | 3.80 Gt | [104] |

| Australia | 30.00 Gt | [51] | |

| Australia | Bowen and Sydney Basins | 11.20 Gt | [104] |

| Brazil | Santa Terezinha Basin | 13.80 Gt | [111] |

| Coal | Saline Aquifers | |

|---|---|---|

| Caprocks | Tight formations | |

| Mechanism | Structural, solubility, residual gas and mineral sequestration | |

| Adsorption sequestration | / | |

| Critical sequestration state | Adsorbed (rapid) | Dissolved (slow) |

| Capacity | Lower North America: 54–113 Gt China: 142.67 Gt | Higher North America: 2379–21,633 Gt China: 143.5 Gt |

| Extra benefits | CBM production | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, B.; Fu, X.; Lu, J.; Huang, M.; Zeng, F. Potential, Efficiency, and Leakage Risk of CO2 Sequestration in Coal: A Review. Processes 2025, 13, 1680. https://doi.org/10.3390/pr13061680

Liu X, Zhang B, Fu X, Lu J, Huang M, Zeng F. Potential, Efficiency, and Leakage Risk of CO2 Sequestration in Coal: A Review. Processes. 2025; 13(6):1680. https://doi.org/10.3390/pr13061680

Chicago/Turabian StyleLiu, Xueliang, Baoxin Zhang, Xuehai Fu, Jielin Lu, Manli Huang, and Fanhua (Bill) Zeng. 2025. "Potential, Efficiency, and Leakage Risk of CO2 Sequestration in Coal: A Review" Processes 13, no. 6: 1680. https://doi.org/10.3390/pr13061680

APA StyleLiu, X., Zhang, B., Fu, X., Lu, J., Huang, M., & Zeng, F. (2025). Potential, Efficiency, and Leakage Risk of CO2 Sequestration in Coal: A Review. Processes, 13(6), 1680. https://doi.org/10.3390/pr13061680